A core melt trap with internal cooling capability

A core melt, internal cooling technology, applied in cooling devices, reactors, nuclear power generation, etc., can solve the problems of not considering the internal cooling method of melt, long melt migration path, and many links, etc., to reduce instantaneous steam The amount of production, the cooling method is reliable, and the effect of reducing the metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

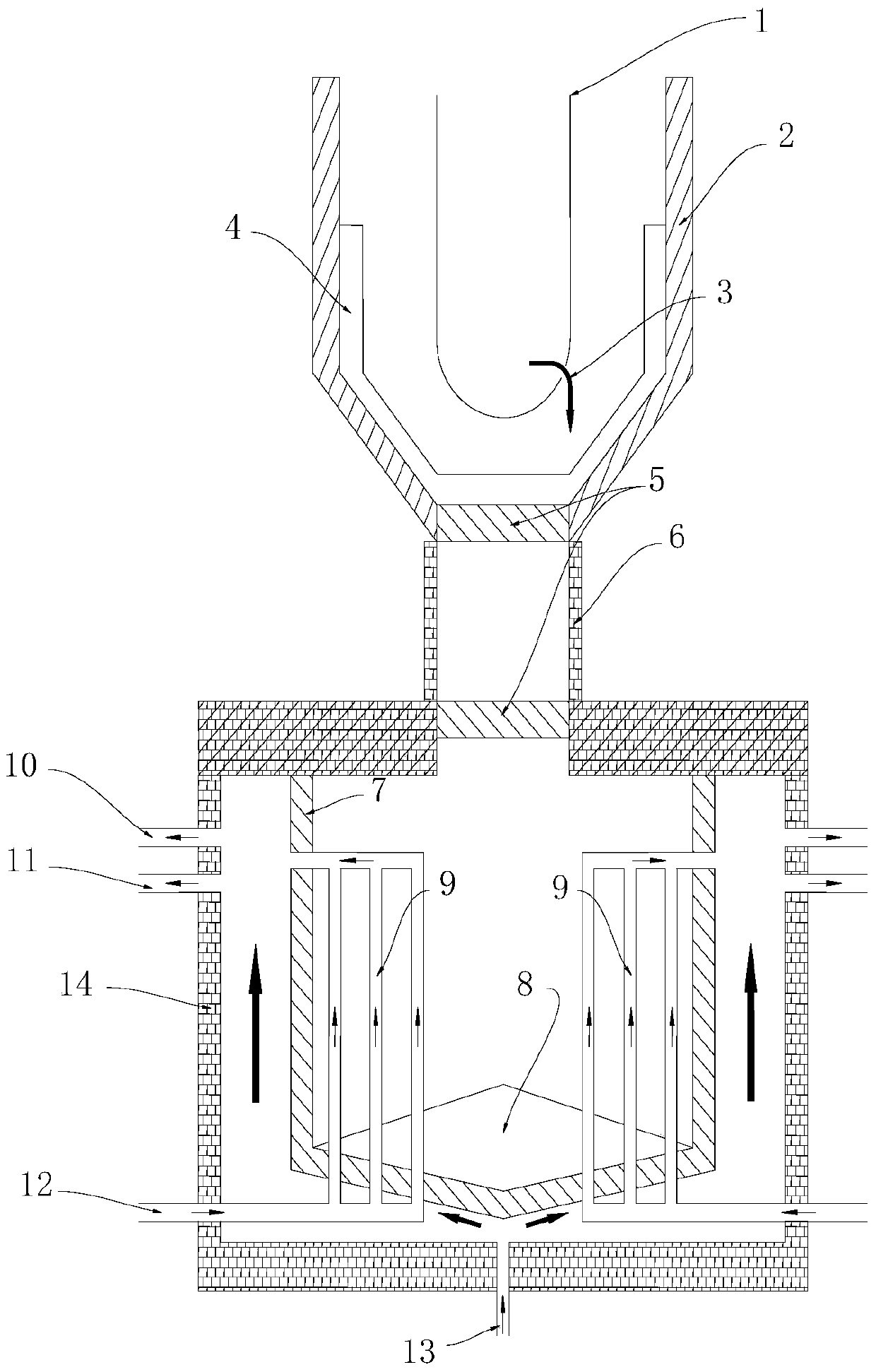

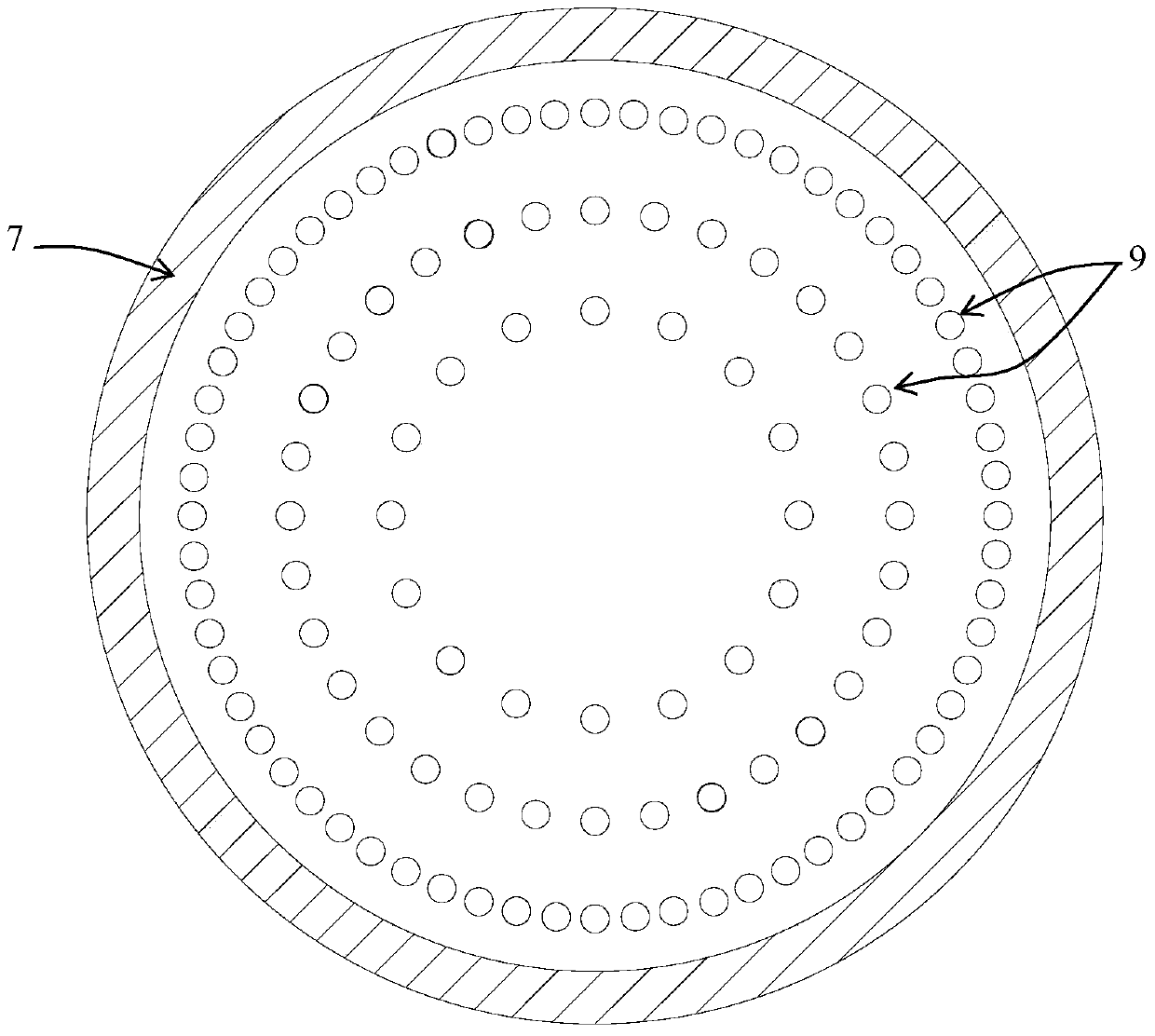

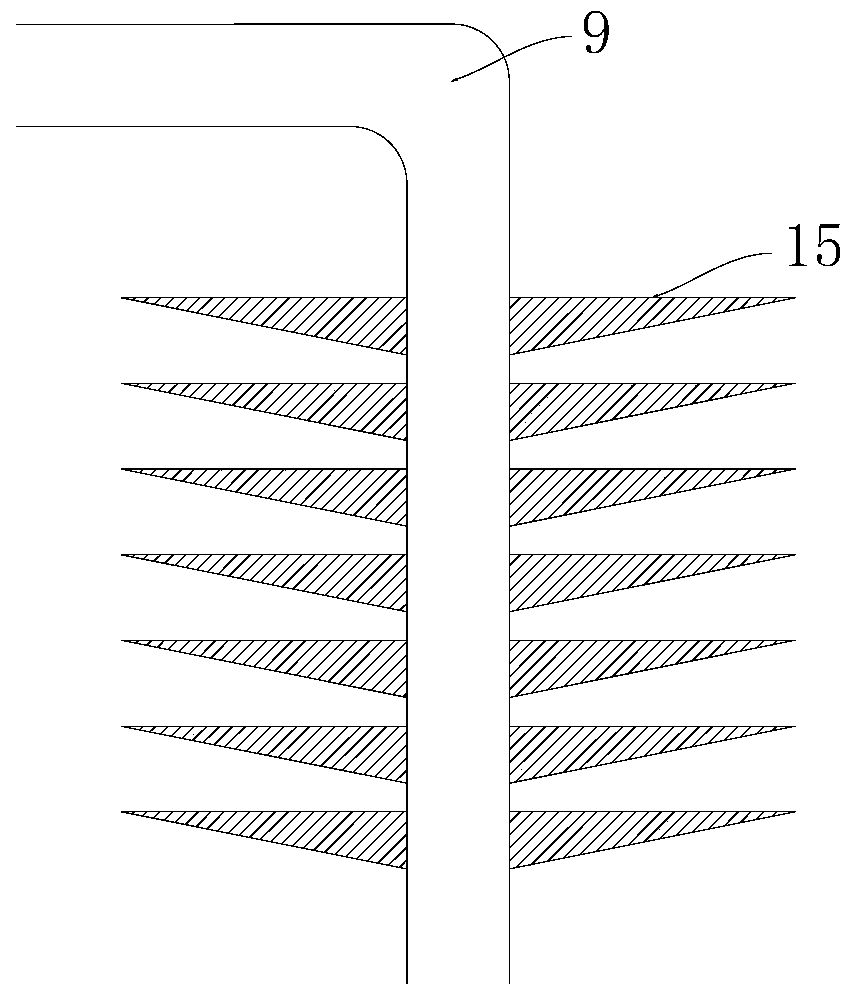

[0025] Such as figure 1 As shown, the present invention provides a core melt catcher with melt internal cooling capability, comprising a melt retention vessel 7, which is located in a reactor pit 2 via a vertical transfer channel 6 In the vertical shaft 14, the upper part of the vertical transportation channel 6 has a fusible layer 5, and the lower part of the reactor pit 2 has a layer of sacrificial concrete 4. In this embodiment, the bottom of the smelt retention vessel 7 is in an inverted conical shape, and the inclination angle of the conical surface is 8-20°. The sacrificial material 8 and the inner tube bundle 9 are arranged inside, and the water inlet 12 of the inner tube bundle is located at the shaft 14 and the smelt retention vessel. 7 bottom, the outlet is located at the upper part of the smelt retention vessel 7. The bottom of the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com