Device combining in-core and out-of-core dwelling of molten material of large-scale passive nuclear power plant

A passive, nuclear power plant technology, applied in nuclear power generation, emergency protection devices, reactors, etc., can solve problems such as failure, release of radioactive substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

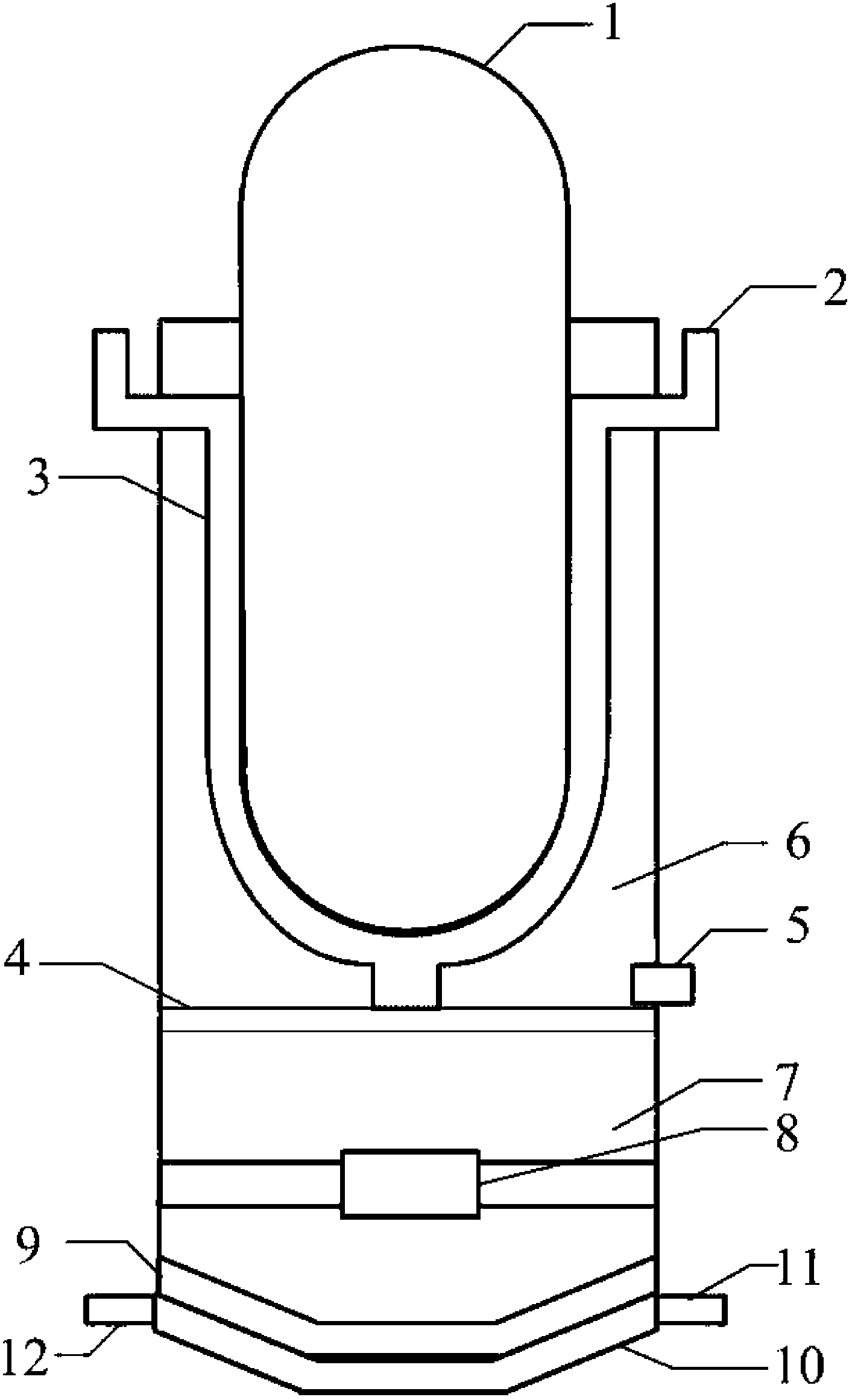

[0013] The technical solution of the present invention is a device that combines the inside and outside of the pile of molten material in a large passive nuclear power plant, such as figure 1 As shown, it includes concrete sacrificial layer 4, core trap chamber 7, core trap refractory layer 8, cooling channel inlet 9, cooling channel outlet 10 and core trap bottom cooling channel 11; wherein, The bottom of the reactor cavity 6 is provided with a concrete sacrificial layer 4, the thickness of which is between 0.2m-4m, and the lower part of the concrete sacrificial layer 4 is provided with a sealed core catcher chamber 7, and the core catcher is made of refractory material , preferably magnesia or zirconia, a pot-shaped core catcher refractory layer 8 is arranged at the lower part of the core catcher chamber 7, and a circular stack is arranged on the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com