Heterostructure heat-conducting filler, preparation method and application thereof, silicone rubber heat-conducting insulating composite material and preparation method of same

A technology of heterogeneous structure and thermally conductive filler, applied in the field of thermally conductive insulating materials, can solve the problems of reducing the insulating properties of materials, weakening the mechanical properties of composite materials, reducing the volume resistance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

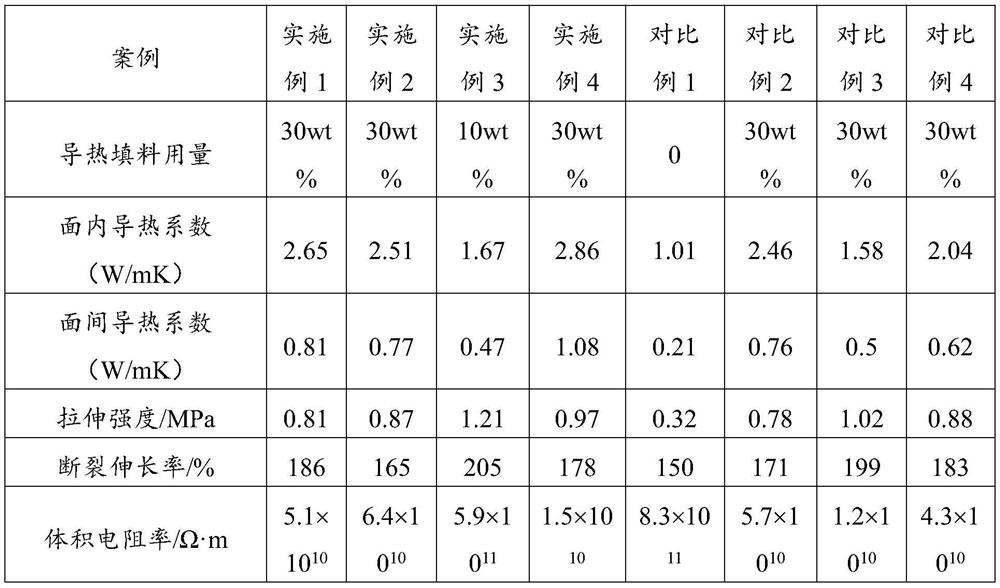

Examples

preparation example Construction

[0022] The invention provides a method for preparing a heat-conducting filler with a heterogeneous structure, comprising the following steps:

[0023] mixing the boron nitride nanosheet dispersion with the gamma-glycidyl etheroxypropyl trimethoxysilanol solution, and performing the first modification to obtain the modified boron nitride nanosheet;

[0024] mixing the aluminum oxide dispersion with the gamma-aminopropyltriethoxysilanol solution to perform a second modification to obtain modified aluminum oxide;

[0025] The modified boron nitride nanosheets, modified aluminum oxide and dispersant are mixed and grafted to obtain a heterostructure thermally conductive filler.

[0026] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0027] In the invention, the boron nitride nano-sheet dispersion liquid is mixed with the gamma-glycidyl etheroxypropyl trimethoxysi...

Embodiment 1

[0064] Disperse 8g of BNNS in 80mL of ethanol, and ultrasonically disperse for 30min to obtain a BNNS dispersion; dissolve 0.8g of GPTMS in 20mL of ethanol, ultrasonically for 20min to dissolve evenly, pour the resulting solution into the BNNS dispersion, and heat at 70°C React for 12 hours; after the reaction, centrifuge the obtained material at 3000rmp for 15 minutes, wash the obtained product with ethanol several times until it is clean, and then dry it in vacuum at 60°C for 12 hours to obtain modified BNNS, which is designated as GPTMS-g-BNNS;

[0065] 8gAl 2 o 3 Disperse in 80mL ethanol, ultrasonically disperse for 30min to make it evenly dispersed, and obtain Al 2 o 3 Dispersion liquid: Dissolve 0.8g APTES in 20mL ethanol, sonicate for 20min, pour the resulting solution into Al 2 o 3 In the dispersion liquid, react at 70°C for 12h; after the reaction is completed, centrifuge the obtained material at 3000rmp for 15min, wash the obtained product with ethanol several ti...

Embodiment 2

[0069] Modified BNNS was prepared according to the conditions of Example 1, which was denoted as GPTMS-g-BNNS;

[0070] Prepare modified alumina according to the conditions of Example 1, which is denoted as APTES-g-Al 2 o 3 ;

[0071] The above 1.5g GPTMS-g-BNNS and 3gAPTES-g-Al 2 o 3 Disperse in 100mL ethanol, react at 70°C with a stirring speed of 2500rmp for 12h; after the reaction, centrifuge the obtained material at 3000rmp for 15min, wash the obtained product with ethanol several times until it is clean, and then dry it in vacuum at 60°C 12h, get heterostructure thermal conductive filler BNNS@Al 2 o 3 ;

[0072] 1.5g of the thermally conductive filler BNNS@Al 2 o 3 Add to 3.1g silicone rubber matrix (RTV-2SR), then add 0.25g crosslinking agent (methyltriethoxysilane) and 4g n-hexane, then stir at 60°C for 30min at a speed of 2000rmp, to the obtained Add 0.15g of catalyst (dibutyltin dilaurate) to the mixture, then stir at 60°C for 10min at a speed of 2000rmp, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com