Method for installing reactor core catcher of nuclear power station

A core capture and installation method technology, applied in nuclear power generation, reactors, nuclear engineering, etc., can solve problems such as poor construction environment, narrow working space, difficult construction and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

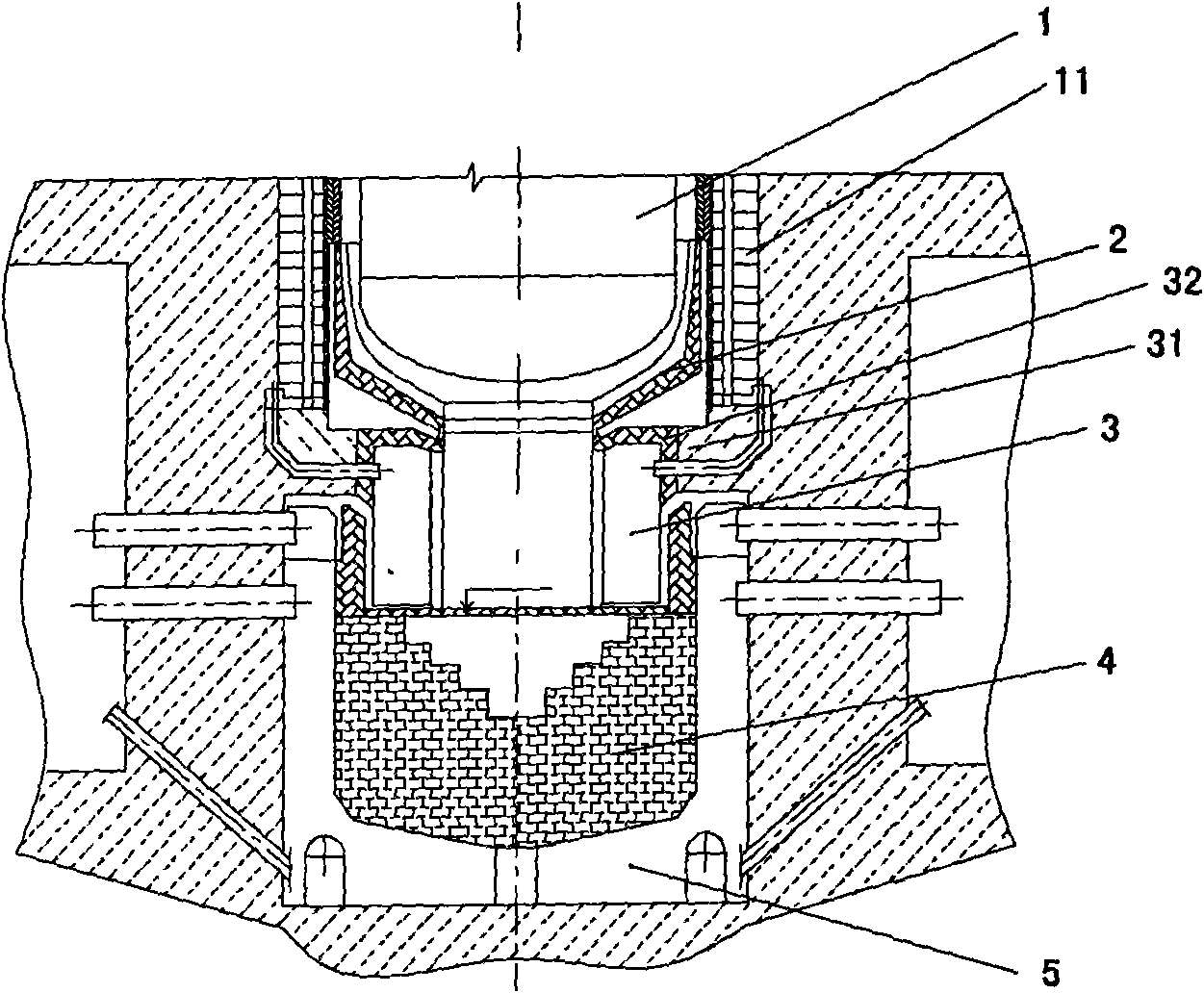

[0019] figure 1 is a component layout diagram of a core catcher for a nuclear power plant according to an embodiment of the present invention. The core traps are arranged from top to bottom along the pressure vessel 1 to the bottom of the reactor shaft. They are: lower base plate 2, ventilation system 3, hanging basket with filling 4, segmental heat exchanger 5.

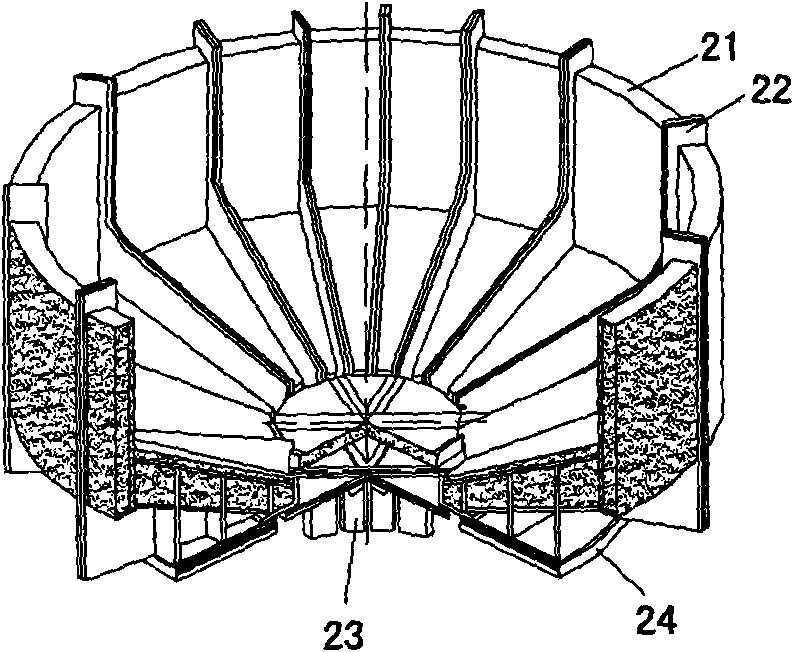

[0020] The lower bottom plate 2 is designed in a funnel shape to completely contain the bottom of the pressure vessel 1, such as figure 2 shown. The top of lower base plate 2 links to each other with the lower insulation layer of dry protection 11, so just guarantees that molten slag can not directly work on dry protection and flows in the hanging basket 4 of band filling along the lower base plate 2 of funnel type.

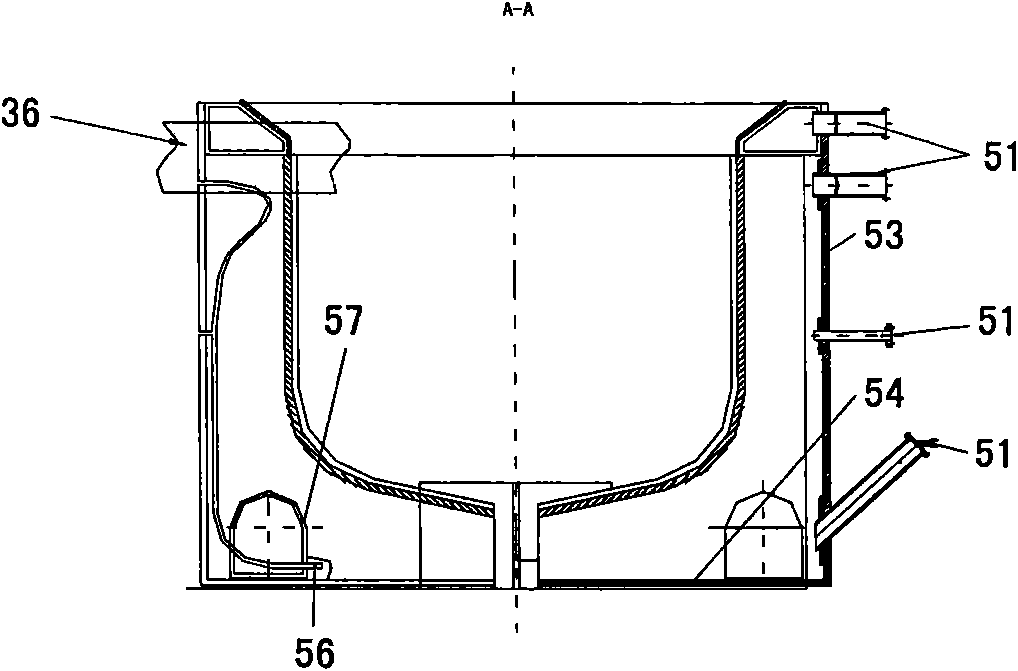

[0021] The ventilation system 3 has a ventilation and cooling function for the reactor shaft equipment under normal operation of the reactor. In the working state of the core catcher, it is equival...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com