Rock sample in-situ fidelity coring system

A fidelity and in-situ technology, applied in the field of oil and gas field exploration, can solve the problems of slow blade cooling speed, short blade service life, fast tool wear, etc., and achieve the effect of accelerating cooling speed, prolonging life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

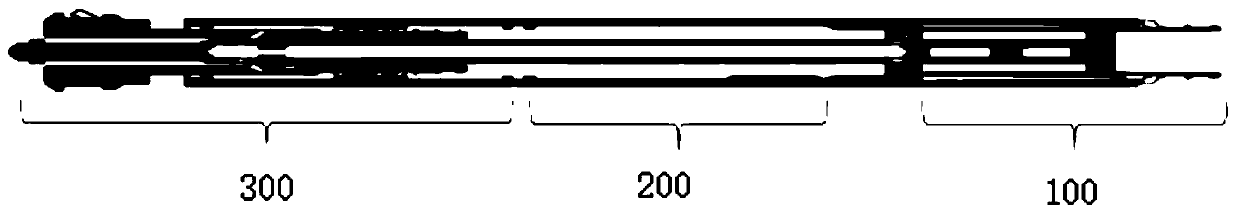

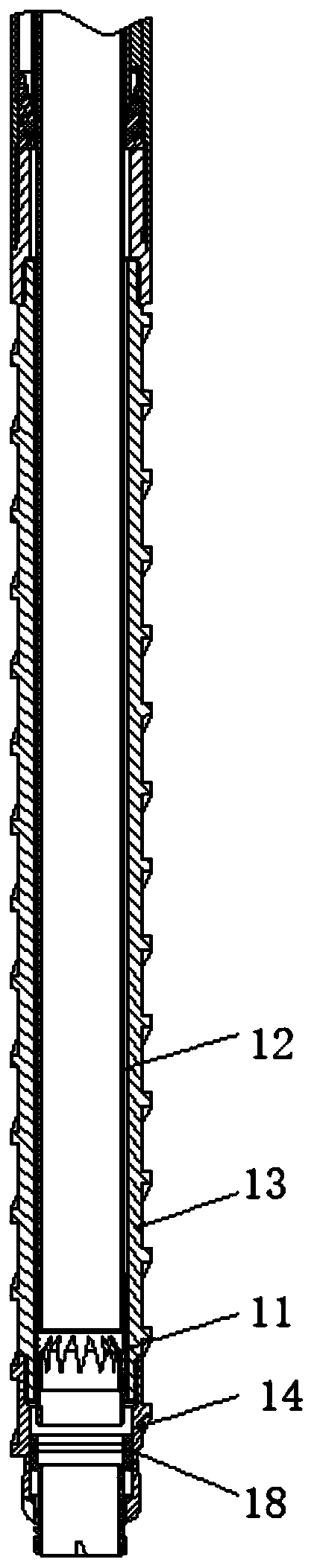

[0054] Such as figure 1 As shown, the rock sample fidelity coring system disclosed in the present invention includes a drive module 300, a fidelity module 200 and a coring module 100 connected in sequence, a coring module core drilling tool, a core sample storage cylinder, a fidelity The module includes the core sample preservation chamber, the drive module includes the core drilling rig, and the core drilling rig includes the unlocking mechanism of the outer cylinder of the drilling rig

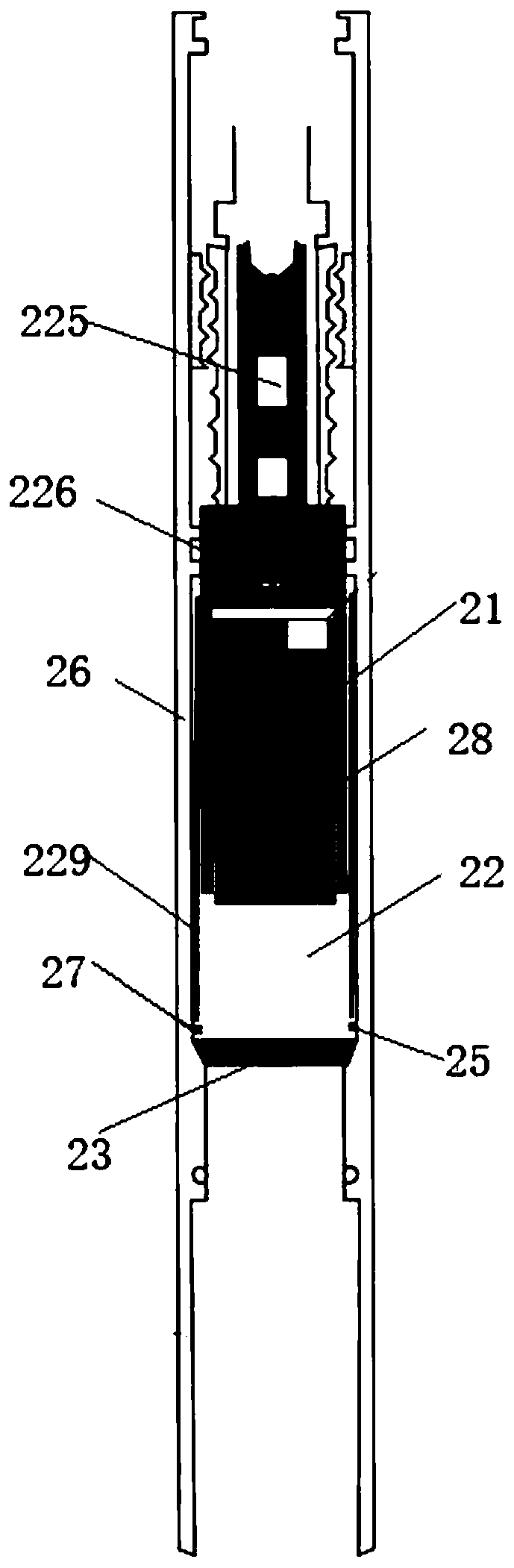

[0055] Such as figure 2 As shown, the rock core preservation chamber includes a mechanical part and a control part, and the mechanical part includes an inner coring barrel 28, an outer coring barrel 26 and an accumulator 229, and the accumulator 229 communicates with the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com