Hole-wall self-adaptive reverse torsion device for coring and drilling in polar hot water

A self-adaptive, hole-wall technology, applied in ice drilling, drilling equipment and methods, earth-moving drilling, etc. The effect of kinking or even breaking, simple structure and clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

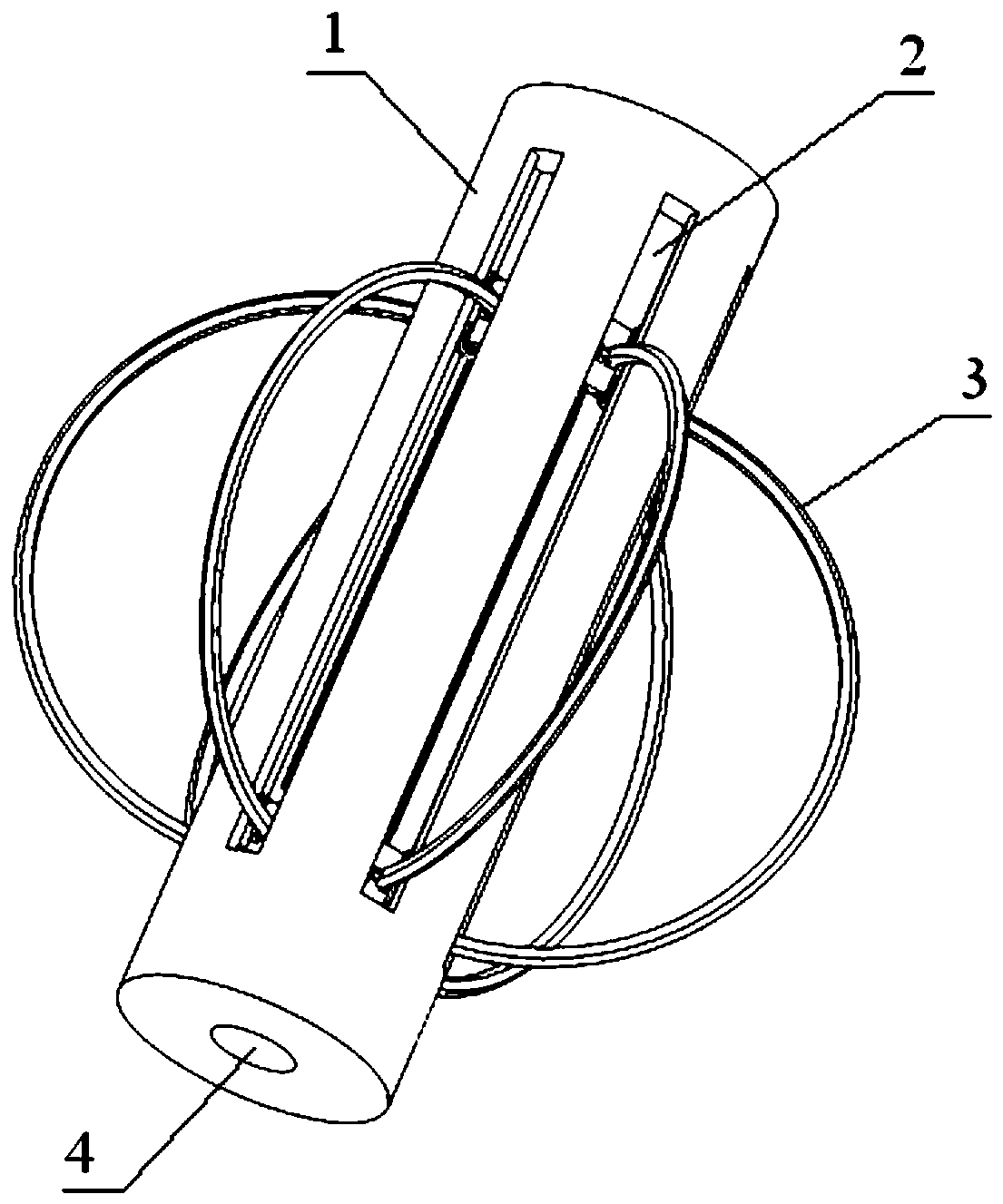

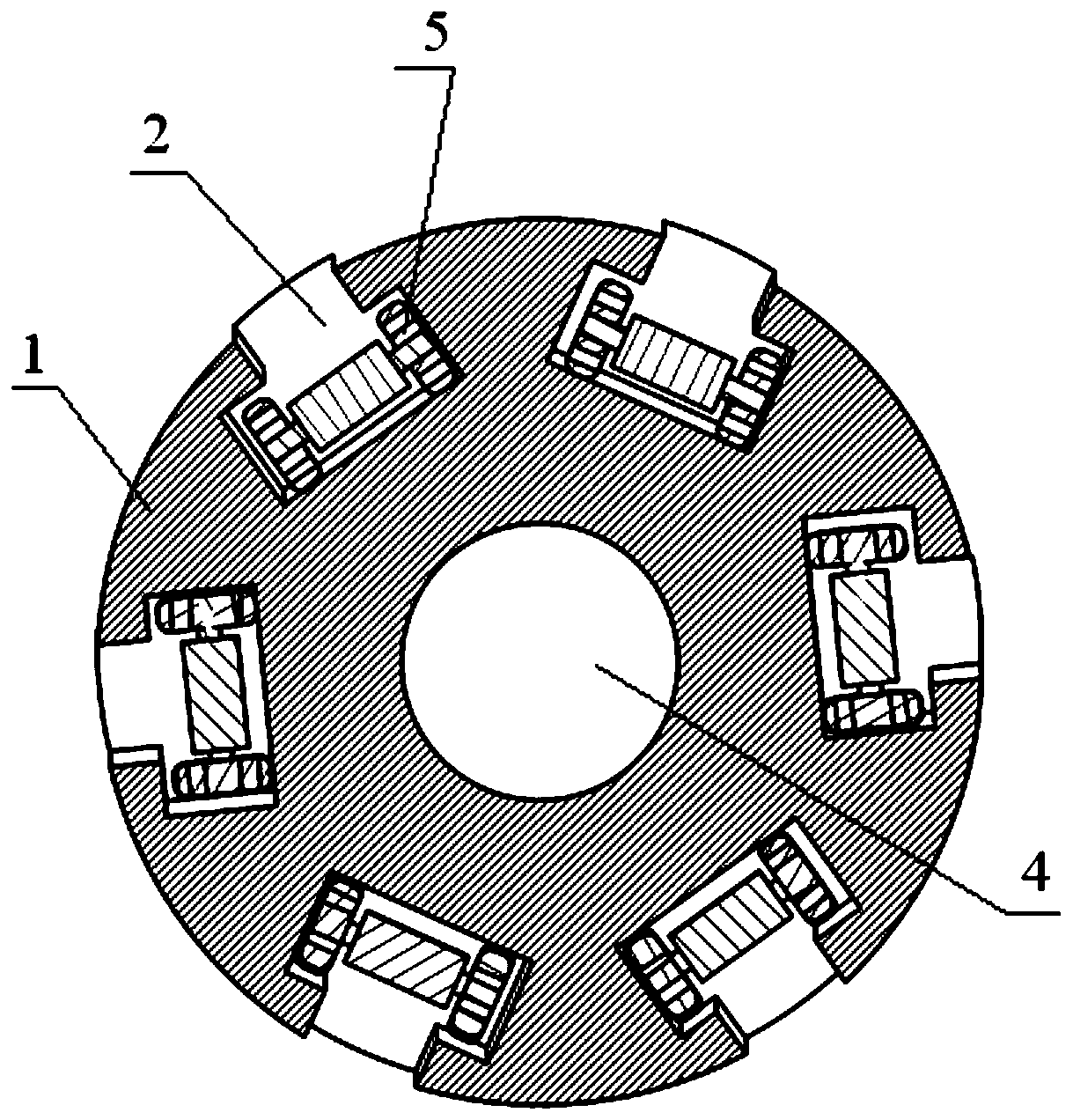

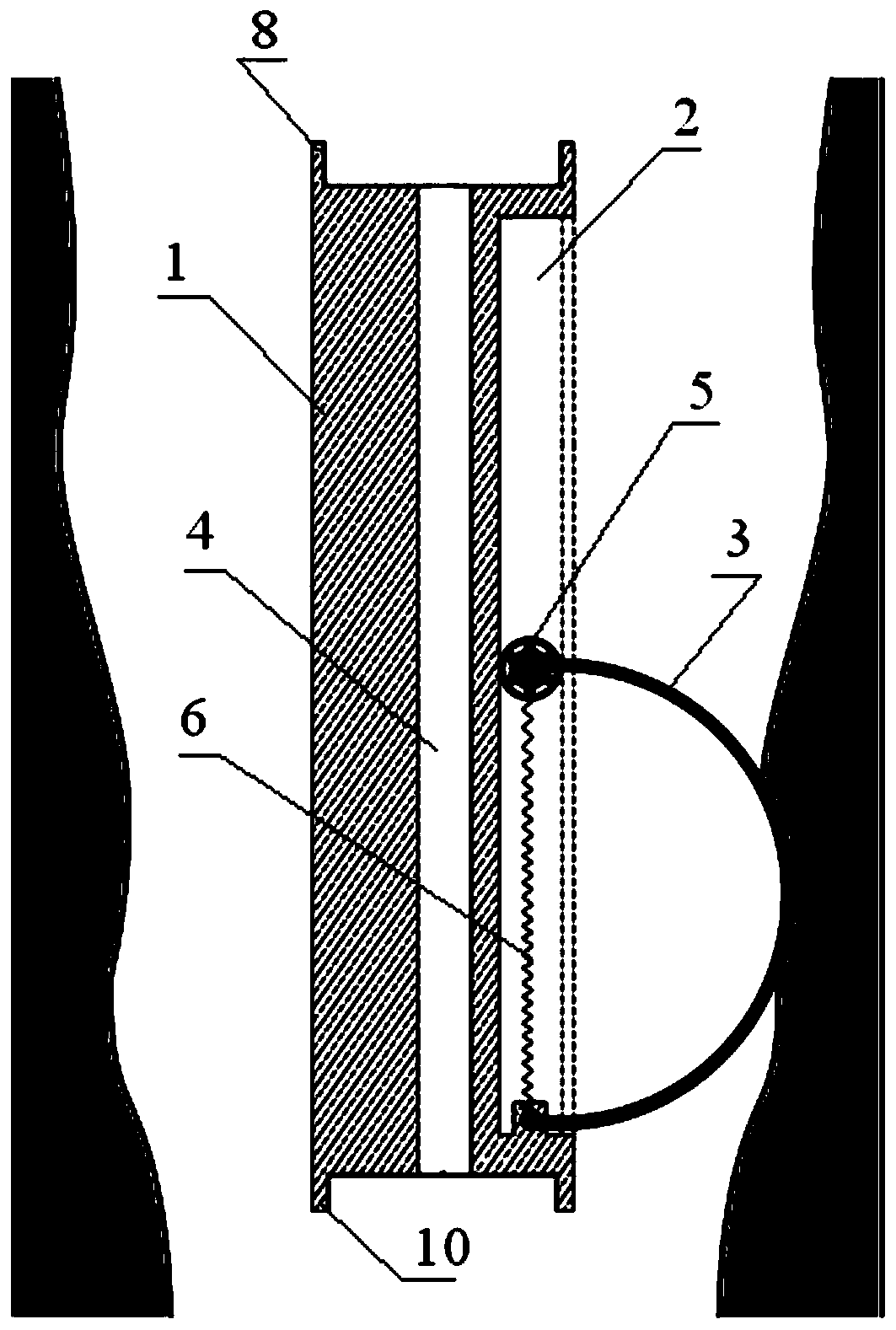

[0021] see Figure 1 to Figure 6 Shown:

[0022] The hole wall self-adaptive anti-torsion device for polar hot water core drilling provided by the present invention is provided with several chutes 2 on the circumference of the device body 1, and the chute 2 is embedded with a support piece 3, and the support piece One end of 3 is a fixed end fixedly connected to one end of the chute 2, the other end of the support piece 3 is a free end that can slide in the chute 2, and a water delivery channel 4 is provided in the device body 1.

[0023] Support sheet 3 is an elastic body, and support sheet 3 is made of elastic material, and the fixed end of support sheet 3 is fixedly connected in the bottom of chute 2, and the free end of support sheet 3 is connected on the axis of a roller 5, and roller 5 is set In the chute 2, the free end of the support piece 3 can slide along the chute 2 under the drive of the roller 5, a coil spring 6 is assembled between the fixed end and the free end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com