BNNS-coated Al2O3 heterostructure heat-conducting filler, preparation and application thereof, heat-conducting insulating composite material and preparation thereof

A technology of heterogeneous structure and thermally conductive filler, applied in the field of thermally conductive insulating materials, can solve the problems of increasing production cost and process difficulty, low thermal conductivity and high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

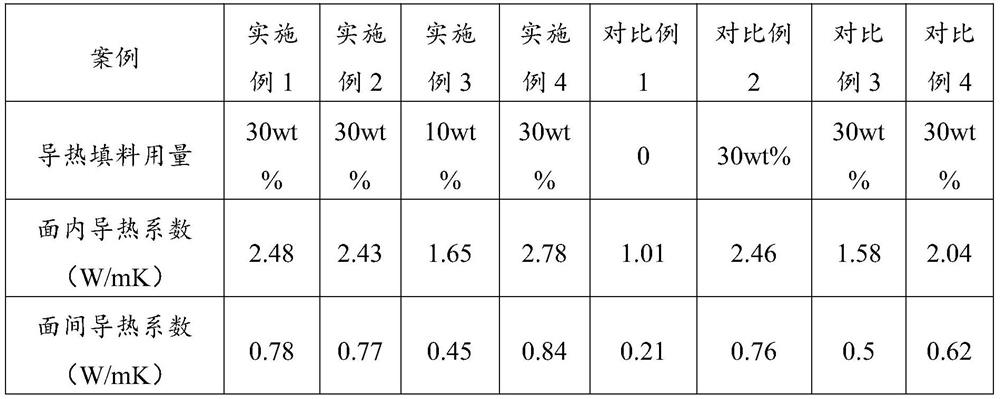

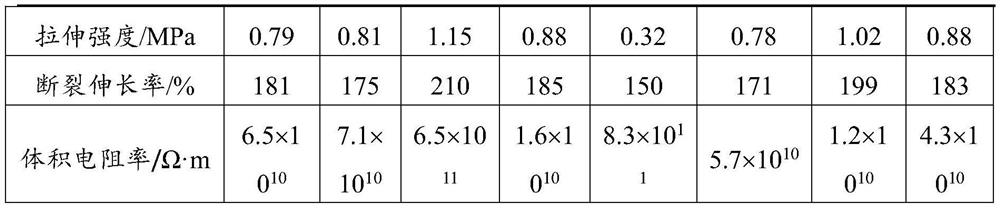

Examples

preparation example Construction

[0022] The invention provides a method for preparing a heat-conducting filler with a heterogeneous structure, comprising the following steps:

[0023] mixing the aluminum salt, the alcohol solution, and the boron nitride nanosheets to obtain an aluminum salt-boron nitride nanosheet dispersion;

[0024] mixing the aluminum salt-boron nitride nanosheet dispersion with an ammonia solution, and precipitating to obtain an aluminum hydroxide-boron nitride nanosheet precursor;

[0025] The aluminum hydroxide-boron nitride nanosheet precursor is calcined to obtain a heterostructure thermally conductive filler.

[0026] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0027] In the invention, the aluminum salt-boron nitride nanosheet dispersion liquid is mixed with an ammonia solution for precipitation to obtain an aluminum hydroxide-boron nitride nanosheet precursor. ...

Embodiment 1

[0059] 12.6gAlCl 3 ·6H 2 O was dissolved in 500mL ethanol solution (where EtOH / H 2 O volume ratio is 19:1), stirring until AlCl 3 ·6H 2 O is completely dissolved to obtain AlCl with a concentration of 0.5 mol / L 3 solution, then add 7.5g of boron nitride nanosheets BNNS, stir at a speed of 3000rmp for 30min until uniform, and obtain AlCl 3 / BNNS dispersion; 100mL of ammonia solution with a concentration of 1.8mol / L was added to the AlCl 3 / BNNS dispersion, continue to stir for 30 minutes, and centrifuge at 4000rmp for 20 minutes to obtain a precipitate. The precipitate is sequentially cycled for ethanol washing-centrifugation twice, and then dried at 60°C for 12 hours to obtain Al(OH) 3 - BNNS precursor;

[0060] 5g of the Al(OH) 3 -BNNS precursors were calcined in a tube furnace, and were calcined at 500°C for 1 h, 700°C for 1 h, 900°C for 1 h and 1200°C for 1 h, and the heating rate was 5°C / min for each calcination temperature to obtain Heterostructure BNNS@Al 2 o 3...

Embodiment 2

[0063]12.6gAlCl 3 ·6H 2 O was dissolved in 500mL ethanol solution (where EtOH / H 2 O volume ratio is 19:1), stirring until AlCl 3 ·6H 2 O is completely dissolved to obtain AlCl with a concentration of 0.5 mol / L 3 solution, then add 2.5g of boron nitride nanosheets BNNS, stir at a speed of 3000rmp for 30min until uniform, and obtain AlCl 3 / BNNS dispersion; 100mL of ammonia solution with a concentration of 1.8mol / L was added to the AlCl 3 / BNNS dispersion, continue to stir for 30 minutes, and centrifuge at 4000rmp for 20 minutes to obtain a precipitate. The precipitate is sequentially cycled for ethanol washing-centrifugation twice, and then dried at 60°C for 12 hours to obtain Al(OH) 3 - BNNS precursor;

[0064] 5g of the Al(OH) 3 -BNNS precursors were calcined in a tube furnace, and were calcined at 500°C for 1 h, 700°C for 1 h, 900°C for 1 h and 1200°C for 1 h, and the heating rate was 5°C / min for each calcination temperature to obtain Heterostructure BNNS@Al 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com