Heavy-caliber base rock boring coring device

A coring device and large-diameter technology, applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve the problems of difficult operation, time-consuming, low safety factor, etc., and achieve high coring success rate and coring efficiency Enhanced, operationally reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

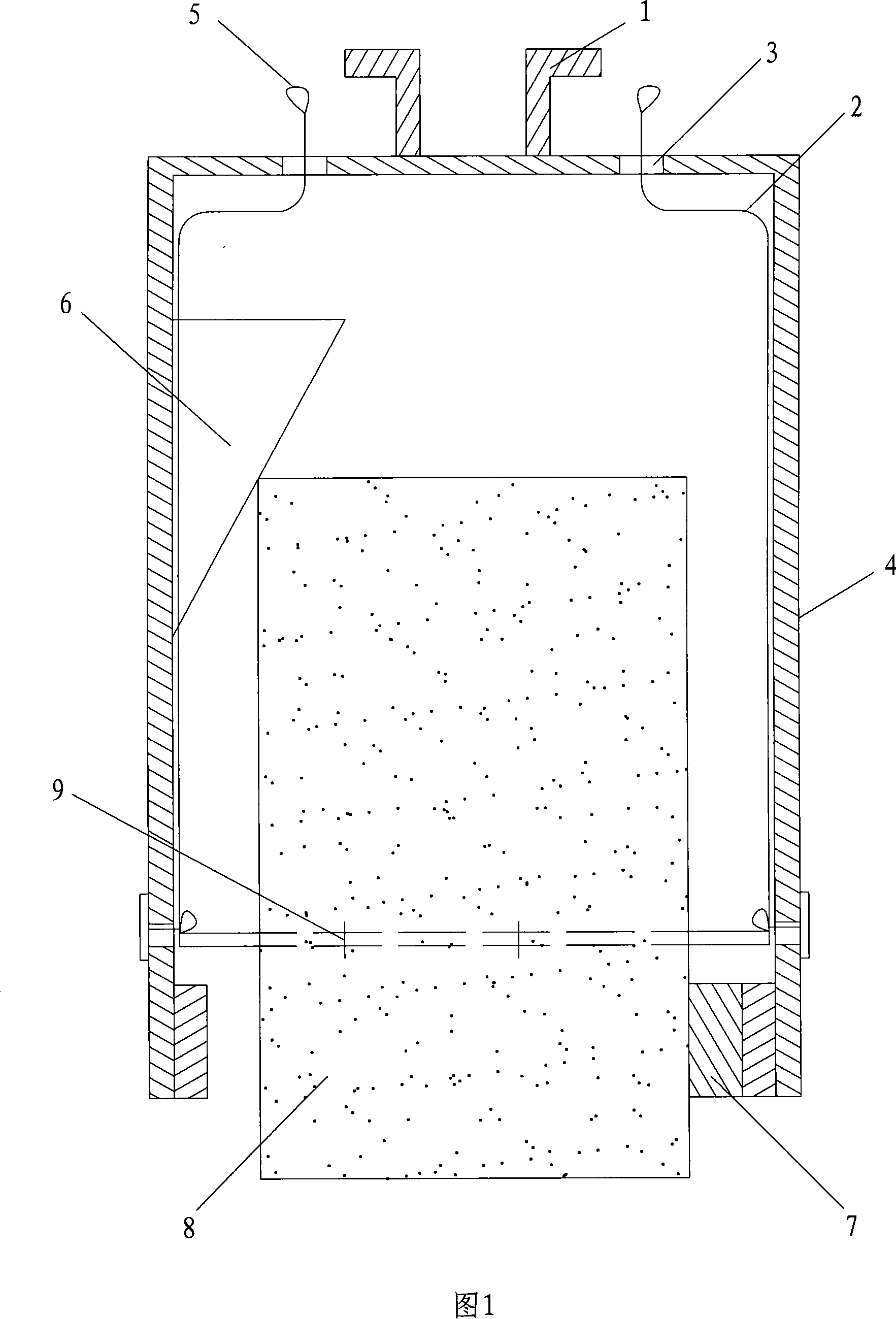

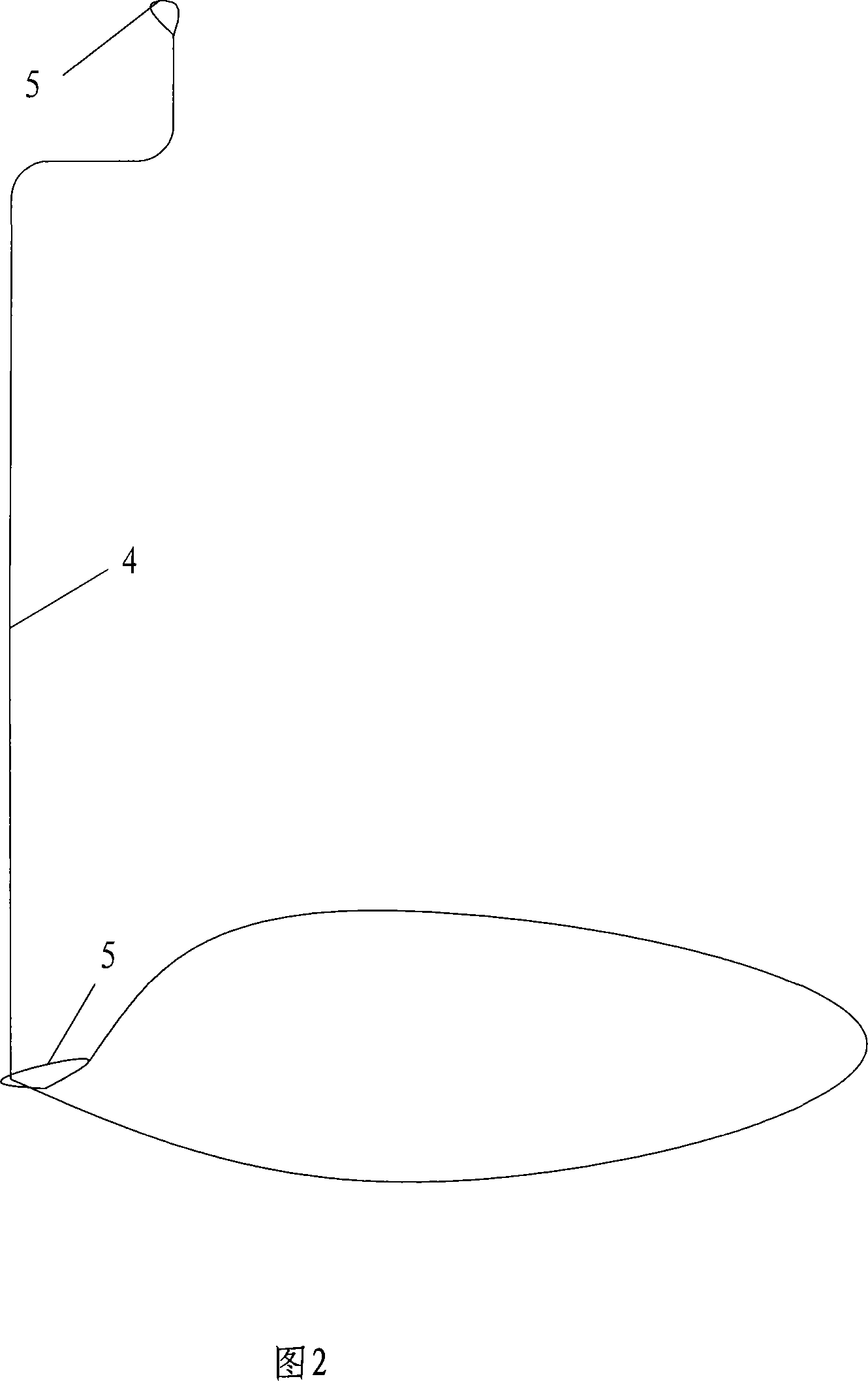

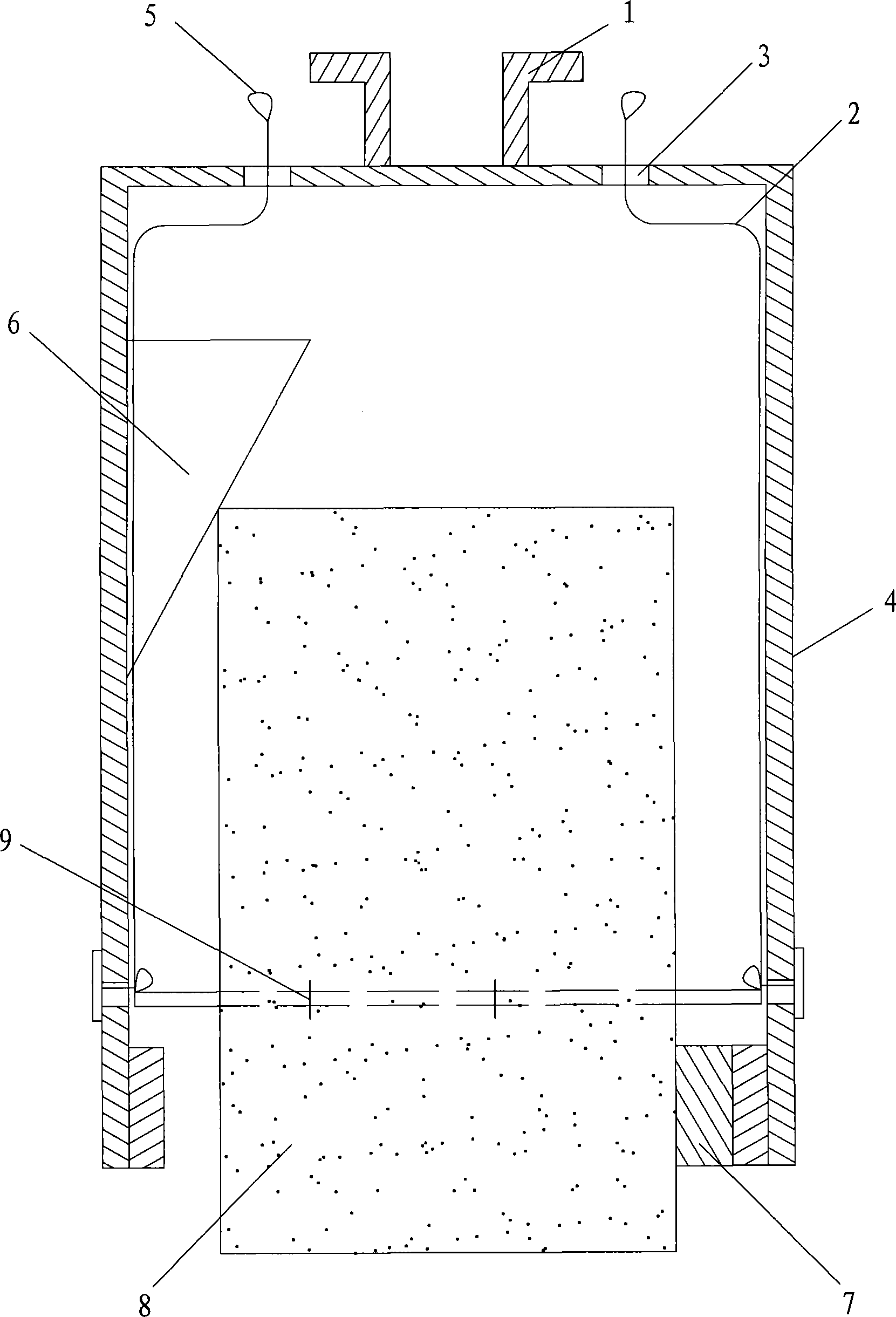

[0014] As shown in Figures 1 and 2, the large-diameter bedrock drilling and coring device of the present invention includes a connecting flange 1, a steel wire rope 2, a rope sleeve hole 3, a guiding coring cylinder 4 and a ring buckle 5, and the connecting flange 1 and the rope The casing holes 3 are all located at the top of the guiding core barrel 4, and the two ends of the steel wire rope 2 are provided with buckles 5, and also include a support block 7 and a wedge 6. One end of the steel rope 2 passes through the buckle 5 at the other end, and the steel rope 2 is another One end is arranged in the lower part of the guide coring cylinder 4 in a ring shape, and is bound on the inner wall of the guide coring cylinder 4 by a fixture 9, and one end of the steel wire rope 2 passing through the ring buckle 5 passes through the rope sleeve hole 3 and is arranged on the guide coring cylinder. Above the cylinder 4, the wedge 6 is arranged on the top of the guiding core cylinder 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com