Split-type hydraulic press rack and mounting method thereof

A hydraulic press and split-type technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to lift as a whole, hoisting, and the overall weight of the frame, etc., achieve simple and fast installation methods, improve service life, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

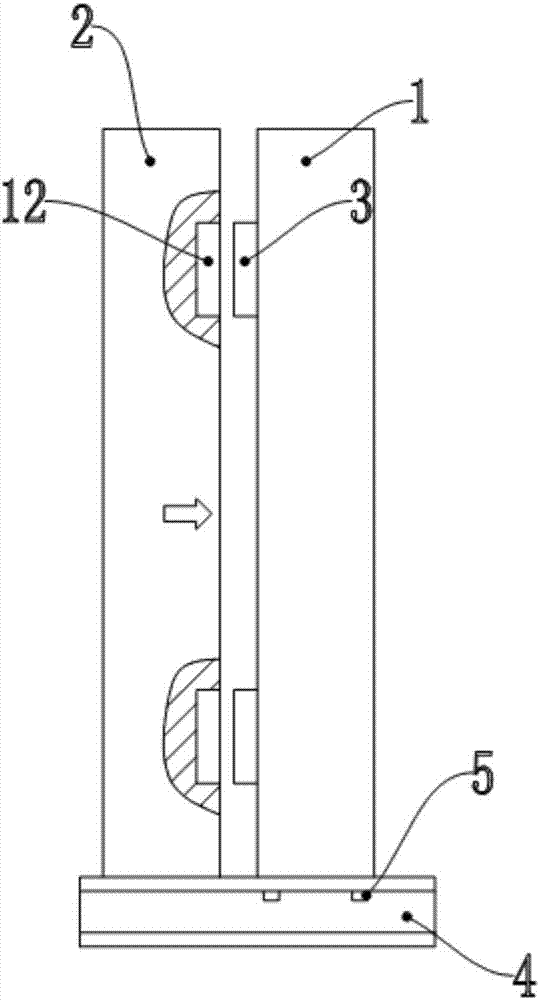

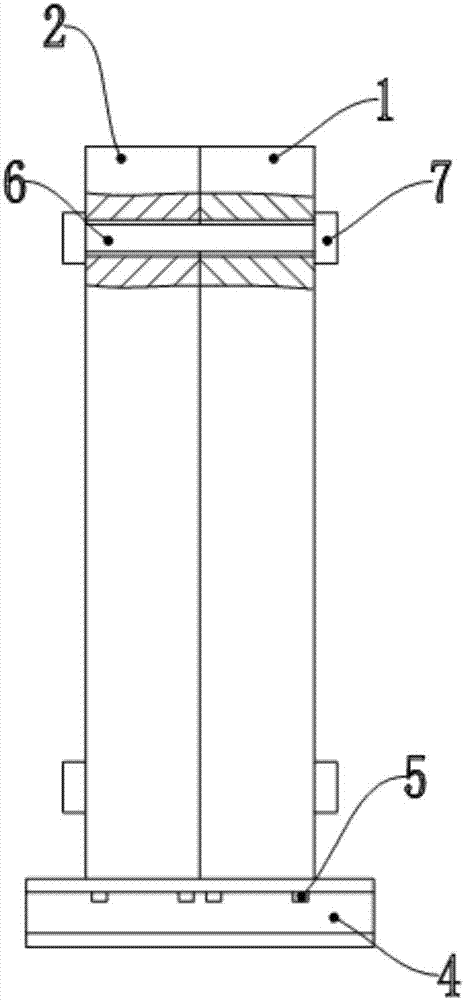

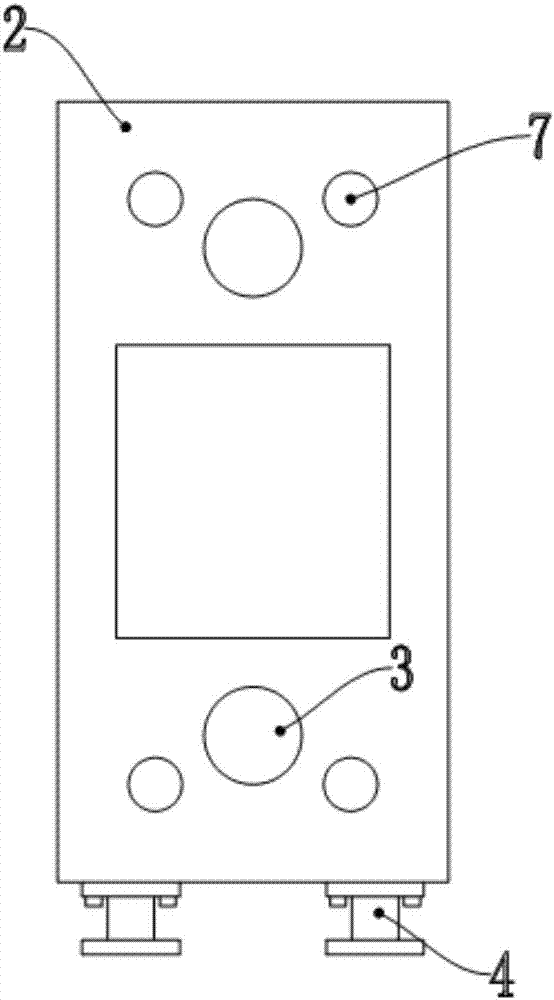

[0028] A split hydraulic machine frame, such as Figure 1-4 As shown, it includes a first frame 1, a second frame 2, a positioning key 3, a leg 4, a leg anchor 5, a pull rod 6 and a pull rod anchor 7, and the first frame 1 is vertically installed on the top of the leg 4 , one side of the first frame 1 is provided with the positioning key 3; one side of the second frame 2 is provided with the positioning key hole 12, by fitting the positioning key 3 with the positioning key hole 12 , so that the first frame 1 and the second frame 2 fit together, and the first frame 1 and the second frame 2 are vertically fixed on the feet 4 through the foot anchors 5;

[0029] The tie rod 6 horizontally passes through one side of the first frame 1 and the second frame 2, and the two ends of the tie rod 6 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com