Patents

Literature

83 results about "Core catcher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A core catcher is a device provided to catch the molten core material (corium) of a nuclear reactor in case of a nuclear meltdown and prevent it from escaping the containment building. A core catcher is made from a special concrete ceramic to prevent material from trickling through; it is also a cooling mechanism to cool down the core material. The core catcher of the European Pressurized Reactor (EPR) has 170 m² expansion area and a mass of 500 t.

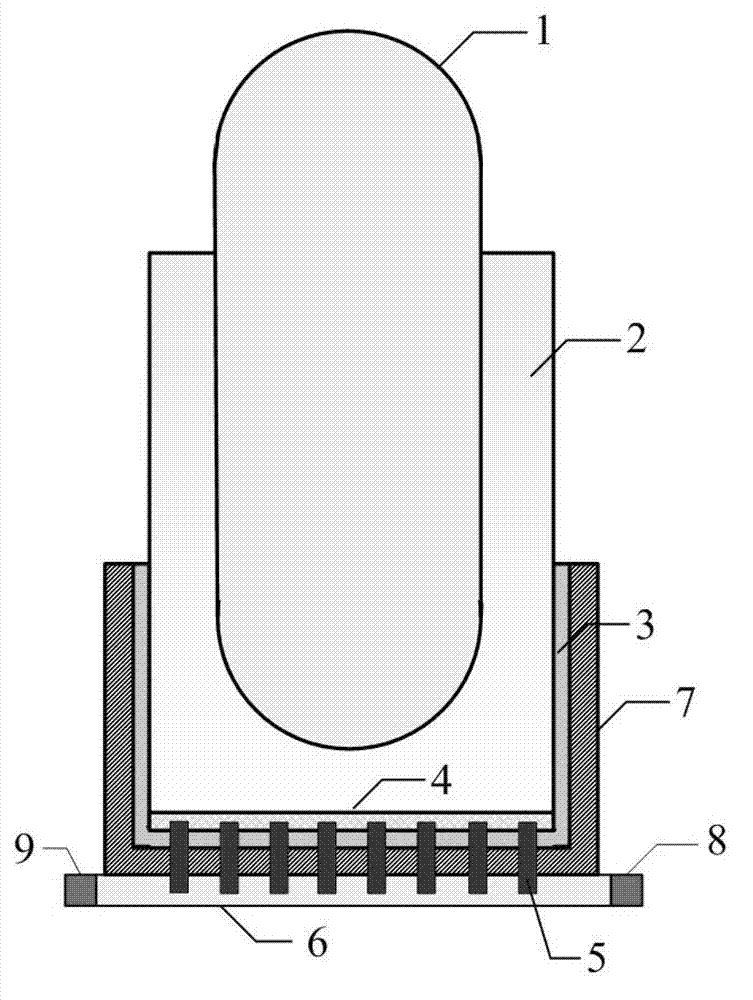

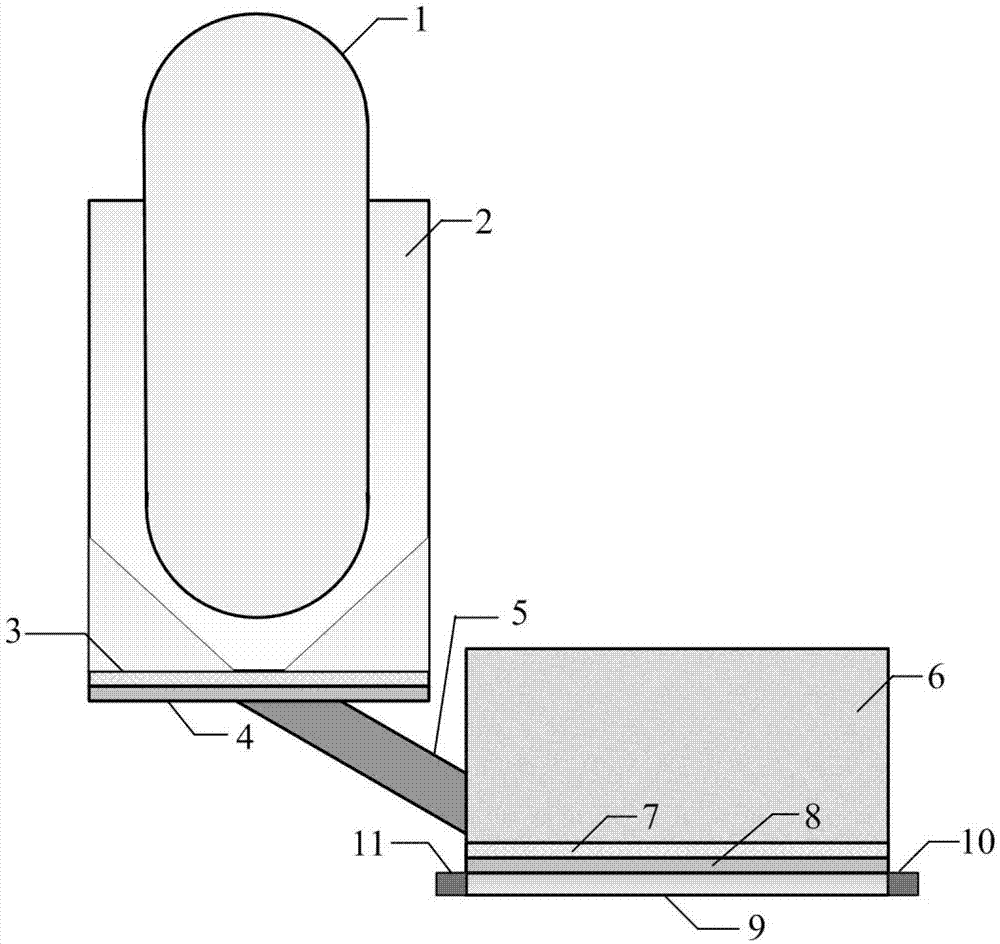

Large-scale passive nuclear plant reactor core catcher with bottom water injection and external cooling

InactiveCN103177778AImplement off-heap retentionImprove securityNuclear energy generationEmergency protection arrangementsNuclear plantCore catcher

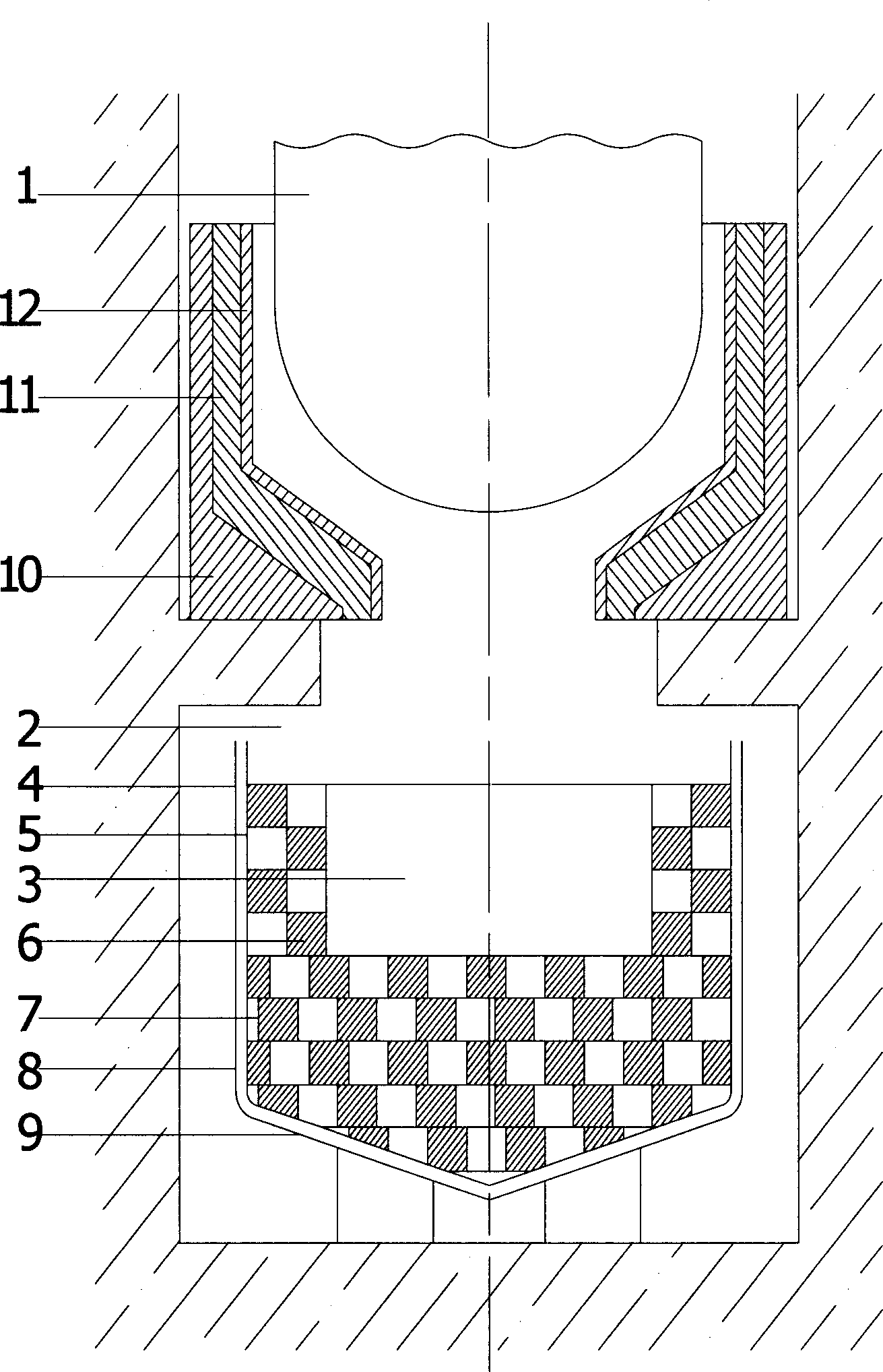

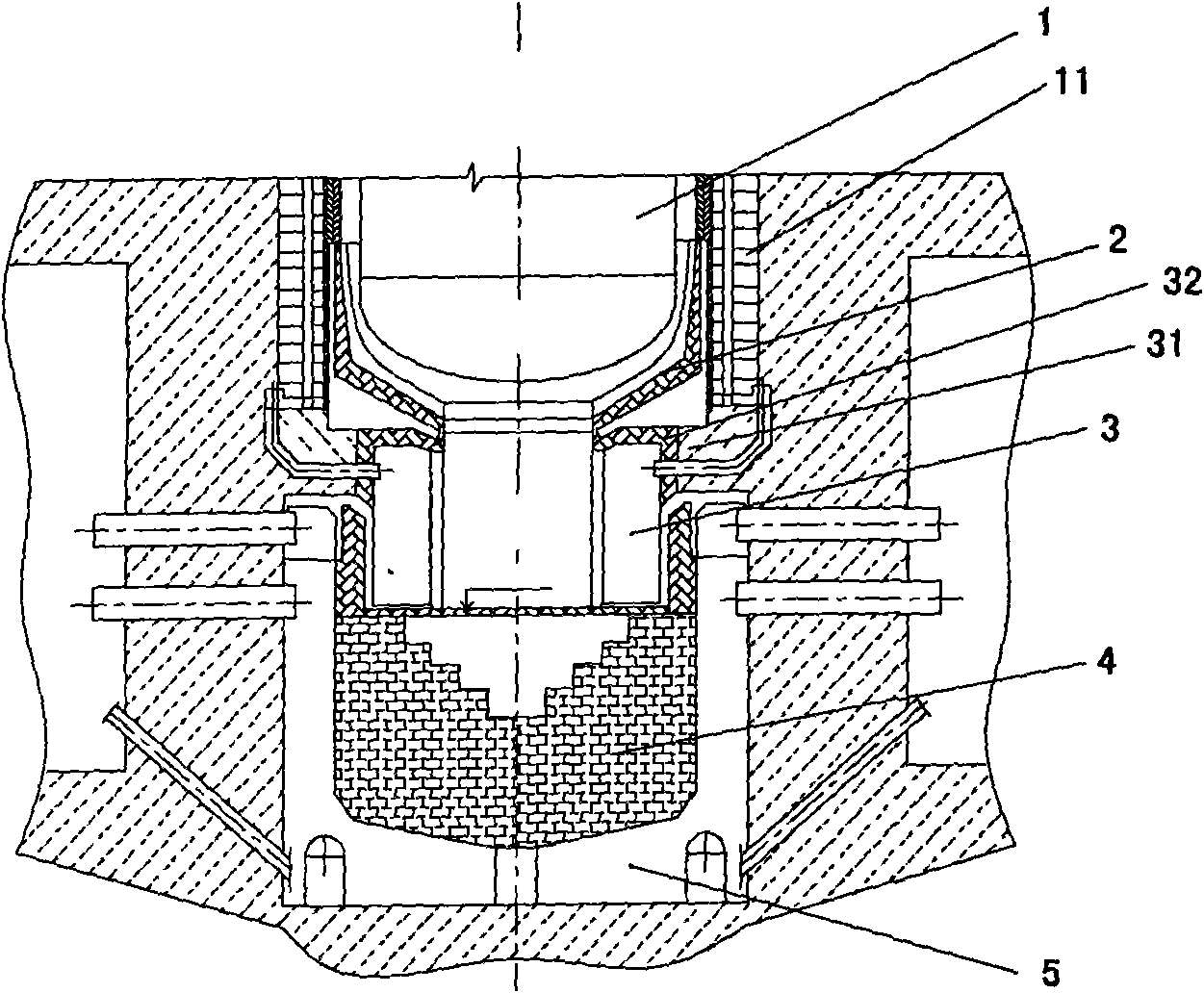

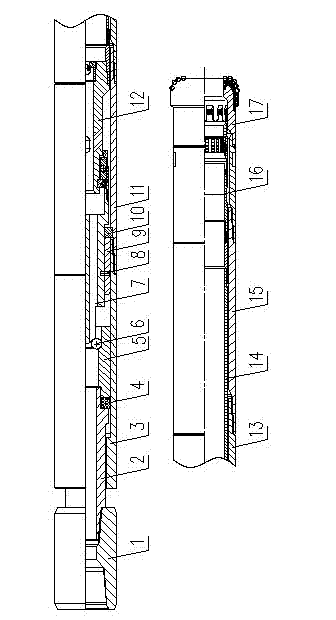

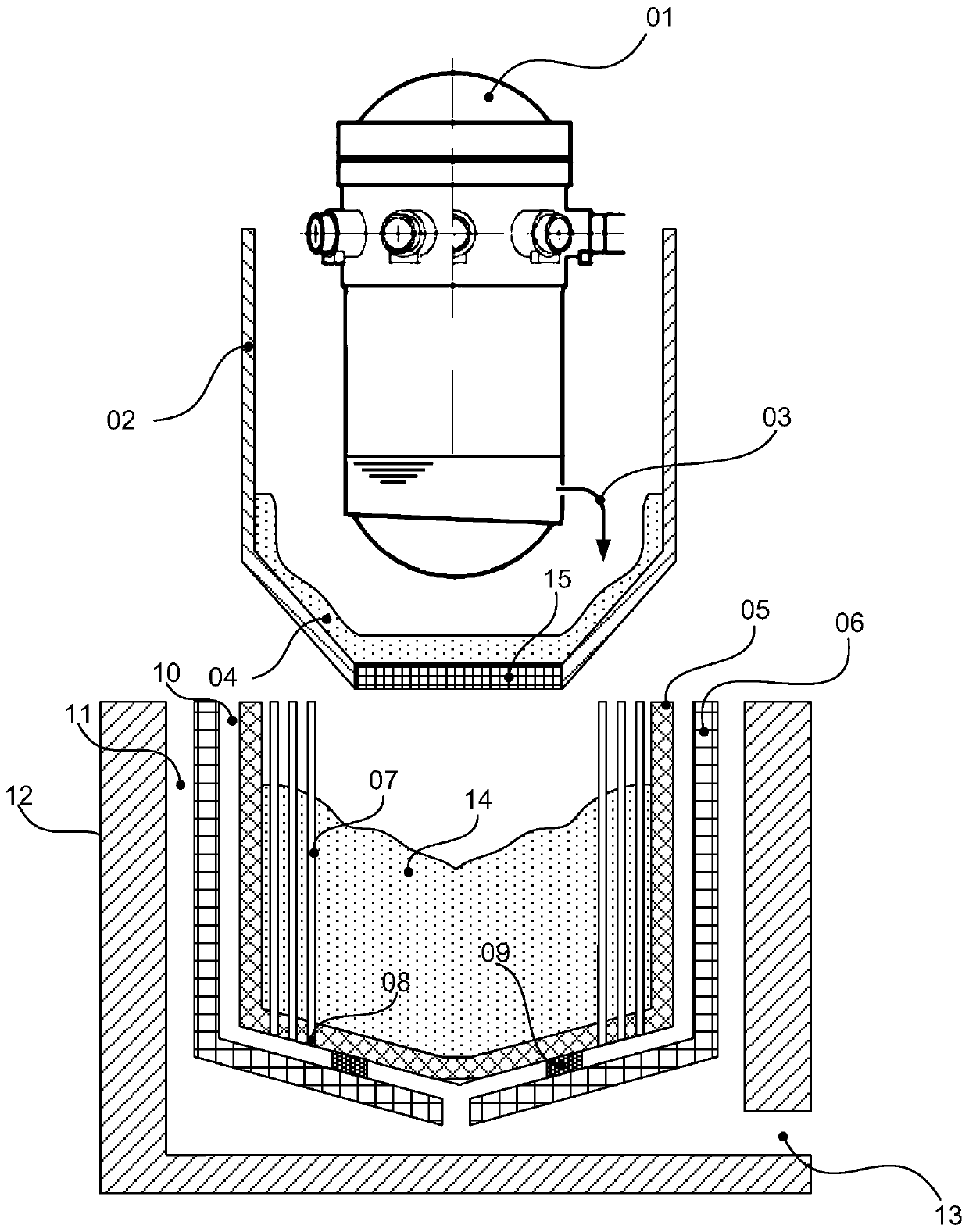

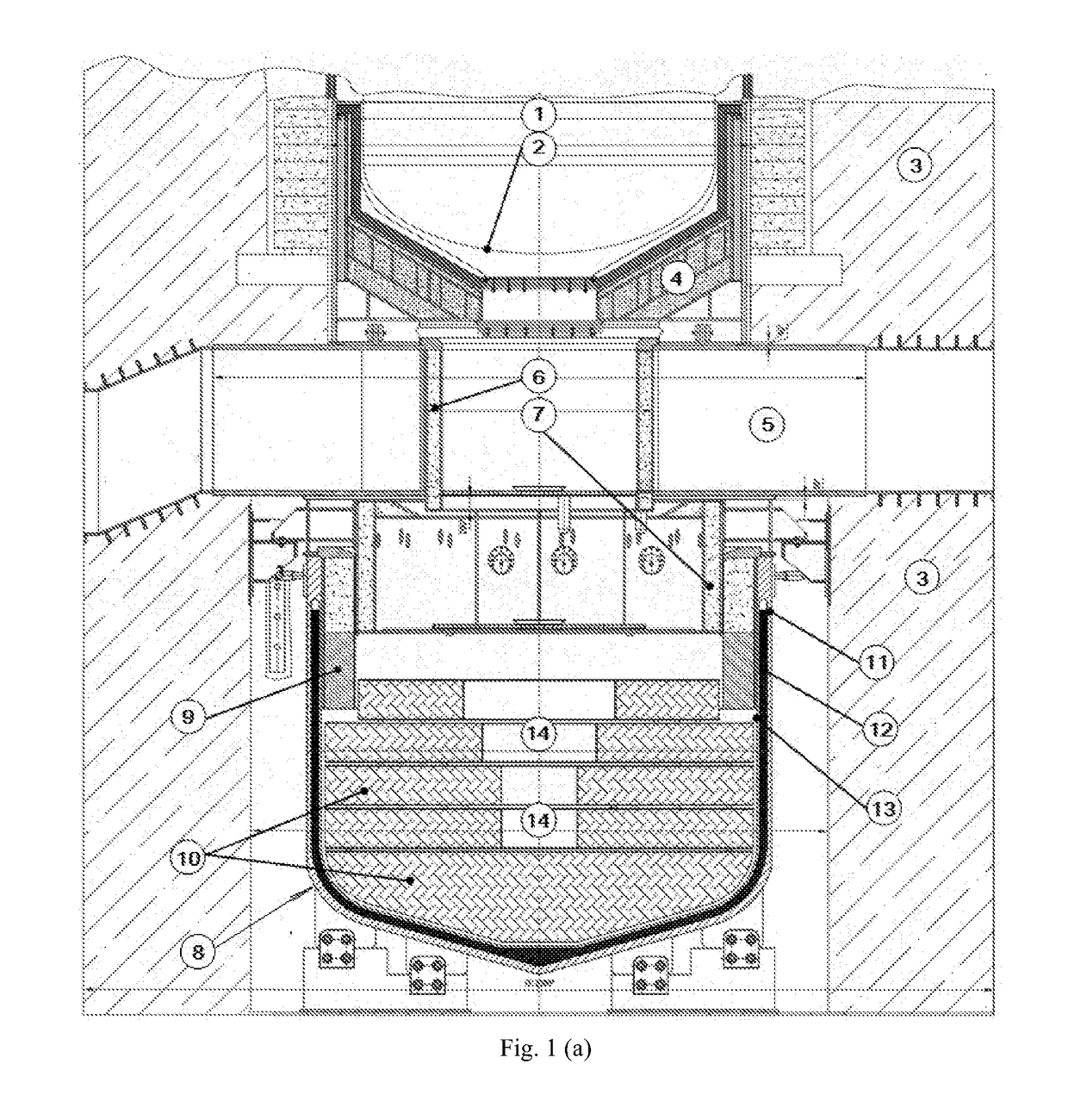

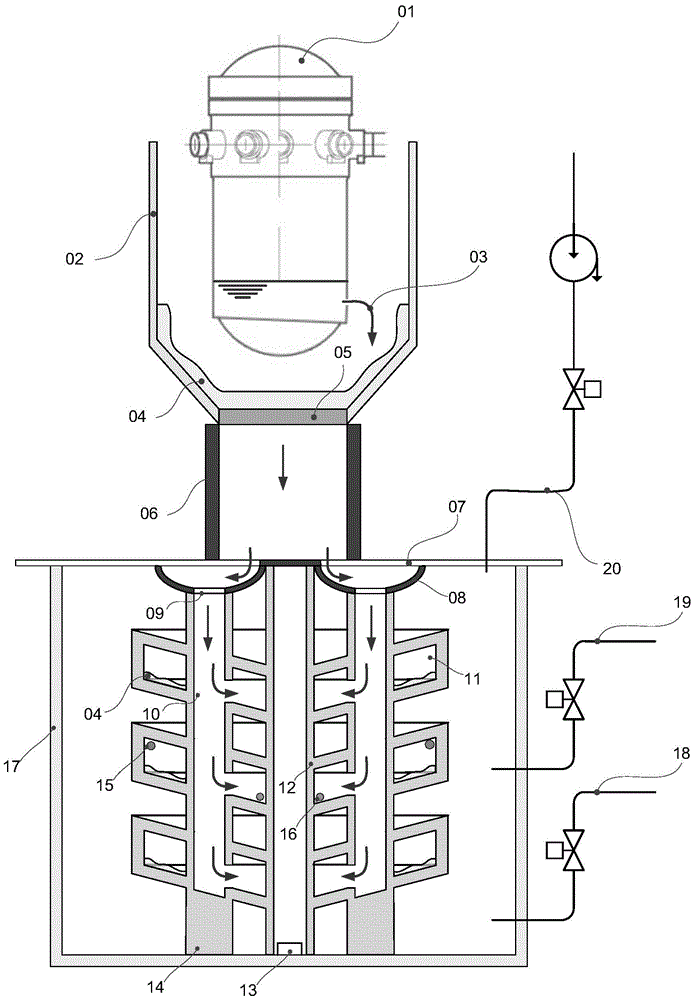

The invention provides a large-scale passive nuclear plant reactor core catcher with bottom water injection and external cooling. The catcher comprises a reactor cavity coating the lower middle part of a reactor pressure vessel, and a reactor cavity concrete soleplate is formed at the bottom of the reactor cavity; a refractory layer is formed on the side surface of the reactor cavity and the bottom of the reactor cavity concrete soleplate; a steel cylinder is sleeved outside the refractory layer; an external cooling passage is formed at the bottom of the steel cylinder, and a cooling passage inlet and a cooling passage outlet are respectively formed at the two outward-extending ends of the external cooling passage; and dozens of nozzles are fixed at the bottom of the steel cylinder, and the upper ends of the nozzles extend into the reactor cavity concrete soleplate while the lower ends of the nozzles extend into the external cooling passage. According to the invention, the dilution and the temperature reduction of a melt are implemented through the melting of concrete by adopting the reactor cavity concrete soleplate as a sacrificial material. A reactor core melt is collected in the refractory layer after the reactor cavity concrete soleplate is molten through, so that the security and the reliability of a nuclear plant are further improved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

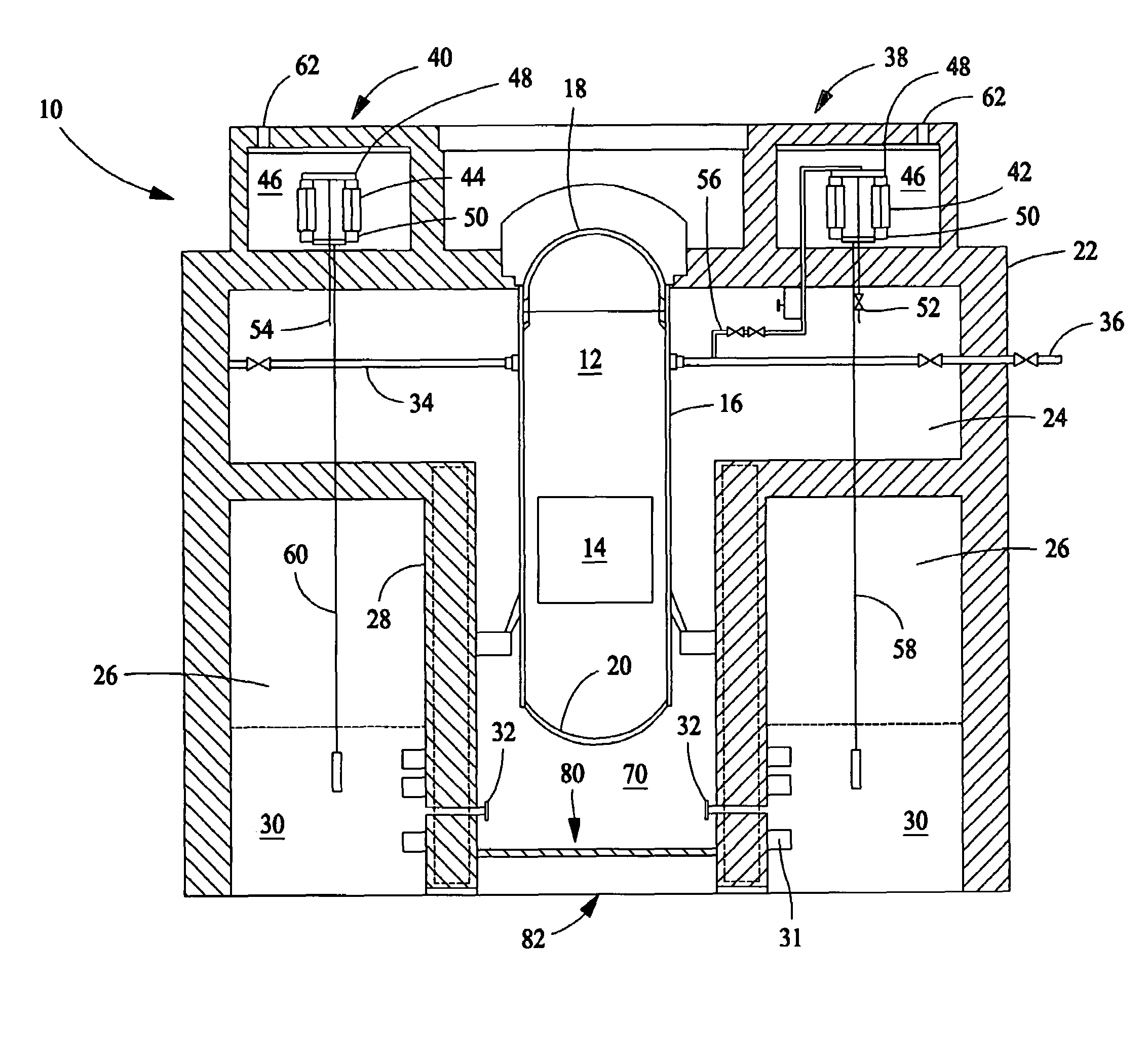

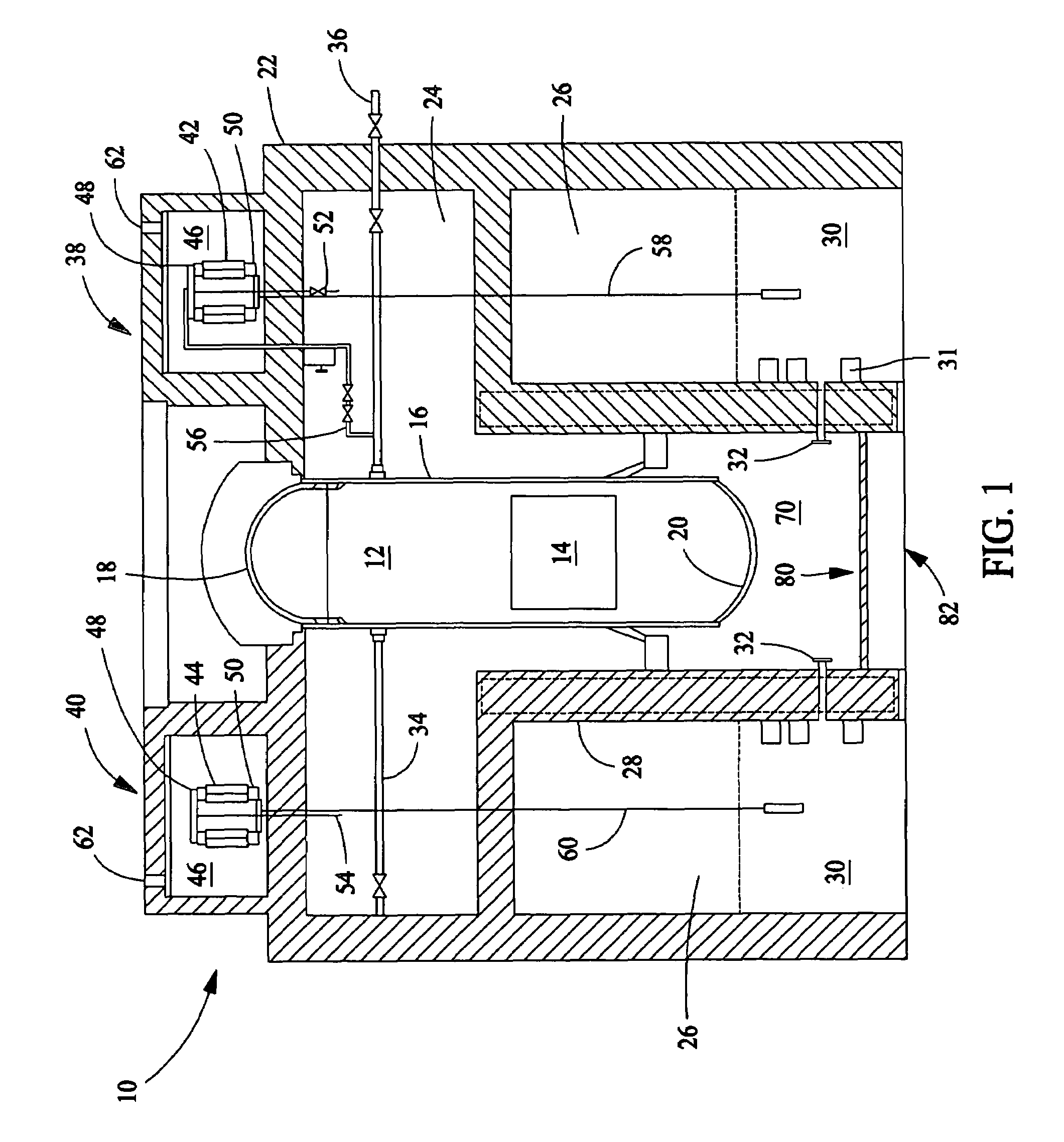

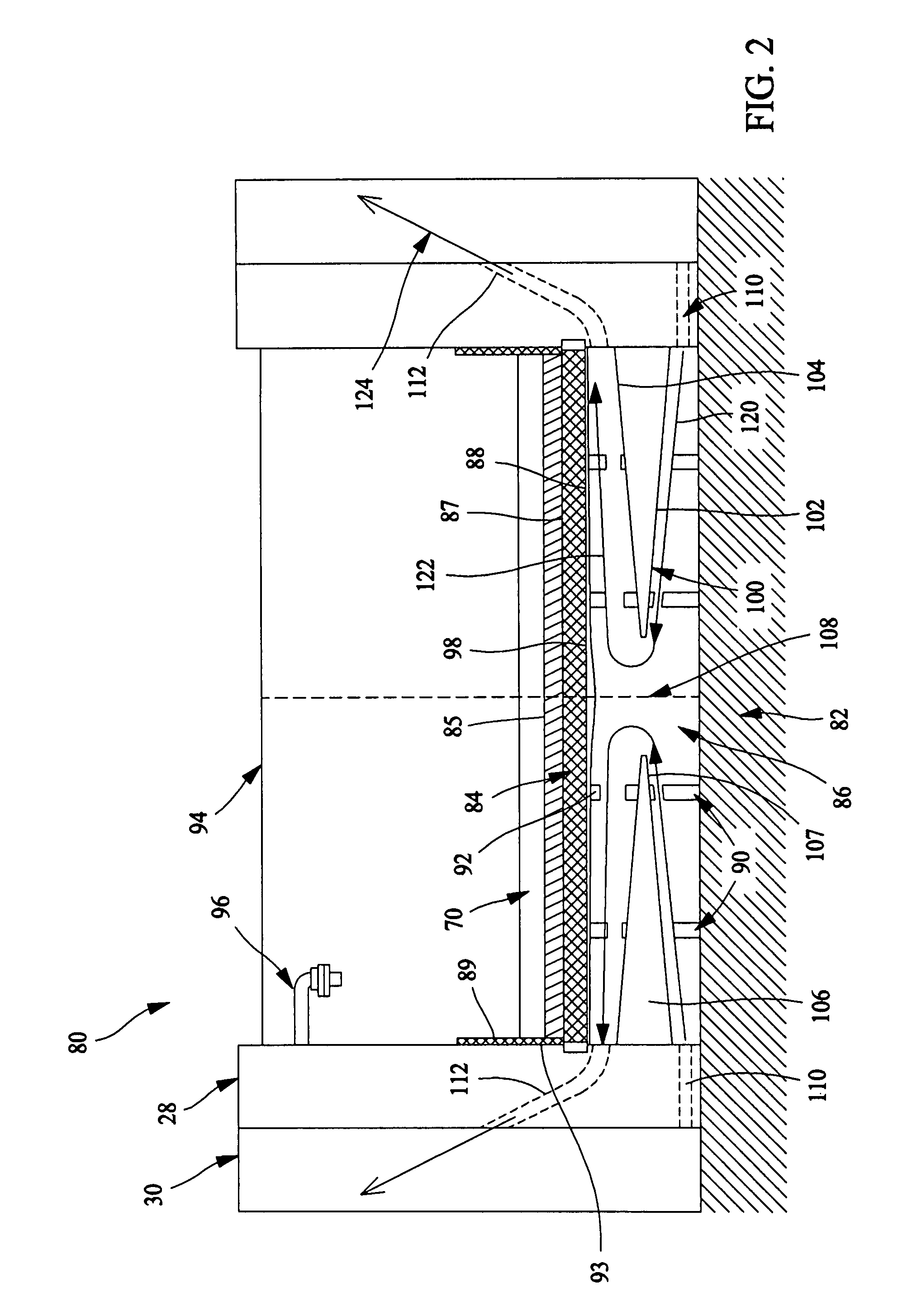

Core catcher cooling

InactiveUS7558360B1Nuclear energy generationEmergency protection arrangementsCore catcherEngineering

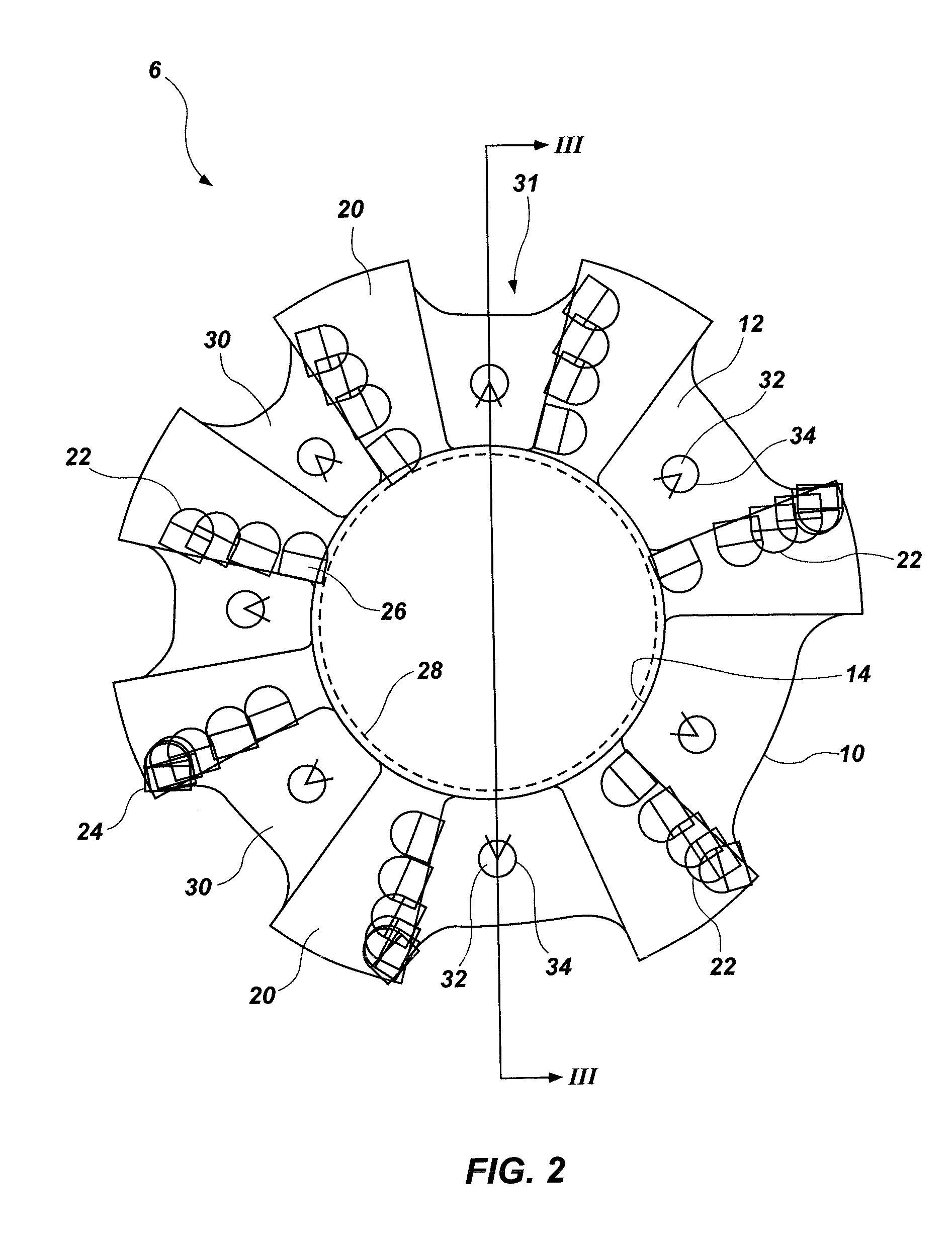

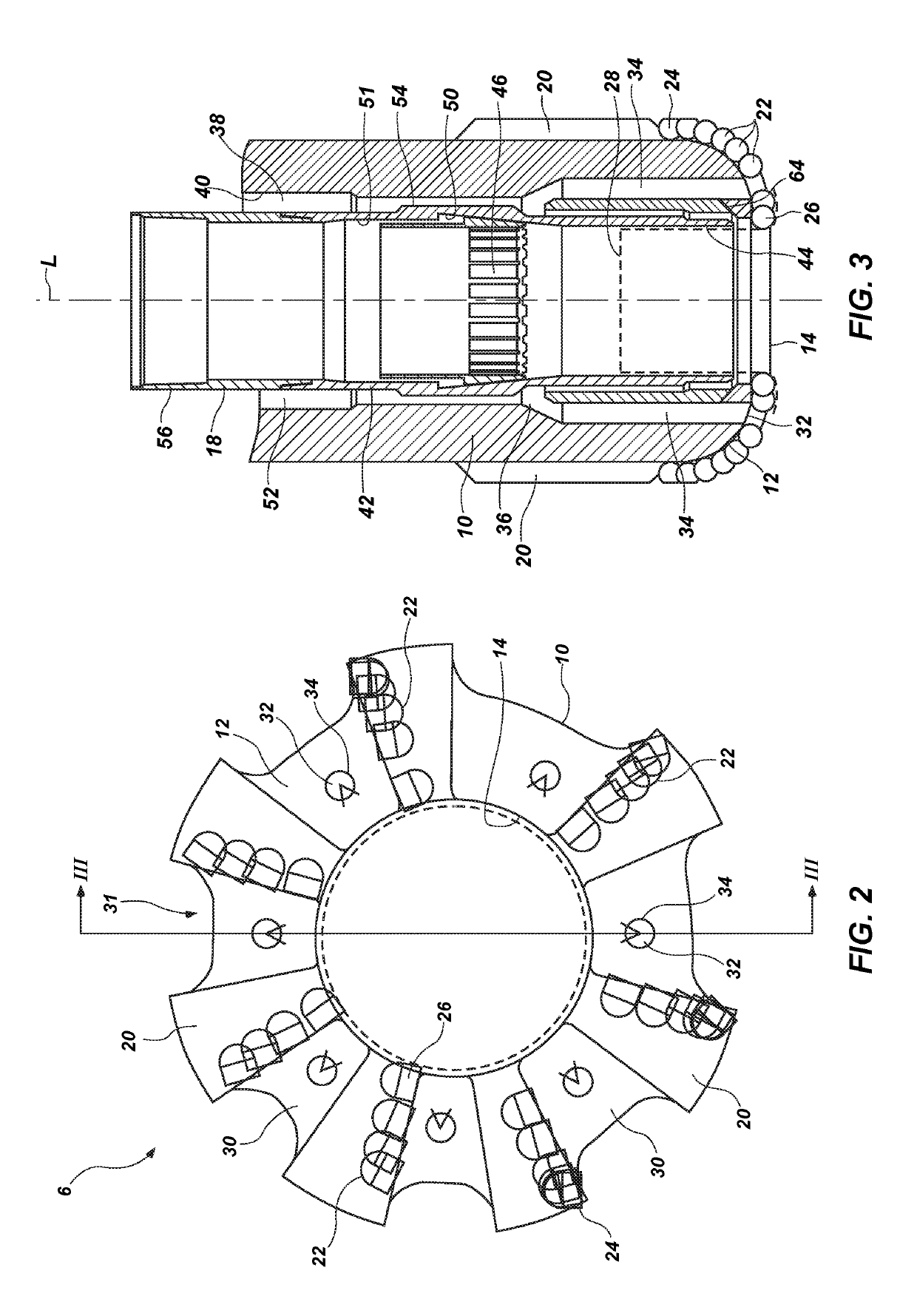

An assembly includes a base grid configured to be disposed below a pressure vessel and spaced vertically above a floor of a containment vessel to define a sump therebetween. The assembly further includes an annular wall extending vertically upwards from the floor and laterally bounding the base grid and the sump. The wall separates the sump from a suppression pool, an inlet passage extending through the wall and providing flow communication between the sump and the suppression pool, and an outlet passage extending through the wall and providing flow communication between the sump and the suppression pool.

Owner:GENERAL ELECTRIC CO

Apparatus for positioning and cooling lining layer of damaged LWR nuclear reactor

InactiveCN1585034AImprove melt fluidityImprove cooling conditionsNuclear energy generationEmergency protection arrangementsCore catcherNuclear reactor

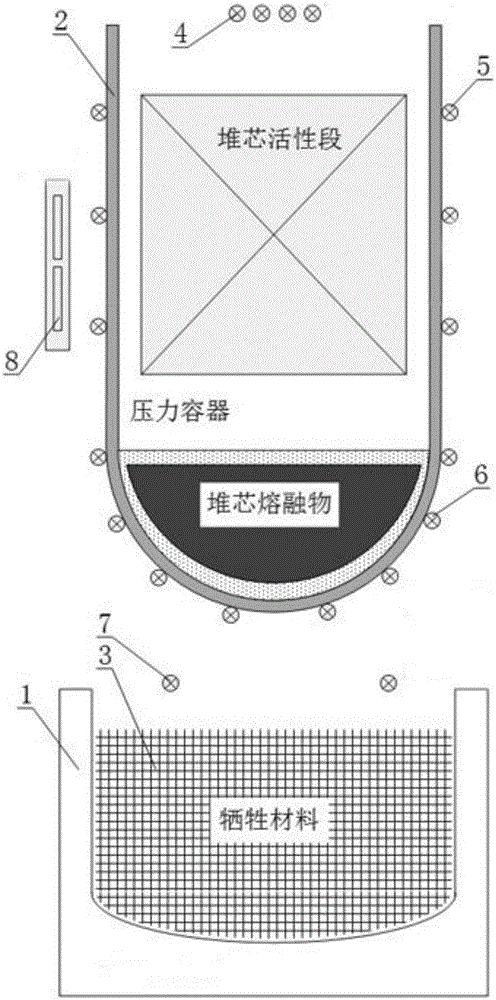

The invention relates to apparatus for positioning and cooling melting lining layer when the melting lining layer flows out of the reactor shell during accident. The improvements of invention are described as following: the design of the cooling lining layer trap which has steel basket shell and arranged in sub-reactor, wherein sacrifice material is filled in the steel basket for diluting the component containing uranium and steel component of the lining layer; the shape (arrangement) of the sacrifice material in reactor core; the choice for optimum number of the sacrifice material; installation of guiding device used for the lining layer flowing into the reactor core trap. Especially, the thickness of bottom of the cooling jacket is larger than the thickness of the side wall thereof for no less than 30%, and the cooling jacket inclines to its center for 10 to 20 degree; the diluent and sacrifice material is made into blocks packed in steel shell.

Owner:V·B·哈本斯基 +17

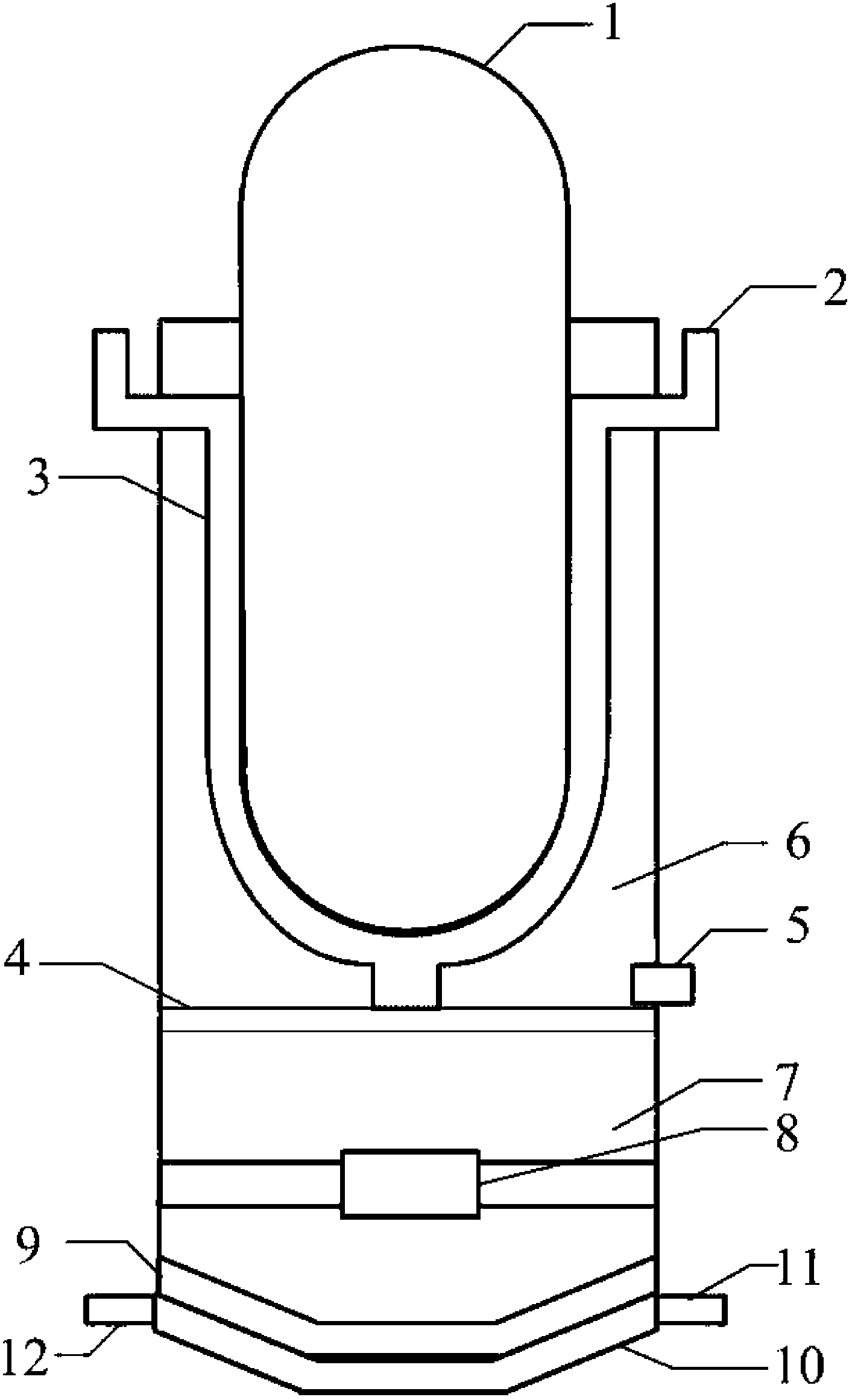

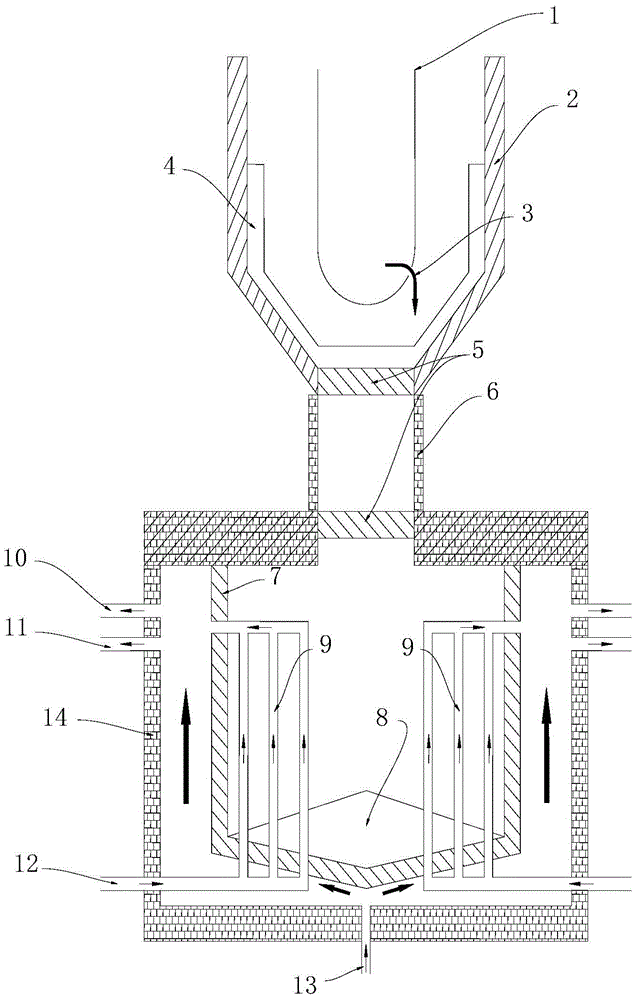

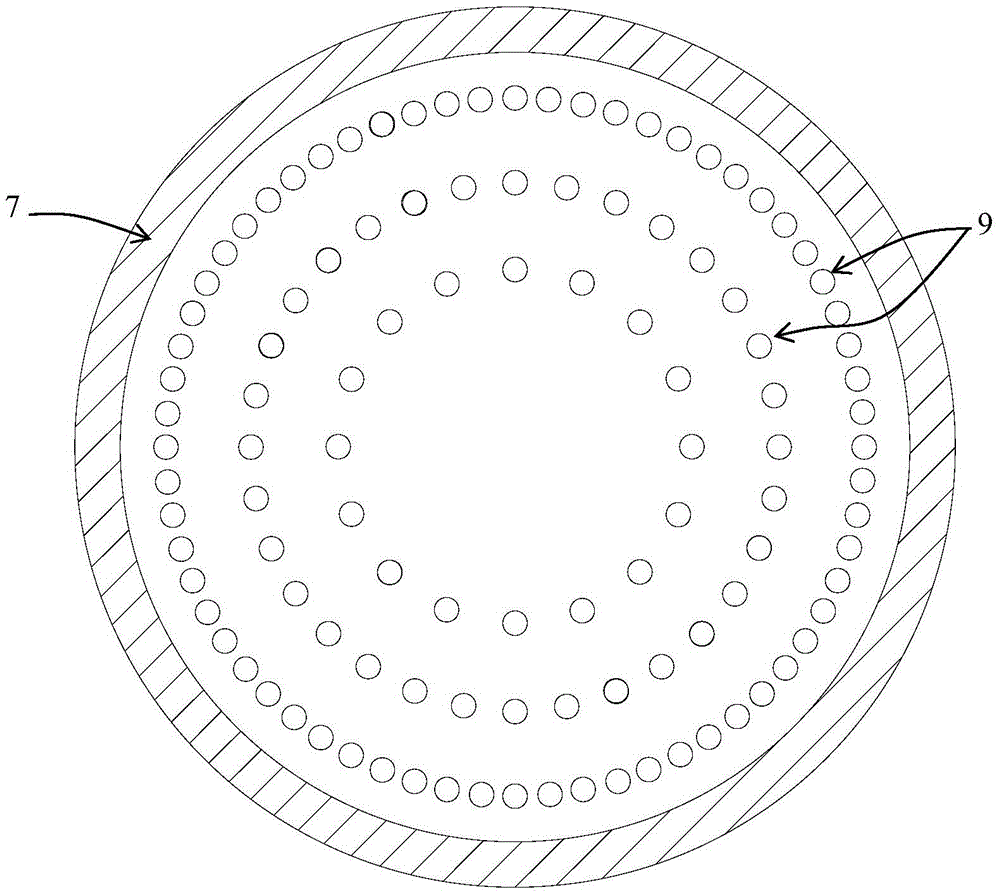

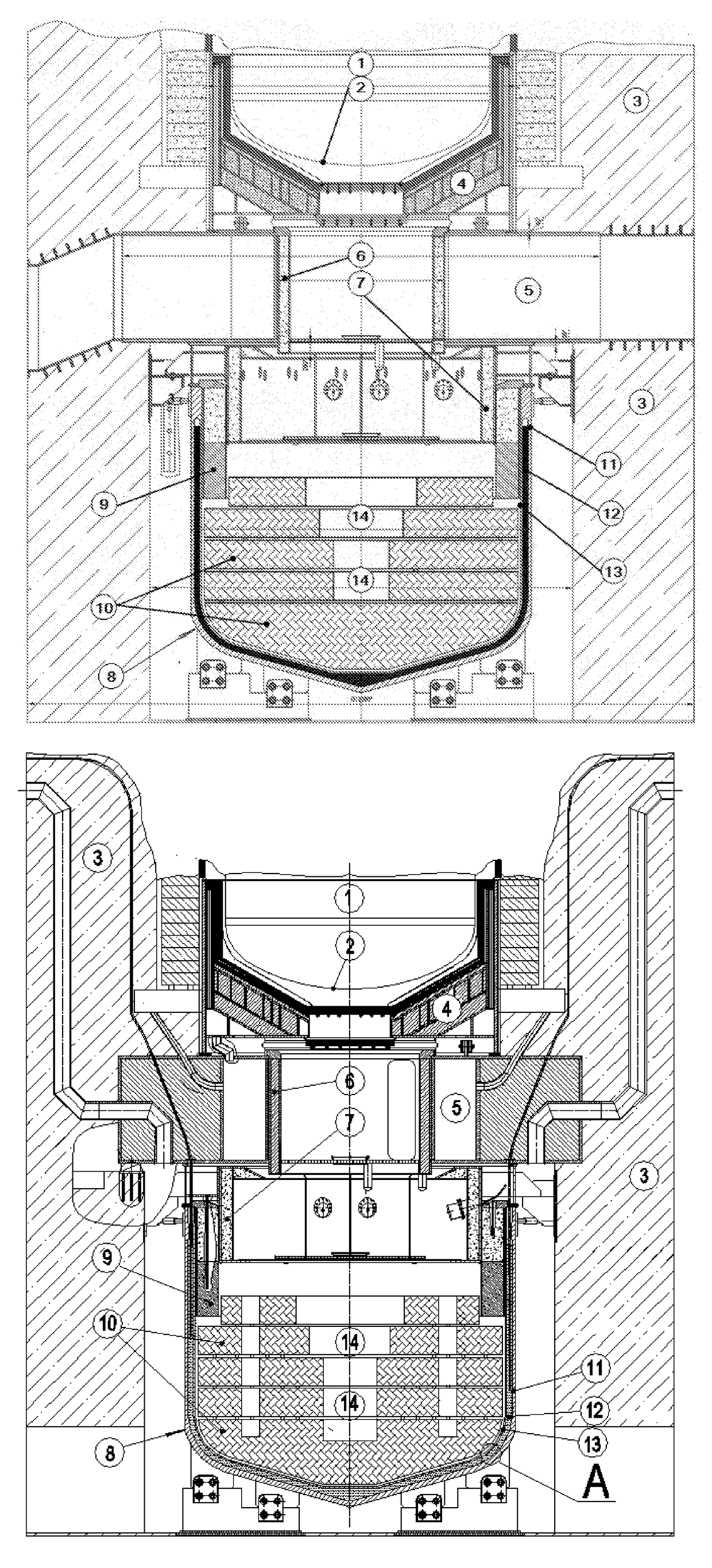

Large passive pressurized water reactor nuclear power plant crucible-type reactor core catcher

InactiveCN103177779AImprove securityImprove reliabilityNuclear energy generationEmergency protection arrangementsNuclear plantCore catcher

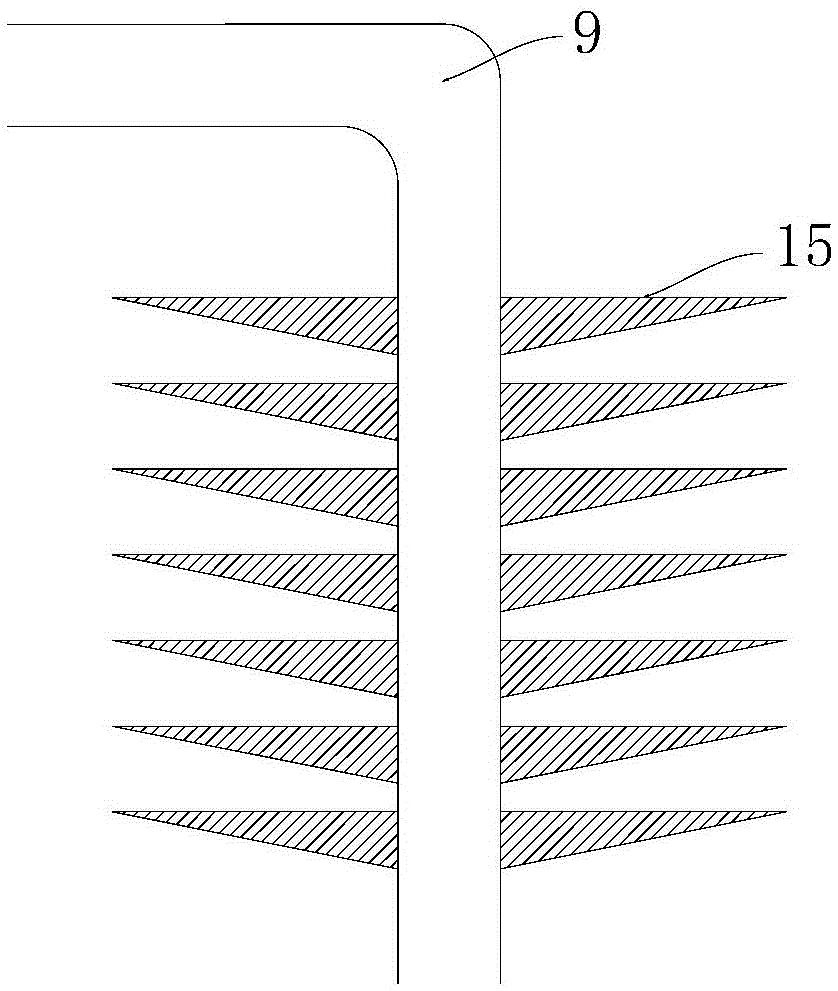

The invention discloses a large passive pressurized water reactor nuclear power plant crucible-type reactor core catcher which comprises a reactor cavity concrete bottom plate (4), a crucible cooling system water filling nozzle (6), a crucible cooling system water vapor outlet (7), a crucible component (8), a crucible cooling system cavity (9) and a melt collector (10). The reactor core catcher is organically combined with an interactive voice response (IVR) system, the safety of the nuclear power plant can be further improved, and the reliability of the system is higher due to the crucible design.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Large-scale passive pressurized water reactor nuclear power plant reactor core catcher with melt expansion room

InactiveCN103165198AIncrease heat transfer areaImprove cooling effectNuclear energy generationEmergency protection arrangementsCore catcherPressurized water reactor

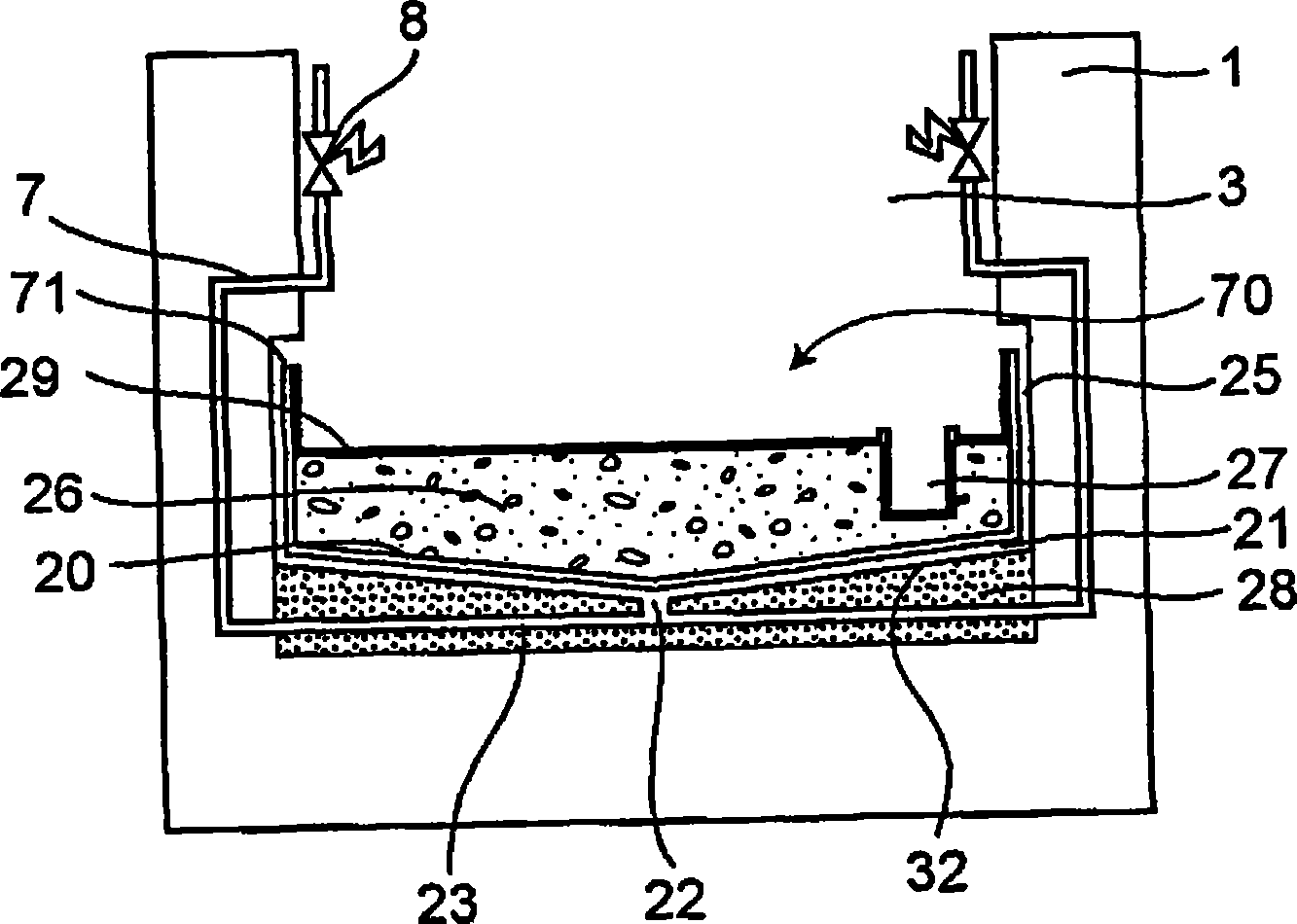

The invention provides a large-scale passive pressurized water reactor nuclear power plant reactor core catcher with a melt expansion room. The large-scale passive pressurized water reactor nuclear power plant reactor core catcher with the melt expansion room comprises a reactor cavity which coats the middle lower portion of a reactor pressure vessel, a reactor cavity concrete base plate is arranged on the lower portion of the reactor cavity, and a reactor cavity refractory layer is arranged on the lower portion of the reactor cavity concrete base plate. The upper end of a melt release passage is communicated with the reactor cavity refractory layer, and the lower end of the melt release passage is communicated with the melt expansion room. The inner wall of the melt release passage surrounds the refractory layer. An expansion room concrete base plate is arranged on the lower portion of the melt expansion room, an expansion room refractory layer is arranged on the lower portion of the expansion room concrete base plate, and an expansion room outside cooling passage is arranged on the lower portion of the expansion room refractory layer. Two ends of the expansion room outside cooling passage extend outwards and are respectively an outside cooling passage entrance and an outside cooling passage exit. The large-scale passive pressurized water reactor nuclear power plant reactor core catcher with the melt expansion room is used for successively implementing expansion, retention and cooling of the melt when the a pressure container loses efficacy and can strengthen capacity of relieving severe accidents of the large-scale passive pressurized water reactor nuclear power plant.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

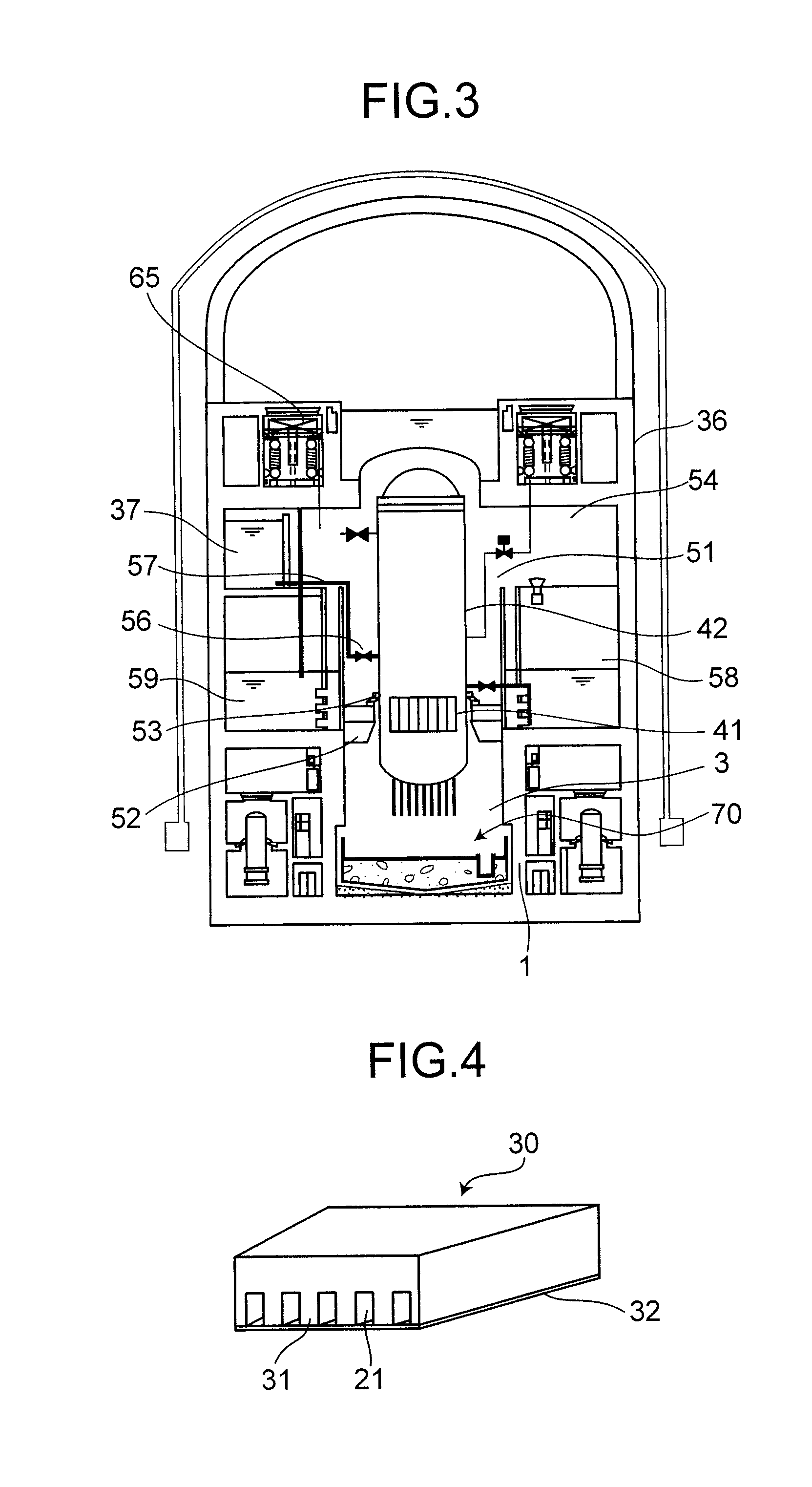

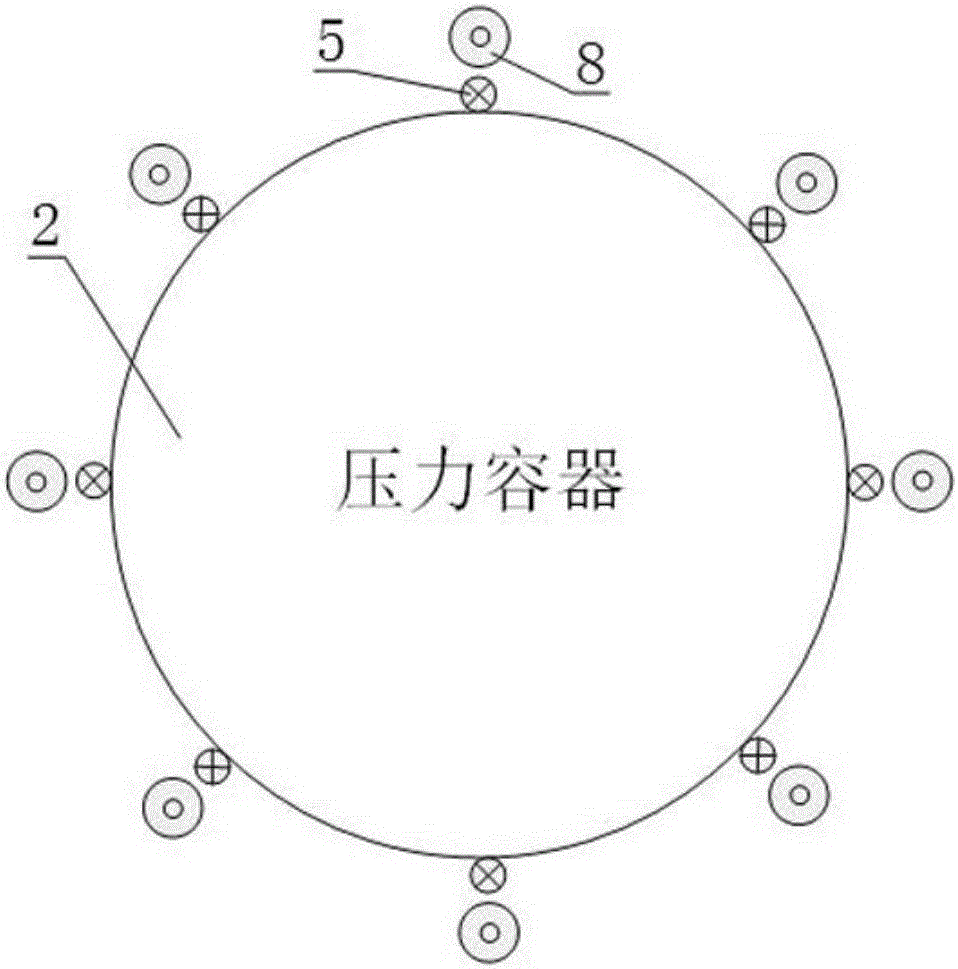

Device combining in-core and out-of-core dwelling of molten material of large-scale passive nuclear power plant

InactiveCN103578580AImplementation of off-stack coolingImplement in-heap retentionNuclear energy generationEmergency protection arrangementsCore catcherPressurized water reactor

The invention provides a device combining in-core and out-of-core dwelling of a molten material of a large-scale passive nuclear power plant. The device comprises a concrete sacrificial layer (4), a core catcher chamber (7), a core catcher refractory layer (8), a cooling channel inlet (9), a cooling channel outlet (10) and a core catcher bottom cooling channel (11). The invention provides a set of device organically combining molten material out-of-core cooling with an IVR (interactive voice response) system, when IVR succeeds, in-core dwelling of the molten material can be realized; and after the IVR fails, out-of-core dwelling of the molten material is realized by passive cooling of the core catcher bottom cooling channel, and the capability of mitigating severe accidents of the large-scale passive pressurized water reactor nuclear power plant is further enhanced.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

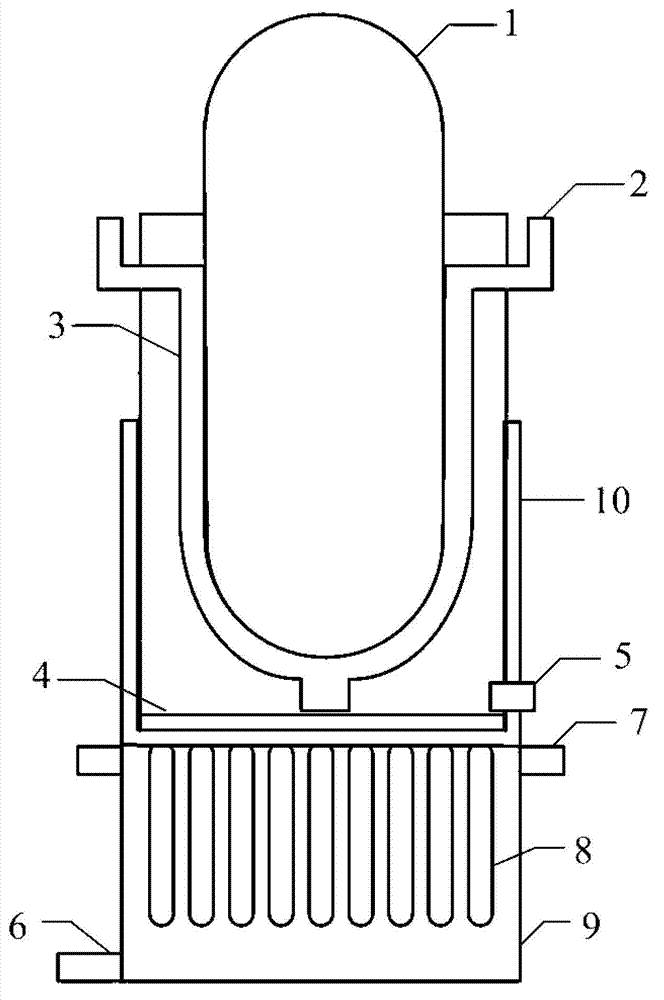

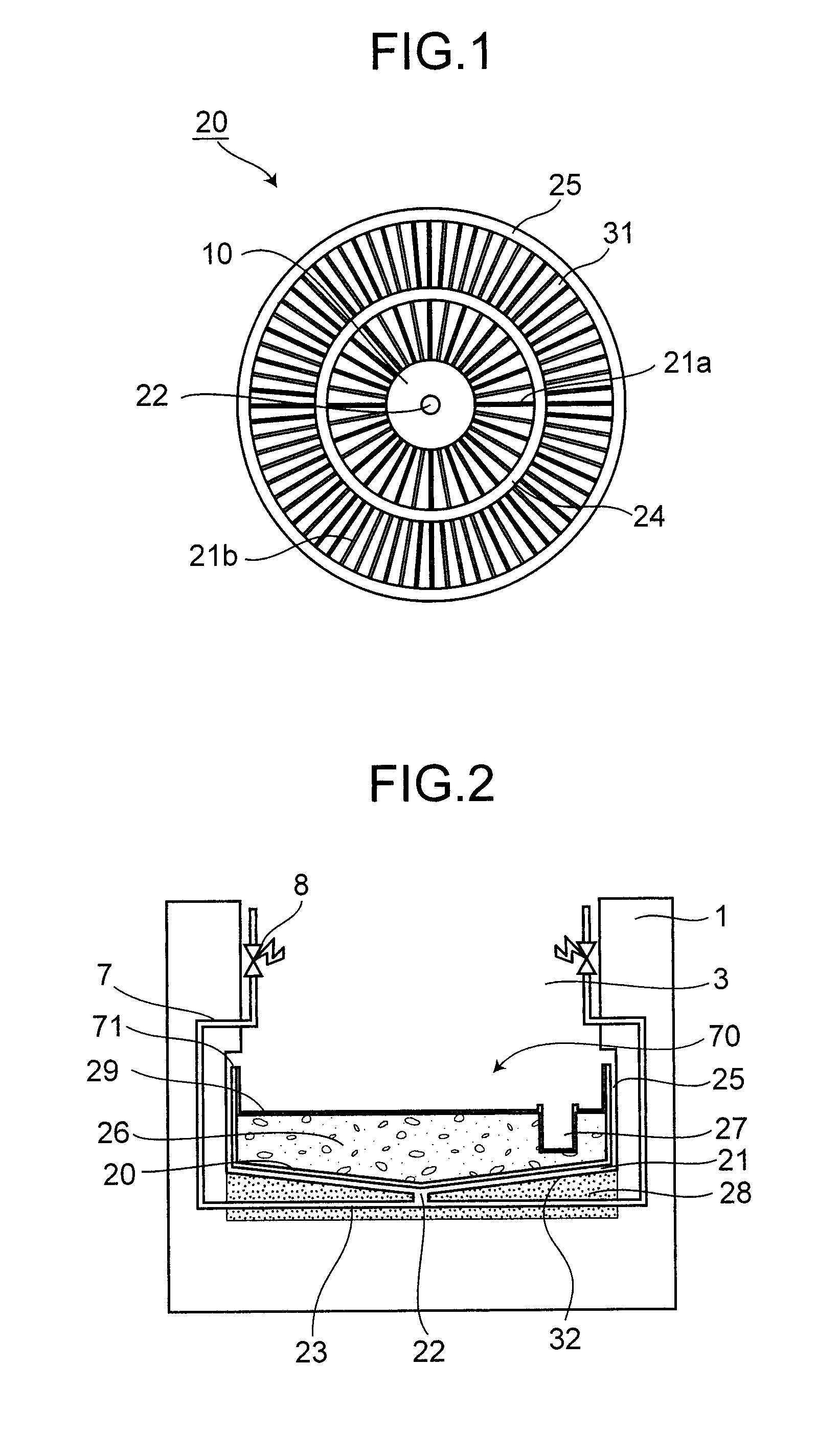

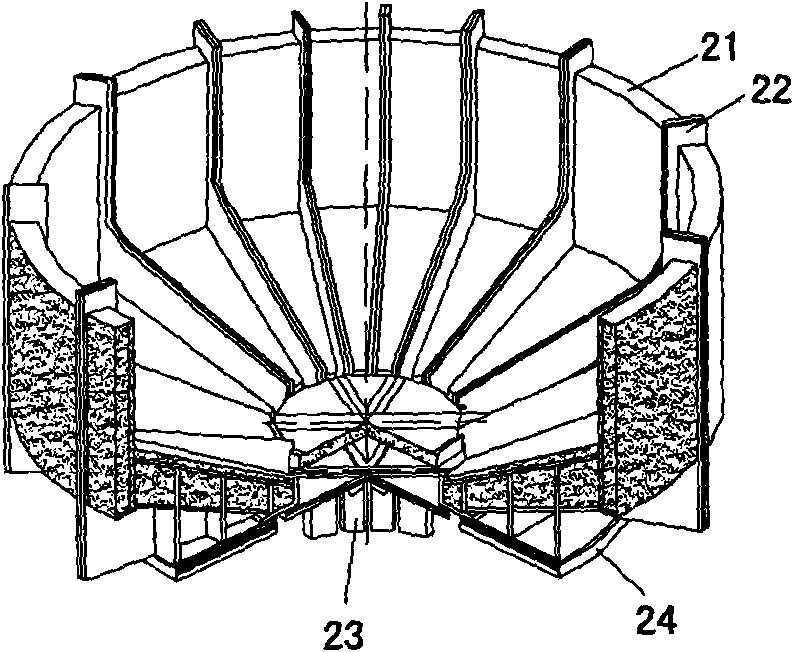

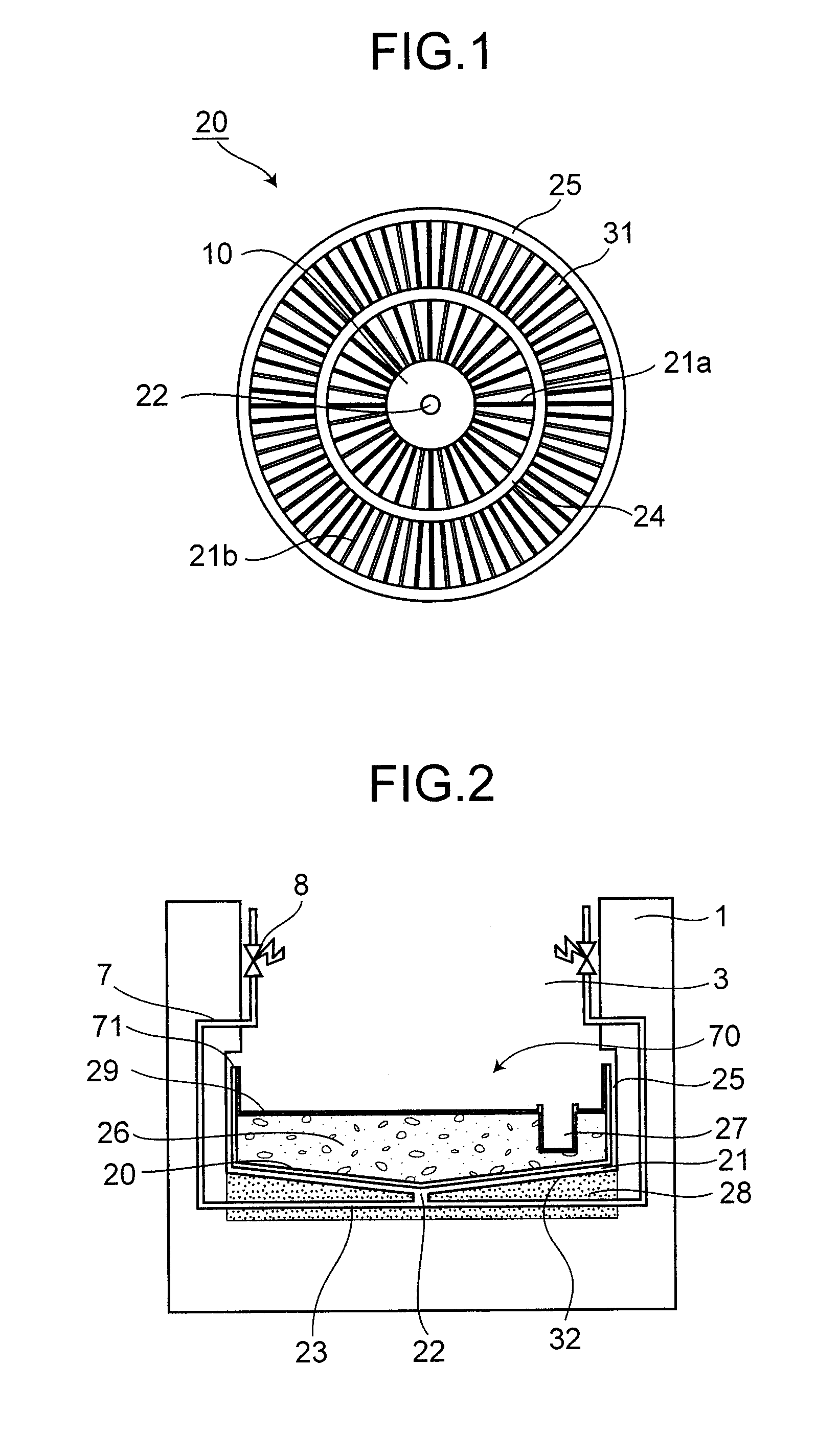

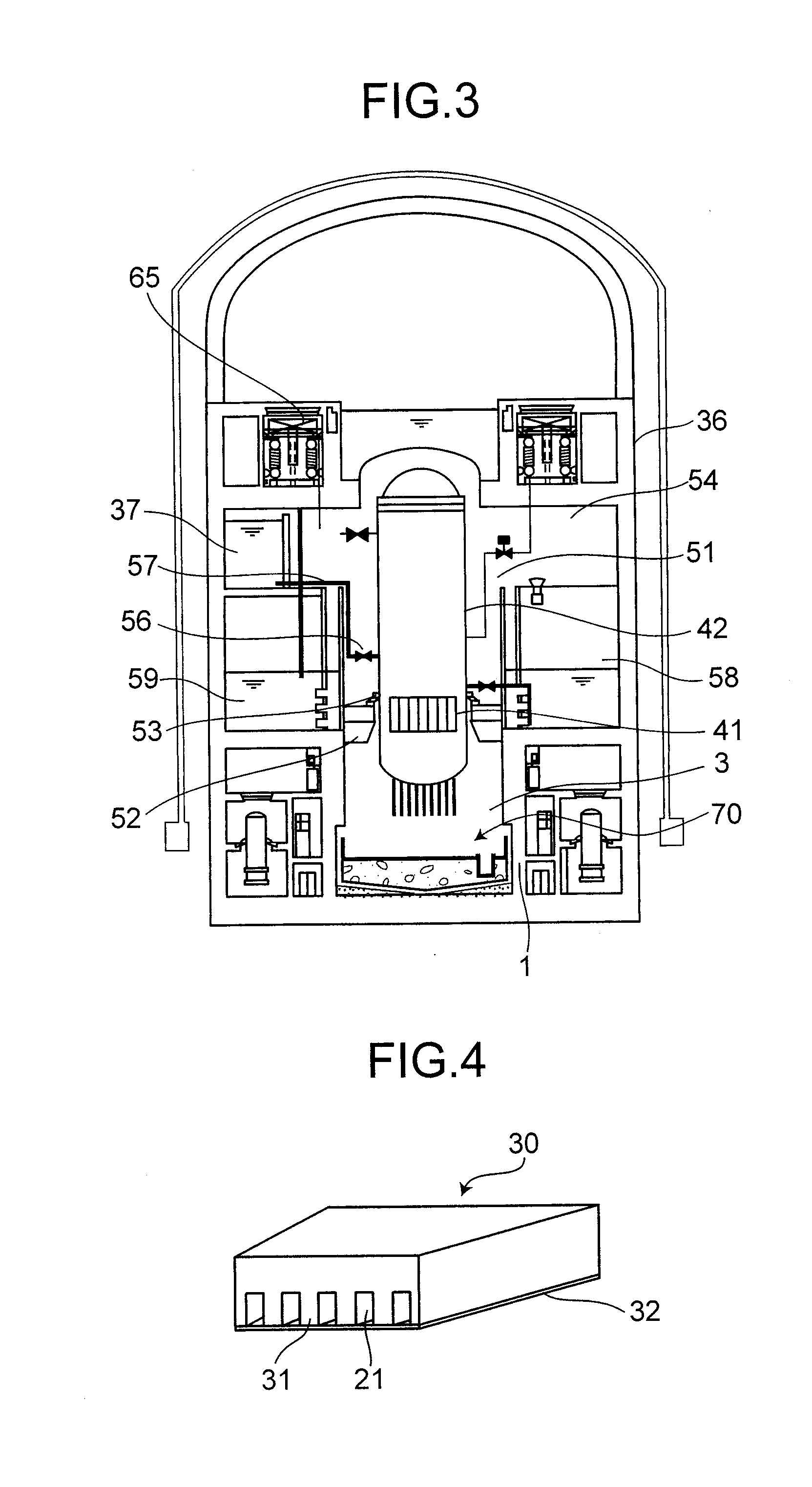

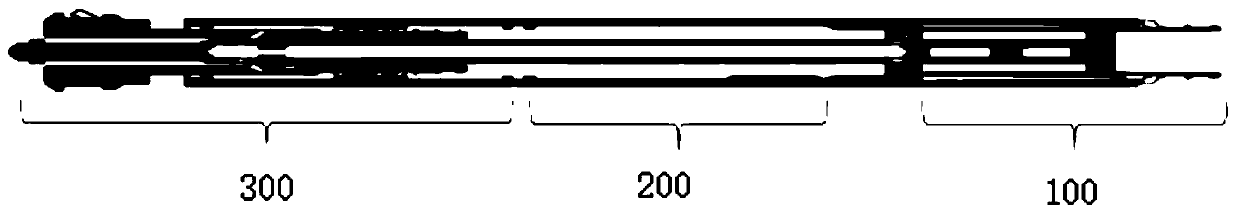

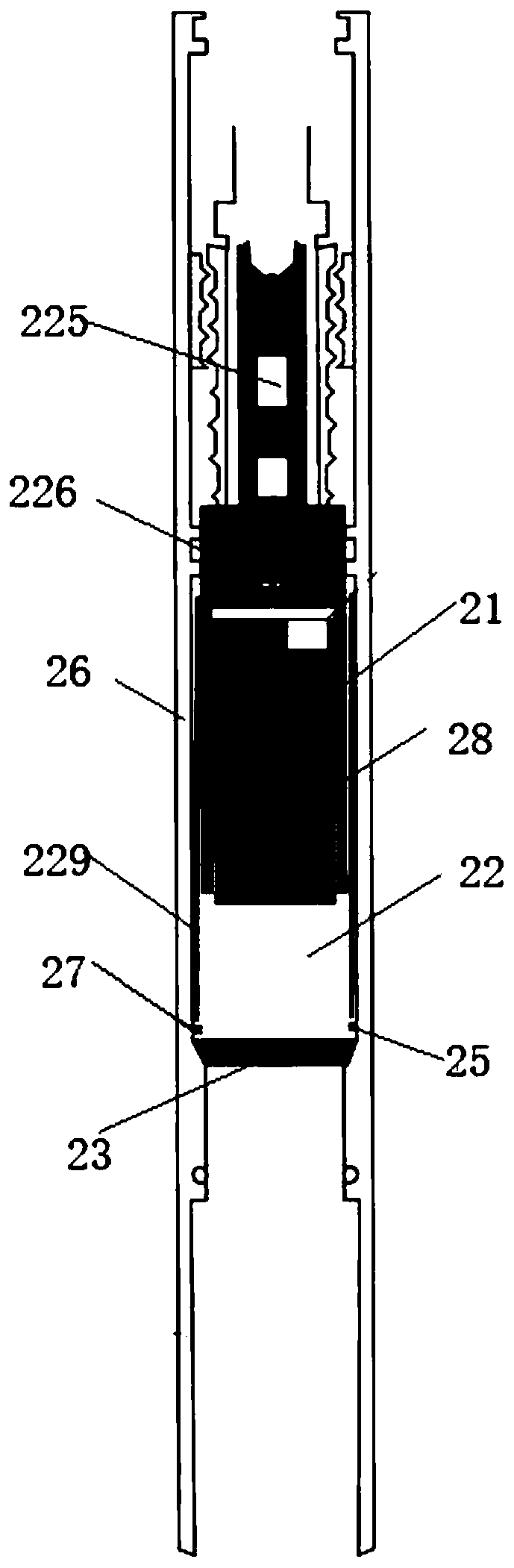

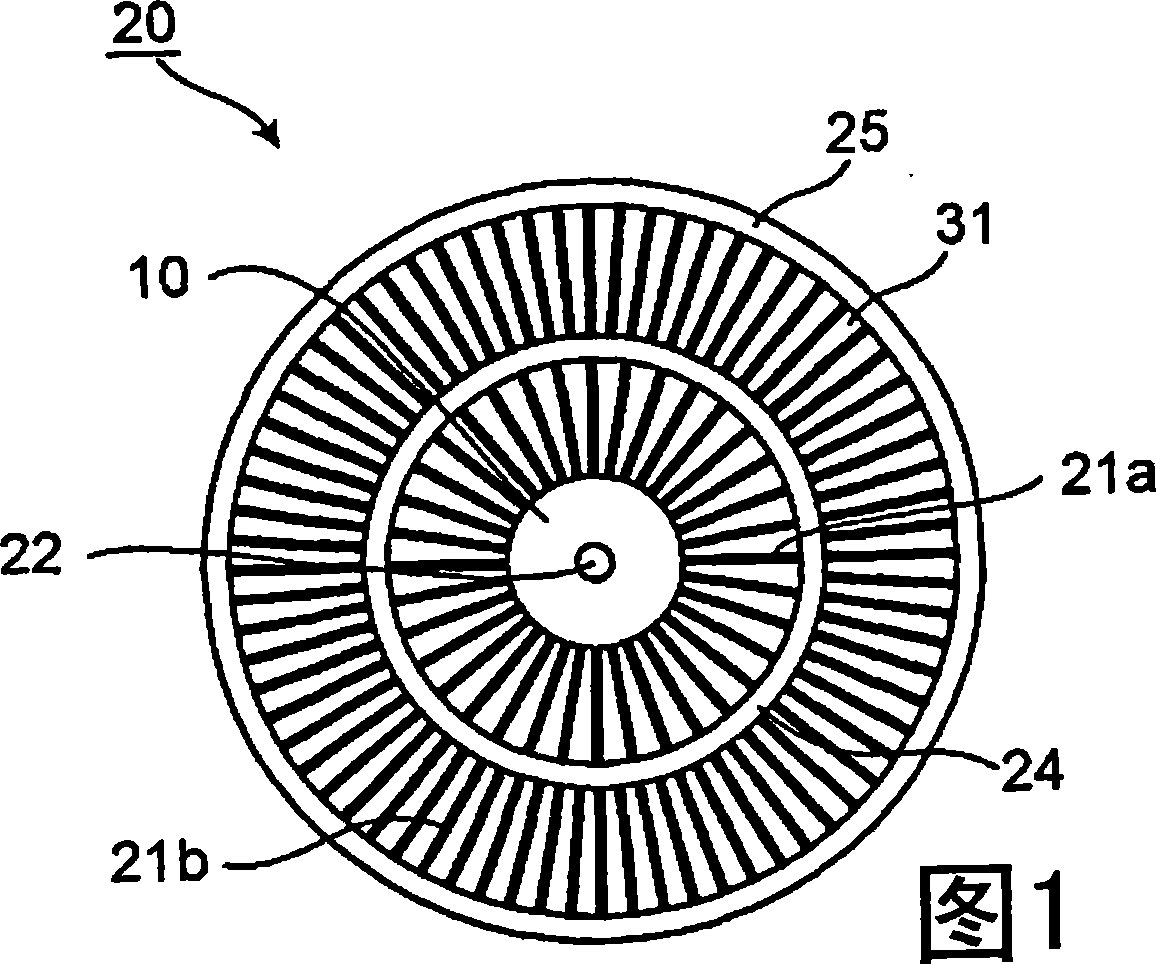

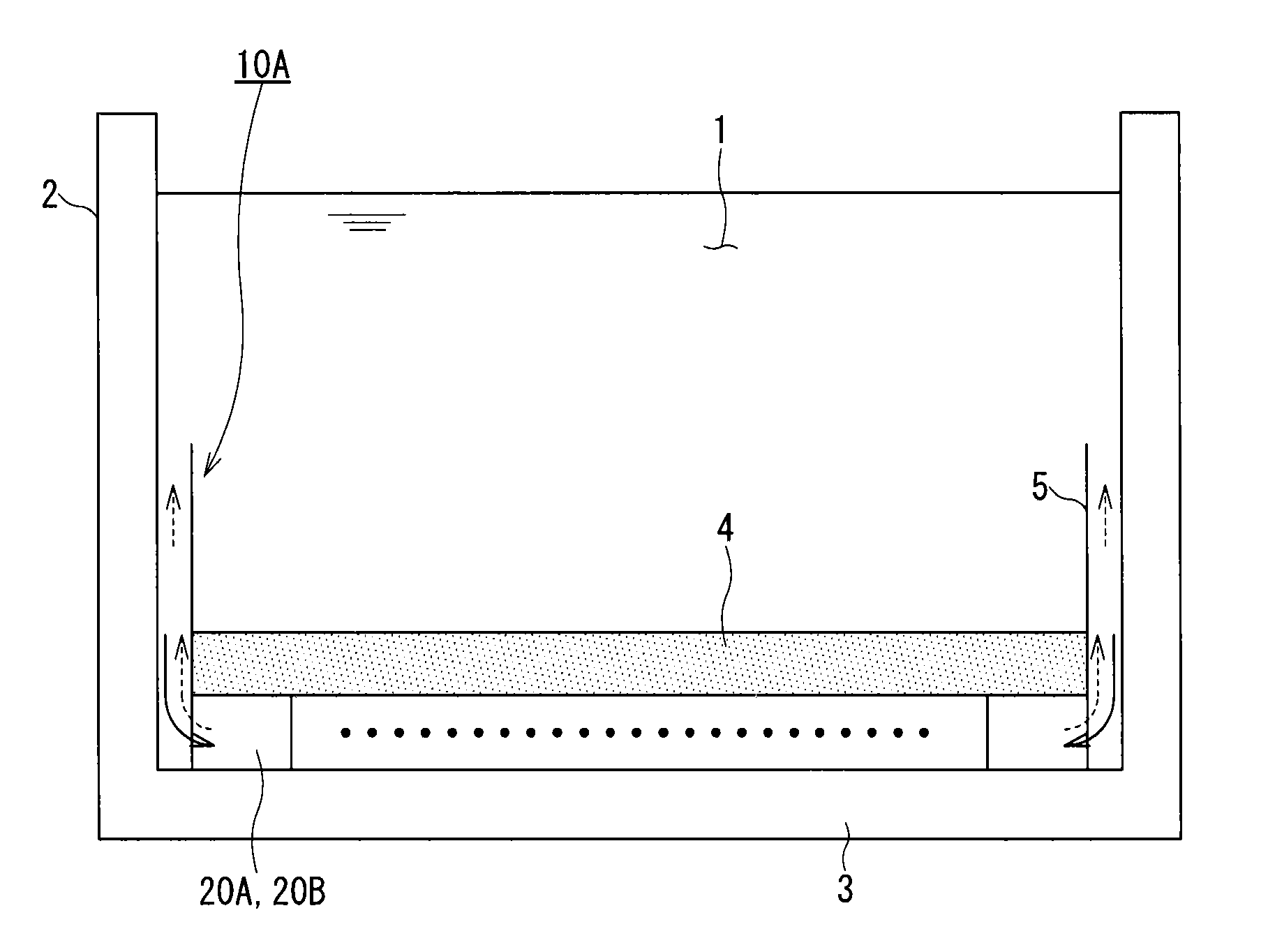

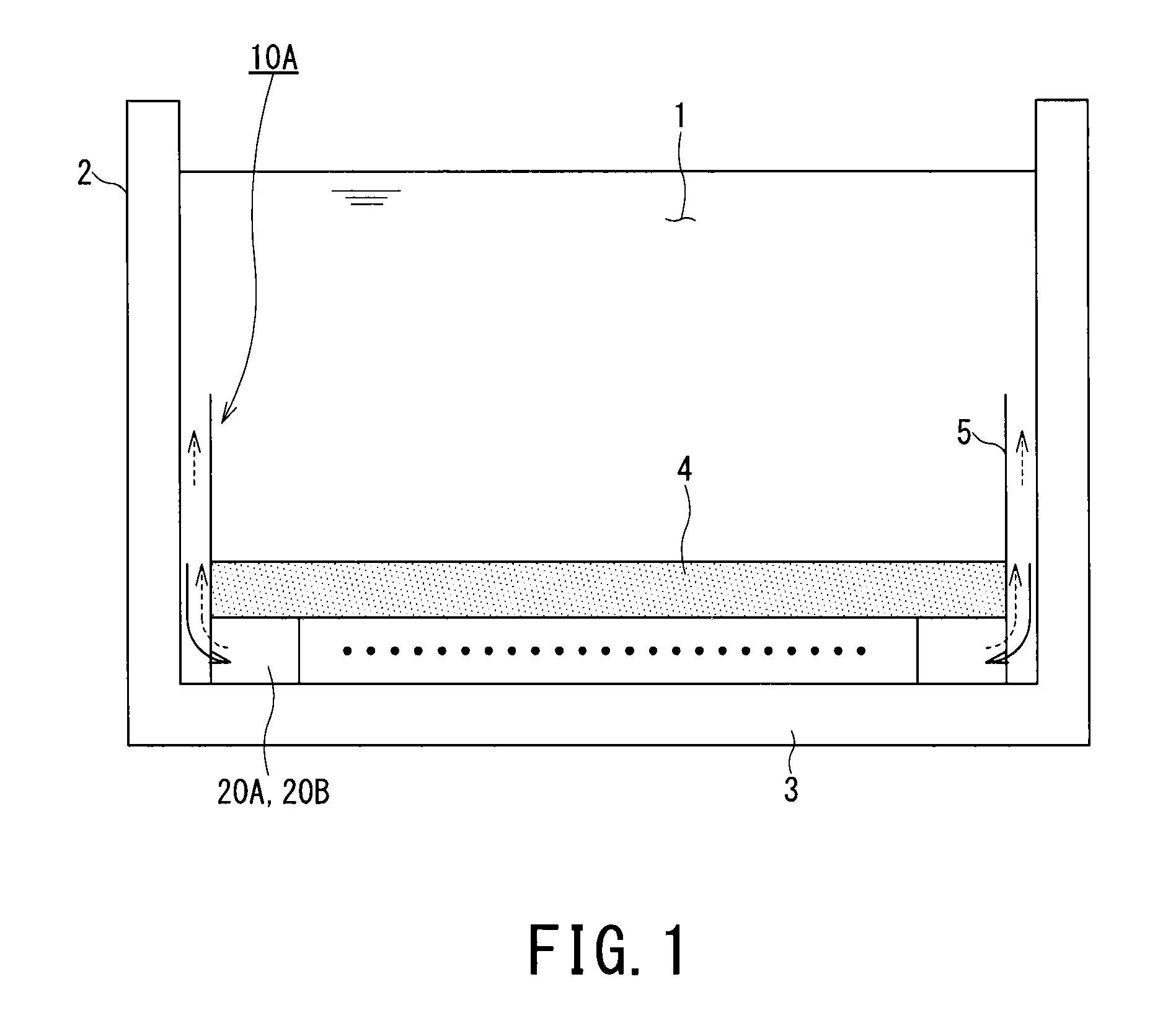

Core catcher, manufacturing method thereof, reactor containment vessel and manufacturing method thereof

Core debris generated during a molten reactor core in a reactor containment vessel penetrating the reactor containment vessel is configured to be caught by a core catcher located beneath the reactor containment vessel which has a main body having first stage cooling water channels and second stage surrounded by cooling fins extending radially. The number of the second stage cooling channels is larger than that of the first stage cooling channels. Cooling water is supplied from a cooling water injection opening and distributed to the first cooling water channels at a distributor. An intermediate header is formed between the first and the second cooling water channels, and the cooling water is distributed to the second cooling water channels uniformly.

Owner:KK TOSHIBA

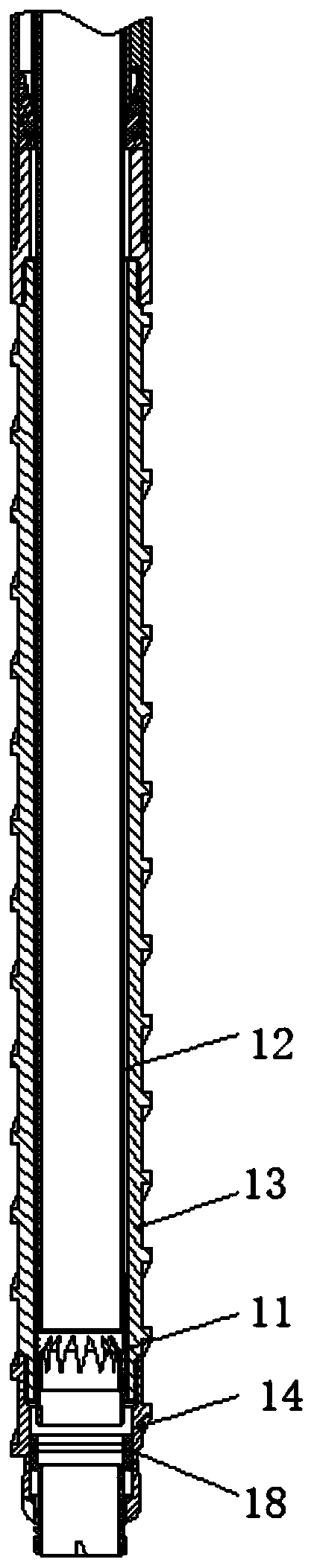

Method for installing reactor core catcher of nuclear power station

ActiveCN102097137ANuclear energy generationEmergency protection arrangementsCore catcherNuclear power

The invention provides a method for reliably installing a reactor core catcher in a narrow reactor vertical shaft, comprising the steps of: (1) installing a forging heat exchange device on a bottom plate of the reactor vertical shaft; (2) installing a hanging basket with fillers; and (3) installing a ventilation system and a lower bottom plate, wherein the step 1 for installing the forging heat exchange device further comprises the steps of: (1a) placing a plurality of forgings of a heat exchange device on the foundation of the reactor vertical shaft in advance, and confirming the actual respective positions of the forgings; (1b) installing a central fixing member and a supporting ribbed plate in the center of the vertical shaft; (1c) installing forgings on two sides of the ribbed plate according to the actual positions, and respectively fixing the forgings on the wall and the bottom plate of the vertical shaft through connecting pieces; and (1d), sequentially installing and welding the supporting ribbed plate and the forgings of the heat exchange device according to certain sequence. Accordingly, the method provided by the invention is favorable for greatly lowering the construction difficult and the construction workload at the same time of ensuring that all the parts of the reactor core capturer are safe and effective.

Owner:CHINA NUCLEAR IND 23 CONSTR

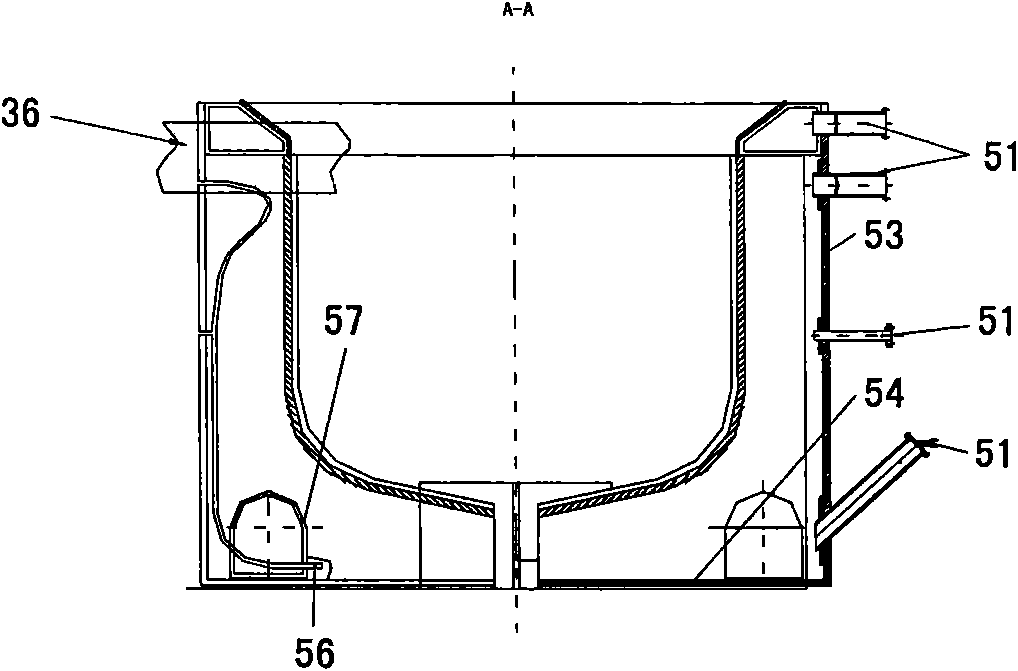

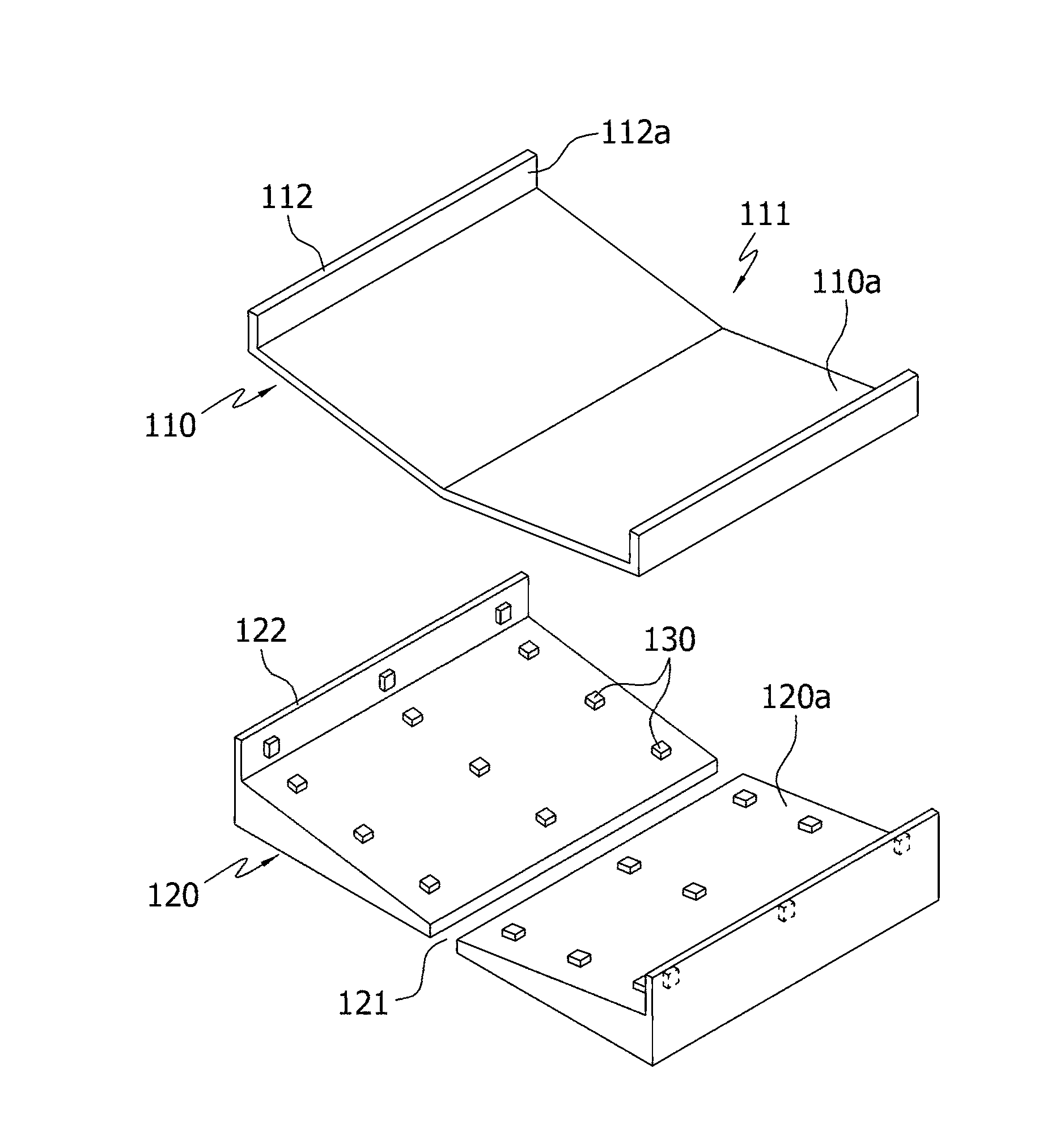

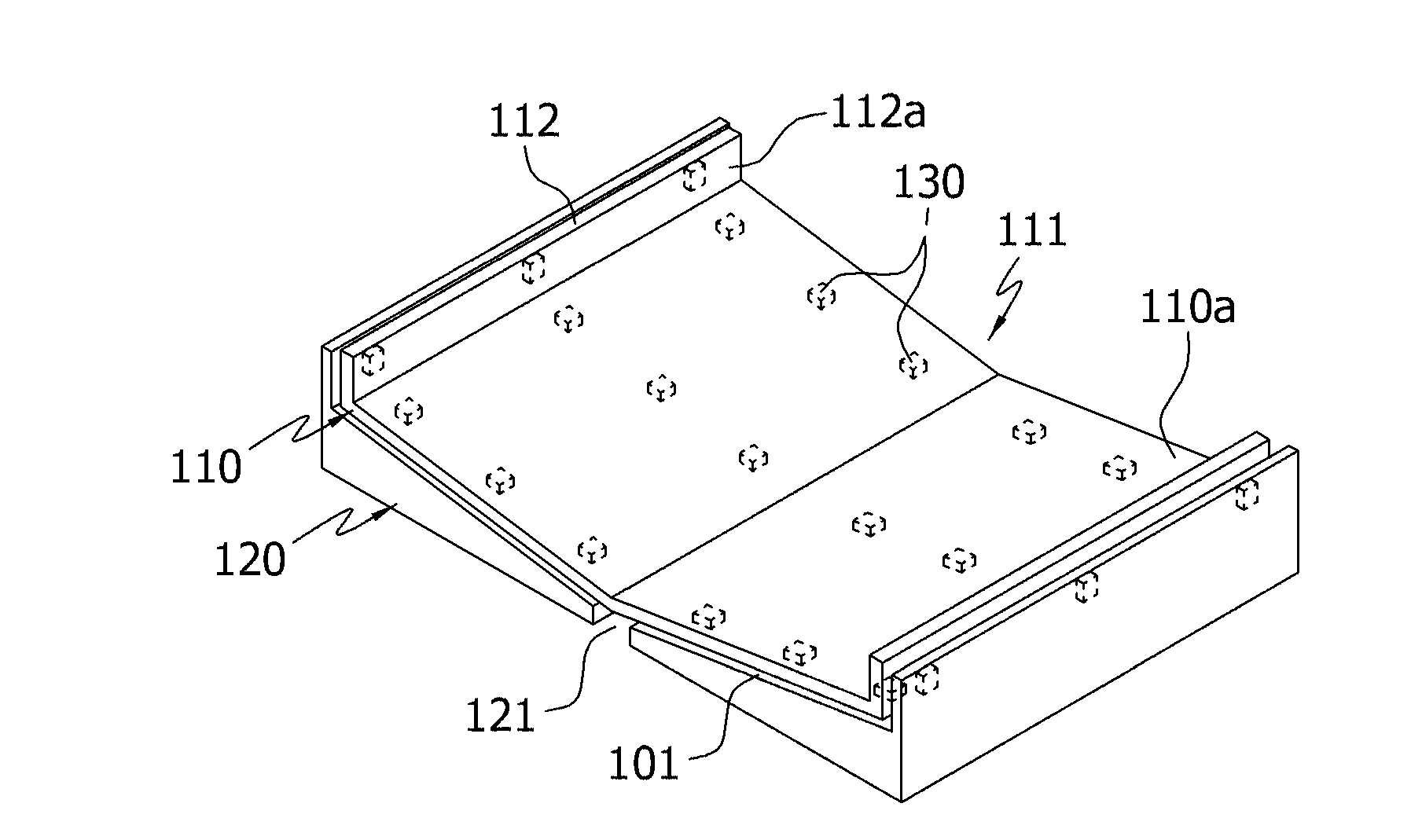

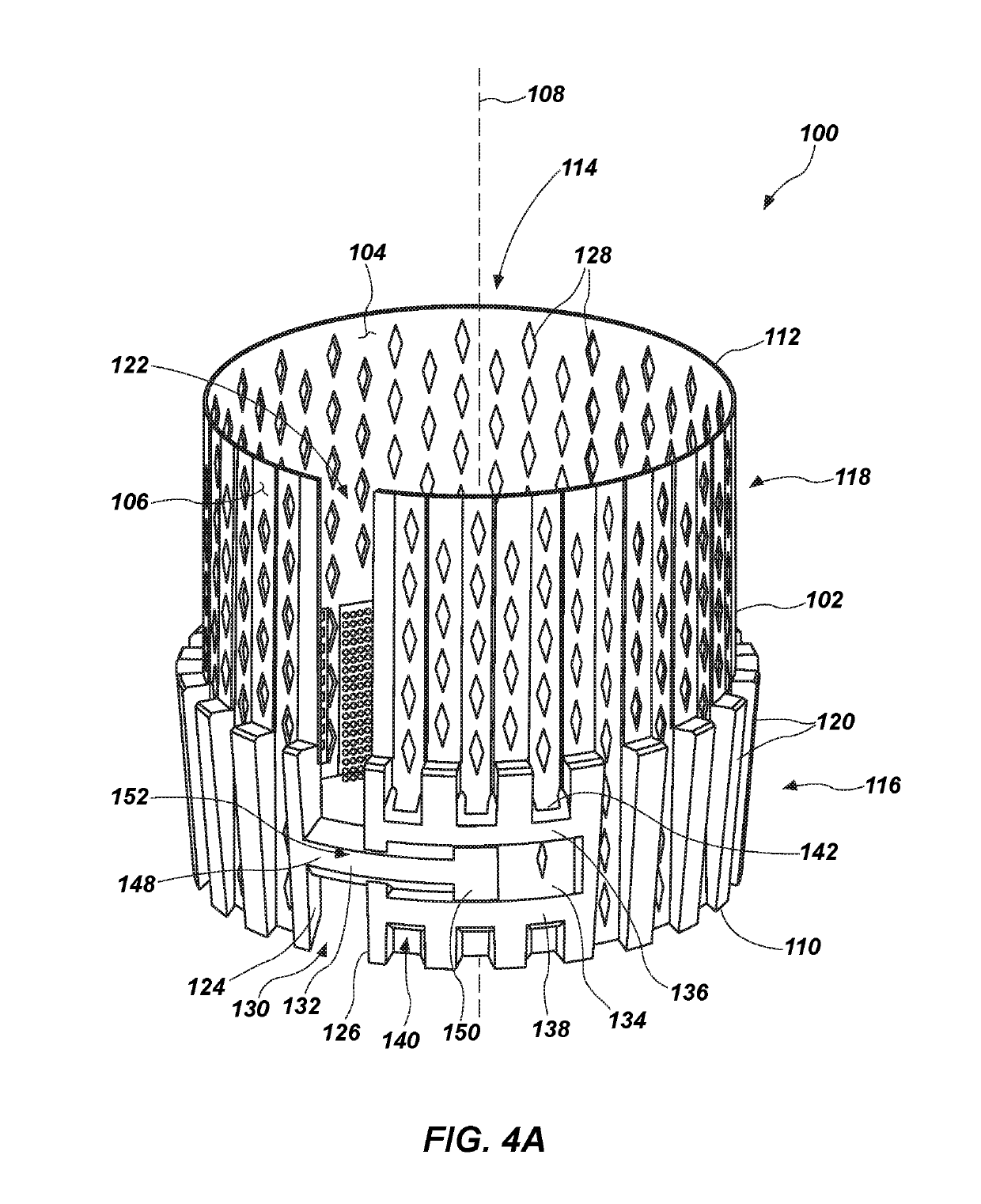

Core catcher having an integrated cooling path

ActiveCN103081023AIncrease heat transfer areaImprove cooling effectNuclear energy generationEmergency protection arrangementsCore catcherNuclear reactor

The object of the present invention is to provide a core catcher having an integrated cooling path, which comprises a structure able to effectively collect, retain and cool molten core material discharged through a damaged part of a nuclear reactor pressure container during a major incident in a nuclear power station. To this end, the present invention is a core catcher which is disposed underneath the nuclear reactor pressure container in order to retain and cool molten core material discharged through a damaged part of the nuclear reactor pressure container and prevent interaction between the molten core material and the pressure-holding structure of the reactor building during a major incident in the nuclear power station, and which comprises: a main container in the shape of an inverted roof which is provided underneath the nuclear reactor pressure container and collects the molten core material; and a lower structure which is disposed below and outside the main container with supports disposed at scattered points placed in between, thereby forming a cooling path having a predetermined spacing for eliminating the heat of the molten core material.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

Core catcher, manufacturing method thereof, reactor containment vessel and manufacturing method thereof

Core debris generated during a molten reactor core in a reactor containment vessel penetrating the reactor containment vessel is configured to be caught by a core catcher located beneath the reactor containment vessel which has a main body having first stage cooling water channels and second stage surrounded by cooling fins extending radially. The number of the second stage cooling channels is larger than that of the first stage cooling channels. Cooling water is supplied from a cooling water injection opening and distributed to the first cooling water channels at a distributor. An intermediate header is formed between the first and the second cooling water channels, and the cooling water is distributed to the second cooling water channels uniformly.

Owner:KK TOSHIBA

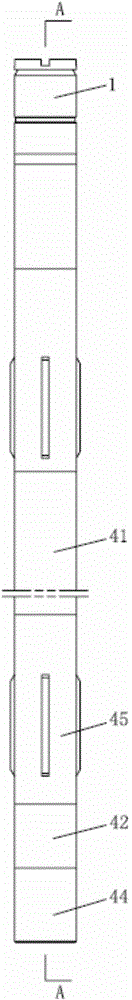

Rock sample in-situ fidelity coring system

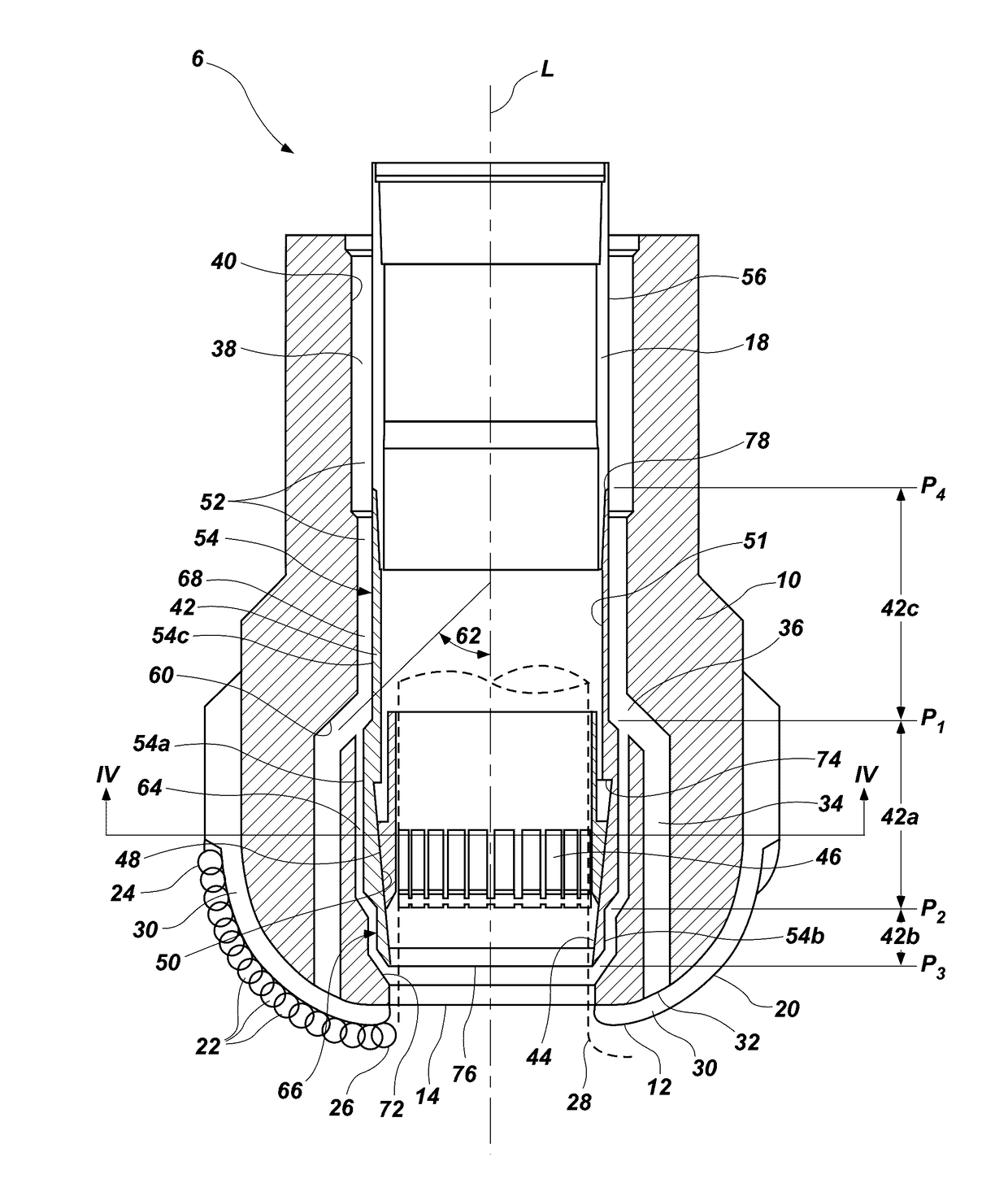

The invention discloses a rock sample in-situ fidelity coring system. The rock sample in-situ fidelity coring system comprises a driving module, a fidelity module and a coring module which are sequentially connected, the coring module comprises a rock core drilling tool and a rock core sample storage cylinder, the fidelity module comprises a rock core sample fidelity cabin, the driving module comprises a coring drill rig, and the coring drill rig comprises a drill rig outer cylinder unlocking mechanism; the rock core drilling tool comprises a coring drill tool, a core catcher and an inner corepipe, the coring drill tool comprises an outer core pipe and a hollow drill bit, and the drill bit is connected with the lower end of the outer core pipe; the lower end of the inner core pipe extendsto the bottom of the outer core pipe, and the inner core pipe is in clearance fit with the outer core pipe; and the rock core sample fidelity cabin comprises an inner coring cylinder, an outer coringcylinder and an energy accumulator, the outer coring cylinder sleeves the inner coring cylinder, the upper end of the inner coring cylinder communicates with a liquid nitrogen storage tank, the liquid nitrogen storage tank is located in the outer coring cylinder, the energy accumulator communicates with the outer coring cylinder, and the outer coring cylinder is provided with a flap valve. According to the rock sample in-situ fidelity coring system, the rock core is advantageously kept the state under the in-situ environment, the drilling speed can be increased, and the coring efficiency is improved.

Owner:SHENZHEN UNIV

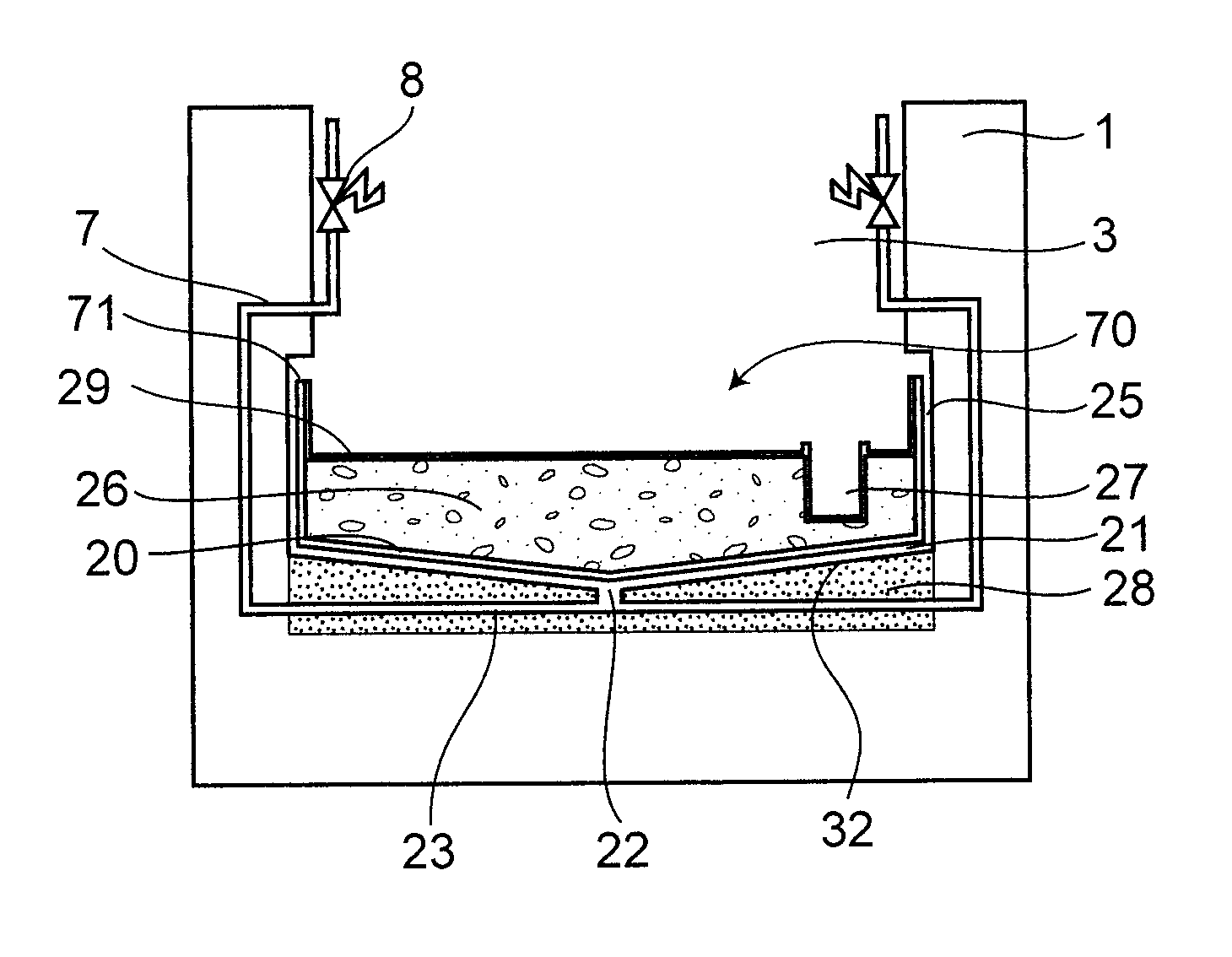

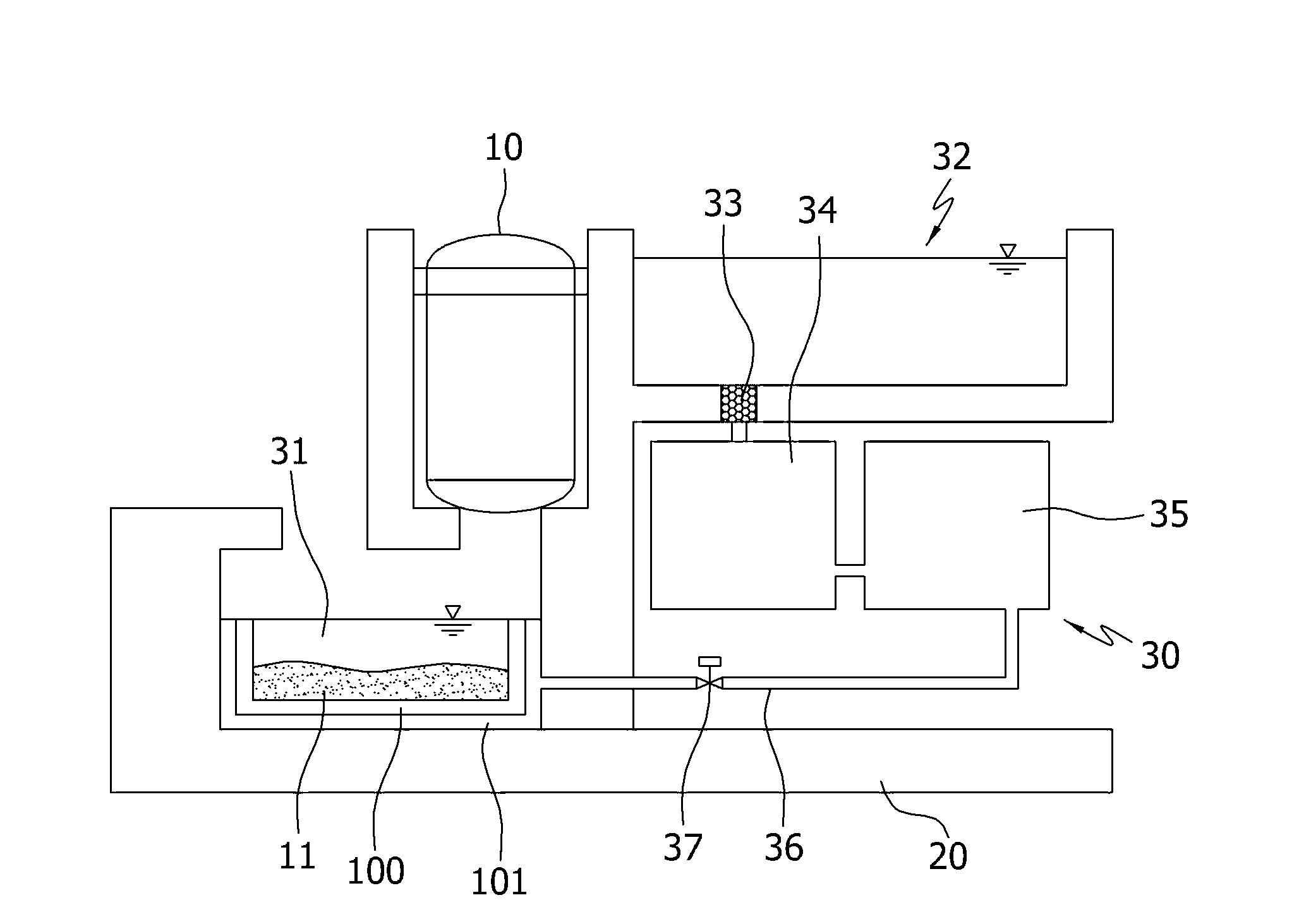

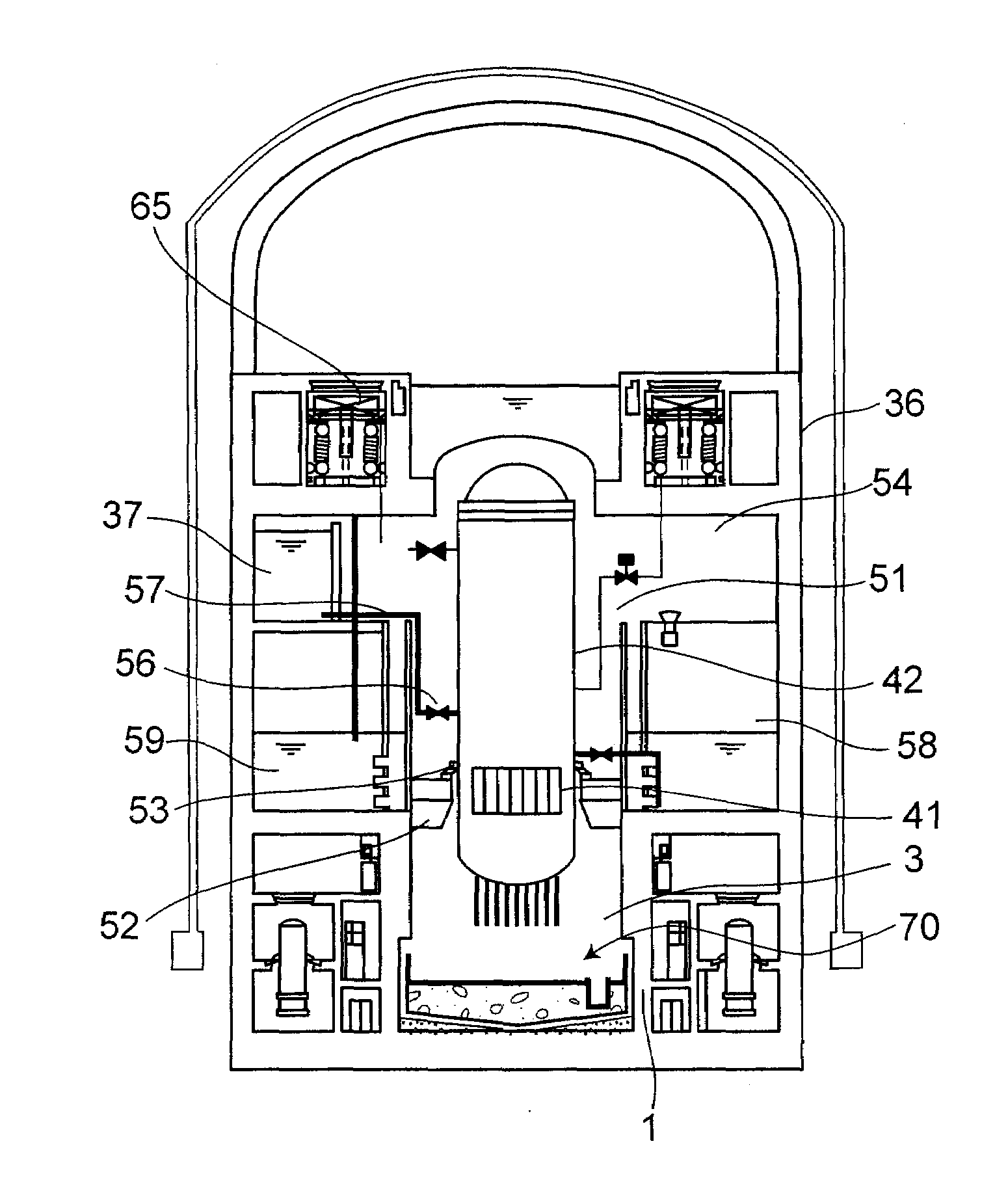

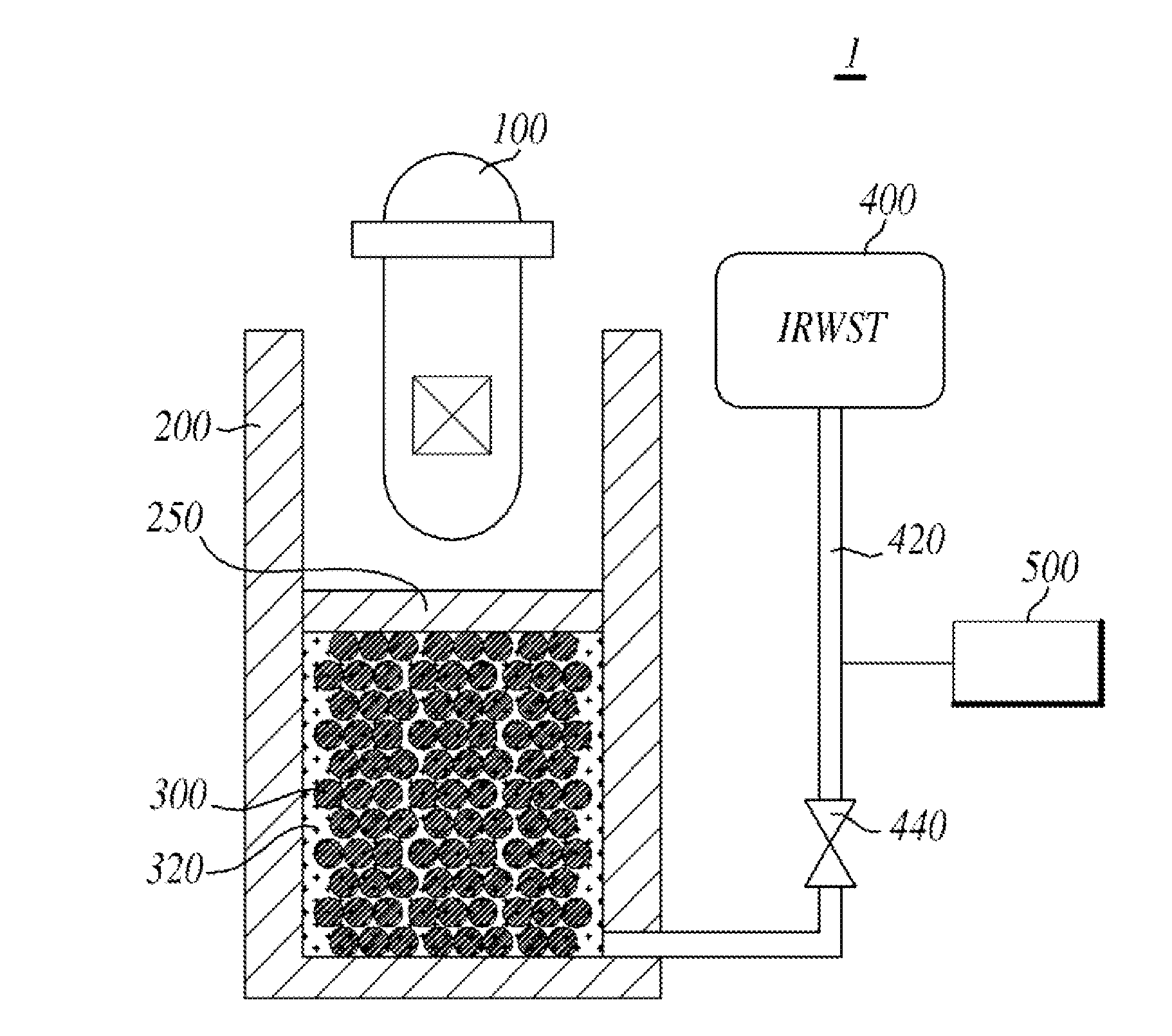

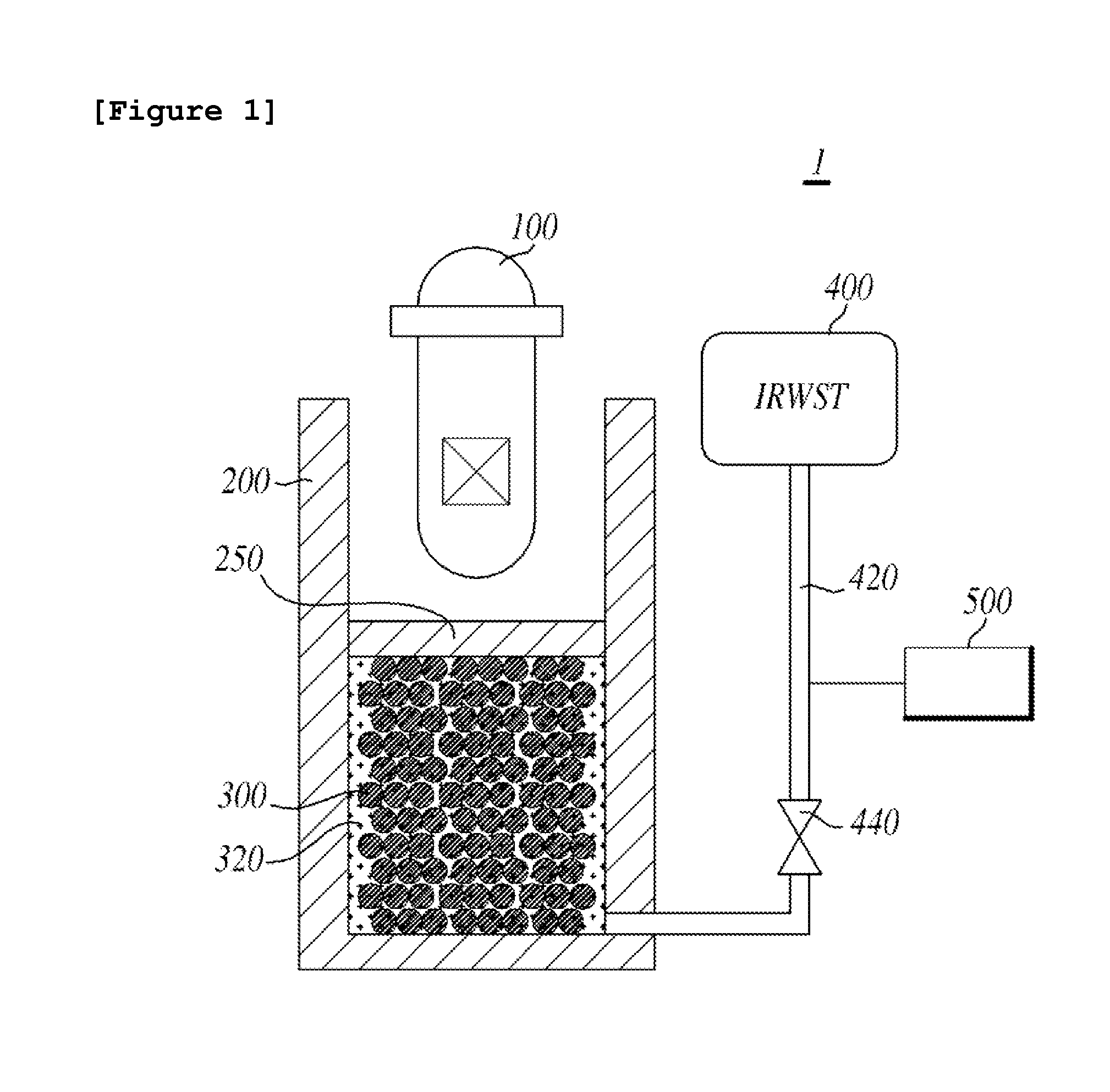

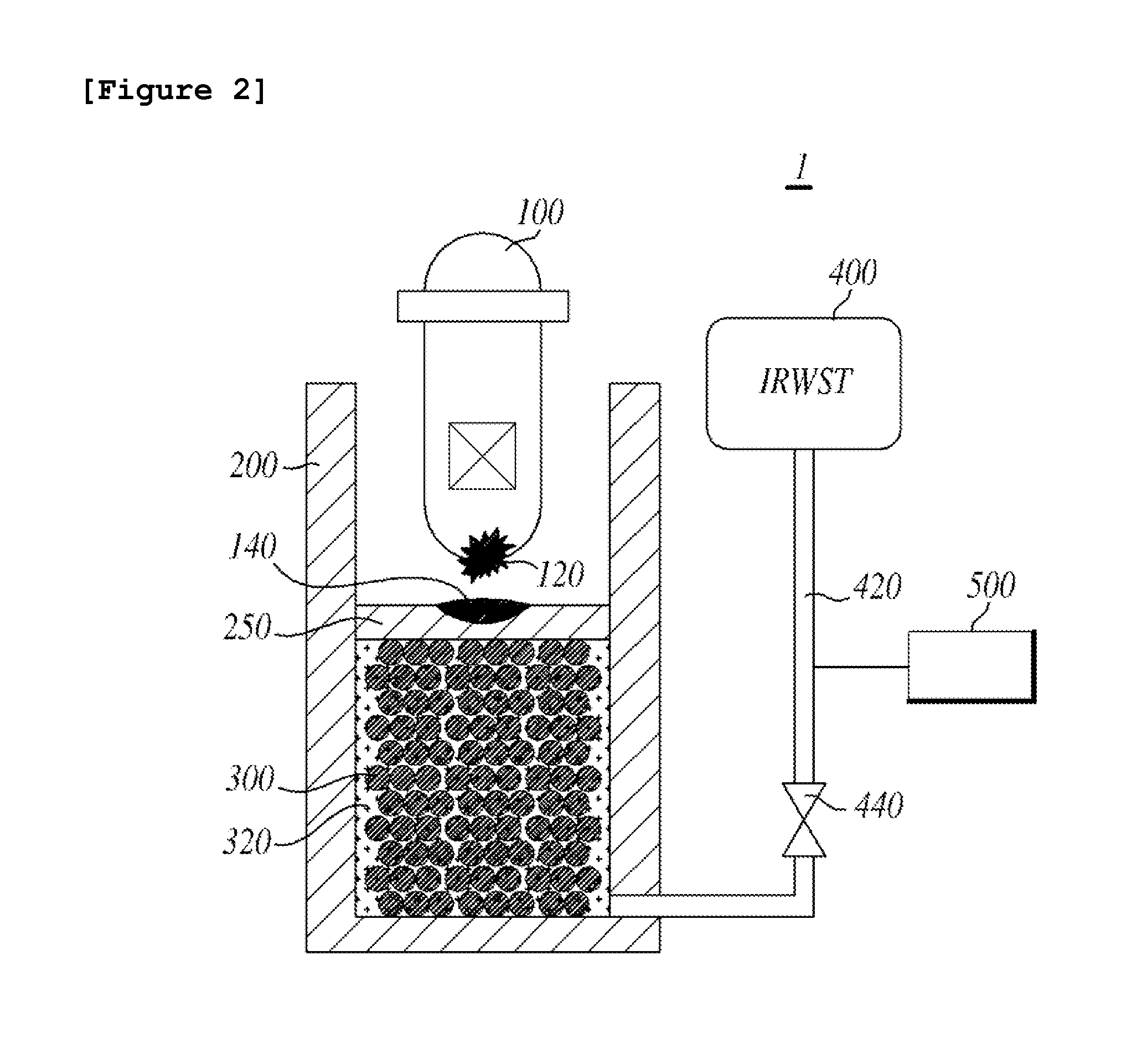

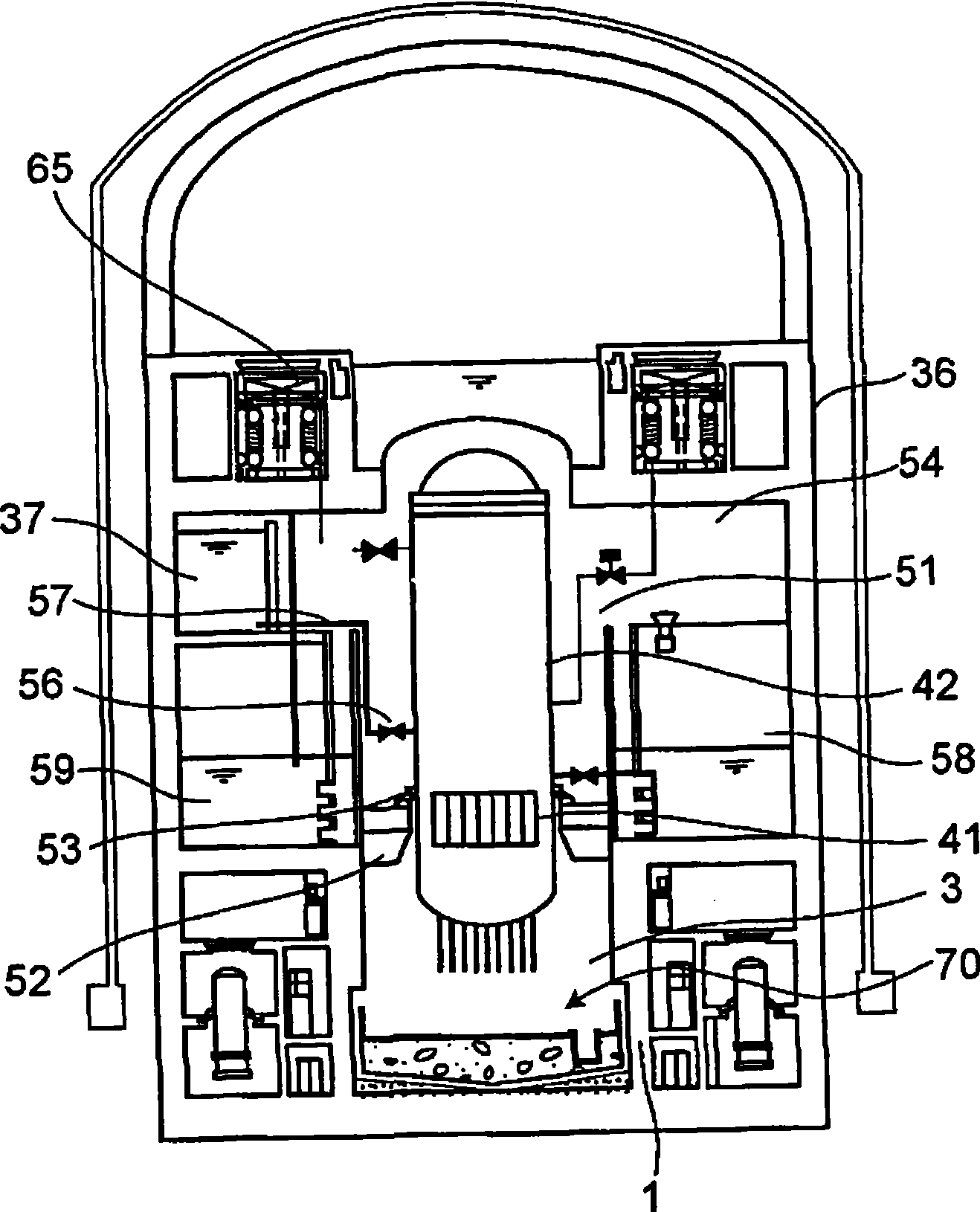

In-vessel and ex-vessel melt cooling system and method having the core catcher

InactiveUS20160141054A1Nuclear energy generationEmergency protection arrangementsCore catcherWater storage tank

The present invention relates to the in-vessel and ex-vessel melt cooling system having the core catcher. This system includes a reactor vessel having the core inside of the vessel, a core catcher that can cool the core melt ejecting from the damaged reactor vessel, a reactor cavity including the reactor vessel and the core catcher, IRWST (In-Containment Refueling Water Storage Tank) that can supply cooling water to the reactor cavity, and a control unit that can cut out the cooling water supply when the reactor cavity is filled with cooling water to the required level.

Owner:KOREA ADVANCED INST OF SCI & TECH

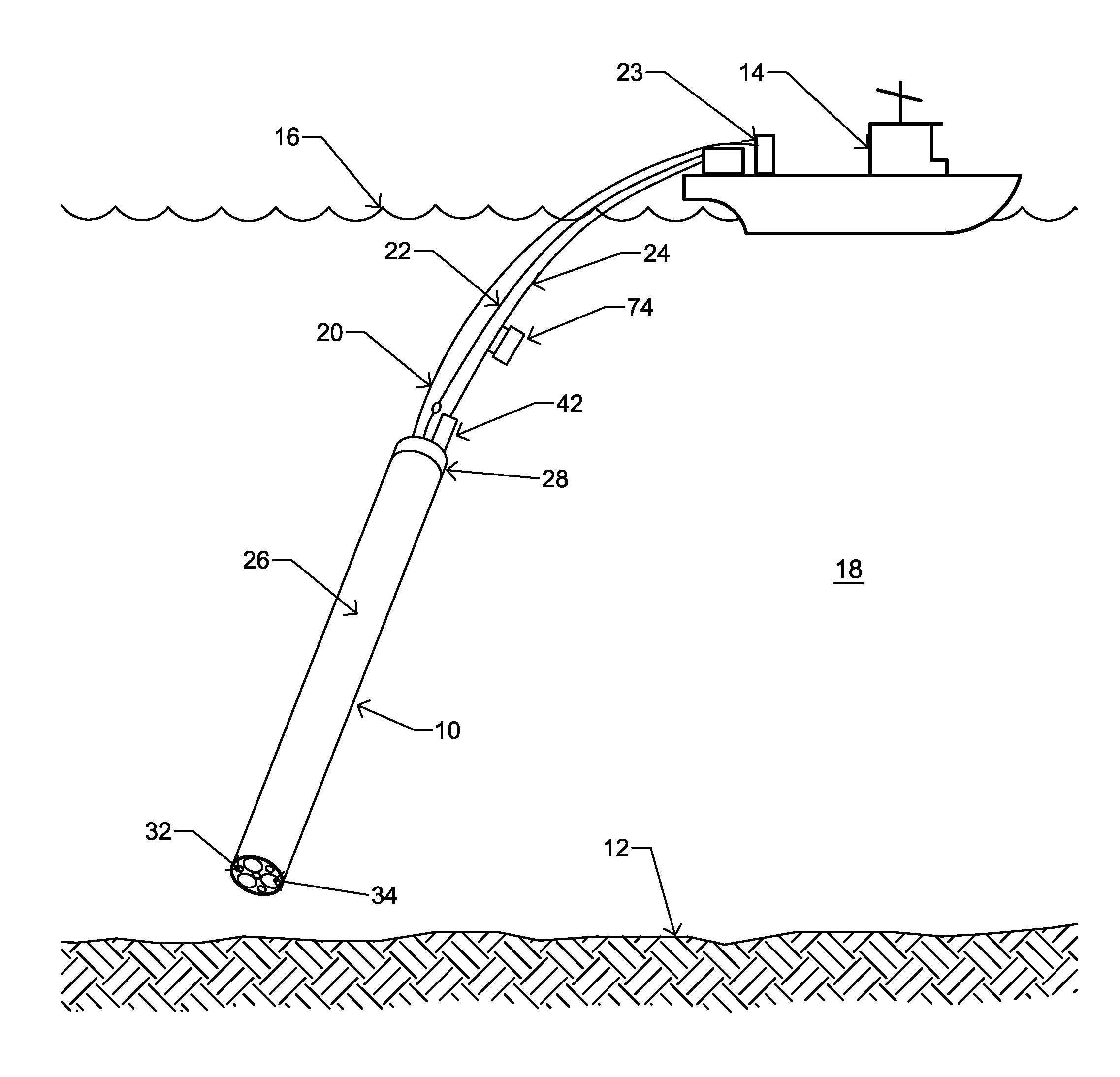

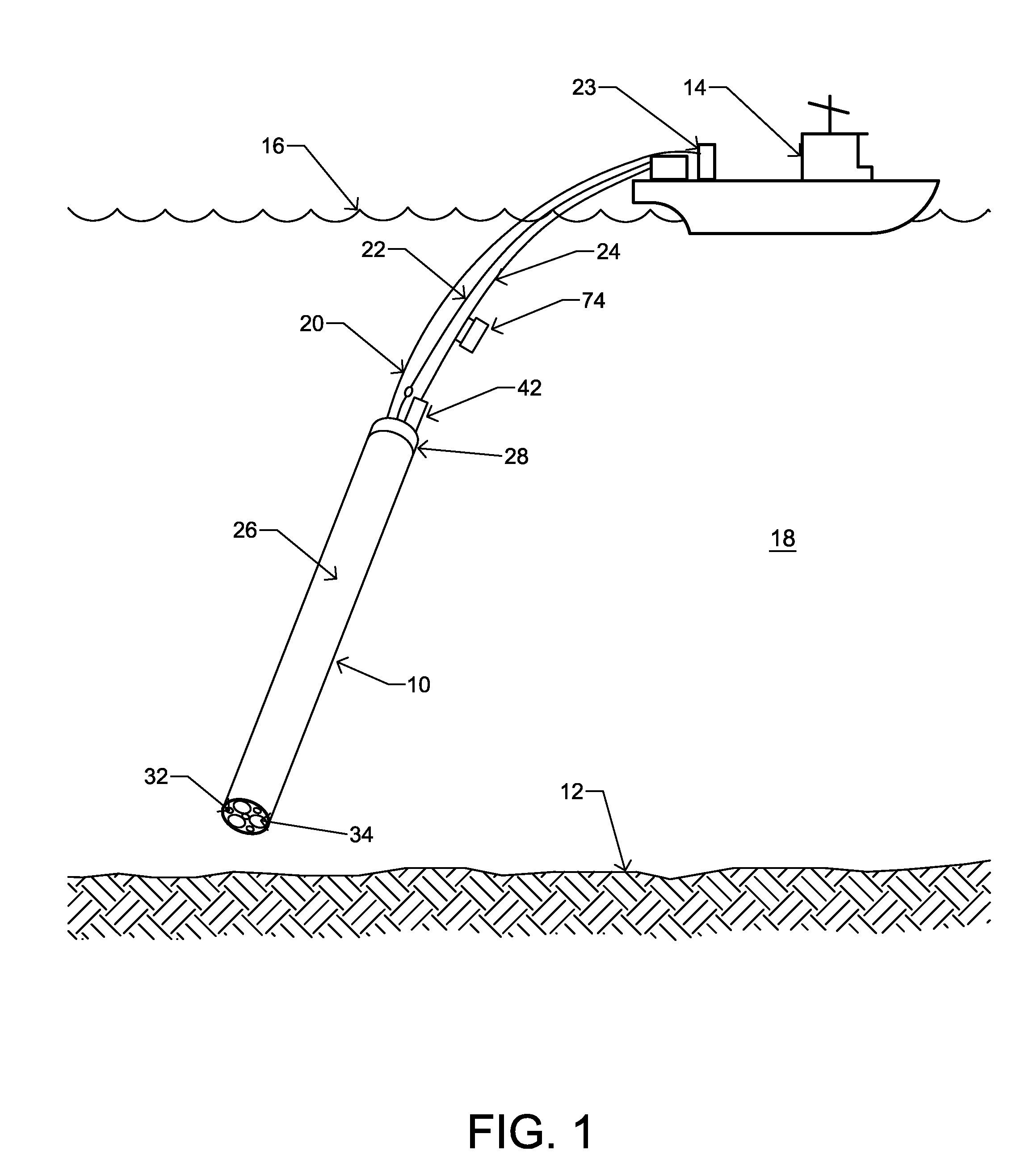

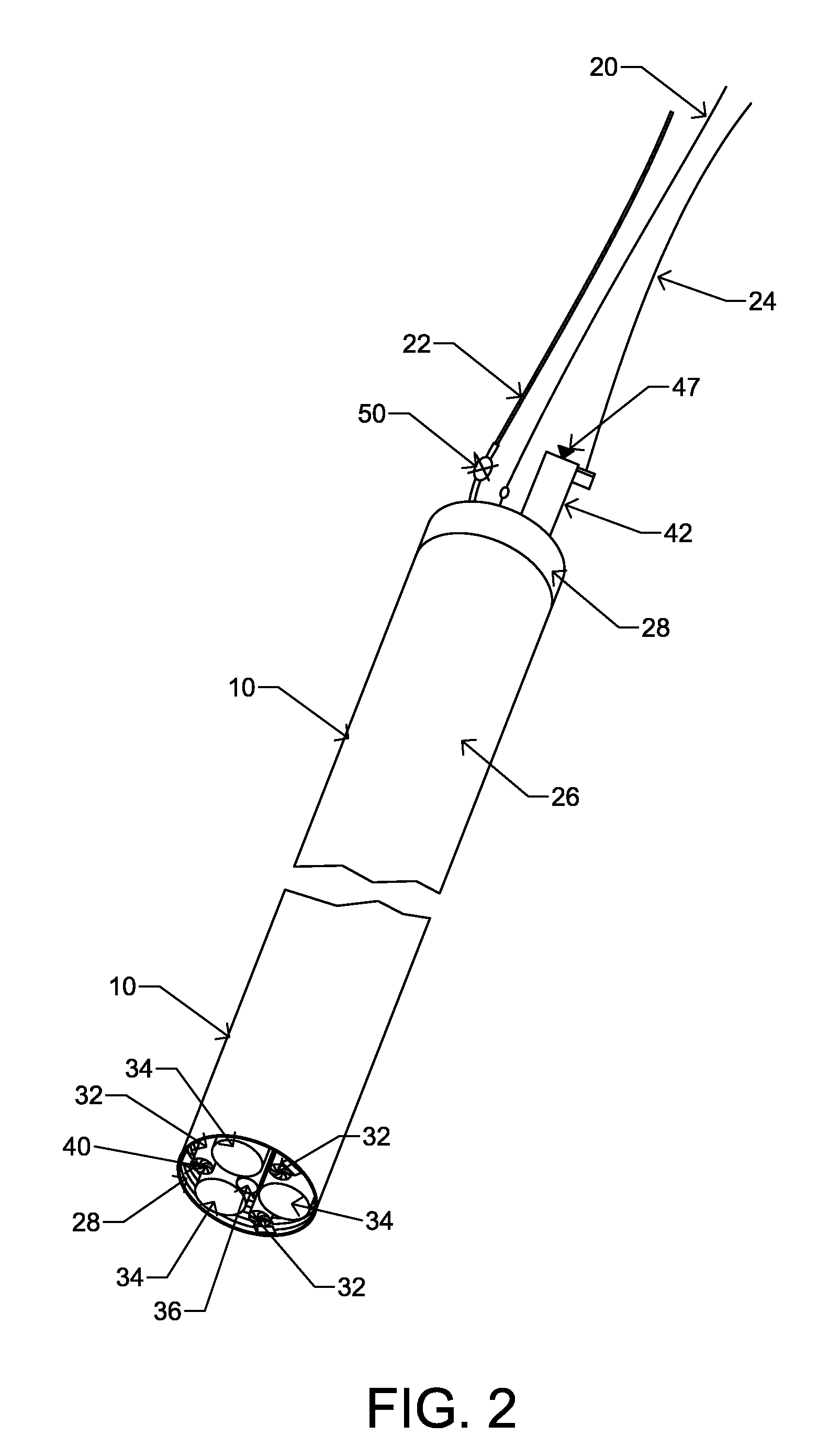

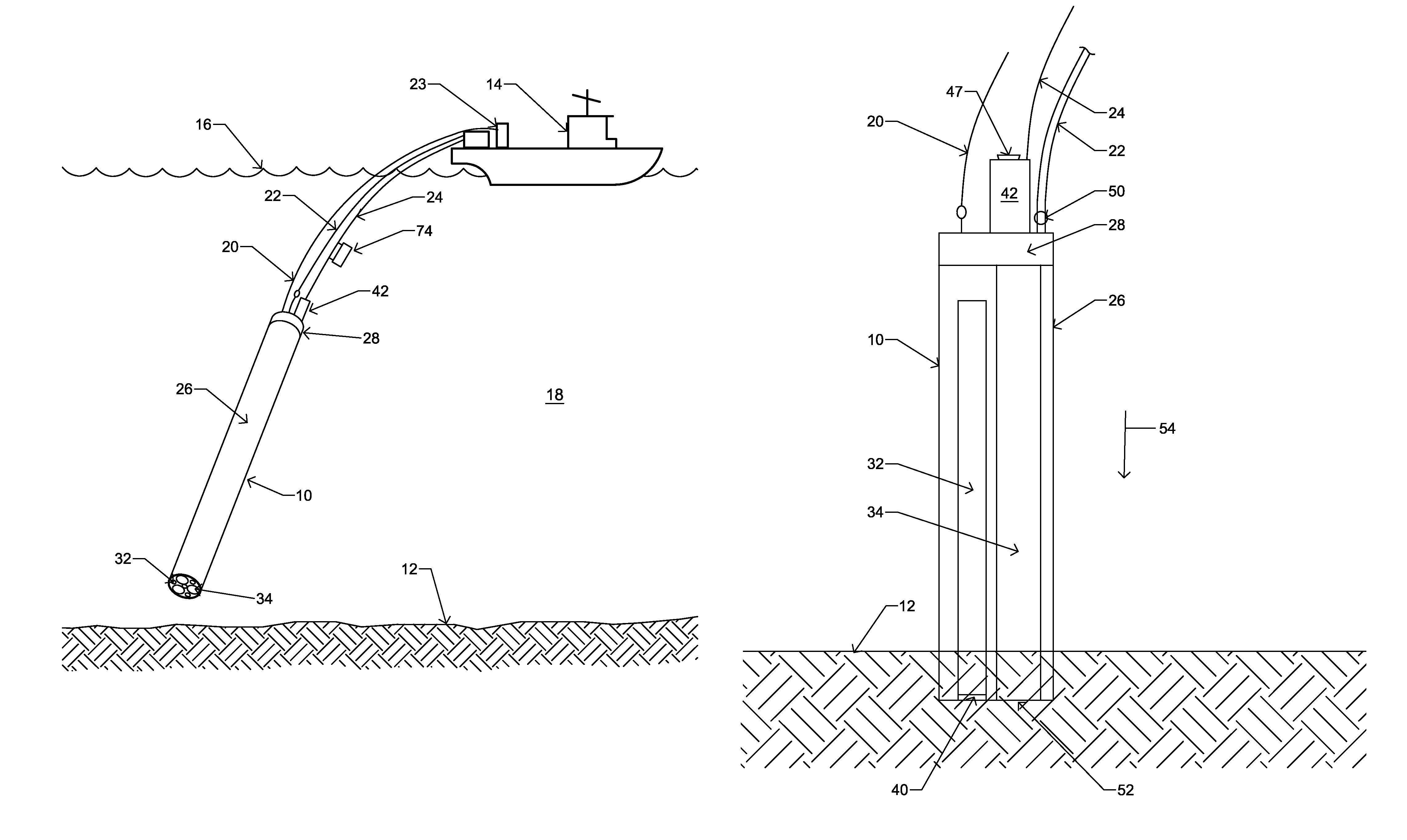

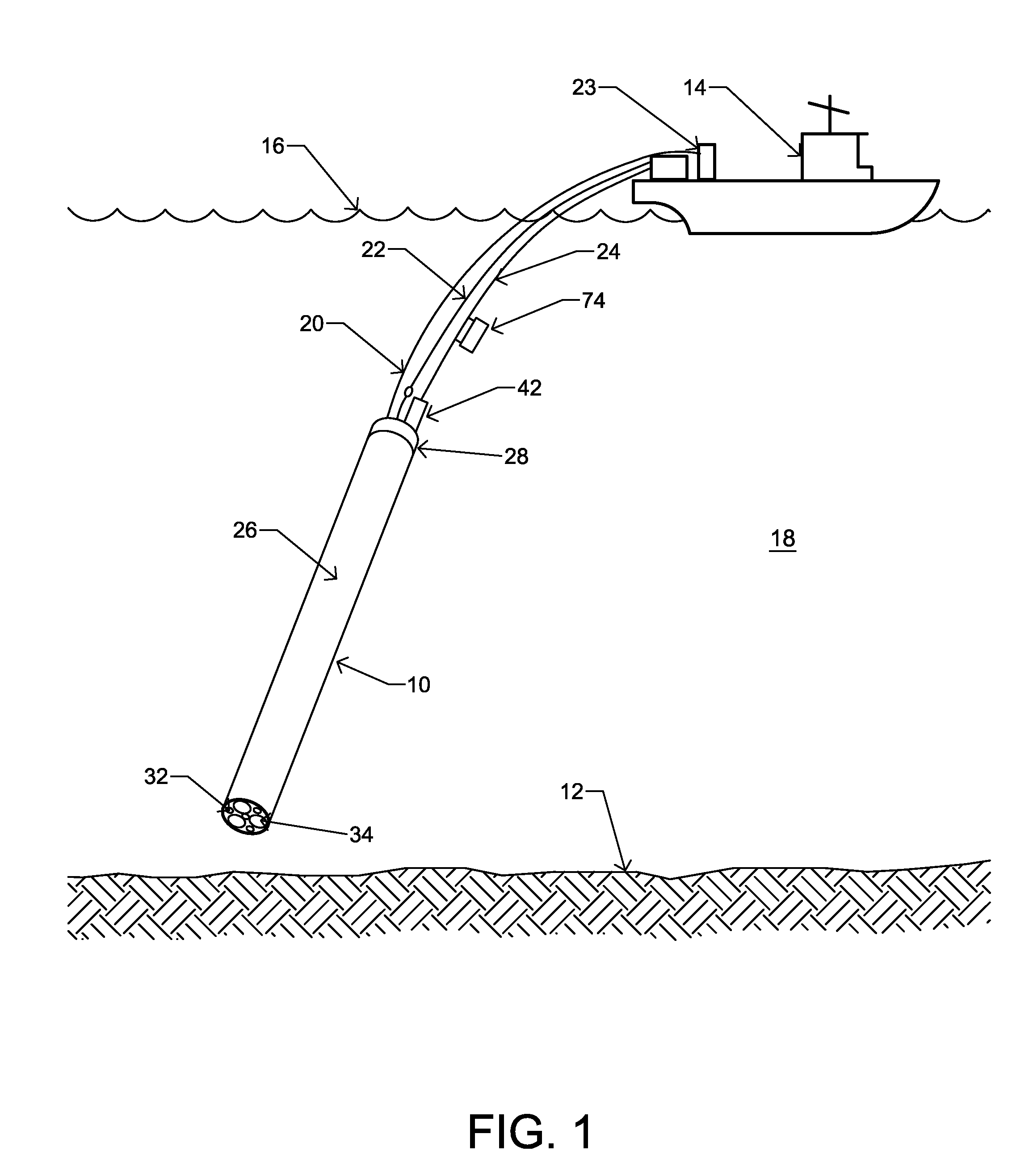

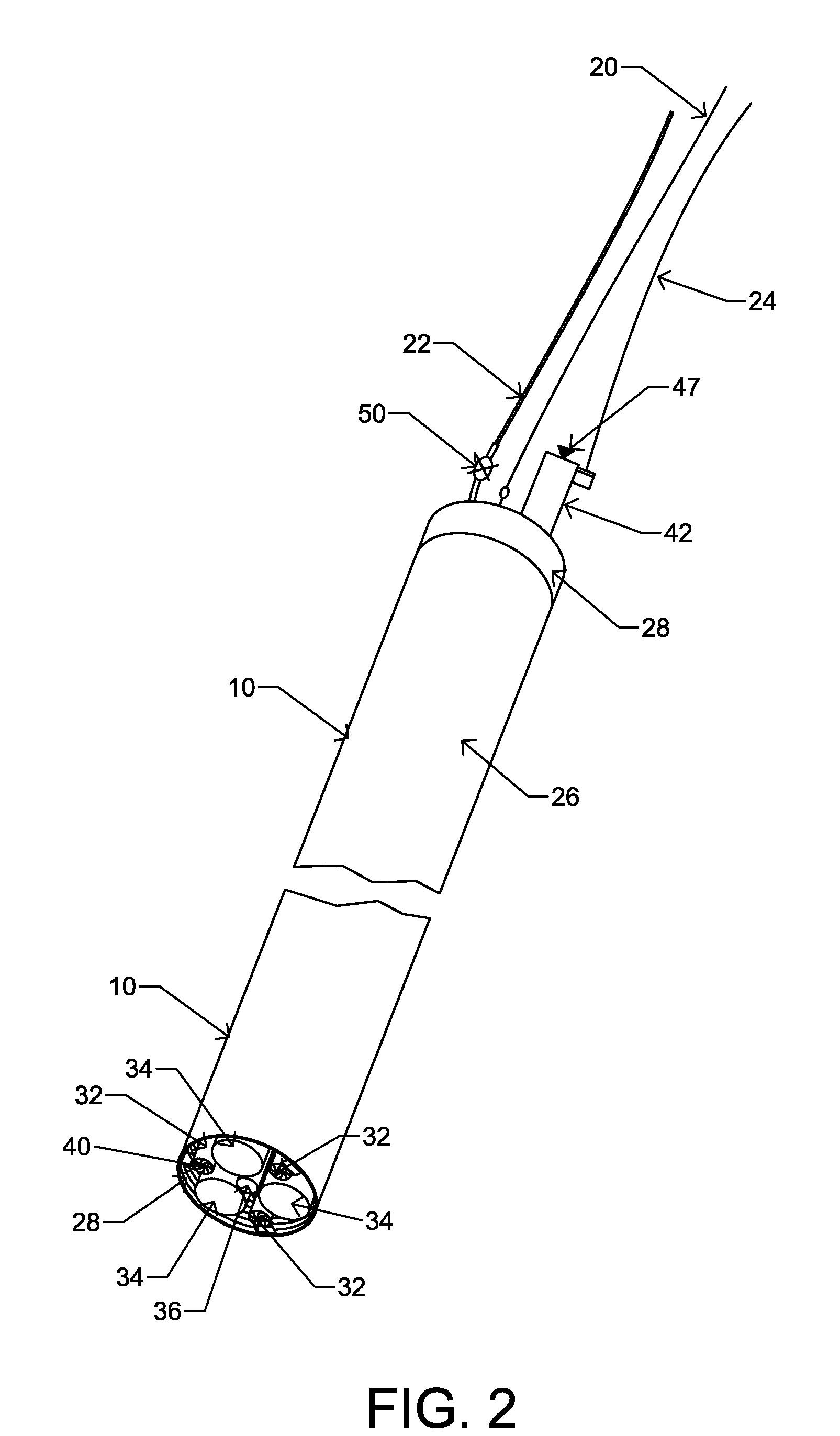

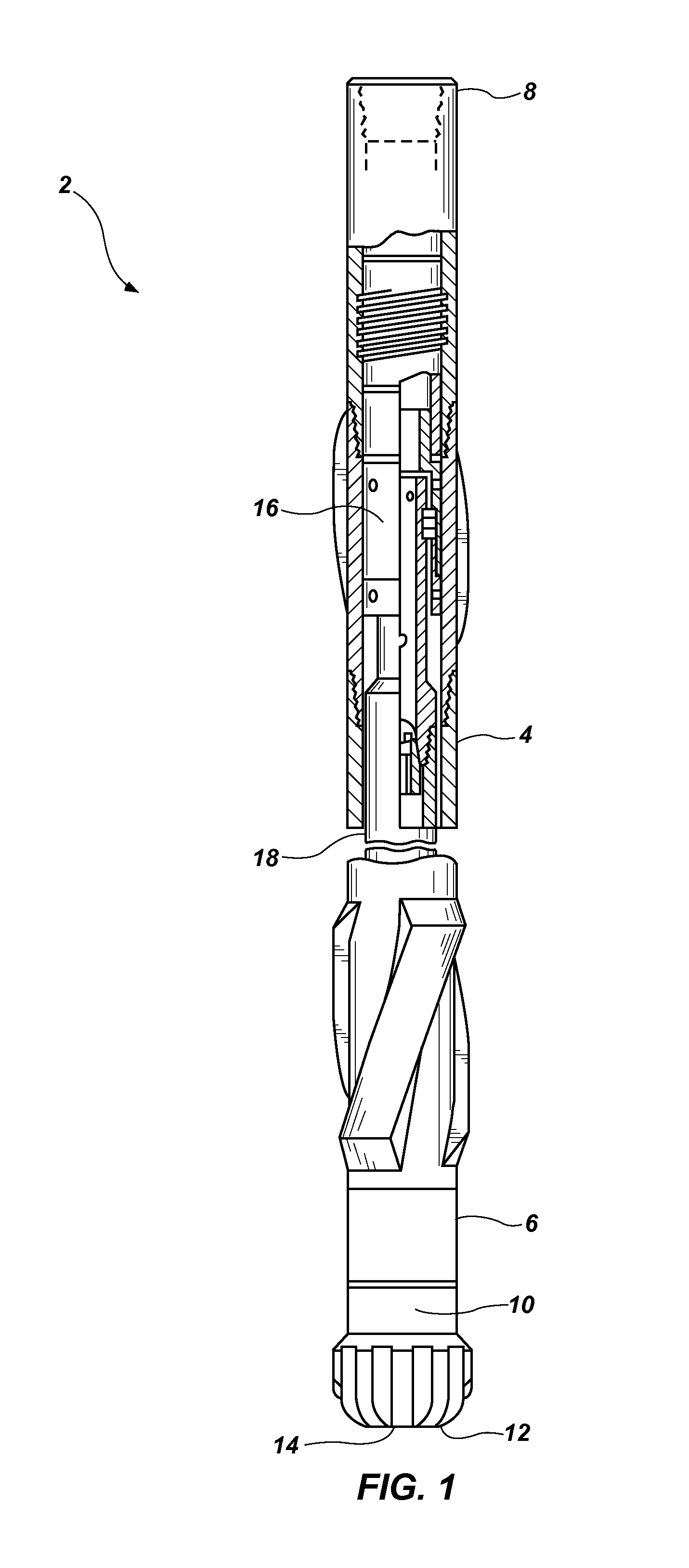

Suction Coring Device and Method

InactiveUS20080179091A1Easy to operateSimple handlingEarth drilling toolsDrill bitsRock coreSuction stress

Devices and methods for obtaining cores from a sea bed. A corer device includes one or more core barrels for retaining a cores and one or more pressure barrels. Fluid pressure within the pressure barrels is selectively varied to cause the corer device to be drawn into and released from the sea bed. The core barrels are provided with core catchers for retaining a core within.

Owner:FOLEY ALAN

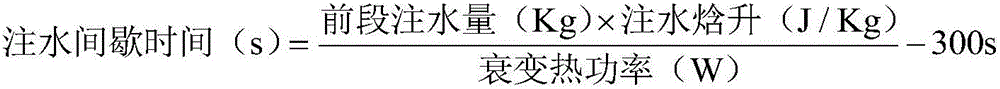

Reactor core water injection evaluation method for nuclear power plant equipped with reactor core catcher

ActiveCN106651217AAvoid explosionReasonable usePower plant safety arrangementNuclear energy generationCore catcherCountermeasure

The invention discloses a reactor core water injection evaluation method for a nuclear power plant equipped with a reactor core catcher. The method comprises the following steps that S1, a reactor core melting process in a pressure container is simplified to three stages; and S2, in combination with a specific reactor core melting process, the water injection evaluation method comprises the following sub-steps of S21, monitoring a process of relocating reactor core molten debris in the pressure container, judging a state of reactor core melting according to instrument monitoring data, and performing analysis in combination with a specific reactor core state to determine a reactor core water injection strategy; S22, monitoring a cooling effect of reactor core water injection, and further adjusting the reactor core water injection strategy; S23, when melt-through of a lower seal head of the pressure container is monitored, stopping water injection; and S24, monitoring melt-through scale and duration of the pressure container, and performing reactor core water injection according to actual position and state of the reactor core molten debris. The method has the beneficial effects that different water injection strategies are given in different accident stages; the water injection flow is controlled according to the cooling effect, so that steam explosion is avoided; and resources are reasonably utilized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Molten core catcher with interior cooling capacity

ActiveCN105551536AIncrease the heat exchange areaIncrease decay heat export powerNuclear energy generationEmergency protection arrangementsCore catcherReactor safety

The invention relates to designing technology of reactor safety systems, specifically to a molten core catcher with interior cooling capacity. The molten core catcher comprises a melt retaining container arranged in a vertical shaft vertically connected with the bottom of a reactor pit, a plurality of interior tube bundles arranged in the melt retaining container and used for injecting a coolant and a sacrificial material arranged in the outer tube walls of the interior tube bundles and in the melt retaining container. Under a working condition of a serious accident, the molten core catcher provided by the invention can realize maximization of removal of the heat of melts by exchanging heat through the tube bundles distributed in the molten core catcher and injecting cooling water formed by later burning-up of the interior tube bundles for cooling, so long-term security of a nuclear power plant after the serious accident is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Suction coring device and method

InactiveUS7918287B2Easy to operateSimple handlingEarth drilling toolsDrill bitsCore catcherEngineering

Devices and methods for obtaining cores from a sea bed. A corer device includes one or more core barrels for retaining a cores and one or more pressure barrels. Fluid pressure within the pressure barrels is selectively varied to cause the corer device to be drawn into and released from the sea bed. The core barrels are provided with core catchers for retaining a core within.

Owner:FOLEY ALAN

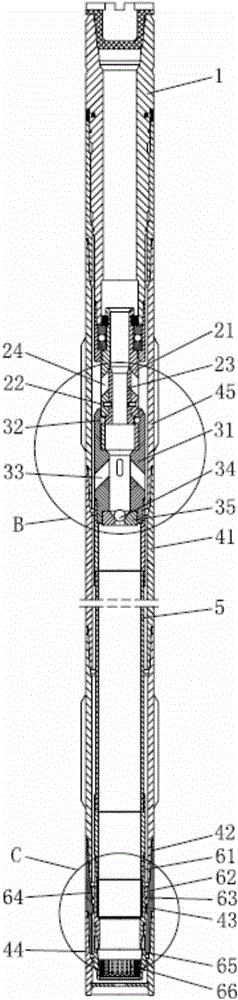

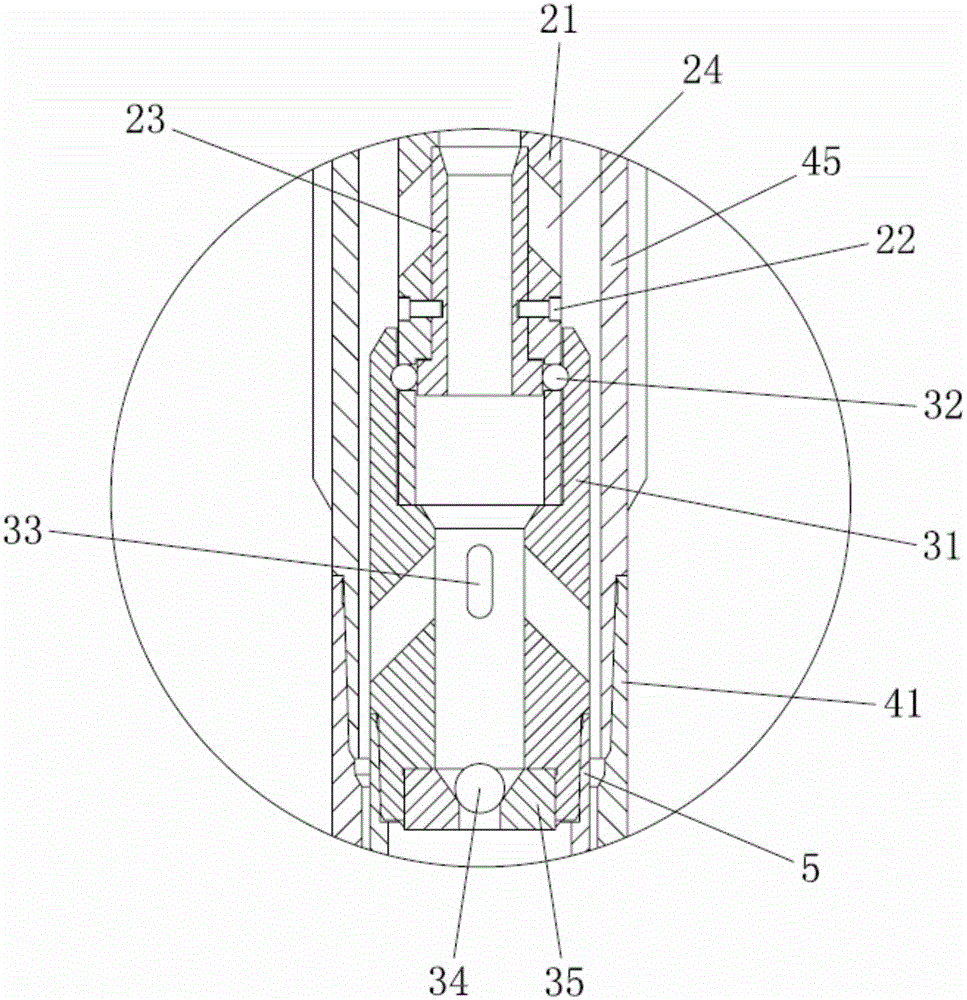

Hydraulic pressure type coring tool

The invention discloses a hydraulic pressure type coring tool which comprises a safe joint, a hydraulic pressurizing device, an outer cylinder assembly, an inner cylinder assembly and a core catcher assembly. The safe joint is of a big-end-up cone shape, the bottom and the top of the safe joint are opened, the middle of the safe joint is connected with the outer cylinder assembly through threads, the lower portion of the safe joint is connected with the hydraulic pressurizing device through threads, the inner cylinder assembly is hung below the hydraulic pressurizing device through a hanging device, the core catcher assembly is arranged on the lower side of the inner cylinder assembly, and the hydraulic pressurizing device, the inner cylinder assembly and the core catcher assembly are located in the outer cylinder assembly. After the hydraulic pressurizing device exerts hydraulic pressure, the hanging device falls off, the inner cylinder assembly and the core catcher assembly fall along with the hanging device, and the core catcher assembly clamps under the action of hydraulic pressure to achieve the aim of completely wrapping a smashing core. When plastic deformation of a core sealing sleeve reaches a certain degree, drilling fluid is discharged from a gap between the core sealing sleeve and a connection sleeve, so that the core can not be compressed excessively, and integrity of the core is guaranteed.

Owner:CCDC PETROLEUM CORING TECH

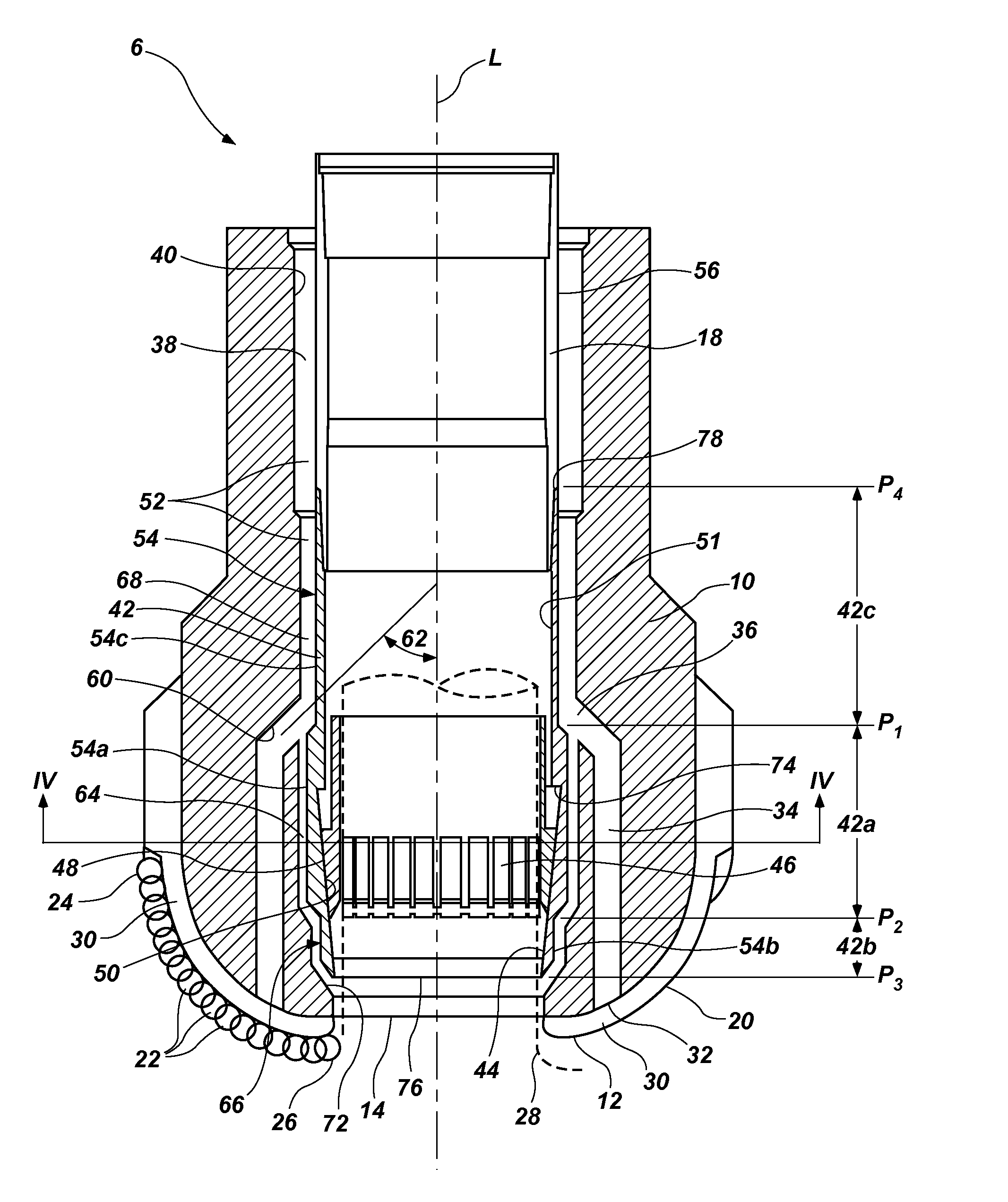

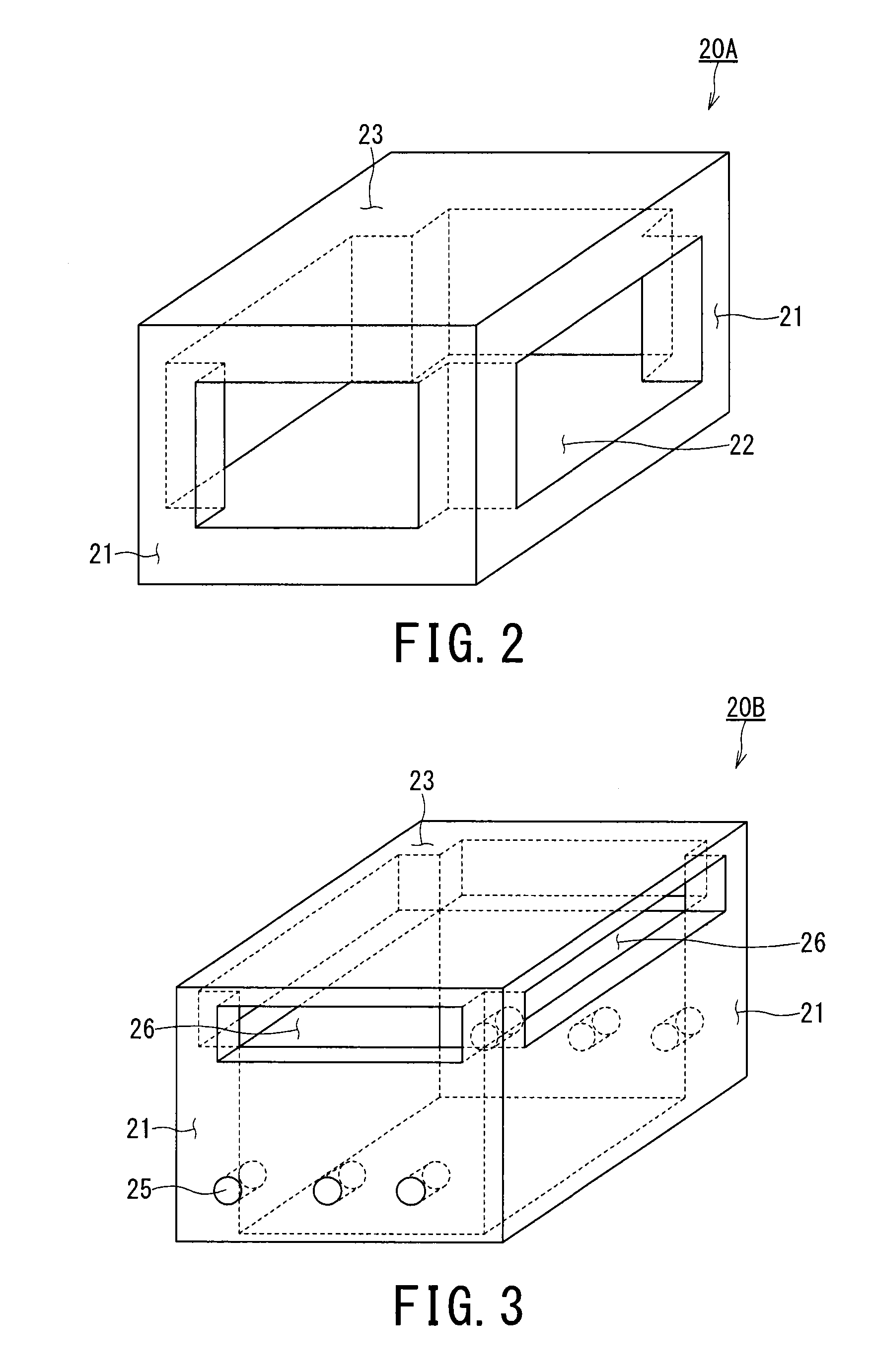

Core catcher and its manufacturing method, and reactor container and its modifying method

ActiveCN101390170AImprove cooling efficiencyNuclear energy generationEmergency protection arrangementsNuclear reactorCore catcher

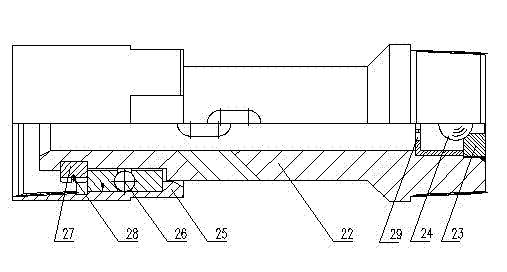

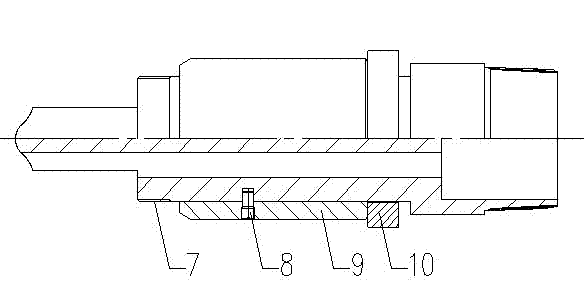

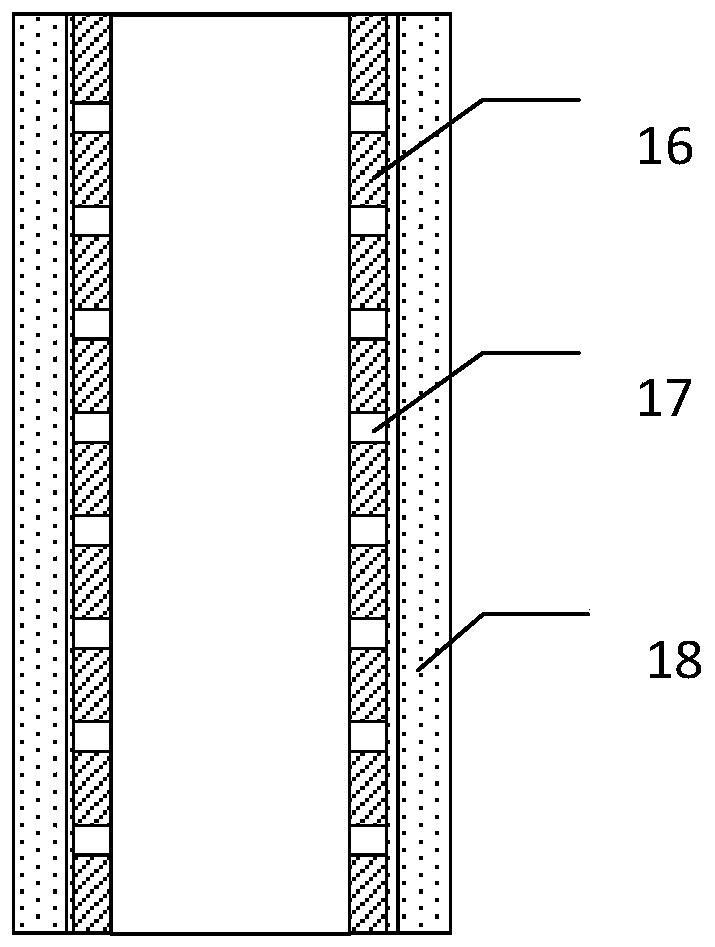

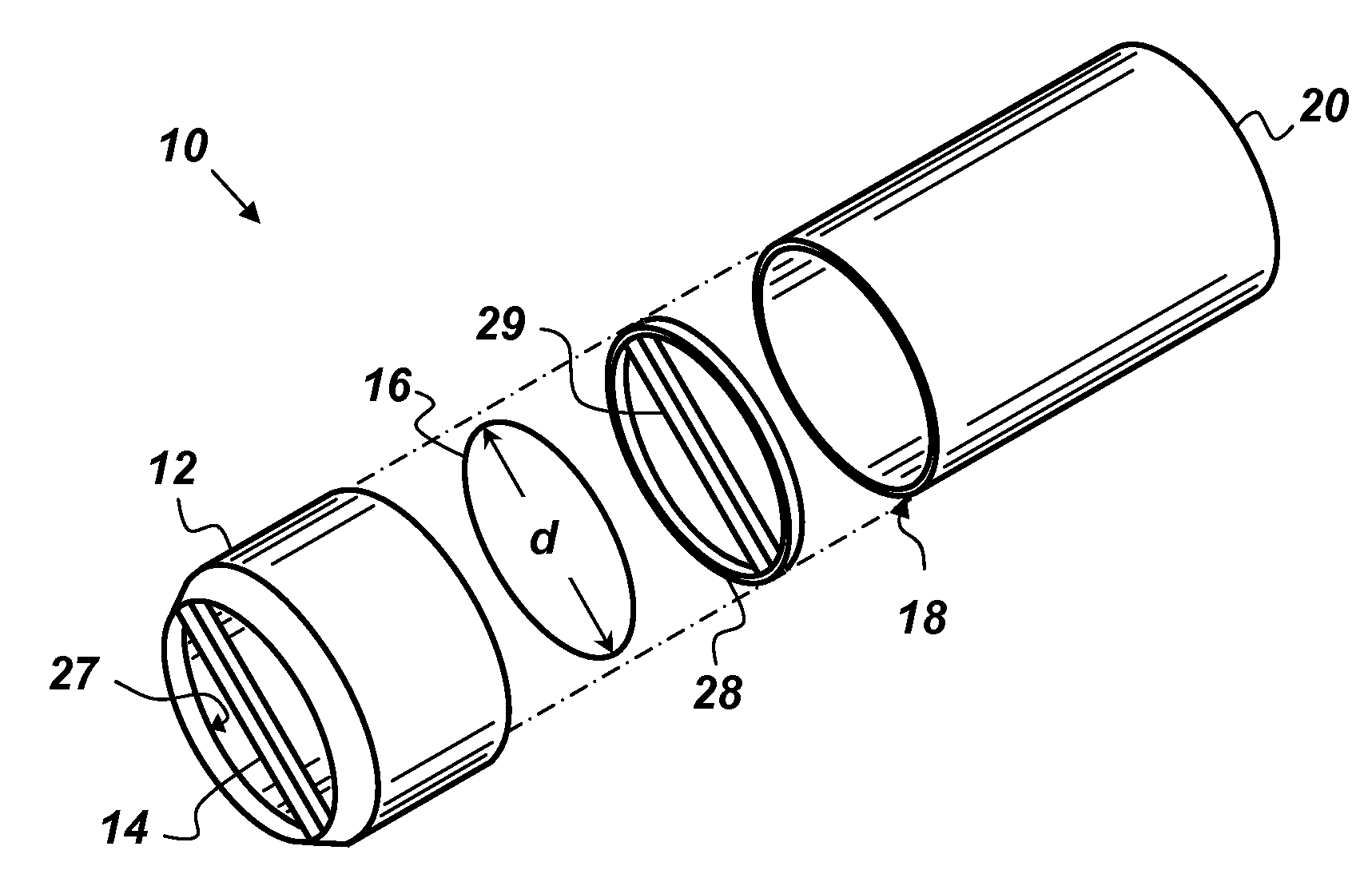

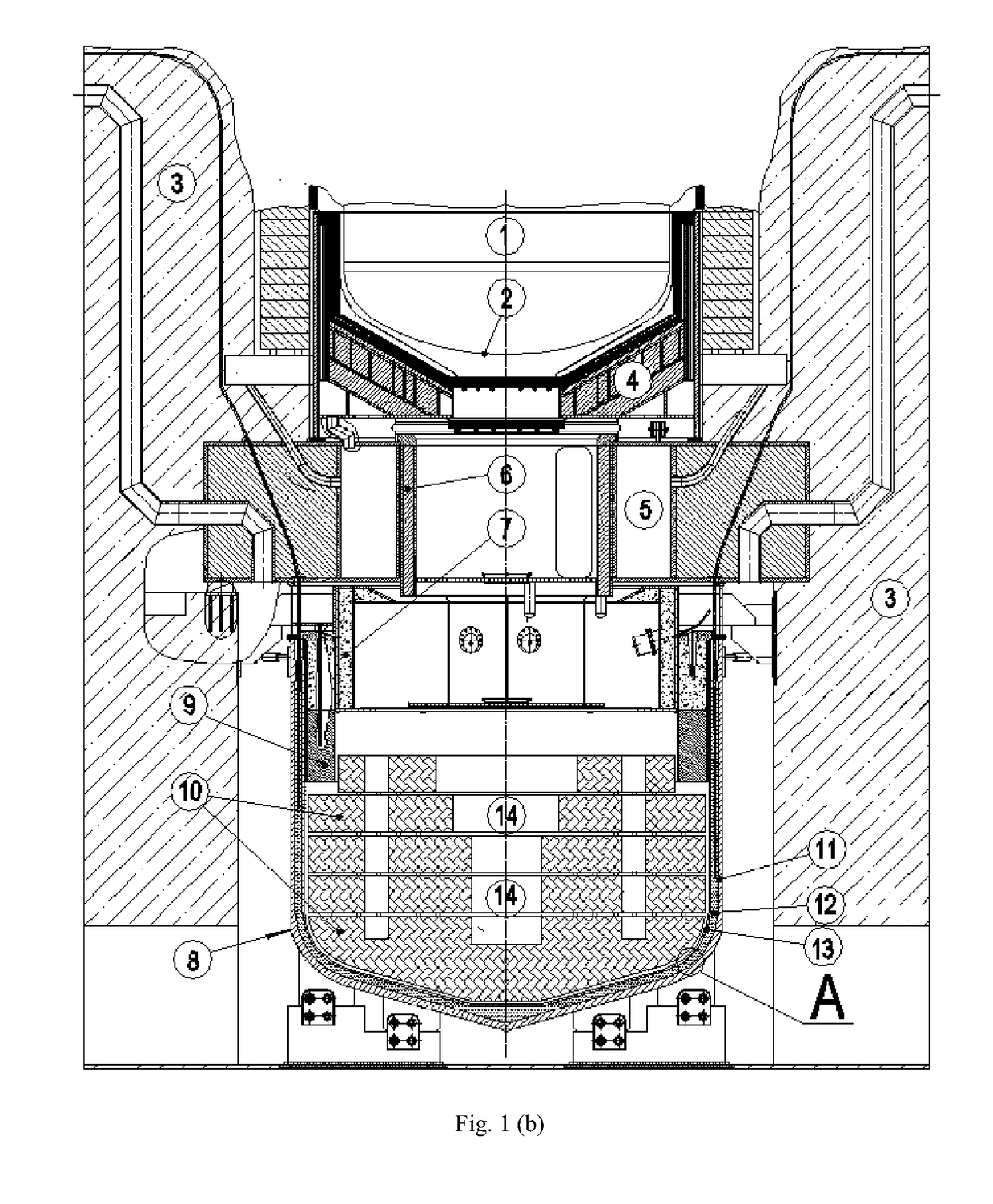

The invention relates to a core catcher and its manufacturing method, and an reactor container and its manufacturing method, to improve the efficiency for cooling the core debris, which is produced when the core in a reactor container melts and flows through the reactor container. The core debris, which is produced when the core in the reactor container melts and flows through the reactor container, is caught by a core catcher including a steel body (20), which is positioned below the reactor container and provided with cooling channels (21a) of a first stage and cooling channels (21b) of a second stage defined by cooling fins (31) extending radially in the reactor container. The number of the cooling channels (21b) of the second stage is larger than that of the cooling channels (21a) of the first stage. The cooling water is fed from a cooling water inlet (22) and distributed into the cooling channels (21a) of the first stage by a distributor (10). Between the cooling channels (21a, 21b) of the first and second stages, there is formed an intermediate header (24) for feeding the cooling channels (21b) of the second stage homogeneously, too, with the cooling water.

Owner:KK TOSHIBA

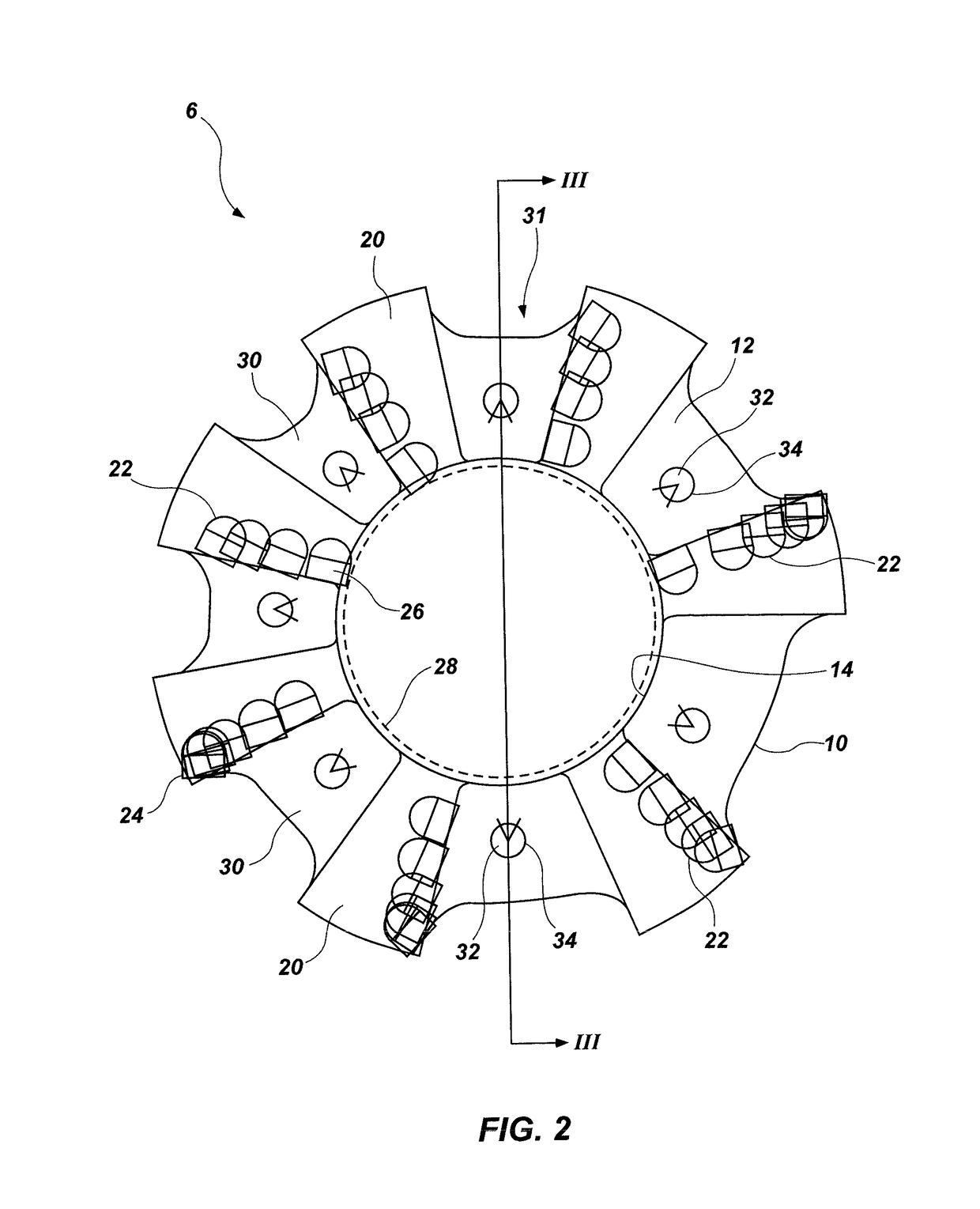

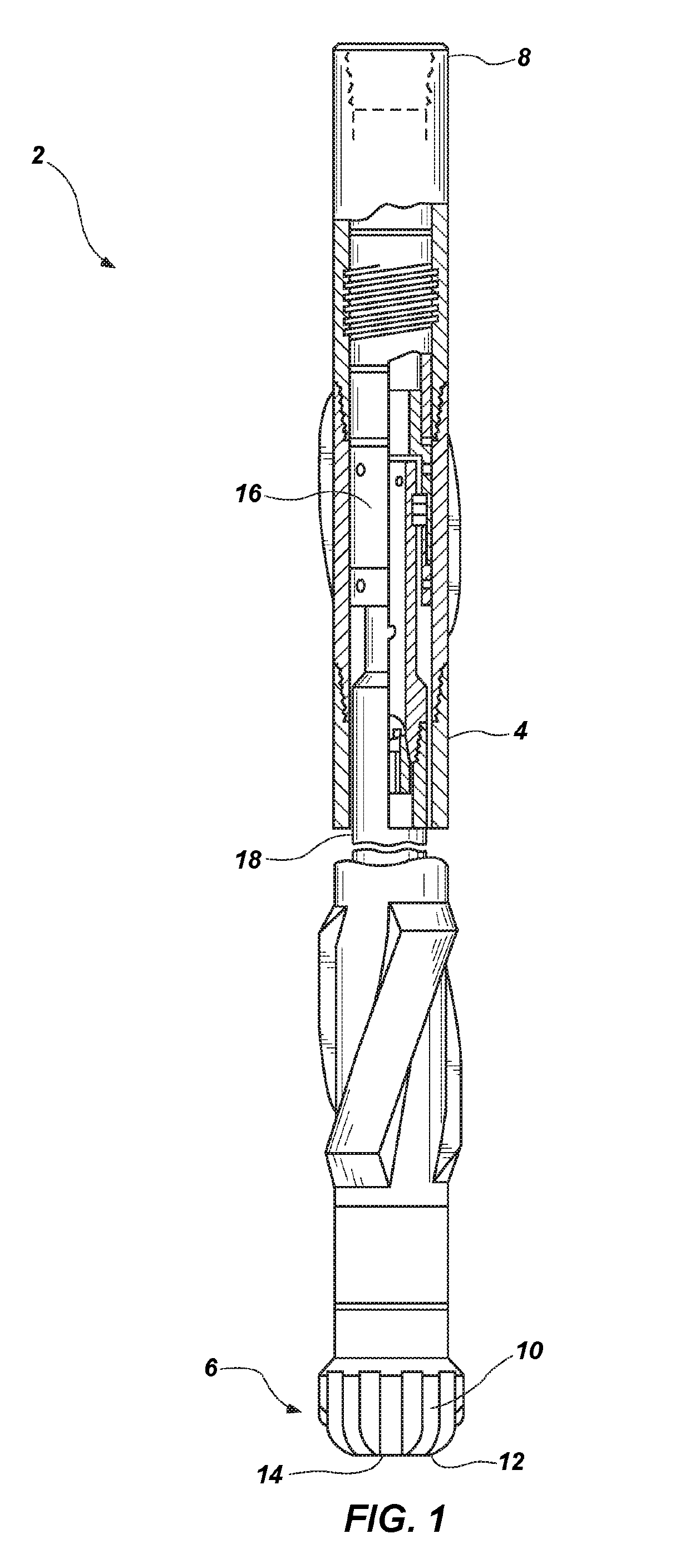

Coring tools and related methods

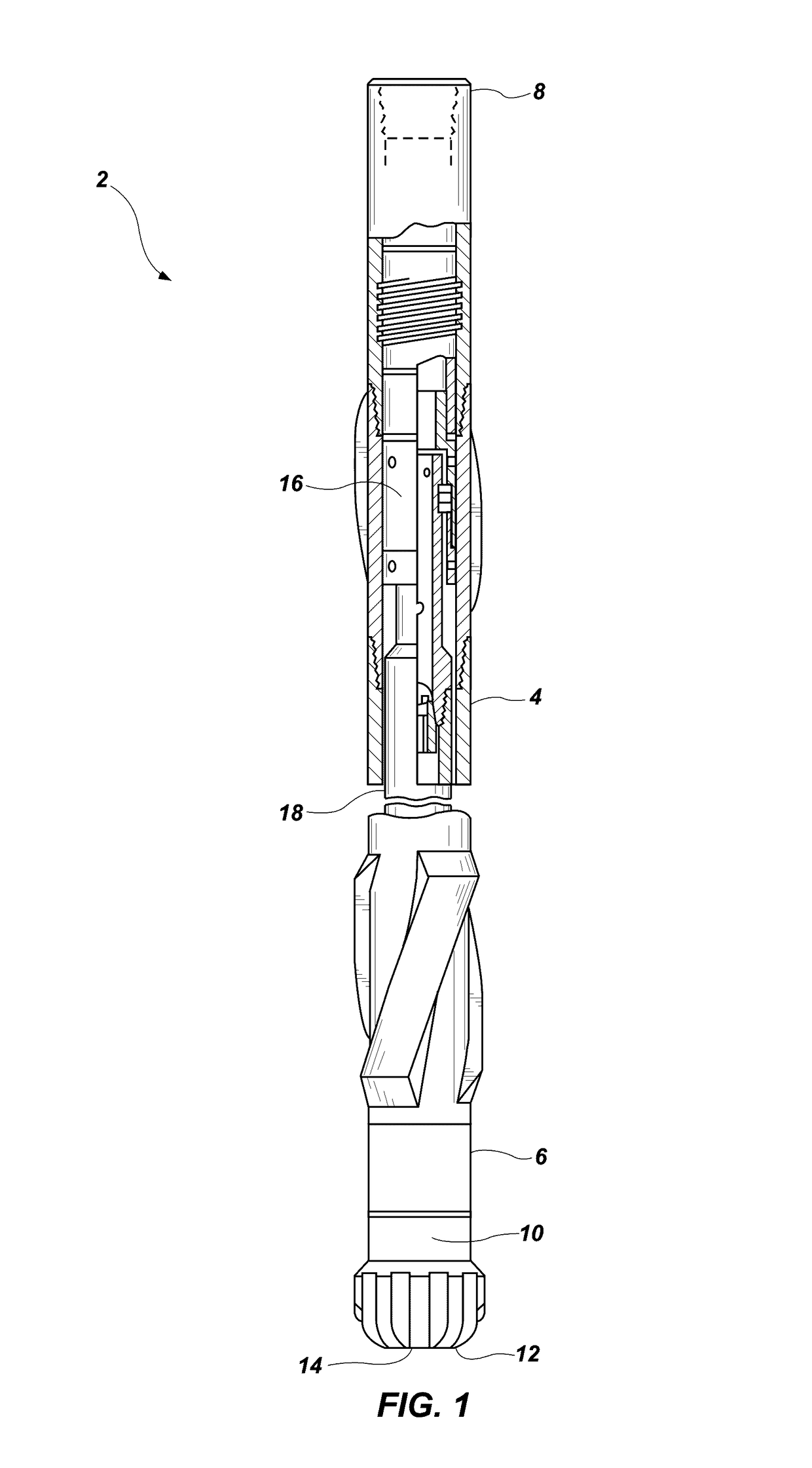

A coring bit for extracting a sample of subterranean formation material from a well bore may include a bit body having a bit face and an inner surface defining a substantially cylindrical cavity of the bit body. A first portion of the inner surface may be configured to surround a core catcher. The coring bit may include a face discharge channel inlet formed in the inner surface of the bit body longitudinally at or above the first portion of the inner surface. The coring bit may also include a face discharge channel extending through the bit body from the face discharge channel inlet to the bit face. A tubular body having a core catcher may be disposed in the coring bit to form a coring tool. Methods of forming such bit bodies may include forming an inlet for a face discharge channel in the inner surface of the bit body at a location longitudinally at or above the first portion of the inner surface and forming a face discharge channel extending from the inlet to the bit face.

Owner:BAKER HUGHES INC

Core catcher

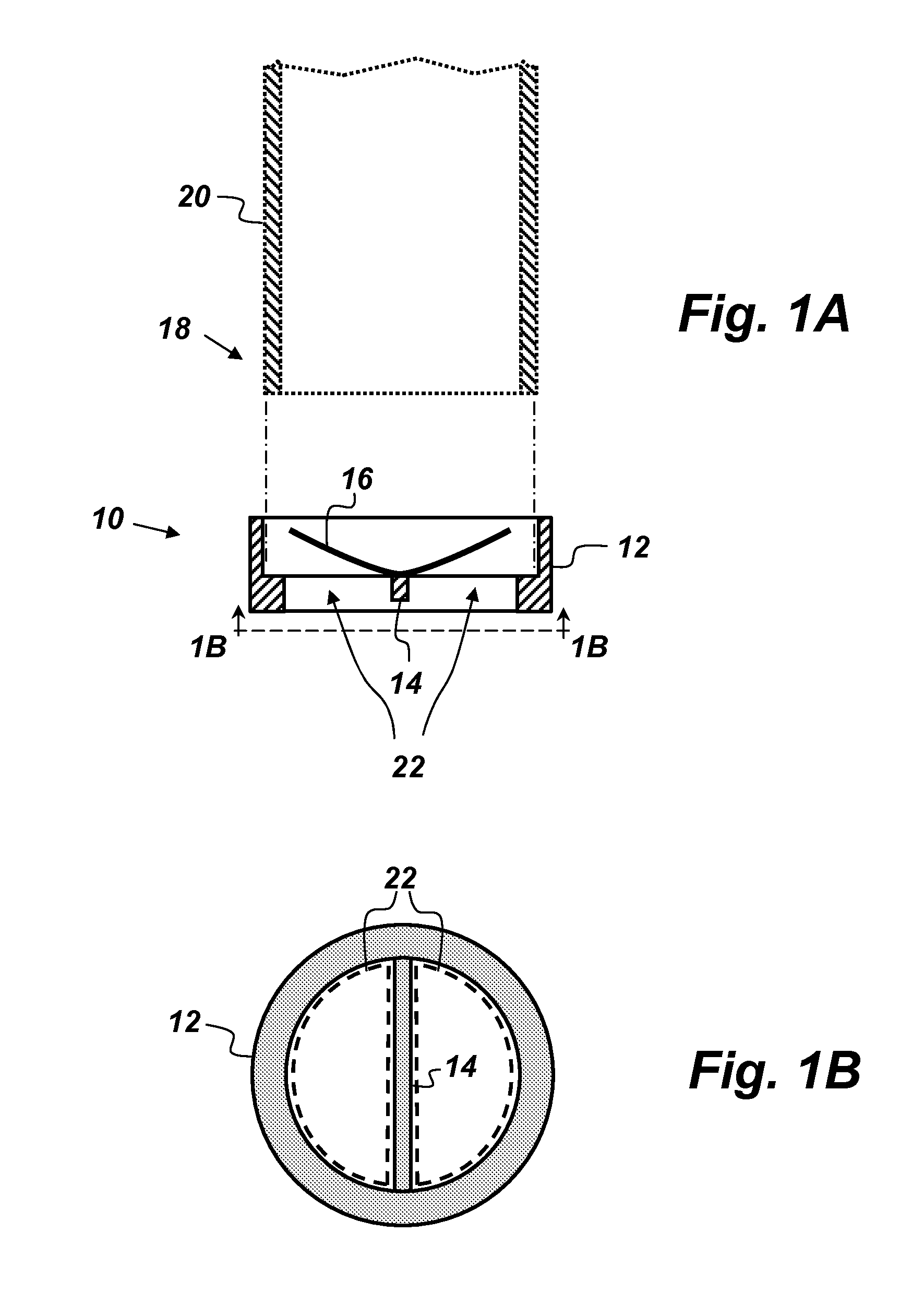

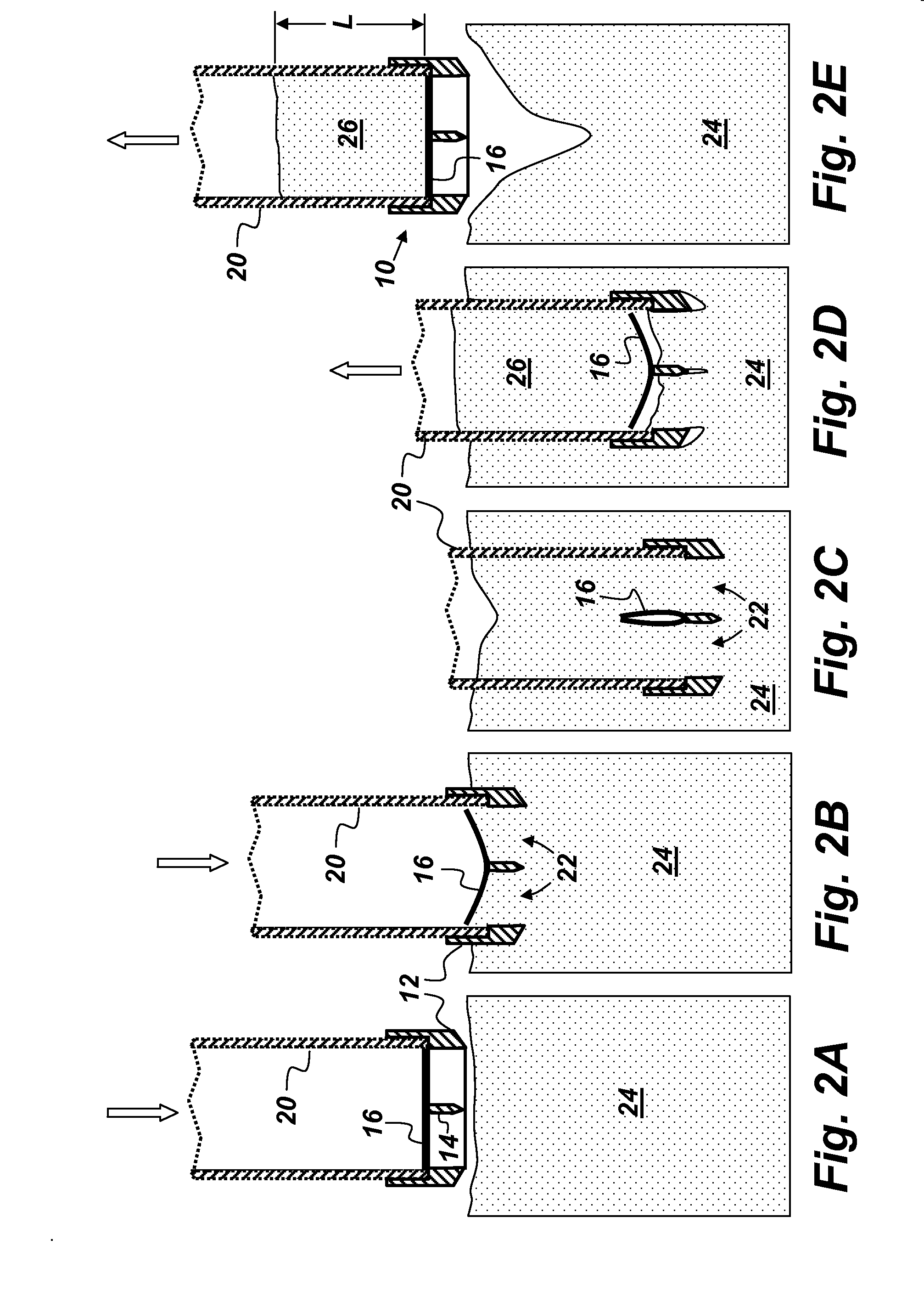

InactiveUS20120300893A1Easy to installNuclear energy generationEmergency protection arrangementsCore catcherEngineering

A core catcher includes a holding surface that catches and holds corium and that introduces a coolant with which surroundings of the core catcher are filled into the core catcher and cool a whole of the core catcher by heat exchange with the introduced coolant. The holding surface and the cooling unit are constructed by arranging blocks which each include a polyhedron having at least one pair of parallel surfaces and having opening portion formed in a surface located in a lateral direction when a first surface that is one of the parallel surfaces is arranged as a bottom surface and are configured such that the polyhedrons communicate with each other via the opening portion when the polyhedrons are arranged adjacent in the lateral direction. The core catcher, as described above, can be achieved easier installation of the blocks without an increase in installation cost.

Owner:KK TOSHIBA

Pressurized coring tool

The invention discloses a pressurized coring tool comprising a pressure bearing device, a rotating assembly and a core catcher assembly, wherein the pressure bearing device comprises a pressure bearing assembly and a pin component, the pressure bearing assembly comprises a pressure bearing piston and a pressure bearing sleeve sheathed on the pressure bearing piston, the pin component comprises a shearing pin; the rotating assembly comprises a core shaft, one end of the core shaft is provided with a rotating device, the other end of the core shaft is provided with an automatic pressure relieving assembly; and the core catcher assembly comprises a connecting sleeve, a clamp seat, a clamp, a pressurized core catcher and a self-locking core catcher, one end of the clamp seat is connected with the lower end of the connecting sleeve, the other end of the clamp seat is connected with the pressurized core catcher, the upper end of the connecting sleeve is connected with an internal cylinder assembly, the clamp is arranged in the clamp seat, and the self-locking core catcher is arranged in the pressurized core catcher. When the pressurized coring tool disclosed by the invention is used for coring, the internal cylinder of a pressurizing tool can rotate along with the rotation of a drilling tool, and the problem that a core entering into the internal cylinder breaks easily is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel siliceous nuclear power sacrificial material and preparation method thereof

The invention discloses a novel siliceous nuclear power sacrificial material and a preparation method thereof. The novel sacrificial material is mainly prepared from 325-335 parts of PII.52.5-grade portland cement, 175-190 parts of pulverized fuel ash, 15-25 parts of silicon powder, 1,650-1,750 parts of quartz sand, 145-155 parts of water, 7-10 parts of water reducing agent, 1-1.5 parts of polypropylene fibers and 0.5-1.5 parts of sulfonated graphene. The preparation technology is simple, and a common forcing-type single-horizontal-shaft concrete mixer is adopted for preparing the nuclear power sacrificial material which is excellent in liquidity, strength and corrosion resistance. The prepared novel siliceous iron nuclear power sacrificial material has the advantages of good working performance, high strength, good corrosion resistance and the like, is mainly applied to a current third-generation nuclear power station reactor core catcher and has high engineering application value.

Owner:NANJING FORESTRY UNIV

Novel ferrosilicon nuclear power sacrifice material and preparation method thereof

The invention discloses a novel ferrosilicon nuclear power sacrifice material and a preparation method thereof. The novel ferrosilicon nuclear power sacrifice material is primarily composed of 375-400parts of PII.52.5 level silicate cement, 130-145 parts of coal ash, 15-25 parts of silicon powder, 950-1100 parts of quartz sand, 900-1050 parts of hematite iron ores, 175-185 parts of water, 7-10 parts of a water reducer, 1-1.6 parts of polypropylene fibers and 0.5-1.6 parts of sulfonated graphene. The preparation process is simple. The nuclear power sacrifice material which is excellent in flowability, strength and corrosion resistance can be prepared by adopting a conventional forced single horizontal shaft concrete mixer. The prepared novel ferrosilicon nuclear power sacrifice material has the advantages of good working property, high strength, good corrosion resistance, is primarily applied to an existing reactor core trap of a third generation nuclear power plant and has wide engineering application value.

Owner:NANJING FORESTRY UNIV

Double-layer crucible reactor core melt capturing device with internal cooling tube

ActiveCN110459333AEasy to stayImprove power efficiencyNuclear energy generationEmergency protection arrangementsCore catcherCrucible

The invention belongs to the technical field of nuclear safety control and relates to a double-layer crucible reactor core melt capturing device with an internal cooling tube. The capturing device comprises a reactor pressure container, an inner crucible, an outer crucible, a cooling runner, a reactor pit, a reactor pit cavity, cooling tubes and cooling tube water inlets, wherein the inner crucible is arranged right below the reactor pressure container, is fixed outside the reactor pressure container and is positioned inside the outer crucible below the reactor pressure container; the coolingrunner in which cooling water flows is formed between the inner curable and the outer crucible; the outer crucible is mounted in the reactor pit cavity formed in the reactor pit; a plurality of cooling tubes are arranged inside the inner crucible; each cooling tube communicates with the cooling runner through the cooling tube water inlet in the bottom of each cooling tube; small holes are formed in side walls of a part of the cooling tubes; the small holes are externally covered by sacrificial concrete protection layers of 5-30mm in thickness. By adopting the capturing device provided by the invention, the retention success rate and the cooling efficiency of a reactor core capturer upon reactor core melts can be remarkably improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Surface Sediment Core Catcher

ActiveUS20150255179A1Prevent escapeNuclear energy generationEmergency protection arrangementsCore catcherFlap valve

A core catcher comprising: a cap configured to be secured to a first end of a core liner such that when the first end of the core liner is inserted into sediment a sample sediment core enters the core liner through the cap; a cross-beam coupled to the cap and mounted across the first end of the core liner such that a cross-section of the first end of the core liner is divided into two openings; a flexible member secured to the cross-beam such that the flexible member, the cross-beam, and the cap form a dual-flap valve designed to allow the sediment core to enter the core liner through the two openings and to prevent the sediment core from escaping the core liner through the cap.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

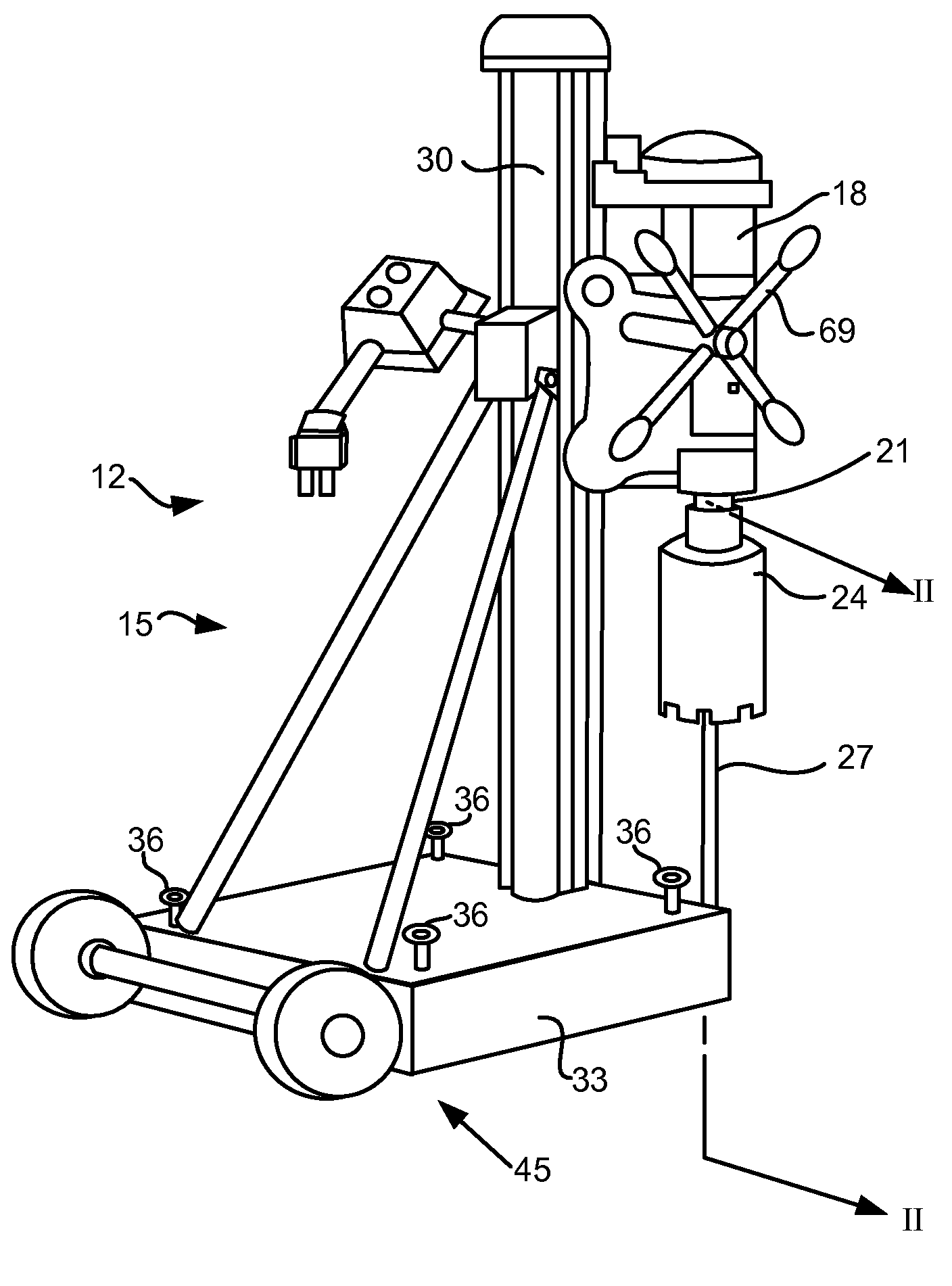

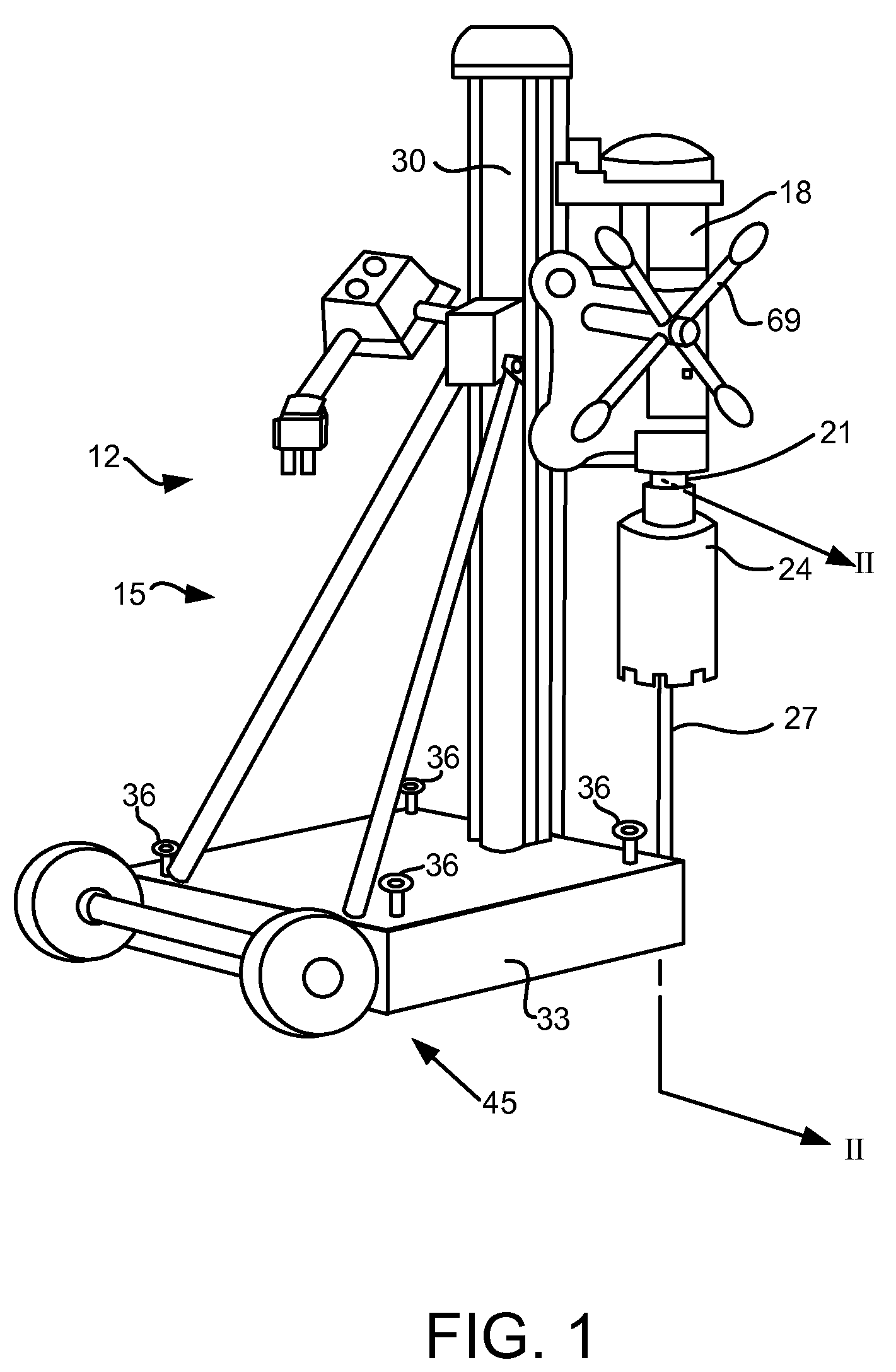

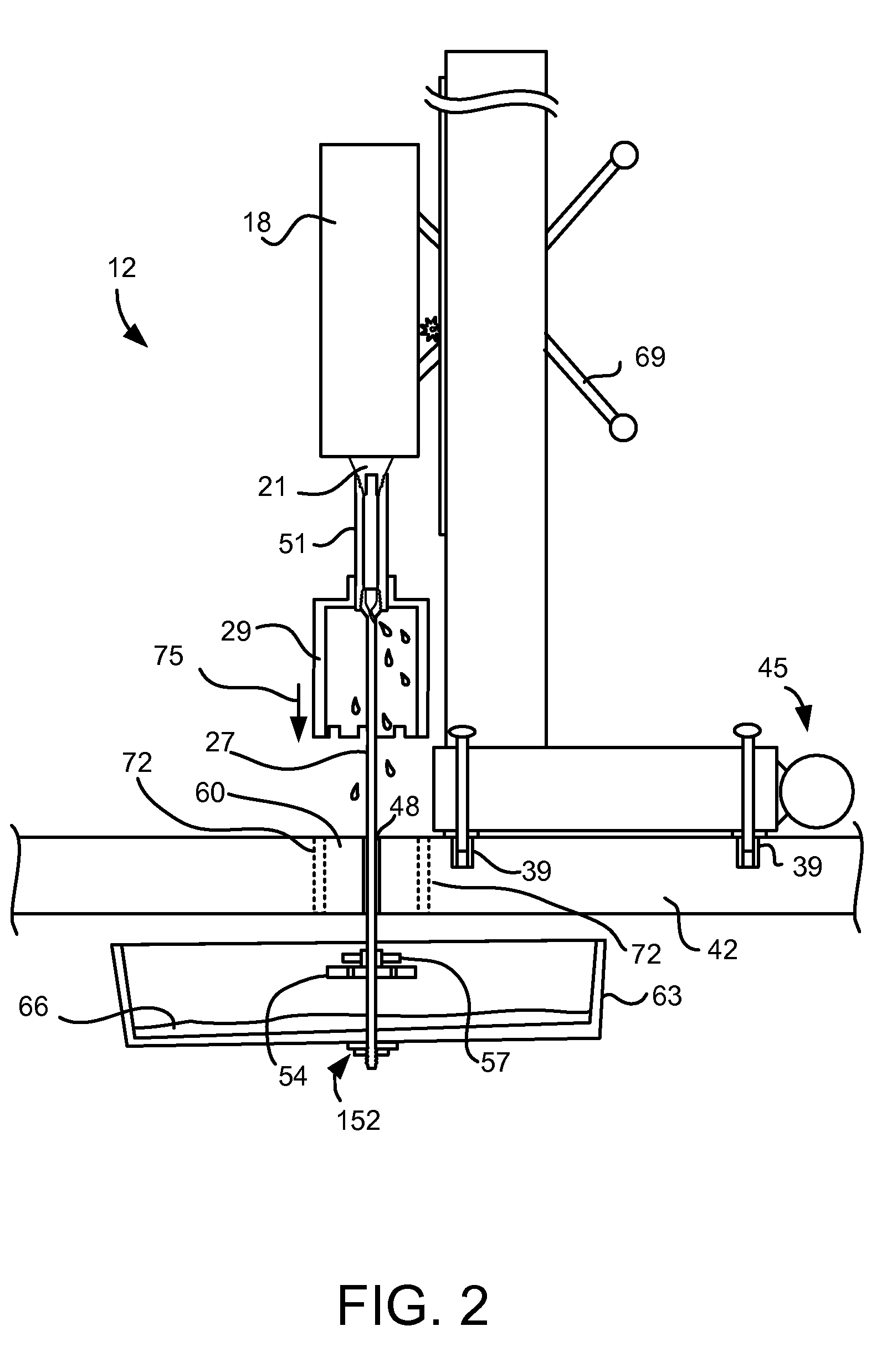

Apparatus, system, and method for catching a core

InactiveUS20090229885A1Reduce the amount requiredReduce risk of damage and harmDrill bitsTransportation and packagingCore catcherPilot hole

A core catcher includes a catcher rod removably attachable to a core drill. The catcher rod is inserted through a pilot hole in a substrate from which a core is to be removed. A catching element is removably attachable such as by clamping the catching element to a distal end of the catcher rod on an underside of the substrate. A bearing may be disposed between the catching element and the substrate. When severed from the substrate, the core falls only a short distance along the catcher rod and comes to rest on the bearing and the catching element. Thus, the core is inhibited from falling to a floor or ground below the substrate. A bucket may also be supported on the distal end of the catcher rod in order to collect cutting fluid.

Owner:IZATT TONY

Water-Cooled Water-Moderated Nuclear Reactor Core Melt Cooling and Confinement System

InactiveUS20170323694A1Improve efficiencySimple structureNuclear energy generationNuclear engineering problemsNuclear reactor coreNuclear plant

The invention relates to safety systems for nuclear power plants (NPP), and can be used in the event of reactor vessel and NPP containment failure. The melt cooling and confinement system includes a cone-shaped guide plate installed under the reactor vessel bottom, cantilever girder installed under the guide plate and supporting the same, core catcher installed under the cantilever girder and equipped with cooled cladding in form of a multi-layer vessel for protection of the external heat-exchange wall from dynamic, thermal and chemical impacts, and filler material for melt dilution inside the multi-layer vessel. The said multi-layer vessel contains external and internal metal walls with filler of poorly heat-conductive in relation to the wall material in between. Filler thickness hfil shall meet the following requirement: 0.8 hext<hfil<1.6 hext, where hext is vessel external wall thickness.

Owner:ATOMENERGOPROEKT

Coring tools and related methods

Owner:BAKER HUGHES HLDG LLC

Molten core catcher capable of guiding layered spreading of melts

ActiveCN105551538AIncrease decay heat export powerIncrease the heat exchange areaNuclear energy generationEmergency protection arrangementsCore catcherReactor safety

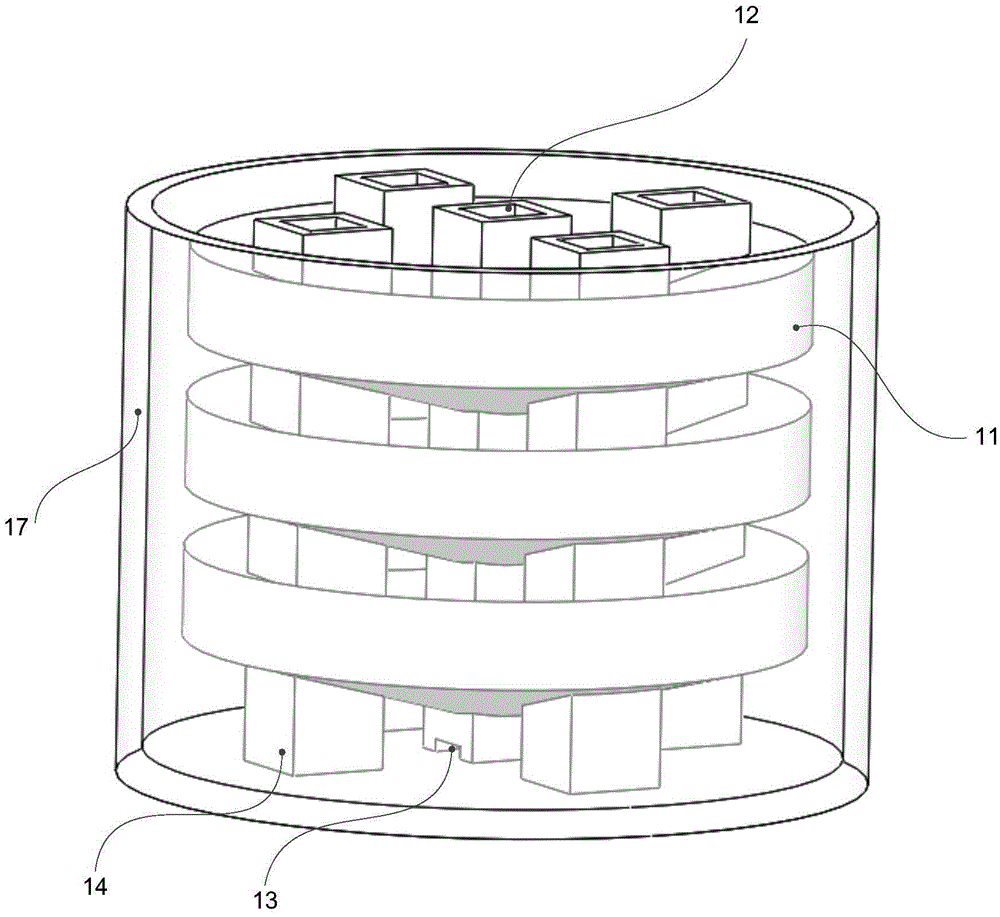

The invention relates to designing technology of reactor safety systems, specifically to a molten core catcher capable of guiding layered spreading of melts. The molten core catcher is arranged in a shaft well vertically connected with the bottom of a reactor pit and comprises multiple layers of melt spreading and detaining chambers, and adjacent melt spreading and detaining chambers for communicated space through a plurality of melt pouring channels. Under a severe accident condition, adequate spreading of the melts is realized through a layered spreading means, so heat of the melts is maximally led out and long-term security of a nuclear power plant after a severe accident is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Coring tools including a core catcher

A core catcher for a coring tool comprises a sleeve comprising a longitudinal axis and at least one slit extending at least partially along a height of the sleeve between an upper end and a lower end thereof. The at least one slit separates a first side surface and a second side surface of the sleeve. The first and second side surfaces are located a first distance and a second distance from the longitudinal axis, respectively, measured in a direction transverse to the longitudinal axis. The core catcher further comprises a bridging element extending at least partially about a sleeve perimeter. The bridging element operatively couples movement of the first side surface and the second side surface to limit a difference between the first and second distances as a width of the at least one slit that separates the first side surface and the second side surface increases or decreases.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com