Reverse osmosis membrane and preparation method thereof

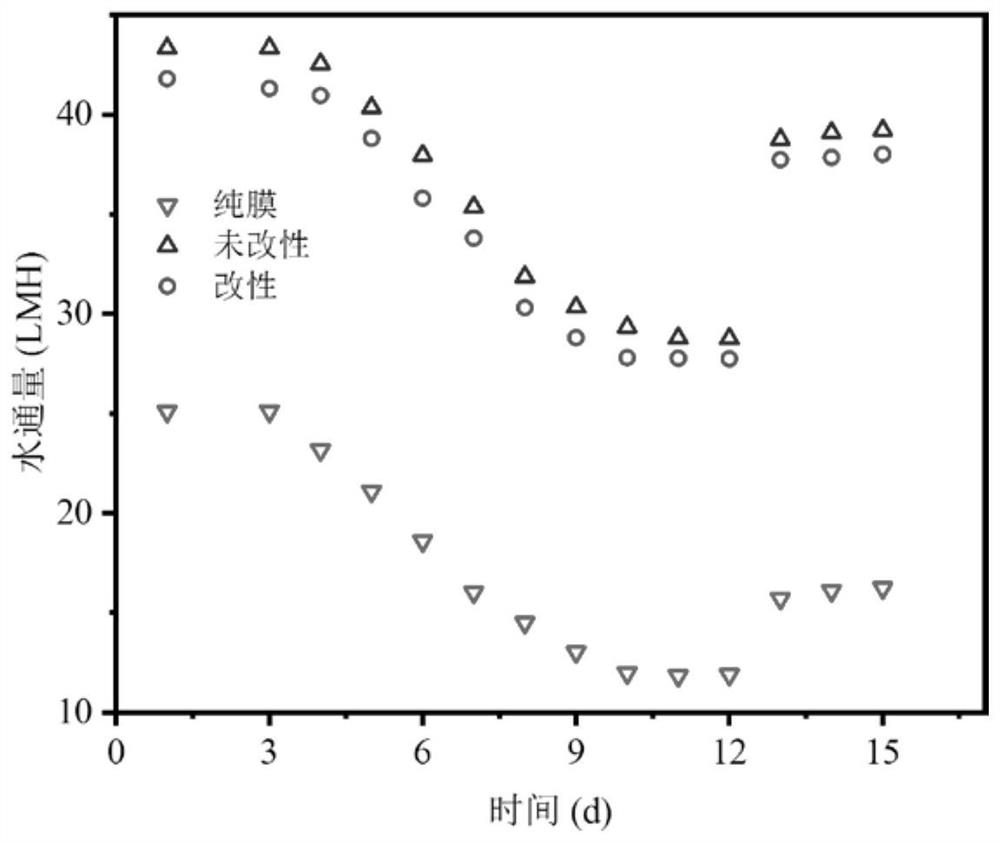

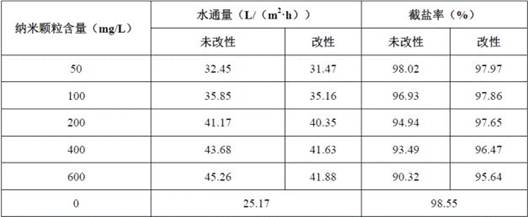

A technology of reverse osmosis membrane and palygorskite, applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of limited application, crystal bundles or aggregates are difficult to disperse uniformly, and achieve strong antifouling performance, good separation performance and the effect of water flux capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] (1) Preparation of KH550 solution: Add KH550 into ethanol, the mass ratio of ethanol to KH550 is 500:1, then stir on a magnetic stirrer for 15 minutes, and finally ultrasonically disperse for 15 minutes to completely hydrolyze it to obtain KH550 hydrolyzed solution ;

[0032] (2) Preparation of modified palygorskite nanoparticles: Palygorskite nanoparticles (diameter 30-60nm, length 500-800nm, cross-sectional area 0.37×0.63 nm 2 ) and KH550 hydrolysis solution are fully mixed according to the palygorskite: KH550 mass ratio of 100:1, and after the ethanol is completely volatilized, dry at 60°C for 10 minutes to obtain modified palygorskite;

[0033] (3) Preparation of aqueous phase solution: add water to 2 g of m-phenylenediamine and 0.1 g of sodium lauryl sulfate to 100 g to obtain an aqueous phase solution;

[0034] (4) Preparation of aqueous phase solution containing modified palygorskite nanoparticles: dissolve the modified palygorskite nanoparticles prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com