Robot end execution protection mechanism with one-way buffering function

A technology of end execution and protection mechanism, applied in the direction of manipulators, manufacturing tools, etc., to achieve the effect of protecting the body of the manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

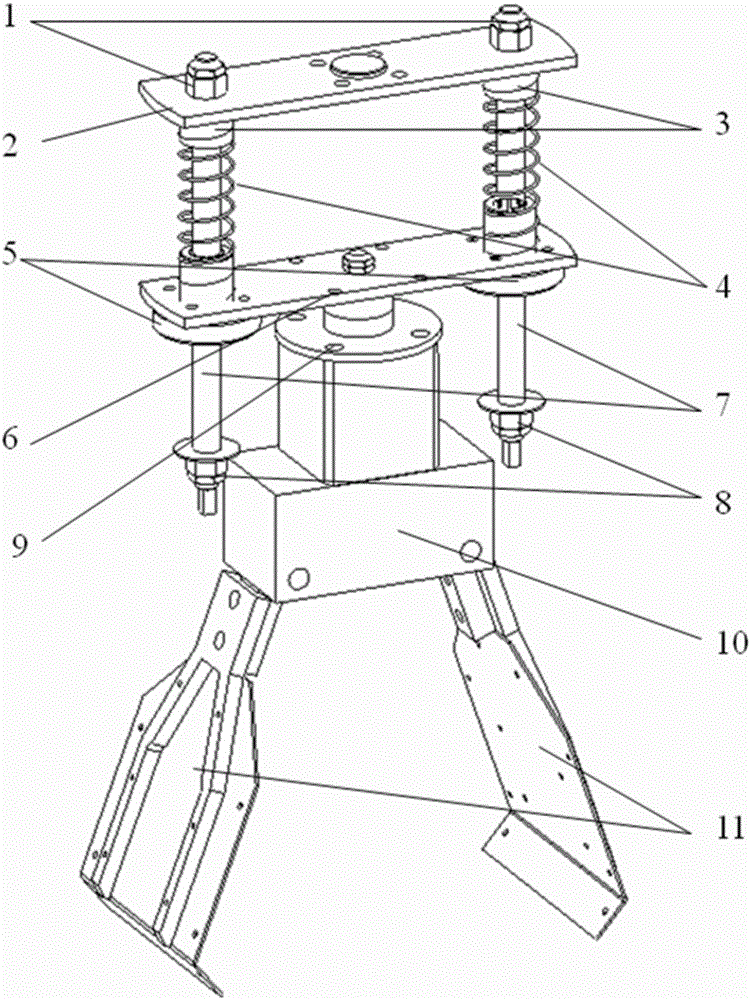

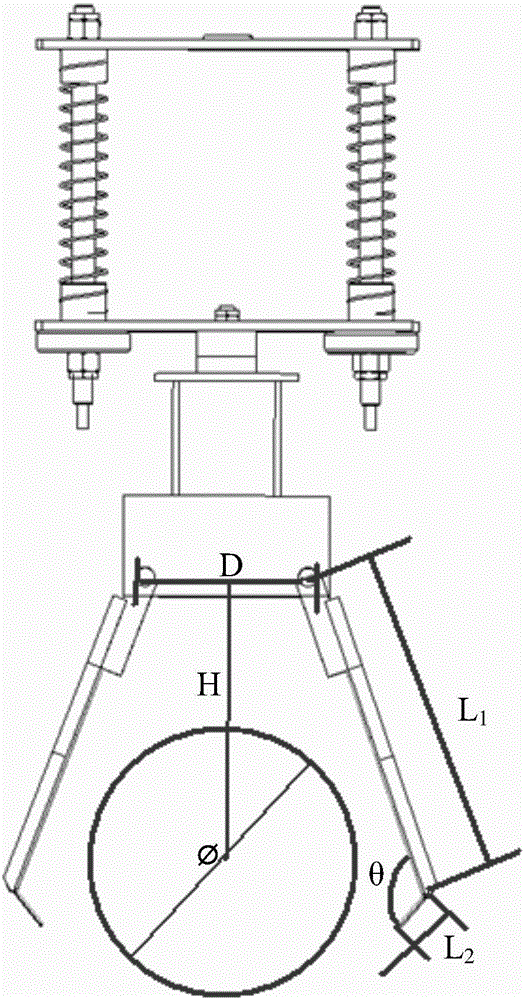

[0019] Ordinary industrial manipulators are connected based on rigid mechanisms. When the end effector has a rigid collision, it will bring a huge impact to the manipulator body or even directly damage the manipulator. This paper proposes a full-degree-of-freedom manipulator end protection mechanism based on a leather bag cylinder. . As the connecting mechanism between the manipulator body and the end effector, the mechanism is elastic in all six degrees of freedom in space. At the same time, the mechanism has a preload in six degrees of freedom. When the load in each direction is less than the corresponding preload, the mechanism acts as a rigid body to ensure the stiffness of the mechanical arm; when the load in a certain direction is greater than the corresponding When the pre-tightening force is applied, the mechanism will compress and deform to absorb the impact potential energy and protect the robot arm body.

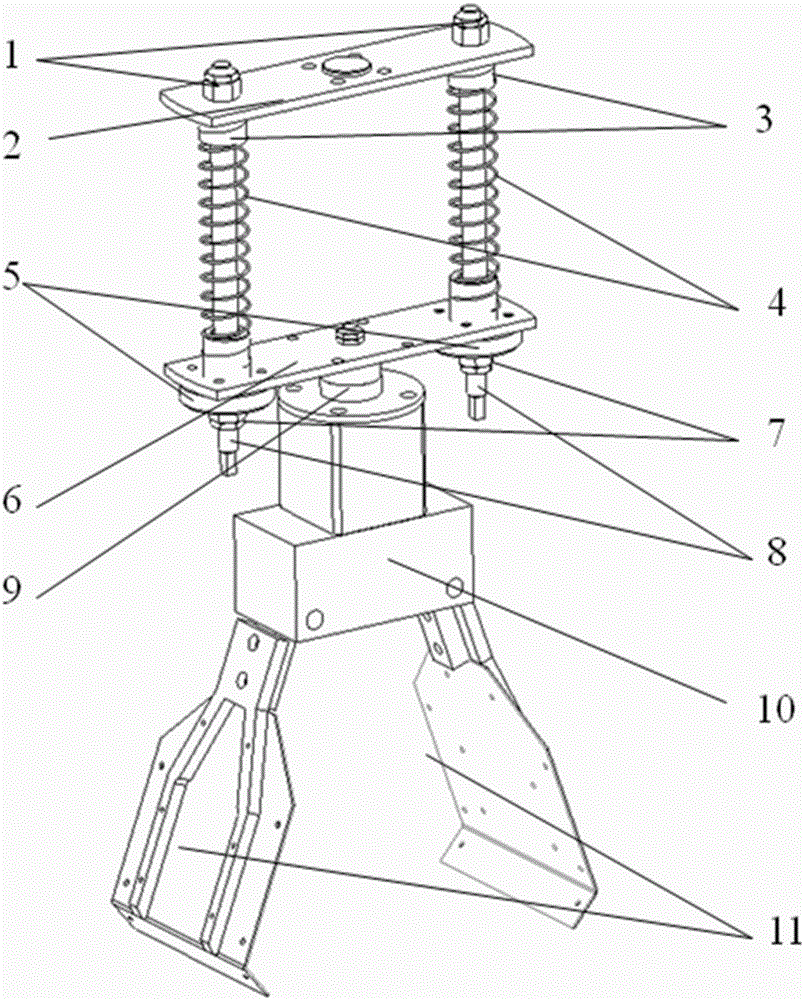

[0020] like figure 1 , 2 , 4, the robot terminal executio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com