Molten core catcher capable of guiding layered spreading of melts

A technology for core melt and expansion function, which is applied in the field of reactor safety system design, can solve the problem of fully expanding the melt without considering the layered expansion method, and avoid failure of protective barriers, reduction of radiation dose, and post-accident treatment work. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

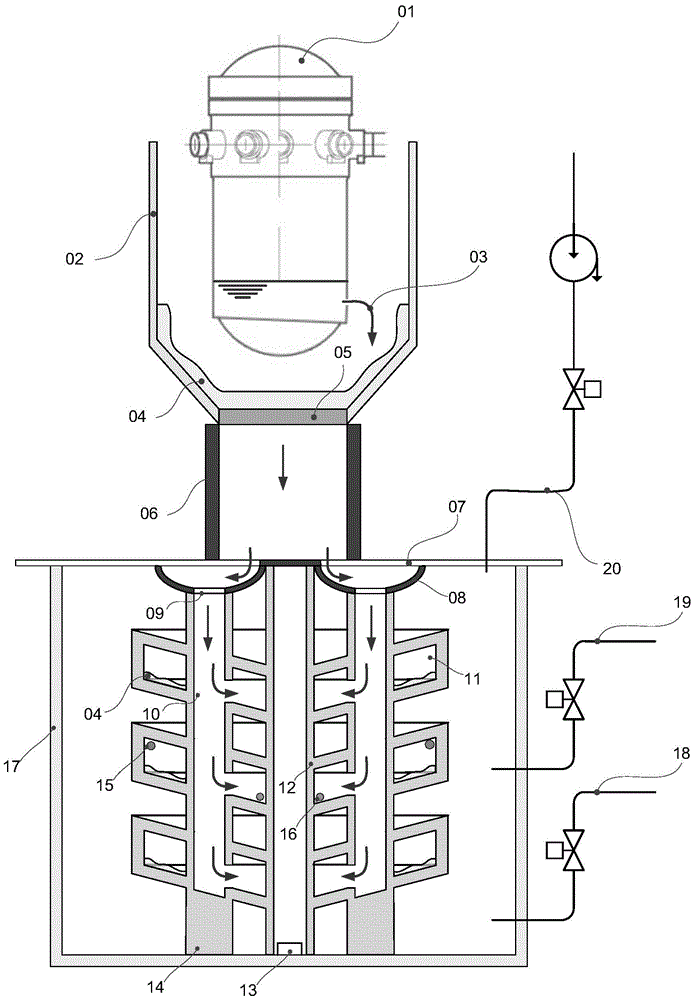

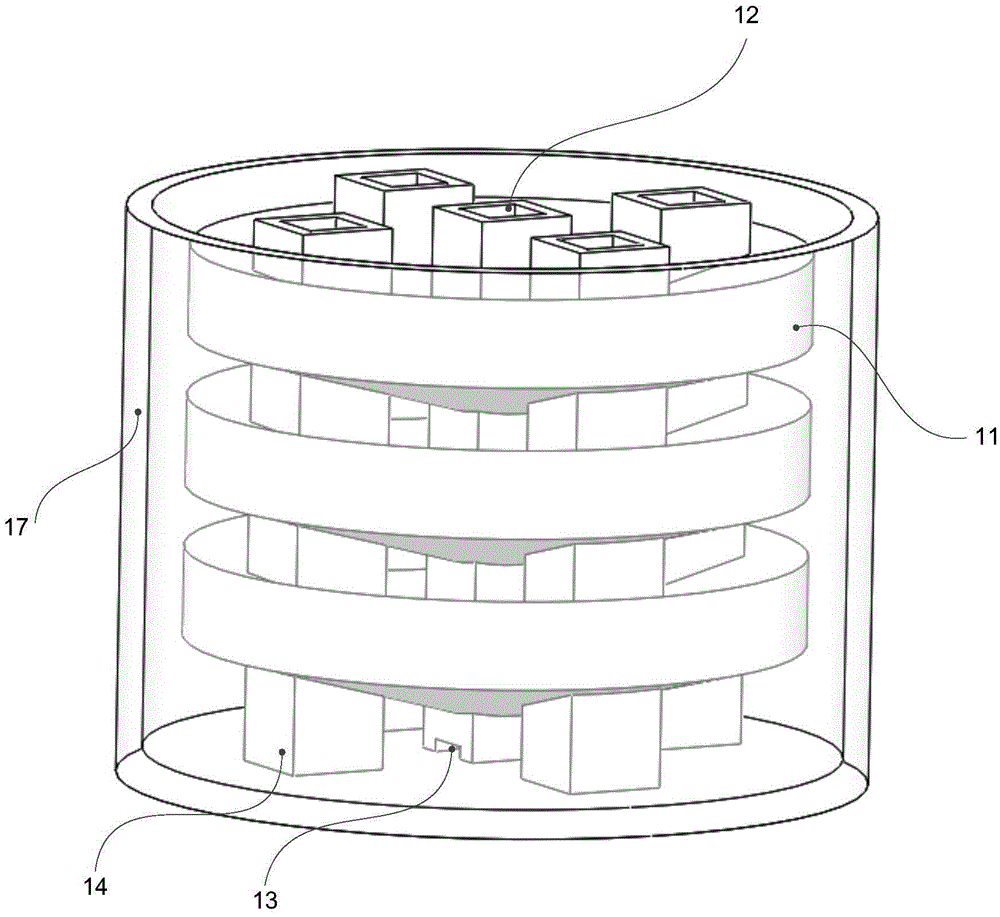

[0021] Such as figure 1As shown, the present invention provides a core melt trap with the function of guiding melt stratification and expansion, located in the vertical shaft 17 connected to the bottom of the reactor pit 2 through the vertical transport channel 6, in the vertical shaft 17 There are multiple layers of molten material extended retention chambers 11 arranged vertically, the distance between two adjacent layers of molten material extended retention chambers 11 is 10-30 cm, and a plurality of molten material perfusion channels 10 are passed between adjacent molten material extended retention chambers 11 form a connected space. The bottom of the molten material expansion retention chamber is inclined, and the height gradually decreases from the outside to the center, with an inclination angle of 10-20°, which is helpful for the expansion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com