A layered forced-spreading core melt trap

A core melt and trap technology, which is applied in the field of core melt traps, can solve problems such as the full expansion of the melt without considering the means of layered forced spreading, so as to avoid failure of protective barriers, reliable cooling methods, total reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

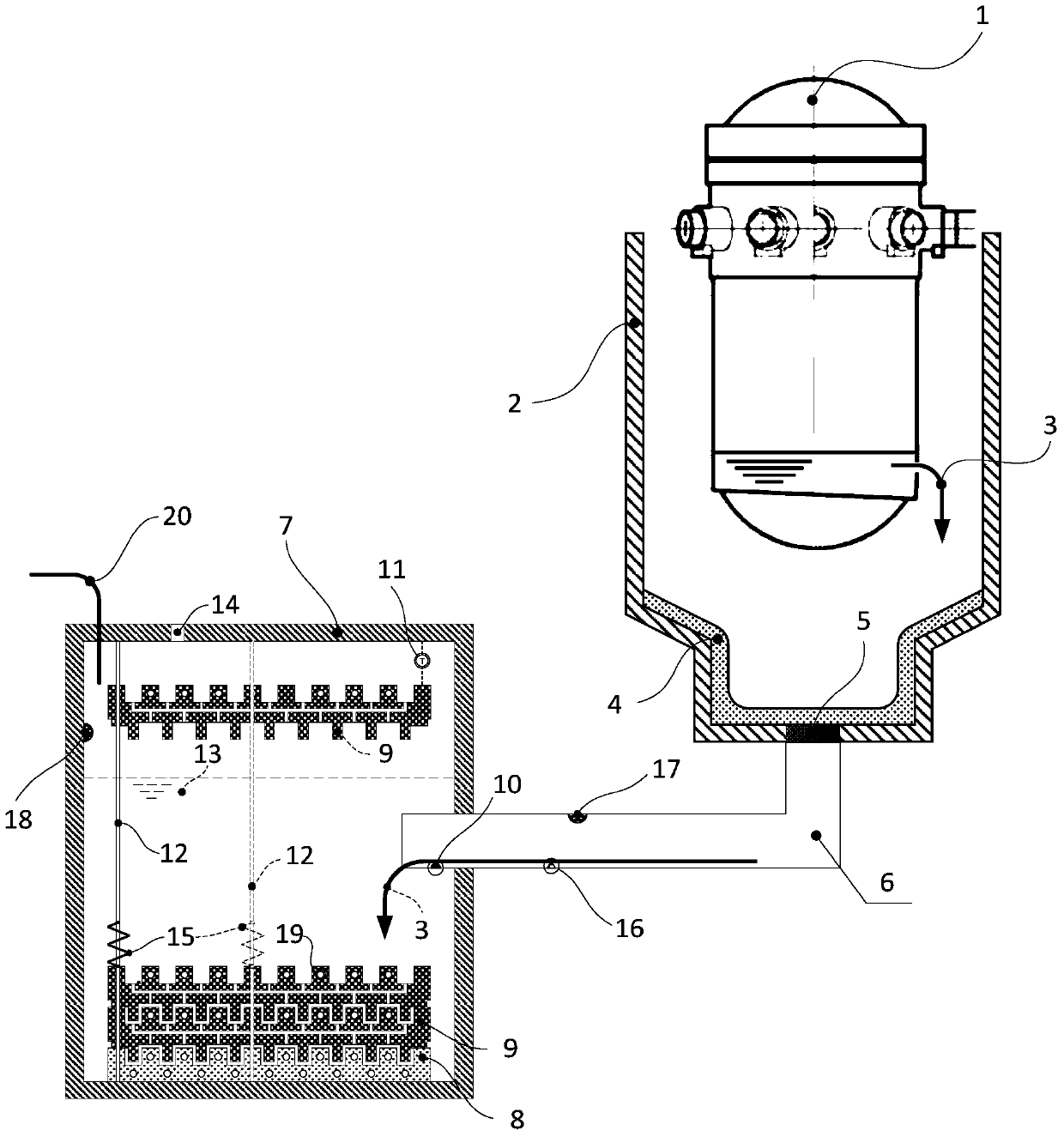

[0041] In embodiment one:

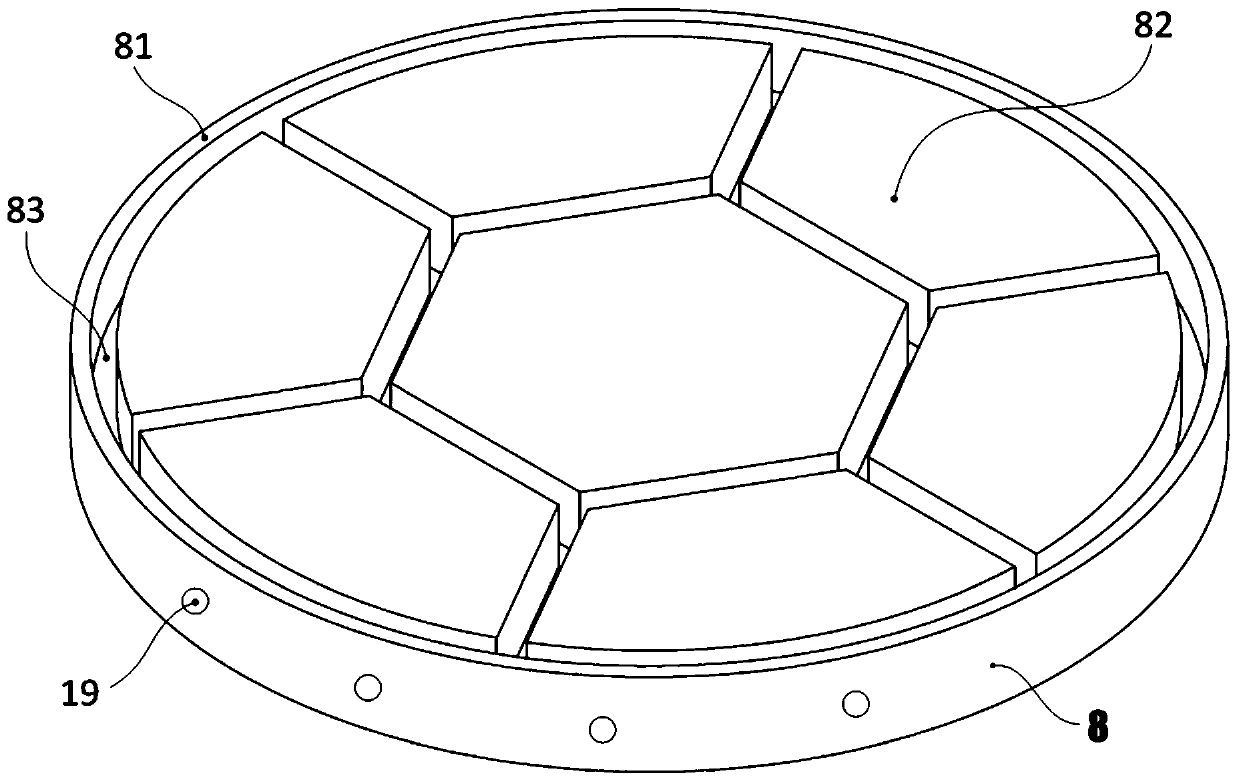

[0042] Trap bottom plate 8 (see figure 2 ) The outer edge of the catcher bottom plate is provided with a contour convex edge 81 of the catcher bottom plate, and the inner plate surface is provided with several polygonal catcher bottom plate protrusions 82 and catcher bottom plate depressions 83;

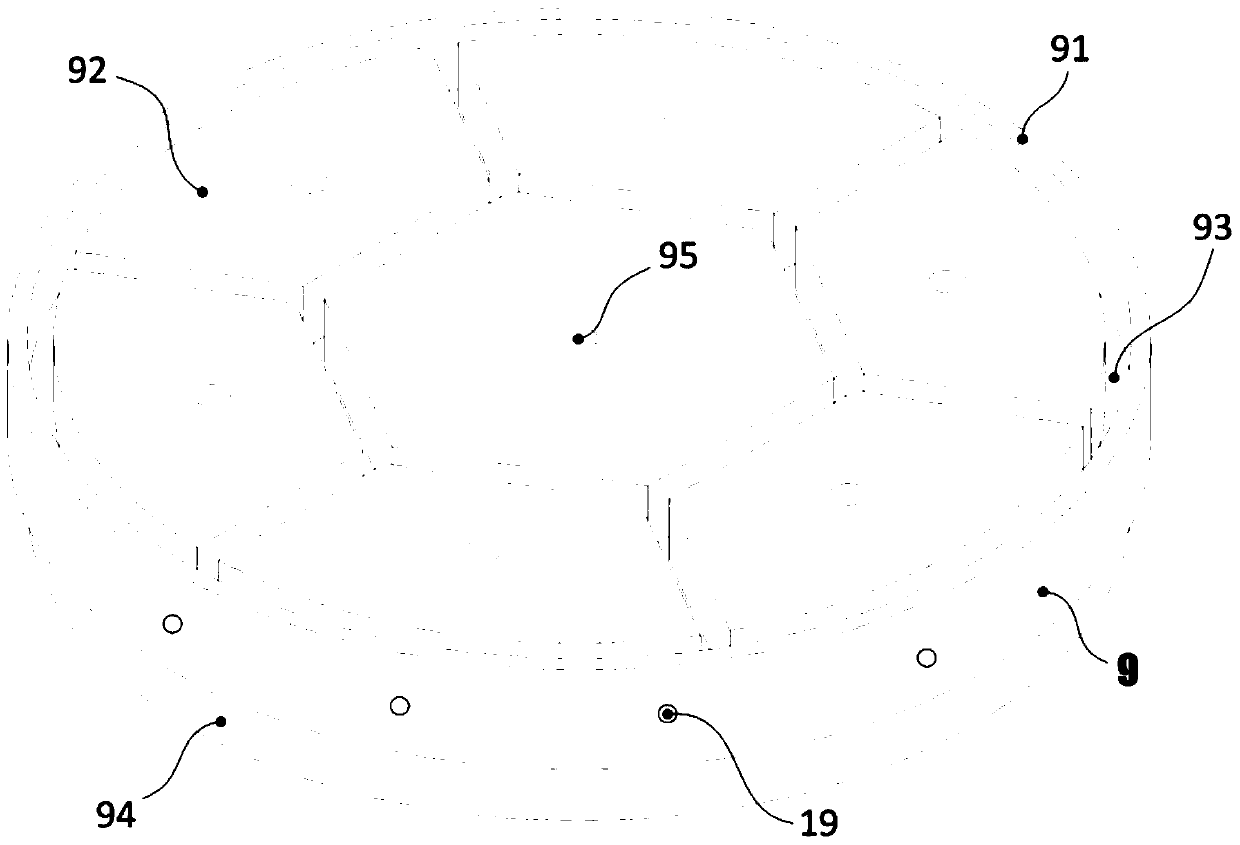

[0043] Such as image 3 , Figure 5 As shown, the outer edge of the upper surface of the catcher cover 9 is provided with a convex edge 91 (protruding upwards) on the catcher cover outline, and a number of catcher cover protrusions 92 are arranged on the inner surface of the upper surface. And catcher cover plate depression 93, catcher cover plate through hole 95 is arranged on catcher cover plate protrusion 92; Figure 4 As shown, the peripheral edge of the lower surface of the catcher cover plate 9 is provided with a convex edge 94 (protruding downward) of the catcher cover plate outline, and several downwardly protruding catches are arranged on the ...

Embodiment 2

[0046] In the second embodiment:

[0047] Such as Figure 7 As shown, the outer edge of the catcher bottom plate 8 is provided with a catcher bottom plate contour convex edge 81, and the inner plate surface is provided with several continuous wave-shaped catcher bottom plate protrusions 82 (wave crests) and catcher bottom plate depressions. 83 (trough);

[0048] Such as Figure 8 , Figure 9 As shown, the outer edge of the upper surface of the catcher cover 9 is provided with a convex edge 91 (protruding upwards) on the catcher cover outline, and a number of catcher cover protrusions 92 are arranged on the inner surface of the upper surface. And the trap cover plate depression 93, the trap cover plate through hole 95 is arranged in the trap cover plate depression 93; as Figure 10 As shown, the peripheral edge of the lower surface of the catcher cover plate 9 is provided with a convex edge 94 (protruding downward) of the catcher cover plate outline, and several downwardly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com