Patents

Literature

87results about How to "Avoid breaking accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

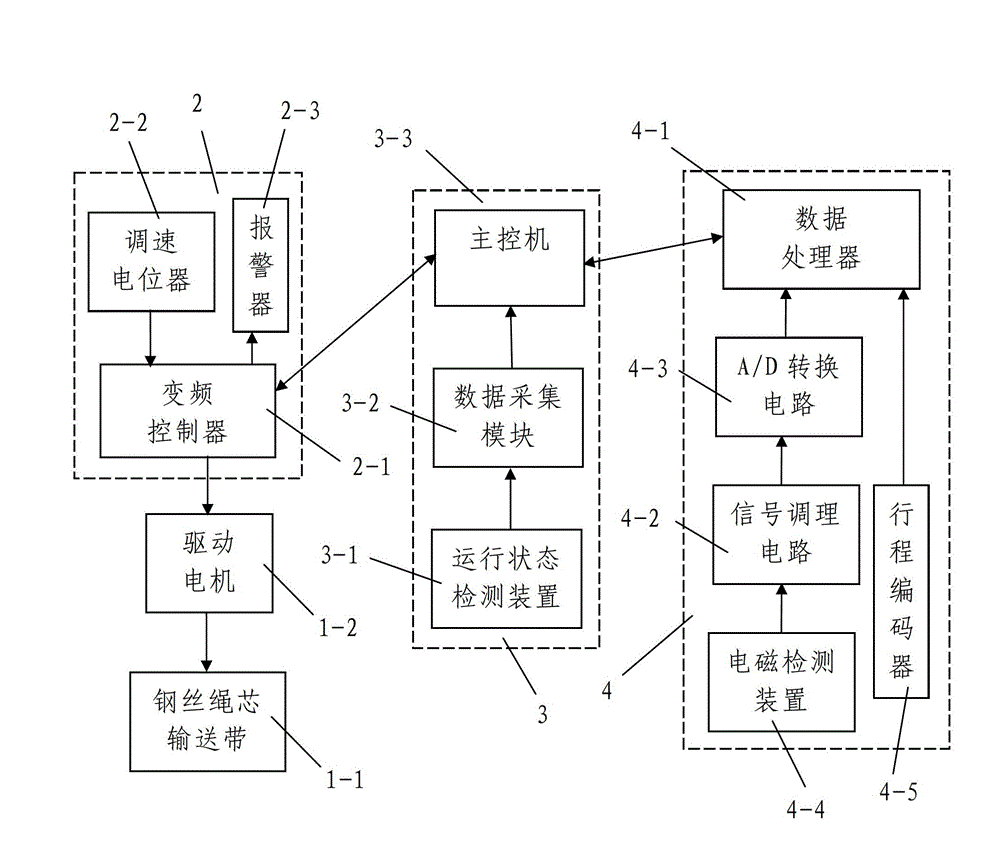

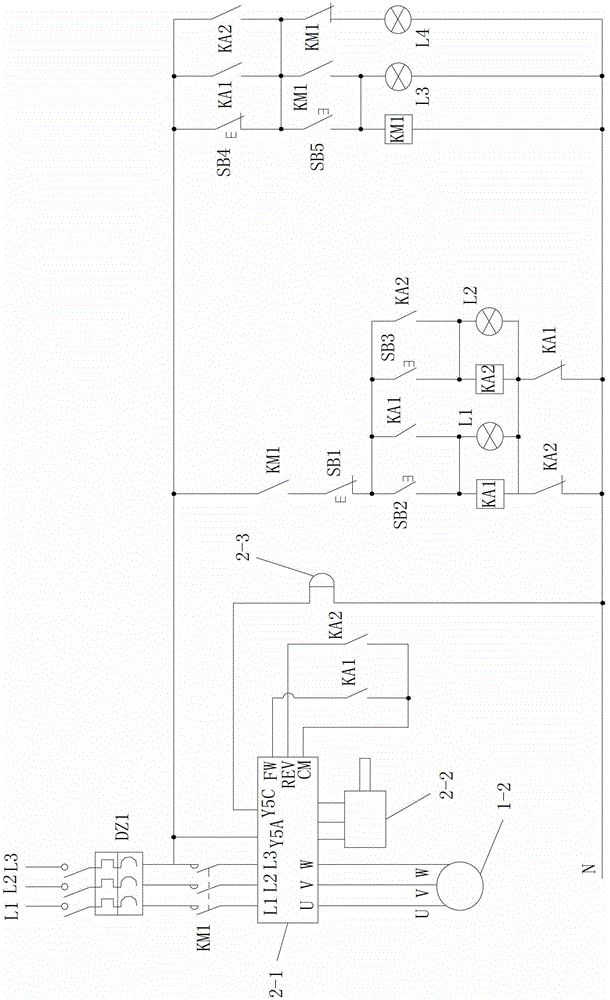

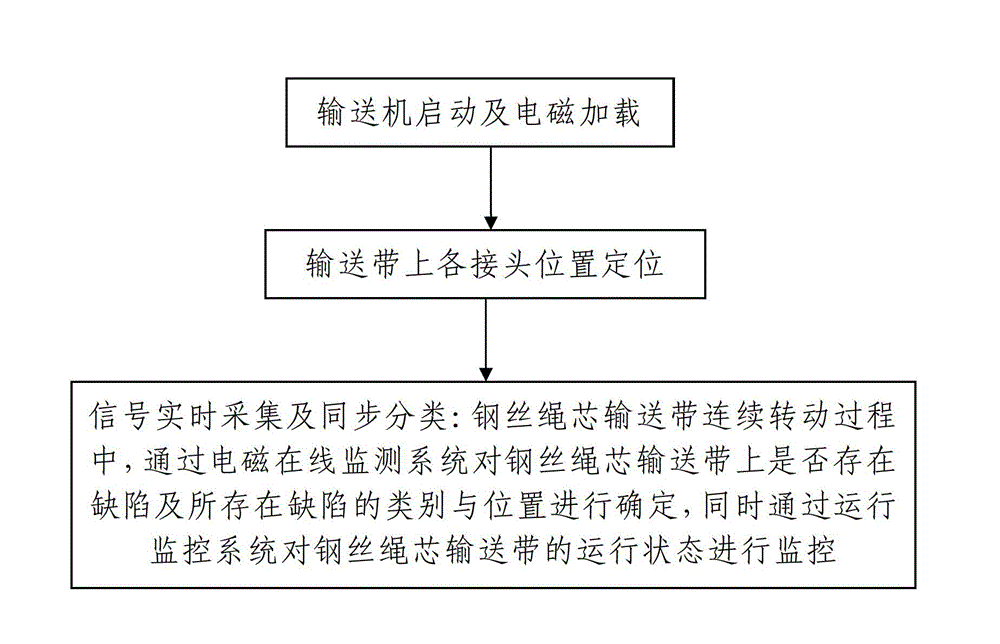

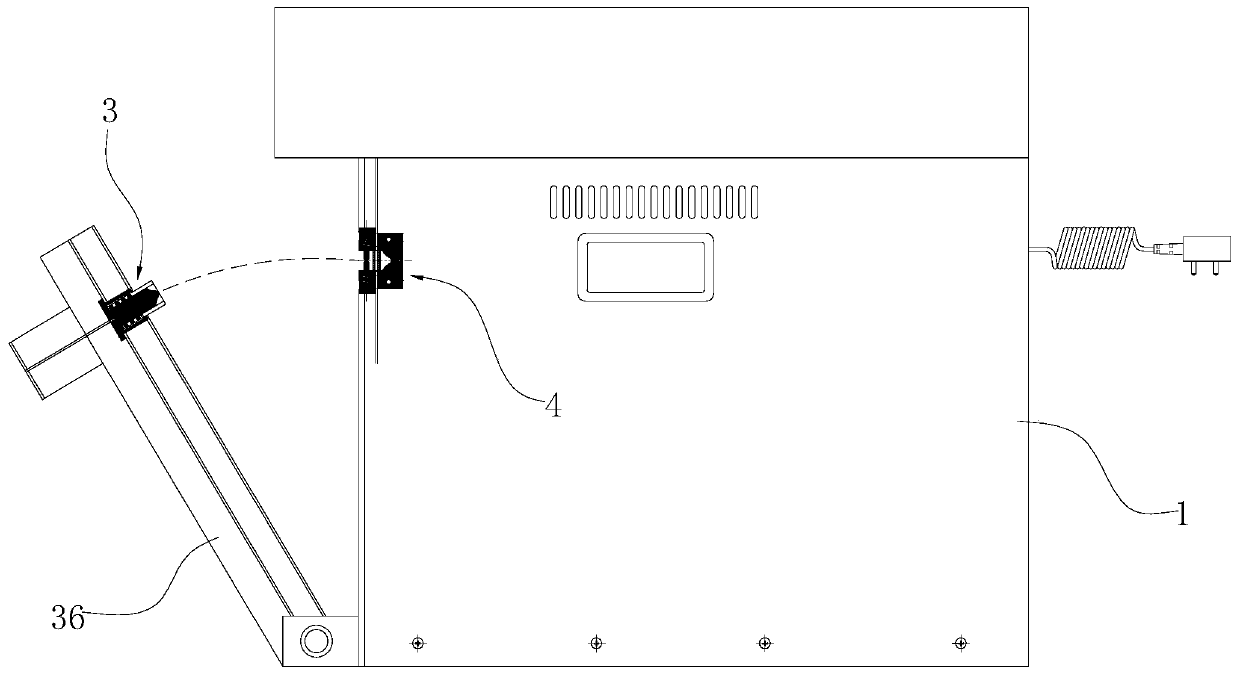

System and method for intelligently monitoring belt-type conveyer for coal mine steel wire rope core

ActiveCN103144937AReasonable designEasy wiringControl devices for conveyorsMonitoring systemEngineering

The invention discloses a system and a method for intelligently monitoring a belt-type conveyer for a coal mine steel wire rope core. A monitoring platform of the monitoring system comprises a variable frequency control system, a running monitoring system for monitoring the running state of a steel wire rope core conveying belt and an electromagnetic online monitoring system for monitoring whether a defect is existent in the steel wire rope core conveying belt or not and the type and the position of the existent defect. The monitoring method comprises the steps as follows: 1, starting the conveyer and electromagnetically loading; 2, positioning the connectors on the conveying belt; and 3, acquiring signals in real time and synchronously classifying the signals, namely in the continuous rotation process of the steel wire rope core conveying belt, whether the defect is existent in the steel wire rope core conveying belt or not and the type and the position of the existent defect are determined by the electromagnetic online monitoring system, and the running state of the steel wire rope core conveying belt is monitored by the running monitoring system at the same time. The system and the method are reasonable in design, simple and convenient to use and operate, convenient to realize, good in using effect and high in practical value, and integrate the functions of variable frequency control, running monitoring and electromagnetic online monitoring.

Owner:XIAN UNIV OF SCI & TECH

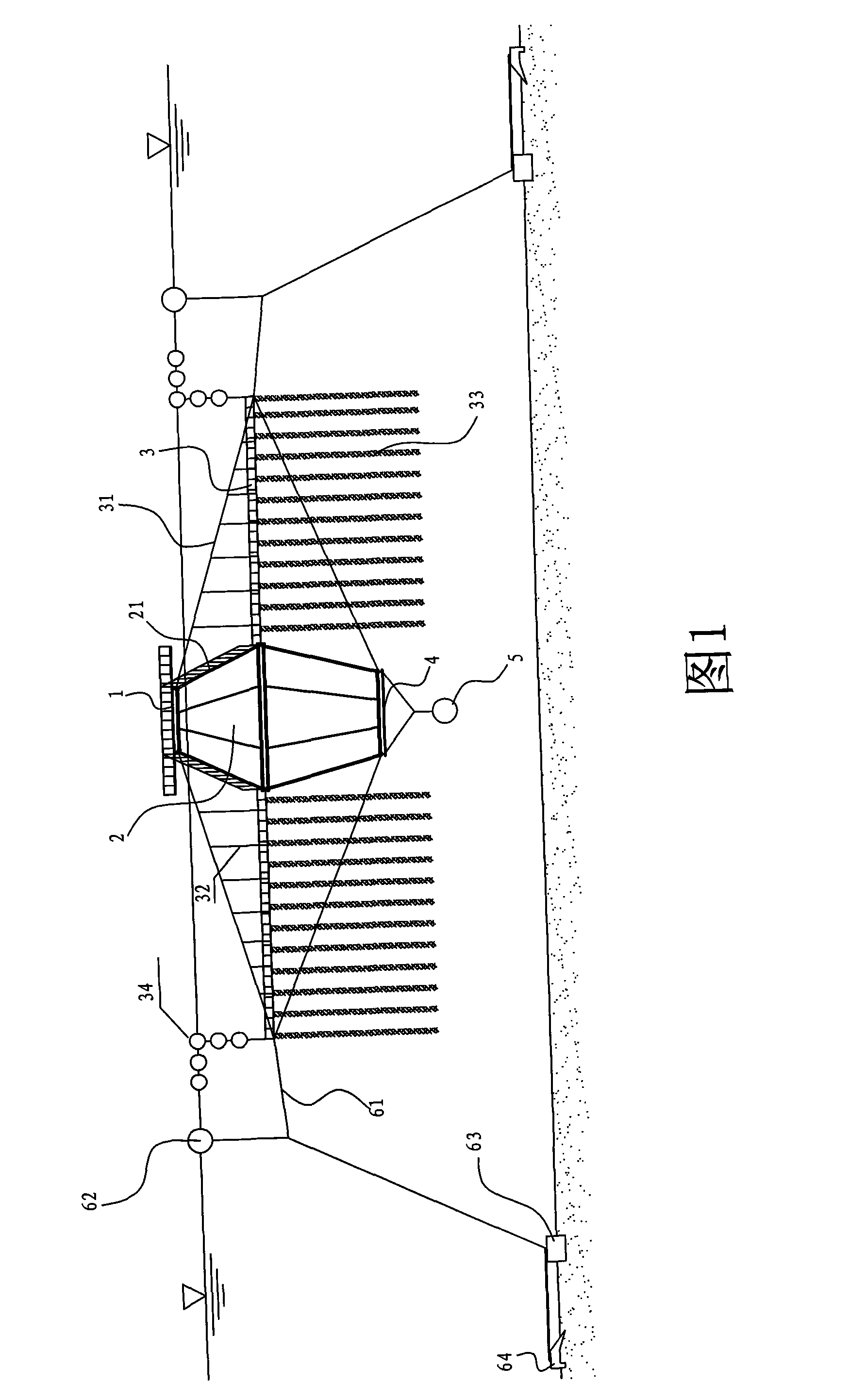

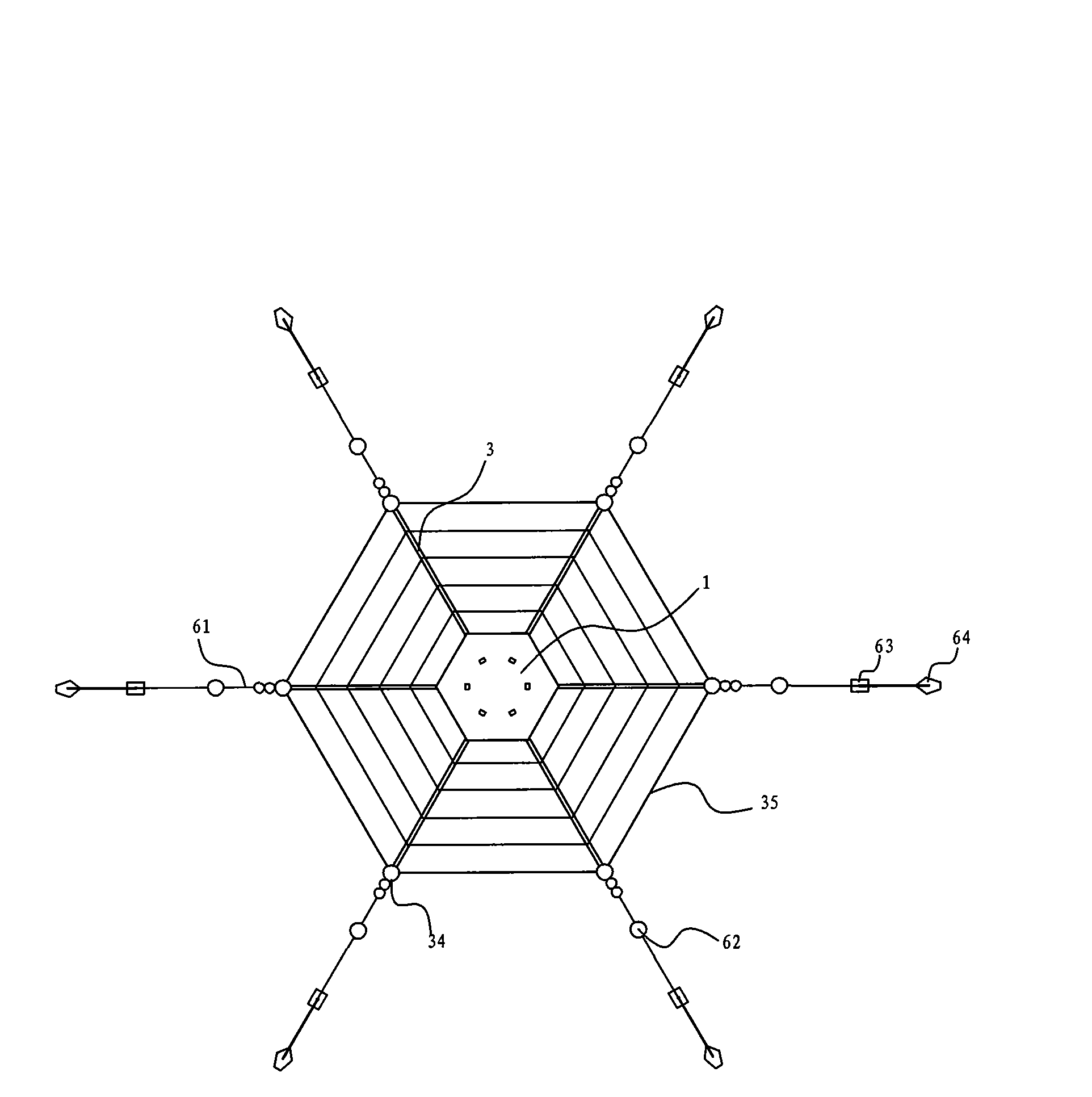

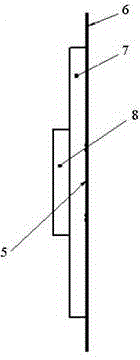

One-piece large raft culturing device

InactiveCN101491207AEasy to operateImprove stabilityClimate change adaptationPisciculture and aquariaRaft cultureEngineering

The invention discloses an integrated large-scale raft type culture device. The culture device comprises a body and a fixed berthing device for fixing the body, wherein the body comprises a PE float of which the top is provided with a working platform, and at least six cantilevers connected with the side of the PE float. The PE float has a cavity; the cantilevers are radially arranged along the side of the PE float; an I-shaped steel bar is connected with the bottom end of the PE float; and a weight is connected with a cable on the underside of the I-shaped steel bar. The culture device has the advantages that: the device has a lower integral center and good stability, and realizes the function of controlling the culture water level conveniently; in addition, the culture device has simple operation, great culture space and high production efficiency; and the operating personnel can walk and patrol on the device so as to conveniently find out hidden dangers and carry out the harvest operation. The integrated large-scale raft type culture device has a reasonable structure, good stability, high culture efficiency, convenient patrol and harvest, and simple water level control.

Owner:ZHEJIANG OCEAN UNIV

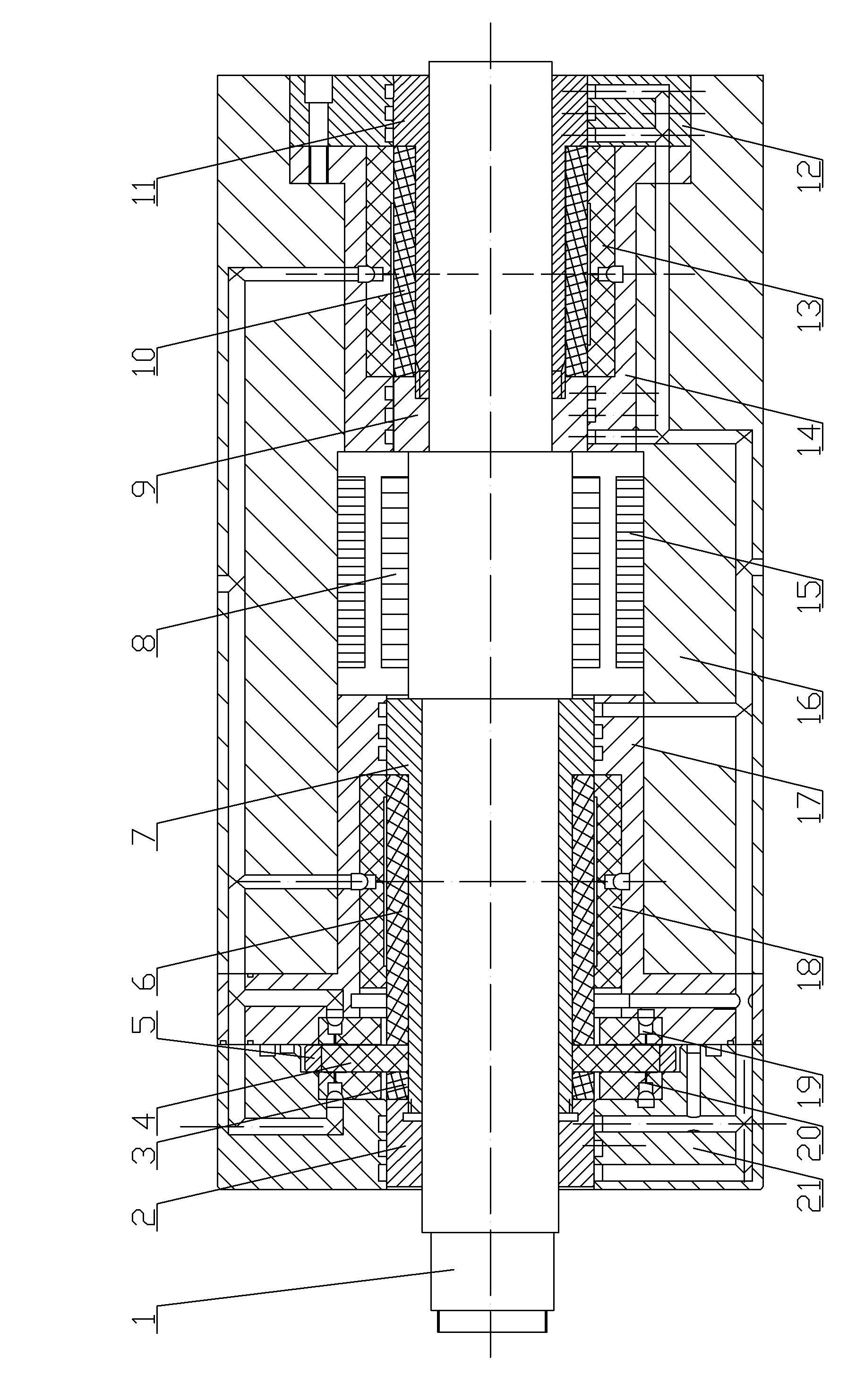

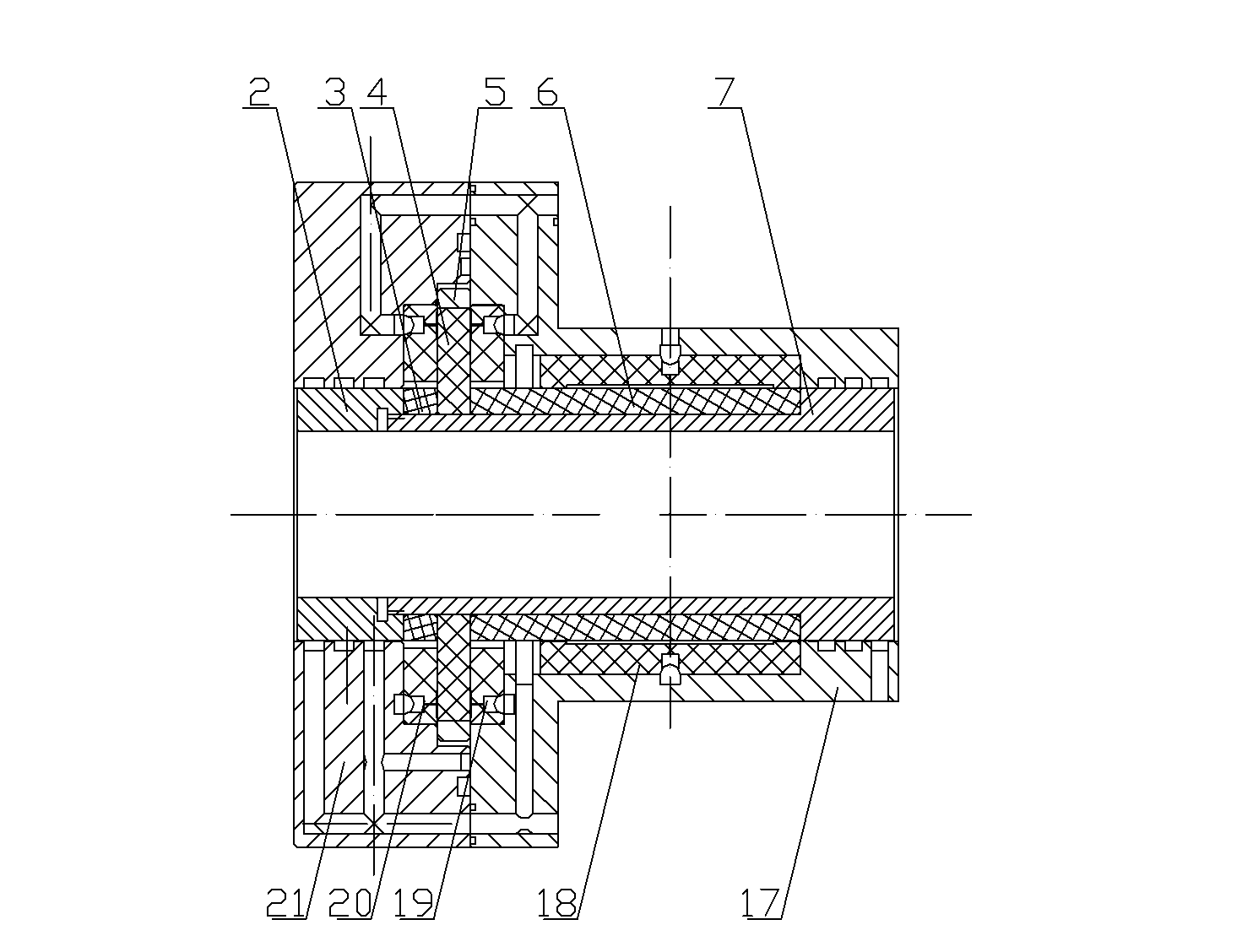

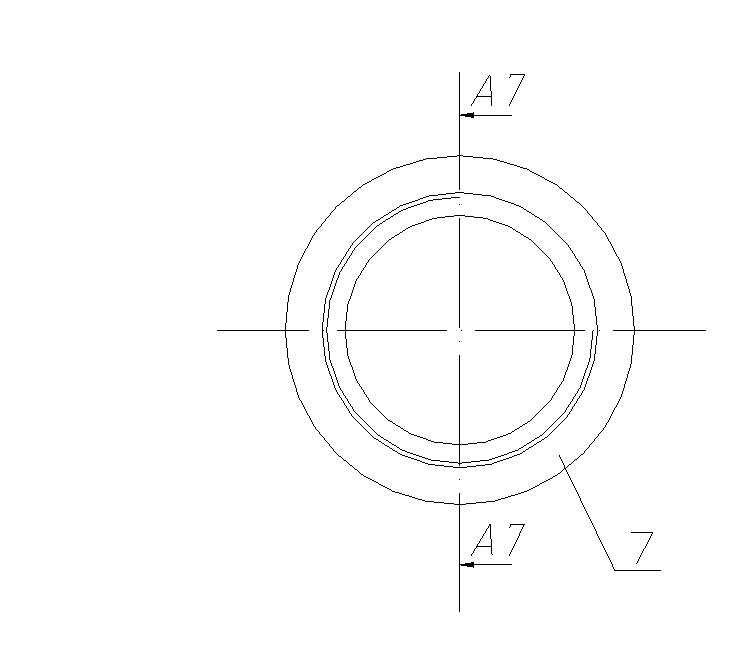

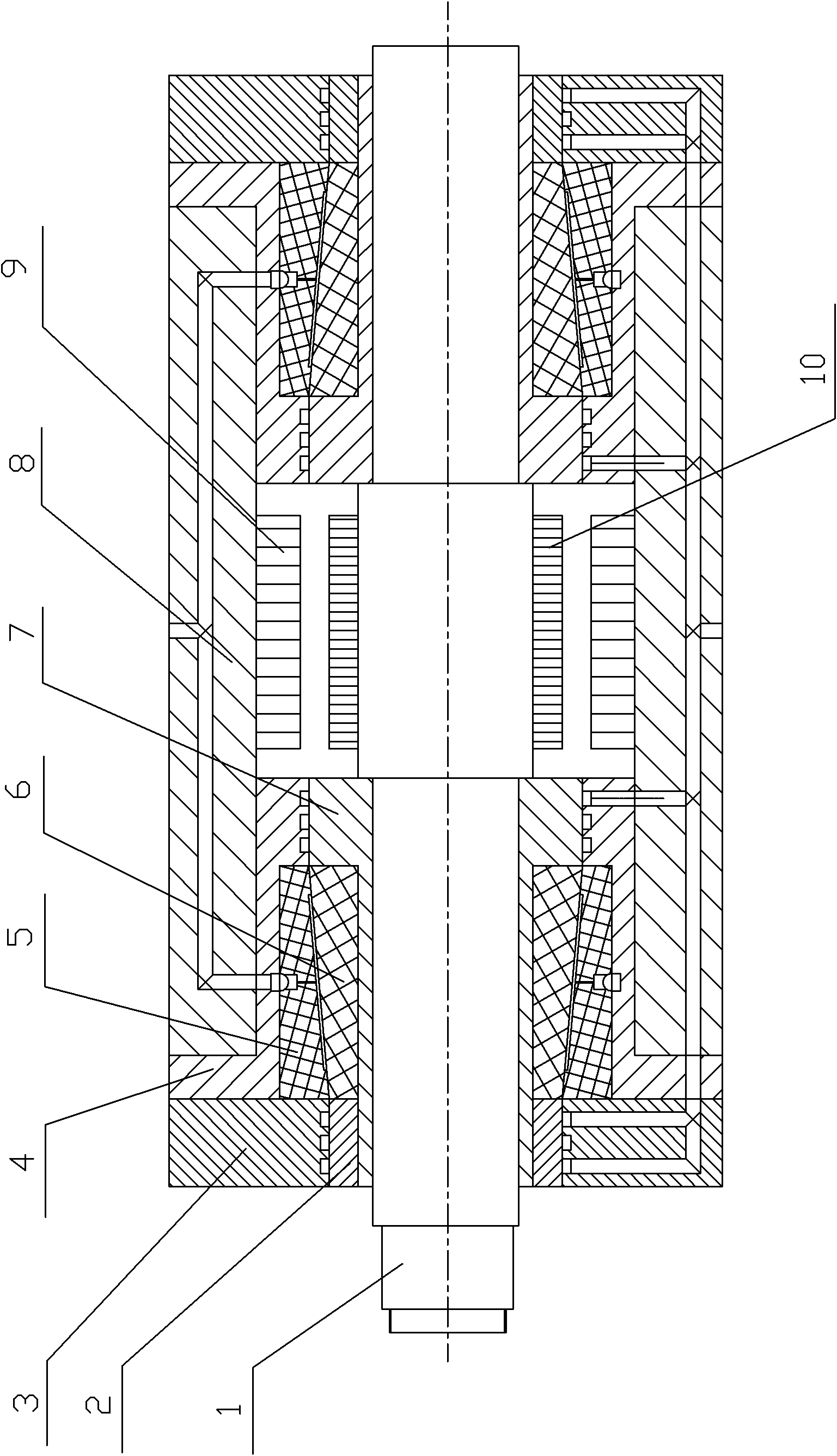

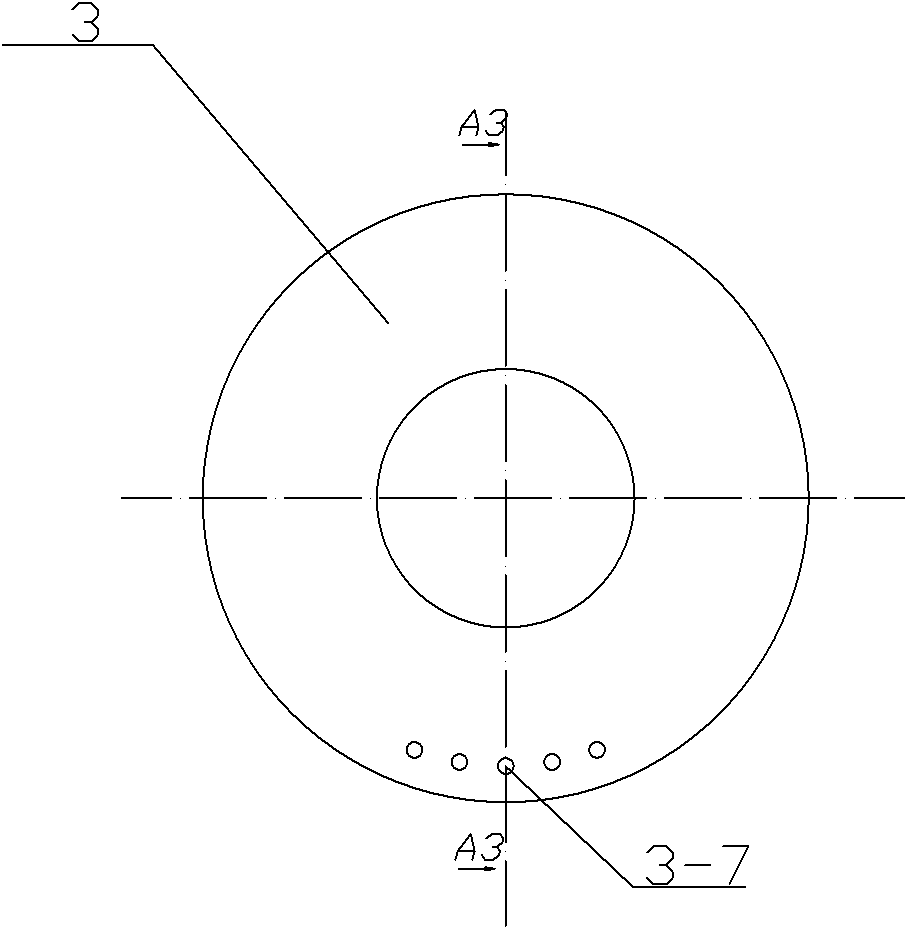

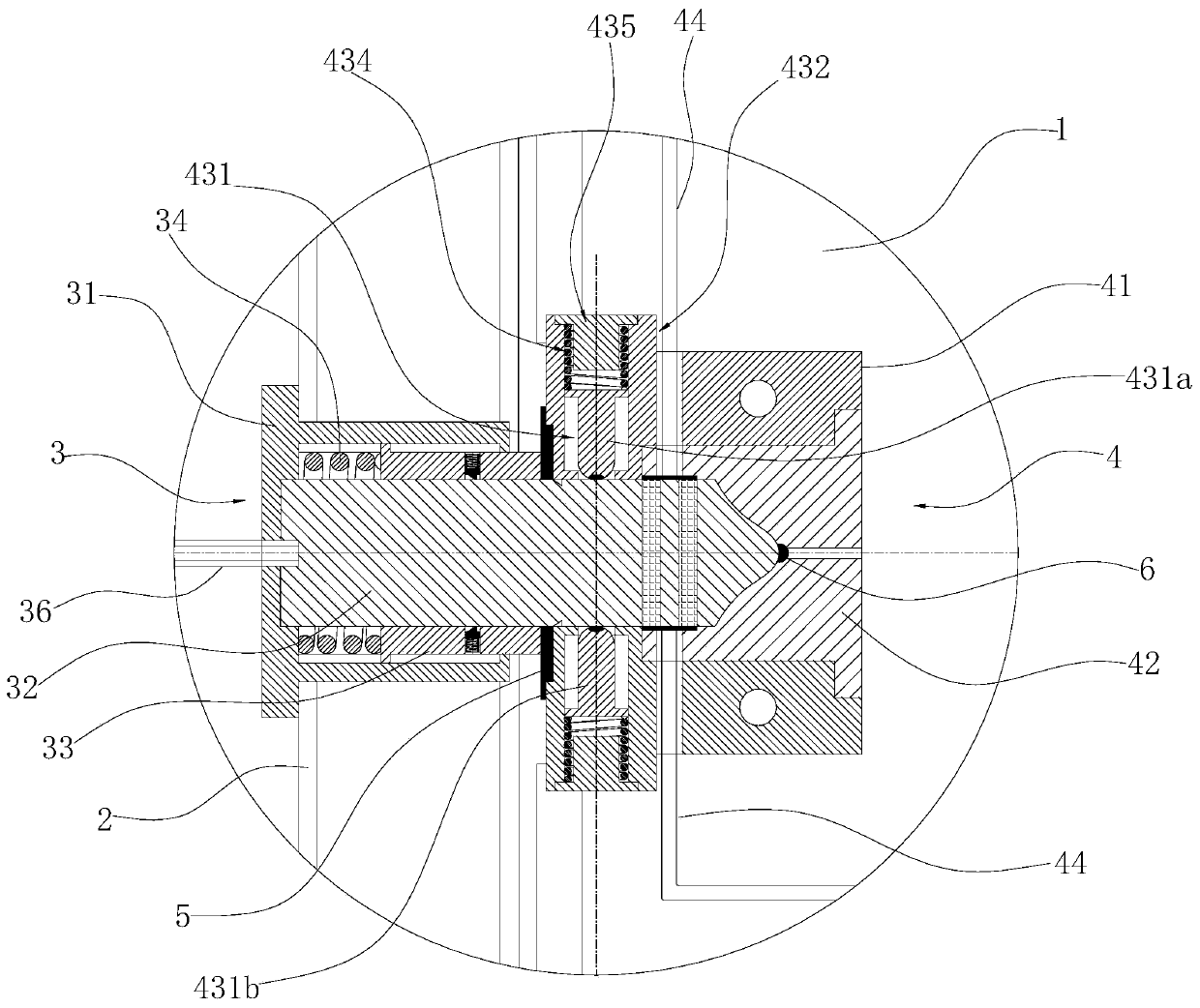

A precision dynamic and static pressure ceramic spindle device

InactiveCN102266951AIncrease speedIncreased operating lifeMaintainance and safety accessoriesThrust bearingEngineering

The invention discloses a precise type dynamic and static pressure ceramic main shaft device. A front radial-bidirectional thrust bearing is mounted at the front end of a main shaft, and a back radial bearing is mounted at the back end of the main shaft. The front radial-bidirectional thrust bearing comprises a front main shaft lining. A front ceramic right shaft sleeve, a thrust ceramic shaft sleeve, a front ceramic left shaft sleeve and a front shaft sleeve end cover are assembled at the external part of the front main shaft lining. A thrust shaft sleeve lining is assembled at the externalpart of the thrust ceramic shaft sleeve. A radial ceramic bearing bush, a left thrust ceramic bearing brush, a right thrust ceramic bearing brush, a front bearing brush lining and a front bearing brush end cover are mounted on a stand. The back radial bearing comprises a back main shaft lining. A back ceramic shaft sleeve and a back shaft sleeve end cover are assembled on the back main shaft lining. A back bearing brush end cover, a back ceramic bearing brush and a back bearing brush lining are mounted on the stand. The edge of a ceramic part can be protected by the precise type dynamic and static pressure ceramic main shaft device, so that the impact resistance is enhanced; the strength of a radial-thrust combined bearing is enhanced; the processibility of the ceramic part is enhanced, and the finished product ratio is increased; and the sealing property of the main shaft is enhanced.

Owner:TIANJIN UNIV

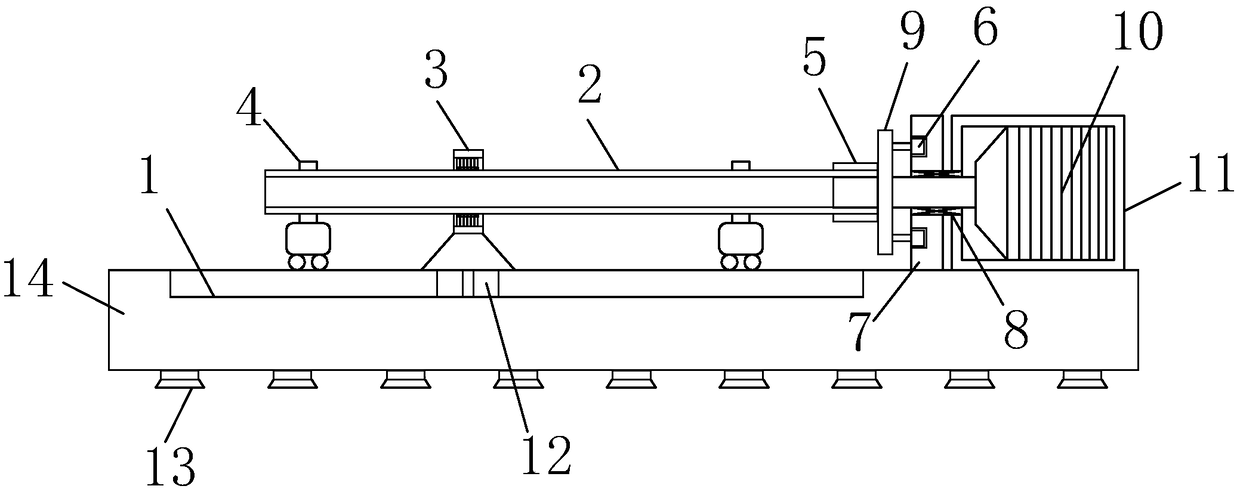

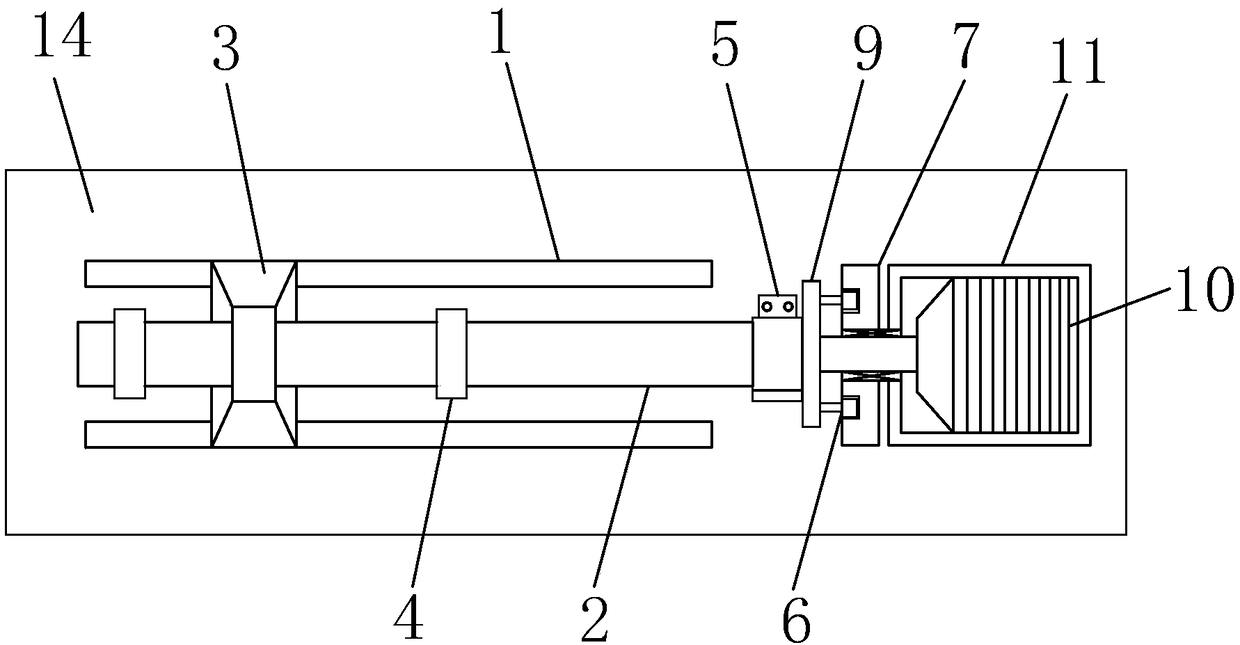

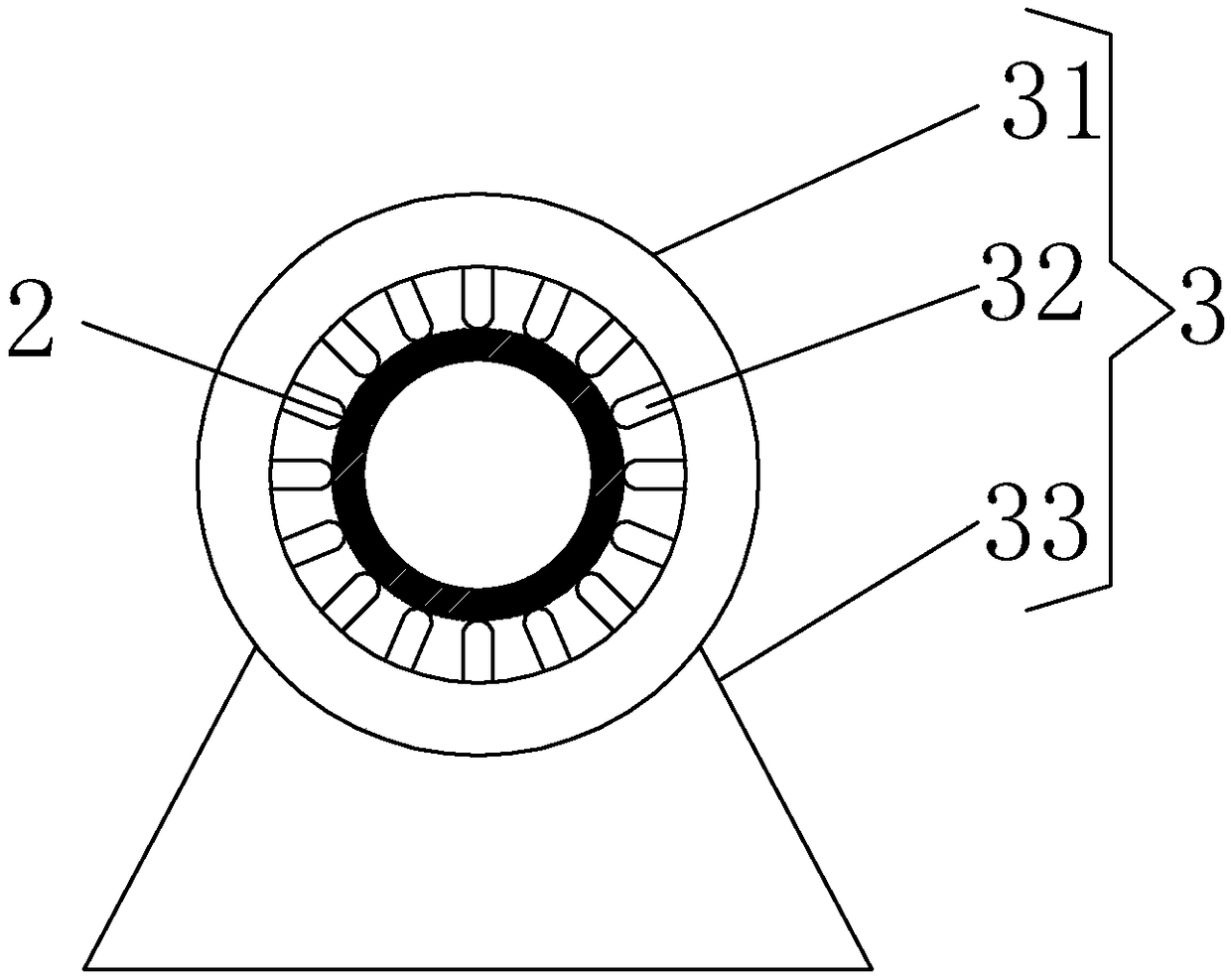

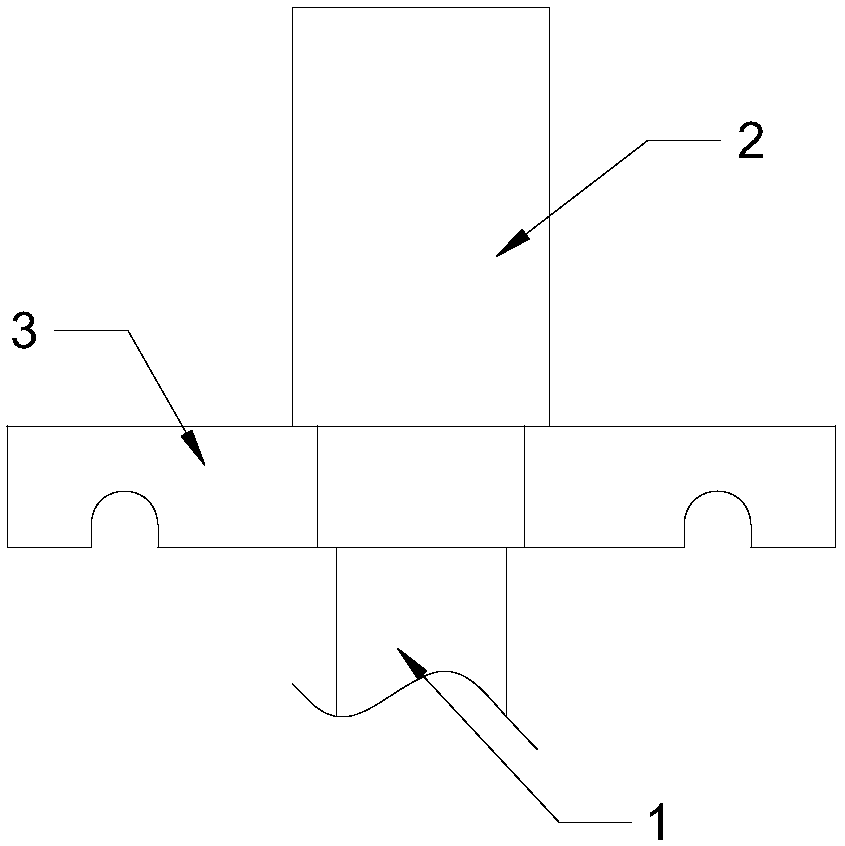

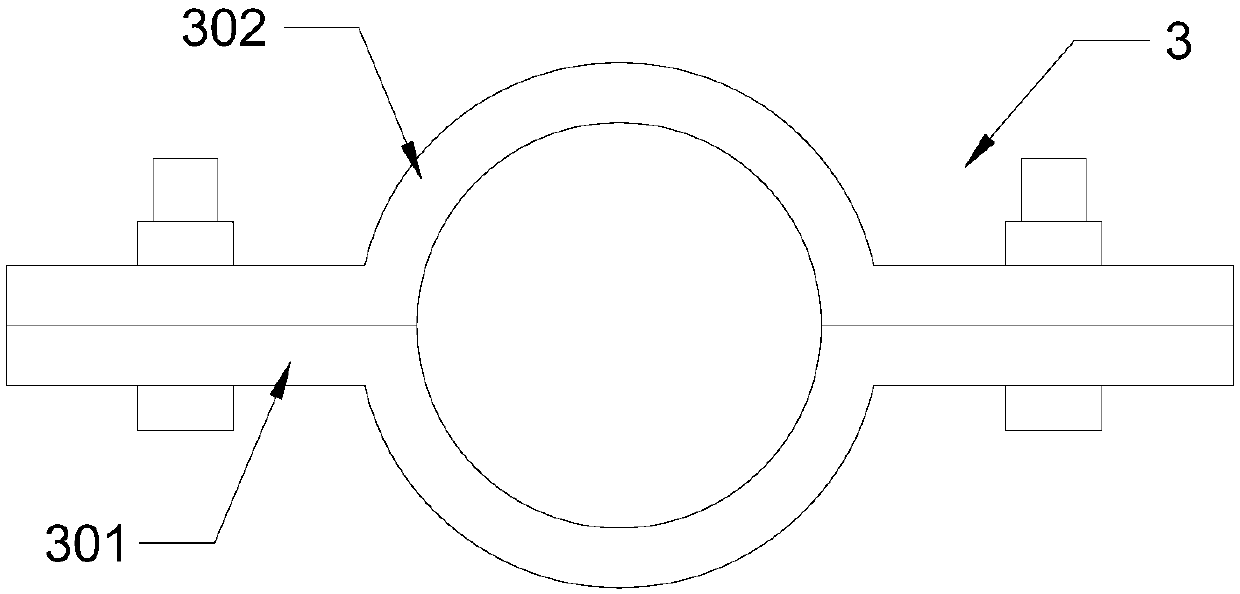

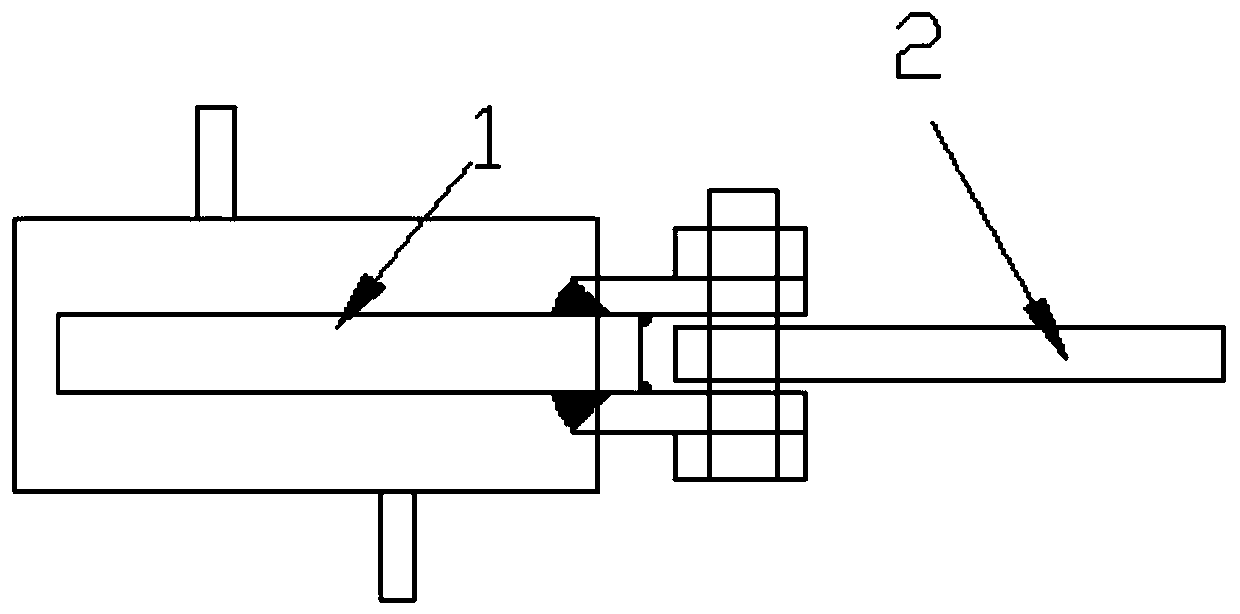

Steel pipe grinding device

InactiveCN109108743AStable clampingImprove grinding effectGrinding carriagesRevolution surface grinding machinesArchitectural engineeringMachining

The invention relates to the technical field of steel pipe machining, in particular to a steel pipe grinding device. The steel pipe grinding device comprises a workbench. A motor box is fixedly mounted on one side of the upper end of the workbench. A quick motor is arranged in the motor box. A bearing plate is vertically mounted at the upper end of the workbench. A bearing is mounted between the motor box and the middle of the bearing plate. Two connecting mechanisms are arranged on one side of the bearing plate. A circular plate is fixedly mounted at the tail end of an output shaft of the quick motor, and the two connecting mechanisms are arranged between one side of the circular plate and the bearing plate. A clamping mechanism is arranged on the other side of the circular plate, and a standard steel pipe part is fixed through the clamping mechanism. A plurality of supporting mechanisms are movably arranged between the standard steel pipe part and the upper end of the workbench. A grinding mechanism is further movably arranged on the outer side of the standard steel pipe part, and two sliding mechanisms are arranged between the lower end of the grinding mechanism and the upper end of the workbench. The steel pipe grinding device is stable in structure, good in steel pipe grinding effect and high in safety.

Owner:温州市宇田钢管有限公司

Electric salvage device

ActiveCN103924940AIncrease salvage areaIncrease success rateBorehole/well accessoriesEngineeringReducer

An electric salvage device comprises clamping jaws, a pull rod, a salvage cylinder body, a lower adaptor, pins, compressed springs, a protective cylinder, a screw, a fixing threaded sleeve, a sheath, a planetary speed reducer, a direct-current motor and an upper adaptor. The upper adaptor is in threaded connection with the sheath, the sheath is in threaded connection with the lower adaptor, the lower adaptor is in threaded connection with the inner periphery of the salvage cylinder body, the outer periphery of the salvage cylinder body is in threaded connection with the upper portion of the protective cylinder, the inside of the sheath is provided with the direct-current motor, the planetary speed reducer and the fixing threaded sleeve from top to bottom, the peripheral side of the lower portion of the protective cylinder is provided with four symmetric clamping jaw grooves, the four clamping jaws connected through the pins are arranged in the clamping jaw grooves, the compressed springs are arranged between the upper portions of the clamping jaws and the protective cylinder, center holes are formed in the fixing threaded sleeve, the lower adaptor and the salvage cylinder body respectively, the screw and the pull rod are arranged in the center holes, the screw and the pull rod are in threaded connection, the pull rod extends to the inner upper portion of the clamping jaws, the direct-current motor is connected with the planetary speed reducer, and the planetary speed reducer is connected with the screw, and therefore the electric salvage device is formed.

Owner:DONGYING XINJI PETROLEUM TECH

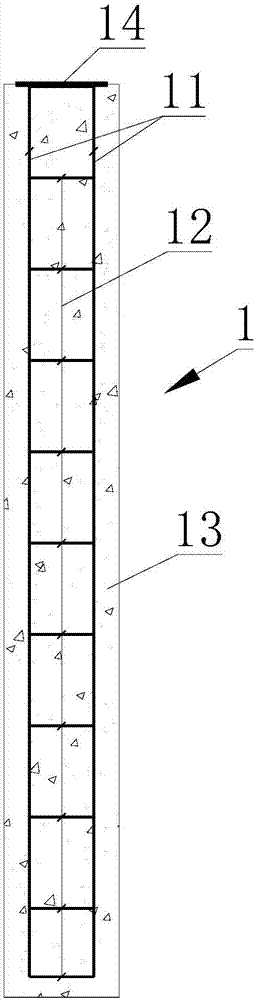

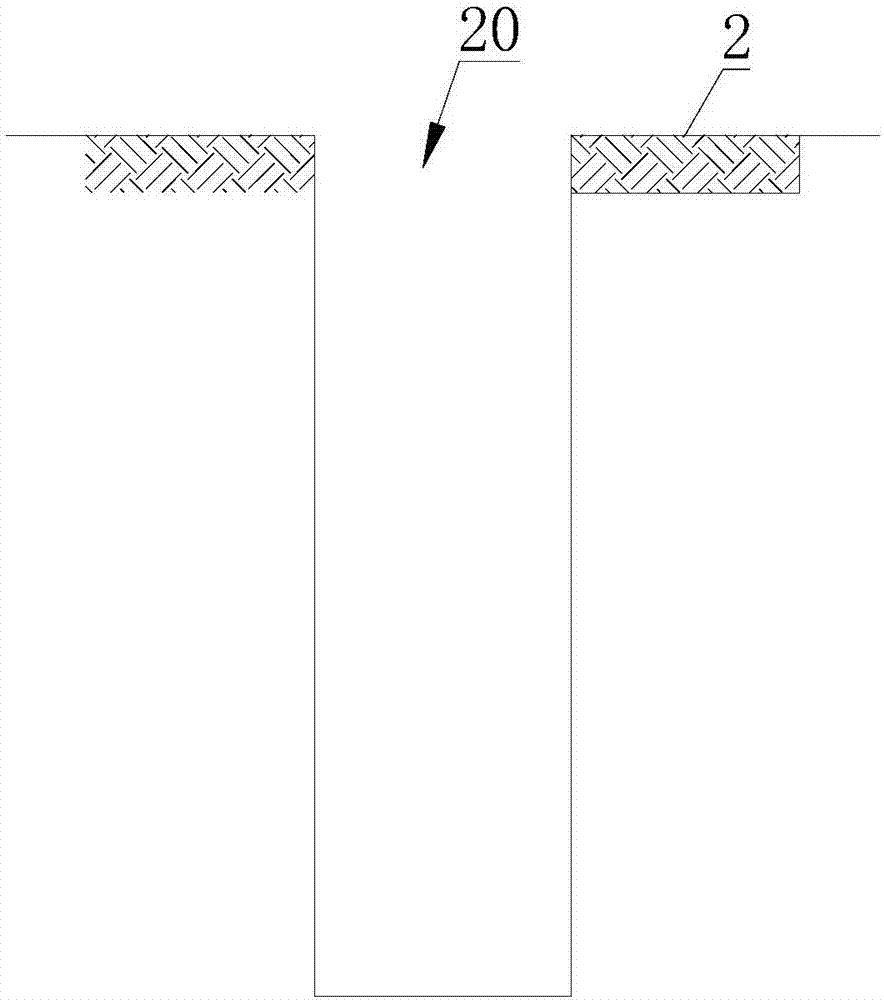

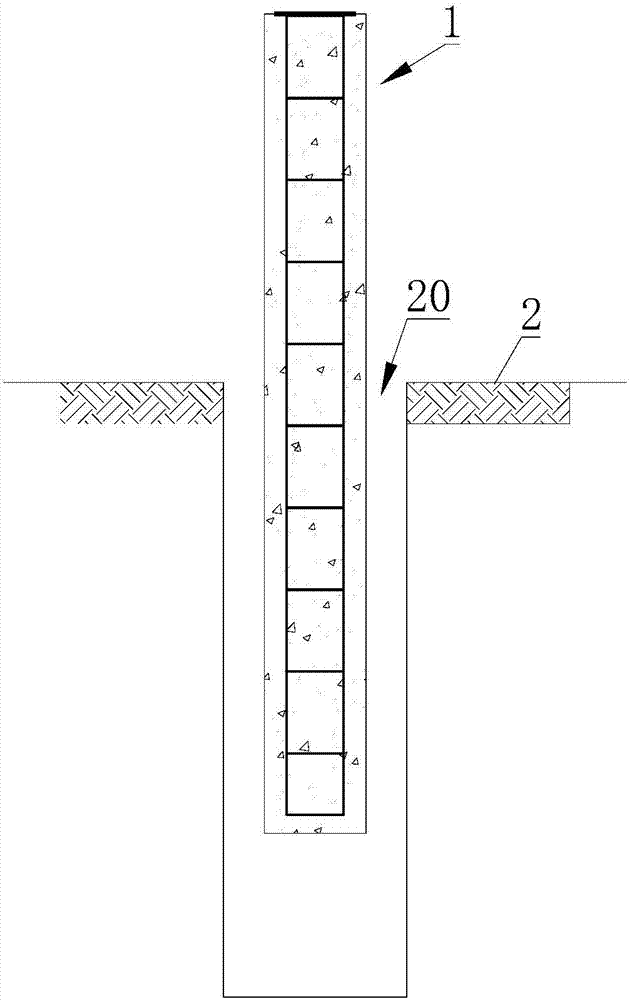

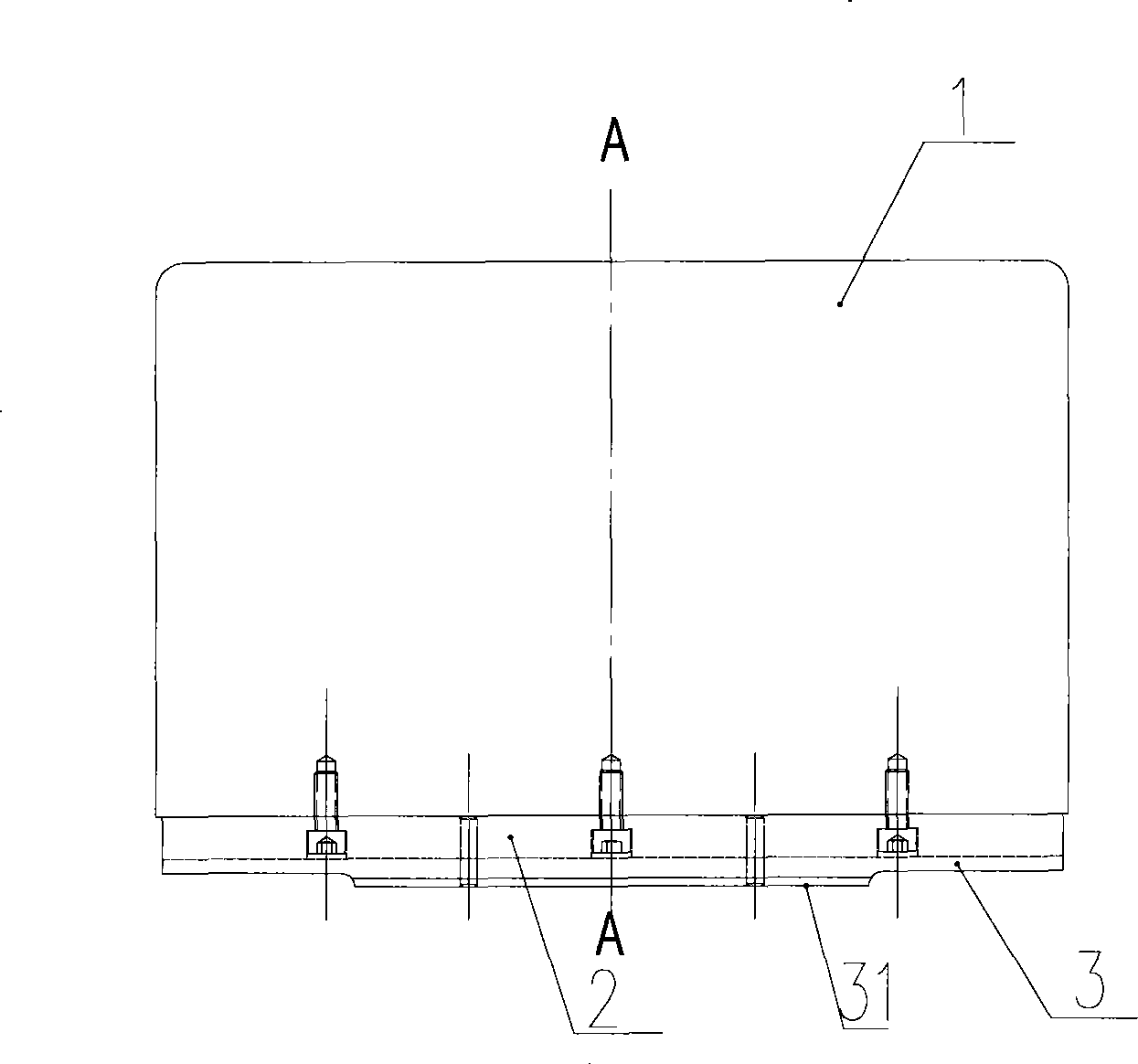

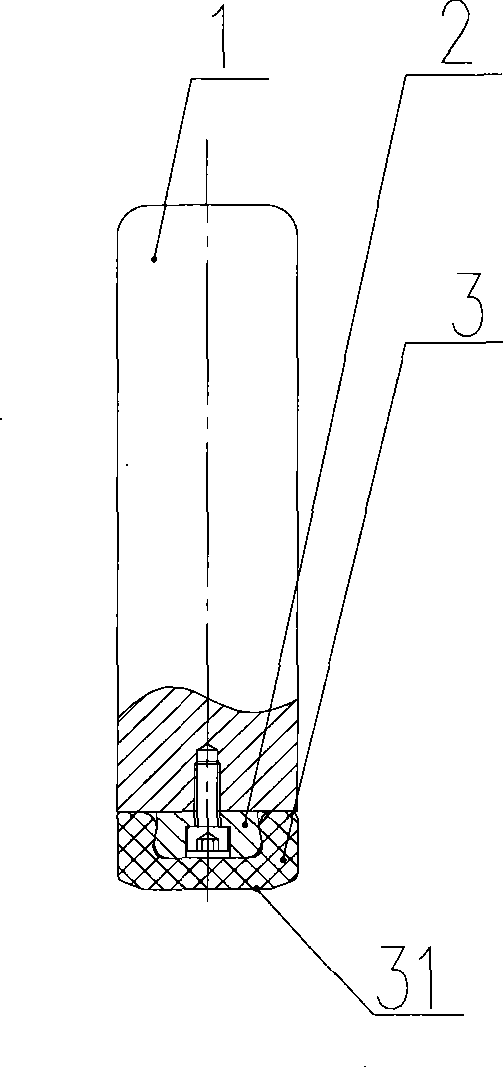

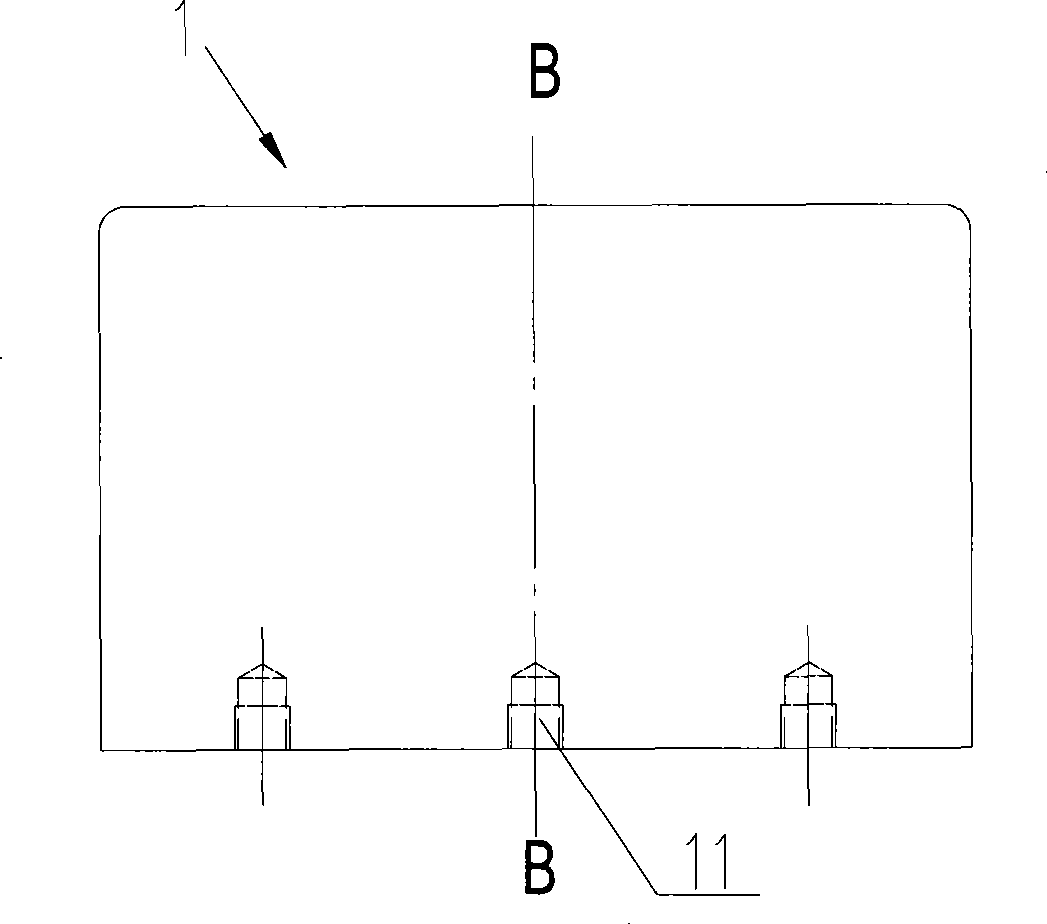

Foundation pile for photovoltaic bracket in frozen soil area and manufacturing method thereof

PendingCN107310022AQuality improvementShort maintenance timeCeramic shaping plantsBulkheads/pilesEngineeringHardness

The invention provides a foundation pile for a photovoltaic bracket in a frozen soil area and a manufacturing method thereof, and belongs to the photovoltaic technical field. The manufacturing method comprises the following steps in sequence: (A) a prefabricated pile body is manufactured at the construction site; and a hole is drilled in the mounting area of the foundation pile; (B) the precast pile body is put in the hole; and (C) fine stone concrete is injected in a gap between the precast pile body and the hole wall for grouting and solidification. The quality is more reliable; the curing time after casting of a cast-in-place pile can be saved to accelerate the construction progress; the accident of breakage of a precast pile foundation caused by excessive hardness of frozen soil is prevented; the purpose of reducing damage to the precast pile body by the frost heaving force of the frozen soil is achieved; and the safety of the pile body is protected.

Owner:山东腾晖电力技术有限公司

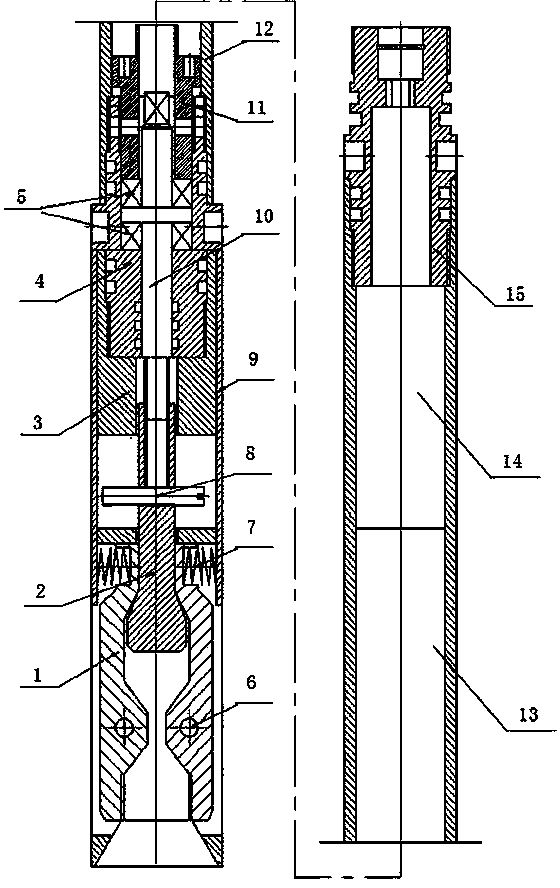

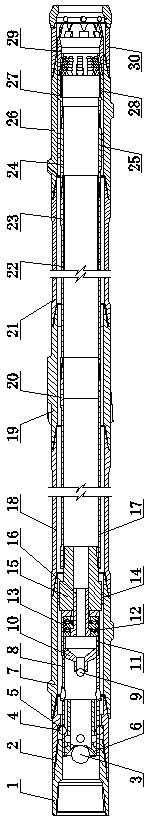

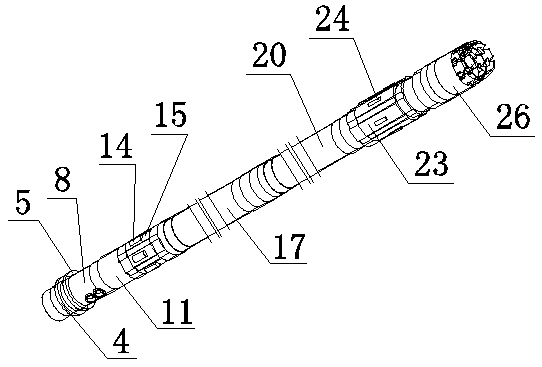

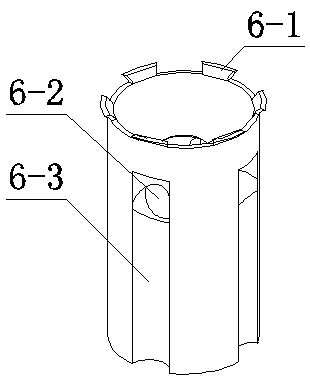

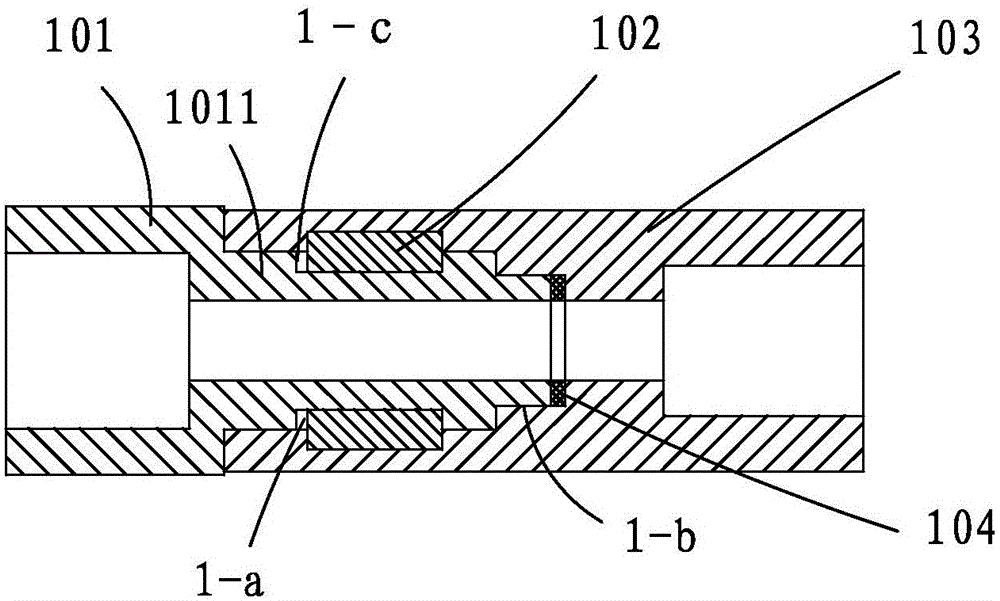

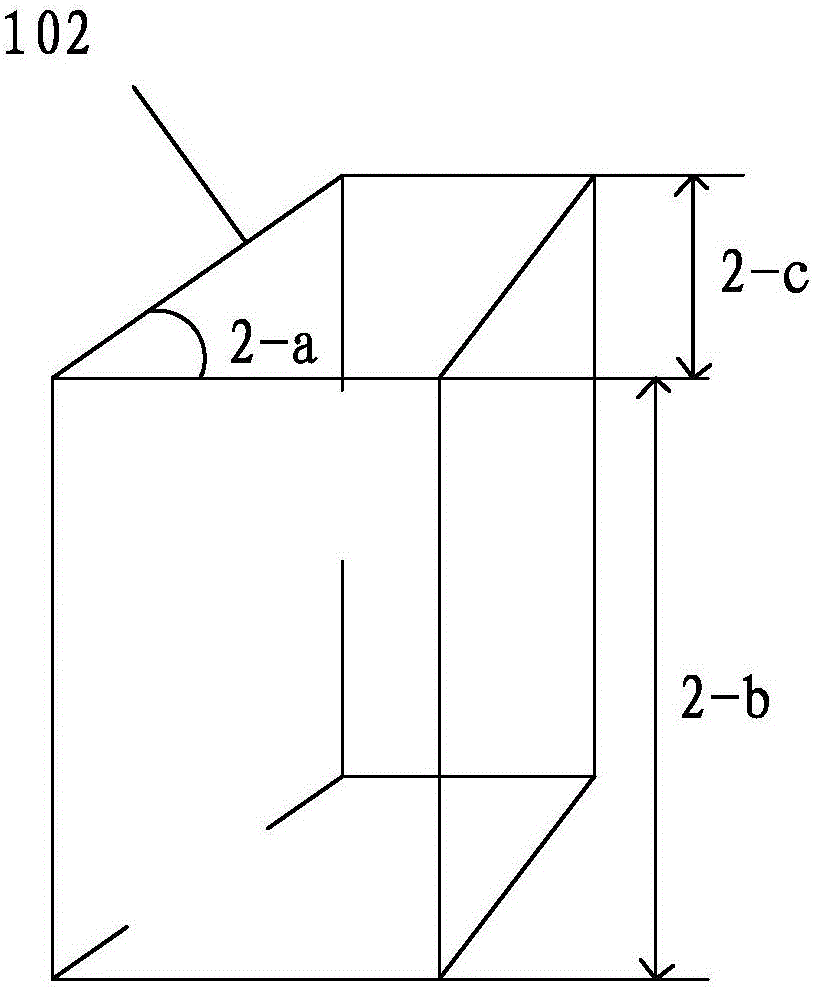

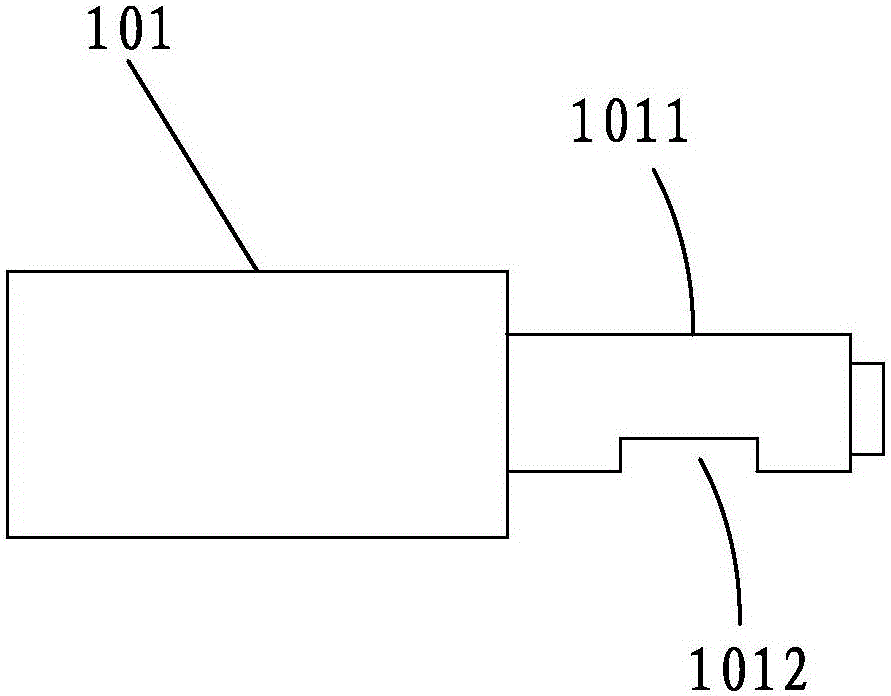

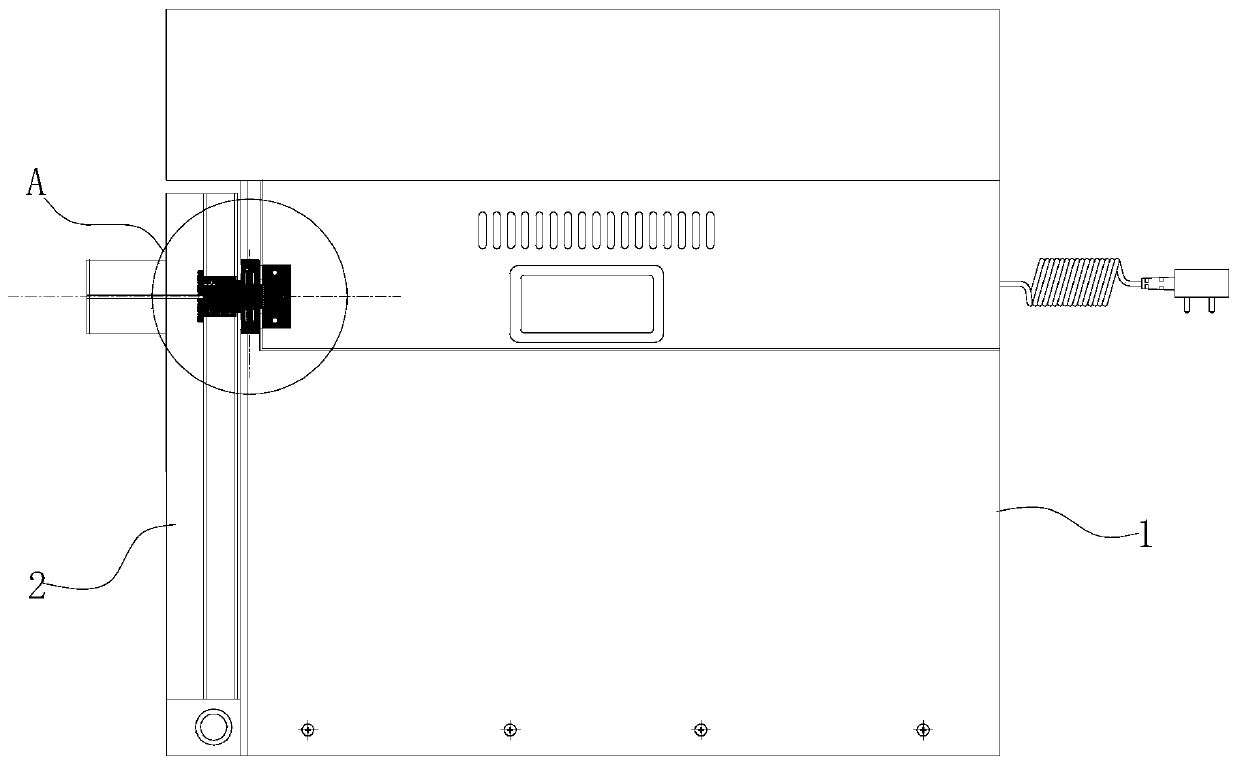

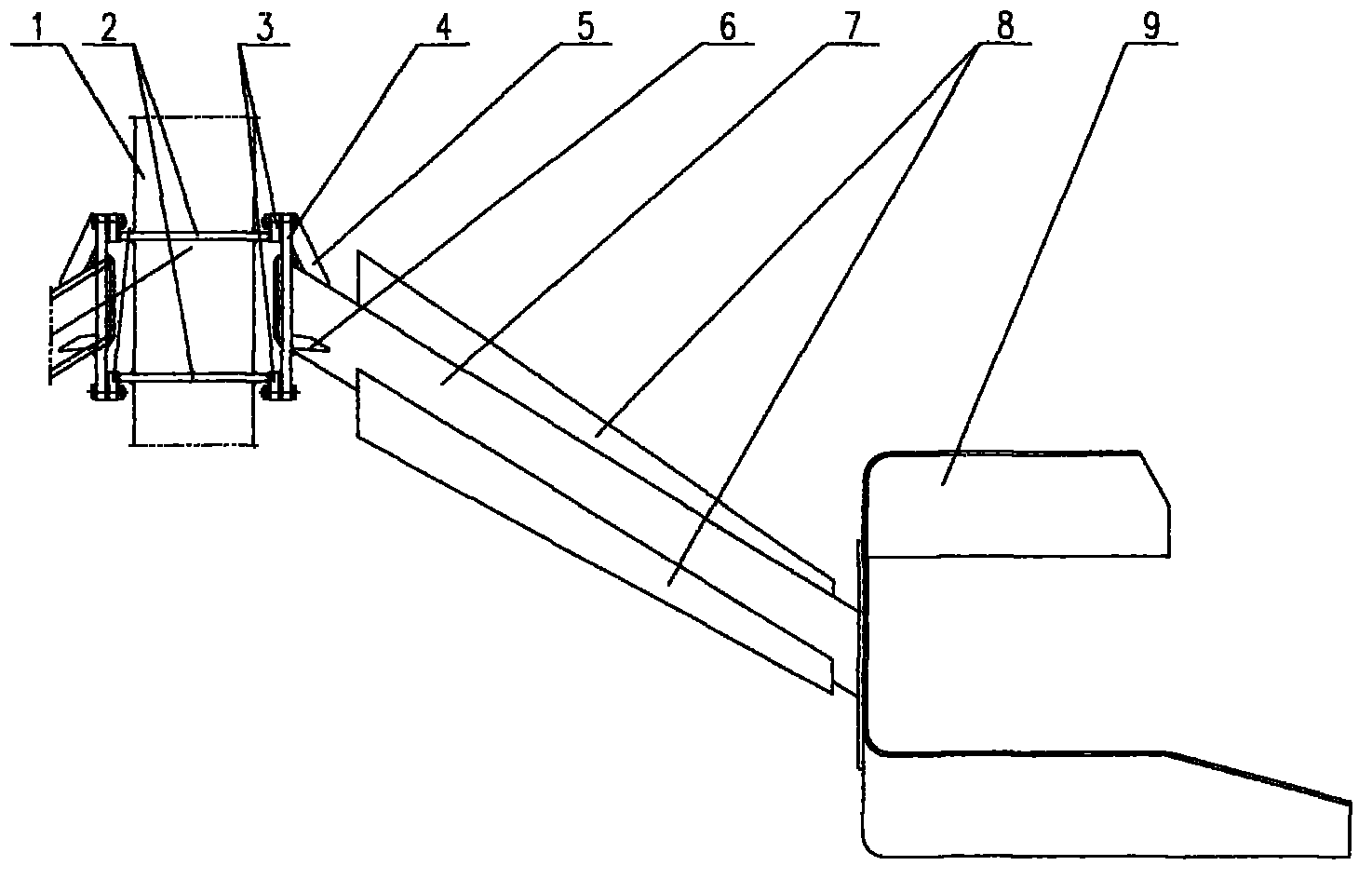

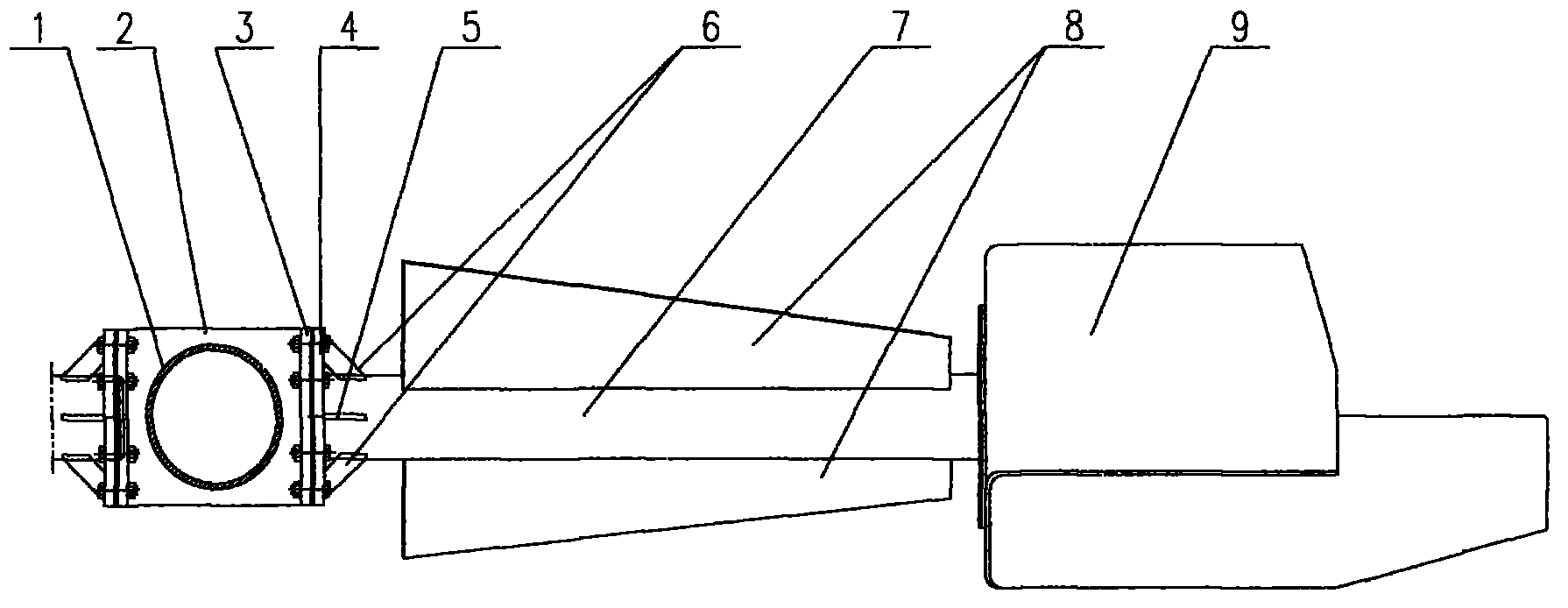

Hydraulic-driving coring tool for complex well

ActiveCN108952610AAvoid stuck core accidentsAvoid breaking accidentsCore removalRock coreEngineering

The invention relates to a hydraulic-driving coring tool for a complex well, and belongs to the technical field of oil drilling exploitation down-hole tools. The hydraulic-driving coring tool is formed by an inner rock core cylinder assembly, an outer rock core cylinder assembly and the like; the outer rock core cylinder assembly is composed of an upper connector, a safety connector, an upper spiral centralizer, a middle spiral centralizer, a lower spiral centralizer, a first-section outer rock core cylinder and a second-section rock core cylinder; the inner rock core cylinder assembly is composed of an inner-cylinder upper shaft, a first-section inner rock core cylinder, a second-section inner rock core cylinder and a dual-layer aluminum alloy liner; a bearing hanging steel ball is hung on an inner shoulder of the safety connector through a ball hanging runway, a clamping sleeve ball base is installed on a hanging assembly, centering of the inner cylinder is guaranteed through an inner-cylinder centralizing mechanism, and the hydraulic-driving coring tool is suitable for large-inclined-well coring; a rock-core-claw assembly is composed of a necking sleeve, a clamp-type rock core claw and a clamping-plate rock core claw, in a soft formation, the hanging steel ball and a ball hole of the clamping sleeve ball base are aligned and slide into the clamping sleeve ball base, the hanging assembly is unlocked, and a rock core is cut off through the clamping-plate rock core claw; in a hard formation, pressure of the inner cylinder is increased and subjected to pump suffocation, a drilling tool is lifted when the pressure reaches 16 MPa, and the rock core is clamped and pulled off through the clamp-type rock core claw. The hydraulic-driving coring tool is suitable for core cutting operation under different geological conditions.

Owner:YANGTZE UNIVERSITY

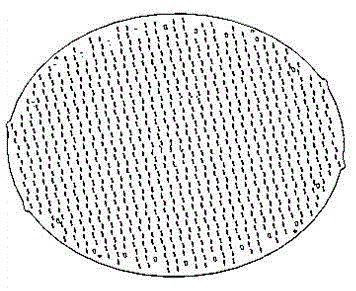

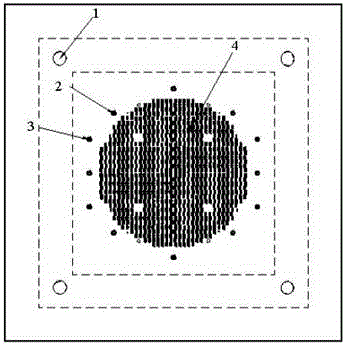

Method for producing millimeter wave antenna slot array sheet

InactiveCN103331471AAvoid clamping deformationReduce stressMilling equipment detailsEngineeringMaterials processing

The invention discloses a method for producing a millimeter wave antenna slot array sheet. The production method selects tooling equipment suitable for clamping a large-area super-thin sheet, can be used for realizing the reliable clamping of a slot array sheet during high-speed machining by matching with a corresponding clamping pressure plate and a reasonable clamping method, and reasonably selects a micro-diameter cutting tool formed by machining a corresponding material as well as a system tool environment and related parameters which conform to the machining of a slot array so as to ensure that a high-speed and high-precision machining process can be realized. The production method can be used for realizing the production of the slot array in the large-area super-thin sheet, and the high-speed machining of high-precision multi-slot graphs.

Owner:SHANGHAI RADIO EQUIP RES INST

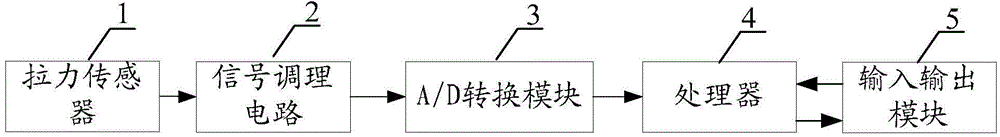

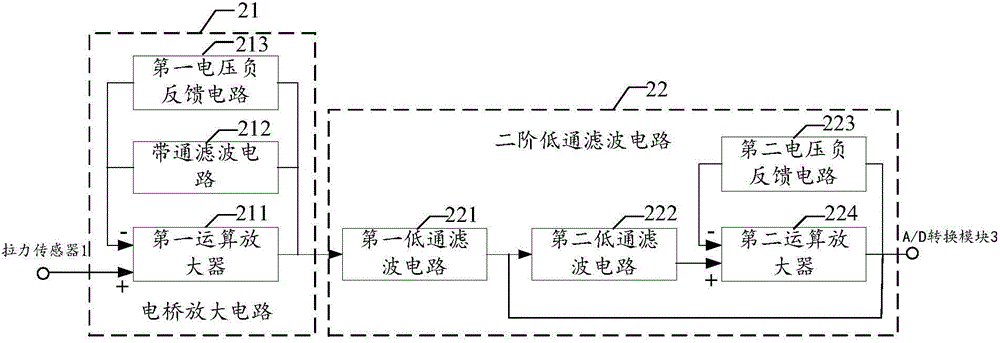

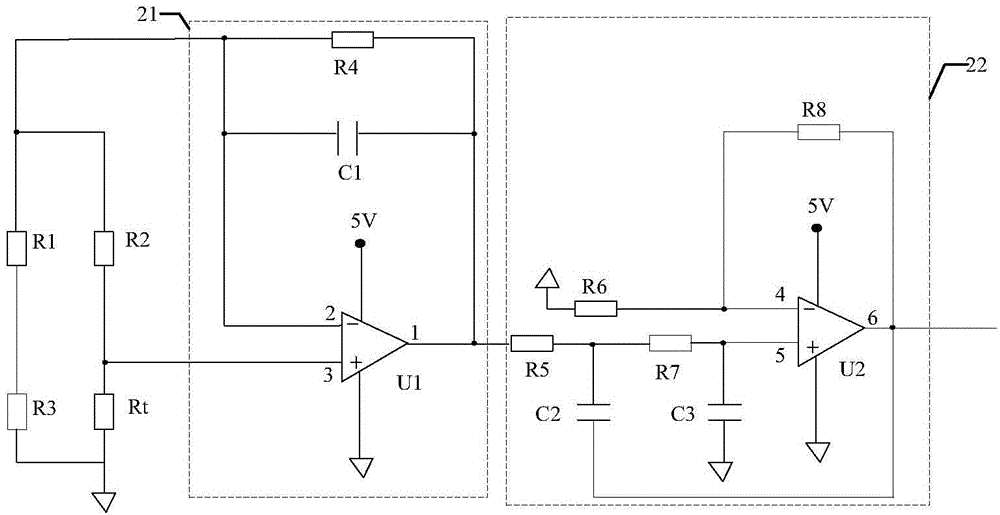

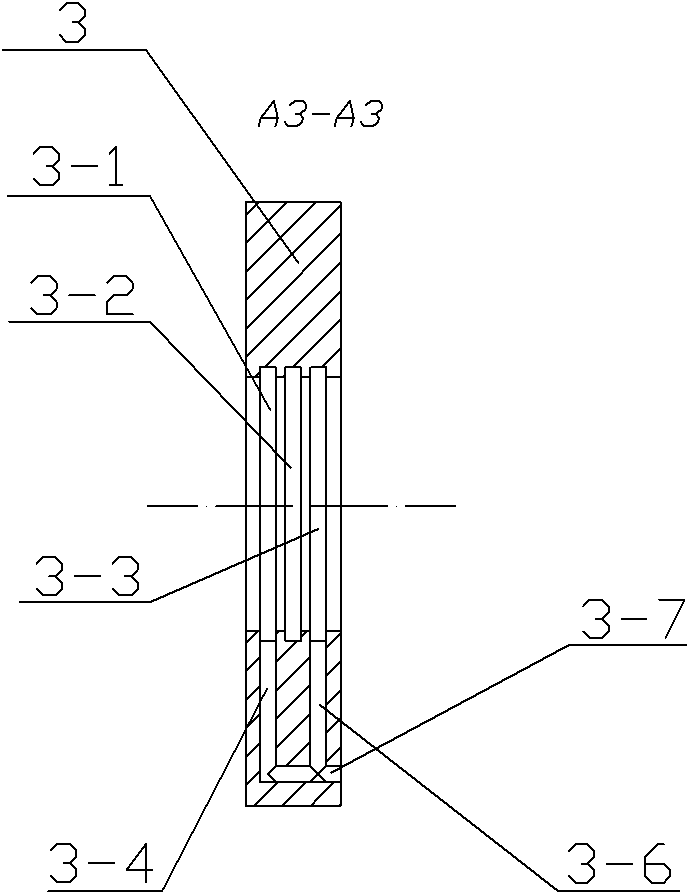

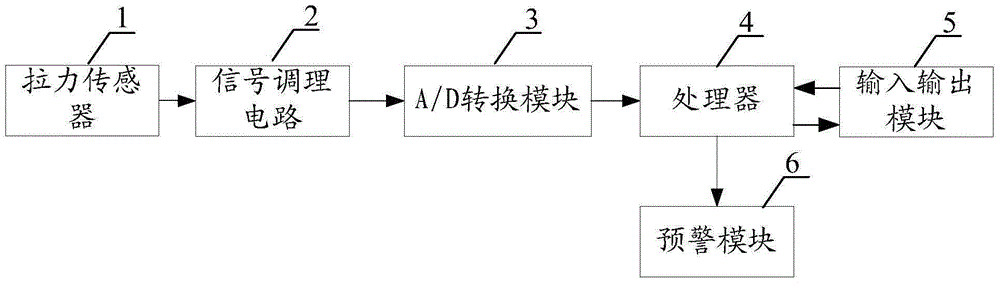

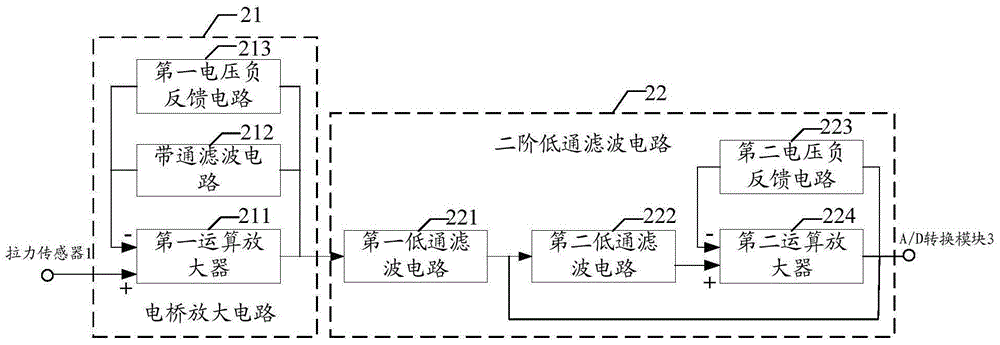

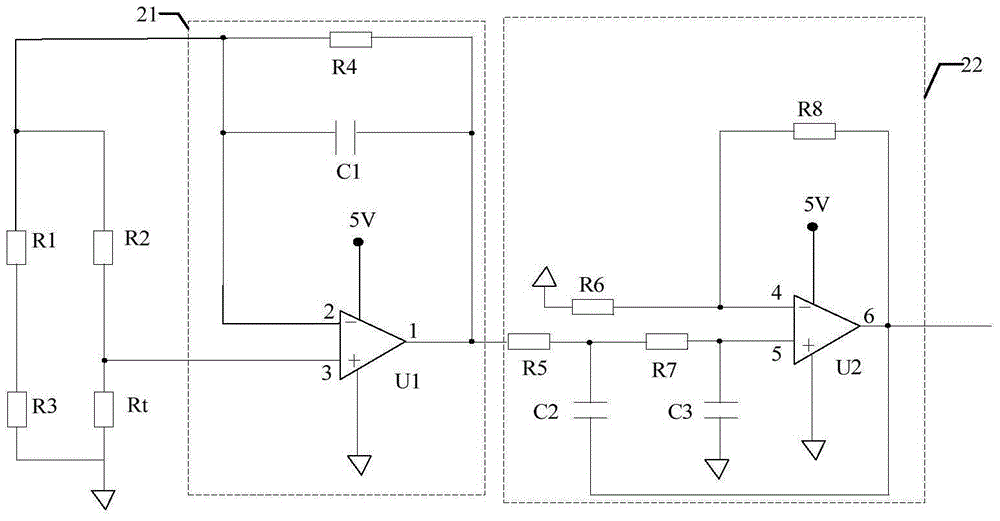

Stress measurement device and method for knob insulator

The invention provides a stress measurement device for a knob insulator. The stress measurement device comprises a tension sensor, a signal conditioning circuit, an A / D (analog / digital) conversion module, a processor and an input / output module, wherein the tension sensor collects tension of a knob insulator busbar pull wire and processes the tension into a micro-voltage signal, the amplitude and frequency of the signal are conditioned by the signal conditioning circuit, a tension value is obtained after conversion by the A / D conversion module, and the stress distribution condition and the maximum stress are obtained in the processor according to an input tension angle parameter and based on the corresponding relation of preset stress distribution and force load; when the maximum stress is larger than a preset threshold, an alarm message is displayed on the input / output module; or otherwise, the stress distribution condition is displayed on the input / output module. With implementation of the embodiment of the invention, the stress state of the knob insulator can be detected on line, and the device is simple and easy to operate and has high safety, reliability and accuracy, so that the knob insulator can be prevented from breaking accidents.

Owner:SHENZHEN POWER SUPPLY BUREAU

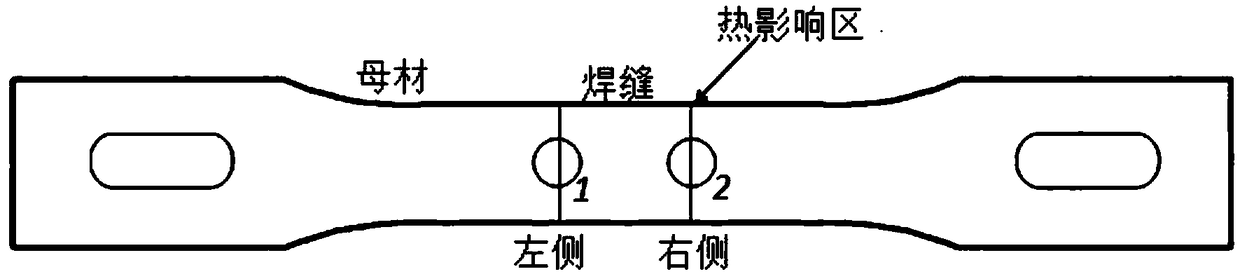

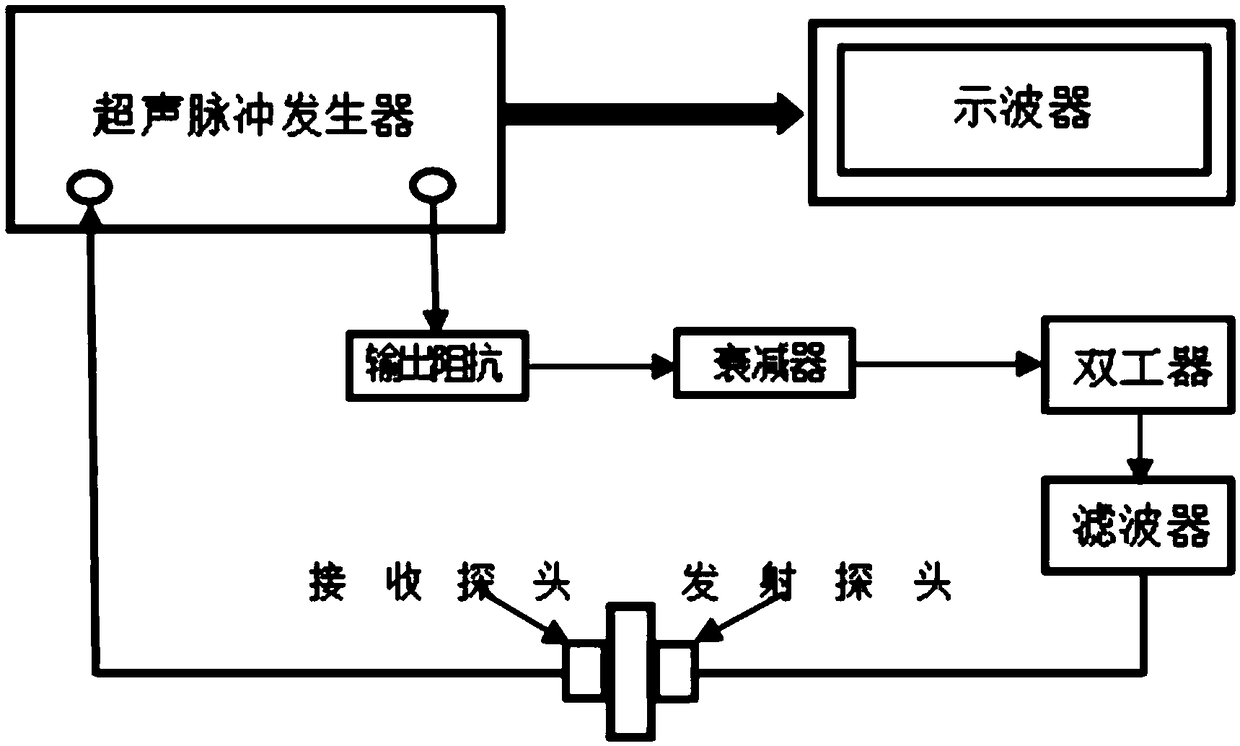

No-destructive testing method and no-destructive testing device for creep cavity damage of igh chromium martensitic heat-resistant steel joint

InactiveCN109142532AHigh sensitivityAvoid breaking accidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalHigher order harmonicsHigh energy

The invention provides a no-destructive testing method and a no-destructive testing device for creep cavity damage of a high chromium martensitic heat-resistant steel joint. The detection difficult problem of the creep cavity damage of a novel high chromium martensitic heat-resistant steel joint is solved by adopting a nonlinear ultrasonic technology. The damage degree of the joint is evaluated byusing high-order harmonics generated by interaction between high-energy radio frequency pulse and micro defects inside a material. According to the no-destructive testing method disclosed by the invention, the high-temperature creep damage degree of the high chromium martensitic heat-resistant steel joint is detected by using a nonlinear ultrasonic technology, and the quantitative relation between a creep cavity and nonlinear ultrasonic parameters is established, so that the quantitative evaluation of the creep cavity damage during the service of the novel high chromium martensitic heat-resistant steel joint is realized and further long-term safe operation of an ultra-thermal power unit is ensured.

Owner:WUHAN UNIV

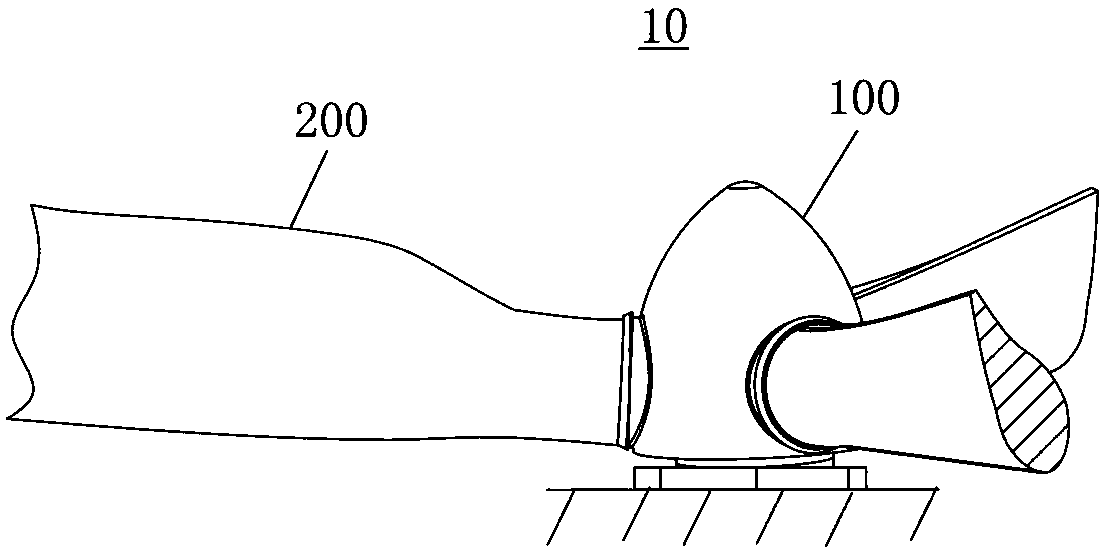

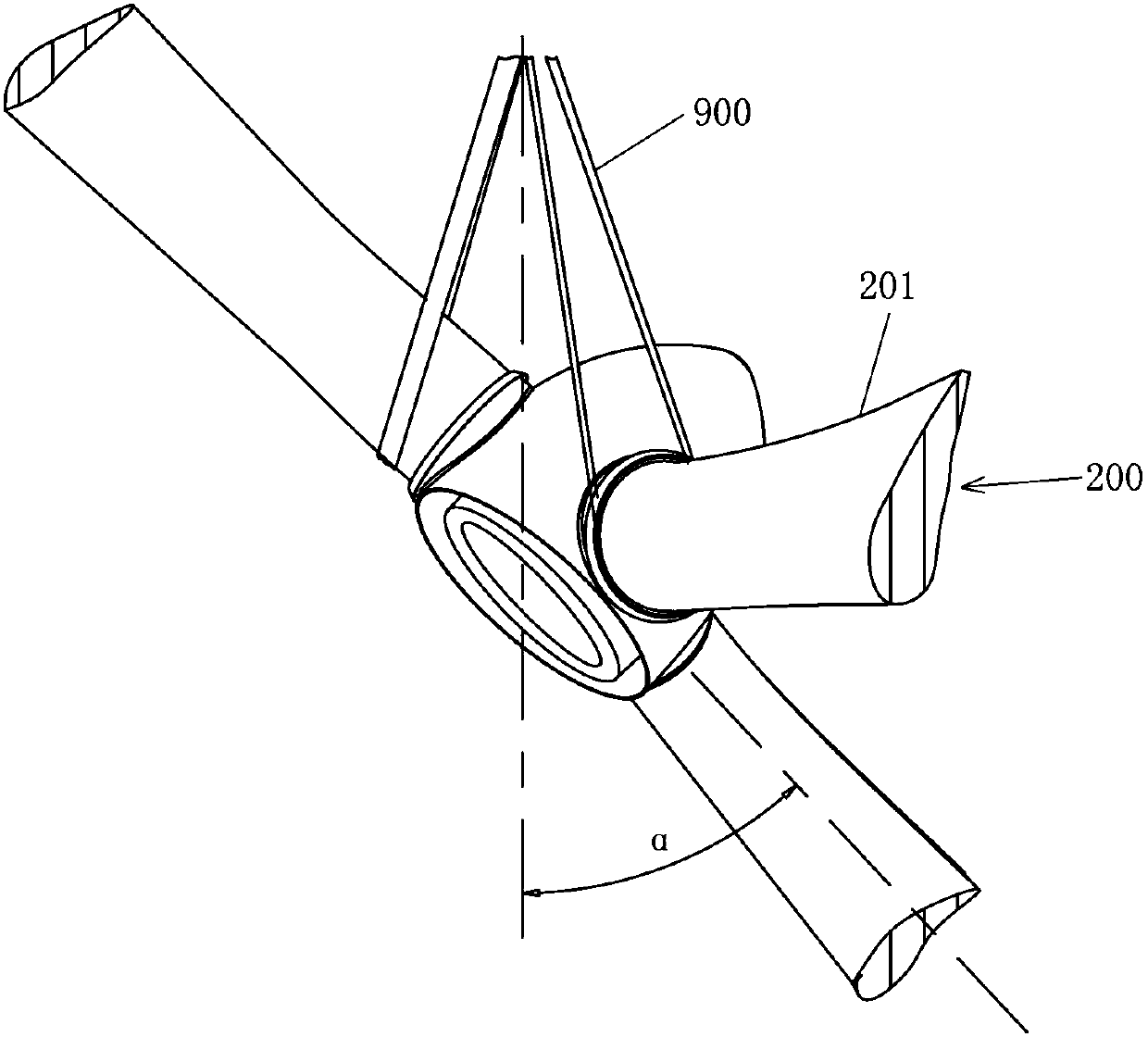

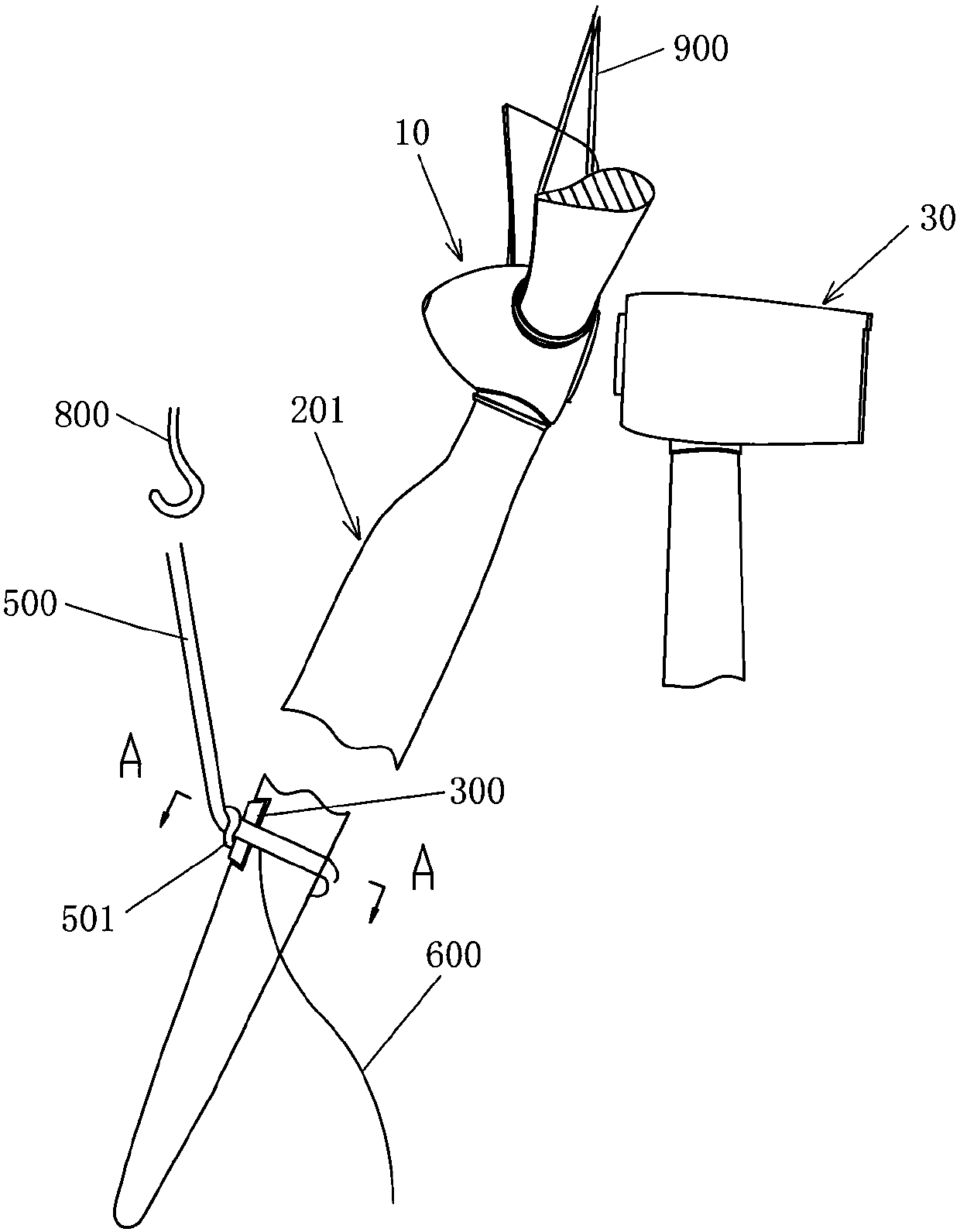

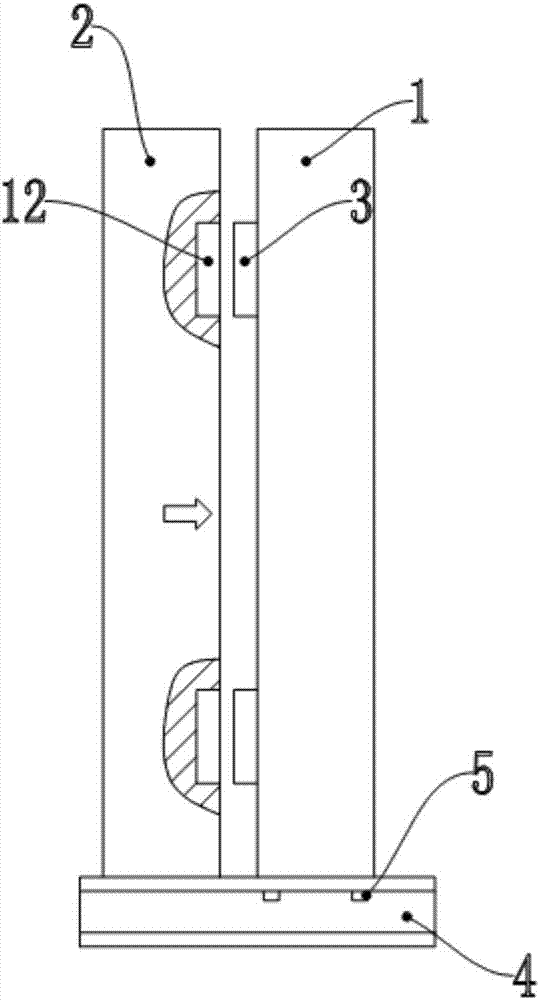

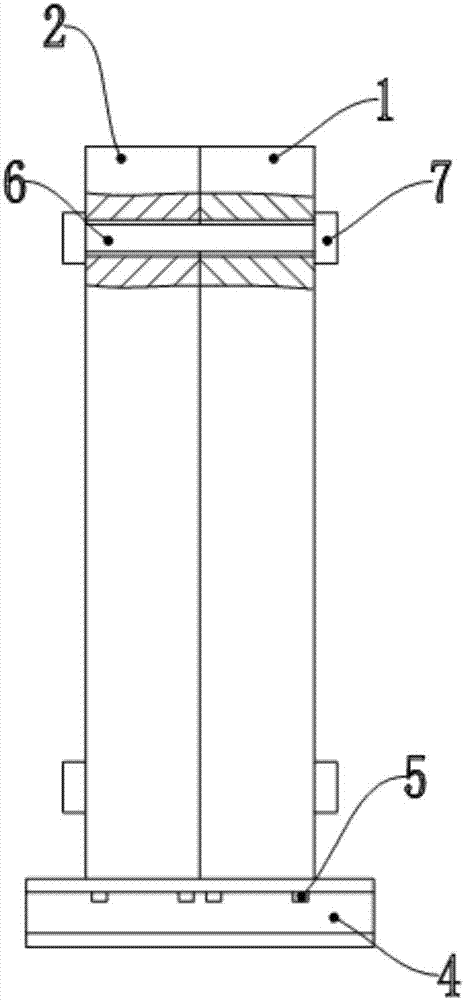

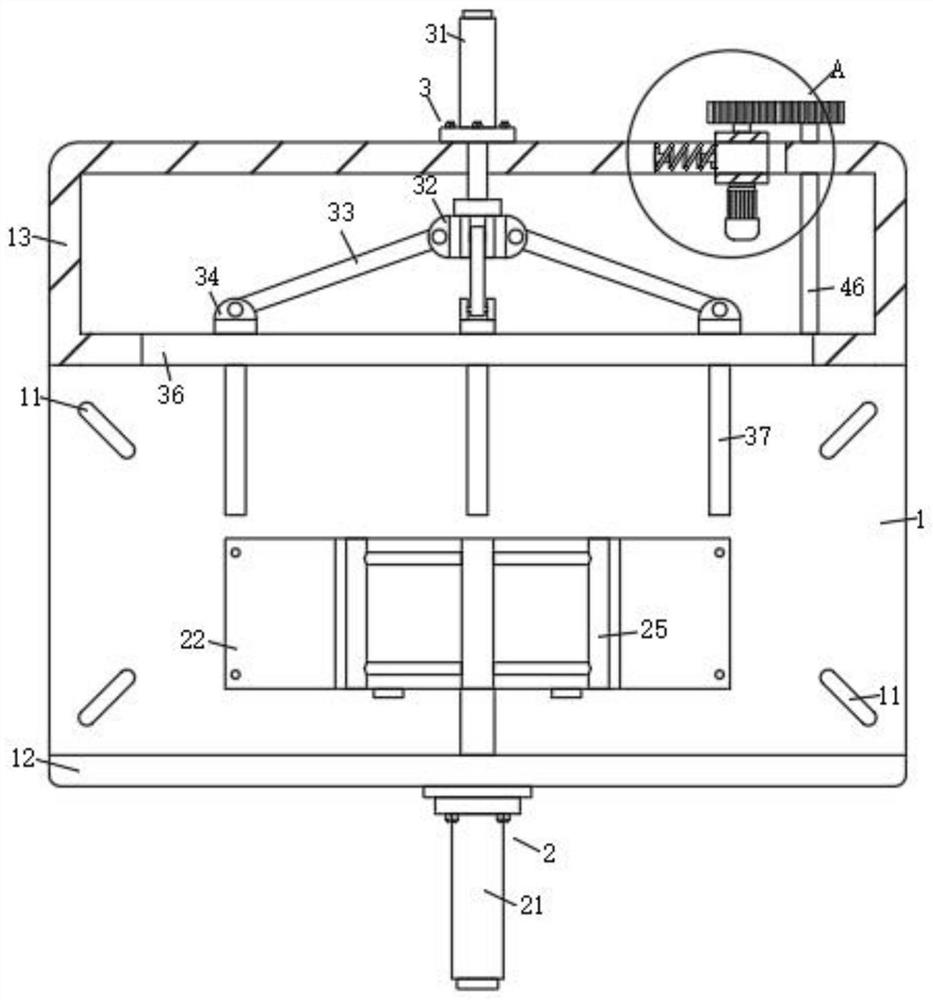

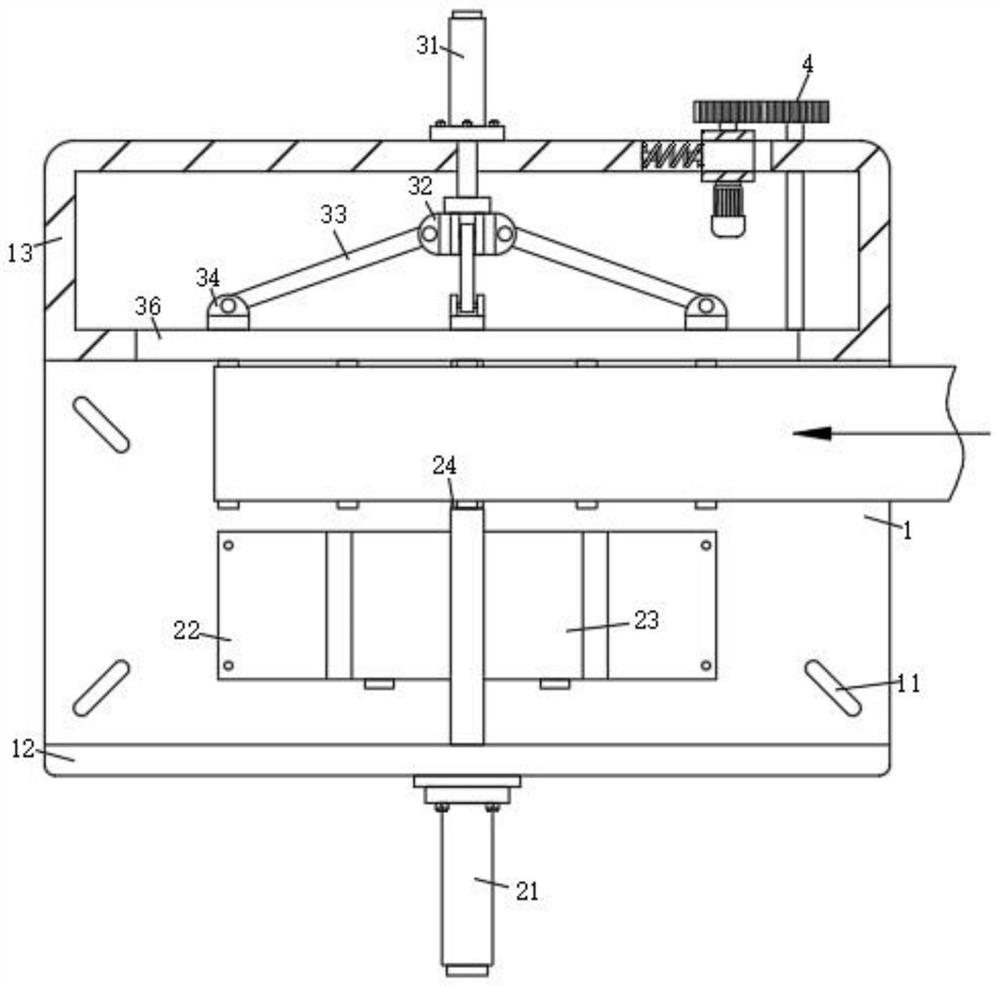

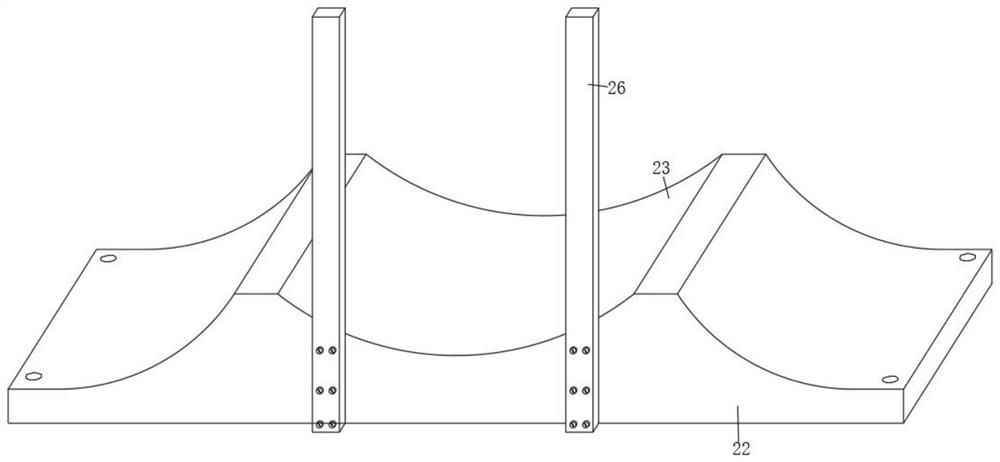

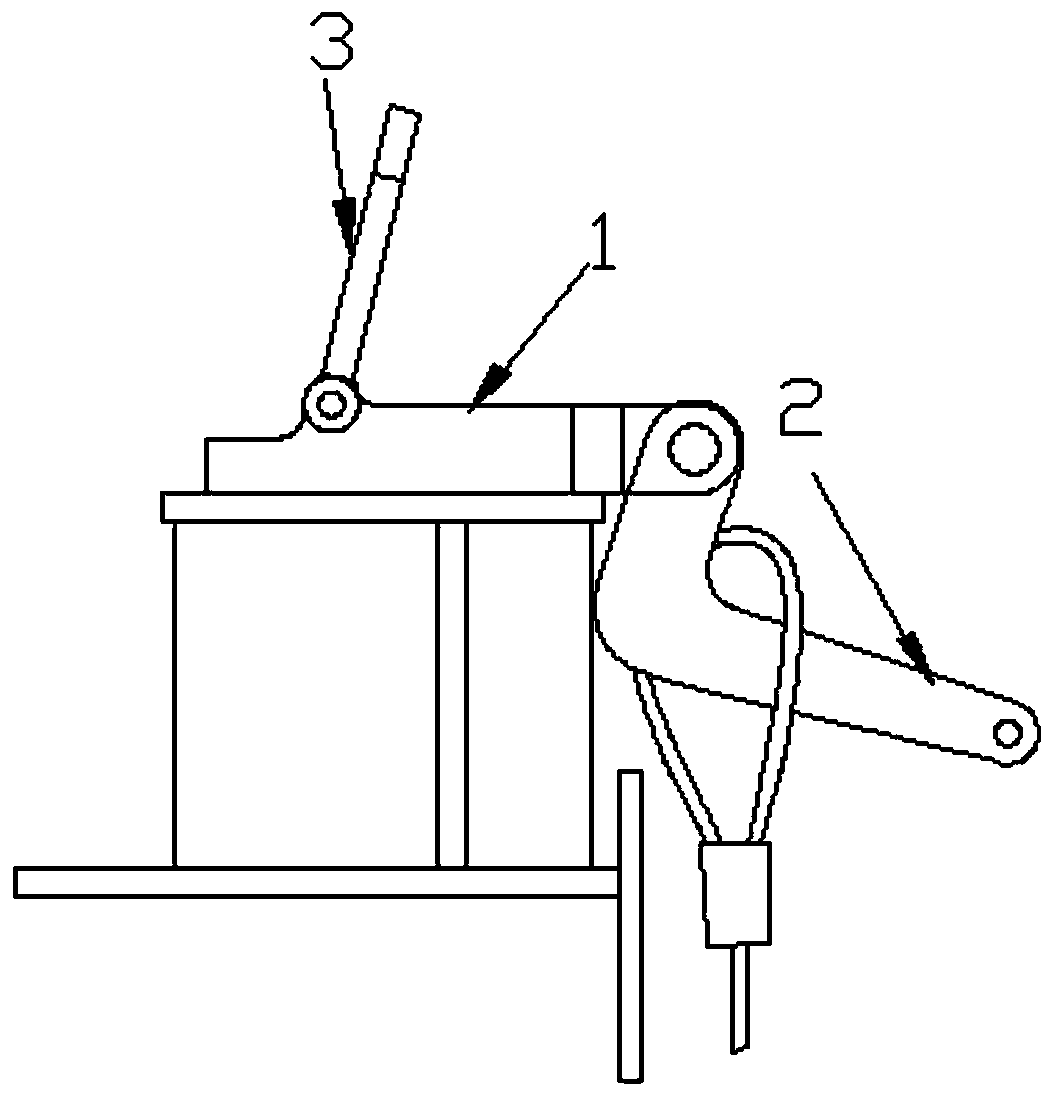

Vane wheel lifting appliance for wind generating set and vane wheel lifting method

ActiveCN107792780AStable supportReduce the accident of fallingMachines/enginesWind energy generationImpellerEngineering

The invention provides a vane wheel lifting appliance for a wind generating set and a vane wheel lifting method. The vane wheel lifting appliance comprises a fist clamp module, a second clamp module,an air cushion controller and one or more lifting lugs, wherein the fist clamp module comprises a first clamp shell and a first air cushion, and the first air cushion is arranged on the surface of theinner side of the first clamp shell. The second clamp module comprises a second clamp shell and a second air cushion, and the second air cushion is arranged on the surface of the inner side of the second clamp shell. The air cushion controller is arranged on the first clamp shell and / or the second clamp shell so that the first air cushion and the second air cushion can be controlled to be inflated or exhausted. The lifting lugs are mounted on the surface of the outer side of the first clamp shell or the second clamp shell, wherein the first clamp shell is detachably combined with the second clamp shell, and under the state that the first clamp shell is combined with the second clamp shell, the first air cushion is opposite to the second air cushion. By means of the vane wheel lifting appliance for the wind generating set and the vane wheel lifting method, the vane wheel lifting appliance is convenient to mount and dismount; and in addition, safety, stability and reliability of supporting and lifting of vane wheels can be improved.

Owner:URUMQI GOLDWIND TIANYI WIND POWER CO LTD

Hydro-hybrid ceramic main shaft device

InactiveCN102151852AImprove the problem of small carrying capacityImprove carrying capacityMetal-working apparatusStress concentrationMetallurgy

The invention discloses a hydro-hybrid ceramic main shaft device which adopts a symmetrically arranged cone bearing structure and a structure of which a ceramic rubbing pair is totally wrapped by metal simultaneously in the aspect of structural design, and avoids shape mutation of all ceramic parts. The hydro-hybrid ceramic main shaft device disclosed by the invention adopts a ceramic hydro-hybrid bearing as the supporting bearing and cone hydro-hybrid bearings as the front bearing and the rear bearing, has the radial pressure bearing function and axial thrust function simultaneously, has a simple structure, and is provided with a conveniently adjusted axial gap; the hydro-hybrid ceramic main shaft device adopts the structure of which the ceramic rubbing pair is totally wrapped by metal, thus breaking of the ceramic parts caused by powerful stretching or higher force applied on the edges of parts is prevented; and all the ceramic parts avoid shape mutation when being designed, thus stress concentration inside the ceramic parts is reduced, and breaking of the ceramic parts caused by self design defects is prevented.

Owner:TIANJIN UNIV

Stress measurement and alarm device and method for knob insulator

ActiveCN104483044ARealize online detectionEasy to operateForce measurementStress distributionSignal conditioning circuits

The invention provides a stress measurement and alarm device for a knob insulator. The stress measurement and alarm device comprises a tension sensor, a signal conditioning circuit, an A / D (analog / digital) conversion module, a processor, an input / output module and a pre-alarm module, wherein the tension sensor collects tension of a knob insulator busbar pull wire and processes the tension into a micro-voltage signal, the amplitude and frequency of the signal are conditioned by the signal conditioning circuit, a tension value is obtained after conversion by the A / D conversion module, and the stress distribution condition and the maximum stress are obtained in the processor according to an input tension angle parameter and based on the corresponding relation of preset stress distribution and force load; when the maximum stress is larger than a preset threshold, an alarm is given through the pre-alarm module; or otherwise, the stress distribution condition is displayed on the input / output module. With implementation of the embodiment of the invention, the stress state of the knob insulator can be detected on line, and the device is simple and easy to operate and has high safety, reliability and accuracy, so that the knob insulator can be prevented from breaking accidents.

Owner:SHENZHEN POWER SUPPLY BUREAU

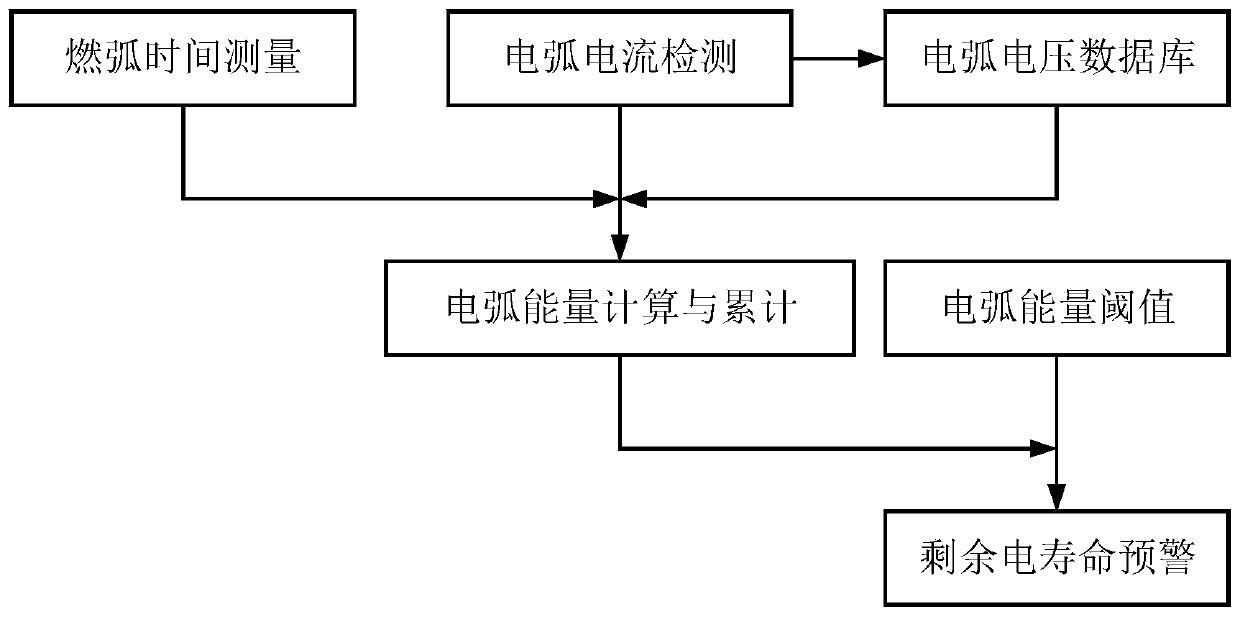

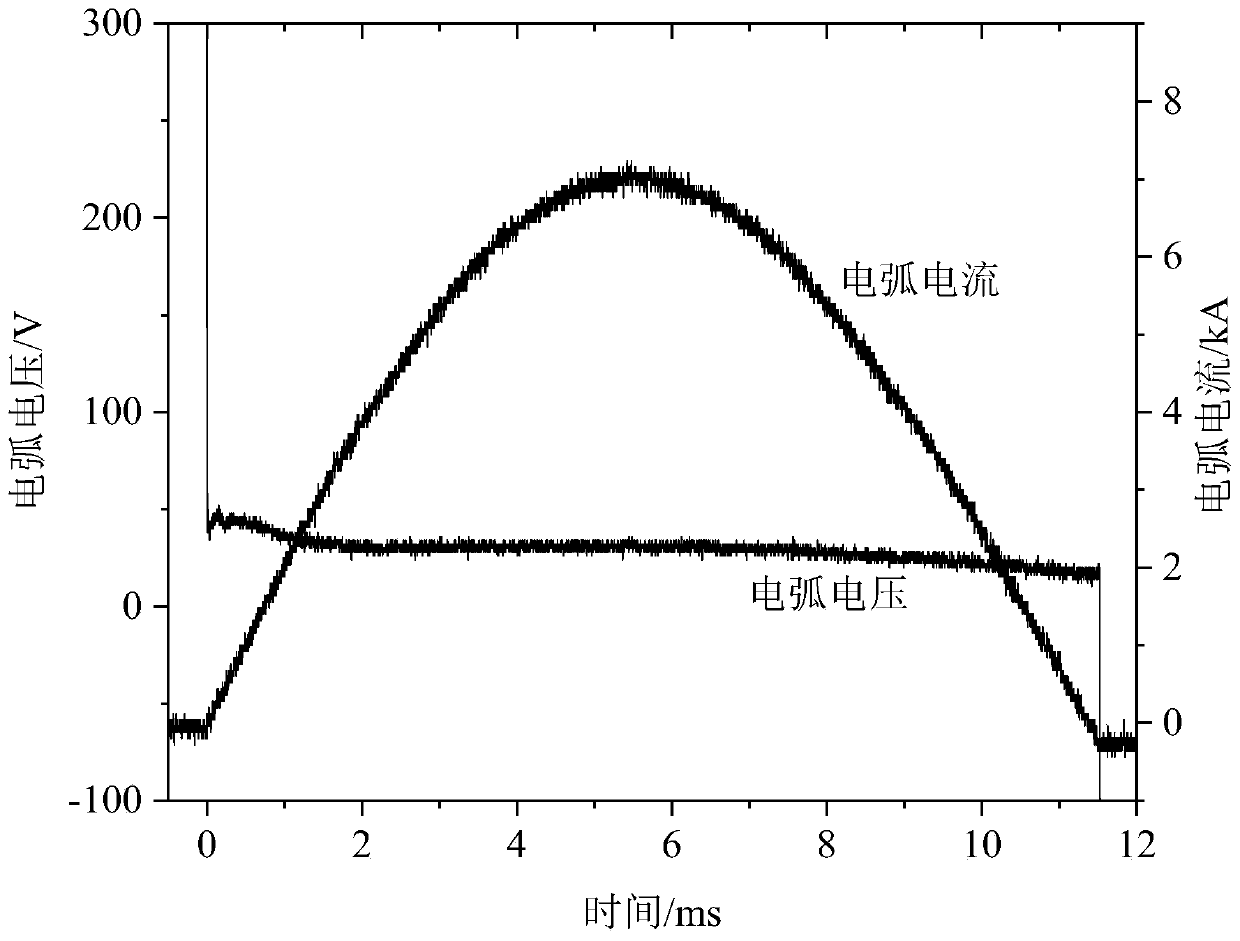

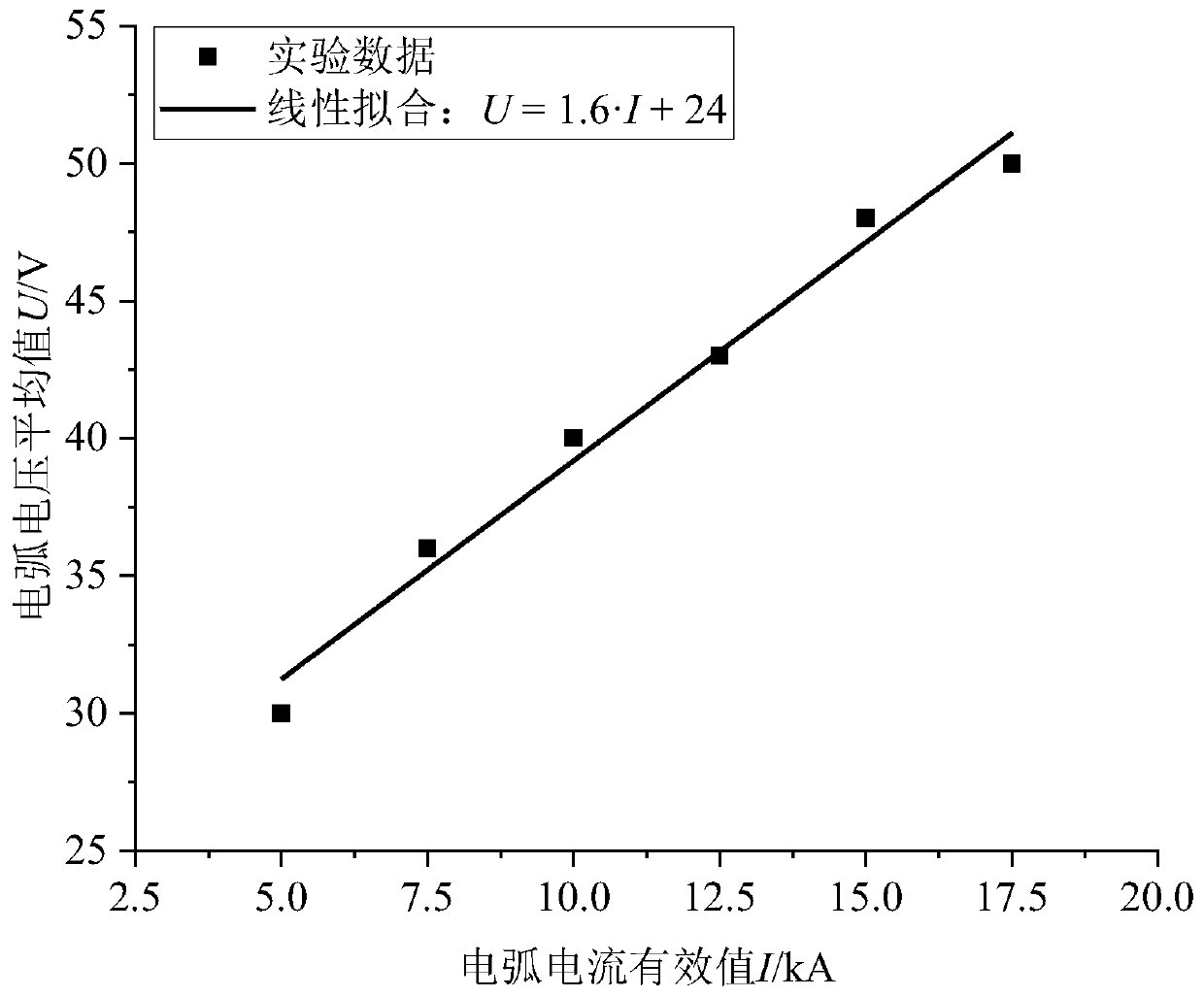

Vacuum circuit breaker electrical life evaluation method based on arc energy

ActiveCN111505496AImprove accuracySimple calculationCurrent/voltage measurementCircuit interrupters testingThermodynamicsProcess engineering

The invention discloses a vacuum circuit breaker electrical life evaluation method based on arc energy, and belongs to the field of vacuum circuit breaker electrical life evaluation. A common commercial vacuum circuit breaker arc voltage database is established based on the experimental data, and meanwhile, the arcing time and the arc current effective value are calculated, then the arc energy accumulation value of a vacuum circuit breaker in each turn-on and turn-off is calculated and is compared with an arc energy threshold value to obtain the residual electric life percentage, so that the working state of the vacuum circuit breaker is evaluated, and whether an early warning prompt is given or not is further determined. According to the method, the problem that the online arc voltage detection is difficult to realize is solved, a foundation is laid for the online monitoring of the electrical life of the vacuum circuit breaker, and the electrical life prediction precision of the vacuum circuit breaker is improved.

Owner:XI AN JIAOTONG UNIV

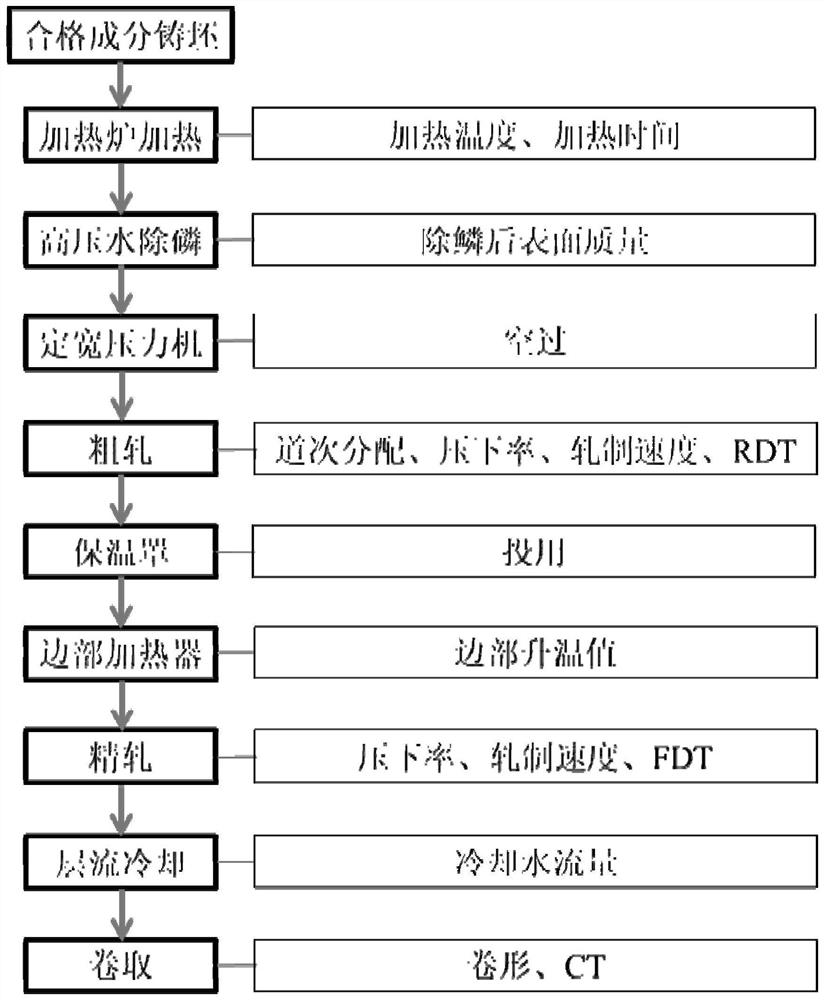

Control method of excellent hot-rolled oriented silicon steel plate shape

ActiveCN112246869AEasy to shapeFulfil requirementsTemperature control deviceWork treatment devicesLaminar coolingStrip steel

The invention discloses a control method of an excellent hot-rolled oriented silicon steel plate shape, and belongs to the field of hot-rolled oriented silicon steel manufacturing. The method comprises the following steps that S1, a heating furnace is used for heating, specifically, the temperature of a soaking section of the heating furnace is 1250-1320 DEG C, and the soaking time is longer thanor equal to 60 min; S2, rough rolling is conducted, specifically, rough rolling is conducted on an E1 / R1 reversible rough rolling machine and an E2 / R2 reversible rough rolling machine in sequence, andthe temperature of an intermediate billet is larger than or equal to 1120 DEG C after rough rolling is finished on the E2 / R2 reversible rough rolling machine; S3, finish rolling is conducted, specifically, seven-rack continuous rolling is adopted, the pass reduction rate in the F1-F7 continuous rolling process is sequentially reduced, the finish rolling F1 reduction rate is 45-50%, and the F7 reduction rate is 5-10%; and S4, laminar cooling is conducted, specifically, the cooling water amount of a nozzle at the edge of strip steel is smaller than that in the middle. According to the method, the defect that in the prior art, the requirements of a hot-rolled oriented silicon steel raw material for performance and plate shape cannot be considered is overcome, the hot-rolled oriented siliconsteel plate with the excellent plate shape is obtained under the condition that it is guaranteed that all key temperature parameters reach the standard, and the obtained plate shape can guarantee thatthe comprehensive yield from the oriented silicon steel raw material to a finished product is larger than or equal to 91%.

Owner:MAANSHAN IRON & STEEL CO LTD

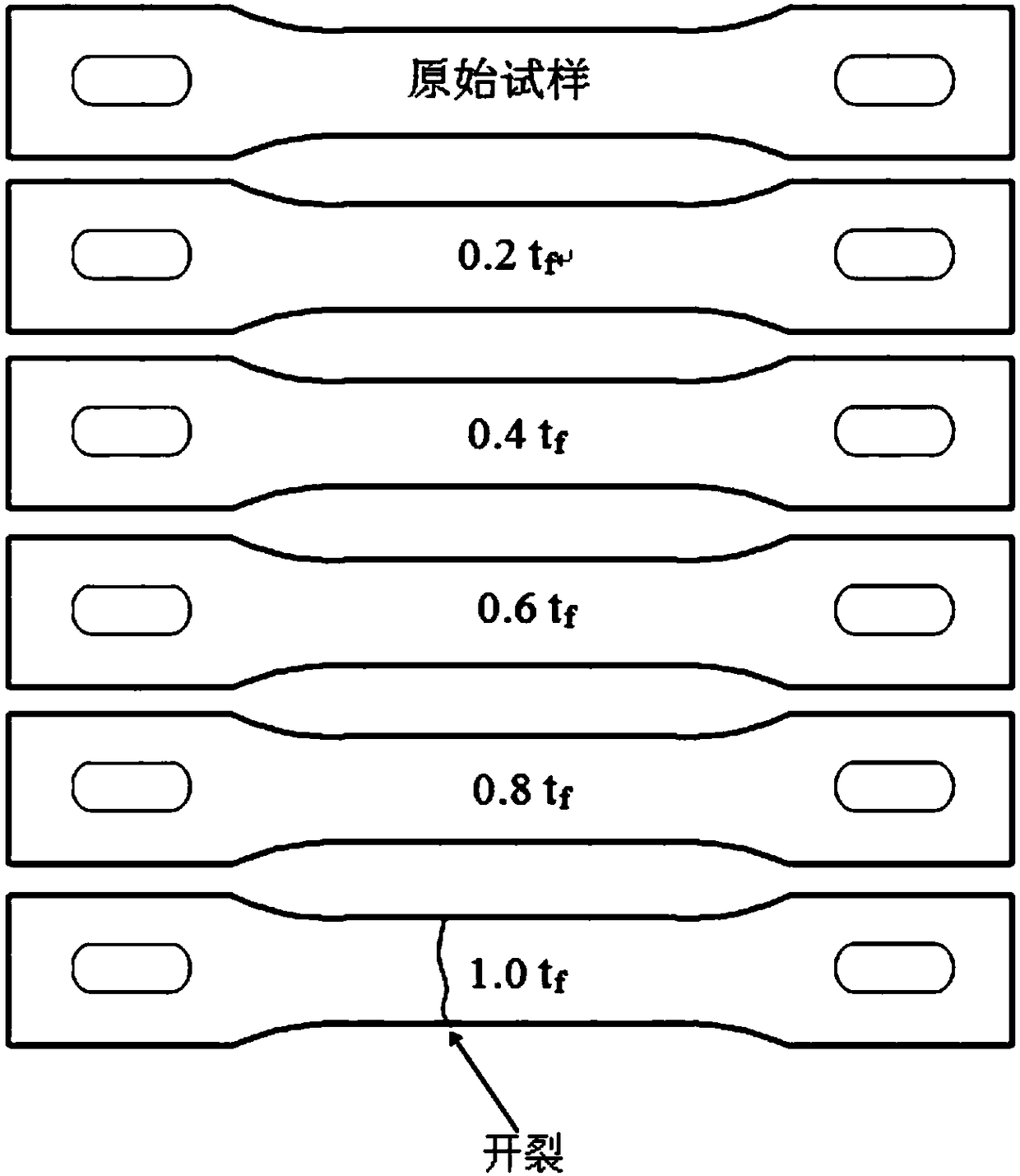

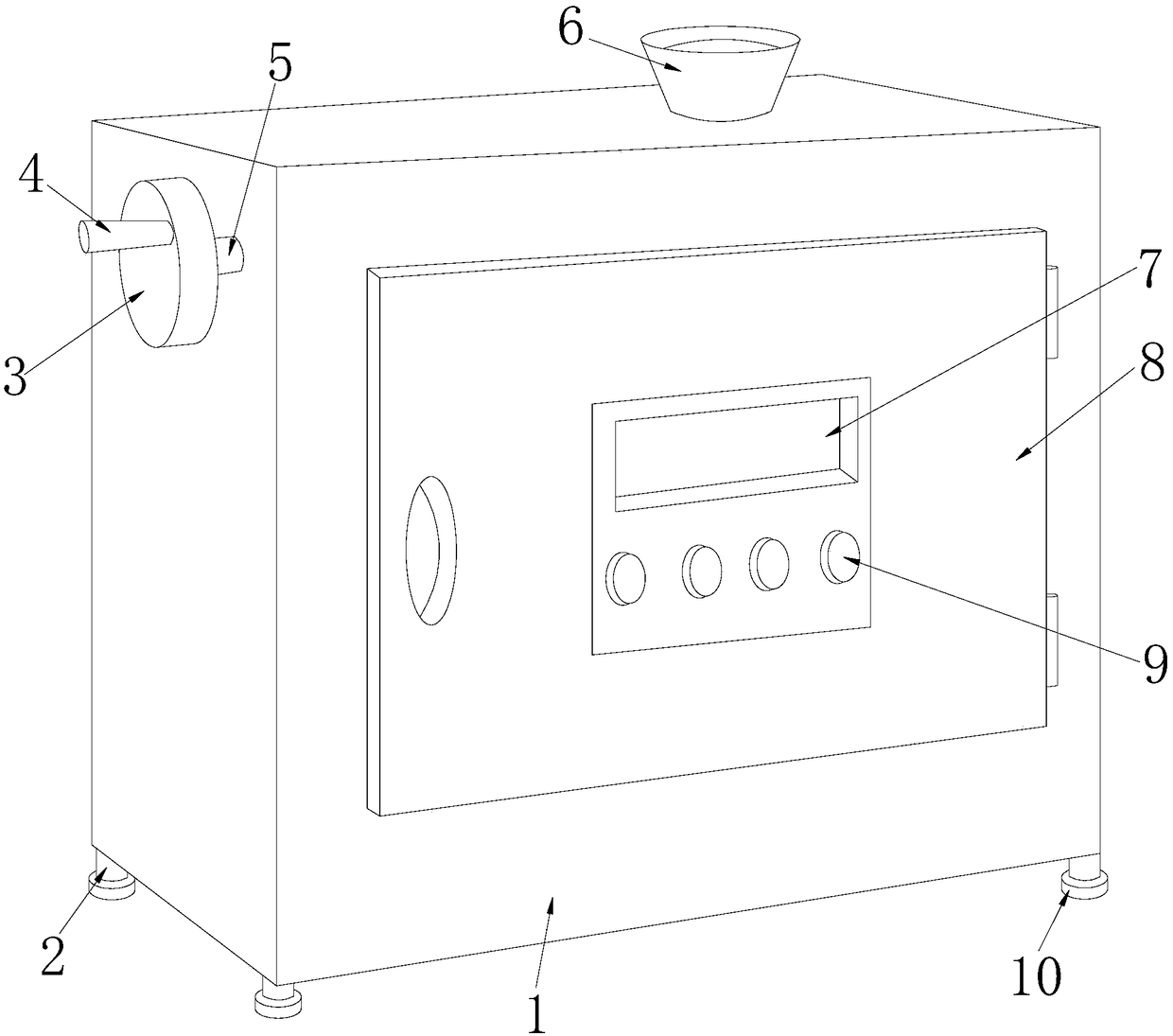

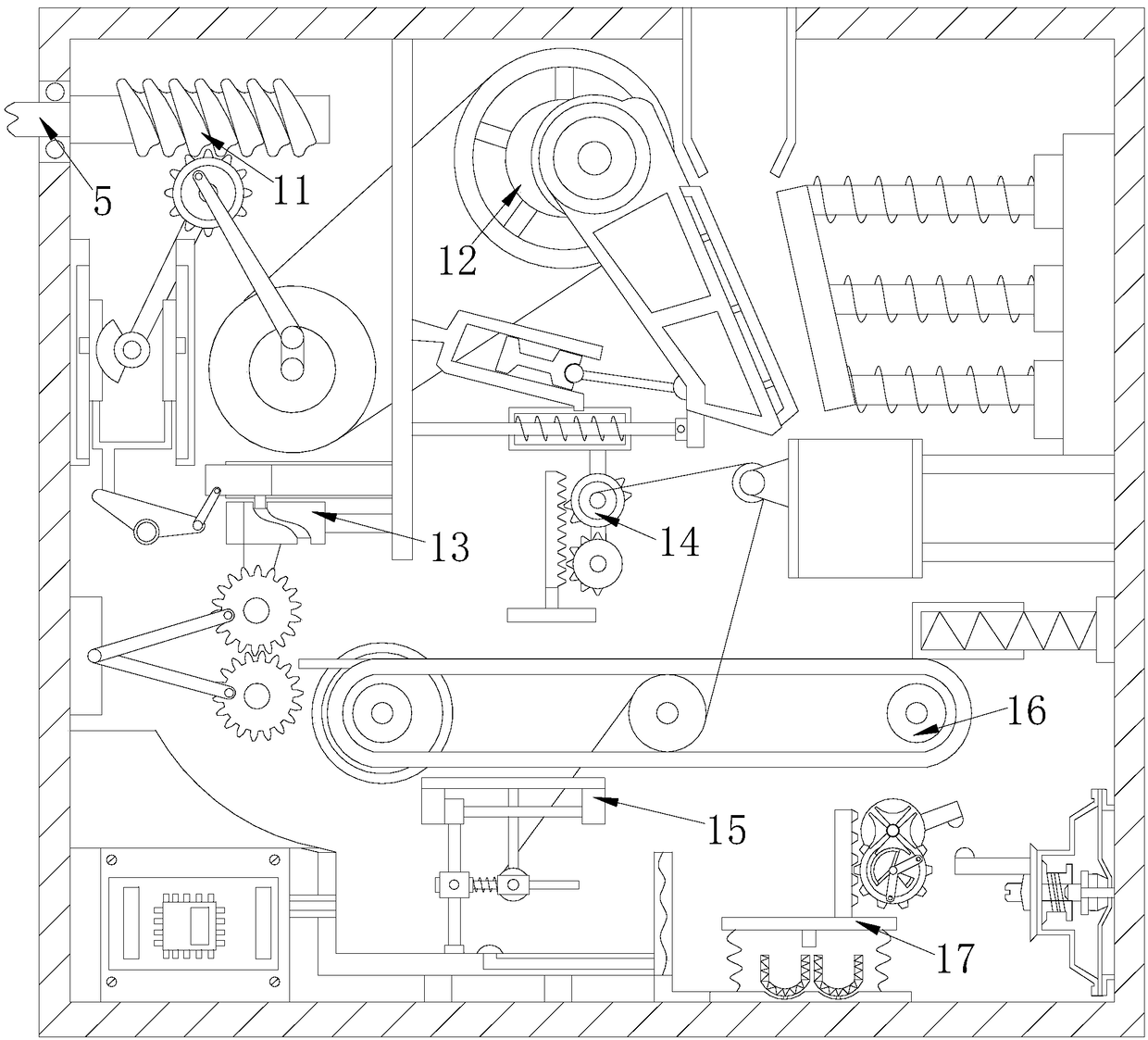

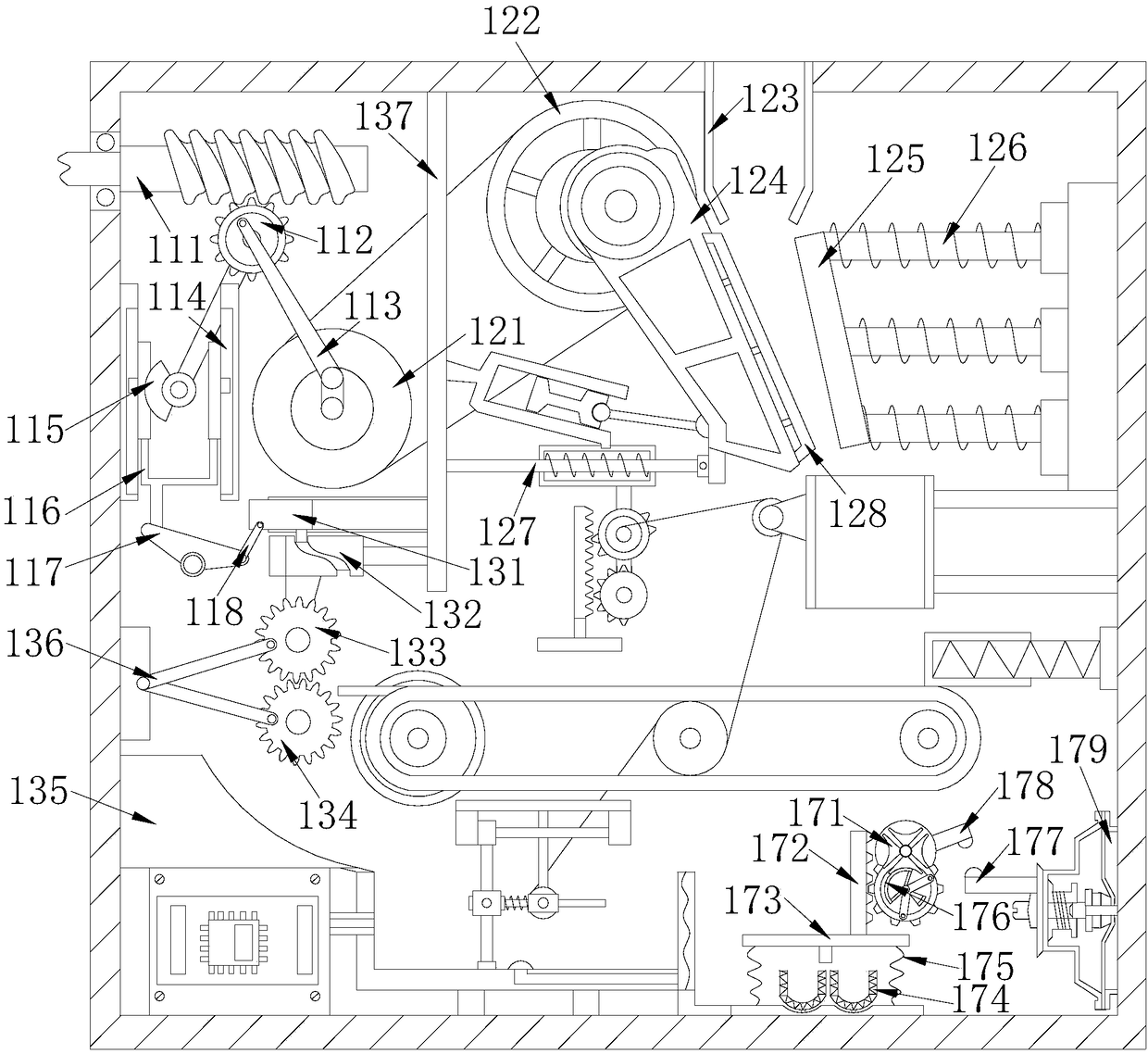

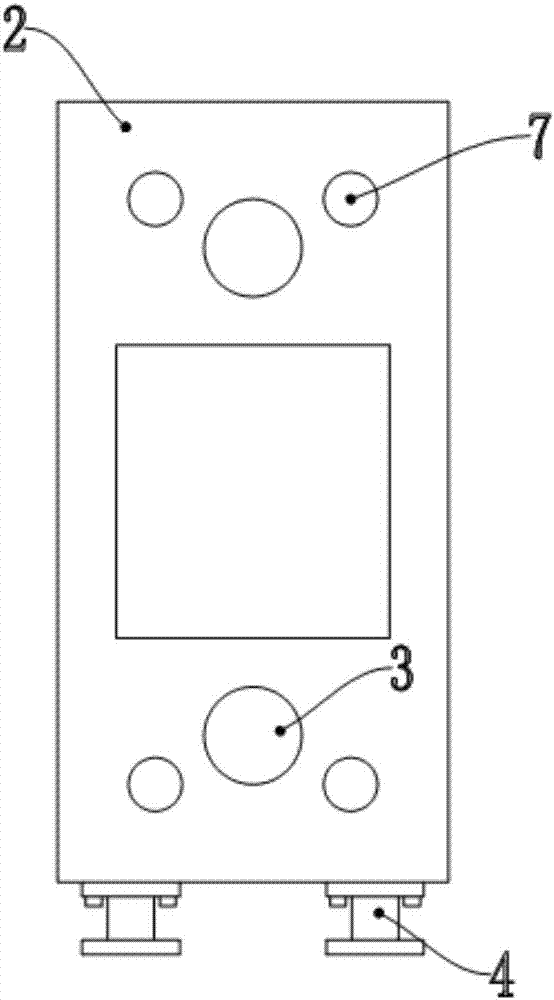

Ultra-multicore ultra-high-speed flat elevator cable testing apparatus

InactiveCN108956321AAchieving tensile strengthThe tensile strength data is accurateTesting dielectric strengthMaterial strength using tensile/compressive forcesUltra high speedEngineering

The invention discloses an ultra-multicore ultra-high-speed flat elevator cable testing apparatus which comprises a cable testing apparatus, connecting posts, a wheel disc, a rocker bar, a drive rod,a receiving hopper, a display screen, a box door, a control panel and anti-slide bottom studs, wherein totally four connecting posts are arranged at the upper ends of the anti-slide bottom studs. Thecable testing apparatus disclosed by the invention is composed of a starting device, an extrusion device, a tensile testing apparatus, a limiting device, an insulation testing apparatus, a feeding mechanism and an alarm device. The apparatus is capable of testing the tensile strength of cables during straightening and bending, so that the tensile strength data of the cables in different states areexact, and the condition that a cable breakage accident easily occurs due to a large data error during use can be avoided. Meanwhile, the apparatus is capable of detecting whether the insulating layer of the cable contains defects, and the phenomenon that electric leakage and electric shock easily occur in the cable operating process can be avoided.

Owner:谢彬彬

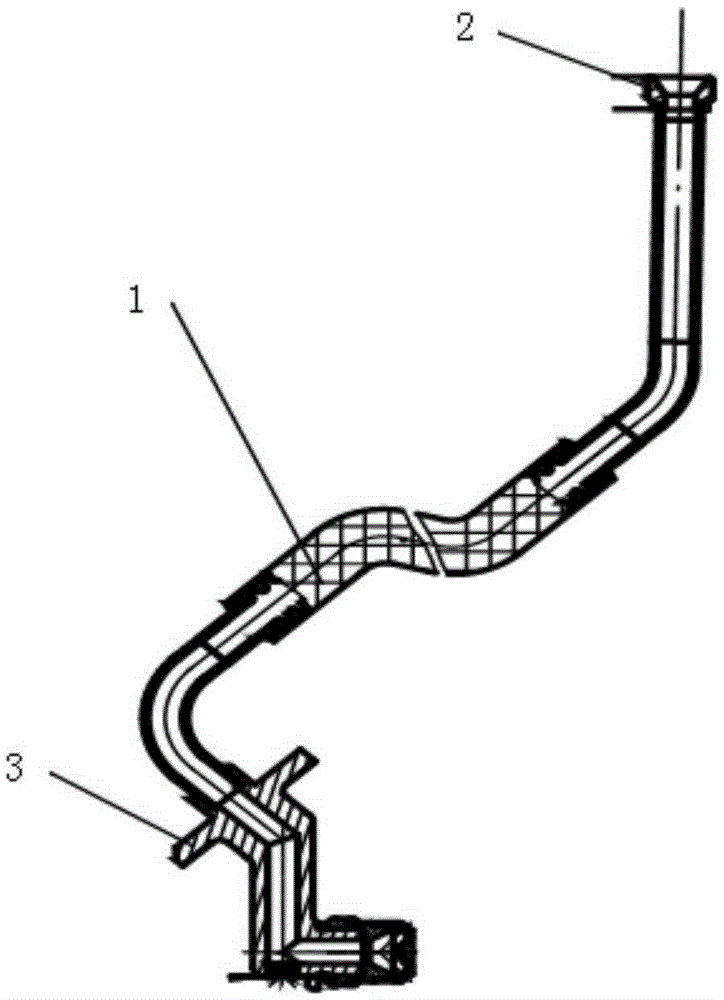

Long-neck gas fuel spray nozzle capable of being adjusted in multiple angles

InactiveCN105299693AReliable structural designCompact designContinuous combustion chamberThermal deformationProduct gas

The invention discloses a long-neck gas fuel spray nozzle capable of being adjusted in multiple angles. The long-neck gas fuel spray nozzle comprises a metal hose, wherein a pipe connector is fixedly connected to one end of the metal hose, and a fuel gas spray nozzle body is fixedly connected with the other end of the metal hose. The metal hose comprises a corrugated pipe which is wrapped by a layer of metal mesh surface. The metal hose is inserted into the fuel gas spray nozzle body and is connected with the fuel gas spray nozzle body in a welded manner. The wall thickness of the corrugated pipe ranges from 0.3 mm to 0.5 mm. The metal mesh face is formed by weaving metal wires, and materials are 1Cr18Ni9Ti. The metal mesh face and the end of the corrugated pipe are fixedly connected. By means of the design that the metal hose is directly welded to the spray nozzle body, assembling of pipe connectors in a gas turbine is reduced; by means of the flexible connection manner, the displacement, generated in the working process of the gas turbine, of a combustion chamber casing part and an outer duct casing part and thermal deformation of a pipeline are automatically adjusted, and the phenomenon that due to rigid connection, assembling stress is generated due to manufacturing deviation, and cracking accidents are caused due to vibration can be avoided; and the spray nozzle body and a fuel gas branch pipe can be conveniently connected, the structure is compact, and the integral design requirement of the gas turbine is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

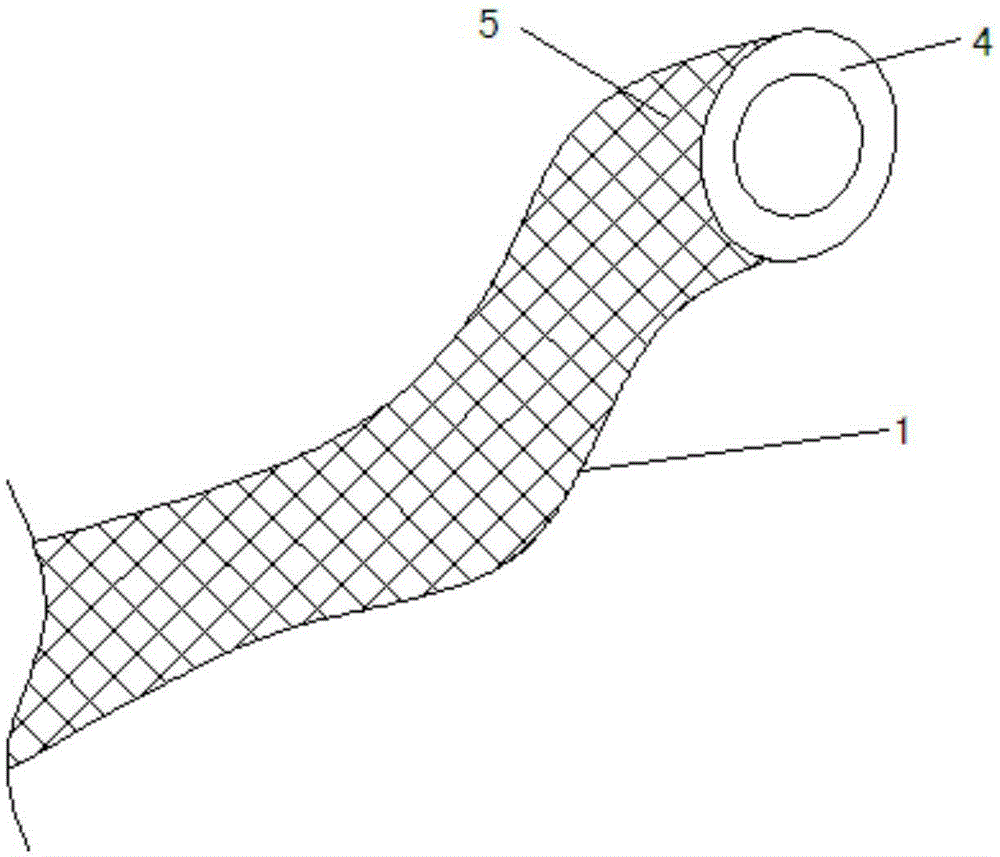

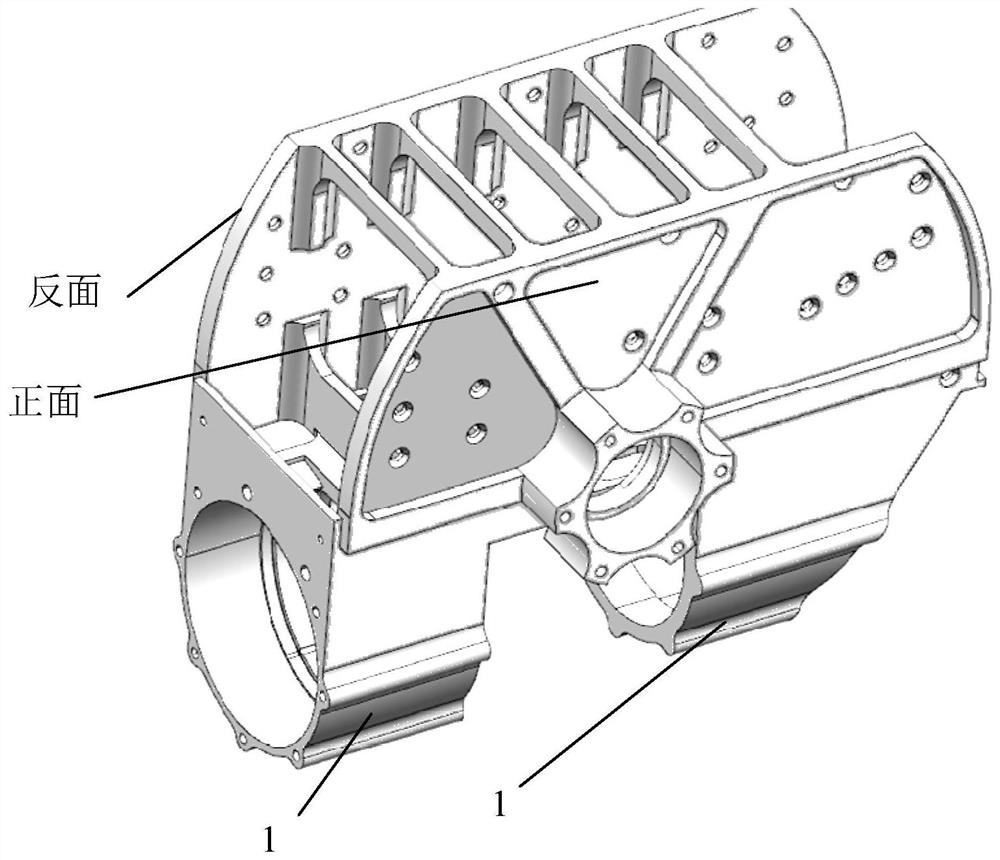

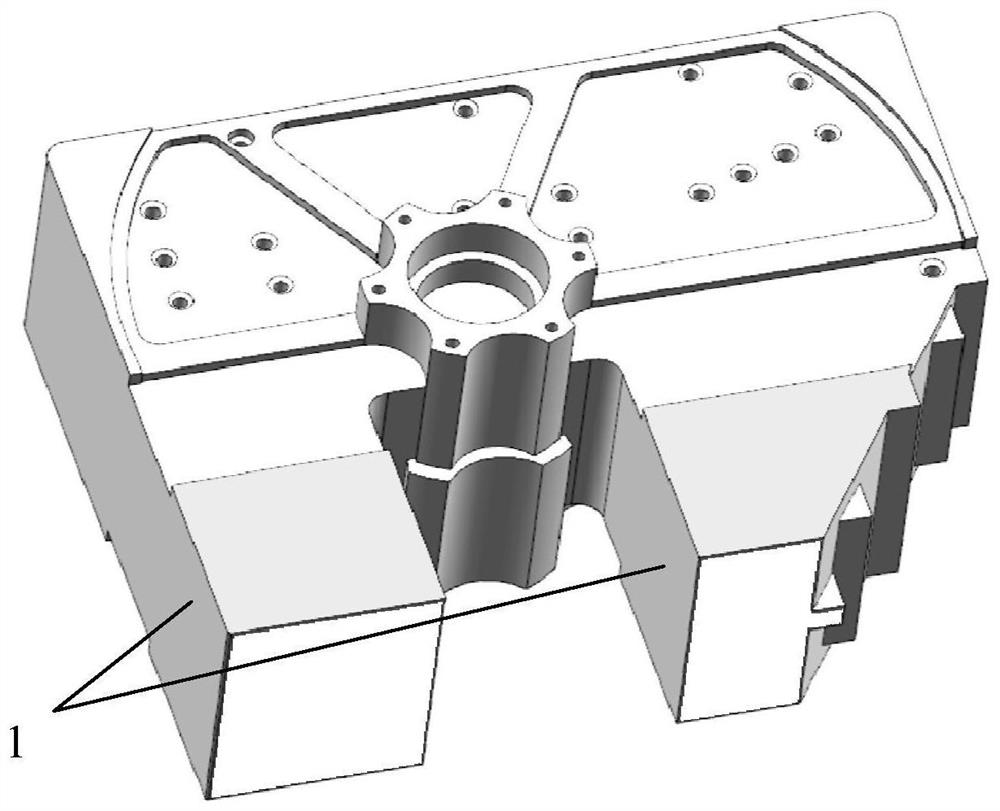

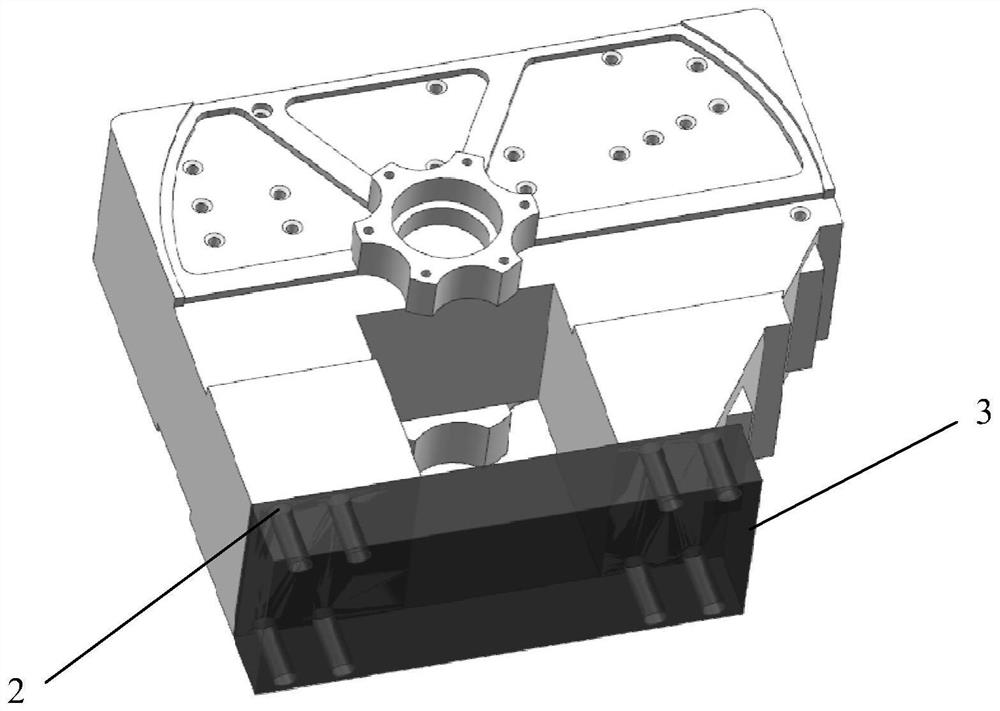

Machining method of weak-rigidity thin-wall hollow structure part

InactiveCN112643101APrevent processing deformationAvoid breaking accidentsMilling equipment detailsPositioning apparatusMachining deformationClassical mechanics

A machining method of a weak-rigidity thin-wall hollow structure part comprises the following steps that the front face and the back face of the weak-rigidity thin-wall hollow structure part are subjected to rough cutting machining, allowance is reserved at a laser cabin, and the reserved allowance serves as a process block; vibration aging treatment is conducted on the weak-rigidity thin-wall hollow structure part through a vibration stress relief device, and the residual stress of the structure part is eliminated; the outer side structure or the inner side structure of the weak-rigidity thin-wall hollow structure part is subjected to finish cutting machining; and the flying wall process block is fixedly installed on the inner side surface or the outer side surface of the weak-rigidity thin-wall hollow structure part, and the inner side structure or the outer side structure of the weak-rigidity thin-wall hollow structure part is subjected to finish cutting machining. By means of the machining method, machining deformation of the weak-rigidity thin-wall structure part is effectively controlled and reduced, and the machining quality is guaranteed.

Owner:SHANGHAI RADIO EQUIP RES INST

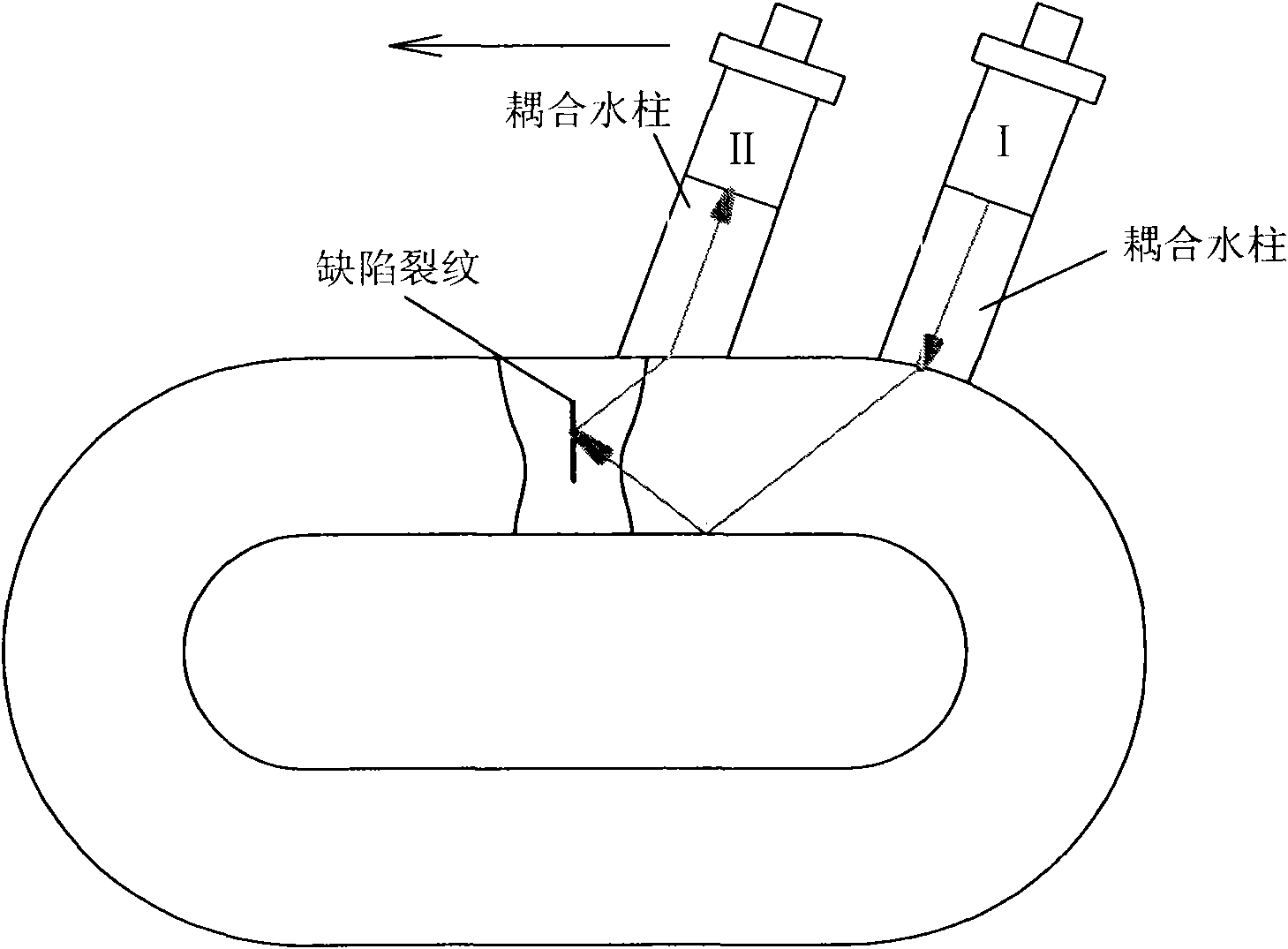

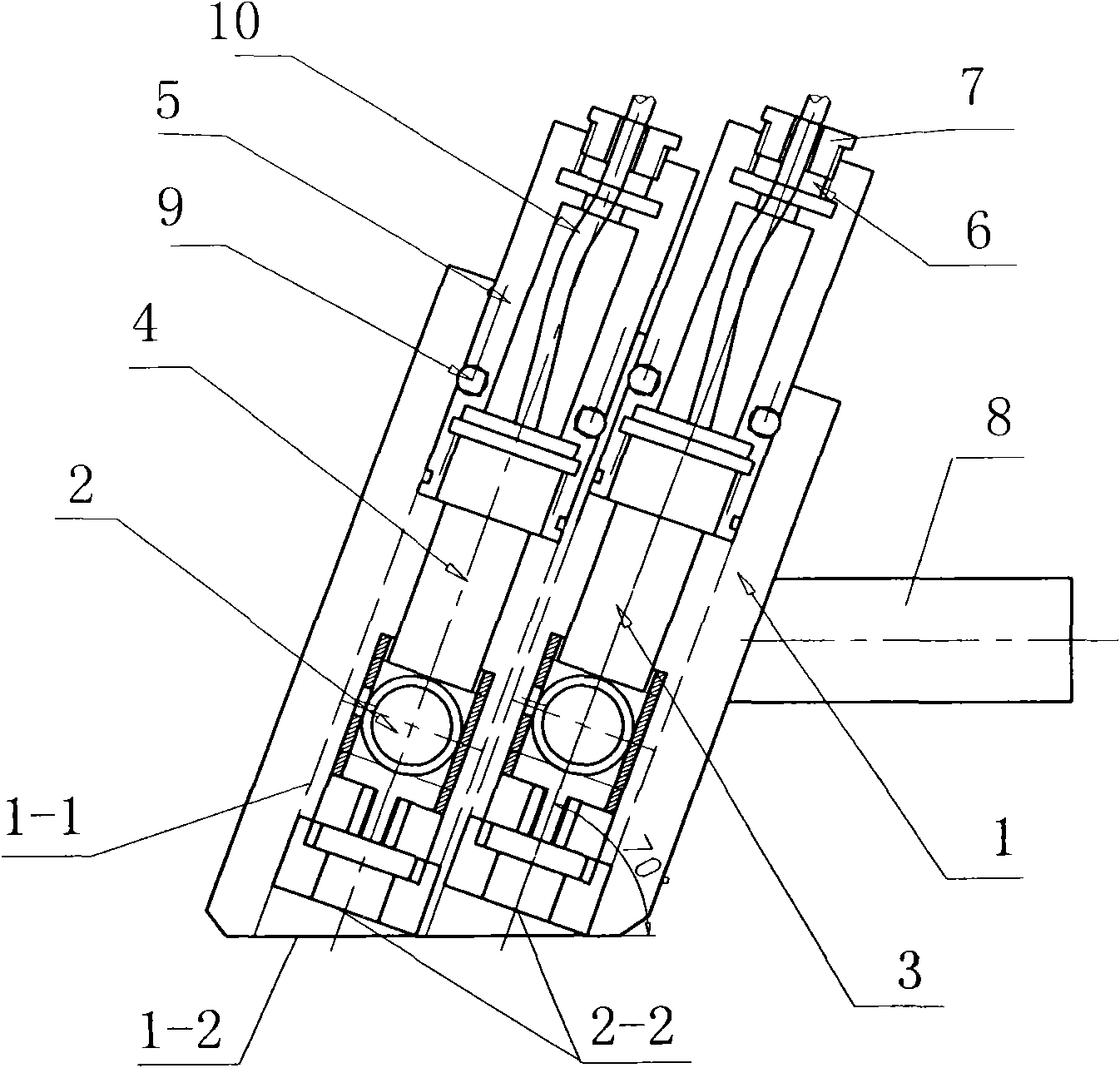

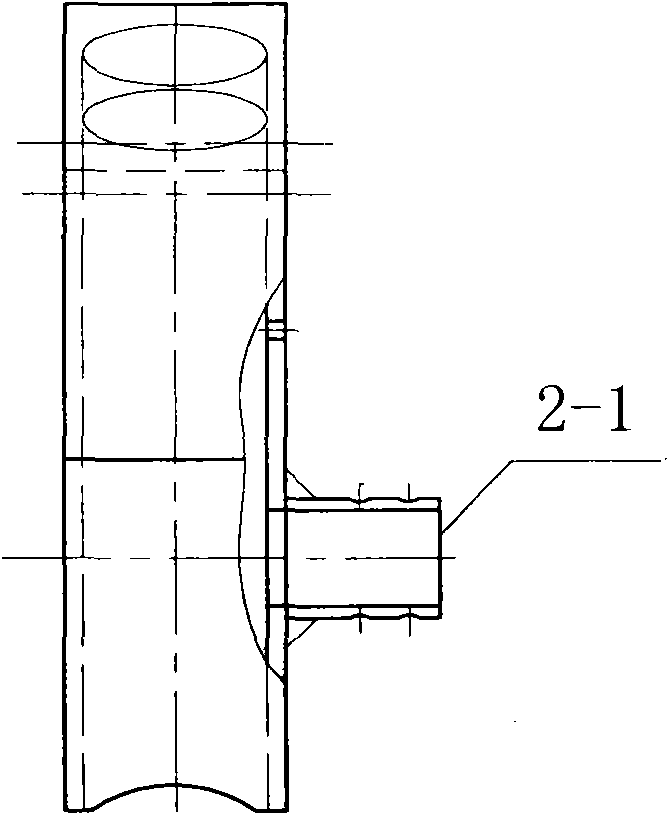

Ultrasonic flaw detection method of scraper circular chains

InactiveCN102183580AImprove directivityImprove transfer efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansEngineeringStandard samples

The invention provides an ultrasonic flaw detection method of scraper circular chains and relates to a mining scraper conveyor. By the method, the problem that breaking accidents of circular chains of the conventional scraper conveyor occur frequently and cannot be prevented is solved. The method particularly comprises the following steps of: 1, operating the scraper conveyor at a low speed of 0.3 to 0.5 m / s; 2, starting a flaw detector and turning on a water supply switch of a special probe to supply water for the probe; 3, using the special probe to slide through a straight section, with weld joints, of each circular chain sequentially, and observing echo of a set position; and 4, comparing with echo generated by a standard sample and calculating flaw depth, wherein a warning threshold value is determined by the standard sample, so that accident preventing warning is realized. By the method, the flaw depth can be calculated according to the echo generated by the standard sample and the echo generated by flaw detection of the actual circular chains and a flaw detection operator sends out fault warning, so that the circular chain breaking accidents of the scraper conveyor are avoided.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

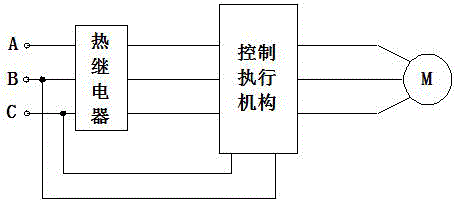

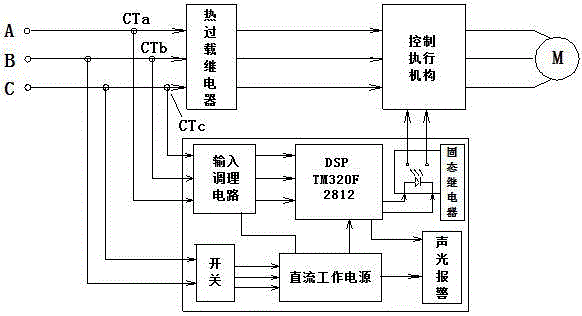

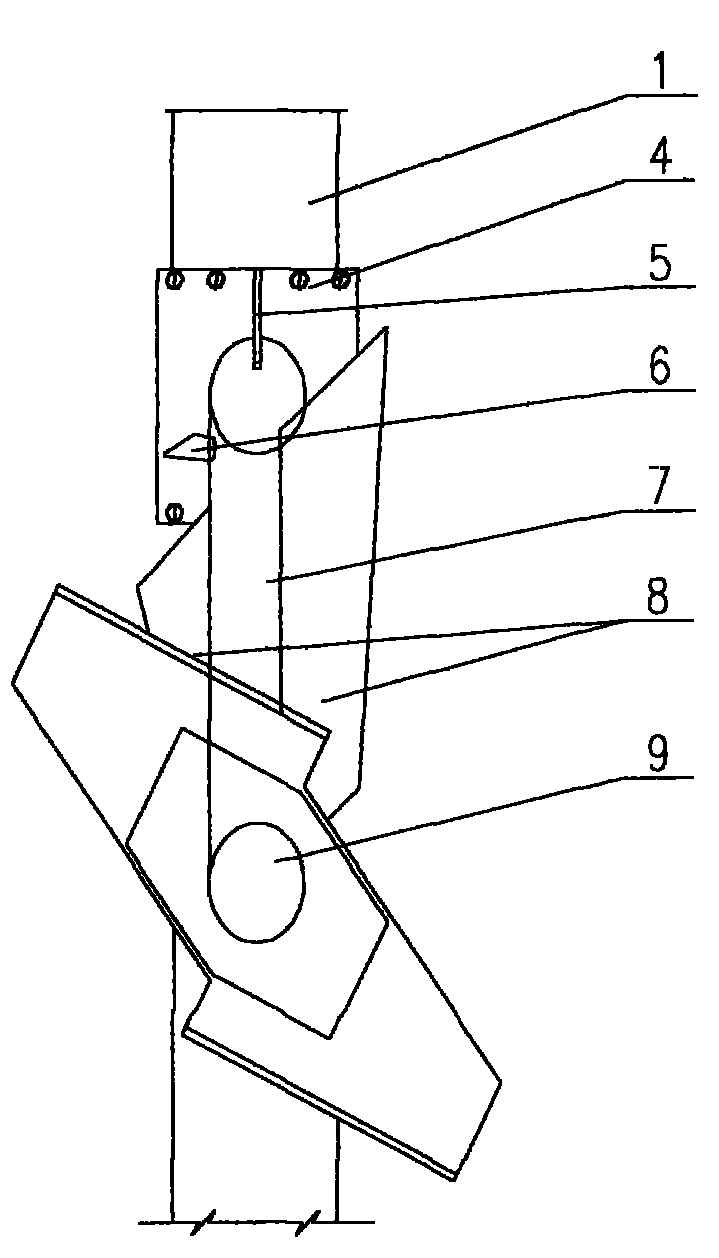

Method for preventing high-voltage power-driven disconnecting switch supporting insulator from being fractured

InactiveCN103560036AOvercome the lack of action lagAvoid breaking accidentsEmergency protective arrangements for automatic disconnectionAir-break switch detailsDrive motorControl theory

The invention discloses a method for preventing a high-voltage power-driven disconnecting switch supporting insulator from being fractured. The method comprises the steps that a cored current transformer is used for sampling a current produced when a disconnecting switch drive motor operates, and a disconnecting switch drive motor control device composed of a high-speed digital signal processor is selected to detect, analyze and compare the operating current waveform characteristics of the disconnecting switch drive motor to judge whether a locked-rotor current occurs or not; the control device controls the operation and the non-operation of the disconnecting switch drive motor at a high speed, the stress of the supporting insulator is prevented from continuing to be enlarged, and the operation is carried out continuously after the reason is checked and removed. The occurrence that the high-voltage power-driven disconnecting switch supporting insulator is fractured due to abnormal stress is avoided. After a DSP control protective device is added into a high-voltage disconnecting switch power-driven operation loop , the defect of the lagging operation of a thermal overload relay is overcome, and the fracture accident of the supporting insulator in the process of running or operating can be effectively prevented. The method is suitable for being used in high-voltage primary equipment of a transformer substation.

Owner:STATE GRID CORP OF CHINA +1

Slave plate structure for lorry coupler buffering device

The invention discloses a slave plate structure for a railway good train coupler buffering device, which comprises a slave plate body and an abrasion plate, wherein the slave plate body is arranged in a coupler tail frame of the coupler buffering device; and the abrasion plate is arranged on one side of the slave plate body, and a main abrasion surface of the abrasion plate is contacted with the coupler tail frame. Because the abrasion coefficient of the abrasion plate is lower, abrasion is only generated on the abrasion plate, and the coupler tail frame has no abrasion basically. Therefore, the condition that the coupler tail frame needs to be welded due to transfinite abrasion cannot occur, and the problem of cracks due to improper welding of the couple tail frame is solved. When the abrasion of the abrasion plate exceeds the limit, only the abrasion plate needs to be replaced, and both the slave plate body and the coupler tail frame can be continuously used so as to save overhaul cost.

Owner:CRRC QIQIHAR ROLLING CO LTD

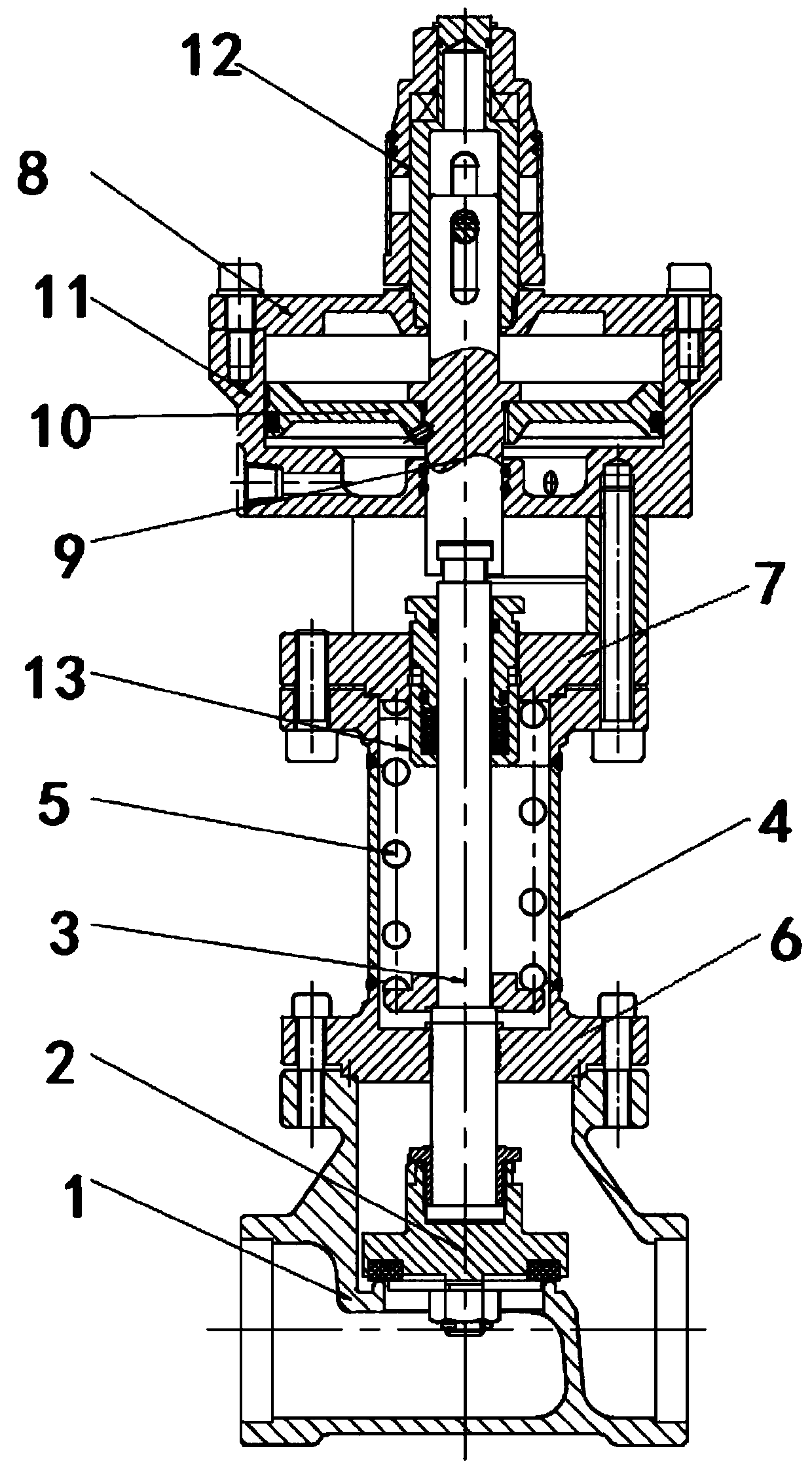

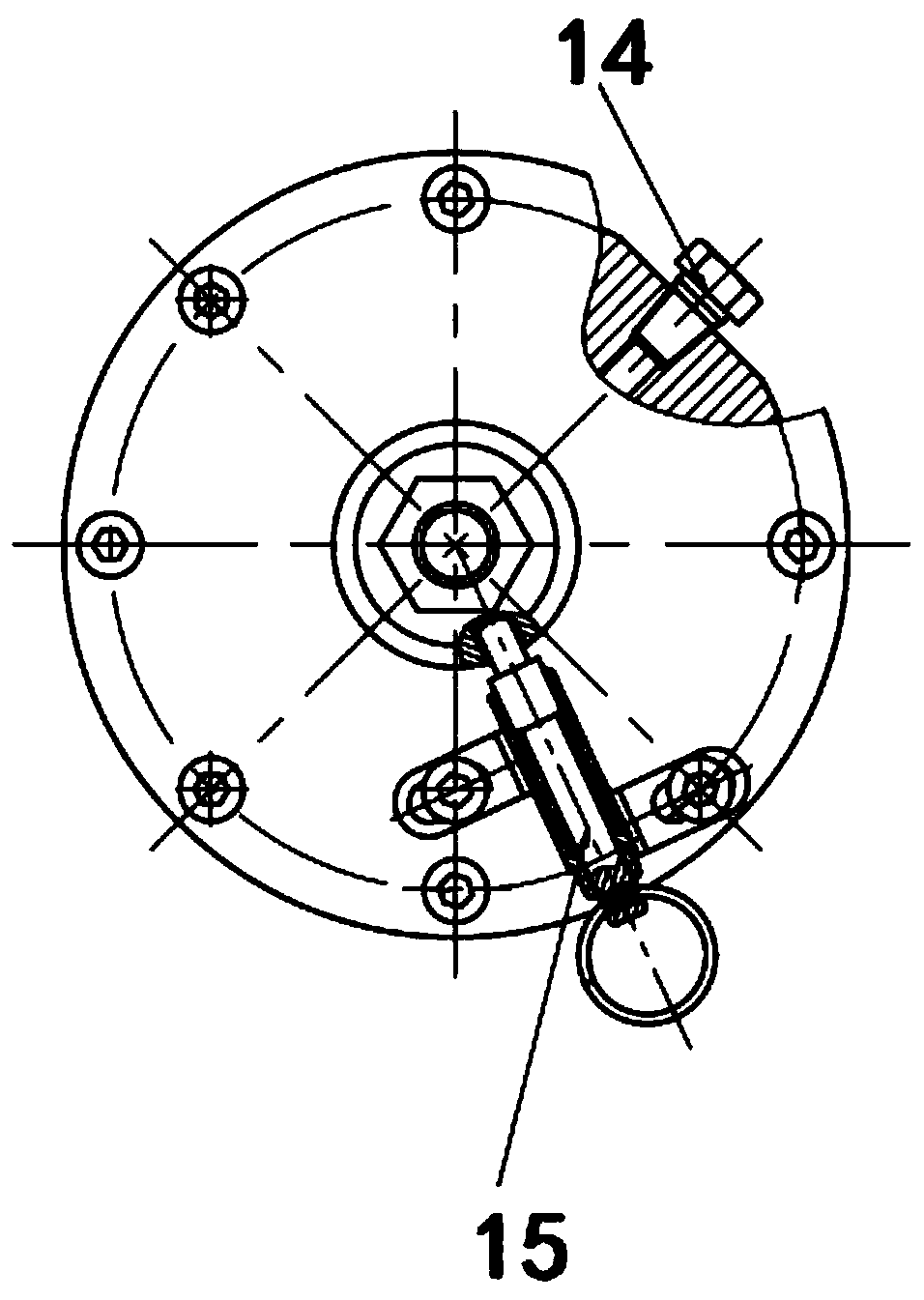

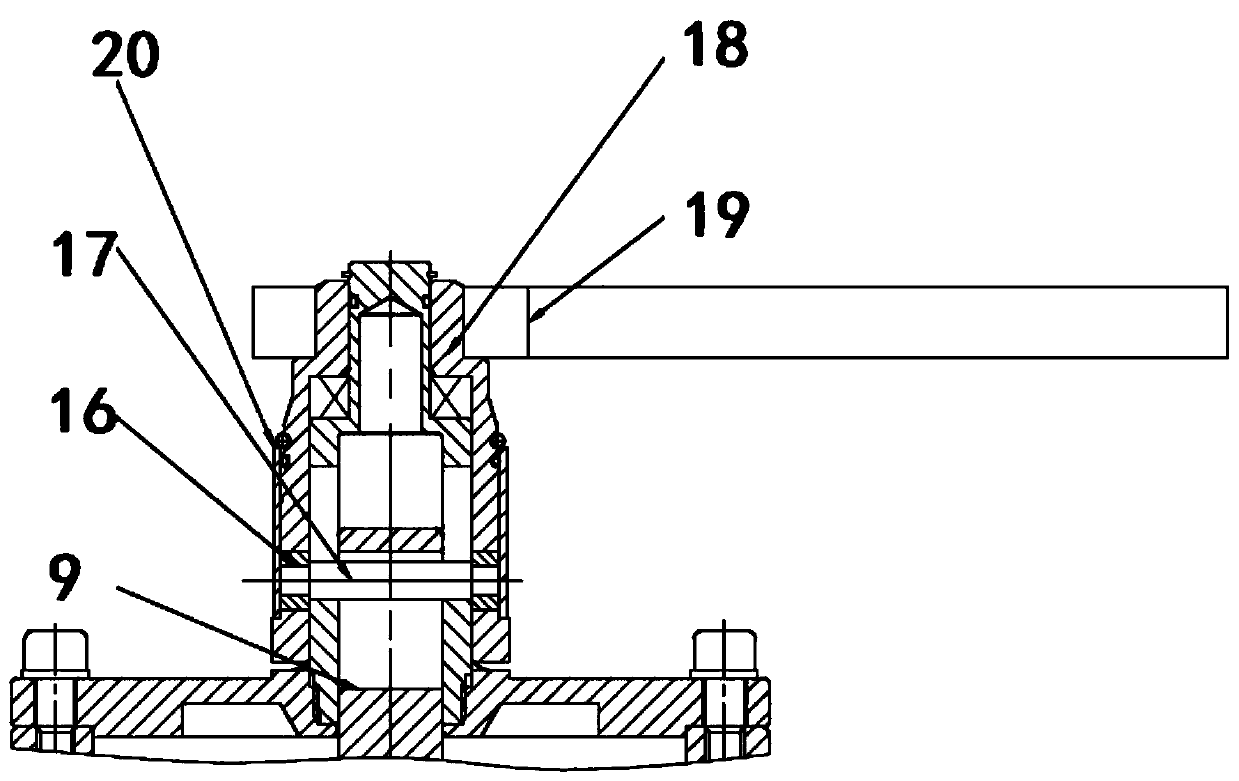

Low-temperature emergency shutoff valve of novel spring air cylinder separation structure

ActiveCN109882624ALower installation heightLowering spring mounting structureSpindle sealingsOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention provides a low-temperature emergency shutoff valve of a novel spring air cylinder separation structure. A valve body is included and comprises a valve cover, an upper cover and a cylinder cover. A valve clack is arranged in the valve body and connected with a valve rod. A connecting pipe is arranged on the outer side of the valve rod. The part between the connecting pipe and the valve rod is sleeved with a spring. The valve rod penetrates through the valve cover and the upper cover to be connected with a connecting rod, and the connecting pipe is located between the valve cover and the upper cover. The connecting rod is fixed to a piston, the piston is connected with an air cylinder body, the air cylinder body is located on the outer side of the piston, and the air cylinder body and the cylinder cover are connected through screws. The valve body further comprises a manual device. The manual device comprises a guiding wheel, a fixing pin, a spiral groove body and a handle,the connecting rod is connected with the fixing pin, the handle is fixedly connected with the spiral groove body, and the guiding wheel and the fixing pin upwards rotate along the spiral groove section of the spiral groove body.

Owner:SHANGHAI FIGURE CRYOGENIC VALVES

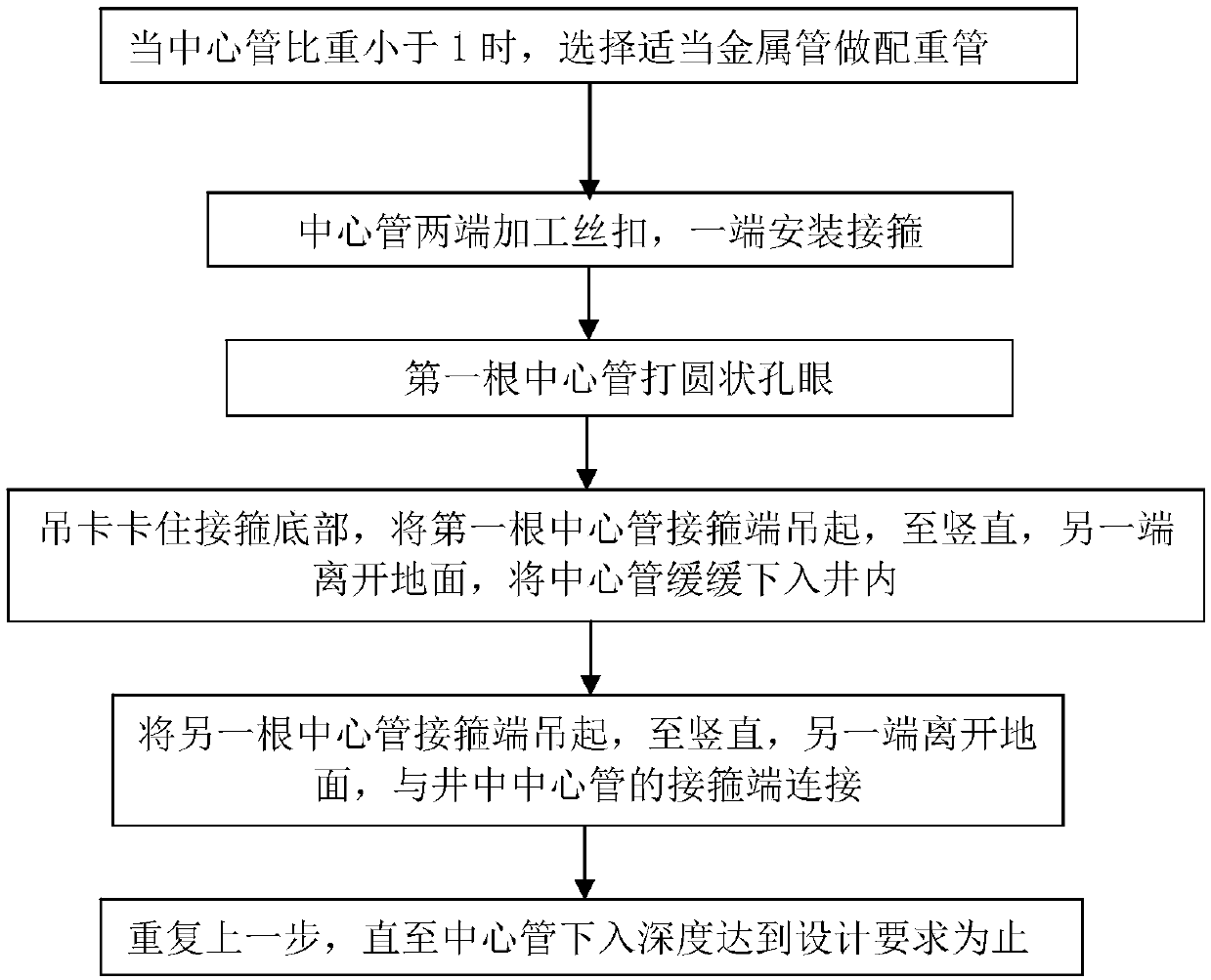

Downward-putting technology for central pipes in vertical well

ActiveCN108049815AProcess advantageAvoid breaking accidentsDrilling rodsLighting and heating apparatusCouplingEngineering

The invention provides a downward-putting technology for central pipes in a vertical well. The downward-putting technology comprises the following steps that 1, when the specific gravity of the central pipes is smaller than 1, a metal pipe is selected as the first central pipe; 2, screw threads are machined at the two ends of the central pipes, and couplings are mounted at one ends of the screw threads; 3, a circular hole is drilled in the circumferential wall of the first central pipe; 4, an elevator is clamped at the bottom of the corresponding coupling, the coupling end of the correspondingcentral pipe is lifted through drilling machine hanging tongs till the central pipe is completely located in the vertical direction, and at the moment, the central pipe is downwards put into the wellslowly the well through the drilling machine hanging tongs; 5, the coupling end of the other central pipe is lifted till the central pipe is vertical, the other end of the central pipe is separated from the ground, and the lifted central pipe is connected with the coupling end of the central pipe in the well; and 6, the step 5 is repeated till the downward-putting depth of the corresponding central pipe meets the design requirement. According to the downward-putting technology, downward putting of the central pipes in the vertical well can be quickly and safely achieved.

Owner:中国煤炭地质总局第二水文地质队

Split-type hydraulic press rack and mounting method thereof

ActiveCN106956461AGuaranteed stiffnessImprove reliabilityPressesIndustrial engineeringHydraulic press

The invention relates to a split-type hydraulic press rack comprising a first frame, a second frame, locating keys, a supporting leg, supporting leg anchoring parts, pull rods and pull rod anchoring parts; the first frame is vertically mounted on the top end of the supporting leg; one side of the first frame is provided with the locating keys; locating key holes are formed in one side of the second frame; the first frame is fitted with the second frame by fitting the locating keys with the locating key holes; and the first frame and the second frame are vertically fixed on the supporting leg by the supporting leg anchoring parts. By changing the structure of the split-type hydraulic press rack, the rack is not needed to be hoisted again after being assembled, so that the problem that an ultralarge hydraulic press rack cannot be wholly hoisted because of being ultraheavy is solved; and the whole hoisting of the rack is simplified to form only single frame hoisting, so that the hoisting difficulty is lowered, it is convenient for production staff to operate equipment, the production cost is reduced, the service life of the rack is prolonged, and the market prospect is wide.

Owner:FOSHAN HENGLITAI MACHINERY

Antistatic flame-retardant PE pipe and preparation method thereof

The invention discloses an antistatic flame-retardant PE pipe and a preparation method thereof. The PE pipe is prepared from 4-6% of fire retardant, 0.5-1.5% of auxiliary flame retardant, 4-6% of antistatic agent and 86-91% of PE base material. The auxiliary components in the formula are concentrated first to prepare dual-resistance master batch, then the master batch is mixed with body resin in proportion, and then the materials are extruded and granulated through a twin-screw extruder. The PE pipe has the advantages of being good in ageing resistance and not prone to embrittlement, having good toughness and impact energy absorption, and being good in rapid crack resistance and corrosion resistance, free of scaling, smooth in inner wall and capable of improving the conveying capacity by 30%.

Owner:SANTEH PIPE & FITTINGNANTONG CO LTD

Automatic cotton yarn textile machine

ActiveCN111826781AWill not be affected by the winding processSave rotation timeLoomsYarnElectric machinery

The invention relates to the technical field of textile machines, in particular to an automatic cotton yarn textile machine. The machine comprises a bottom plate, an alignment mechanism, a distance adjusting mechanism and a driving mechanism. Positioning grooves are formed in the four corners of the bottom plate correspondingly. The two sides of the bottom plate are fixedly connected with a vertical plate and a main shell correspondingly. The distance adjusting mechanism and the driving mechanism are arranged in the main shell, and the alignment mechanism is arranged on the vertical plate. According to the automatic cotton yarn textile machine, a driving motor drives transmission wheels and a rotating plate, insertion columns can rotate along with the rotating plate to wind woven cloth, then a cloth roller is pushed by a pushing cylinder to enter the inner side of a woven cloth roll, sliding blocks can get close to each other through the contraction of a hydraulic rod, and therefore the cloth roller can replace the supporting positions of the insertion columns; and when the pushing cylinder contracts, the cloth roller can be reset to a limiting base. Meanwhile, the remaining wovencloth is hung on a winding structure again, when a worker carries the rolled cloth roller, the winding working procedure of the next cloth roller cannot be affected, and the alternating time is saved.

Owner:临邑恒丰纺织科技有限公司

Bolt type tool joint

The invention provides a bolt type tool joint which comprises a male tool joint body, a female tool joint body and a bolt. A first bolt opening is formed in the male tool joint body, a second bolt opening is formed in the female tool joint body, the bolt penetrates through the first bolt opening and the second bolt opening, the bolt is a rectangular right-angle table body, and the width of the bolt is smaller than the diameter of the male tool joint body. The bolt type tool joint is convenient to detach and can be conveniently used by a user.

Owner:福建省正丰信息技术发展有限公司

Door body switch structure for cooking device and cooking device

ActiveCN110584464AImprove convenienceAvoid bendingSteam cooking vesselsRoasters/grillsElectricityElectric wire

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

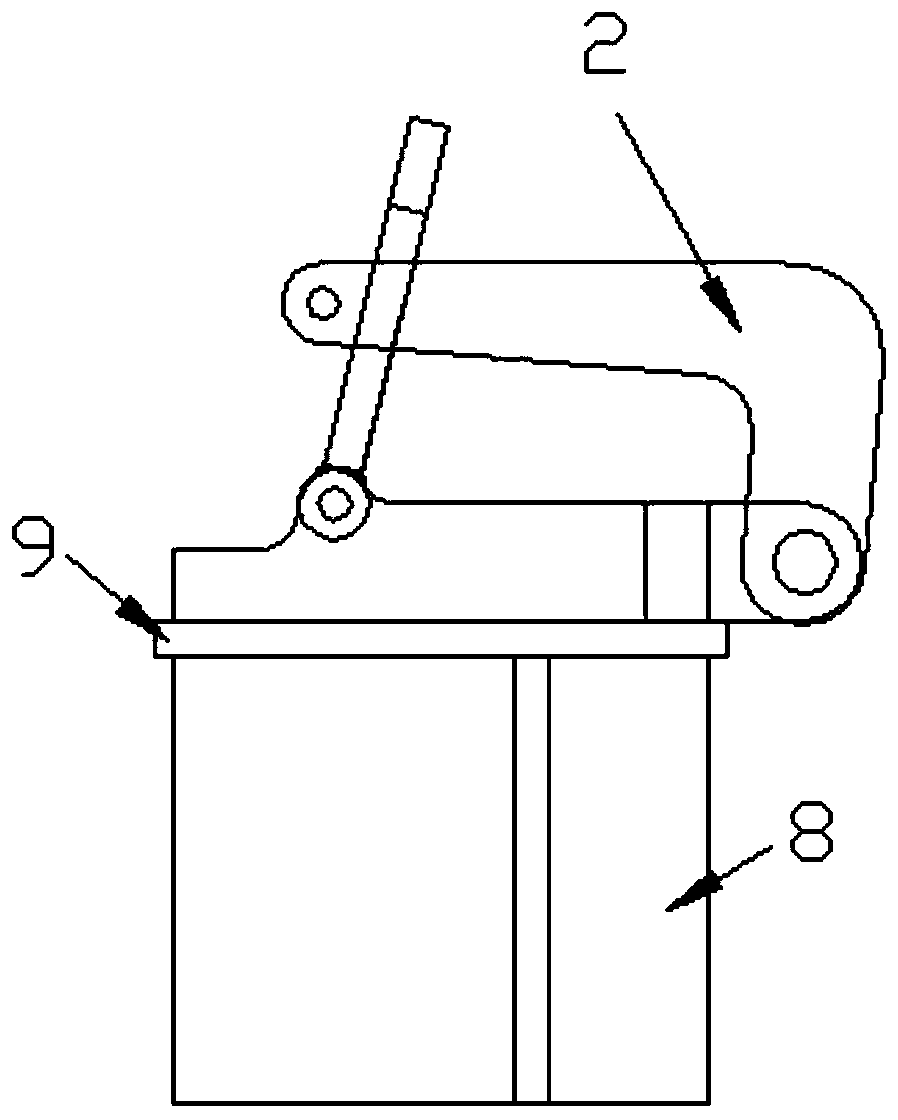

Tool for quickly loosening reserved rope and anchor chain

ActiveCN111439341AAvoid breaking accidentsGuaranteed stabilityWaterborne vesselsPull forceSupport point

The invention discloses a tool for quickly loosening a reserved rope and an anchor chain. The tool comprises a base structure fixed to the deck surface of a ship, a hook loosening bottom plate is fixedly arranged on the base structure, a hook provided with the reserved rope or the anchor chain is hinged to the hook loosening bottom plate, a clamping plate used for clamping the hook is further hinged to the hook loosening bottom plate, and the hinge points of the hook and the clamping plate on the hook loosening bottom plate are spaced; and a safety auxiliary groove used for sharing stress is formed in the surface of the hook, or a safety auxiliary hole used for sharing stress is formed in the hook, a steel wire rope used for sharing stress is fixedly arranged on the base structure, one endof the steel wire rope is fixedly connected to the base structure, and the other end of the steel wire rope is connected to the base structure in a fastening or clamping mode. The supporting point oftension is changed, shackles do not need to be disassembled, through mechanical calculation, the mechanical steering working principle and the lever principle, the acting point of force is transferred, the force is reduced, operation is convenient, the hook loosening speed is increased, and the cross arm recycling operation waiting time is shortened.

Owner:CHENGXI SHIPYARD +1

Stirring paddle for mechanical stirring apparatus

The present invention relates to a stirring paddle for a mechanical stirring apparatus. The stirring paddle comprises a stirring paddle support base and stirring paddle blades, wherein the stirring paddle support base comprises a stirring main shaft, a support plate fixedly arranged on the stirring main shaft and a fixation frame connected with the support plate. The stirring paddle has characteristics of simple and unique structure, low cost and short production cycle, provides creative improvement for the stirring paddle for the existing domestic mechanical stirring equipment, is suitable for hydrometallurgy, chemical industry, phosphate fertilizer, and other industries, and provides significant economic benefits and social benefits. In addition, based on a large amount of designs, manufactures and installations of stirring equipment and various steel components, the stirring paddle is completed through careful design calculation and assurance of the strength required by stirring.

Owner:NO 9 METALLURGICAL CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com