High-precision table type rotating ultrasonic rock coring device

A technology of rotating ultrasonic and coring device, which is applied in the direction of extracting undisturbed core devices, drilling with vibration, and earth-moving drilling, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

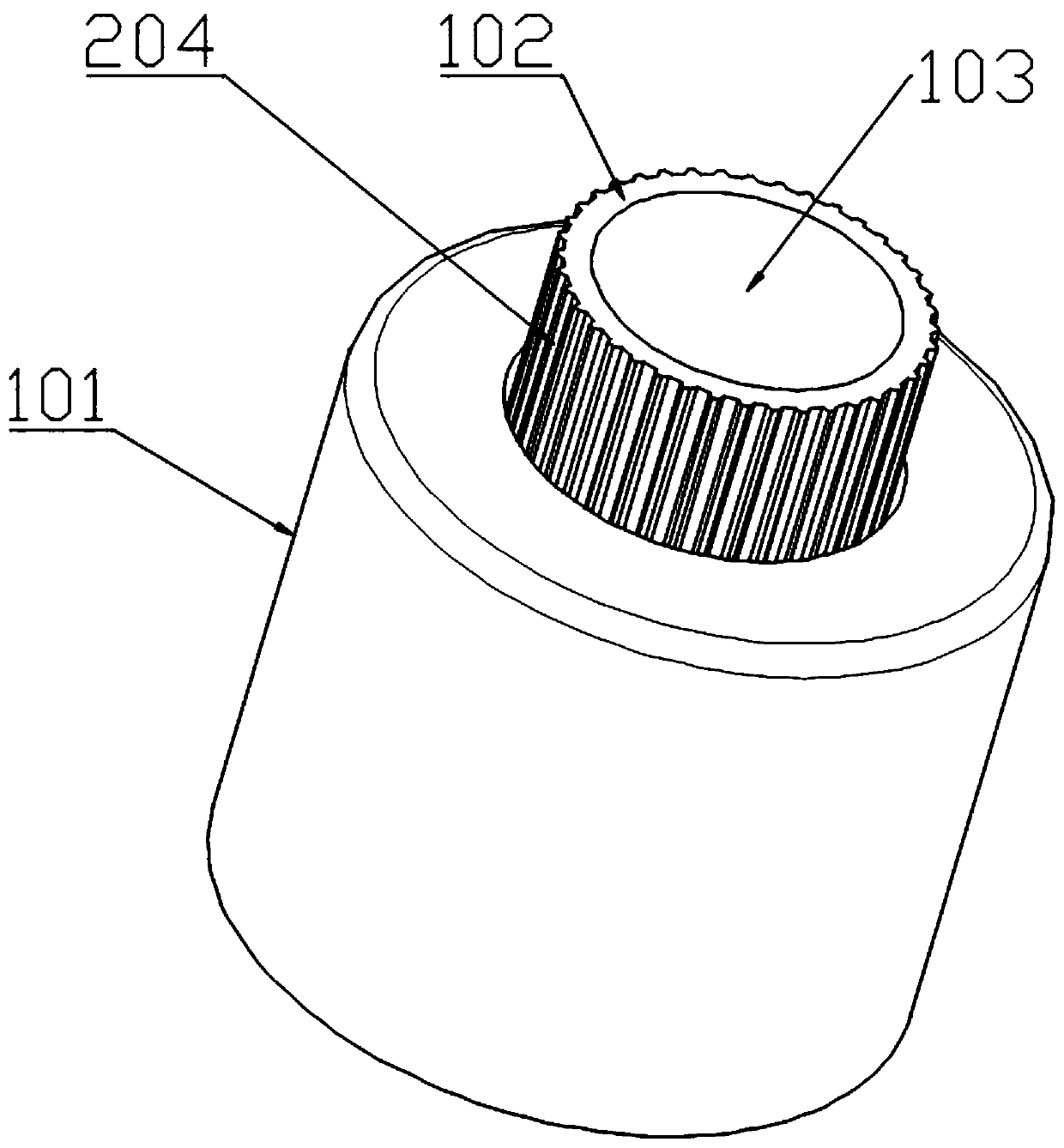

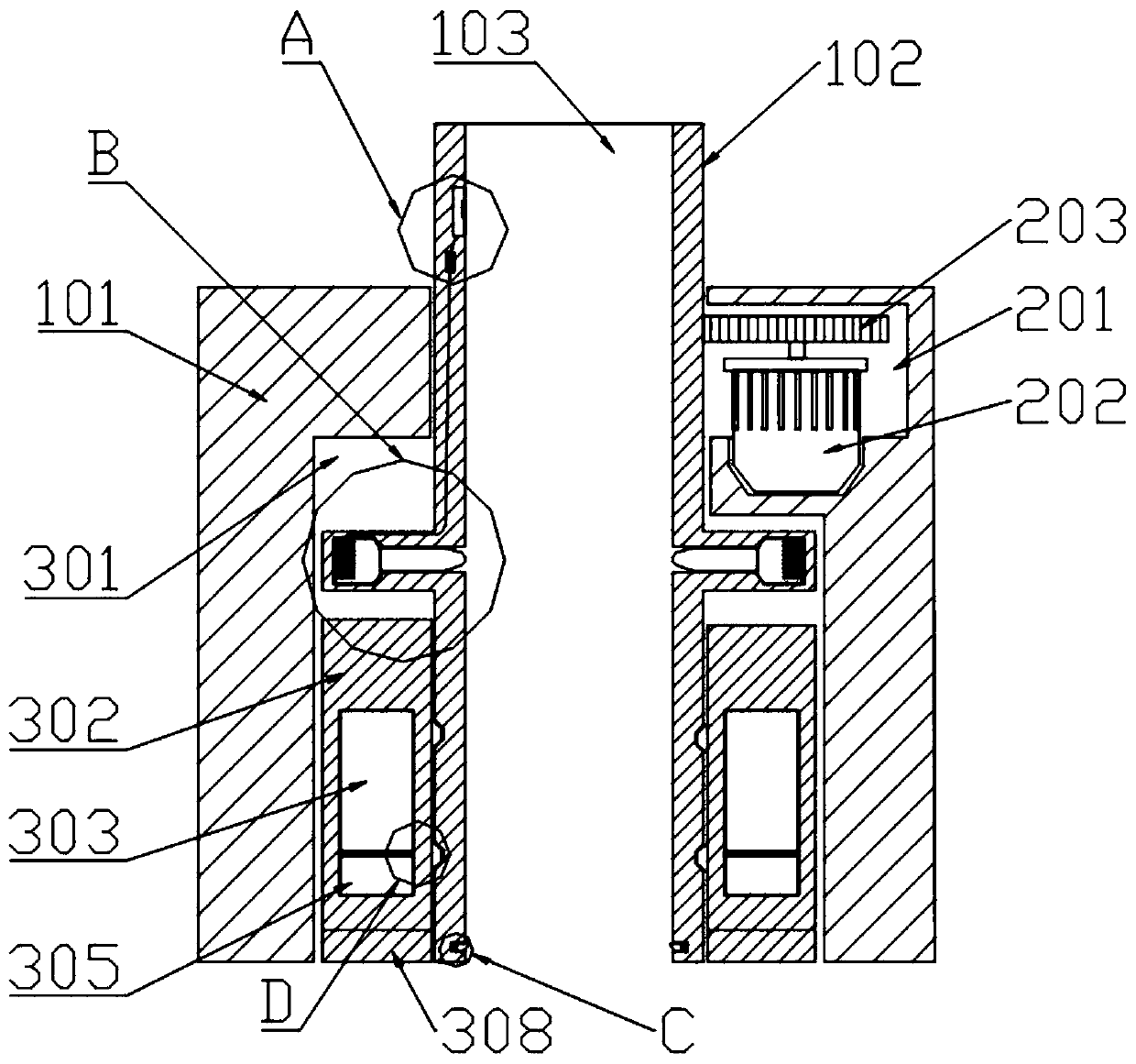

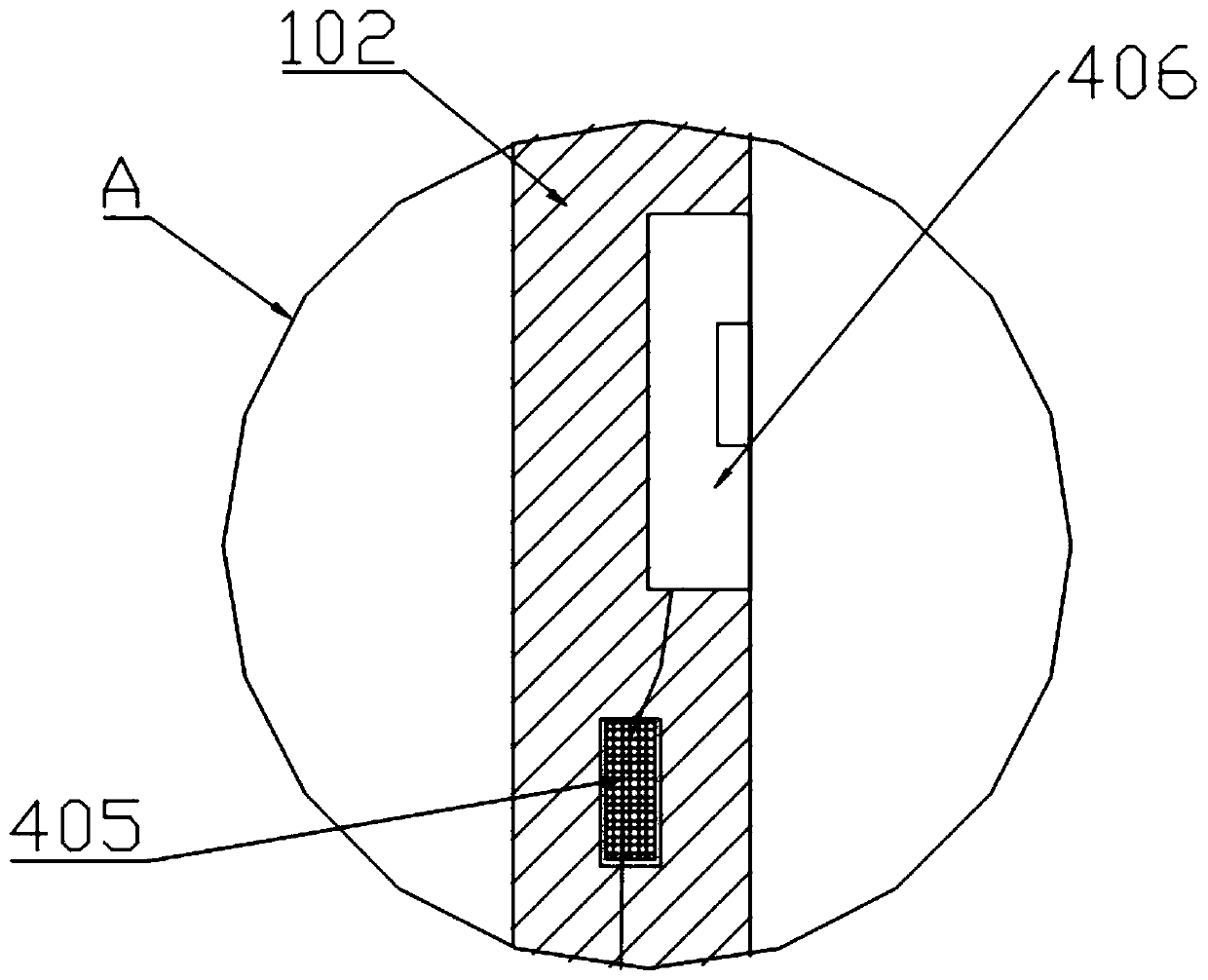

[0022] Example: such as Figure 1~6 As shown, a high-precision desktop rotary ultrasonic rock coring device includes a support assembly, a transmission assembly, an ultrasonic lithotripsy assembly, a cutting assembly, and a core lifting assembly. The role of components, the upper end of the support assembly is equipped with a transmission assembly, the transmission assembly is the power source for the operation of the device, the lower end of the support assembly is equipped with an ultrasonic lithotripsy assembly, the ultrasonic lithotripsy assembly plays the role of breaking rocks, and the middle of the support assembly is set There is a cut-off assembly, the cut-off assembly plays the role of cutting and segmenting the rock sample, the bottom of the support assembly is provided with a coring lifting assembly, and the coring lifting assembly plays the role of snapping in and supporting the rock coring sample.

[0023] The support assembly includes a counterweight housing 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com