core melt trap

A technology of core melt and melt, which is applied in the field of nuclear power, can solve the problems of low cooling efficiency of the core catcher, achieve the effects of weakening the accumulation effect, simplifying the post-accident treatment, and improving the coolability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

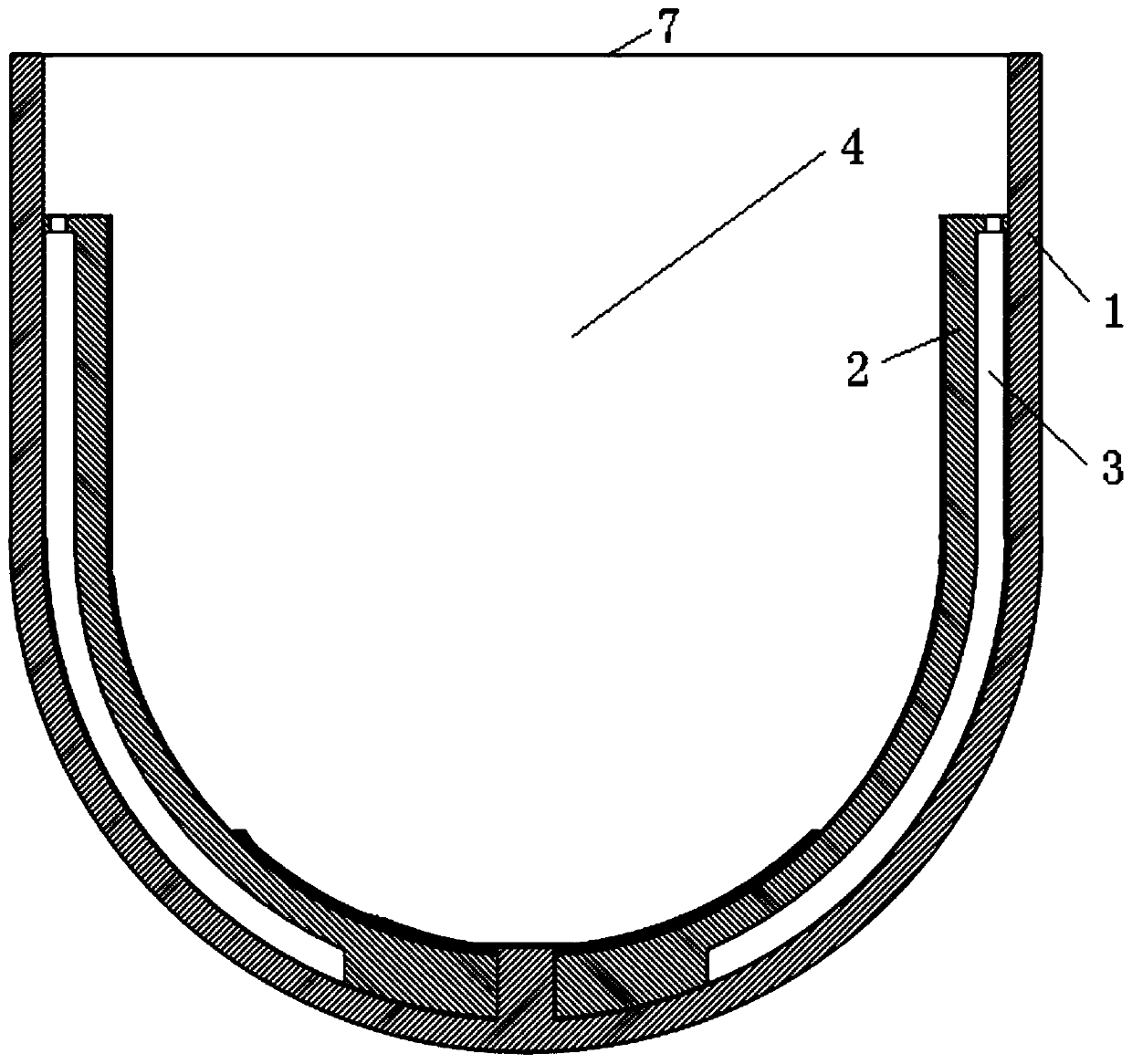

[0034] Such as figure 1 As shown, this embodiment provides a core melt collection device, comprising a collection cylinder 1 in the form of a crucible for collecting core melt, located below the pressure vessel of the reactor, and the pressure vessel of the reactor is arranged on In the pit of the reactor, the bottom of the pit of the reactor is connected to the opening of the catch cylinder through a communication channel, and the core melt collection device also includes a first partition assembly 2, which separates the catch cylinder 1 At least two trapping chambers are nested sequentially from outside to inside, and the inlet of the trapping chamber communicates with the opening 7 of the trapping cylinder.

[0035] Specifically, the first partition assembly 2 separates the collection cylinder 1 into two collection chambers arranged sequentially from outside to inside, namely the first collection chamber 3 and the second collection chamber 4, the first partition The assemb...

Embodiment 2

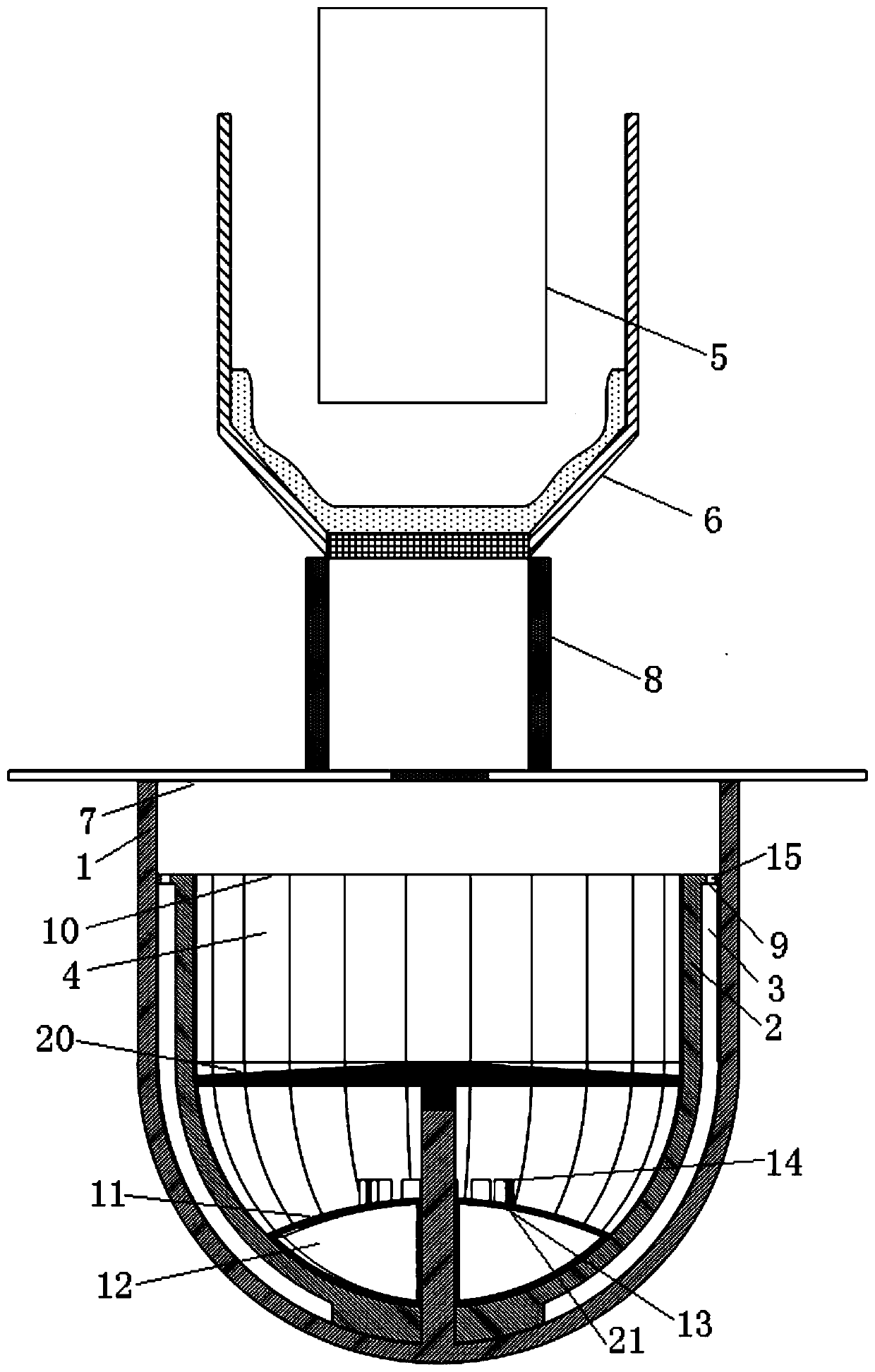

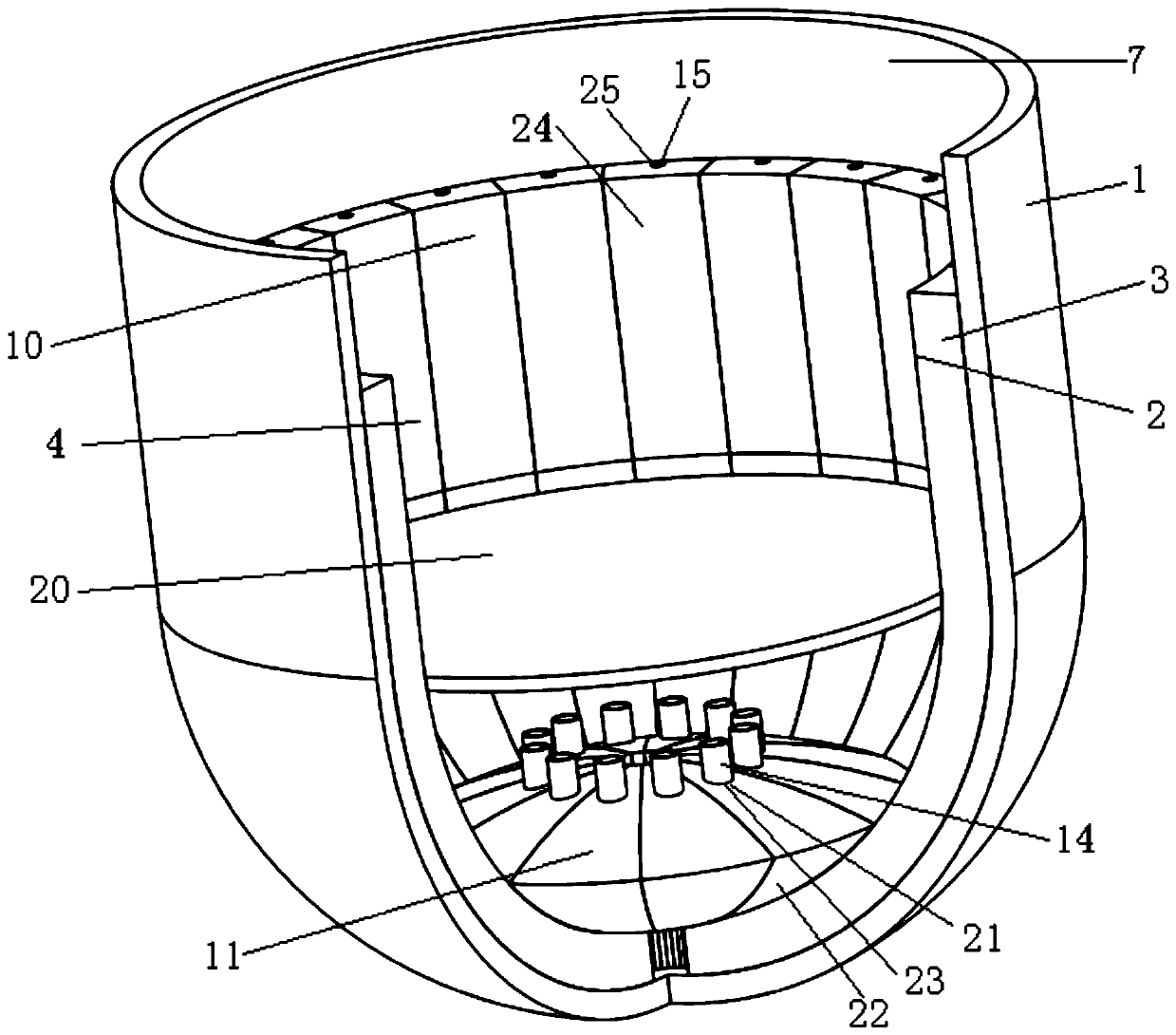

[0039] Such as Figure 2-6 As shown, the present embodiment provides a core melt collection device, comprising a collection cylinder 1 in the form of a crucible for collecting core melt, located below the reactor pressure vessel 5, and the reactor pressure vessel 5 It is arranged in the reactor pit 6, and the bottom of the reactor pit 6 is connected with the opening 7 of the catch cylinder through a communication channel 8. The core melt trap also includes a first partition assembly 2, which will The collection cylinder 1 separates at least two collection chambers nested in sequence from outside to inside, and the inlet of the collection chamber communicates with the opening 7 of the collection cylinder.

[0040] Specifically, the first partition assembly 2 separates the collection cylinder 1 into two collection chambers arranged sequentially from outside to inside, namely the first collection chamber 3 and the second collection chamber 4, the first partition The assembly 2 i...

Embodiment 3

[0063] This embodiment provides a core melt collection device, which differs from the core melt collection device in Embodiment 2 in that: the elevation of the inlet of the inner collection chamber in this embodiment is located at: 100% of the stack The retention of core melt corresponds to 20% of its liquid level elevation, and the elevation of the inlet of the trap chamber closest to the inner wall of the trap cylinder is located at: 95% of its liquid level corresponding to 100% core melt retention .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com