Patents

Literature

50results about How to "Improve coring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

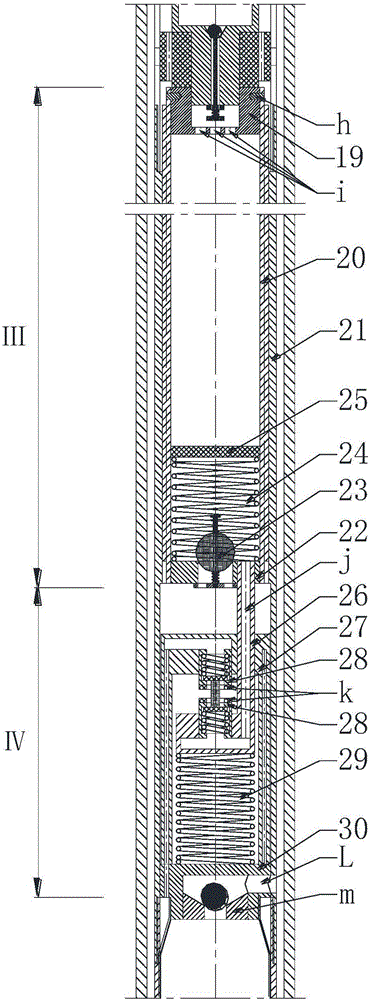

Rock sample in-situ fidelity coring system

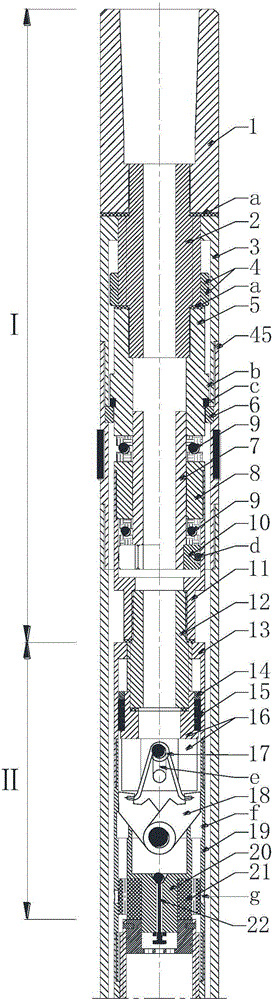

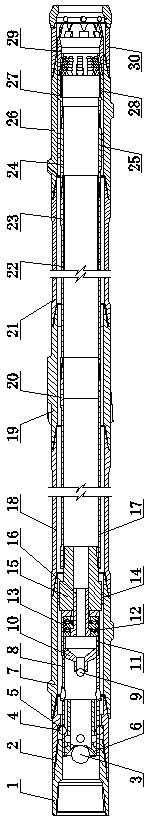

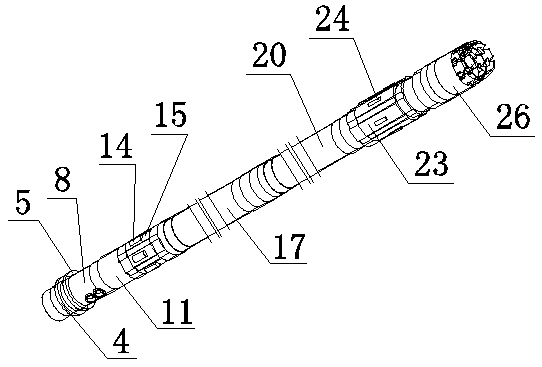

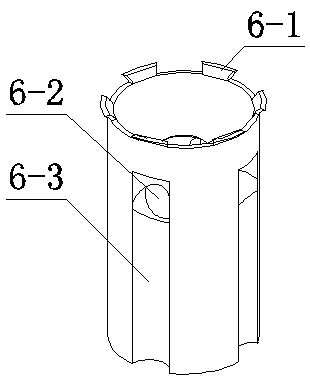

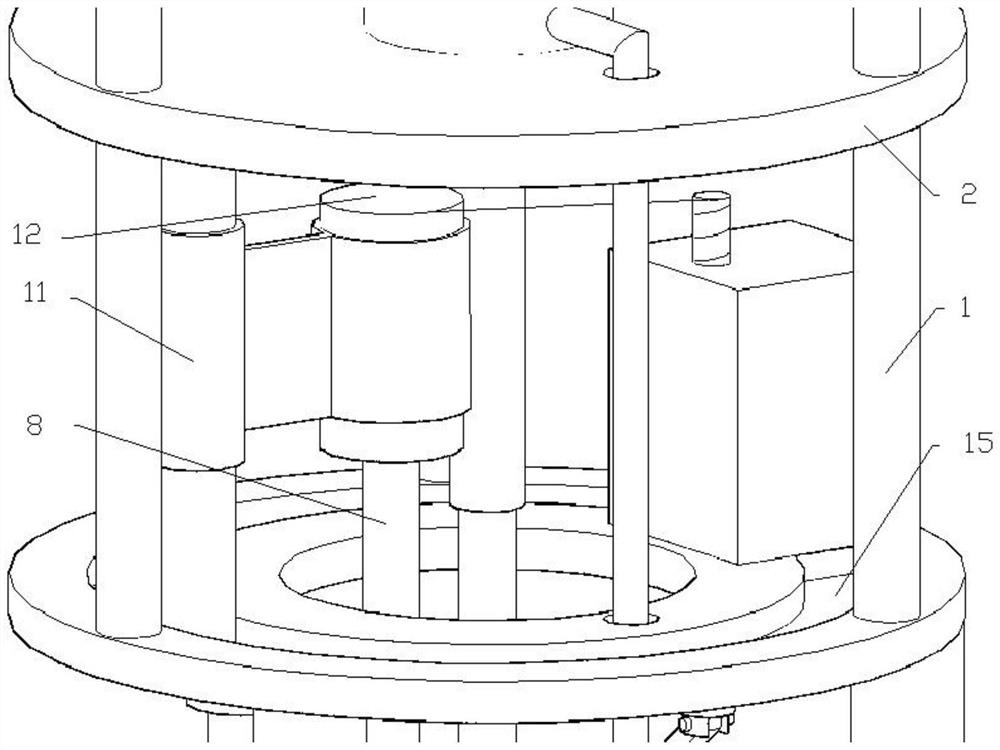

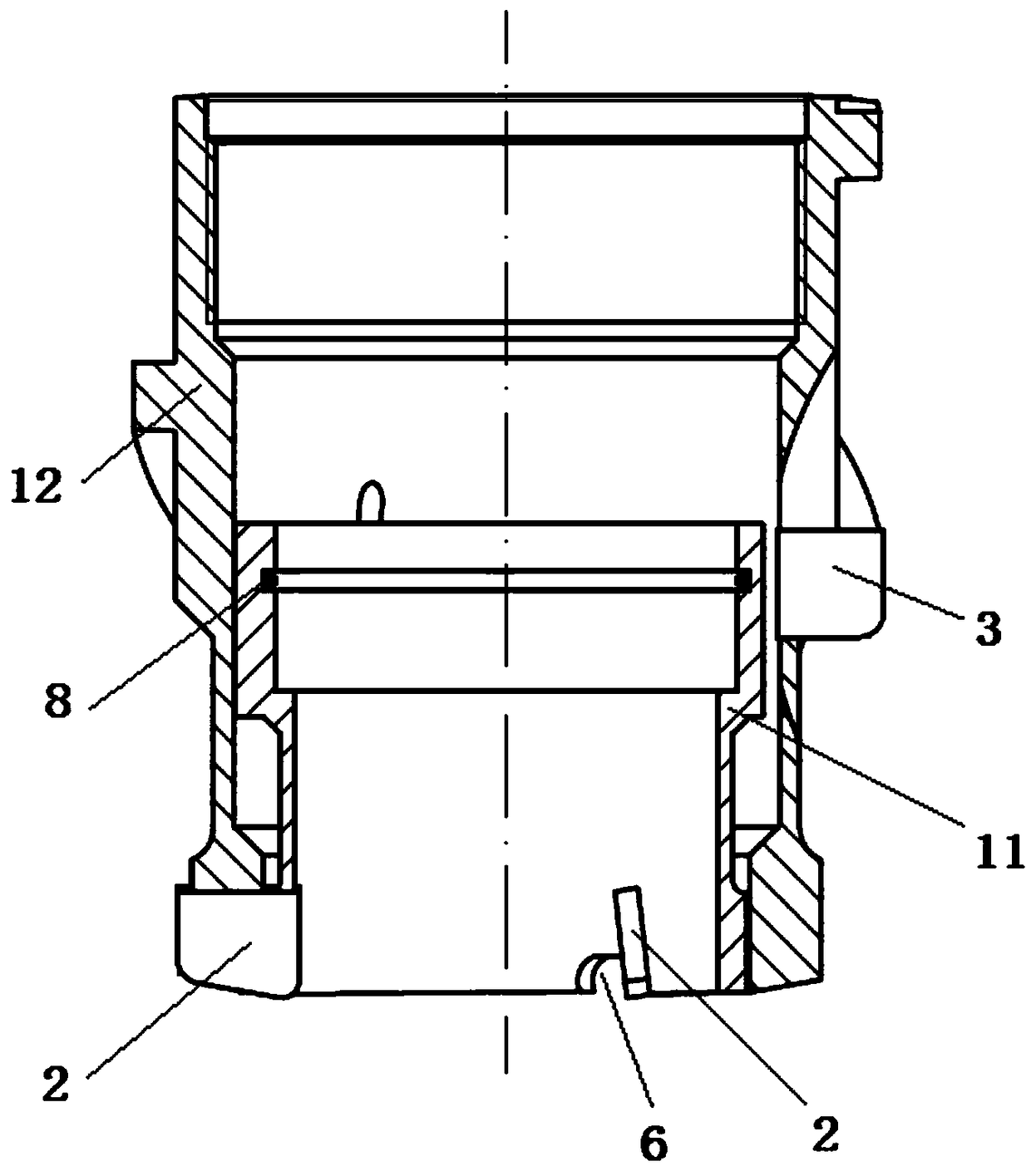

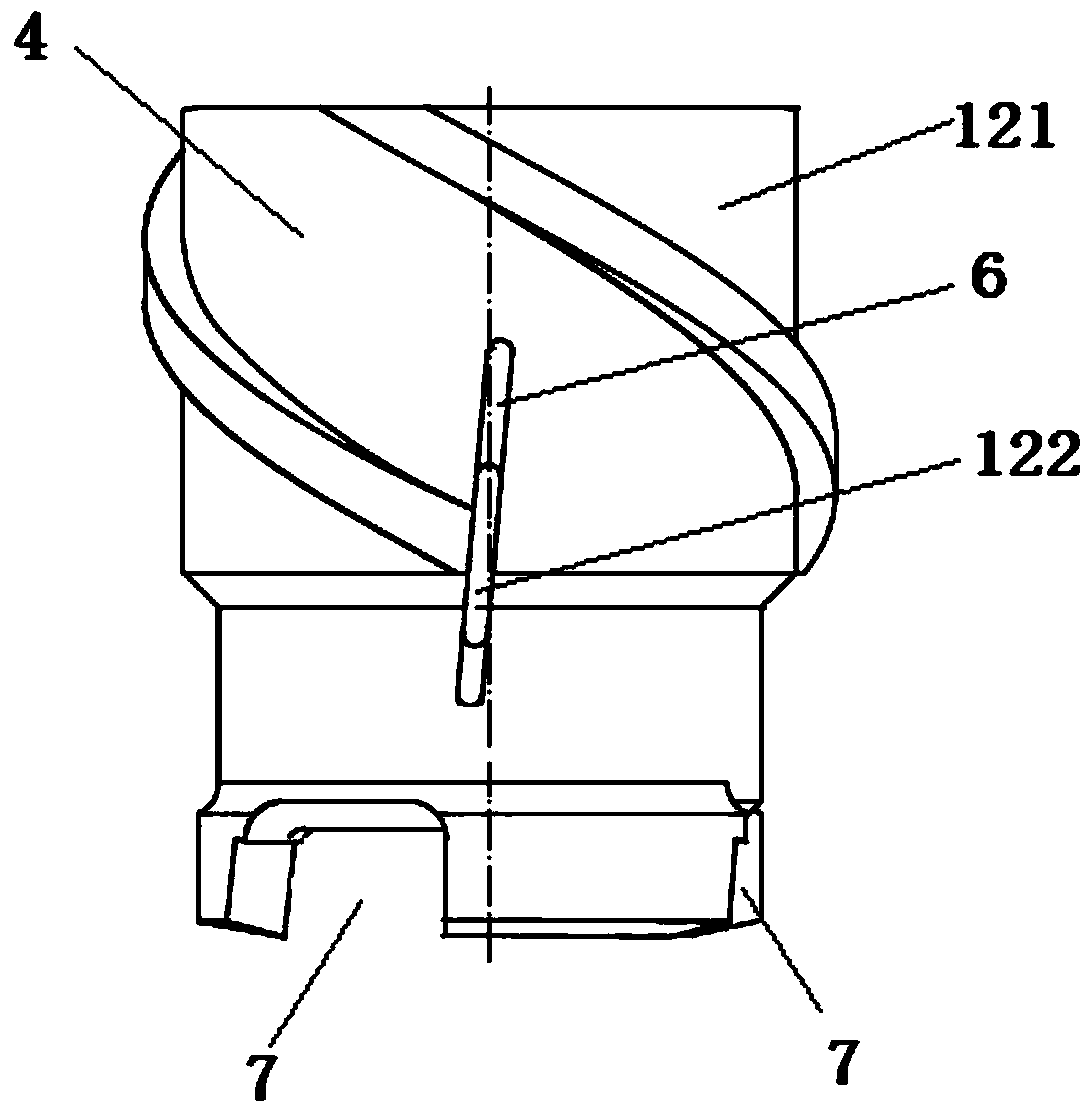

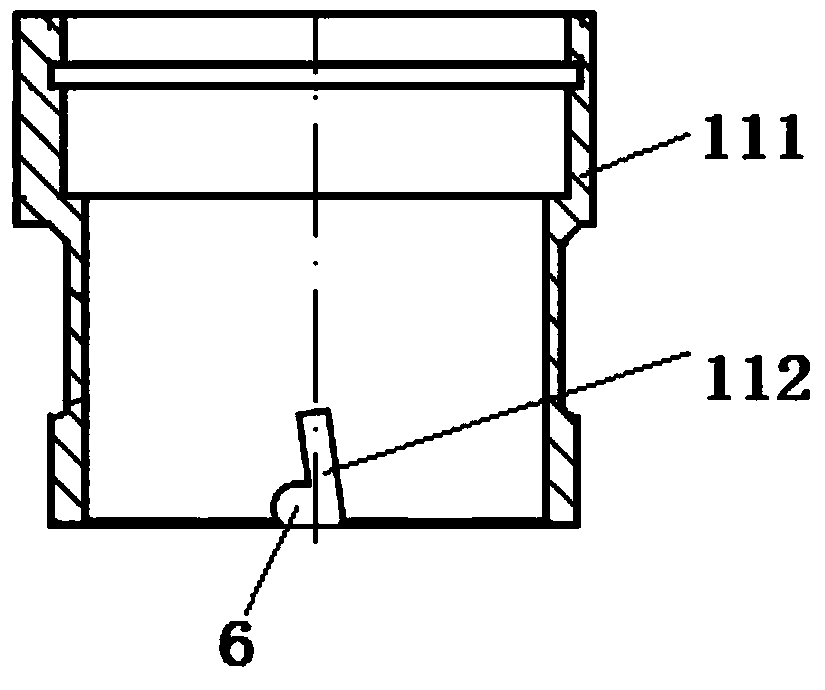

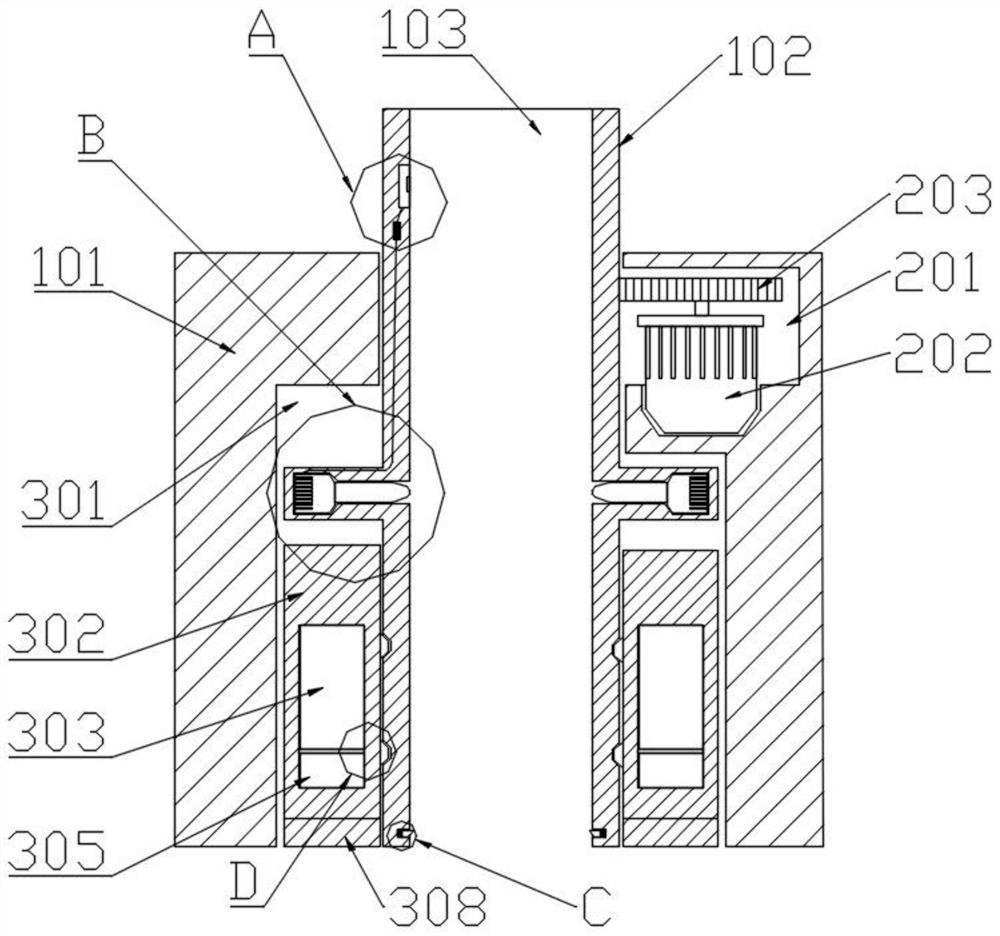

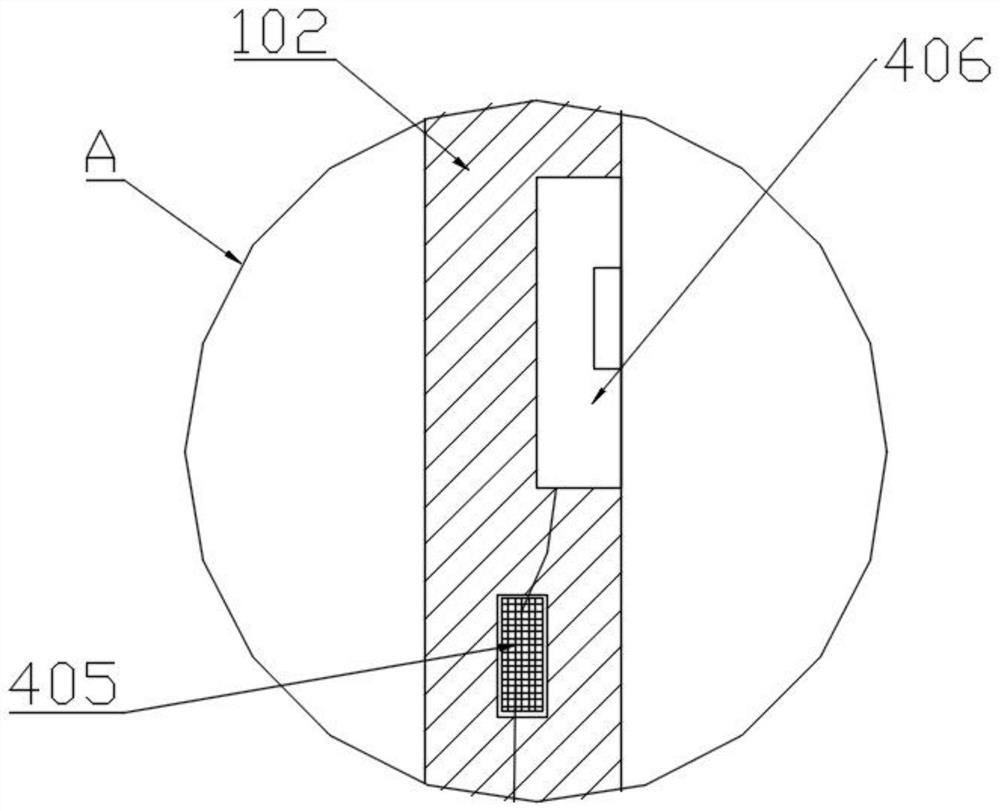

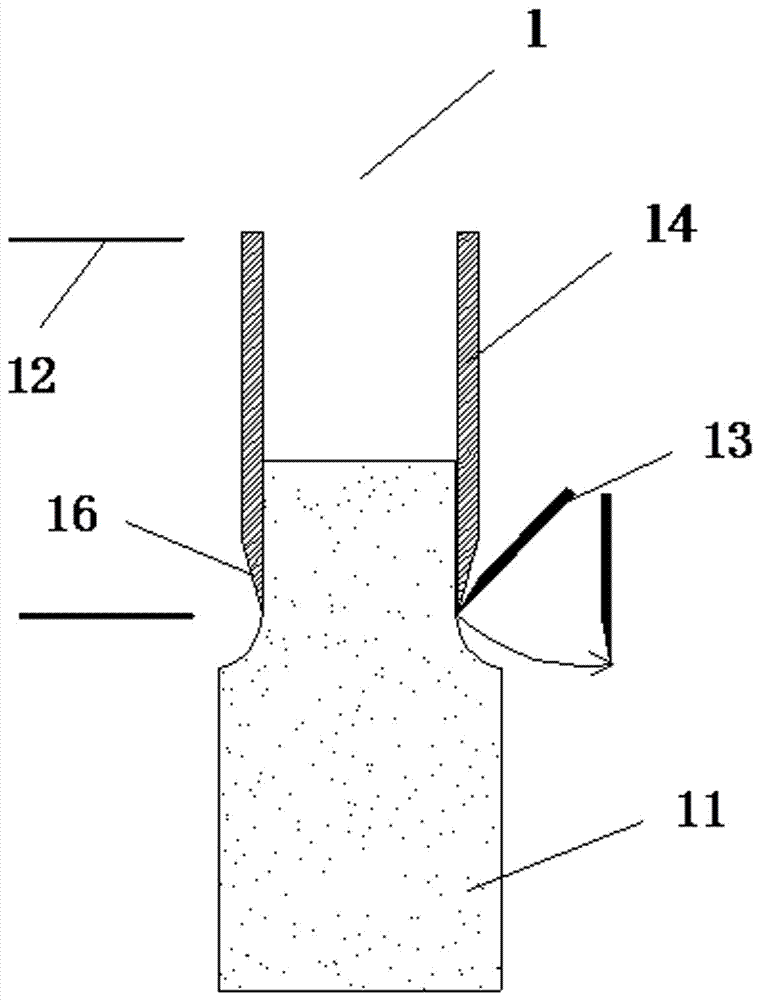

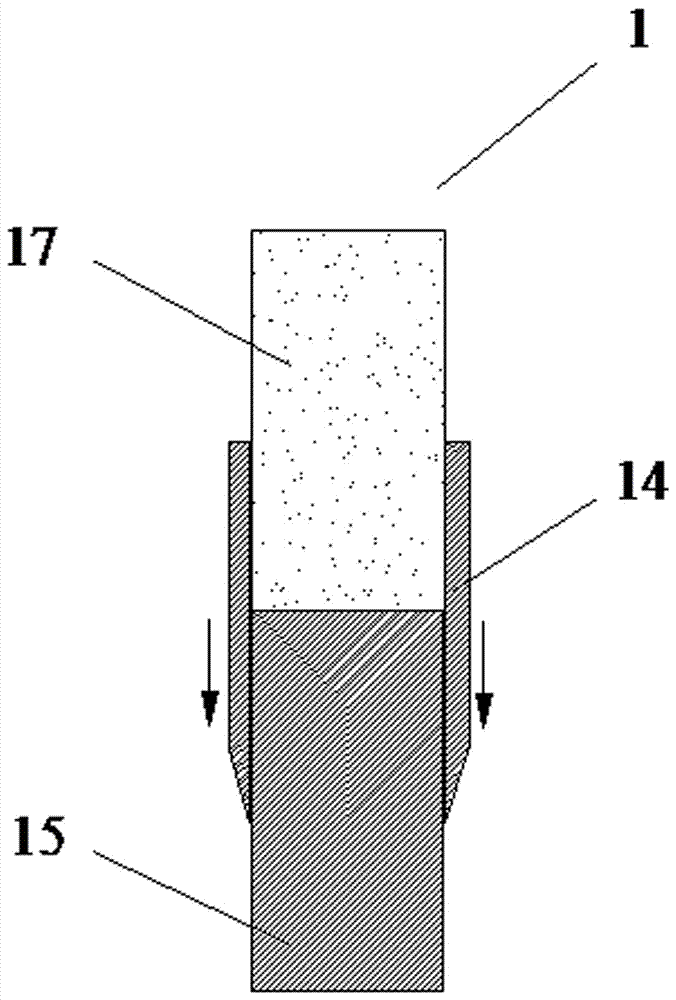

The invention discloses a rock sample in-situ fidelity coring system. The rock sample in-situ fidelity coring system comprises a driving module, a fidelity module and a coring module which are sequentially connected, the coring module comprises a rock core drilling tool and a rock core sample storage cylinder, the fidelity module comprises a rock core sample fidelity cabin, the driving module comprises a coring drill rig, and the coring drill rig comprises a drill rig outer cylinder unlocking mechanism; the rock core drilling tool comprises a coring drill tool, a core catcher and an inner corepipe, the coring drill tool comprises an outer core pipe and a hollow drill bit, and the drill bit is connected with the lower end of the outer core pipe; the lower end of the inner core pipe extendsto the bottom of the outer core pipe, and the inner core pipe is in clearance fit with the outer core pipe; and the rock core sample fidelity cabin comprises an inner coring cylinder, an outer coringcylinder and an energy accumulator, the outer coring cylinder sleeves the inner coring cylinder, the upper end of the inner coring cylinder communicates with a liquid nitrogen storage tank, the liquid nitrogen storage tank is located in the outer coring cylinder, the energy accumulator communicates with the outer coring cylinder, and the outer coring cylinder is provided with a flap valve. According to the rock sample in-situ fidelity coring system, the rock core is advantageously kept the state under the in-situ environment, the drilling speed can be increased, and the coring efficiency is improved.

Owner:SHENZHEN UNIV

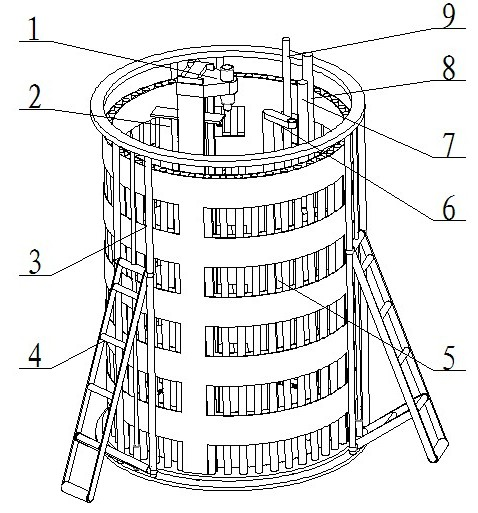

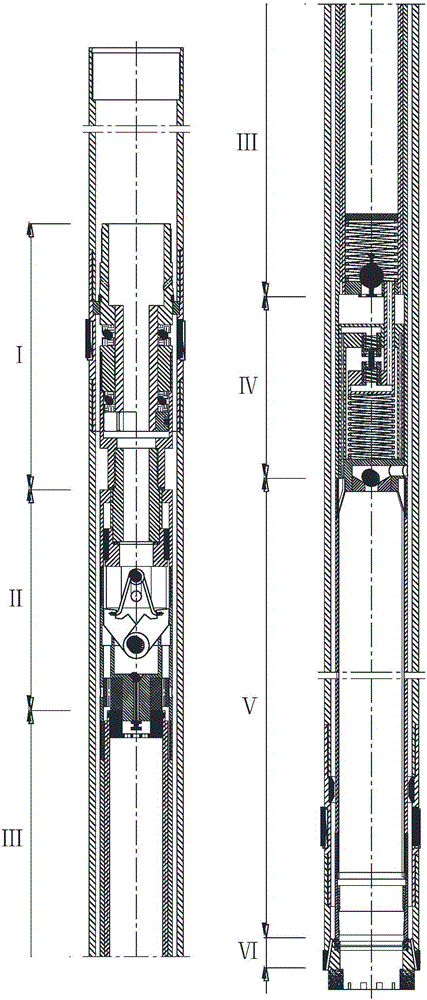

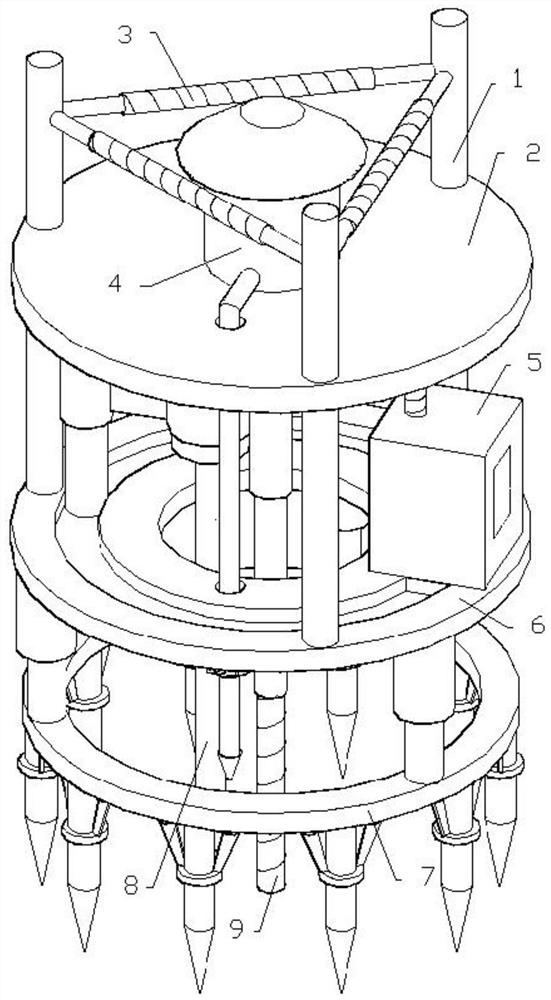

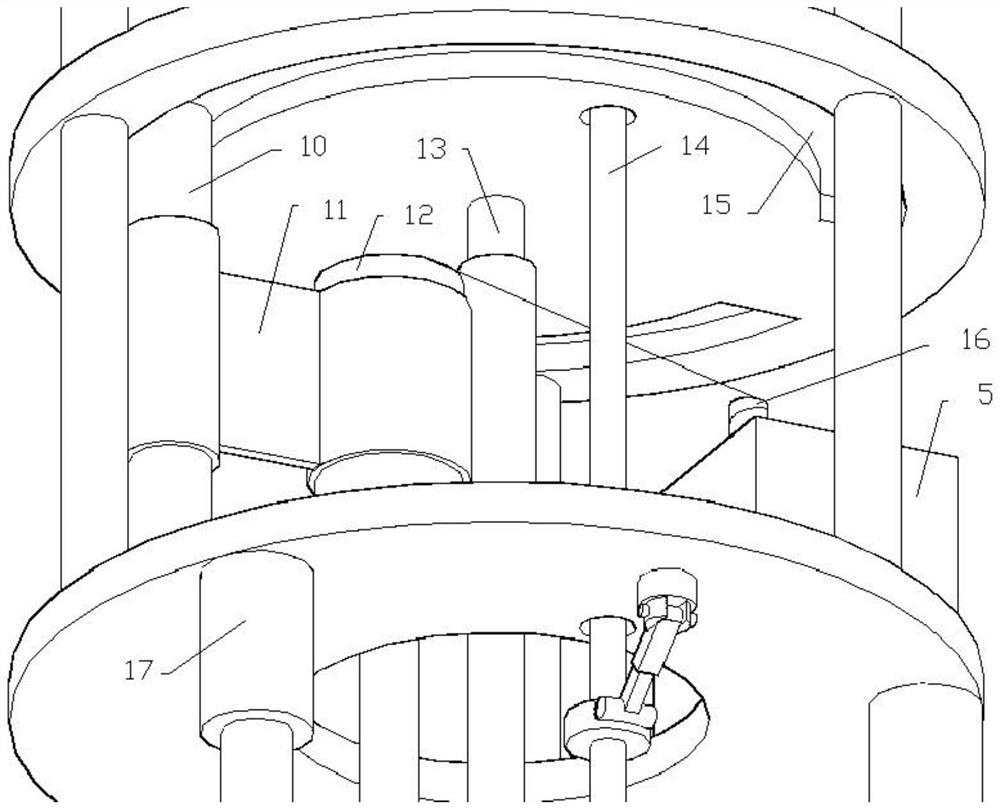

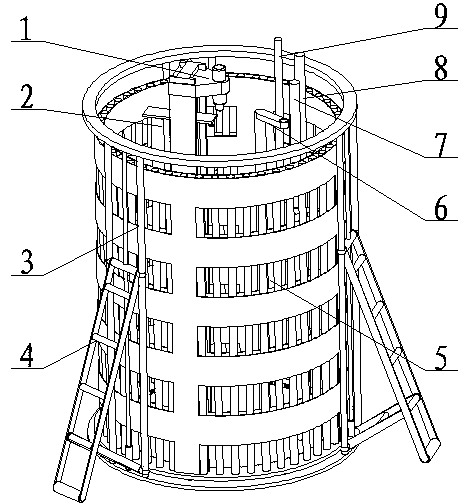

Novel submarine deep hole pressure maintaining and core drilling rig

InactiveCN102606074AEasy to operateReduce use costUnderwater drillingCore removalHydraulic motorManipulator

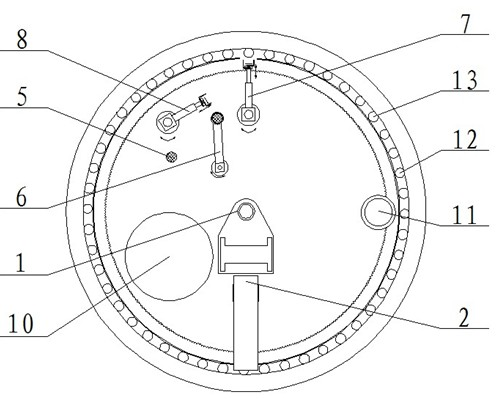

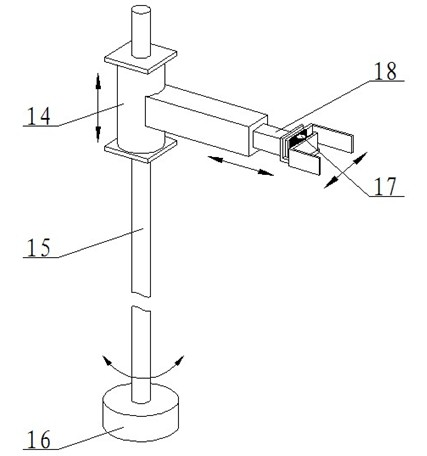

The invention relates to a novel submarine deep hole pressure maintaining and core drilling rig. The space of a drilling rig is insufficiently used by an existing device, and the processes of drilling, sampling and pressure maintaining for samples are complicated. The novel submarine deep hole pressure maintaining core drilling rig comprises an outer frame, a support leveling mechanism, a drilling pipe and core barrel storage mechanism, a power head mechanism, a rope core-stripping mechanism, a main manipulator, an auxiliary manipulator, an assembly manipulator, a pressure maintaining cover storage mechanism, a hydraulic motor, a drilling pipe, a core barrel and a hydraulic power system, wherein the main manipulator (the auxiliary manipulator) comprises a hydraulic lifting cylinder, a rotary support column, a base, a pipe taking gripper and a telescopic arm, and the assembly manipulator comprises a rotary support column, an upper pressing cover arm, a lower pressing cover arm, a rotary cover mechanism and a base. The space of the drilling rig is sufficiently used for storing more drilling pipes and core barrels, the drilling rig is applicable to multi-depth drilling places, the pressure of a sample can be maintained, operation is convenient in the pressure maintaining process, and cost is low.

Owner:HANGZHOU DIANZI UNIV

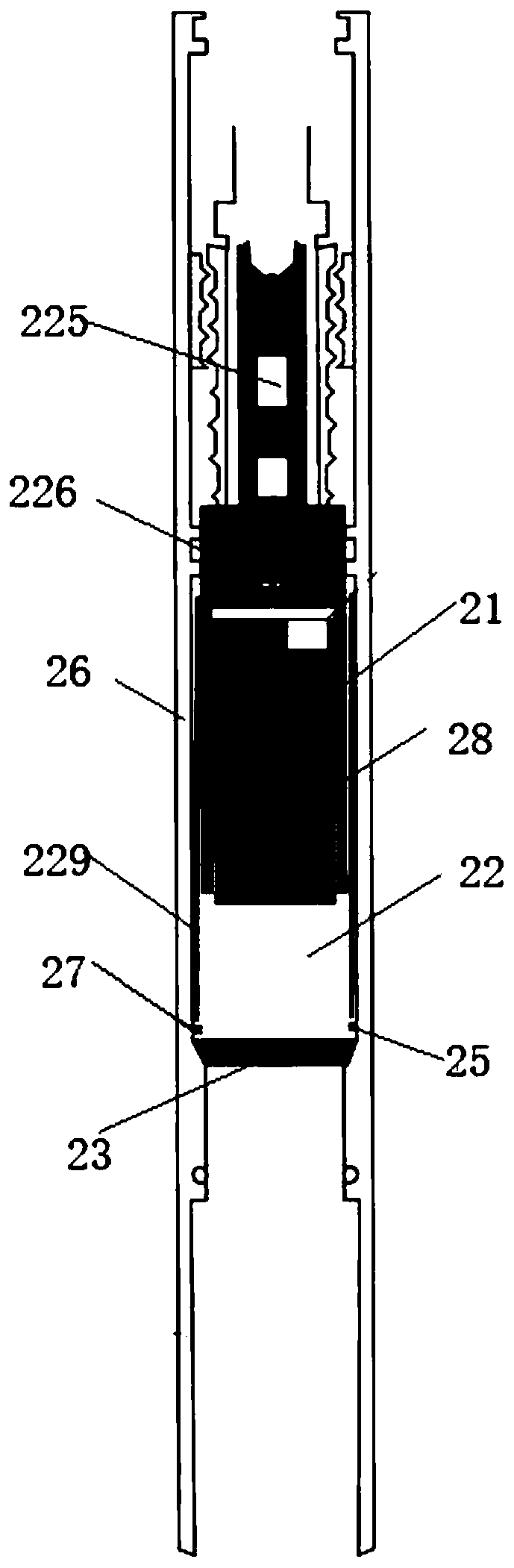

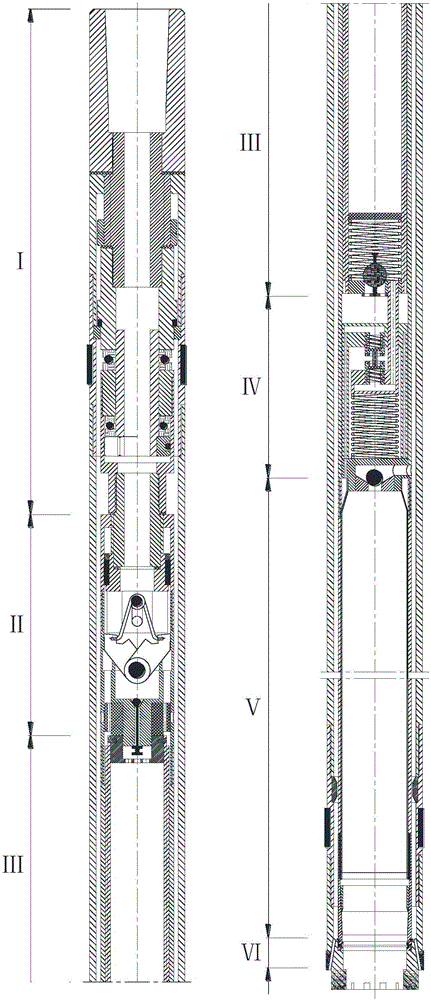

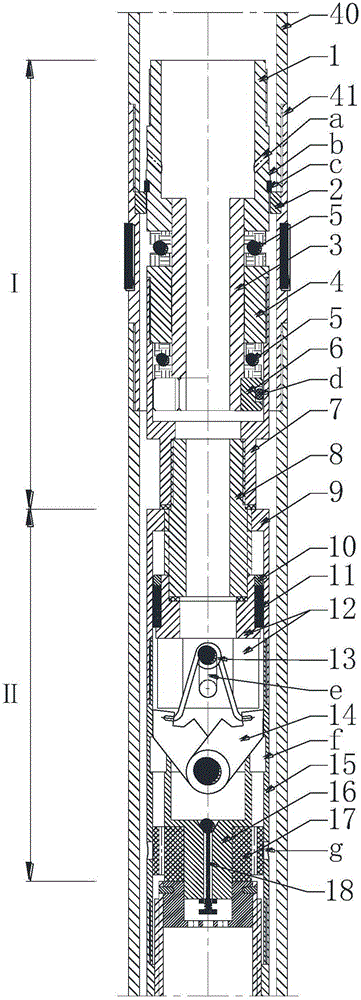

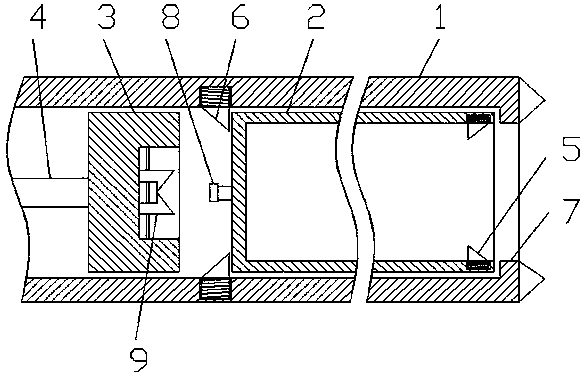

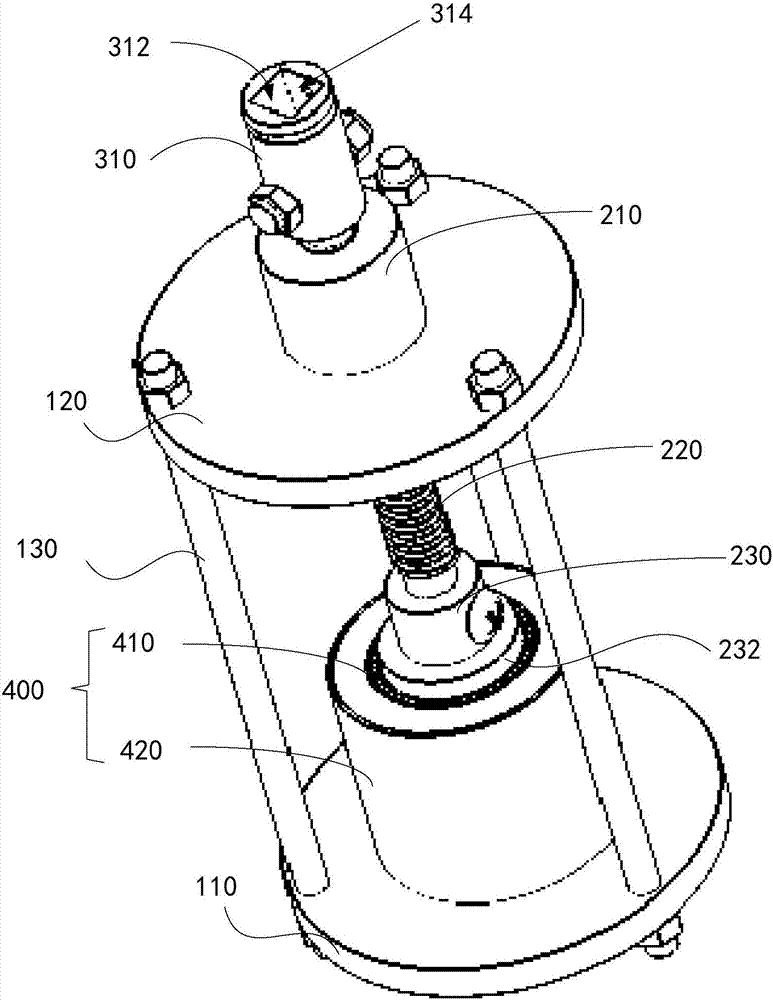

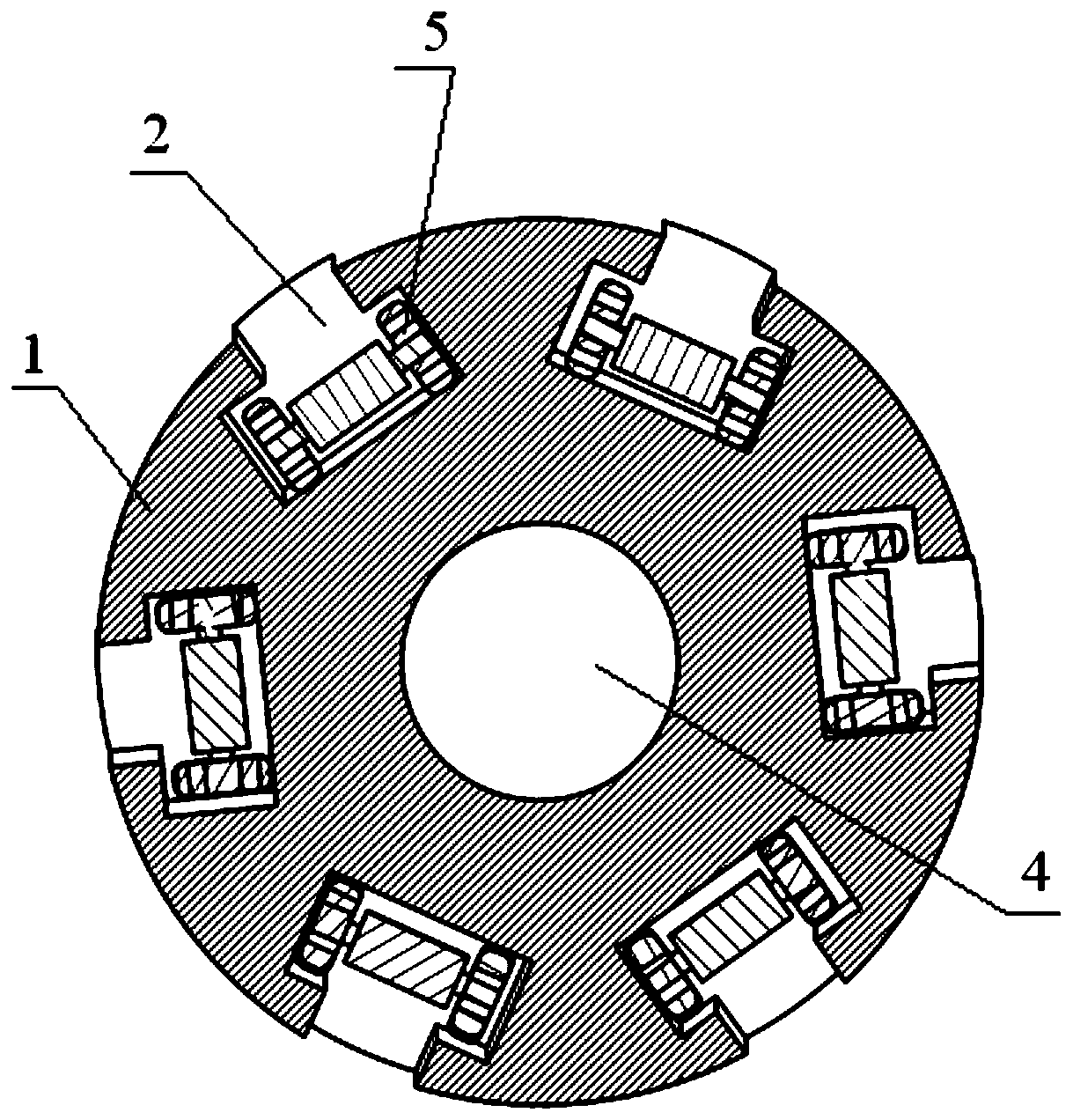

Coring drilling tool based on hydraulic clamping coring

ActiveCN105909202AIncrease heart rateGuarantee the quality of coringEngine sealsCore removalDrill bitPressure injection

The invention discloses a coring drilling tool based on hydraulic clamping coring. The coring drilling tool comprises a force transferring power distribution mechanism, a guide limiting mechanism, a pressure storage mechanism, a lifting pressure injection mechanism, a hydraulic core clamping mechanism, a side spraying drill bit power distribution mechanism, an outer tube assembly and a sealing system, wherein the guide limiting mechanism is butted with the force transferring power distribution mechanism; the pressure storage mechanism is butted with the guide limiting mechanism; the lifting pressure injection mechanism is butted with the pressure storage mechanism; the hydraulic core clamping mechanism is butted with the lifting pressure injection mechanism; the side spraying drill bit power distribution mechanism is butted with the hydraulic core clamping mechanism; the hydraulic core clamping mechanism comprises a bottom bearing platform, a hydraulic membrane, a core inner tube, a clamp spring seat and a clamp spring. The coring drilling tool can reach 100 percent coring rate in soft, loose and broken complex stratums where coring is difficult, provides fully automatic three-dimensional stress to clamp, bind and control cores based on hydraulic pressure, meanwhile is matched with a conventional core clamping and cutting device, and has the characteristics of high reliability, high coring efficiency, high coring quality, high core recovery percentage, wide applicable stratum range and good automation property.

Owner:CCCC FHDI ENG

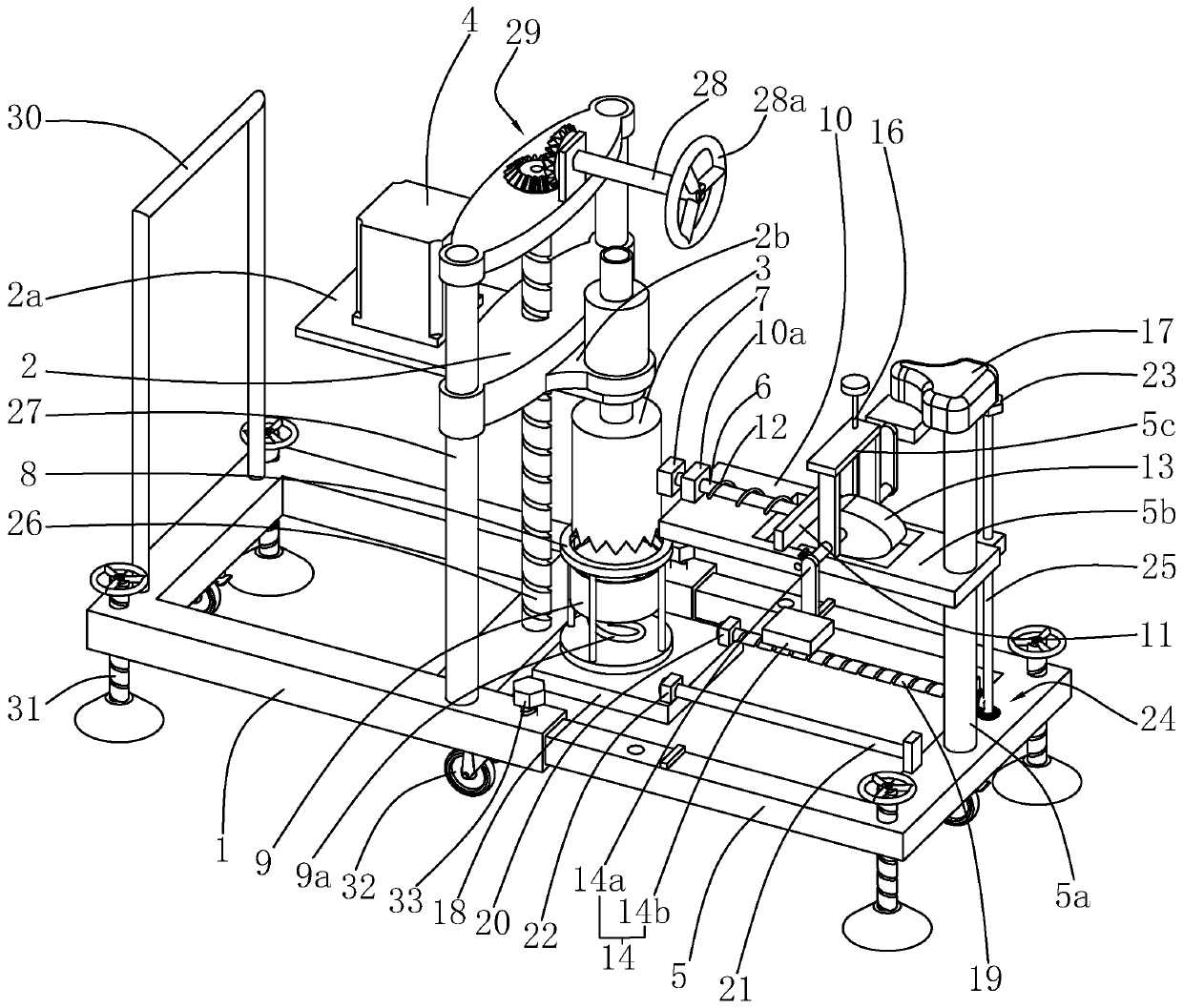

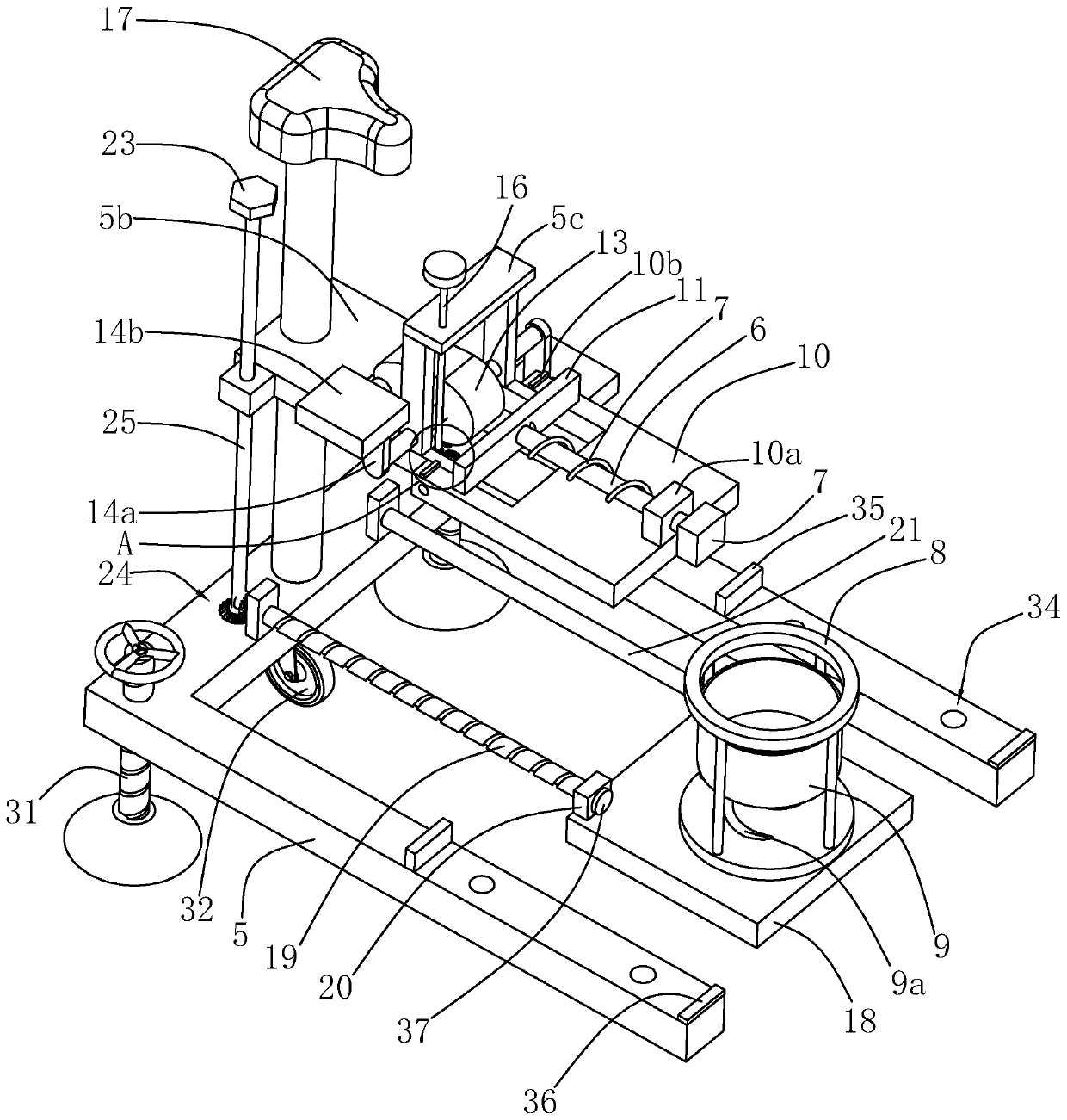

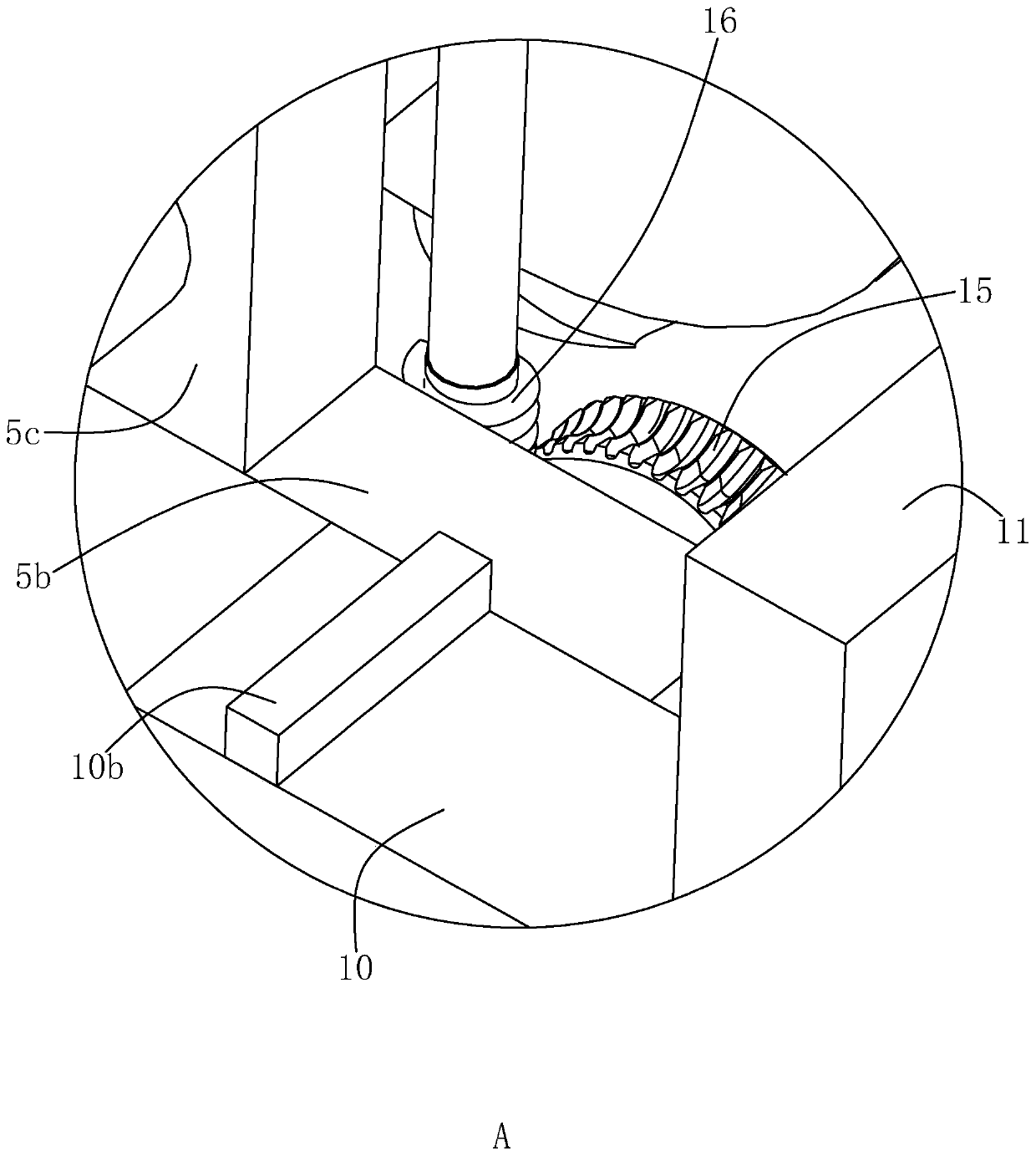

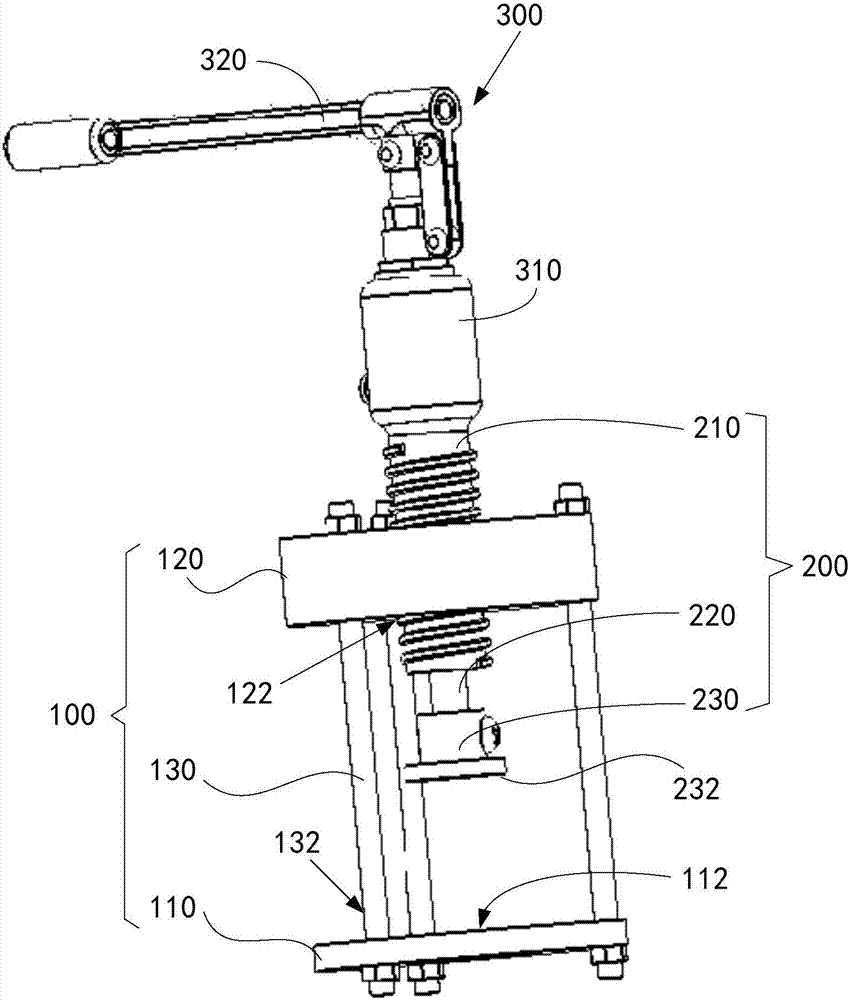

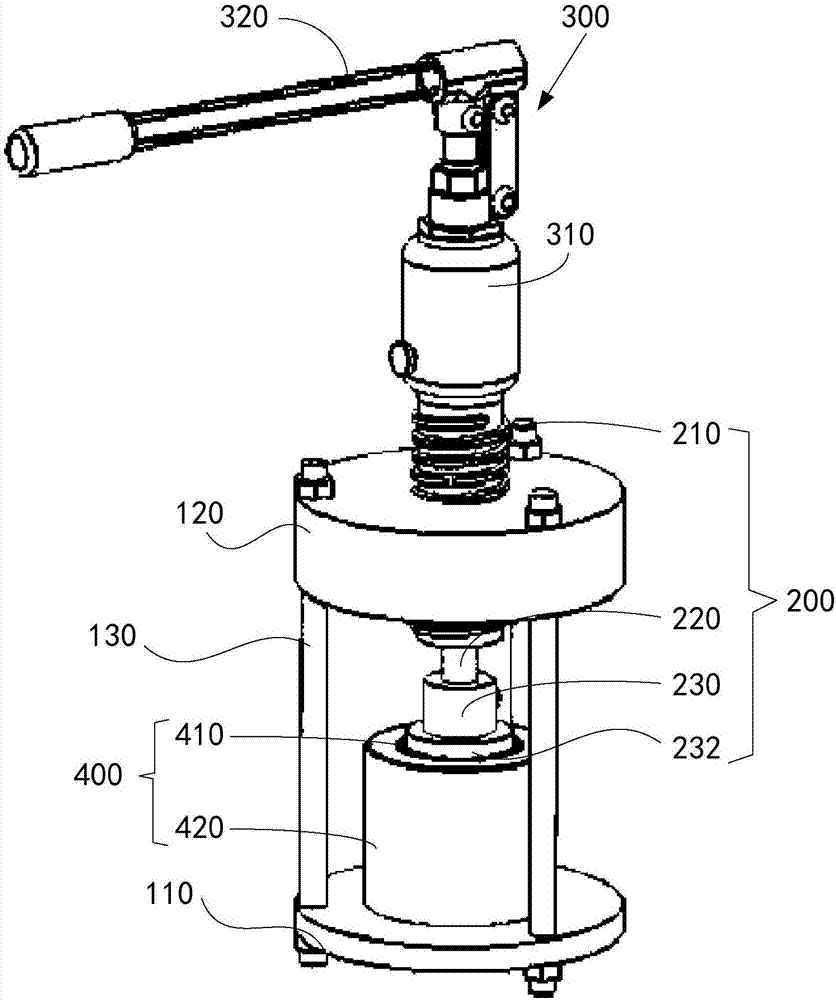

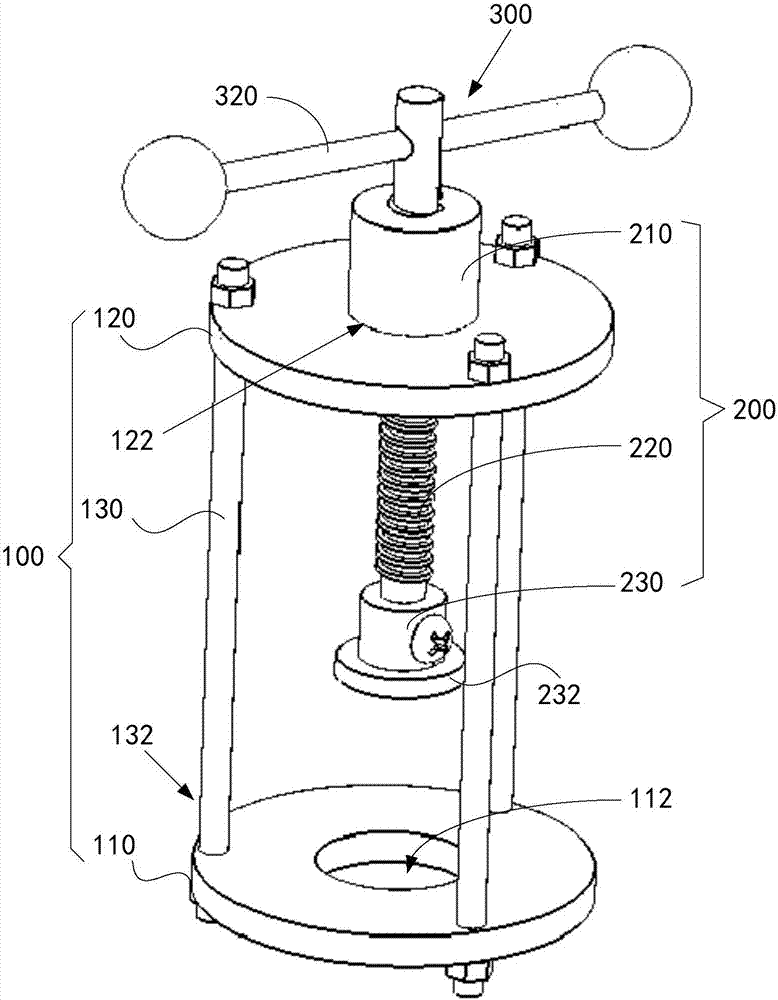

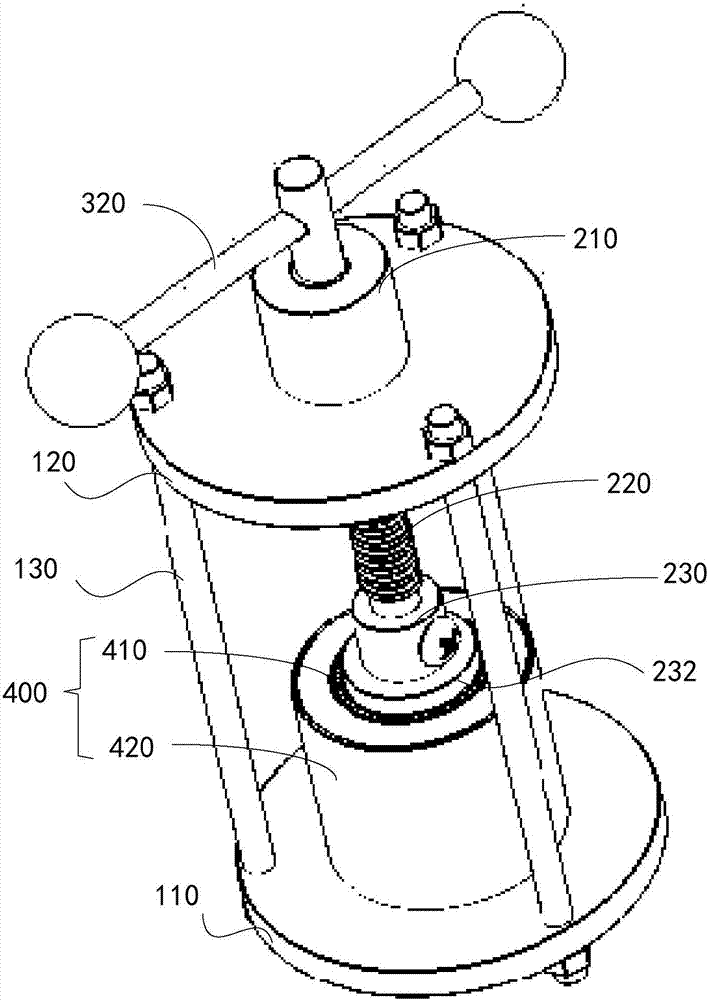

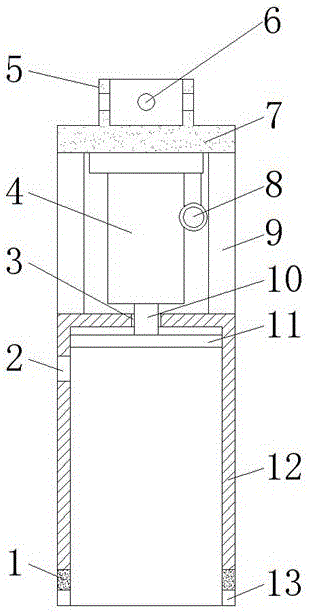

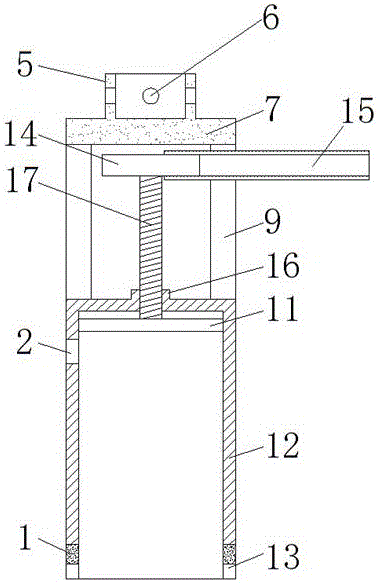

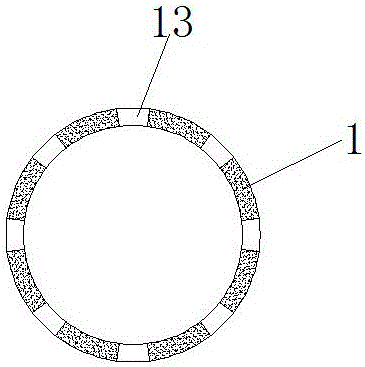

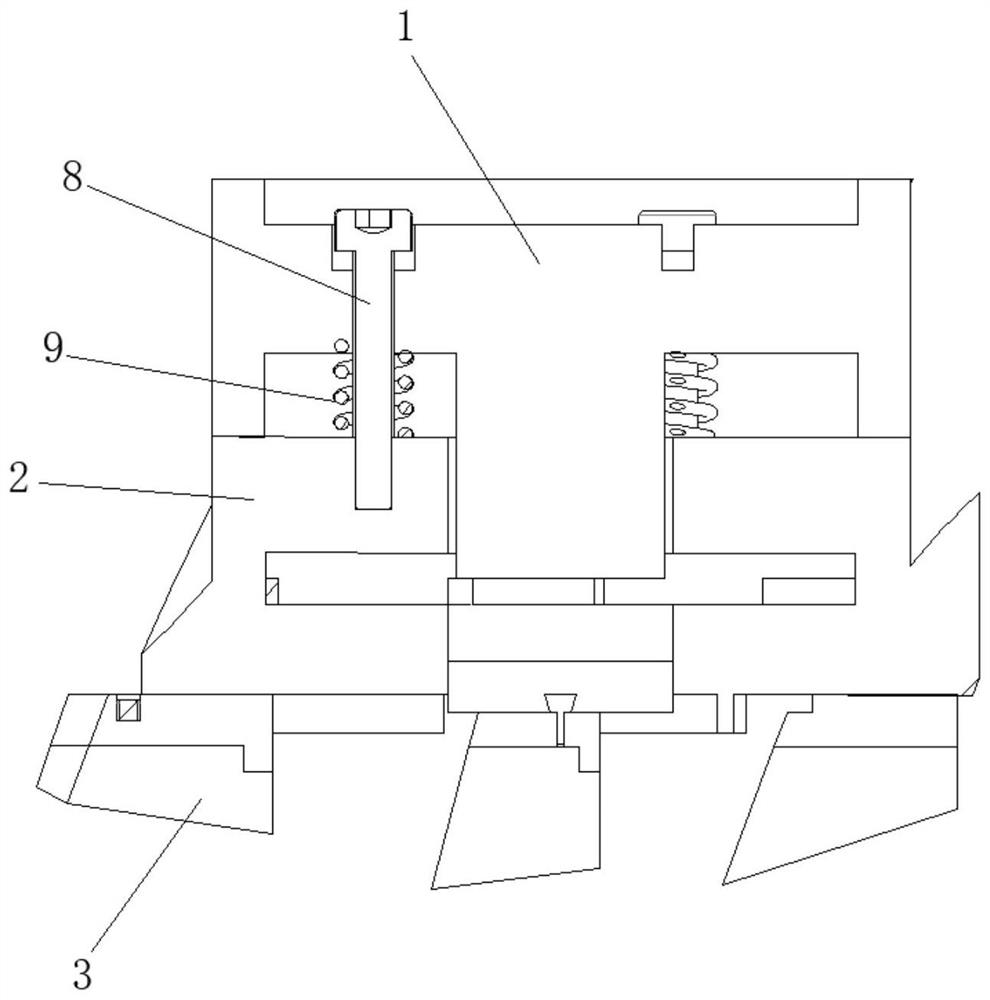

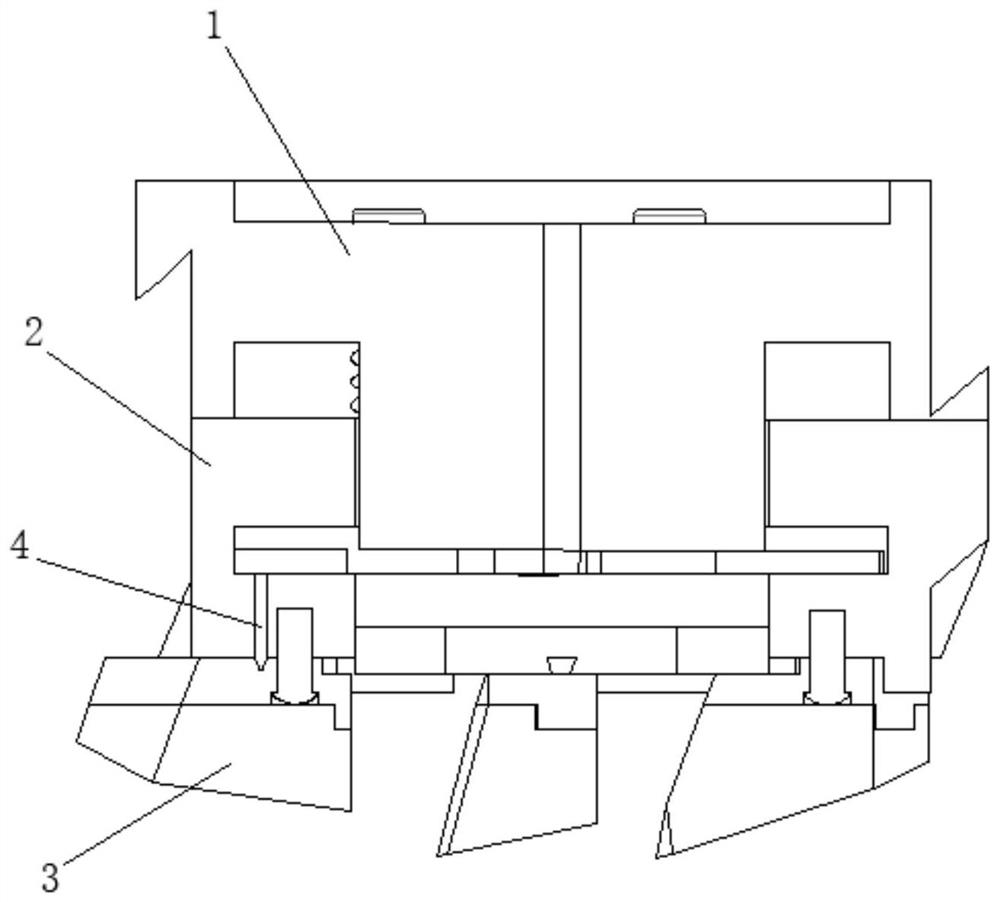

Concrete drilling and coring machine

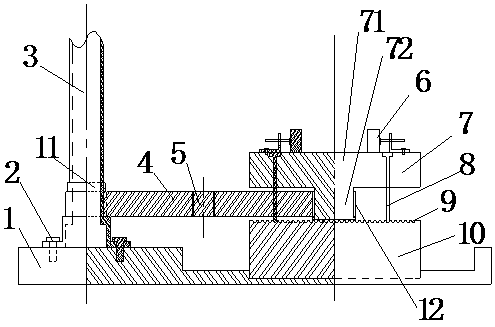

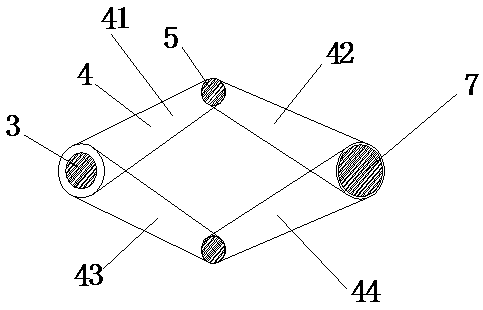

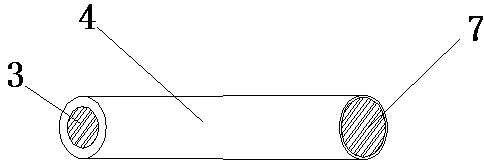

ActiveCN111119774AIncrease contact areaImprove job stabilityDerricks/mastsCore removalMachineDrill bit

The invention relates to the technical field of construction machinery, in particular to a concrete drilling and coring machine. The concrete drilling and coring machine is characterized by comprisinga rack, a lifting frame and a coring bit, wherein the lifting frame is slidably arranged on the rack, and the coring bit is arranged on the lifting frame. The concrete drilling and coring machine further comprises a sliding frame, a coring mechanism and a counterweight mechanism, wherein the sliding frame is slidably connected to the rack, and a fastener is arranged between the rack and the sliding frame. The coring mechanism comprises a knocking assembly, a supporting assembly and a driving assembly, wherein the knocking assembly comprises a knocking rod and a buffering piece, the knocking rod is arranged on the sliding frame, and the buffering piece is arranged at one end of the knocking rod. The supporting assembly comprises a supporting frame and a supporting tank, the supporting frame is erected on the sliding frame, the supporting tank is slidably arranged on the supporting frame, and an elastic telescopic piece is arranged between the supporting tank and the supporting frame. The driving assembly is used for driving the knocking rod to move, and the counterweight mechanism is arranged on the sliding frame. The drilling and coring machine can improve the stability of equipment in the drilling process, and workers can conveniently take out a concrete core from an inner cavity of the coring bit.

Owner:厦门市政工程研究所有限公司

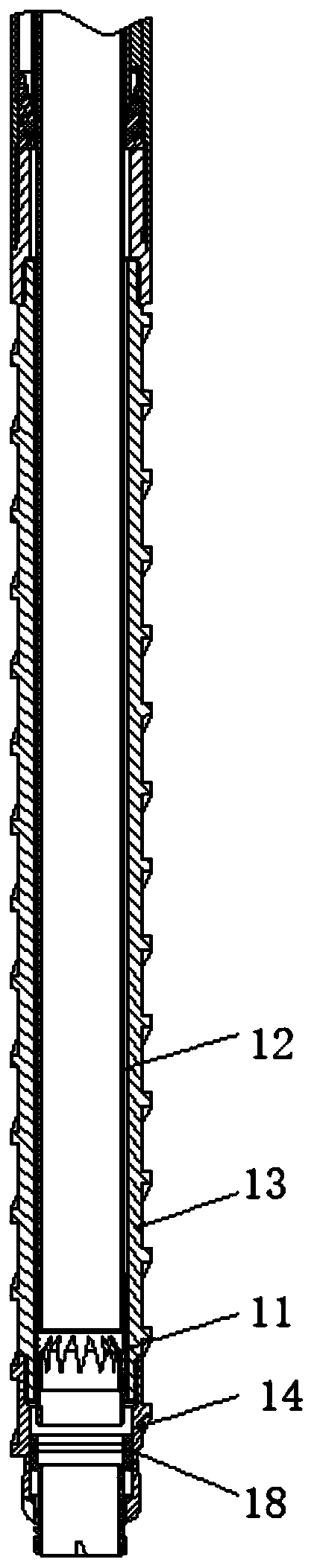

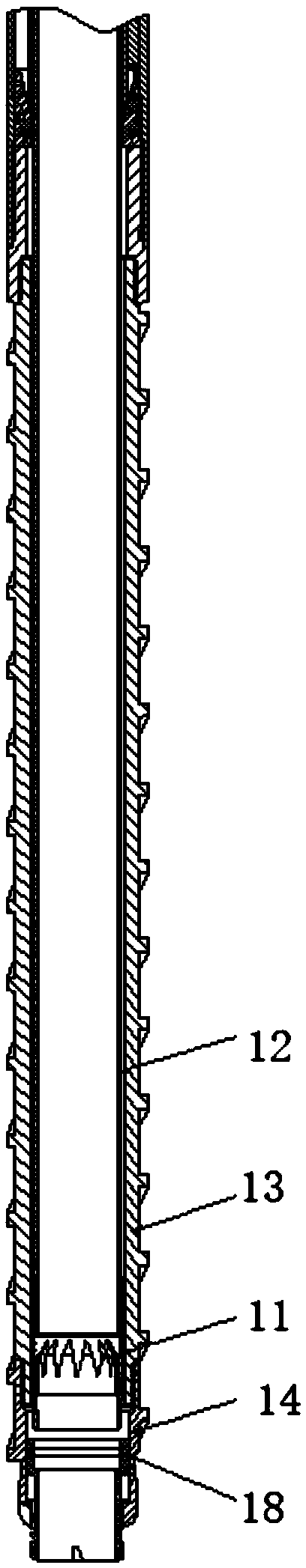

Hydraulic-driving coring tool for complex well

ActiveCN108952610AAvoid stuck core accidentsAvoid breaking accidentsCore removalRock coreEngineering

The invention relates to a hydraulic-driving coring tool for a complex well, and belongs to the technical field of oil drilling exploitation down-hole tools. The hydraulic-driving coring tool is formed by an inner rock core cylinder assembly, an outer rock core cylinder assembly and the like; the outer rock core cylinder assembly is composed of an upper connector, a safety connector, an upper spiral centralizer, a middle spiral centralizer, a lower spiral centralizer, a first-section outer rock core cylinder and a second-section rock core cylinder; the inner rock core cylinder assembly is composed of an inner-cylinder upper shaft, a first-section inner rock core cylinder, a second-section inner rock core cylinder and a dual-layer aluminum alloy liner; a bearing hanging steel ball is hung on an inner shoulder of the safety connector through a ball hanging runway, a clamping sleeve ball base is installed on a hanging assembly, centering of the inner cylinder is guaranteed through an inner-cylinder centralizing mechanism, and the hydraulic-driving coring tool is suitable for large-inclined-well coring; a rock-core-claw assembly is composed of a necking sleeve, a clamp-type rock core claw and a clamping-plate rock core claw, in a soft formation, the hanging steel ball and a ball hole of the clamping sleeve ball base are aligned and slide into the clamping sleeve ball base, the hanging assembly is unlocked, and a rock core is cut off through the clamping-plate rock core claw; in a hard formation, pressure of the inner cylinder is increased and subjected to pump suffocation, a drilling tool is lifted when the pressure reaches 16 MPa, and the rock core is clamped and pulled off through the clamp-type rock core claw. The hydraulic-driving coring tool is suitable for core cutting operation under different geological conditions.

Owner:YANGTZE UNIVERSITY

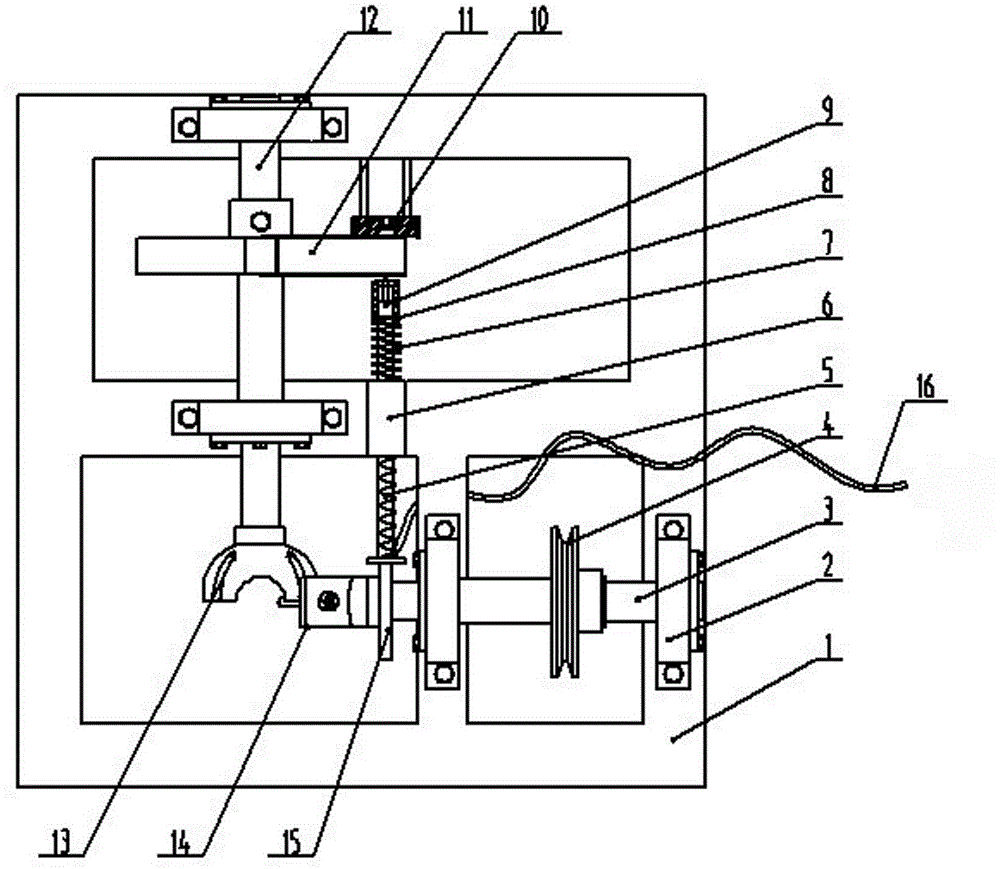

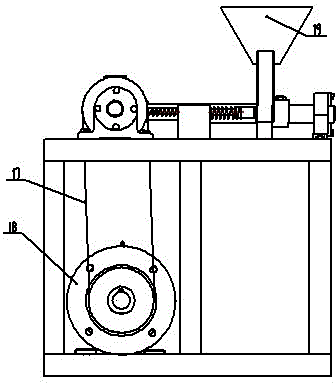

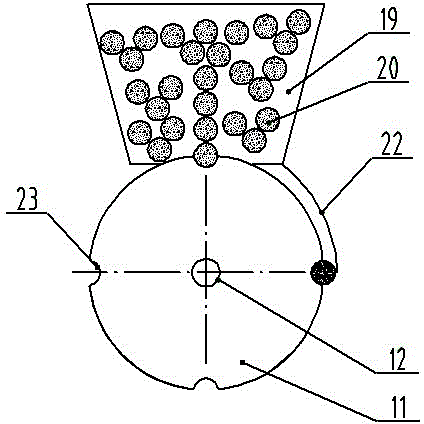

Pneumatic fresh lotus plumule removing machine

The invention discloses a pneumatic fresh lotus plumule removing machine which comprises a framework, a spindle, a bearing, a driven shaft, a belt pulley and a motor. A cam and a sheave shifting plate are arranged at one end of the spindle, the sheave shifting plate is connected with a sheave on the driven shaft, a rotary drum is mounted on the driven shaft and rotates along with the driven shaft, grooves which are uniformly distributed are formed in the side surfaces of the rotary drum, and a feed hopper is mounted above the rotary drum; the cam on the spindle is in contact with a through transmission rod, the through transmission rod is arranged in a guide sleeve, a spring is sleeved on the through transmission rod, a through female die and a hollow punch die are arranged at an end of the through transmission rod and are opposite to the horizontal radial edge of the rotary drum, and one end of a pressure air pipe is connected with an air inlet of the through transmission rod and is communicated with the hollow punch die. The pneumatic fresh lotus plumule removing machine has the advantages that owing to a pressure plumule removing principle, a plumule removing rate can be obviously increased, a damage rate can be reduced, and lotus seeds are attractive in appearance after plumule of the fresh lotus seeds are removed; the plumule of the unshelled lotus seeds can be automatically removed, accordingly, the manual labor intensity can be relieved, and the plumule removing efficiency can be improved.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

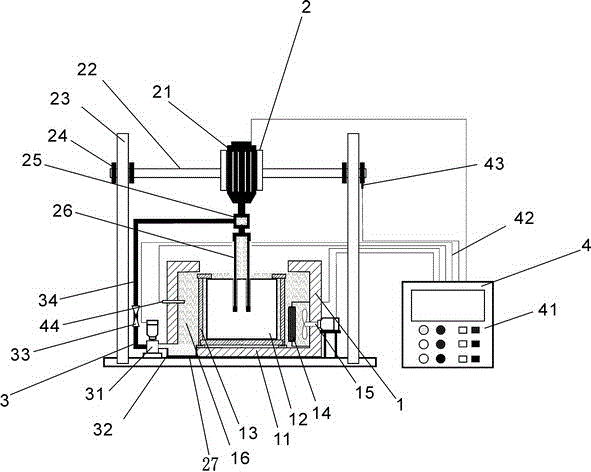

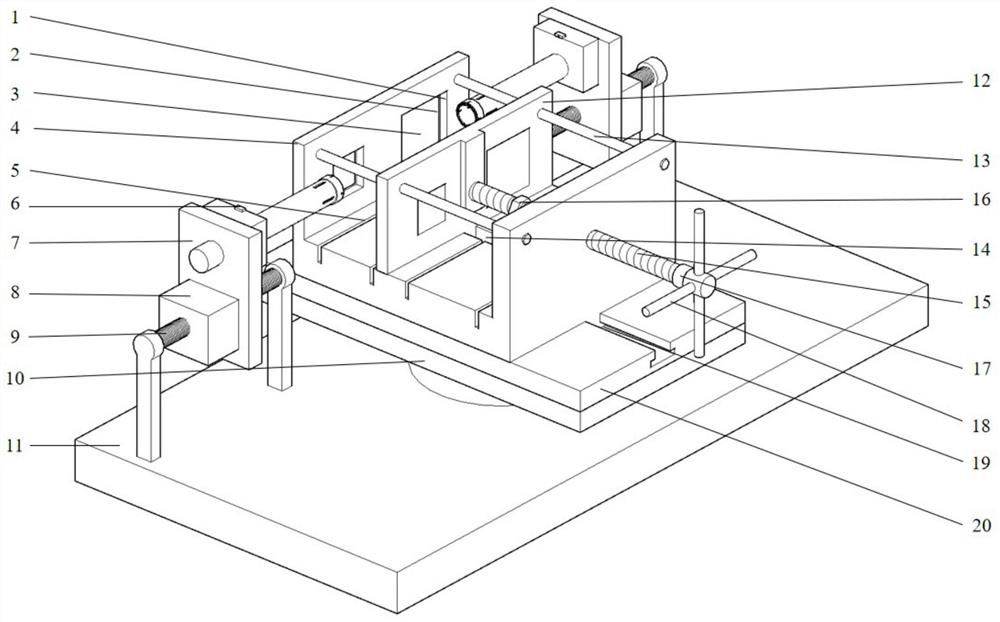

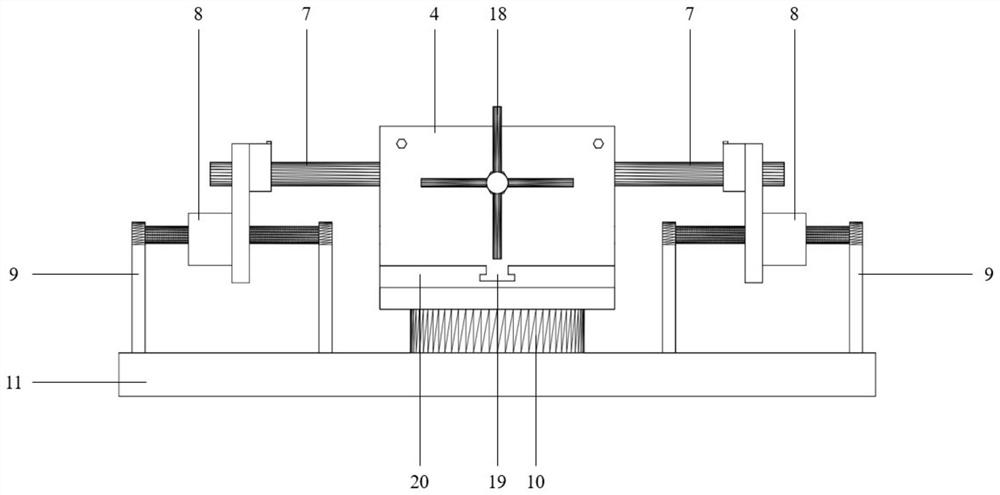

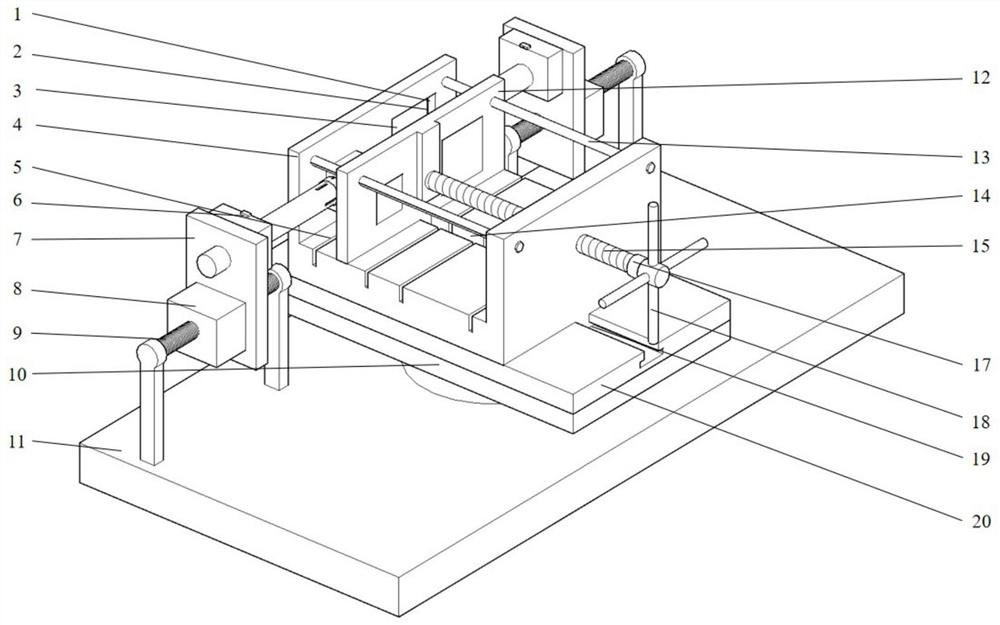

High temperature drilling experiment device

PendingCN105863627AImprove coring efficiencyLow costBorehole/well accessoriesAutomatic control for drillingData acquisitionEngineering

The invention discloses a high temperature drilling experiment device. The high temperature drilling experiment device is composed of a high temperature fluid chamber, a rotary drilling system, a flushing fluid circulating system and a drilling control recording system; the high temperature fluid chamber and the flushing fluid circulating system are fixedly arranged in the rotary drilling system respectively, and the drilling control recording system is connected with the high temperature fluid chamber, the rotary drilling system and the flushing fluid circulating system through cables respectively. According to the high temperature drilling experiment device, a high temperature formation condition is simulated in a laboratory for drilling experiments, small-size drill bit rock drilling experiments are carried out, mechanism changes of high temperature formation drilling rock breaking and drill bit abrasion features are researched through data collection for the rock breaking effect and efficiency, drilling parameters and the like, the drilling rules are summarized to be used for guiding drill bit structure design and drilling parameter selection of an ultra deep well and a hot dry rock formation, and a basis is provided for improving the coring efficiency and reducing the cost.

Owner:JILIN UNIV

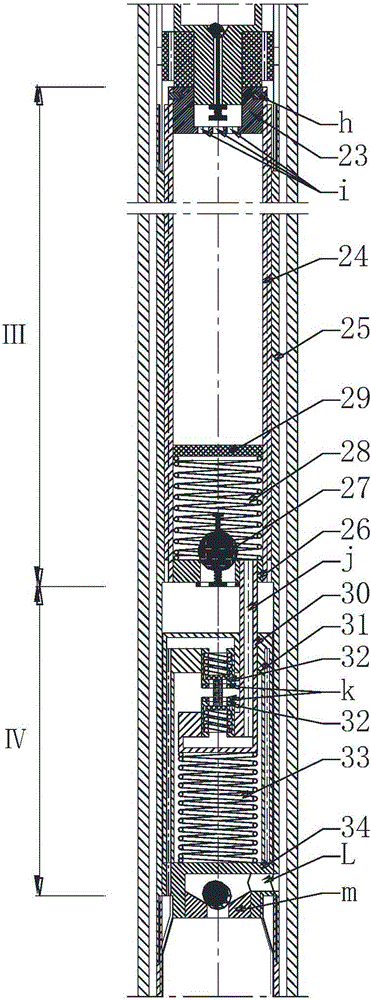

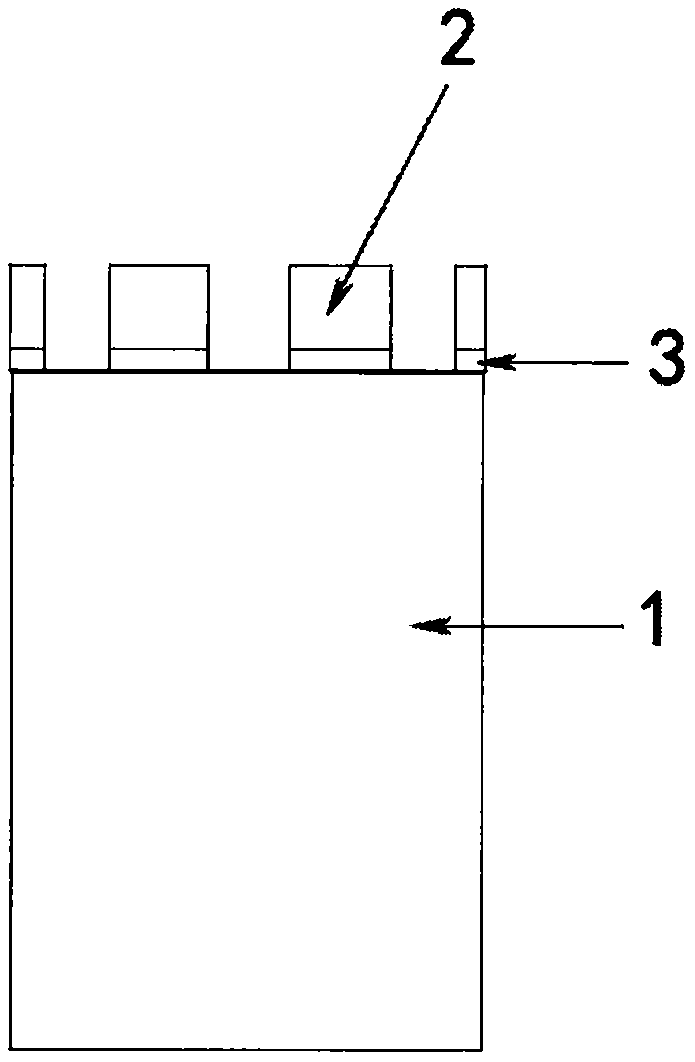

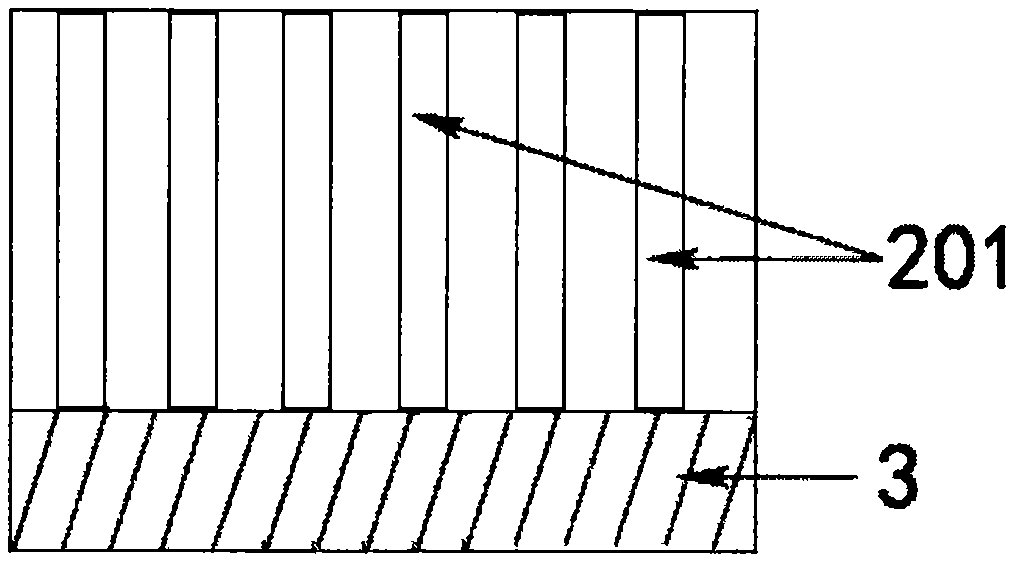

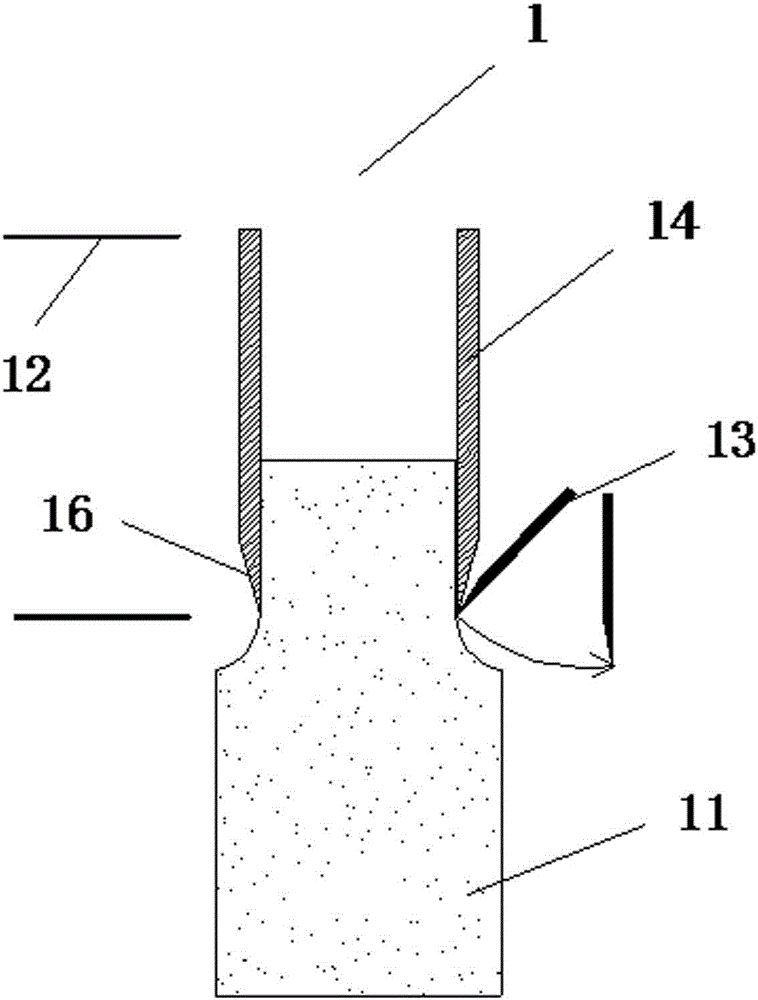

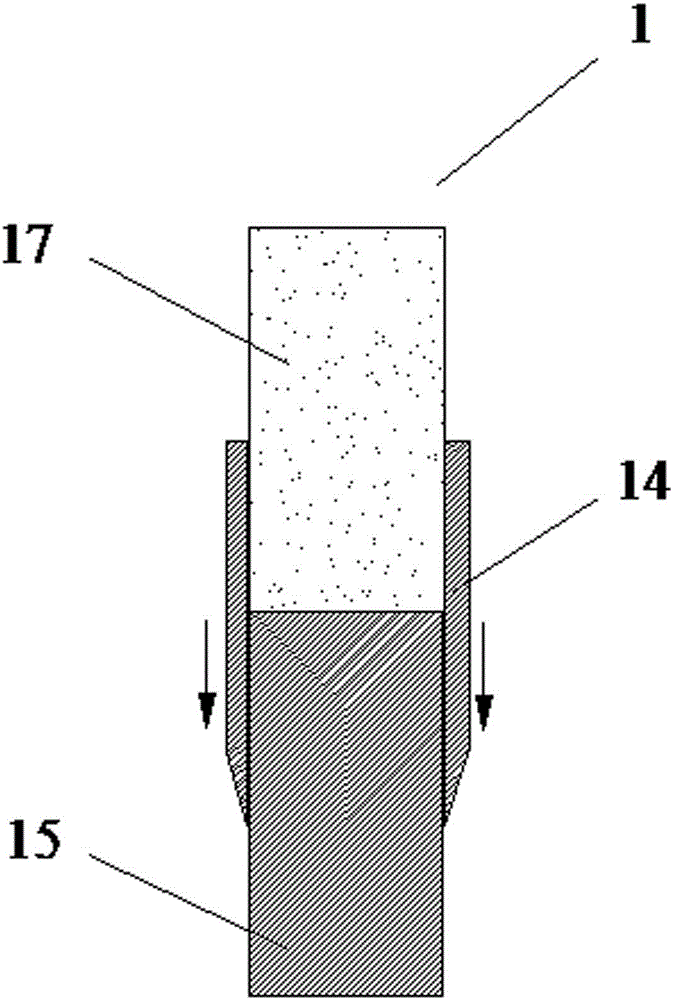

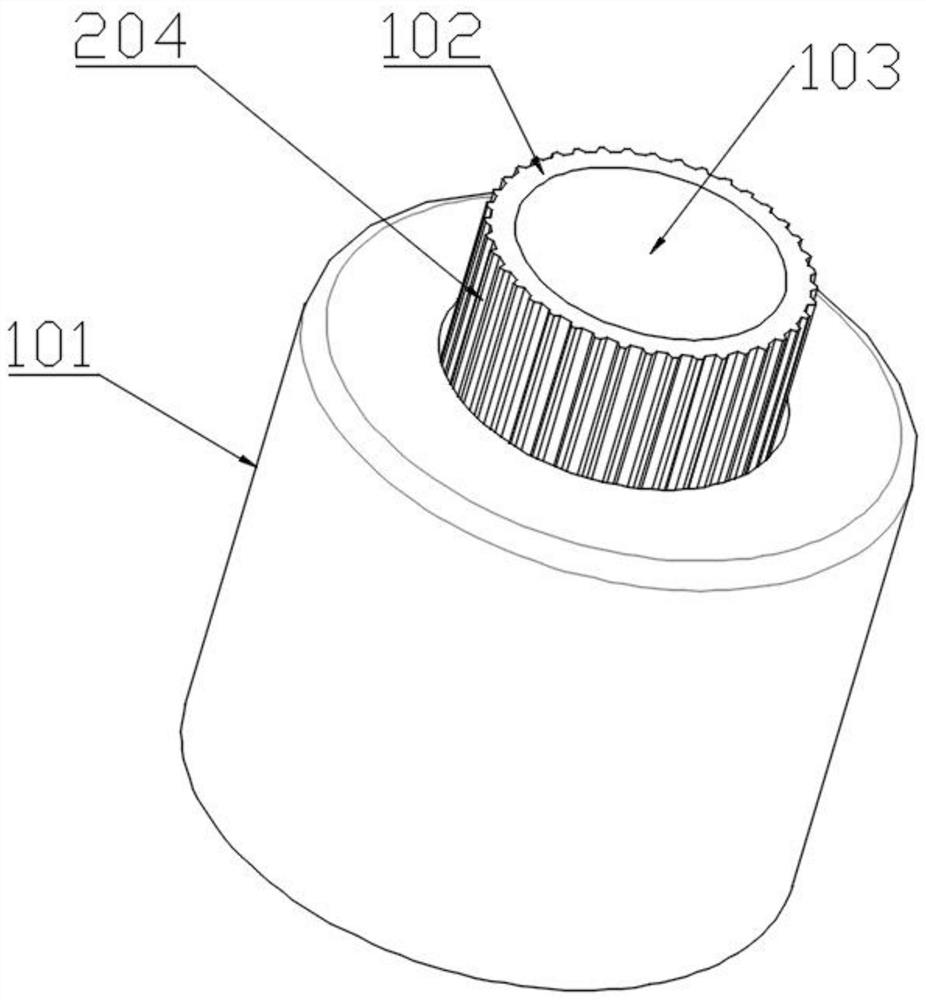

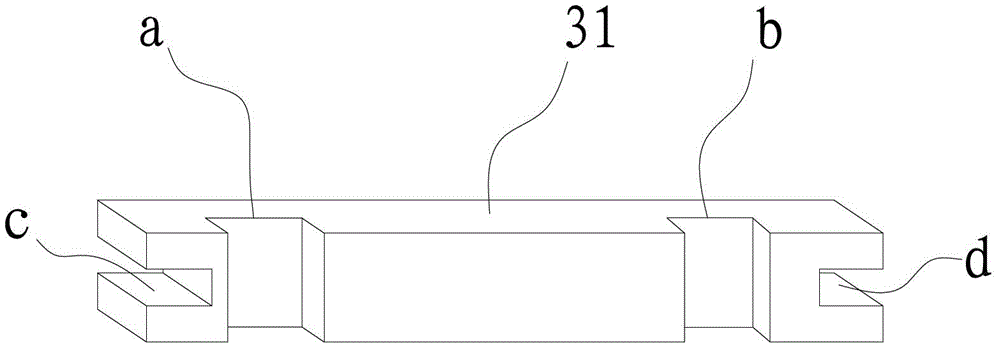

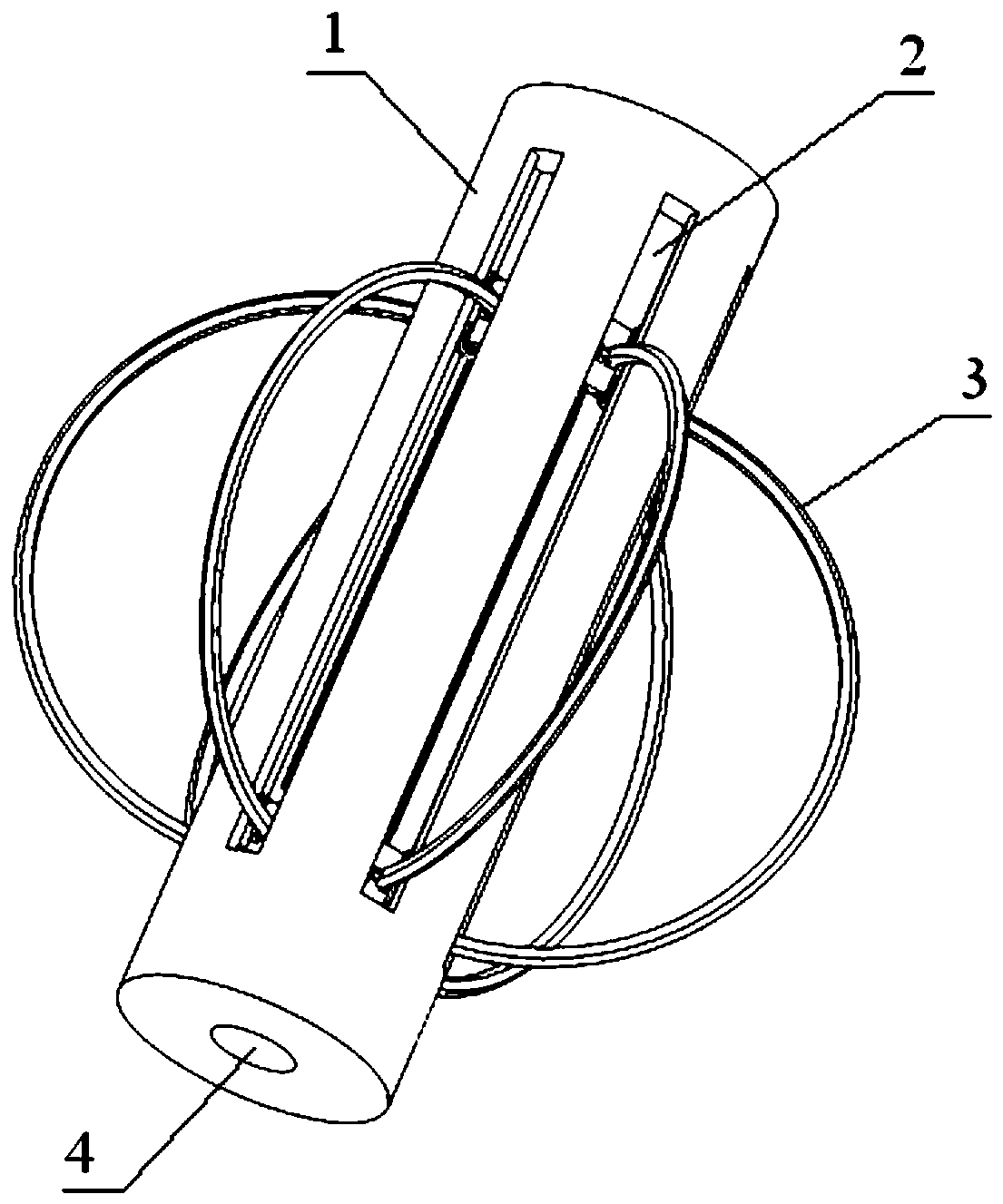

Fidelity retaining type coring device for rock sample

The invention discloses a fidelity retaining type coring device for a rock sample. The coring device comprises a rock core drilling tool, a rock core sample storage cylinder and a rock core sample fidelity retaining cabin; the rock core drilling tool comprises a coring drilling tool body, a core capturing device and an inner core pipe; the coring drilling tool body comprises an outer core pipe anda hollow drill bit, wherein the drill bit is connected to the lower end of the outer core pipe; the lower end of the inner core pipe extends to the bottom of the outer core pipe; the inner core pipeis matched with the outer core pipe in a clearance fit mode; the rock core sample fidelity retaining cabin comprises an inner coring barrel, an outer coring barrel and an energy accumulator; the outercoring barrel sleeves the inner corking barrel; the upper end of the inner coring barrel is communicated with a liquid nitrogen storage tank, and the liquid nitrogen storage tank is located in the outer corking barrel; the energy accumulator is communicated with the outer coring barrel; and the outer coring barrel is provided with a flap valve. The coring device has the advantages that a rock core can keep the state of the rock core in an in-situ environment, in addition, the drilling speed can be increased, and the coring efficiency can be improved.

Owner:SHENZHEN UNIV

Diamond coring bit and a laser welding preparation process thereof

InactiveCN109736713AImprove coring efficiencyFast deliveryDrill bitsConstructionsTool bitSpecial design

The invention discloses a diamond coring bit and a laser welding preparation process thereof, and belongs to the technical field of diamond coring bits. The diamond coring bit is formed by connectinga metal base body and diamond tool bits, and the tool bits are evenly distributed on the end face of the metal base body. A transition layer is arranged between the metal base body and the diamond tool bit, a plurality of strip-shaped grooves are evenly formed in the side surface of the diamond tool bit, and the side surface of the wavy tooth structure is formed. And the metal base body and the tool bit are connected into a whole through a laser welding process. Through the special design of the shape of the tool bit, the high-speed coring drill bit can play a very good water cooling role during large-depth drilling, and meanwhile, the continuous wave tooth structure on the inner wall of the tool bit is more beneficial to timely discharging of smashed silt, so that very good cutting performance is kept. By optimizing the components of the tool bits and the transition layer and optimizing technological parameters such as laser power and welding speed, a welding seam with excellent performance is obtained.

Owner:江苏友美工具有限公司

Hydraulic rock core lifting device for exploratory boring

ActiveCN106014314AIncrease heart rateGuarantee the quality of coringCore removalDouble tubeRock core

The invention discloses a hydraulic rock core lifting device for exploratory boring. The device comprises a waterproof transfer mechanism, a diversion limiting mechanism, a pressure storage mechanism, an elevation injection molding mechanism, a hydraulic core clamping mechanism, a lateral jet drill bit transfer mechanism and a sealing system, wherein the diversion limiting mechanism is butted with the waterproof transfer mechanism; the pressure storage mechanism is butted with the diversion limiting mechanism; the elevation injection molding mechanism is butted with the pressure storage mechanism; the hydraulic core clamping mechanism is butted with the elevation injection molding mechanism; the lateral jet drill bit transfer mechanism is butted with the hydraulic core clamping mechanism. The device can be directly matched with a double-tube drilling tool and a rope core drill to achieve a coring rate of 100 percent for a complicated difficult-to-core formation such as a soft and loose formation and a broken formation; in addition, a rock core can be fully automatically lifted, bundled and controlled under three-dimensional stress on the basis of hydraulic pressure; moreover, a conventional core clamping and cutting device is matched to achieve the characteristics of high reliability, high coring efficiency, high coring quality, high rock core collection rate, wide applicable formation range, high automation performance and the like.

Owner:CCCC FHDI ENG

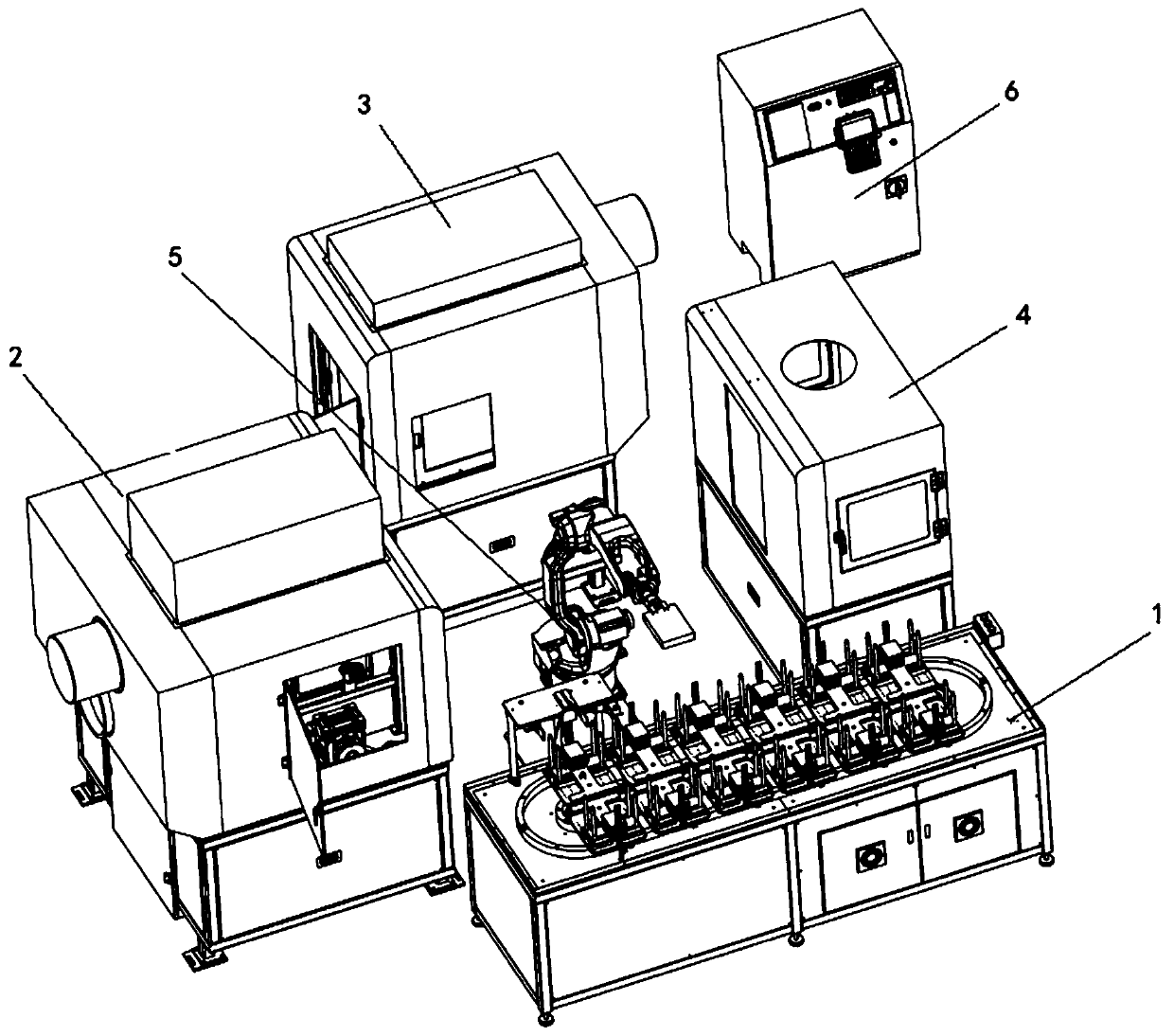

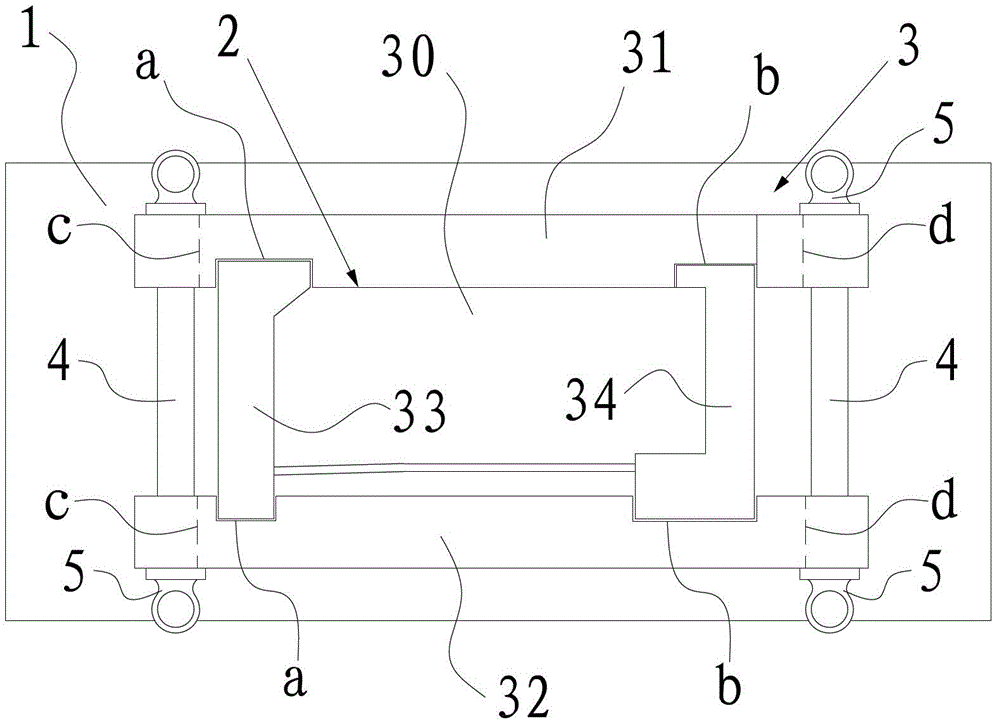

Automatic dismounting line of power battery and dismounting method thereof

PendingCN109860752ARealize automated productionImprove cutting efficiencyWaste accumulators reclaimingBattery recyclingManipulatorEngineering

The present invention discloses an automatic dismounting line of power battery and a dismounting method thereof. The automatic dismounting line comprises an intelligent stock bin, a housing annular cutting device, a pole head cutting device, a coring device, a manipulator and a control cabinet. The intelligent stock bin, the housing annular cutting device, the pole head cutting device and the coring device are put in order in a clockwise direction in a horizontal plane and form a middle space, and the manipulator is located at the middle space. A dismounting platform is employed to research and develop the automatic production of processes such as power battery dismounting and core separation for automatic demands of the harmless dismounting of the power battery monomers and separation ofthe core pack and the housing in a certain dimension range.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

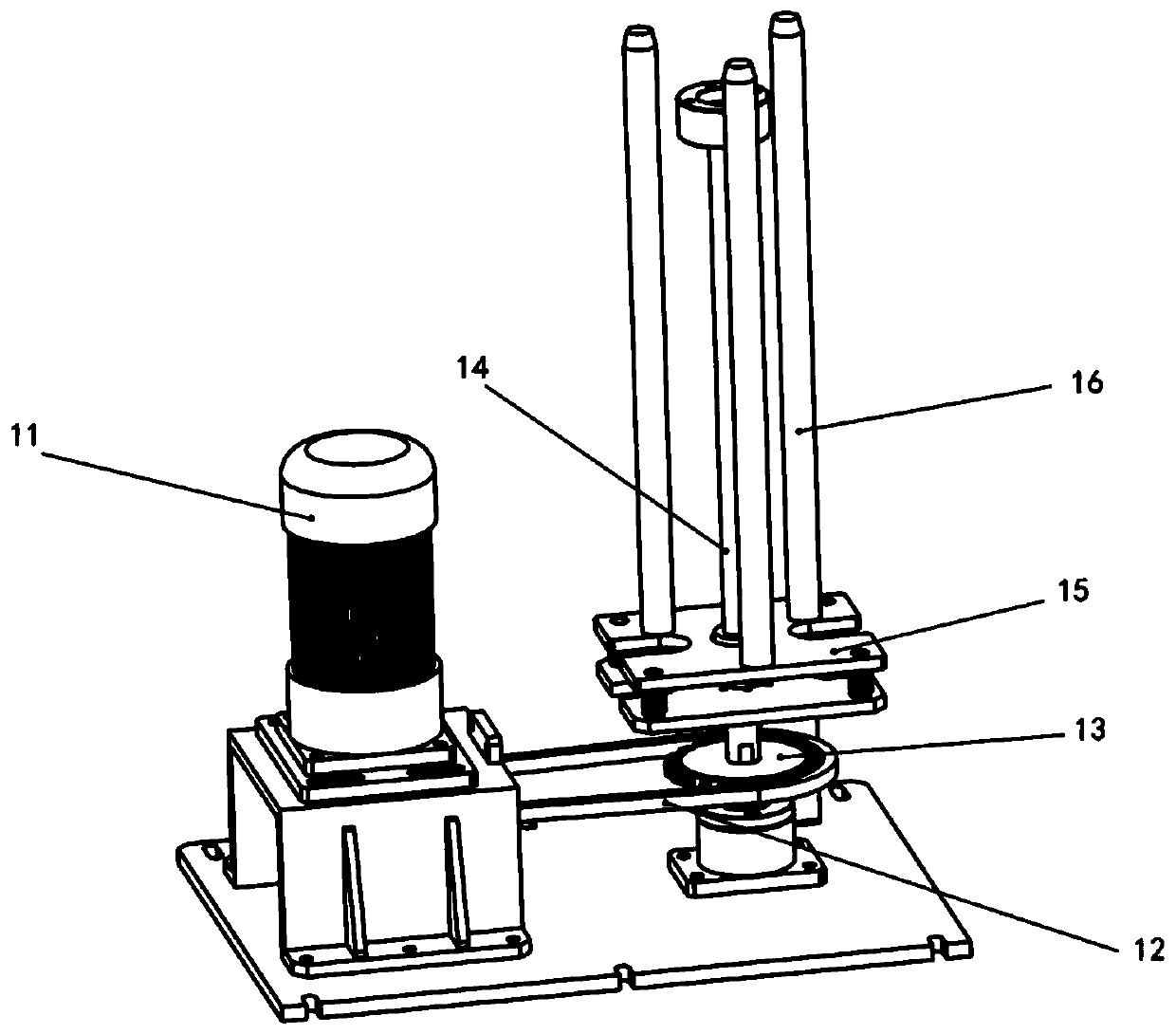

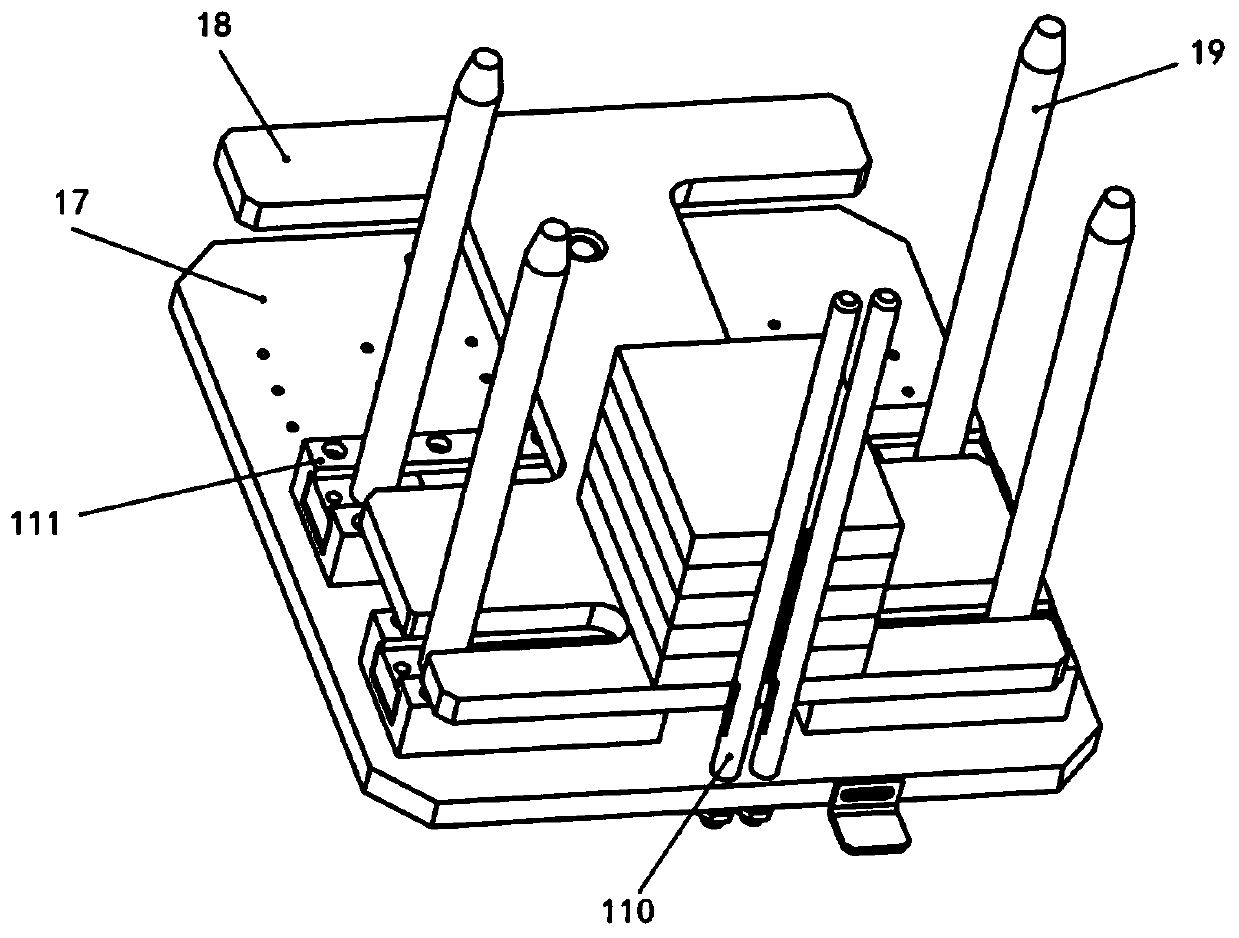

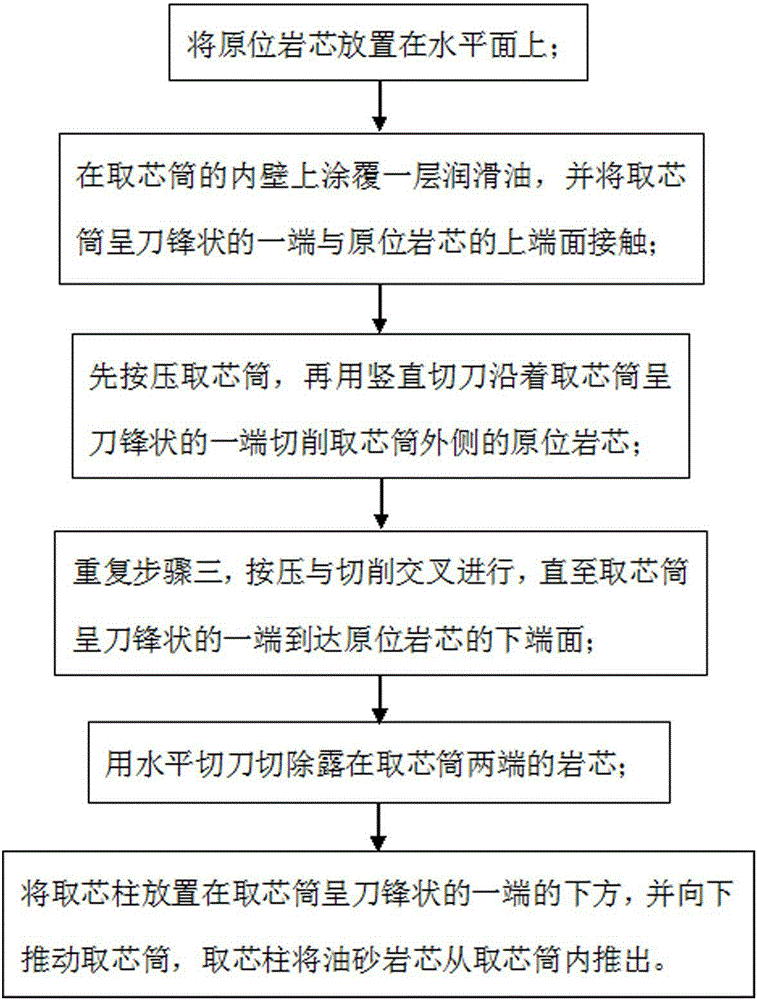

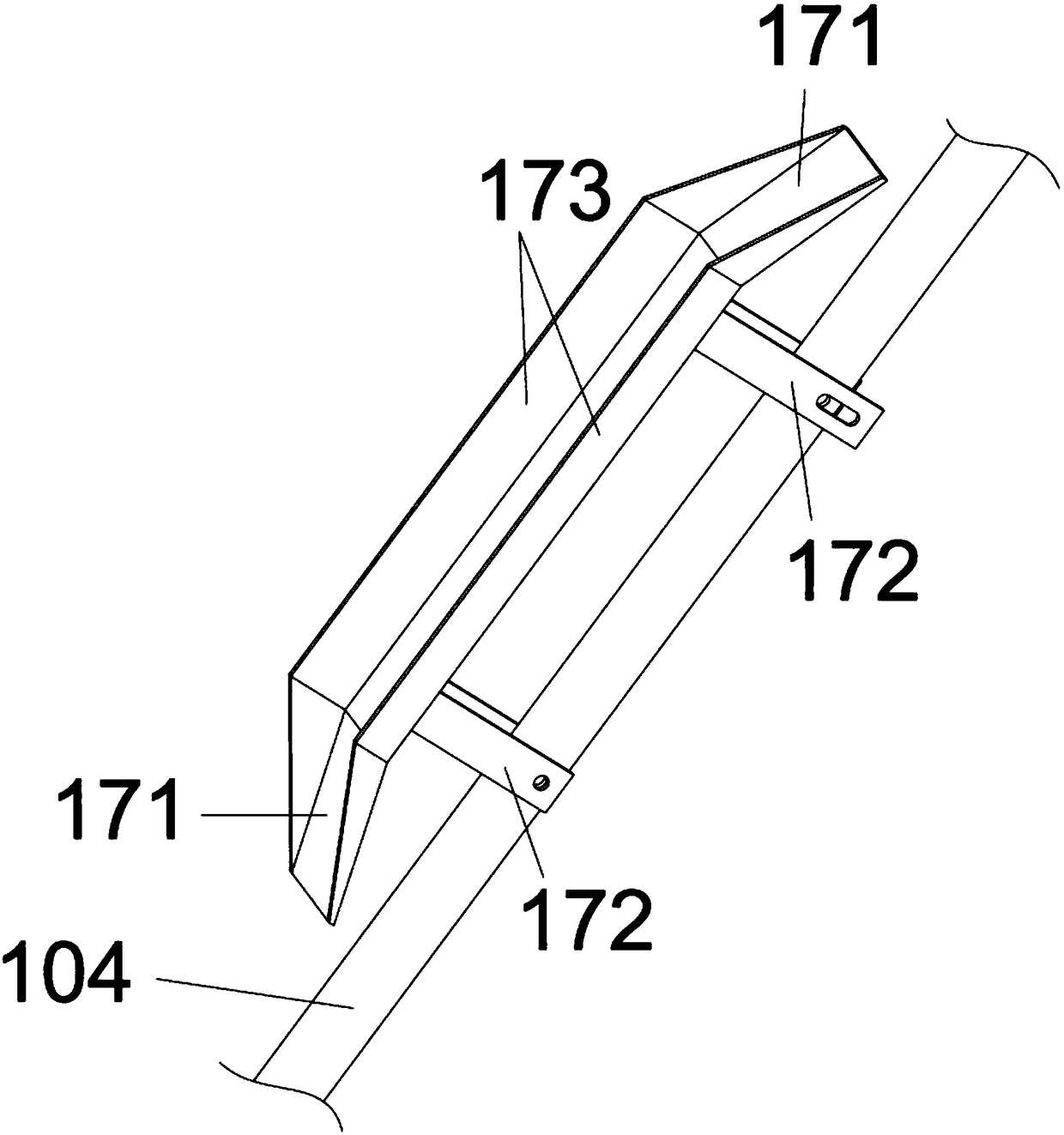

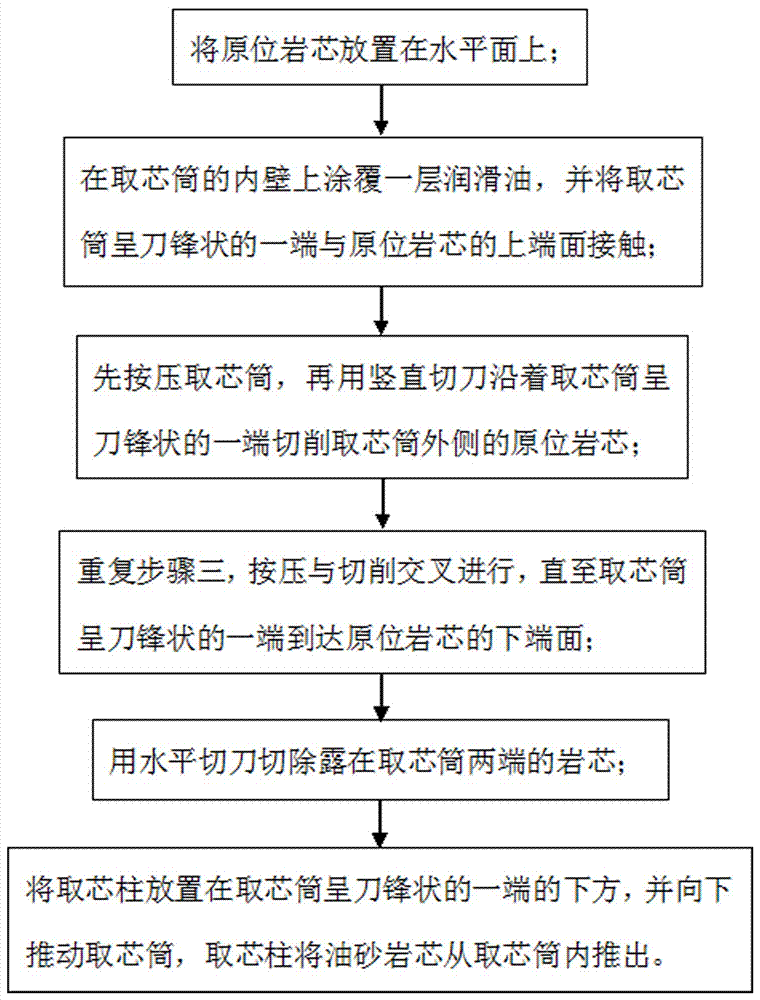

Method for taking oil sand rock core

The invention discloses a method for taking an oil sand rock core. The method sequentially includes: coating a layer of lubricating oil on the inner wall of a core taking barrel, and allowing the blade-shaped end of the core taking barrel to contact with the upper end face of an in-situ rock core; pressing the core taking barrel, and using a vertical cutter to cut the in-situ rock core on the outer side of the core taking barrel along the blade-shaped end of the core taking barrel; using a horizontal cutter to cut off the rock core exposed at two ends of the core taking barrel; placing a core taking column below the blade-shaped end of the core taking barrel, and downwardly pushing the core taking barrel to allow the core taking column to push the oil sand rock core out of the core taking barrel. The method uses an oil sand rock core taking device. The oil sand rock core taking device comprises the in-situ rock core, the horizontal cutter, the vertical cutter, the core taking barrel and the core taking column, wherein one end of the core taking barrel is blade-shaped, and the core taking barrel and the vertical cutter jointly cut the in-situ rock core. The method has the advantages that the method is high in core taking efficiency and low in cost, control system operation can be achieved, precise core taking is achieved, and the produced oil sand rock core is complete in shape and suitable for tri-axial experiments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Broken rock coring device for geotechnical engineering investigation

PendingCN112014147AReduce vibrationIncrease adoption rateWithdrawing sample devicesCircular discDouble tube

The invention discloses a broken rock coring device for geotechnical engineering investigation. The device comprises a disc-shaped top plate, a hollow disc-shaped bottom plate and a circular ring pressing plate which are sequentially arranged on the same normal from top to bottom. The top plate and the bottom plate are connected and fixed through three connecting columns which are distributed in aregular triangle shape at the corresponding positions of the peripheral edges. The bottom plate and the pressing plate are connected through three hydraulic piston cylinders which are distributed ina regular triangle shape at the corresponding positions of the peripheral edges. A mucilage box is arranged in the center of the upper surface of the top plate, an outlet of the mucilage box is externally connected with a liquid conveying pipeline, the liquid conveying pipeline penetrates through through holes in the top plate and the bottom plate and extends to one side of a single-action double-pipe drilling tool, and the lower end of the liquid conveying pipeline is supported by a supporting assembly on the lower surface of the bottom plate. According to the device, high stress generated bya hard soil layer can be reduced in the coring process, the stability of the coring structure is guaranteed, meanwhile, the coring efficiency and quality can be improved, and a high-quality rock coreis provided for subsequent detection.

Owner:GUIZHOU UNIV OF ENG SCI

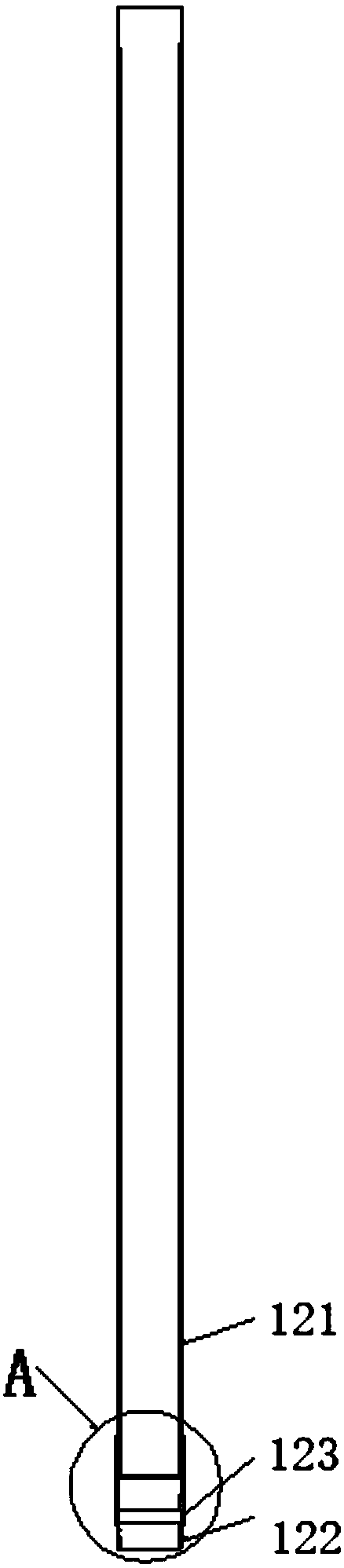

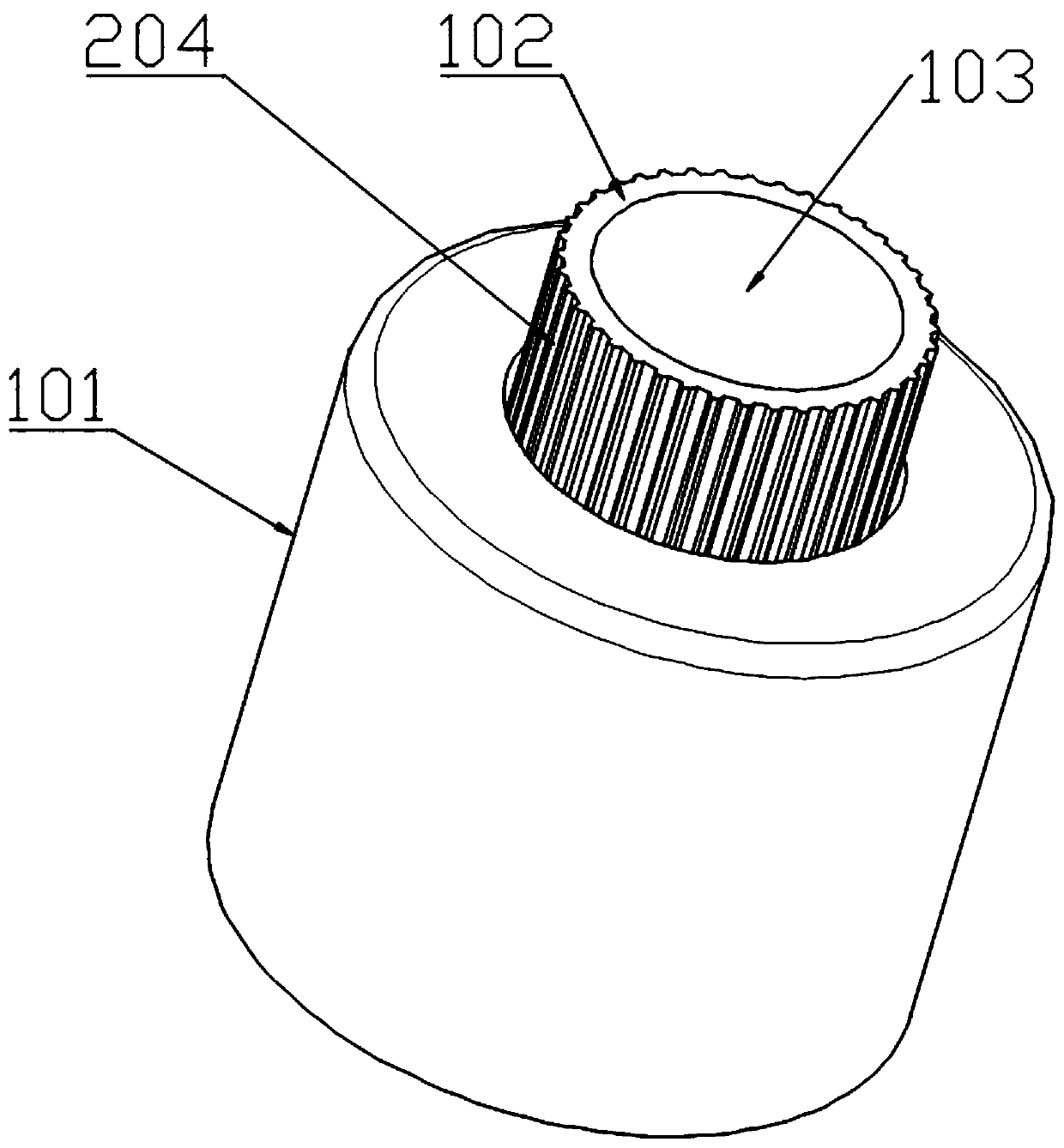

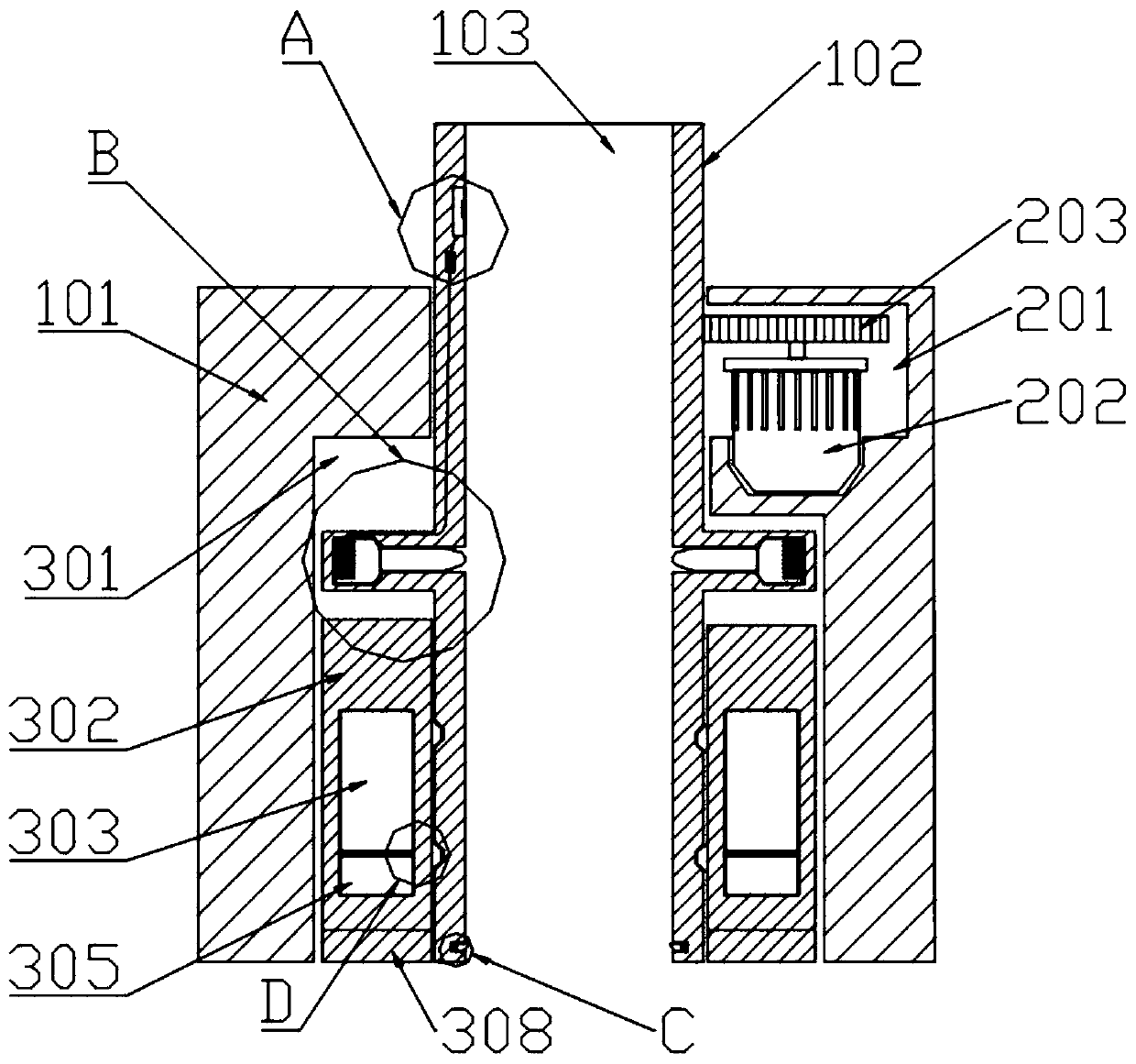

Hard rock core drill bit

PendingCN108930517AReduce disturbanceIncrease drilling speedDrill bitsCore removalRock coreEngineering

The invention relates to a hard rock core drill bit. The hard rock core drill bit comprises an outer core tube and a hollow boring bit. The boring bit is installed at the lower end of the outer core tube, and spiral grooves are separately formed in the outer walls of the outer core tube and the boring bit. The spiral grooves on the boring bit are continuous with the spiral grooves on the outer core tube. The boring bit includes an inner boring bit and an outer boring bit, and the inner boring bit is installed in the outer boring bit. A first stage blade is arranged at the lower end of the inner boring bit, and a second stage blade is arranged on the outer wall of the outer boring bit. The first stage blade and the second stage blade are separately provided with coolant loop holes. In the hard rock core drill bit, the boring bit is divided into two-stage blades, the blade at the lowermost end is used for drilling a small hole first, and then the upper blade is used for broaching, so that the drilling rate can be improved, and the core-taking efficiency is improved. The coolant loop holes are separately formed in the blade portions to spray a coolant out through the through holes tocool the blades, the cooling rate of the blades is accelerated, the abrasion of a tool is reduced, and the life of the blades is prolonged. The outer core tube is provided with the spiral grooves continuous with the boring bit, and with the outer core tube being screwed into a rock stratum, the outer core tube creates a confined space for the coring tool to prevent contamination of a fidelity cabin.

Owner:SICHUAN UNIV +1

Reciprocating type coring method and device for rock stratum sampling

The invention relates to a reciprocating type coring method for rock stratum sampling. The method comprises the following steps: (1) carrying out drilling by a hollow drill pipe with front end provided with a coring cabin according to a predetermined drilling path, and when the drilling depth reaches the coring length, stopping drilling, and enabling the rock core to enter the coring cabin; (2) when the hollow drill pipe is immobilized, taking out the coring cabin along an inner hole of the hollow drill pipe, and then taking out the rock core from the coring cabin; (3) pushing the coring cabininto the front end of the hollow drill pipe along the inner hole of the hollow drill pipe to be fixed, and then carrying out drilling and coring according to the predetermined drilling path; and (4)repeating the steps (1) to (3) till the total drilling depth reaches a predetermined depth. According to the method and the device, the coring efficiency of the rock stratum can be improved greatly, the work strength is reduced and the coring precision and quality are improved.

Owner:HENAN POLYTECHNIC UNIV

Novel submarine deep hole pressure maintaining and core drilling rig

InactiveCN102606074BEasy to operateReduce use costUnderwater drillingCore removalHydraulic motorLeveling mechanism

The invention relates to a novel submarine deep hole pressure maintaining and core drilling rig. The space of a drilling rig is insufficiently used by an existing device, and the processes of drilling, sampling and pressure maintaining for samples are complicated. The novel submarine deep hole pressure maintaining core drilling rig comprises an outer frame, a support leveling mechanism, a drilling pipe and core barrel storage mechanism, a power head mechanism, a rope core-stripping mechanism, a main manipulator, an auxiliary manipulator, an assembly manipulator, a pressure maintaining cover storage mechanism, a hydraulic motor, a drilling pipe, a core barrel and a hydraulic power system, wherein the main manipulator (the auxiliary manipulator) comprises a hydraulic lifting cylinder, a rotary support column, a base, a pipe taking gripper and a telescopic arm, and the assembly manipulator comprises a rotary support column, an upper pressing cover arm, a lower pressing cover arm, a rotary cover mechanism and a base. The space of the drilling rig is sufficiently used for storing more drilling pipes and core barrels, the drilling rig is applicable to multi-depth drilling places, the pressure of a sample can be maintained, operation is convenient in the pressure maintaining process, and cost is low.

Owner:HANGZHOU DIANZI UNIV

Core taking device used for taking out wire core of high voltage cable

InactiveCN107221888AEasy to take outWill not polluteWithdrawing sample devicesApparatus for removing/armouring cablesHigh-voltage cableEngineering

The invention relates to a core remover for taking out the wire core of a high-voltage cable, which includes a support assembly, and the support assembly includes a first mounting seat, a second mounting seat opposite to the first mounting seat, and a fixed mounting seat. A support rod between the first mounting base and the second mounting base, the first mounting base is provided with a wire core outlet, and the second mounting base is provided with an installation through hole opposite to the wire core outlet and a telescopic assembly, the telescopic assembly includes a mating seat fixed on the second mounting seat and a telescopic rod slidingly connected to the mating seat, one end of the telescopic rod is set through the installation through hole, and the other One end is provided with a drive assembly for driving the telescopic rod to rotate. The core remover for taking out the core of the high-voltage cable is convenient for taking out the core, and the cable insulation or the core will not be polluted during the process of taking out the core, so as to ensure the reliability of the data of the tide test or the silicone oil boiling test.

Owner:GUANGZHOU POWER SUPPLY CO LTD

Core taker for taking out wire core of high-voltage cable

InactiveCN107221889AEasy to take outWill not polluteWithdrawing sample devicesApparatus for removing/armouring cablesEngineeringHigh pressure

The invention relates to a core taker for taking out the wire core of a high-voltage cable. The core taker comprises a support assembly including a first mount base, a second mount base opposite to the first mount, and a support rod fixedly connected between the first mount base and the second mount base, the first mount base being provided with a wire core outlet, the second mount base being provided with a mounting through hole opposite to the wire core outlet; and a telescopic assembly including a lead screw nut base fixedly disposed on the second mount base and a lead screw in threaded driving engagement with the lead screw nut base. One end of the lead screw passes through the mounting through hole. The other end of the lead screw is provided with a driving assembly for driving the lead screw to rotate. The core taker for taking out the wire core of a high-voltage cable can easily take out the wire core, cannot pollute the insulation or the wire core of the cable during the wire core taking process, and guarantees the data reliability of a humidity test or a silicone oil test.

Owner:GUANGZHOU POWER SUPPLY CO LTD

Road survey coring bit facilitating core separation

The invention discloses a core drill bit for road surface survey which is convenient for core removal, which comprises a core tube, the top of the side of the core tube is provided with a first through hole, and the bottom of the core tube is provided with a diamond cutter head. The bottom of the diamond cutter head is surrounded equidistantly with chip removal gaps. A bracket is installed on the outside of the top of the core tube. The top of the bracket is welded with a top plate. There are four mounting holes around equidistantly. The coring bit for pavement investigation which is convenient to remove the coring facilitates the detachment of the coring pipe and the core column, improves the coring efficiency, facilitates the survey work, and solves the problem of using the coring bit of the coring machine for coring. The core column is easily stuck in the coring tube, and it is very inconvenient to take it out, which brings some troubles to the coring work, and is suitable for popularization and use.

Owner:侯如升

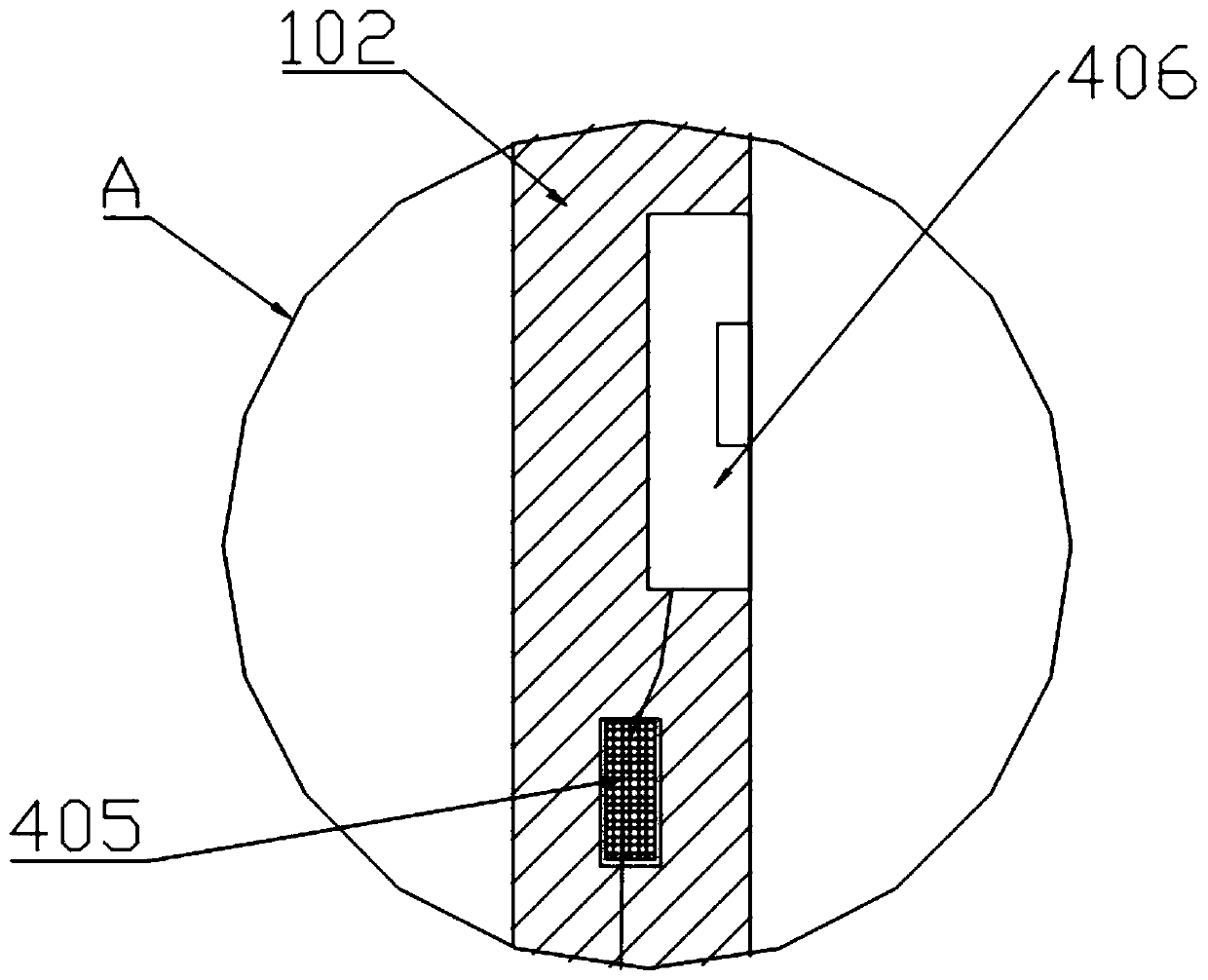

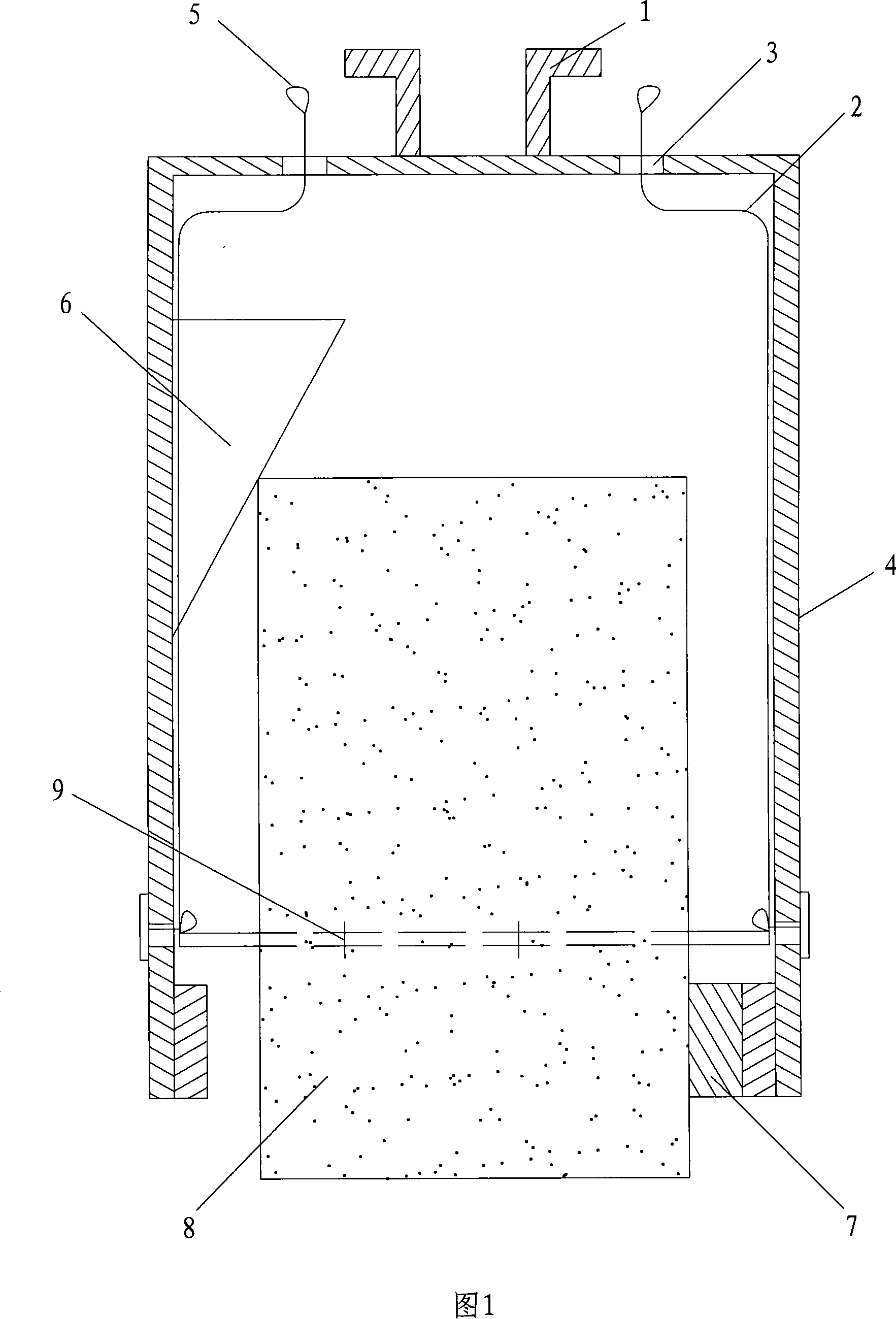

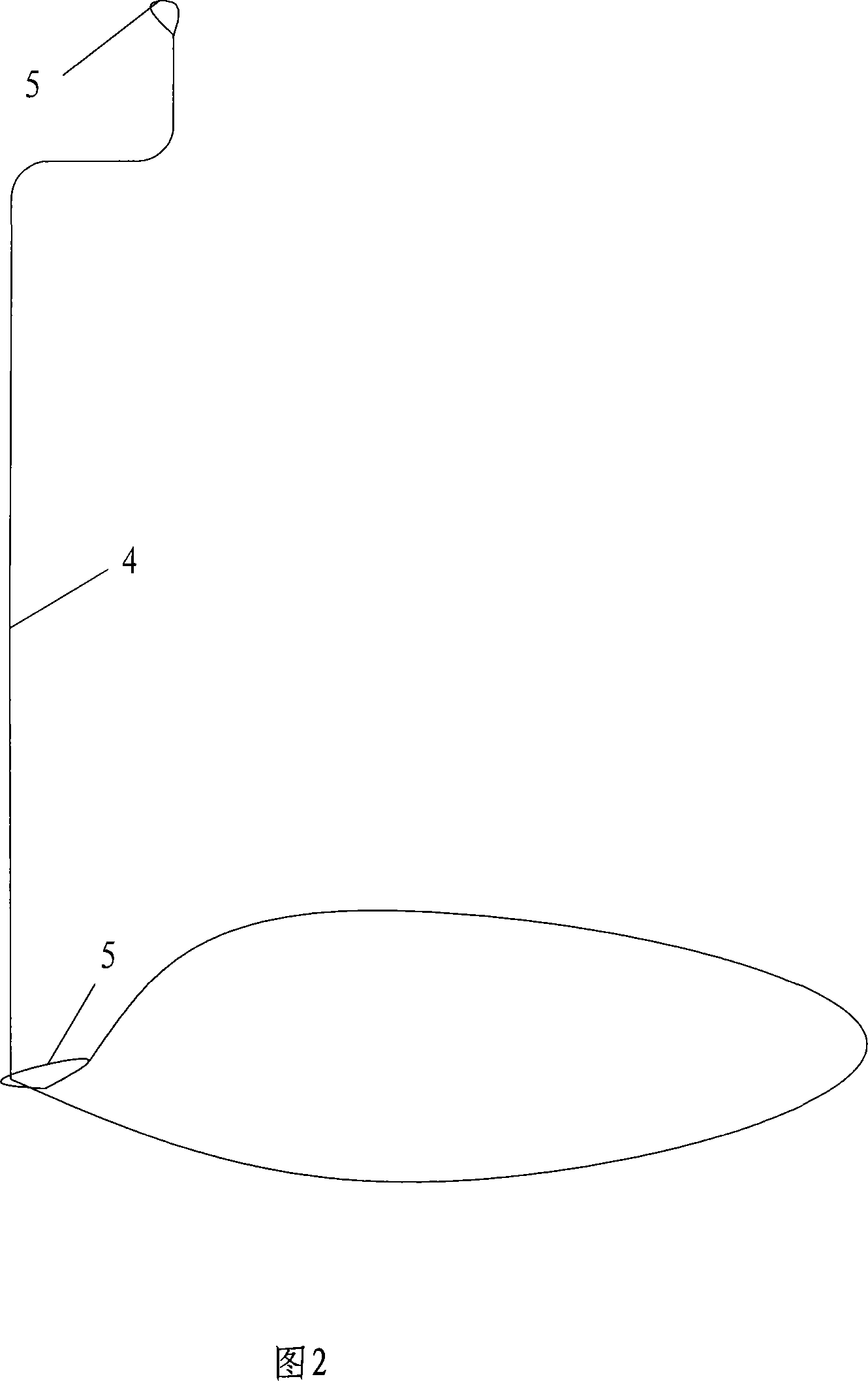

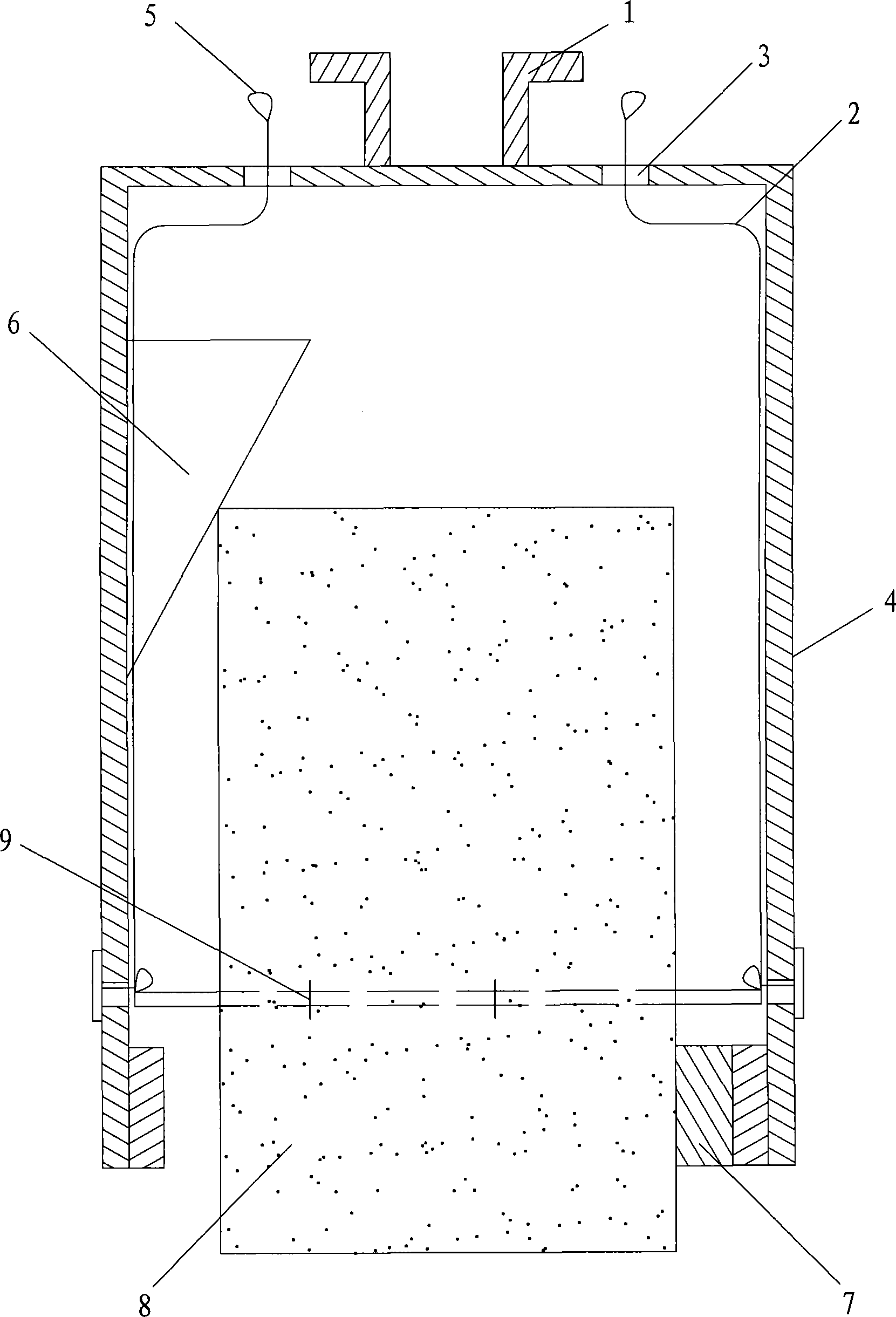

Drilling and coring device for early-age concrete

InactiveCN113008612AIncrease chip removal spaceImprove precision controlAnalysing solids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesLaser rangingClassical mechanics

The invention relates to a drilling and coring device for early-age concrete. The device is composed of a positioning groove, a wave velocity measuring probe, a fixed support, a drainage tank, a laser range finder, a coring drill bit device, a motor, a thread fixing assembly, a hydraulic jack, a base, a movable fixing plate, an auxiliary positioning rod, a propelling screw, an electronic torque measuring meter, a torque measuring meter handle, a T-shaped sliding groove plate, a notch, a chip removal opening and carborundum particles. According to the wave velocity condition of the cubic sample measured by the wave velocity measuring probe, the sample is subjected to stage treatment under different wave velocity levels, so that double-end-face coring is realized, and the coring efficiency is greatly improved; the coring bit device is subjected to nickel plating treatment, the bit part is provided with the chip removal opening, and the notch part is electroplated with carborundum, so that a larger chip removal space is provided in the early-age concrete drilling and coring process, and the problems are solved that the internal cementing capacity of the early-age concrete is poor, the gelation structure strength is low, and the friction force between the inner wall of the drill bit and the core sample is too large, so that the core sample is broken and has unfilled corner.

Owner:ANHUI UNIV OF SCI & TECH

Drilling coring device with flexible drill bits

The invention relates to the technical field of drilling devices, and provides a drilling coring device with flexible drill bits. The device comprises a mounting seat, the drill bits mounted on the mounting seat in a manner of floating up and down and drilling tools hinged to the drill bits through hinge mechanisms. Therefore, the drilling tools can rotate between the folded positions where the drilling tools are folded inwards and the unfolded positions where the drilling tools are unfolded outwards, positioning mechanisms are arranged on the mounting seat, and can be matched with the drilling tools to limit rotation of the drilling tools when the drilling tools move to the unfolded positions. The actual working feed amount of the drilling tools can be adjusted by changing the positions of the drilling tools, so that the drilling coring device can cope with an unknown geological environment, and the coring efficiency is improved. Meanwhile, in the lifting process after coring is completed, the drilling tools rotate to the folded position, so that damage to a coring hole and the requirement for lifting force are reduced, the possibility of drill jamming is reduced, and the continuity of the coring process is improved.

Owner:SHENZHEN UNIV

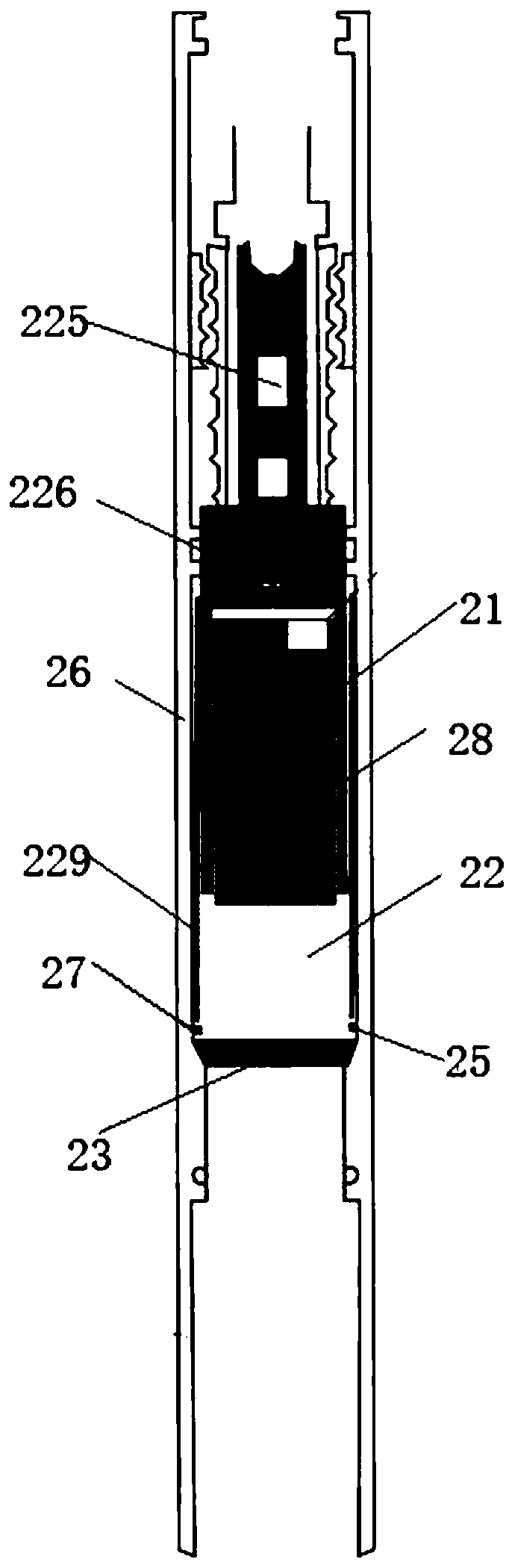

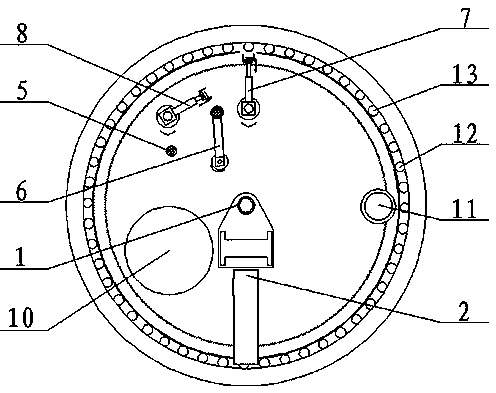

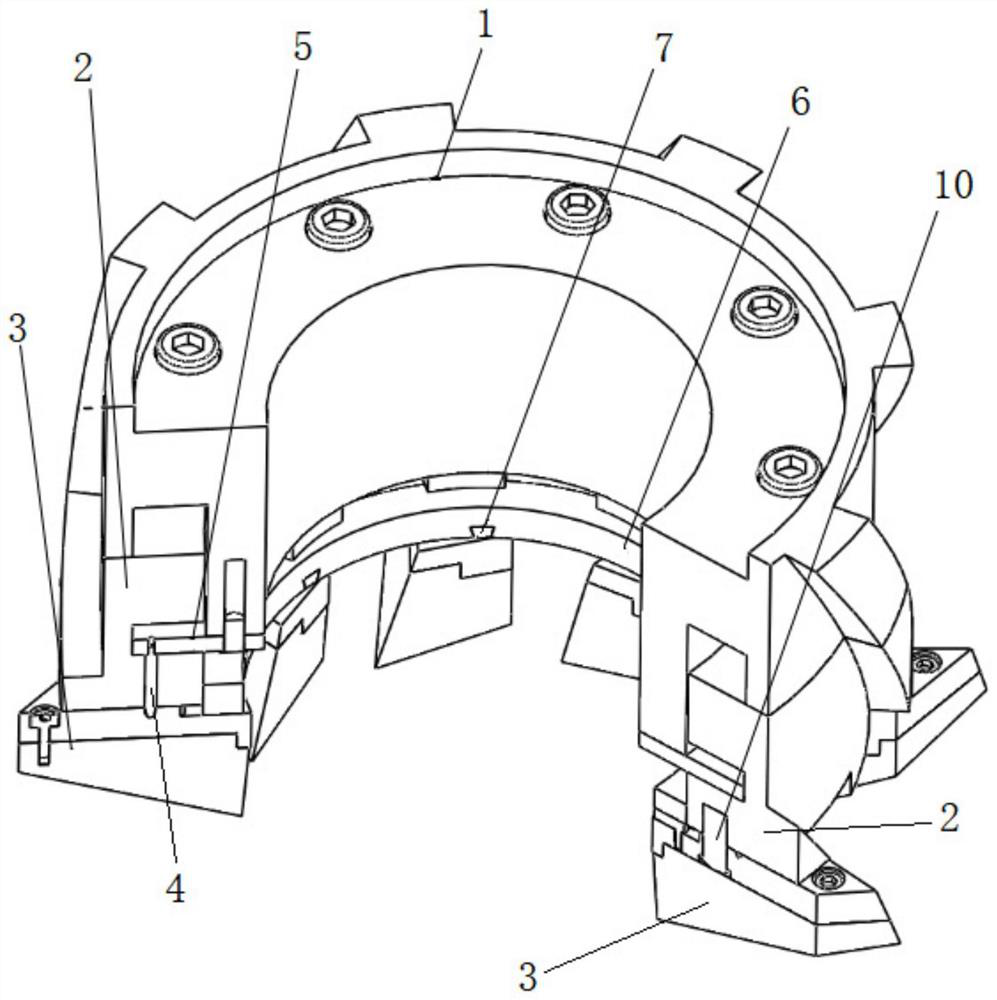

High-precision table type rotating ultrasonic rock coring device

ActiveCN111322026AGet rid of operabilityGet rid of the tedious process of coring with the help of ropeVibration drillingCore removalRock coreResonance

The invention discloses a high-precision table type rotating ultrasonic rock coring device, and belongs to the technical field of rock coring. The device comprises a supporting assembly, a transmission assembly and an ultrasonic rock breaking assembly. The supporting assembly is located on the outmost side of the whole device, the transmission assembly is located on the upper end in the supportingassembly, the ultrasonic rock breaking assembly is mounted on the lower end in the supporting assembly, the device is scientific and reasonable, use is safe and convenient, ultrasonic vibration is used for carrying out resonance breaking on the rock, compared with a traditional manner that a drill bit drills for coring, the coring efficiency is greatly improved, a rock sample can be subjected tosurface grinding through the device, the surface of a coring sample is flat, the rock sample can enter a coring groove favorably, a related worker can carry out observing and research, when the top end of the coring rock sample reaches the height of a distance sensor, the device can cut off the rock sample, the cut-off rock coring sample can be conveniently taken out by an operator from the top ofa coring groove, and convenience and rapidness are achieved.

Owner:丁建利

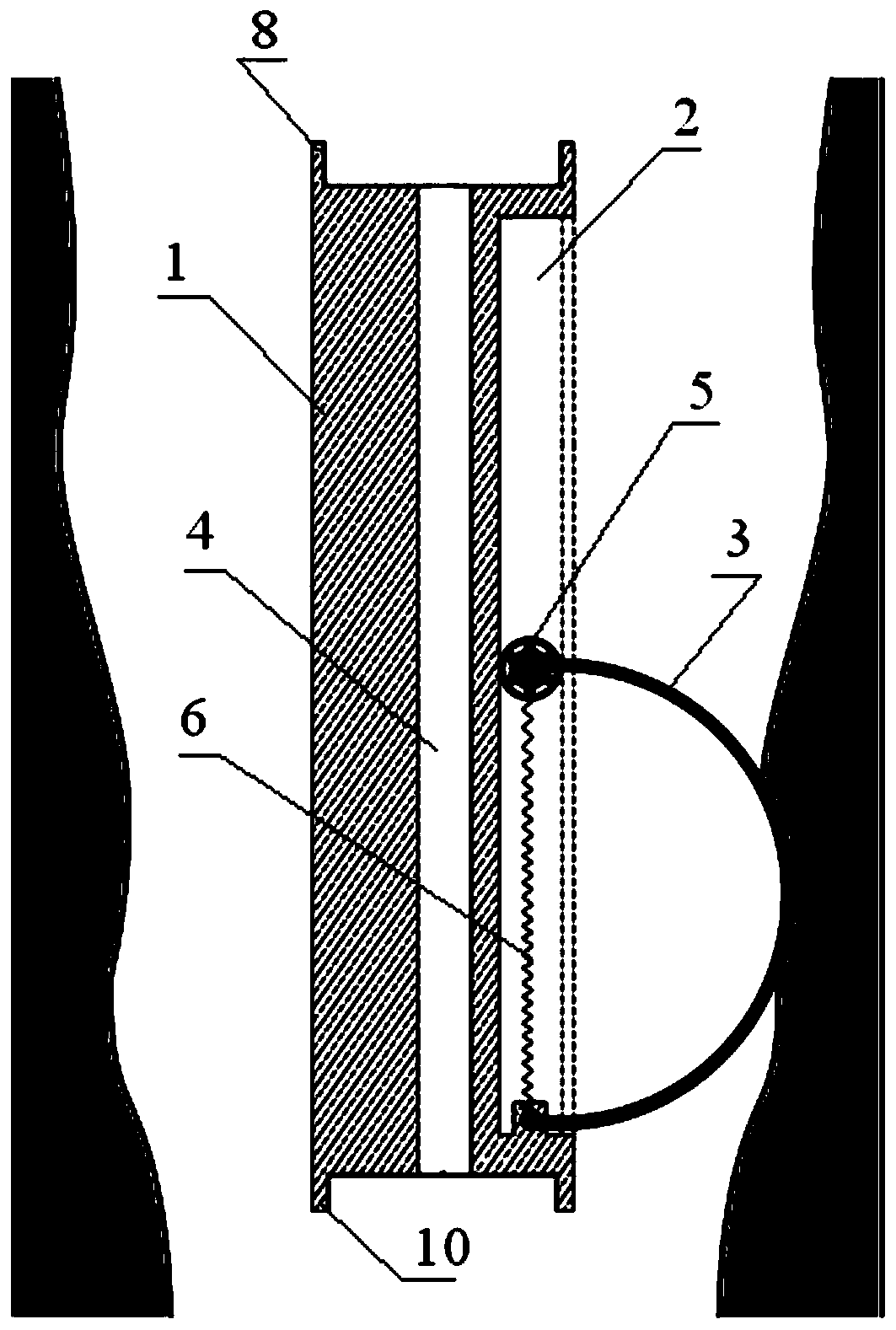

Heavy-caliber base rock boring coring device

InactiveCN101205800BImprove coring efficiencySolve the technical problem of high risk of going down the wellCore removalBedrockEngineering

The invention discloses a heavy-caliber bedrock drilling core device which comprises an adapting flange, a wire rope, a wiring sleeve hole, a guiding core barrel and annular beckets, wherein, the adapting flange and the wiring sleeve hole are arranged on the top of the guiding core barrel; the annular beckets are arranged on both ends of the wire rope; the invention also comprises a supporting block and a wedge block; one end of the wire rope passes through annular beckets on the other end, and the other end of the wire rope forms the shape of a ring and is arranged on the lower part of the guiding core barrel and bound on the inner wall of the guiding core barrel through a fixture; one end of the wire rope which passes through the annular beckets is arranged on the upper part of the guiding core barrel after passing through the wiring sleeve hole; the wedge block is arranged on the upper part of the guiding core barrel; the supporting block is welded at the bottom of the guiding corebarrel. The heavy-caliber bedrock drilling core device of the invention does not need pumping and does not need staff to go down a well as well, thereby core efficiency is greatly improved and technical problems of long time of pumping which is repeated time after time for heavy-caliber bedrock drilling, great pumping difficulty and great downhole risk of the operation staff are solved; moreover,the invention has the advantages of simple structure, reliable operation and high core success ratio.

Owner:长江岩土工程有限公司

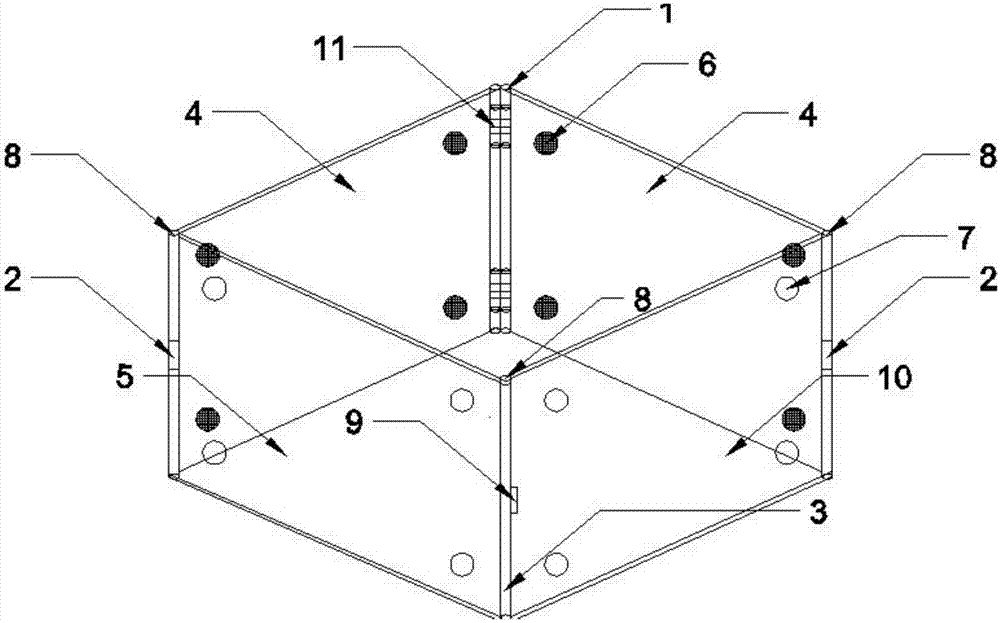

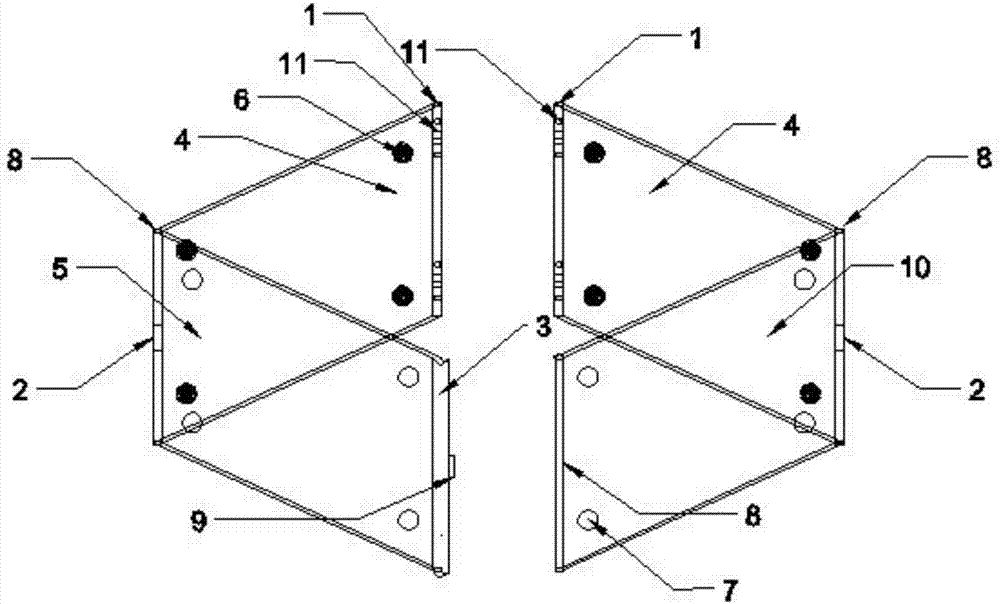

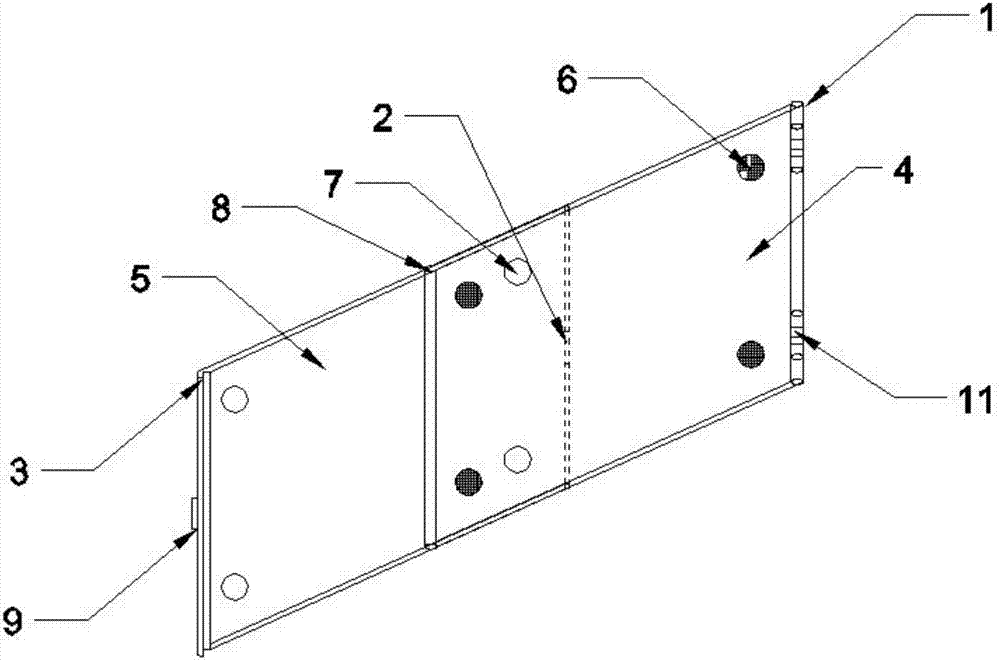

Novel protection cover for indoor rock-drilling and coring

InactiveCN107505162ASplash protectionImprove coring efficiencyWithdrawing sample devicesEngineeringCoring

The invention relates to a protective cover for rock drilling and coring, in particular to a novel indoor protective cover for rock drilling and coring. A protective measure method is provided, which can simply and effectively prevent splashing of water droplets in the process of drilling and coring. And it brings convenience to experimenters, simple operation, easy transportation and storage, and improves coring efficiency. The invention is a square protective cover, the shape of which can be designed according to the specific coring platform. It consists of four square plates of equal size. The head plate has a buckle groove and buckle, the tail plate has a protruding shaft that fits with the head plate, and there are two identical hollow plates connected by hinges in the middle, and the connection with the head and tail plates is a hollow Buckle connection. After the protective cover is taken off, it can be stretched and folded into the size of a board. Easy to operate, safe and simple, easy to transport and store, improve coring efficiency and reduce laboratory stains.

Owner:ANHUI UNIV OF SCI & TECH

A high-precision desktop rotary ultrasonic rock coring device

ActiveCN111322026BEasy accessEasy to observe and studyVibration drillingCore removalCrushed stoneUltrasonic vibration

The invention discloses a high-precision table type rotating ultrasonic rock coring device, and belongs to the technical field of rock coring. The device comprises a supporting assembly, a transmission assembly and an ultrasonic rock breaking assembly. The supporting assembly is located on the outmost side of the whole device, the transmission assembly is located on the upper end in the supportingassembly, the ultrasonic rock breaking assembly is mounted on the lower end in the supporting assembly, the device is scientific and reasonable, use is safe and convenient, ultrasonic vibration is used for carrying out resonance breaking on the rock, compared with a traditional manner that a drill bit drills for coring, the coring efficiency is greatly improved, a rock sample can be subjected tosurface grinding through the device, the surface of a coring sample is flat, the rock sample can enter a coring groove favorably, a related worker can carry out observing and research, when the top end of the coring rock sample reaches the height of a distance sensor, the device can cut off the rock sample, the cut-off rock coring sample can be conveniently taken out by an operator from the top ofa coring groove, and convenience and rapidness are achieved.

Owner:丁建利

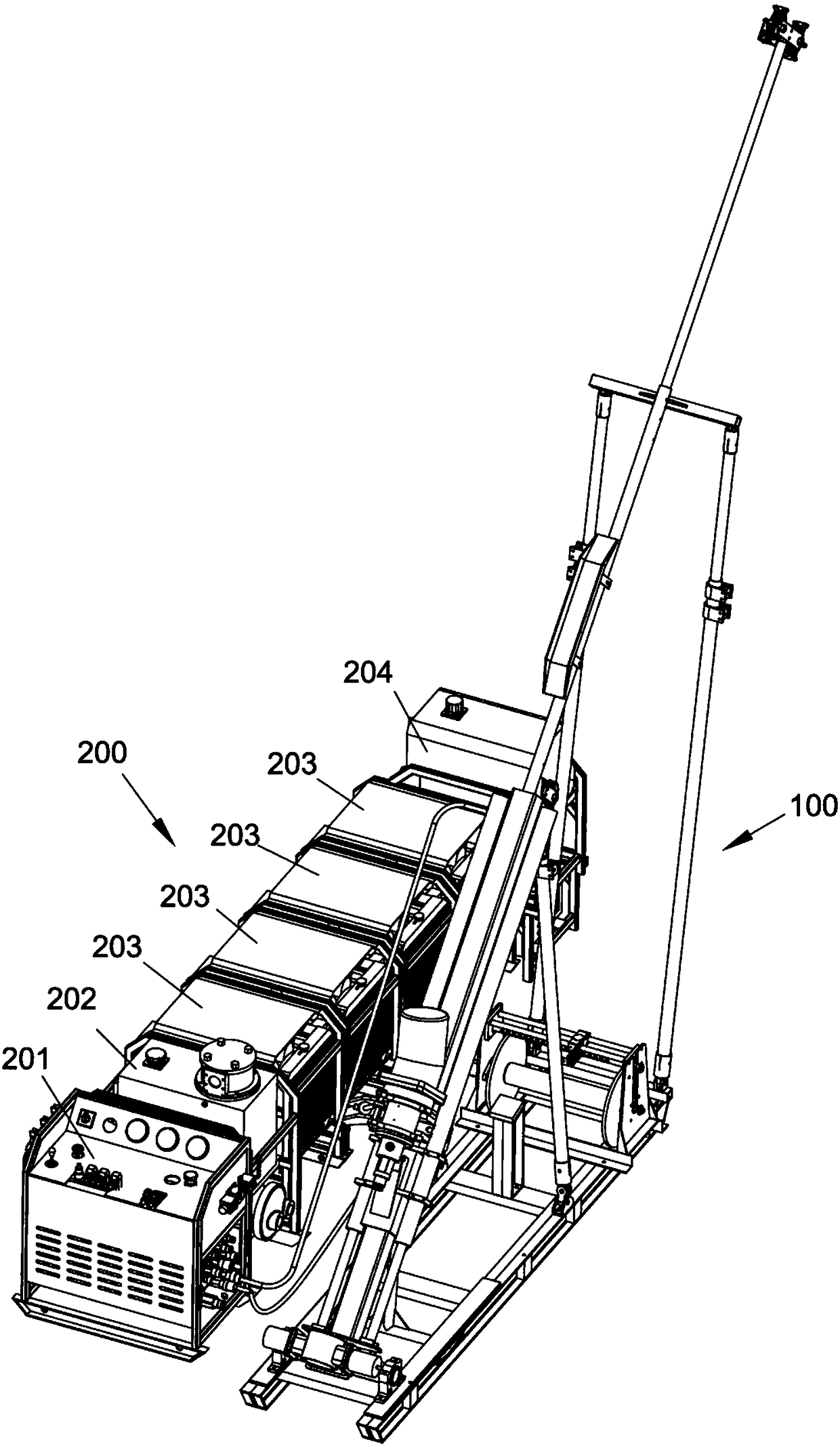

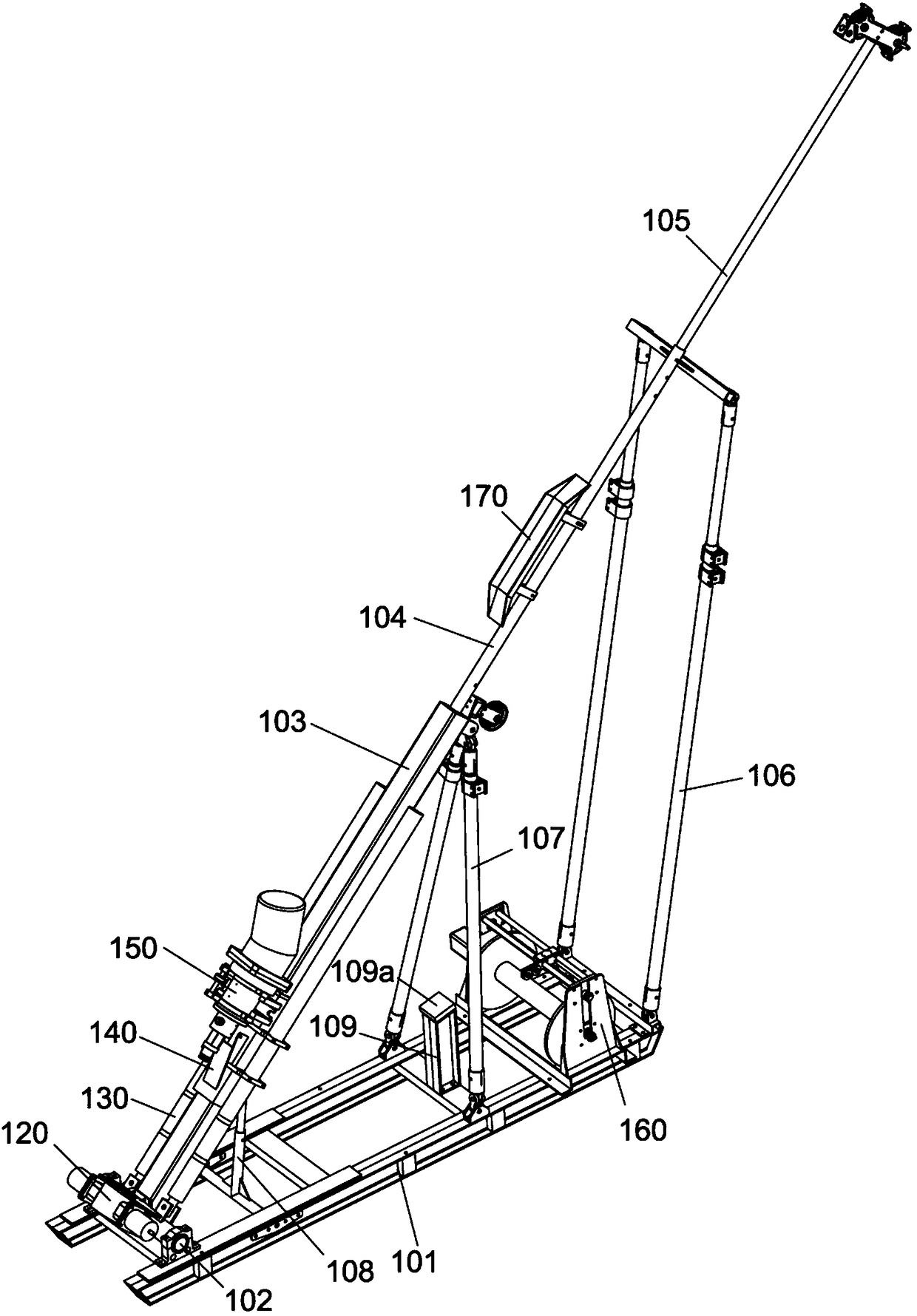

A kilometer-level core drilling rig

The invention discloses a kilometer-scale core drill which comprises a power assembly and a machine frame assembly, wherein the power assembly comprises an operating platform, a hydraulic oil tank, a diesel engine and a plurality of engines; the machine frame assembly comprises a double-rail pedestal, a big-frame guide rail, a power head and a power head saddle; one end of the big-frame guide rail is connected with a rotating shaft of the double-rail pedestal through a guide rail rotating shaft and the other end of the big-frame guide rail is fixedly connected with a first-level mast; a drilling rod holder is arranged at the connecting end of the big-frame guide rail and the guide rail rotating shaft; saddle oil cylinders are arranged on two sides of the big-frame guide rail and are used for driving the power head saddle to slide along the big-frame guide rail; the power head is arranged on the power head saddle; the other end of the first-level mast is connected with a second-level mast. The kilometer-scale core drill provided by the invention is convenient to disassemble, can drill deep holes and is convenient to operate.

Owner:四川诺克钻探机械有限公司

A kind of coring method of oil sand core

The invention discloses a coring method for oil sand cores. The sequence is as follows: a layer of lubricating oil is coated on the inner wall of the core cylinder, and the blade-shaped end of the core cylinder is connected to the upper surface of the core in situ. End-face contact; press the core barrel, and cut the in-situ rock core outside the core barrel with a vertical cutter along the blade-shaped end of the core barrel; use a horizontal cutter to cut off the core exposed at both ends of the core barrel; The coring column is placed under the blade-shaped end of the coring barrel, and the coring barrel is pushed down, and the coring column pushes the oil sand core out of the coring barrel. The coring method uses a coring device for oil sand cores. The device includes an in-situ rock core, a horizontal cutter, a vertical cutter, a coring barrel and a coring column. One end of the coring barrel is in the shape of a blade. The core barrel and the vertical cutter work together to cut the in-situ rock core. The coring method has high coring efficiency and low cost, and can be operated by a control system to make the coring process more accurate, and the prepared oil sand core has a complete shape and is suitable for triaxial experiments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

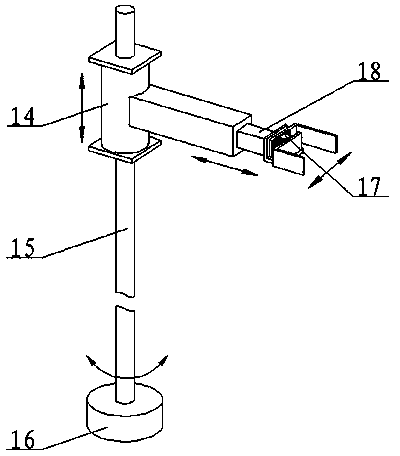

A kind of vertical drilling coring machine and coring method with arbitrary positioning of specimen disk

InactiveCN106840753BEasy to adjust the clamping directionIncrease freedomWithdrawing sample devicesCantileverMechanical engineering

The invention discloses a vertical drilling and coring machine with arbitrarily positioned test piece disk, which comprises a frame, a test piece disk and a base, the frame and the test piece disk are connected by a cantilever telescopic assembly, and the cantilever The cantilever-type telescopic assembly is four arms hinged by symmetrically arranged rotating shafts. The cantilever-type telescopic assembly is rotatably connected with the frame and the specimen disk. A base is also provided directly below the specimen disk. Supported by the cantilever telescopic assembly, it is suspended above the base, and the base is provided with a hemispherical groove, and the test piece plate is fixed with the hemispherical groove of the base through the touch-down bolt with a hemispherical end. The technical effect of the invention is: the position of the test piece disk can be adjusted arbitrarily, multiple elastic clamps are avoided, and the coring efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

A core box specially used for producing the core shell of the front pump cover

ActiveCN103341590BIntegrity guaranteedReduce corner damageFoundry moulding apparatusMechanical engineeringPhysics

The invention relates to a mud core box specially used for producing a front pump cover core shell. The mud core box comprises a bottom plate and a core mold, wherein the core mold is arranged on the bottom plate and forms a mold cavity together with the bottom plate; the appearance of the mold cavity is the same as that of the front pump cover core shell; the core mold comprises a bottom die and a plurality of modules; the bottom die is arranged on the bottom plate and the same as one side of the front pump cover core shell in shape; the plurality of modules are enclosed at the periphery of the bottom die and detachably connected together; and the mud core box also comprises a lock mechanism which is used for relatively locking the plurality of modules. By adopting the core mold, the mold cavity which is the same as the front pump cover core shell in appearance is formed by the plurality of modules and the bottom die in a splicing manner; and the stability of the mold cavity is met under the effect of the lock mechanism. In addition, only the lock mechanism needs to be unlocked when the core is taken, then and the plurality of modules enclosed on the bottom die are removed, so that the integrity of the mud core is ensured, the damage to a corner of the mud core is reduced, and meanwhile, the coring efficiency is improved.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

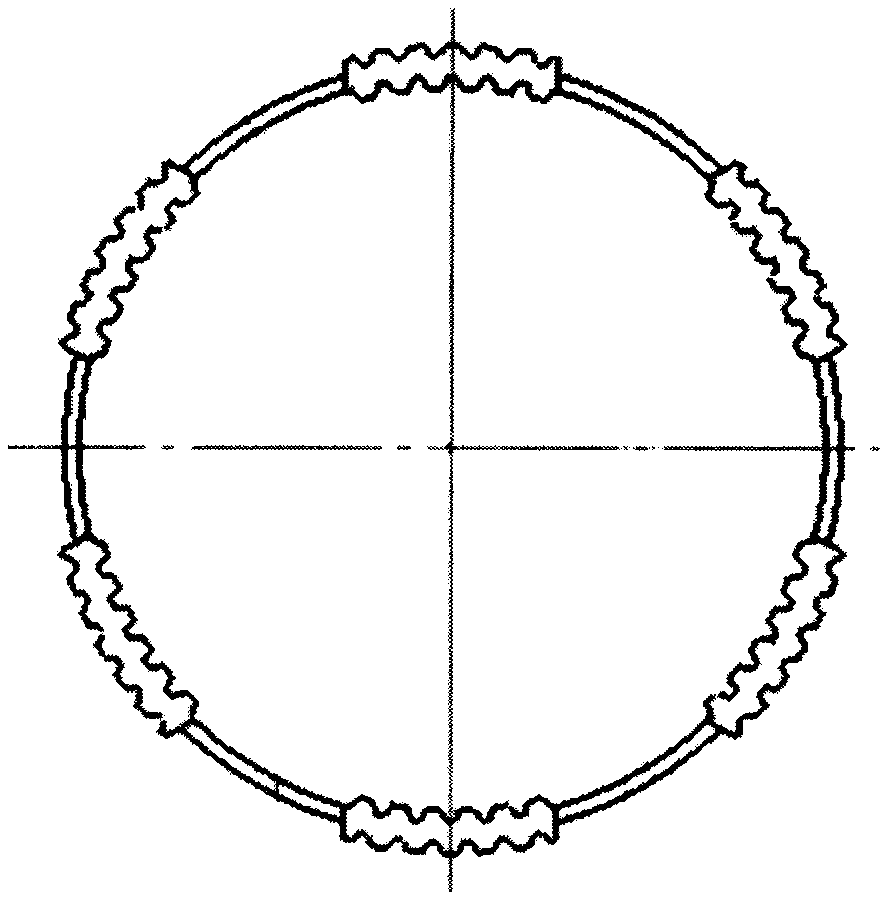

Hole-wall self-adaptive reverse torsion device for coring and drilling in polar hot water

PendingCN110005338ASolve the problem of not being able to apply hot water drilling into irregular boreholesNo kinks or even breaksIce drillingCoil springCoring

The invention discloses a hole-wall self-adaptive reverse torsion device for coring and drilling in polar hot water. A plurality of sliding grooves are formed in the circumference of a device body, supporting sheets are embedded in the sliding grooves, one ends of the supporting sheets are fixed ends and are fixed connected to one ends of the sliding grooves, the other ends of the supporting sheets are free ends and can slide in the sliding grooves, and a water conveyance passage is formed in the device body. The supporting sheets are elastic bodies and made of elastic materials, the fixed ends of the supporting sheets are fixed to the bottoms of the sliding grooves, the free ends of the supporting sheets are connected to a middle shaft of a roller, the roller is arranged in the sliding grooves, the free ends of the supporting sheets can be driven by the roller to slide along the sliding grooves, helical springs are assembled between the fixed ends and the free ends of the supporting sheets, and knife edges are arranged at the outer edges of the supporting sheets. The hole-wall self-adaptive reverse torsion device has the beneficial effects that the diameter of a reverse torsion sheet can be automatically adjusted to be suitable for different apertures, the efficiency of drilling and coring is greatly improved, and the situation that a hot water hose is twisted along with rotation of a drill tool and even broken is completely eliminated.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com