Organic light emitting compound material and application thereof

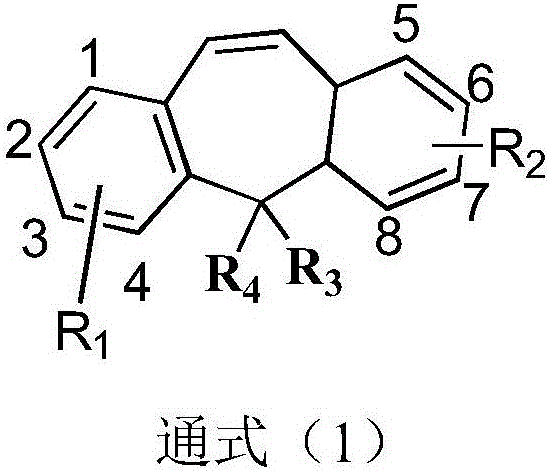

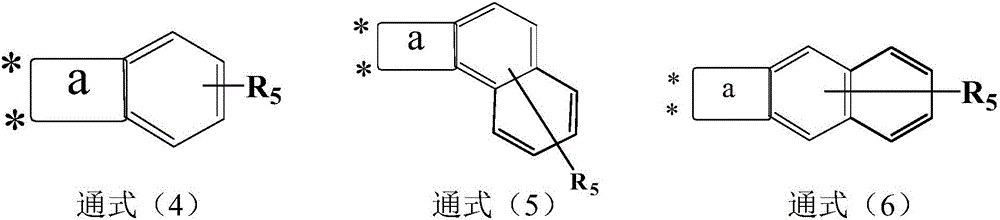

A compound and organic technology, applied in silicon organic compounds, luminescent materials, organic chemistry, etc., can solve the problems of lack of efficient and stable main materials, difficulty in achieving full-color RGB, insufficient efficiency, and insufficient lifespan, and achieve good industrialization prospects. Good singlet energy level, color purity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 (compound 05)

[0054] The concrete synthetic route of this compound is provided now:

[0055]

[0056] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol compound 1, 0.0105mol o-hydroxyphenylboronic acid, 50ml each of toluene, ethanol, and water, and 0.05g pd (pph 3 ) 4 (Tetraphenyltriphenylphosphine palladium), 0.025mol sodium carbonate, heated to reflux for 12 hours, the reaction was complete; naturally cooled, filtered, the filtrate was rotary evaporated, passed through a silica gel column, and mixed solvent with toluene:ethanol=1:2 (volume ratio) After beating and recrystallization, white intermediate A was obtained.

[0057] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol of intermediate A, 0.025mol of potassium carbonate, 150ml of NMP, and stir for 12 hours at 150°C. After the reaction was complete, it was naturally cooled to room temperature. The reaction solution was added to a separatory funnel, 400ml of wate...

Embodiment 2

[0060] Example 2 (compound 14)

[0061] The concrete synthetic route of this compound is provided now:

[0062]

[0063] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol compound 2, 0.012mol (2-fluorophenyl) phenylamine, 0.03mol sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150ml toluene, heated to reflux for 20 hours, the reaction was complete; naturally cooled, filtered, the filtrate was rotary evaporated, passed through a silica gel column, beaten with a mixed solvent of toluene:ethanol=3:1 (volume ratio), and recrystallized White Intermediate B.

[0064] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol of intermediate B, 0.025mol of potassium carbonate, 150ml of NMP, and stir for 15 hours at 150°C. After the reaction was complete, it was naturally cooled to room temperature. The reaction solution was added to a separatory funnel, 400ml of water was added, extracted three times with ethyl a...

Embodiment 3

[0067] Example 3 (compound 40)

[0068] The concrete synthetic route of this compound is provided now:

[0069]

[0070] 250ml four-necked bottle, under nitrogen protection, add 0.01mol intermediate C, 0.025mol 1-naphthylboronic acid, 0.05g pd (pph 3 ) 4 (tetraphenyltriphenylphosphine palladium), 0.025mol sodium carbonate, each 60ml of toluene, ethanol, water, heated to reflux for 15 hours, the reaction was complete; naturally cooled, filtered, and the filtrate was rotary evaporated, crossed a silica gel column, and used toluene:ethanol=1 : 2 (volume ratio) mixed solvent beating, obtain white solid after recrystallization, purity (HPLC) is 98.5%, yield 62.7%.

[0071] Elemental analysis structure (molecular formula C 53 h 37 N): theoretical value C, 92.54; H, 5.42; N, 2.04;

[0072] Test values: C, 92.61; H, 5.50; N, 1.89.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com