A double-layer crucible core melt collection device with internal cooling pipes

A core molten material and double-layer crucible technology, applied in cooling devices, emergency protection devices, reactors, etc., can solve the problems of failure of the lower head of the reactor pressure vessel, melting of fuel elements, and damage to the integrity of the containment vessel. Improve retention success rate and cooling efficiency, improve reliability, and enhance overall cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

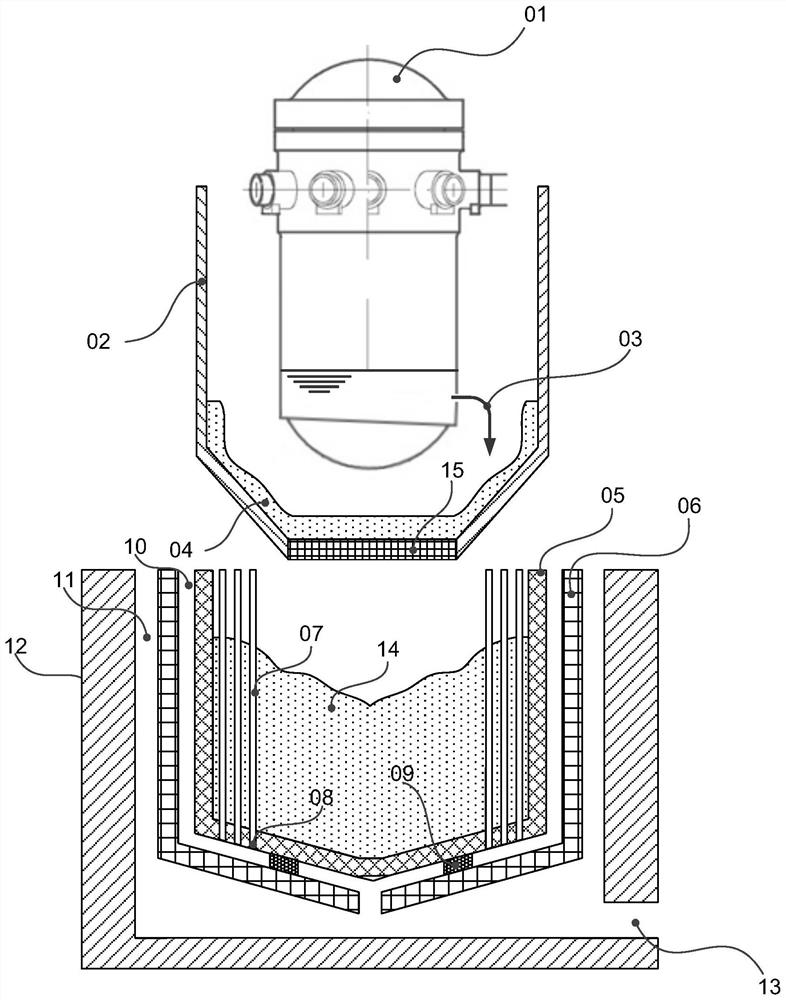

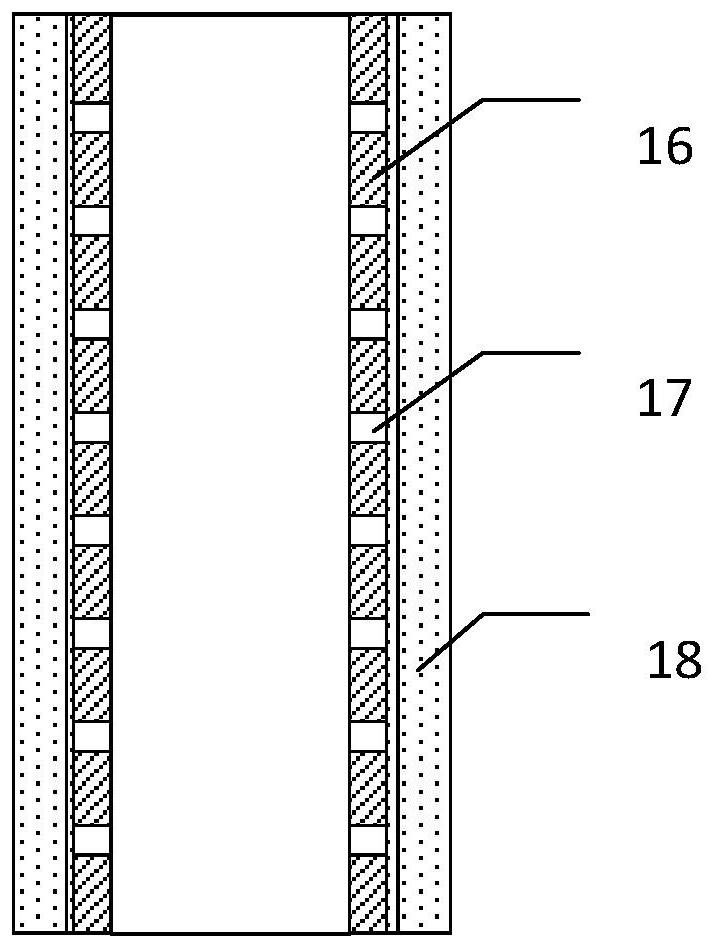

[0038] The composition structure of an exemplary double-layer crucible core melt trapping device with internal cooling pipes of the present invention is as follows: figure 1 As shown, it includes reactor pressure vessel 1, high temperature resistant drainage protection layer 2, path 3 for core molten material sprayed out from the pressure vessel after the accident, special concrete 4, inner crucible 5, outer crucible 6, cooling pipe 7, cooling Pipe water inlet 8, support base 9, cooling flow channel 10, stack pit cavity 11, stack pit 12, cooling water injection port 13, sacrificial material stack 14, fusible metal grid plate 15.

[0039] The inner crucible 5 is arranged directly below the reactor pressure vessel 1, and it is fixed in the outer crucible 6 located outside the reactor pressure vessel 1 below the reactor pressure vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com