Bolt type tool joint

A drill pipe joint and plug-type technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of weakening the strength of the drill pipe joint, fracture of the drill pipe joint, and high equipment costs, so as to reduce the labor intensity of disassembly and improve Strength, the effect of reducing drill pipe fracture accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

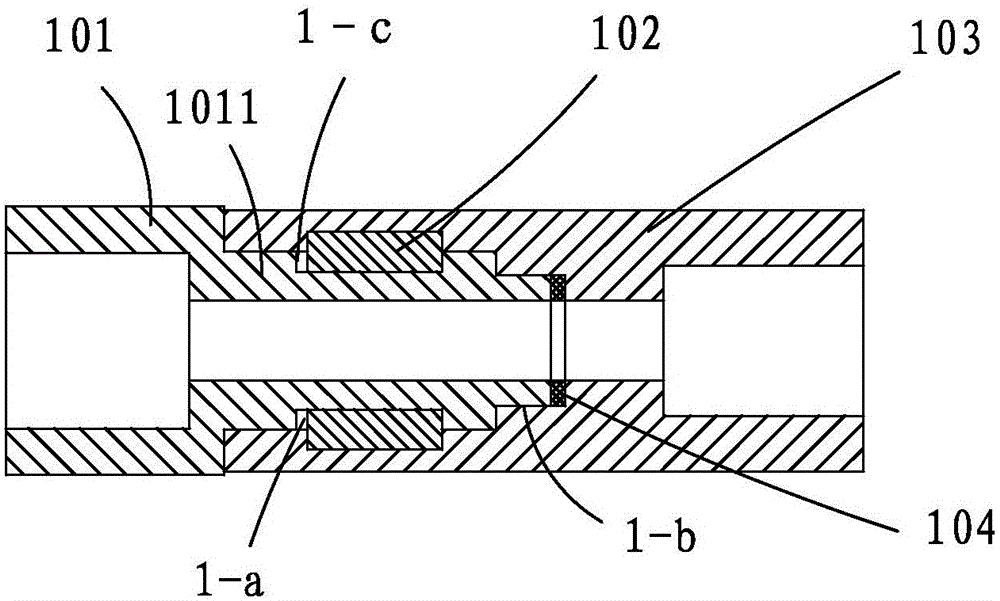

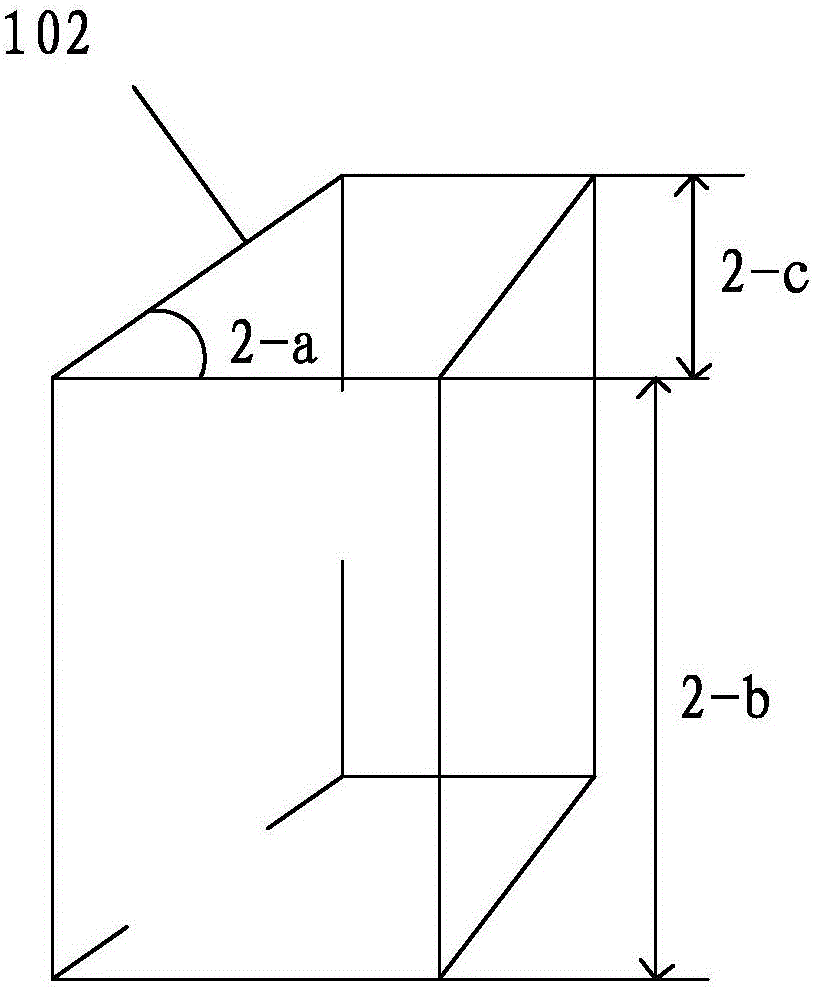

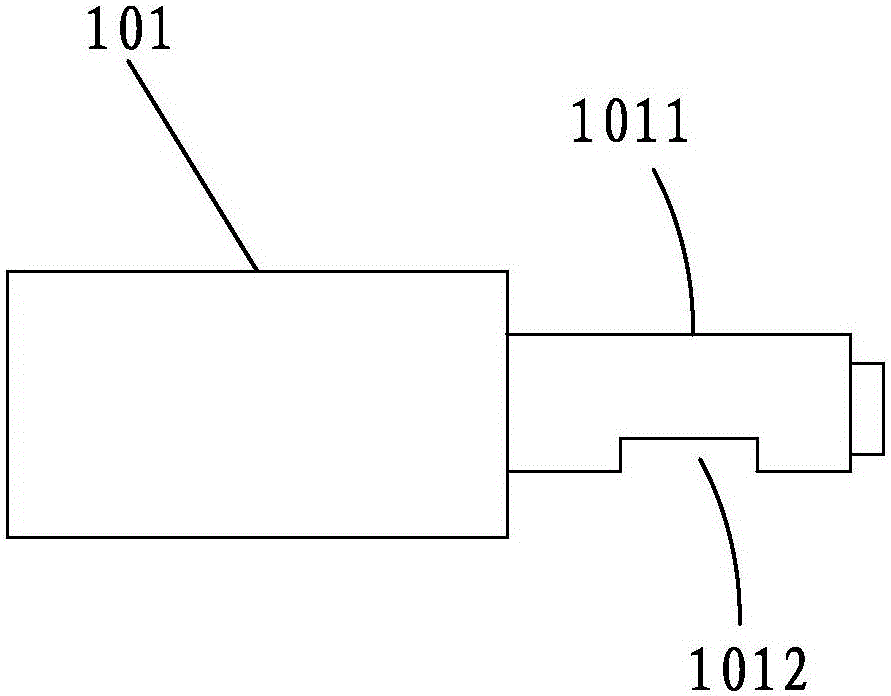

[0015] Such as figure 1 , figure 2 as well as image 3 As shown, the plug-type drill pipe joint of the present invention includes a drill pipe male joint 101, a latch 102, a drill pipe female joint 103 and a gasket 104, and the drill pipe male joint 101 is provided with a first pin opening 1-a, The drill pipe female joint 103 is provided with a second pin opening 1-b, the pin 102 passes through the first pin opening 1-a and the second pin opening 1-b, and the pin 102 is a rectangular right-angle platform body, the second pin opening 1-b is a right-angled trapezoid, the pin 102 just passes through the second pin opening 1-b, and the width of the pin 102 is smaller than that of the drill pipe male joint 101 (or drill pipe The diameter of the female joint 103), the drill pipe male joint 101 is provided with a protrusion 1011, the first pin opening 1-a is a groove 1012 on one side of the protrusion 1011, and the second pin opening 1 -b just passes through the groove 1012, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com