Pre-stress steel-concrete tower cylinder for wind turbine generator

A technology of prestressed steel and wind turbines, applied in wind power generation, installation/support of wind turbine configuration, sustainable manufacturing/processing, etc., can solve the difficulty in meeting large-scale wind turbines. Concrete construction quality is difficult to guarantee, formwork disassembly is cumbersome, etc., to achieve the effect of being conducive to the safe and stable operation of the structure, facilitating tension and anchoring operations, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

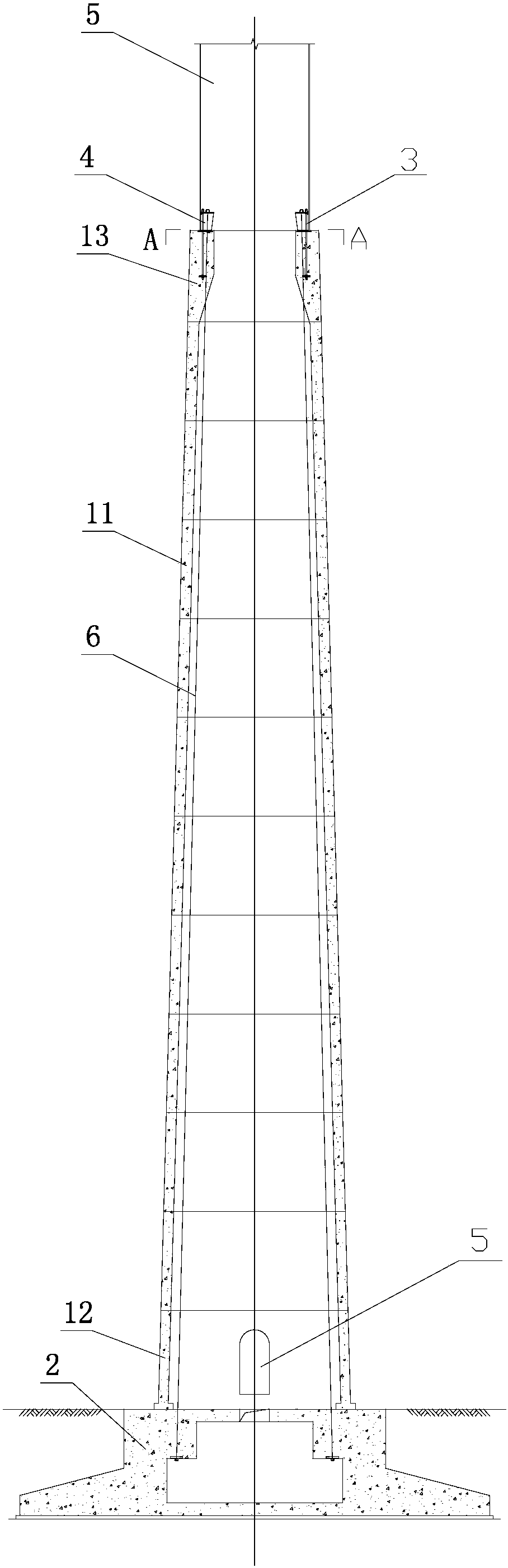

[0034] This embodiment is a prestressed steel concrete tower of a wind turbine, in which the concrete tower is 48 meters high. The present invention will be further described in detail below with reference to the accompanying drawings.

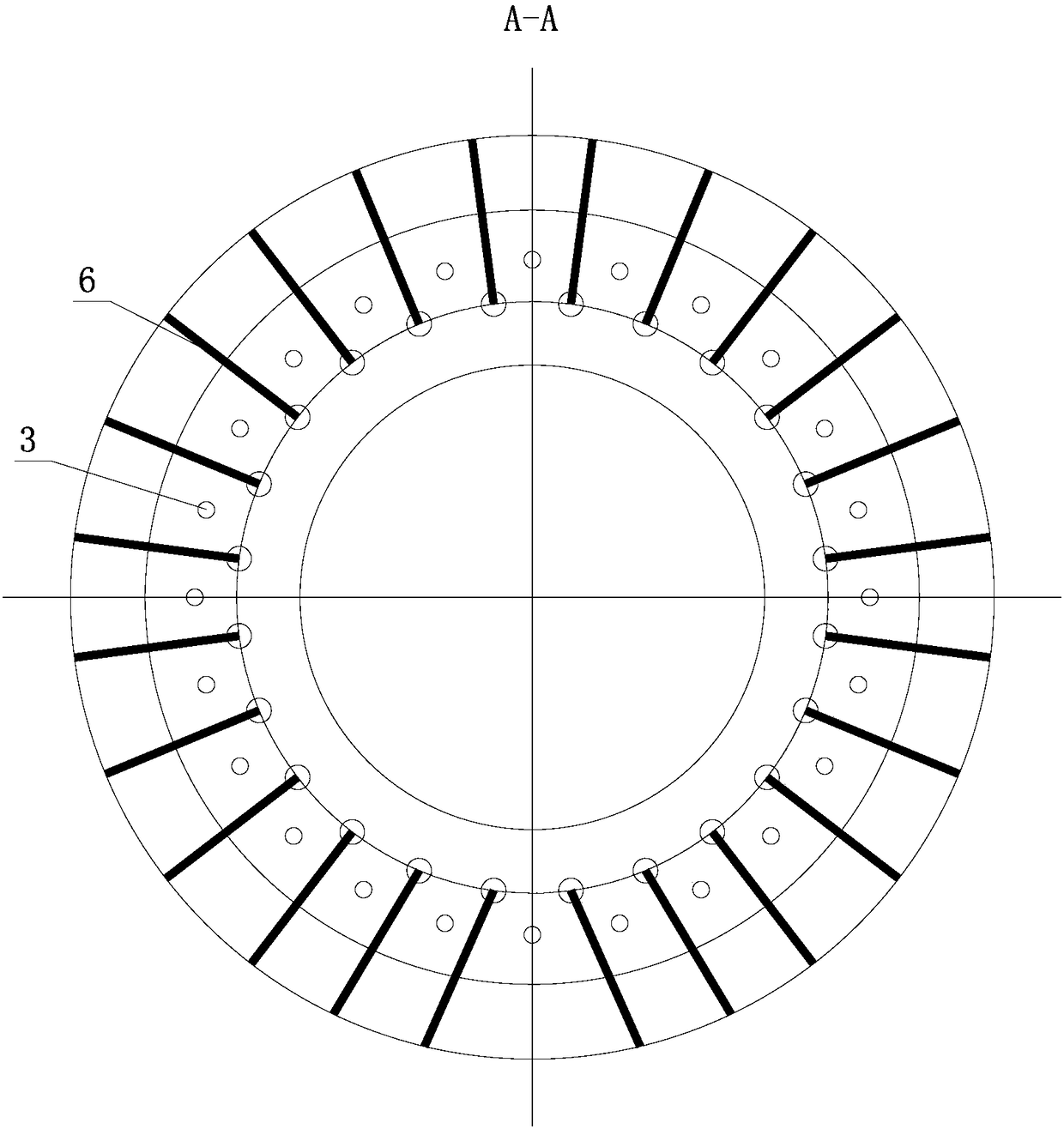

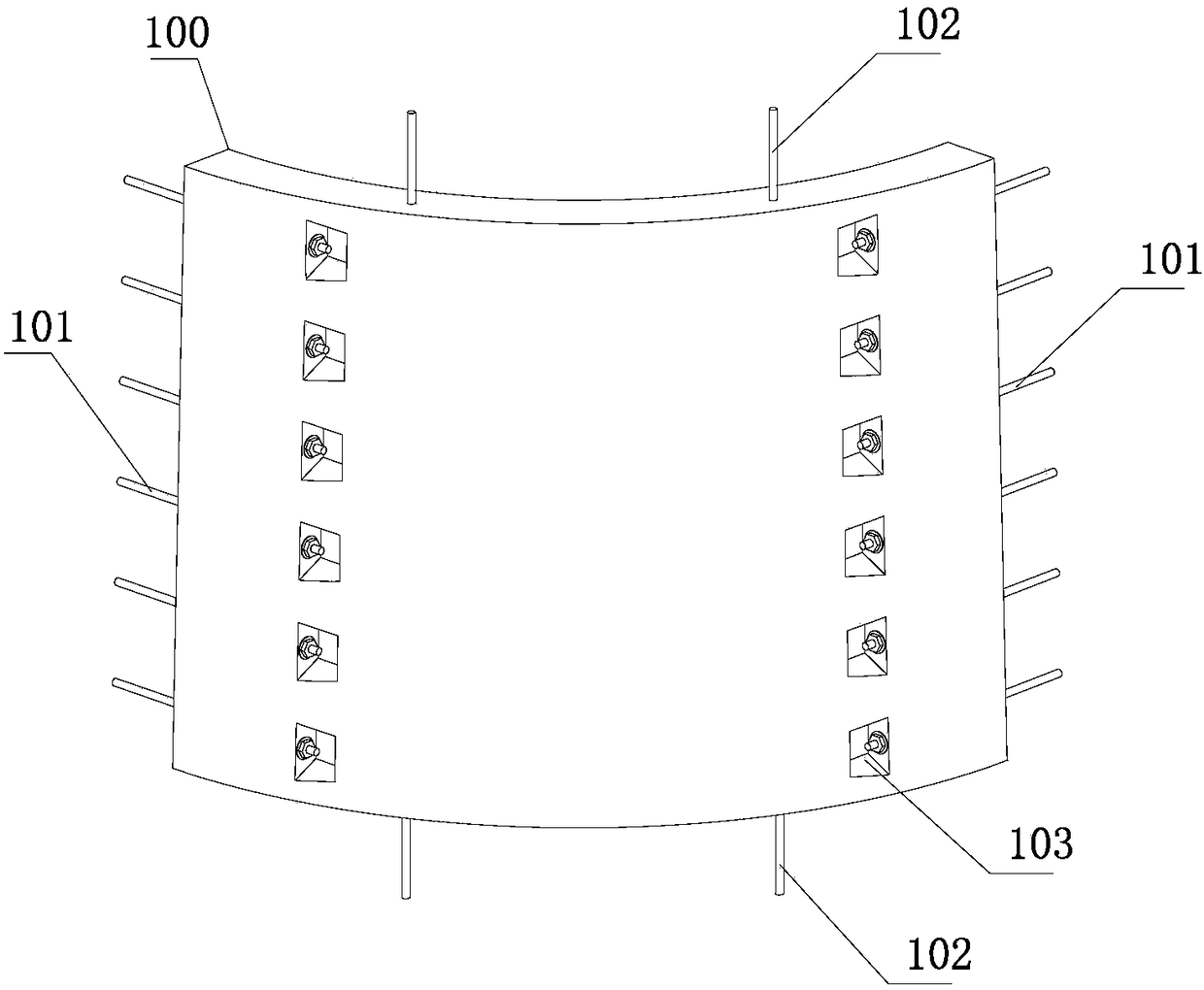

[0035] Such as Figure 1~Figure 9 As shown, the concrete tower tube is formed by staggered connection of the bottom section 12, the top conversion section 13 and ten middle sections 11, and the segmentation method is horizontal segmentation; each section of the tower tube consists of four pieces of the same 1 / 4 circle 100 pieces of curved precast concrete are spliced together, and the method of slicing is vertical slicing. All concrete tower segments 100 are uniformly prefabricated and maintained in the prefabrication plant and transported to the site for splicing and hoisting. After the splicing of the entire concrete tower is completed, it is in the shape of a towering truncated cone. The top outer diameter of the tower tube is 5.2m, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com