A group retention and cooling system for core melt

A core melt and cooling system technology, applied in cooling devices, reactors, greenhouse gas reduction, etc., can solve the problem of not considering the grouping of core melts to capture and cool them, so as to improve the decay heat export power of melts , the cooling method is reliable, and the effect of simplifying the post-accident treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

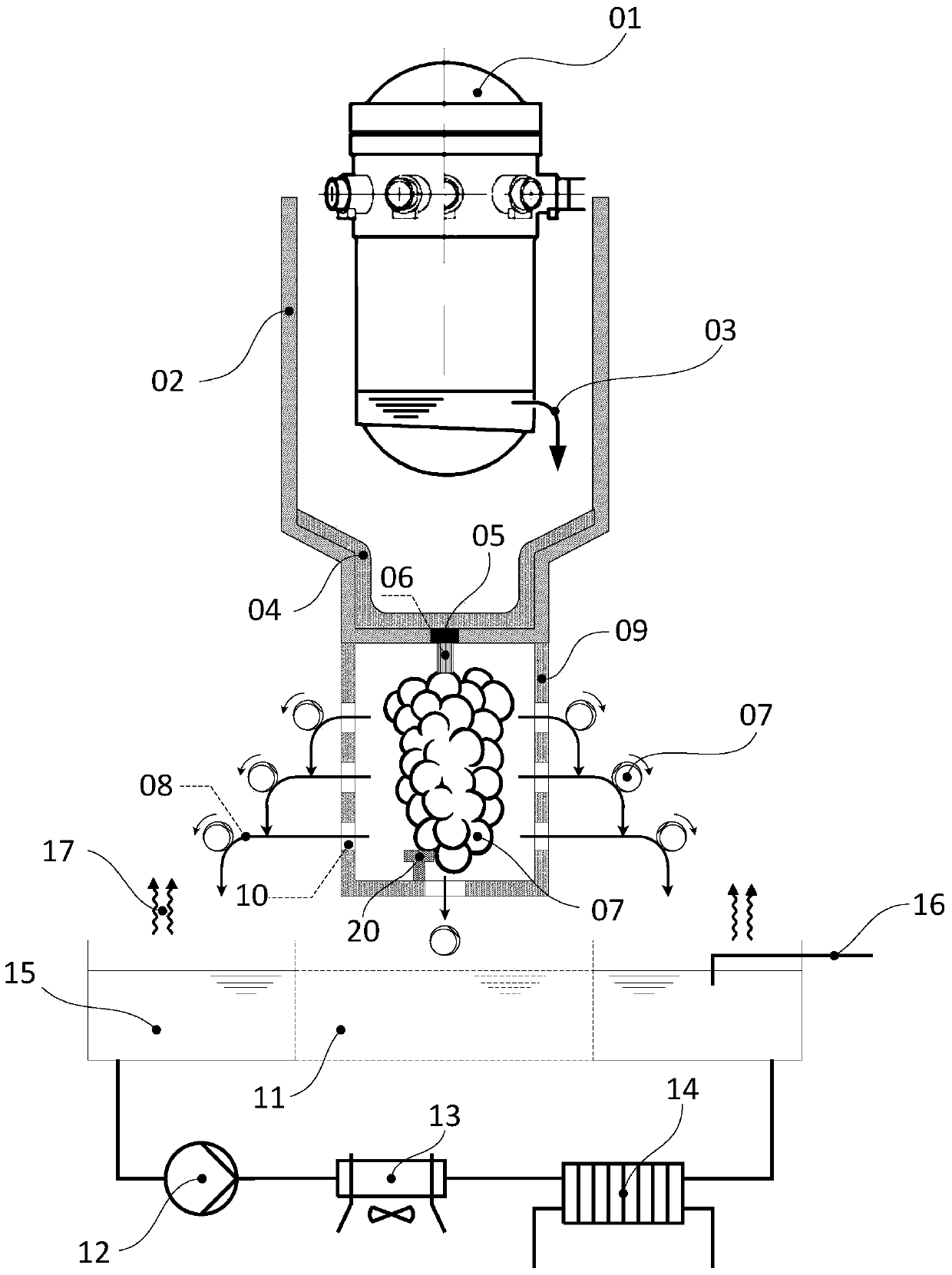

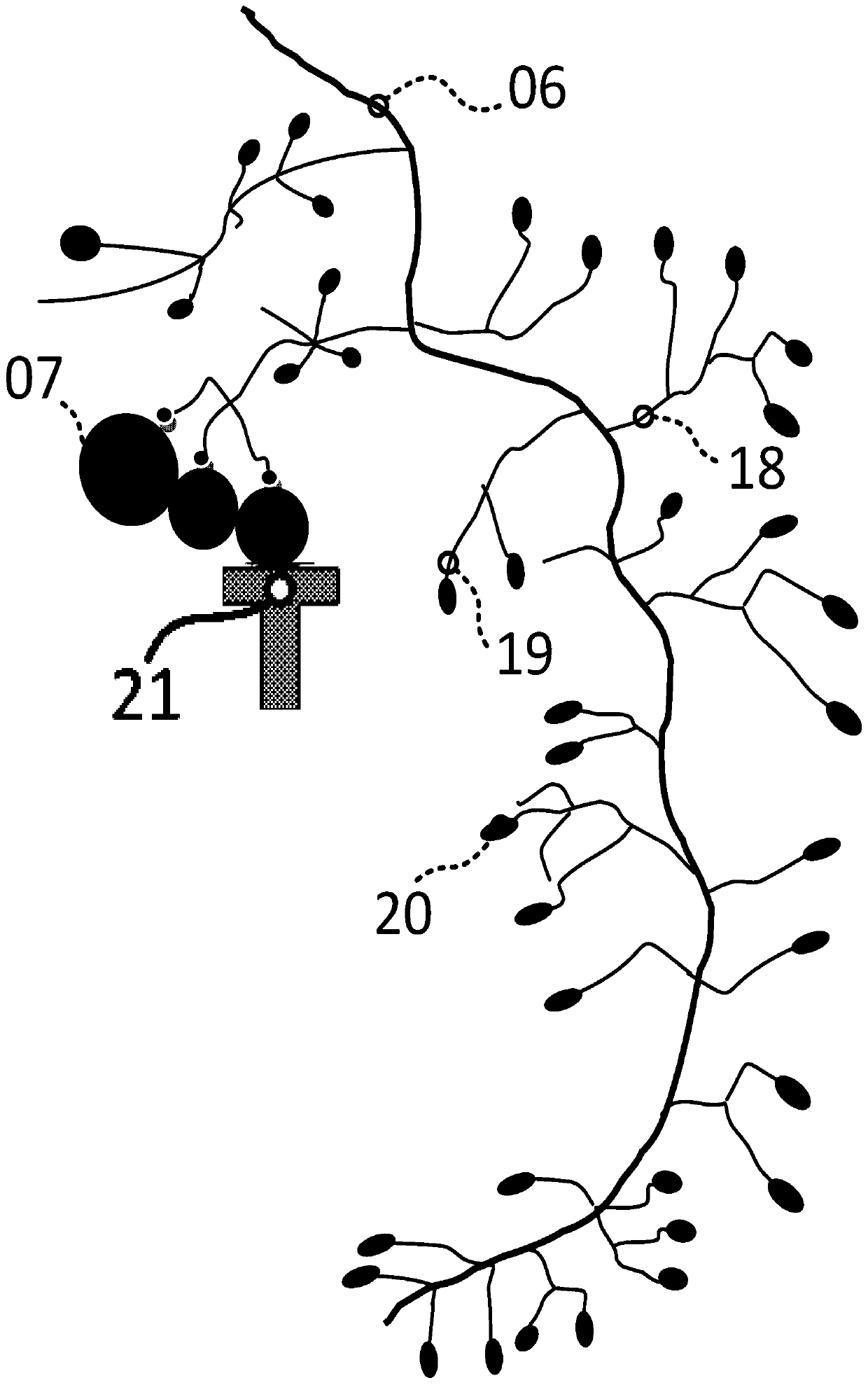

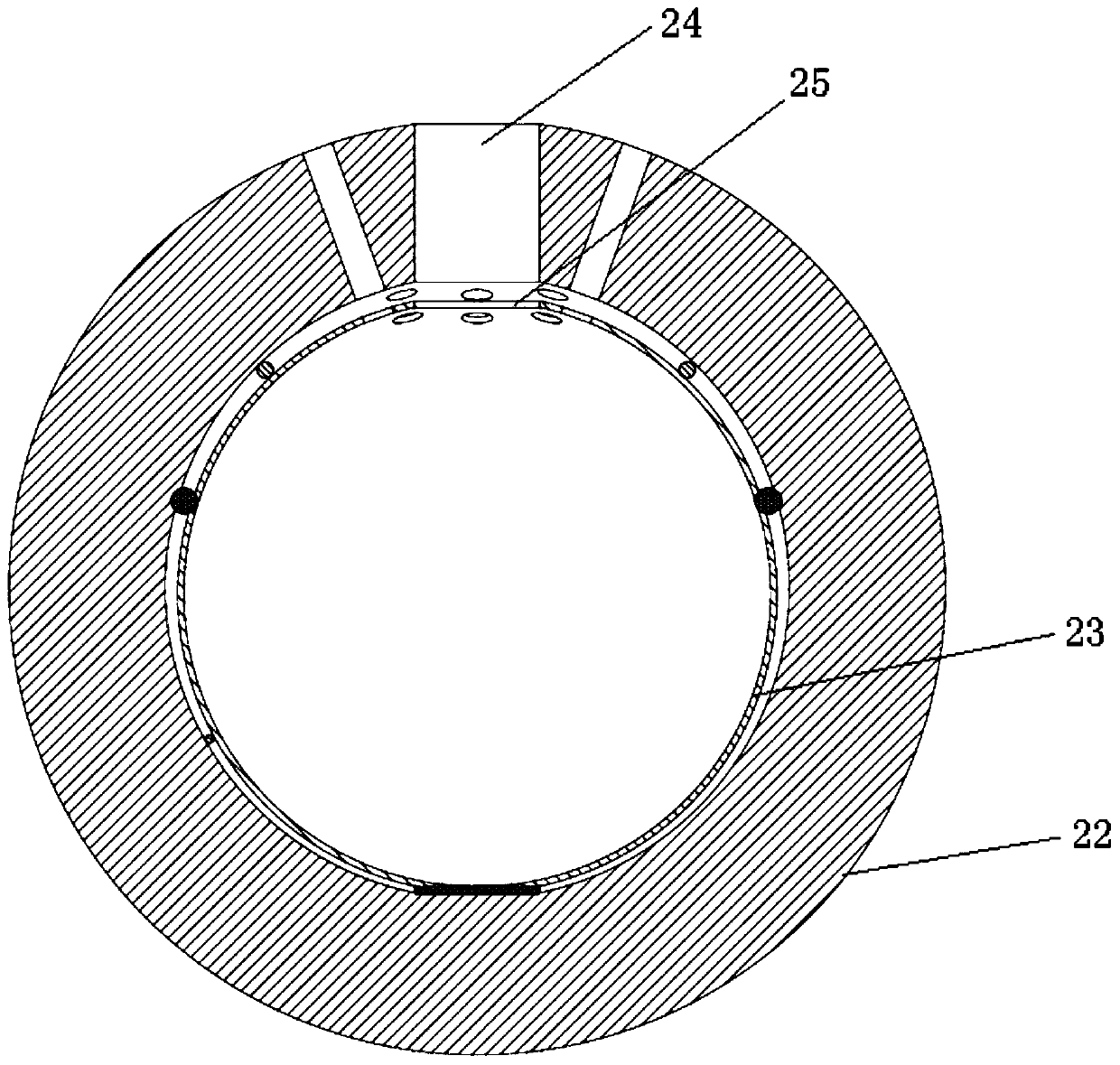

[0020] Such as figure 1 Shown is a group retention and cooling system for core melt provided by the present invention, including a group retention system and a cooling system. The group retention system includes a molten material retention container loading well 09 arranged at the bottom of the reactor cavity 02 and a plurality of molten material retention containers 07 arranged in the molten material retention container loading well 09 . A plurality of melt retention containers 07 are connected to the reactor cavity 02 through multi-stage melt transport channels, and a melt retention container transfer device 08 is pierced on the melt retention container loading well 09, and the melt retention container transfer device 08 connected to the cooling system. The cooling system includes a melt cooling water pool and a cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com