Foundation pile for photovoltaic bracket in frozen soil area and manufacturing method thereof

A manufacturing method and technology for photovoltaic support, which are applied in infrastructure engineering, sheet pile walls, manufacturing tools, etc., can solve problems such as failure to meet design strength requirements, prefabricated pile foundation fracture, cold brittle fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

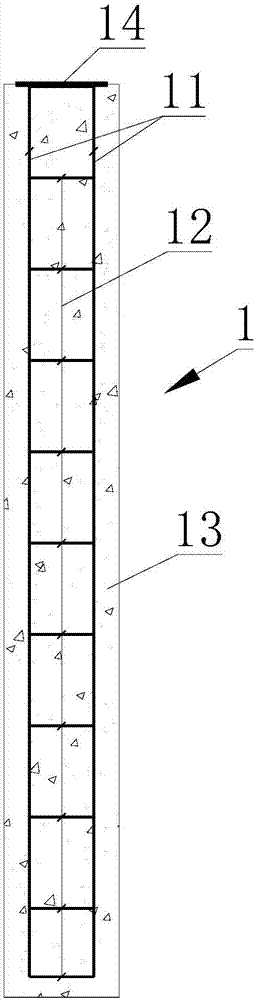

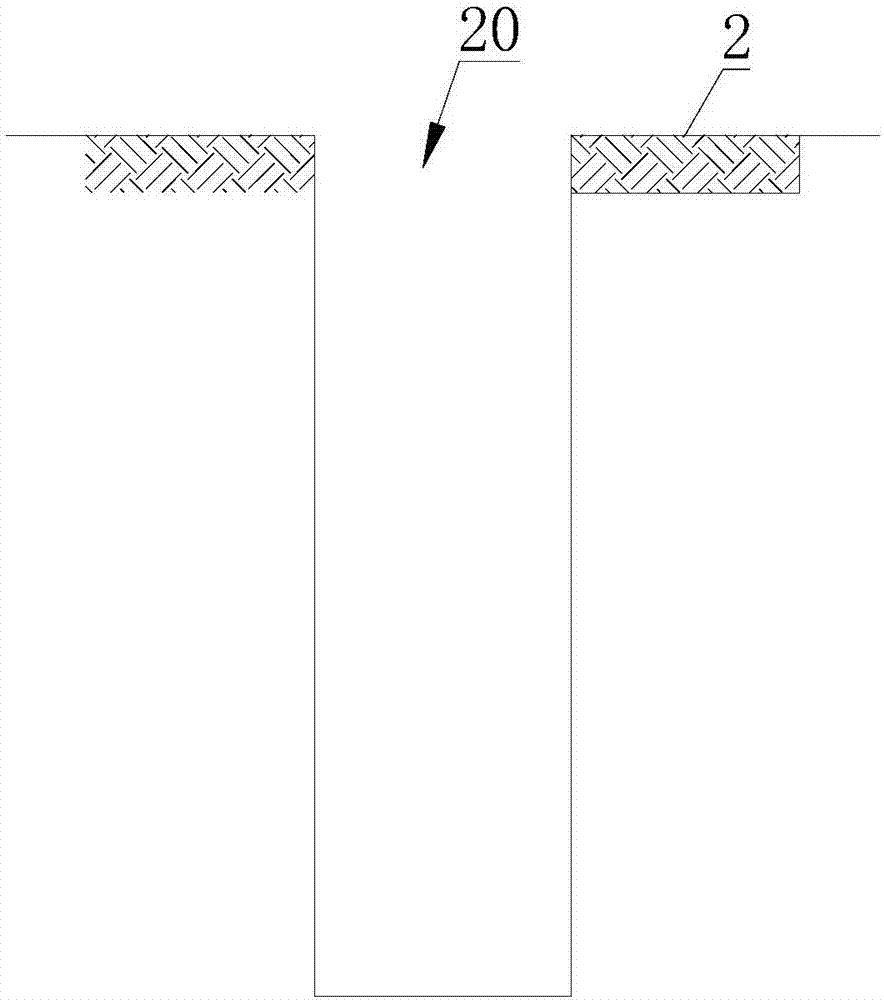

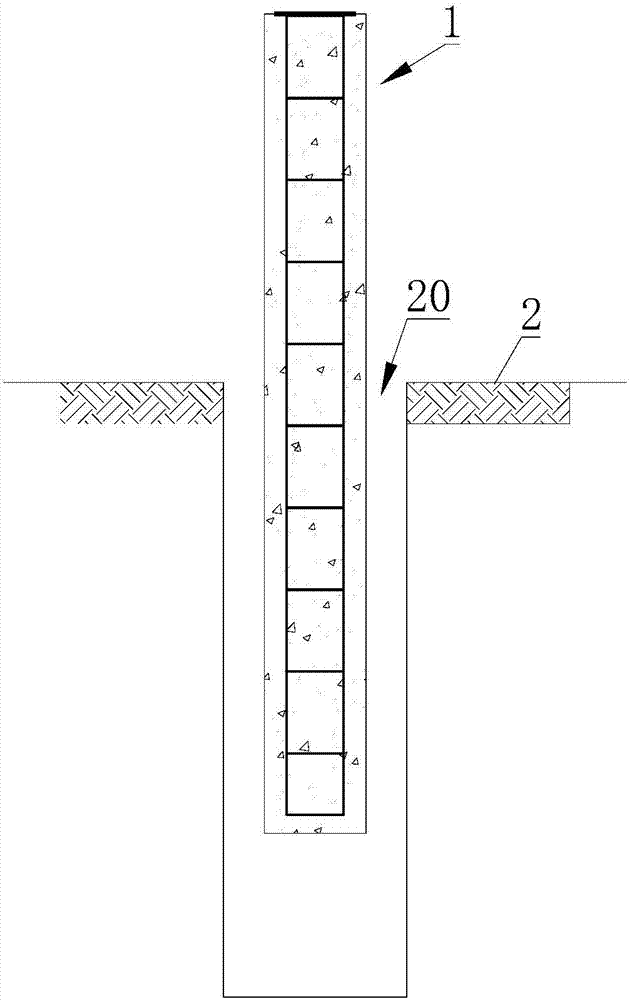

[0045] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

[0046] The present invention aims to provide a method for making foundation piles suitable for photovoltaic supports in frozen soil areas, which can address the problems existing in winter construction in frozen soil areas. The present invention first solves the problem that concrete cast-in-place piles are not suitable for maintenance, and the pile quality is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com