Patents

Literature

41results about How to "Not easy to embrittle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

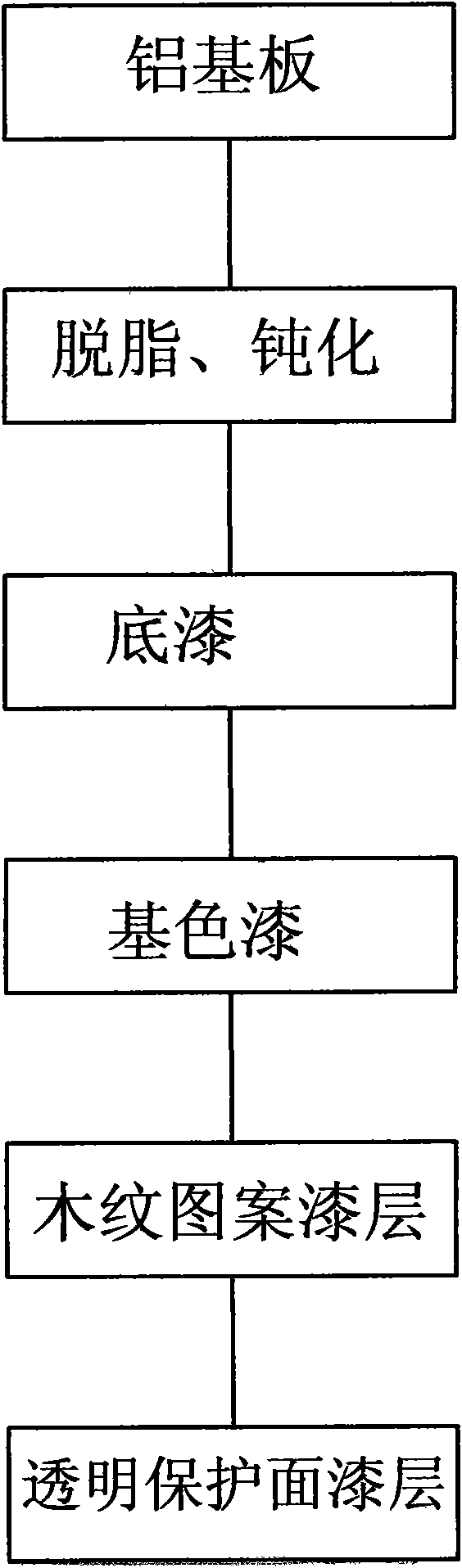

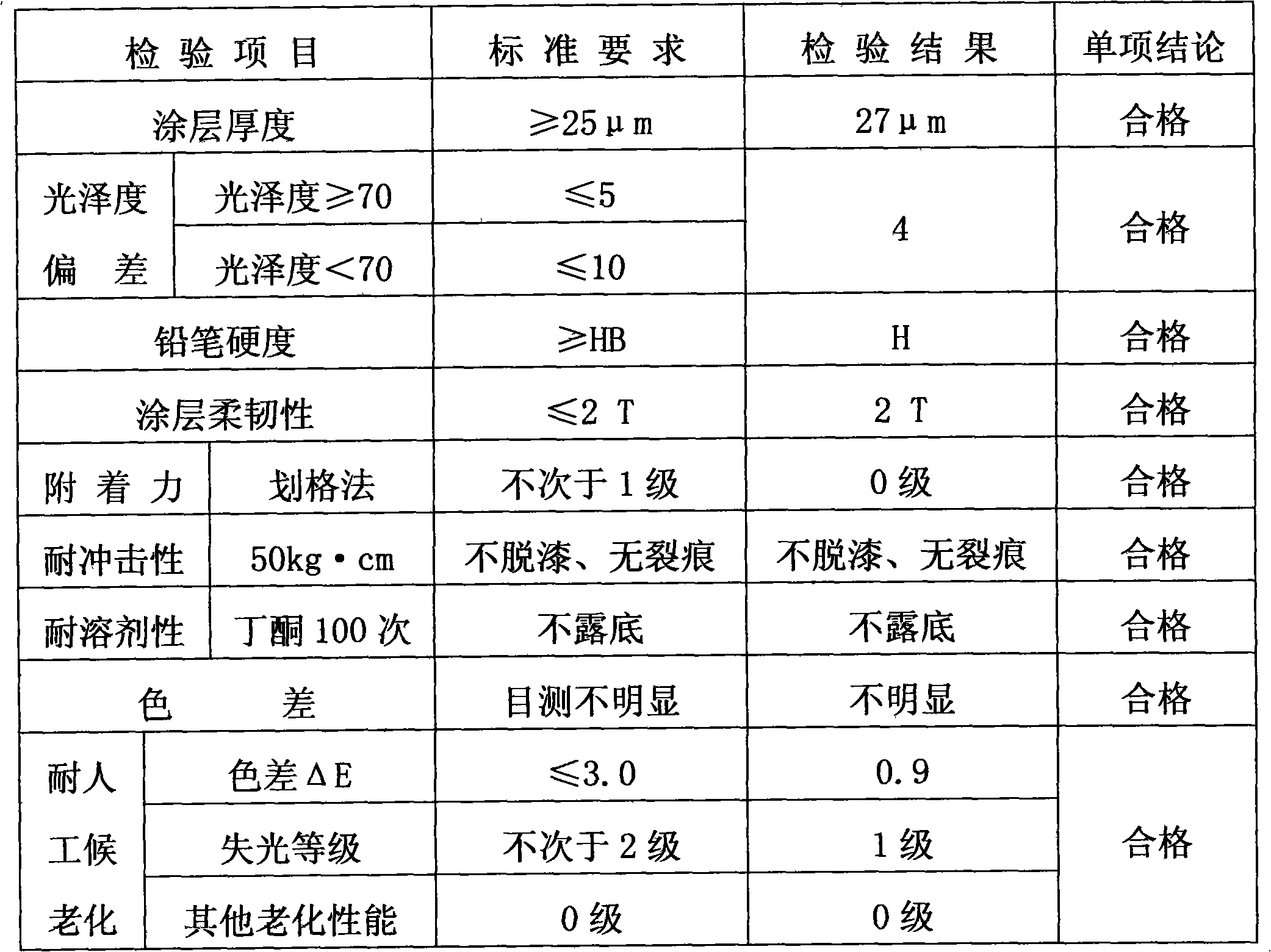

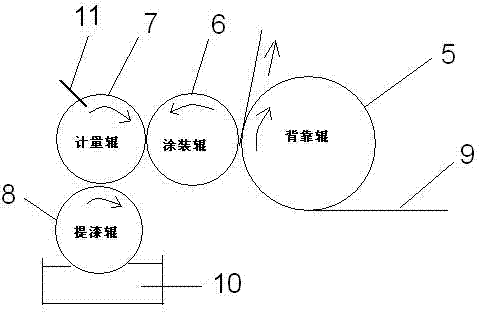

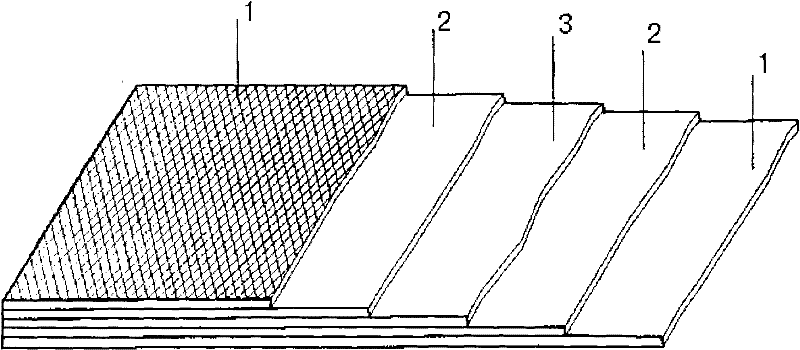

Process for manufacturing wood grain color coated aluminum plate

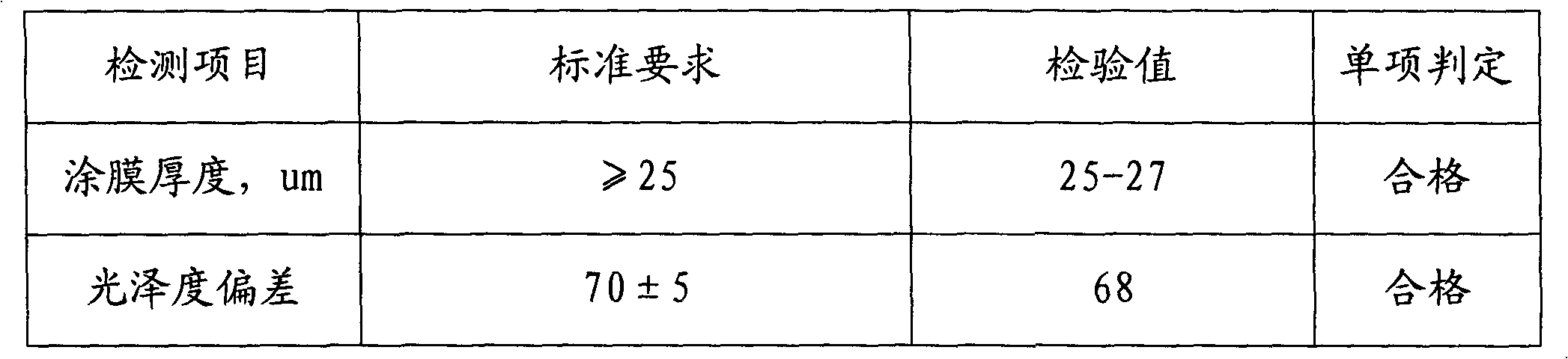

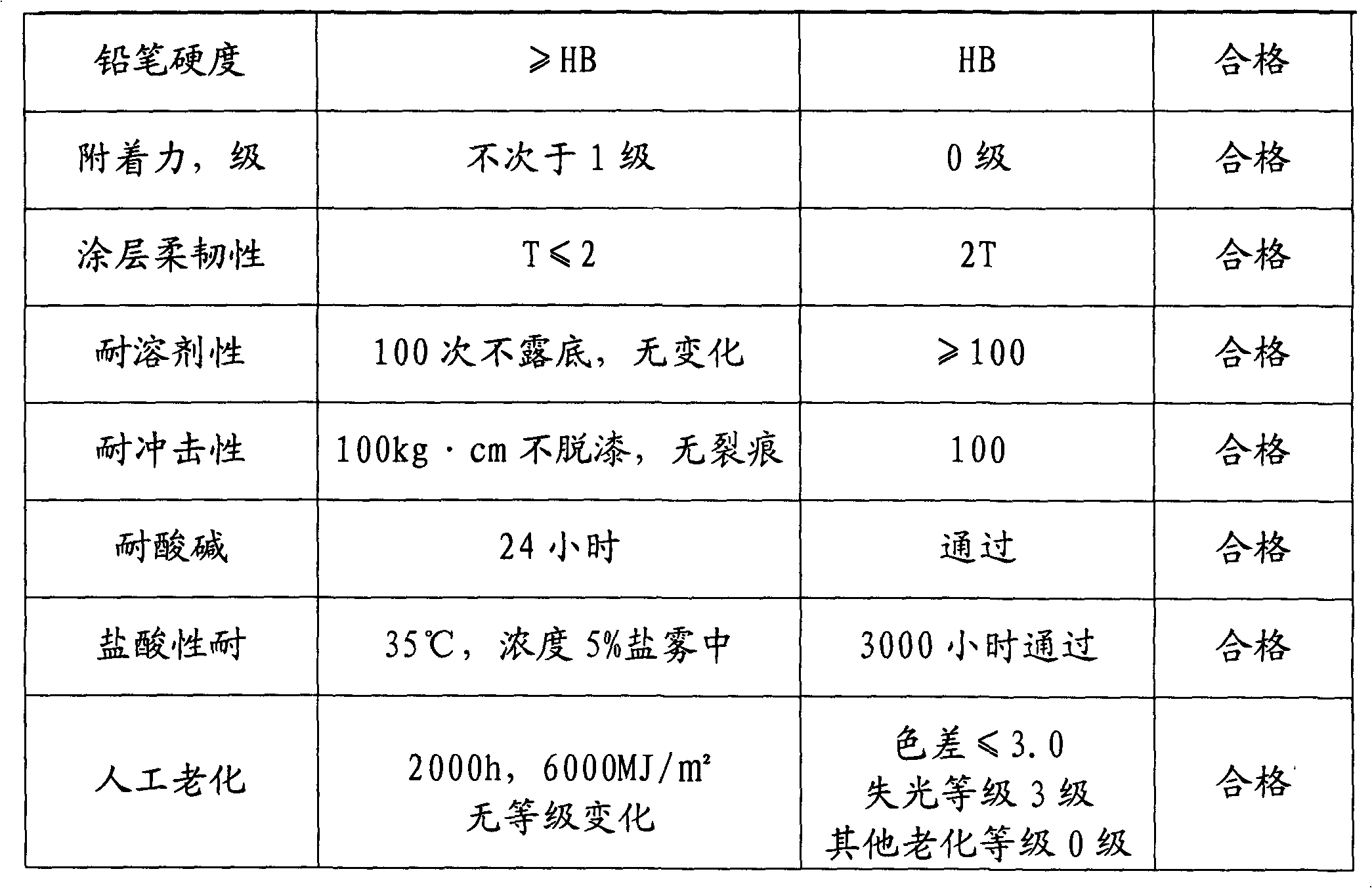

ActiveCN101590466ANot easy to fall offNot easy to embrittlePretreated surfacesCoatingsLacquerAluminum substrate

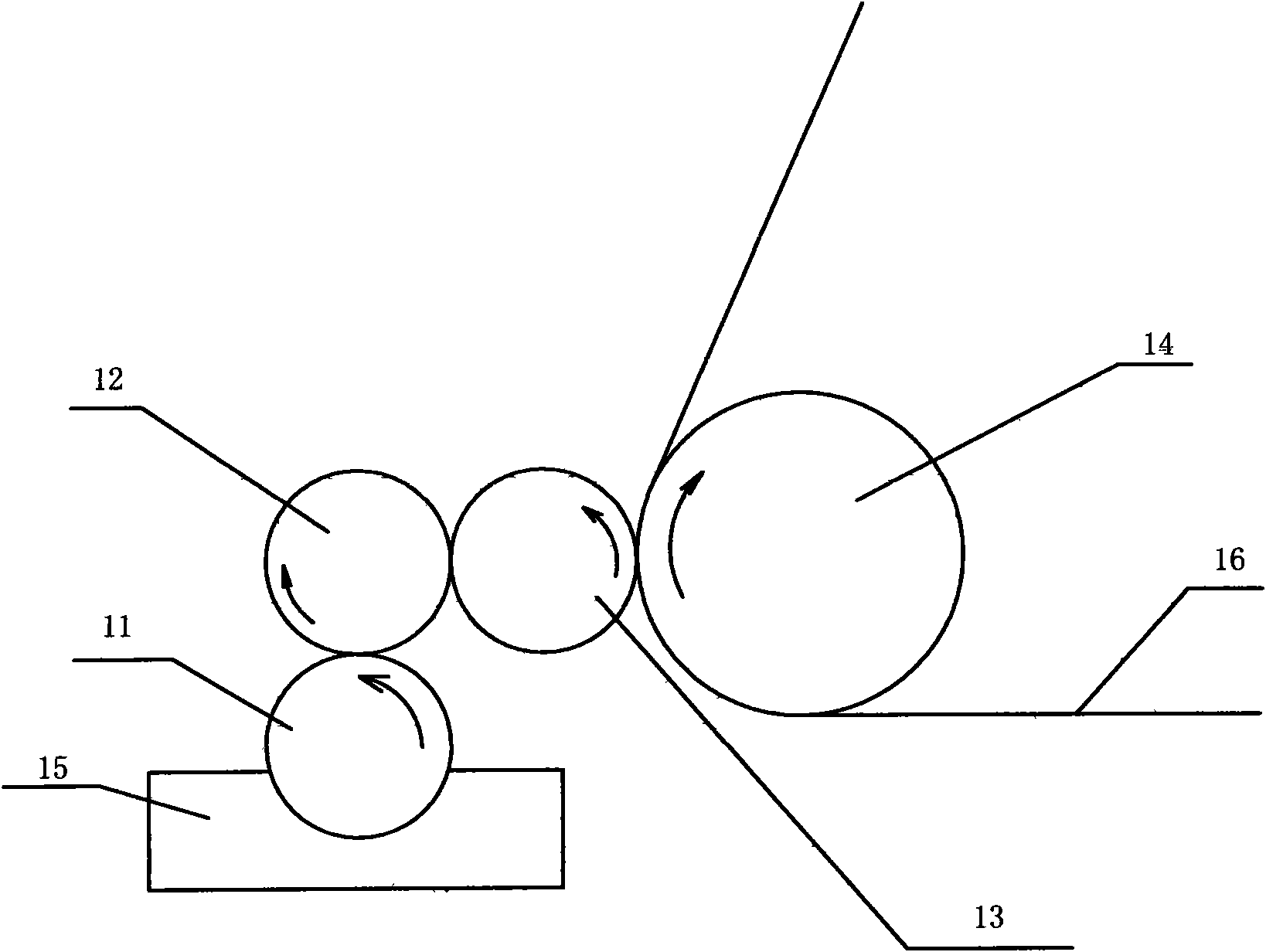

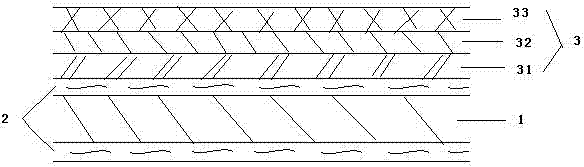

The invention discloses a process for manufacturing a wood grain color coated aluminum plate. The process comprises the following steps: carrying out degreasing and passivating pretreatment processes for an aluminum substrate; coating a layer of polyurethane paint on a passive film layer, baking the polyurethane paint in an oven to form a film so as to form base paint, then coating a layer of fluorocarbon resin paint on the base paint, baking the fluorocarbon resin paint in the oven to form a film so as to form primary color paint, and combining the base paint and the primary color paint to form a primary color base paint layer; coating a layer of fluorocarbon resin paint on the primary color base paint layer through a coating roller engraved with wood grains, and baking the fluorocarbon resin paint in the oven to form a firm so as to form a wood grain pattern paint layer; and coating a layer of fluorocarbon resin varnish on the wood grain pattern paint layer, and baking the fluorocarbon resin varnish in the oven to form a film so as to form a transparent protective finishing paint layer. The wood grain color coated aluminum plate manufactured by the process has color and wood floral patterns, is not easy to shed or tender each coating, and has good weather resisting property.

Owner:ZHEJIANG WONDERFUL WALL BUILDING MATERIALS

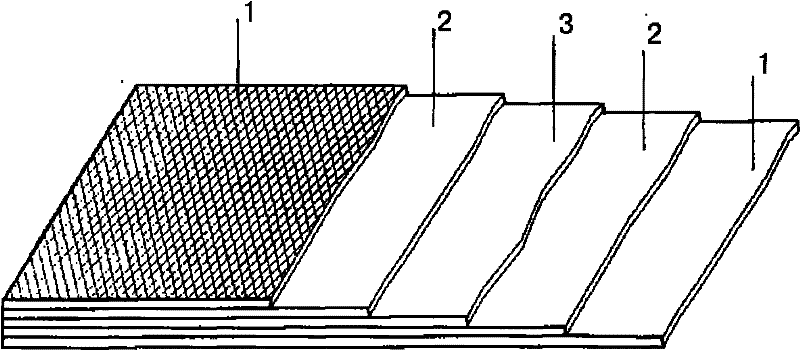

Clean water stone line painted aluminium plate and manufacturing process thereof

ActiveCN102312539AStable control dosageImprove coating efficiencyCovering/liningsPretreated surfacesWeather resistanceAdhesive

The invention mainly discloses a clean water stone line painted aluminium plate and a manufacturing process thereof. The manufacturing process comprises the following steps: 1, providing continuous aluminum base plates, degreasing and washing before processing, passivating one layer of compact oxidation film as a passivation film layer; 2, painting a base color bottom painting layer so as to ensure that the whole painting painting layer has good adhesive and the base color can be endowed to the whole painting layer; 3, painting clean water stone line pattern painting layer by a pattern roller so as to endow patterns to the whole painting layer; and 4, finally painting a transparent protective surface painting layer so as to protect the color and the clean water stone line patterns of the whole painting layer against being damaged. The invention provides the manufacturing process of the clean water stone line aluminium plate. The clean water stone line painted aluminium plate simultaneously has the color and the clean water stone line patterns, and the painting layers cannot easily drop or embrittle, and have good weather resistance.

Owner:ZHEJIANG WONDERFUL WALL BUILDING MATERIALS

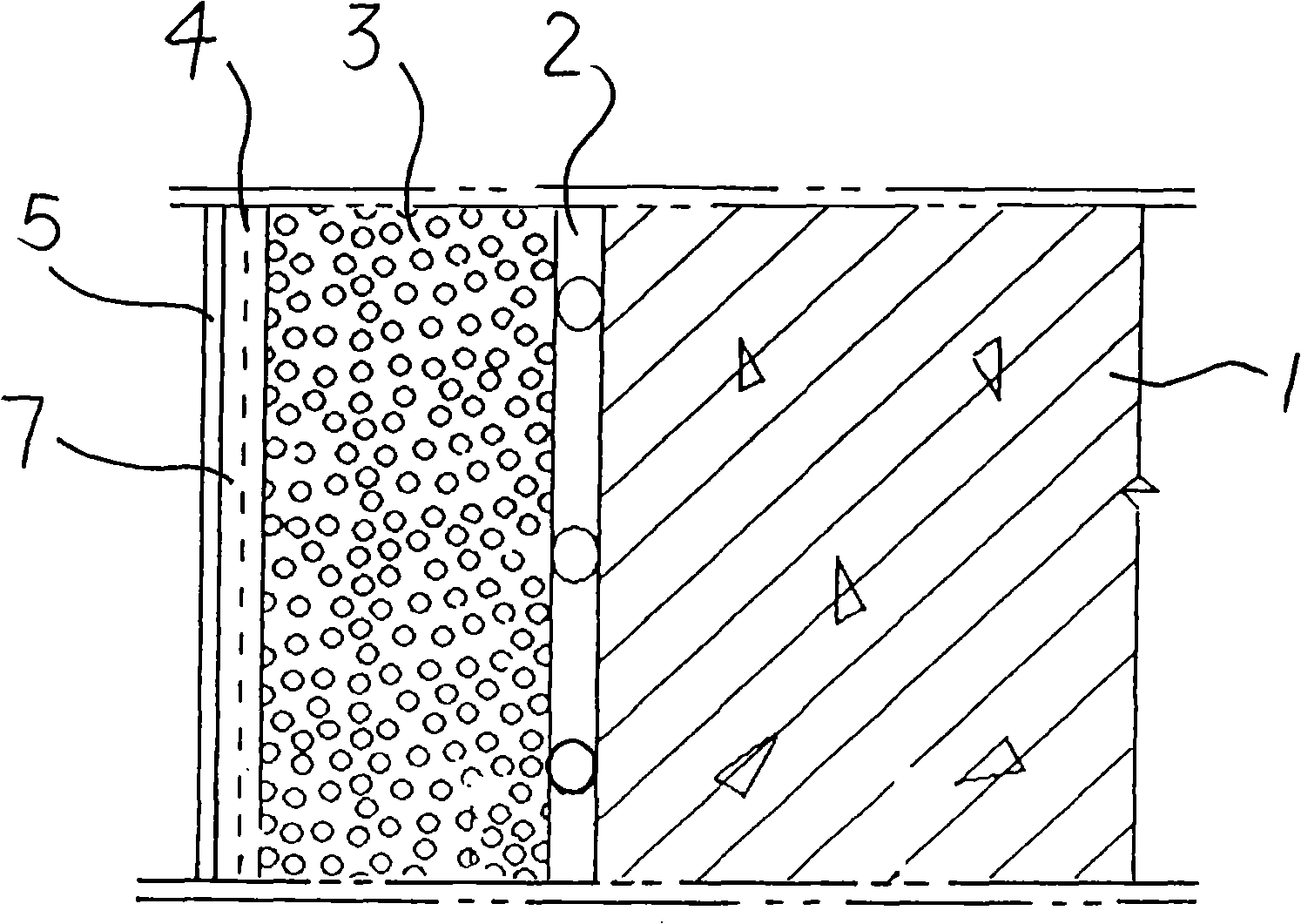

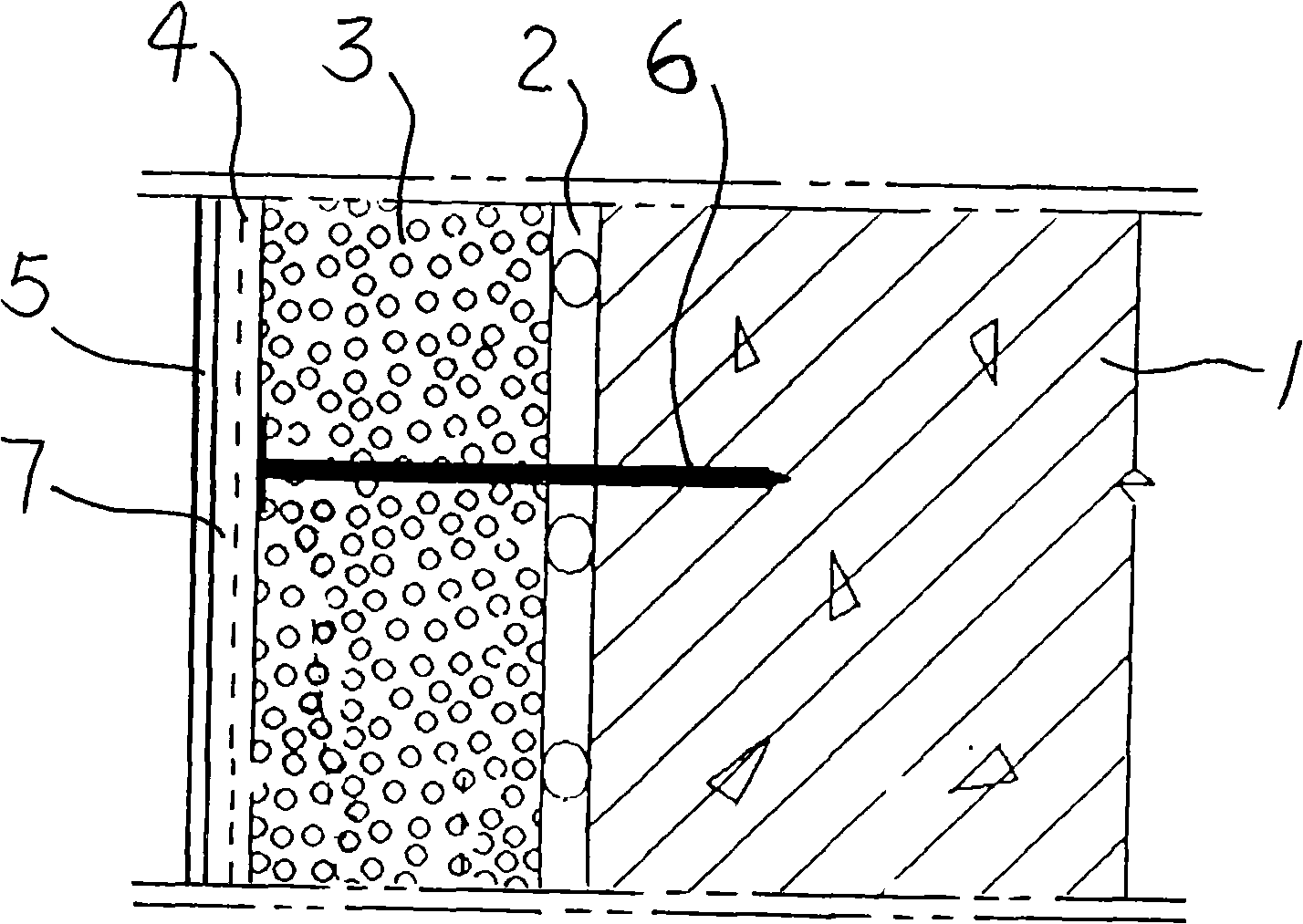

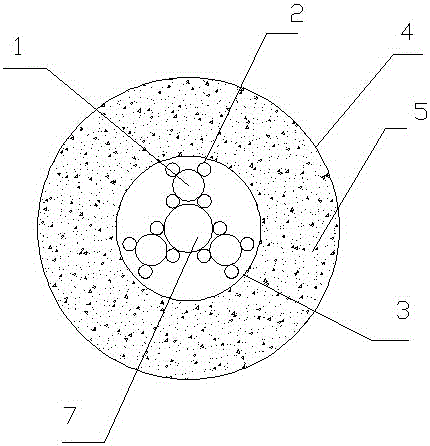

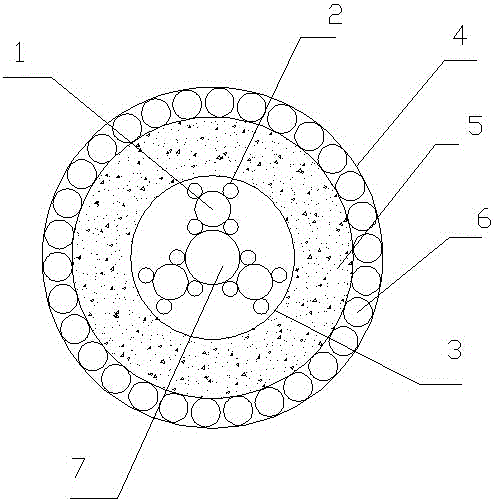

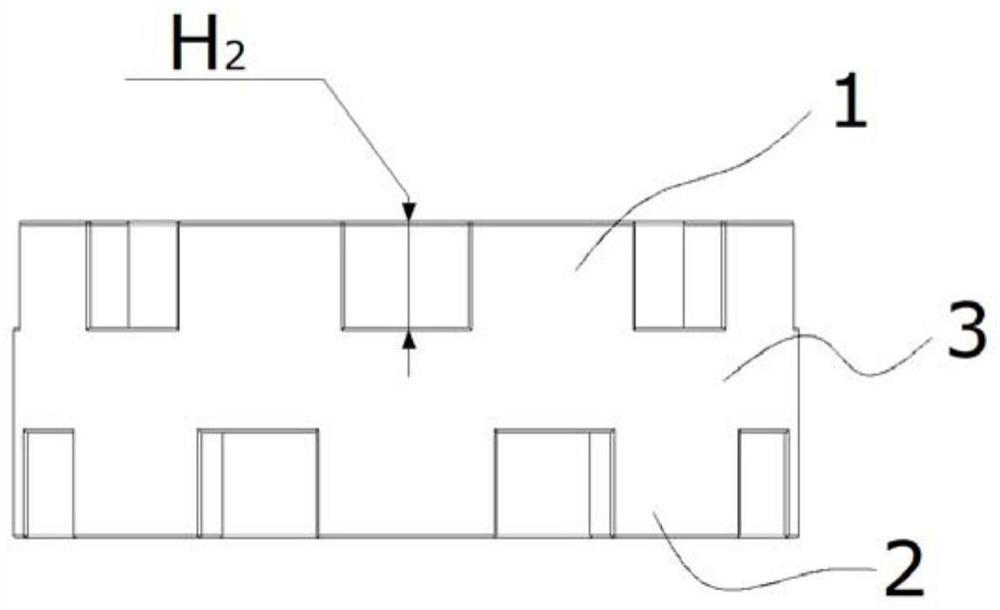

Construction method of building wall

The invention relates to the building construction technical field, in particular to a construction method which is suitable for various industrial and civil building walling having the requirement of energy conservation in a large part of China under different climate conditions. The construction method comprises the following steps that: a bonding agent is used for bonding an insulation board on the walling; mortar is coated on the insulation board and a piece of medium-alkali mesh cloth is wrapped in the mortar; and coating is plastered on the mortar, and the insulation board is a foam glass insulation board. The construction method effectively utilizes waste resources, reduces the environmental pollution, improves the utilization rate of energy, not only solves the problems of cracking and hollowing of the building walling but also improves the heat-insulating property, guarantees the elegant appearance of a veneer of the building walling, prevents the occurrence of a fire disaster, and protects the life and property safety of people.

Owner:上海永丽节能墙体材料有限公司

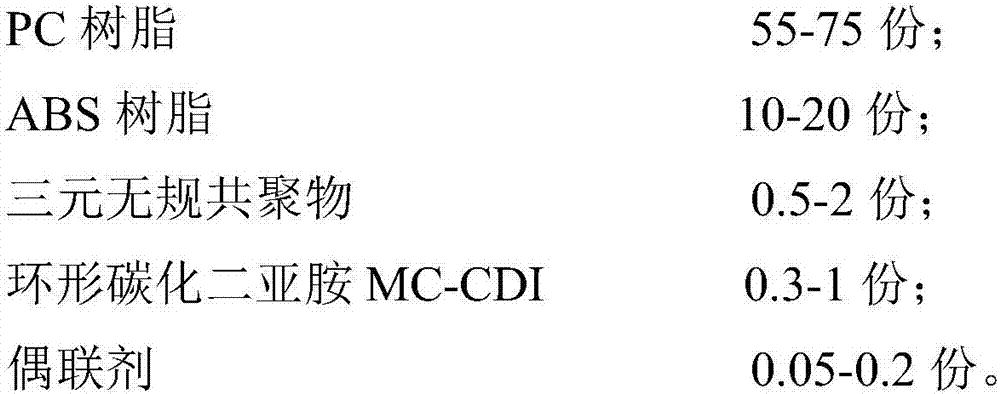

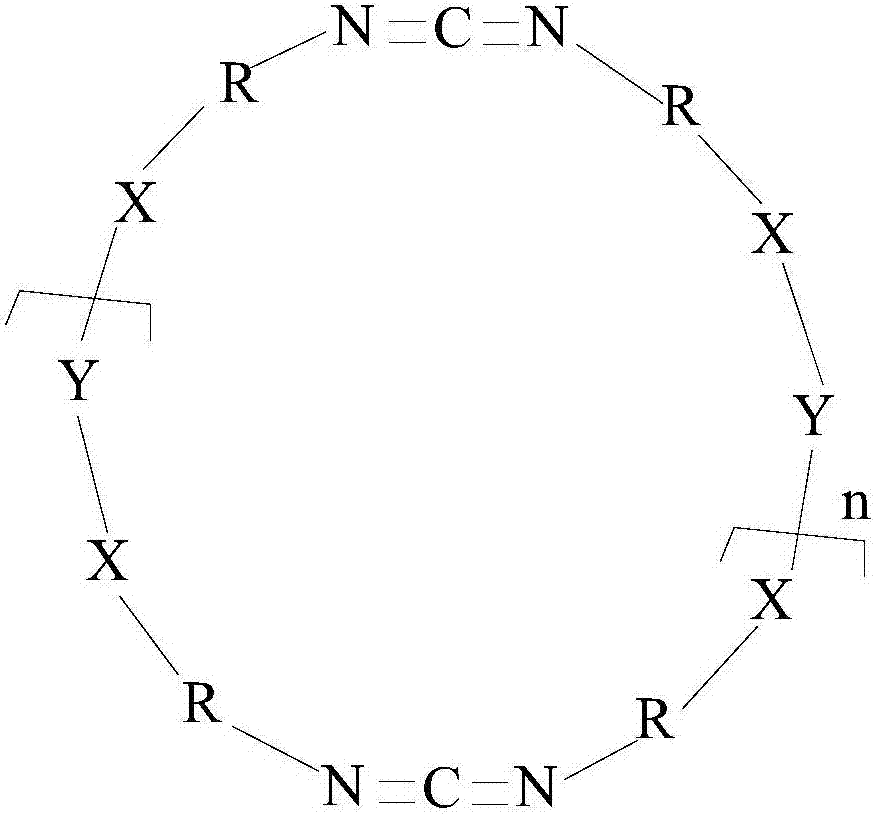

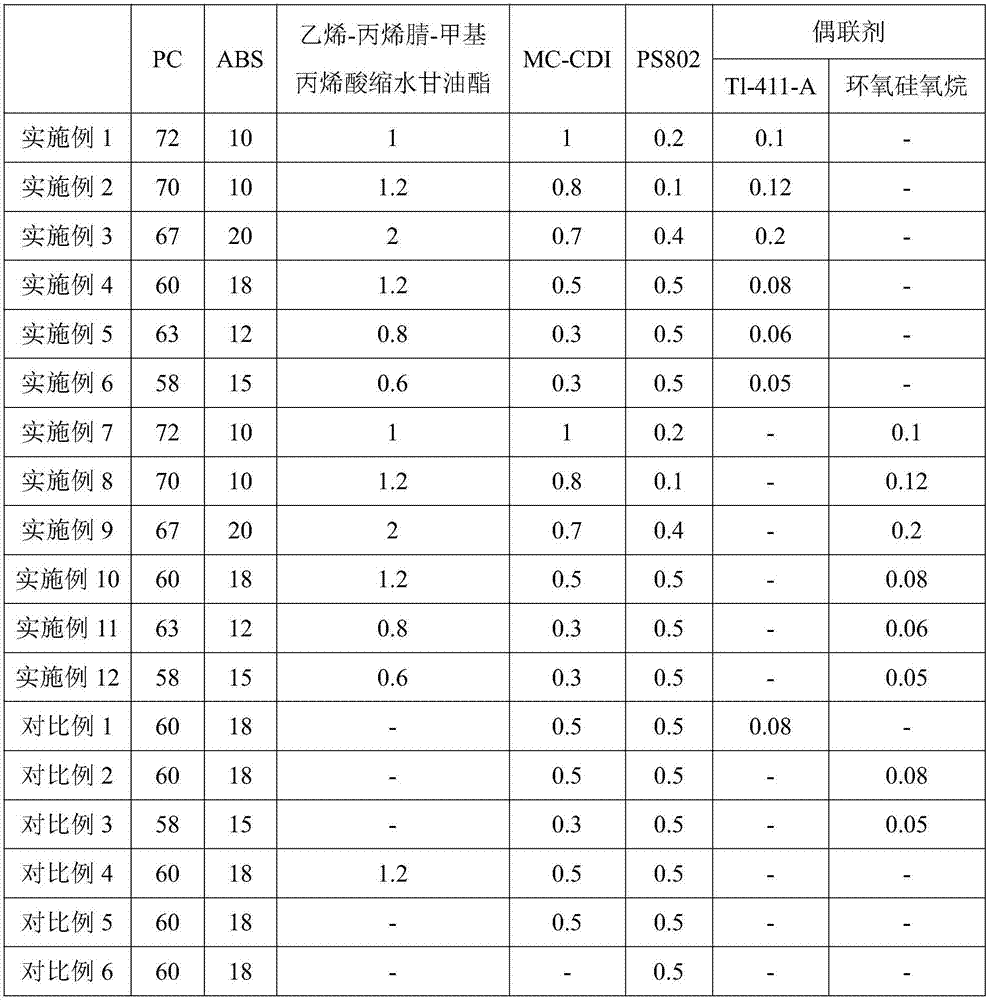

Hydrolysis-resistant PC-ABS alloy

The invention discloses a hydrolysis-resistant PC-ABS alloy which is prepared from the following raw materials in parts by weight: 55-75 parts of PC resin, 10-20 parts of ABS resin, 0.5-2 parts of a random terpolymer, 0.3-1 part of cyclic carbodiimide and 0.05-0.2 part of a coupling agent. The PC-ABS alloy resists high temperature and high humidity, is difficult in hydrolysis, embrittling and pulverization and has better mechanical properties such as bending strength, mechanical shock strength.

Owner:SUZHOU SUNWAY POLYMER

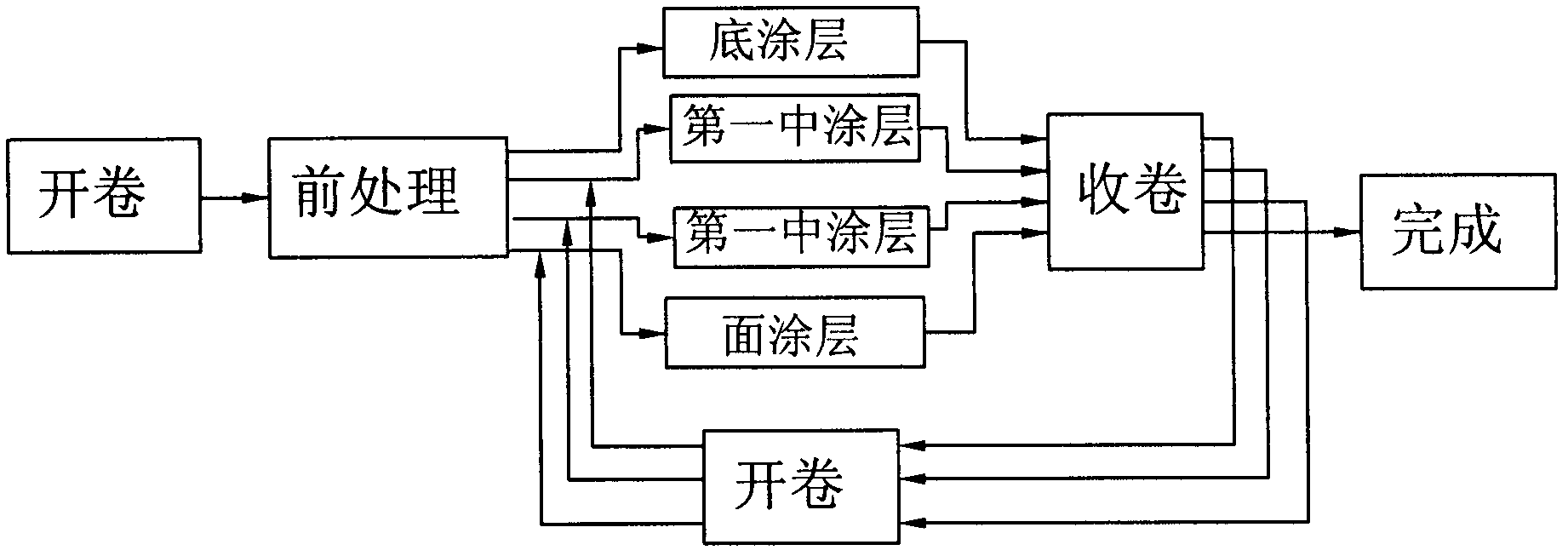

Manufacture method for stone pattern color-coating aluminum plate

ActiveCN103100515ANot easy to fall offNot easy to embrittlePretreated surfacesSpecial surfacesWeather resistanceMetallurgy

The invention discloses a manufacture method for a stone pattern color-coating aluminum plate. The method comprises the process of performing pretreatment processing on the aluminum plate, coating a bottom-layer coating on the surface of the pretreated aluminum plate, baking the bottom-layer coating in an oven so as to form a bottom coating layer; coating a first middle-layer coating on the bottom coating layer, baking the first middle-layer coating in the oven to form a first middle coating; coating a second middle-layer coating on the first middle-layer coating, baking the second middle-layer coating in the oven to form a second middle coating; coating a face-layer coating on the second middle-layer coating, baking the face-layer coating in the oven to form a face coating; finishing coating the stone pattern color coating aluminum plate, and rolling the coated aluminum plate. By means of the method, the stone pattern color-coating aluminum plate is provided with stone patterns, the coatings are coated and are baked by the high temperature oven for multiple times, the coatings are not easy to falling off and embrittlement, is good in adhesive force and performance of gloss, flexibility, impact resistance, weather resistance and the like.

Owner:CHANGZHOU LIDAO METALLIC MATERIAL MFG

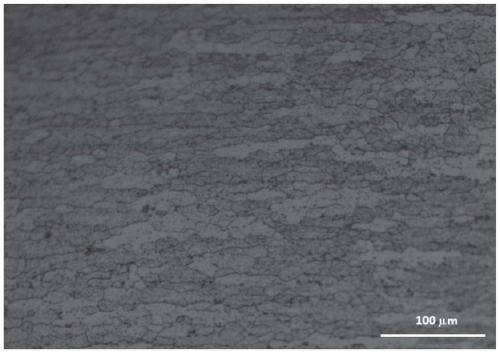

6005A aluminum alloy for automobiles and crash box processing method

The invention discloses a 6005A aluminum alloy for automobiles and a crash box processing method. The 6005A aluminum alloy for automobiles comprises the following components in percentage by weight: 0.75-0.80% of Si, 0.15-0.20% of Fe, less than or equal to 0.10% of Cu, 0.28-0.30% of Mn, 0.63-0.68% of Mg, 0.06-0.10% of Cr, less than or equal to 0.10% of Zn, less than or equal to 0.10% of Ti and thebalance of Al. The crash box processing method adopts the aluminum alloy. the aluminum alloy is capable of weakening the segregation, at crystal boundaries, of surplus Si, so that embrittlement is not easy to cause and alloy materials are not easy to craze during compression degeneration. The 6005A aluminum alloy crash box prepared by the process satisfies the conditions that the tensile strengthRm is greater than or equal to 280 MPa, the yield strength RP0.2 is greater than or equal to 260 MPa and the elongation percentage A is greater than or equal to 10%; and the crash box is symmetric, uniform in deformation and free of craze at folds during compression degeneration.

Owner:山东友升铝业有限公司

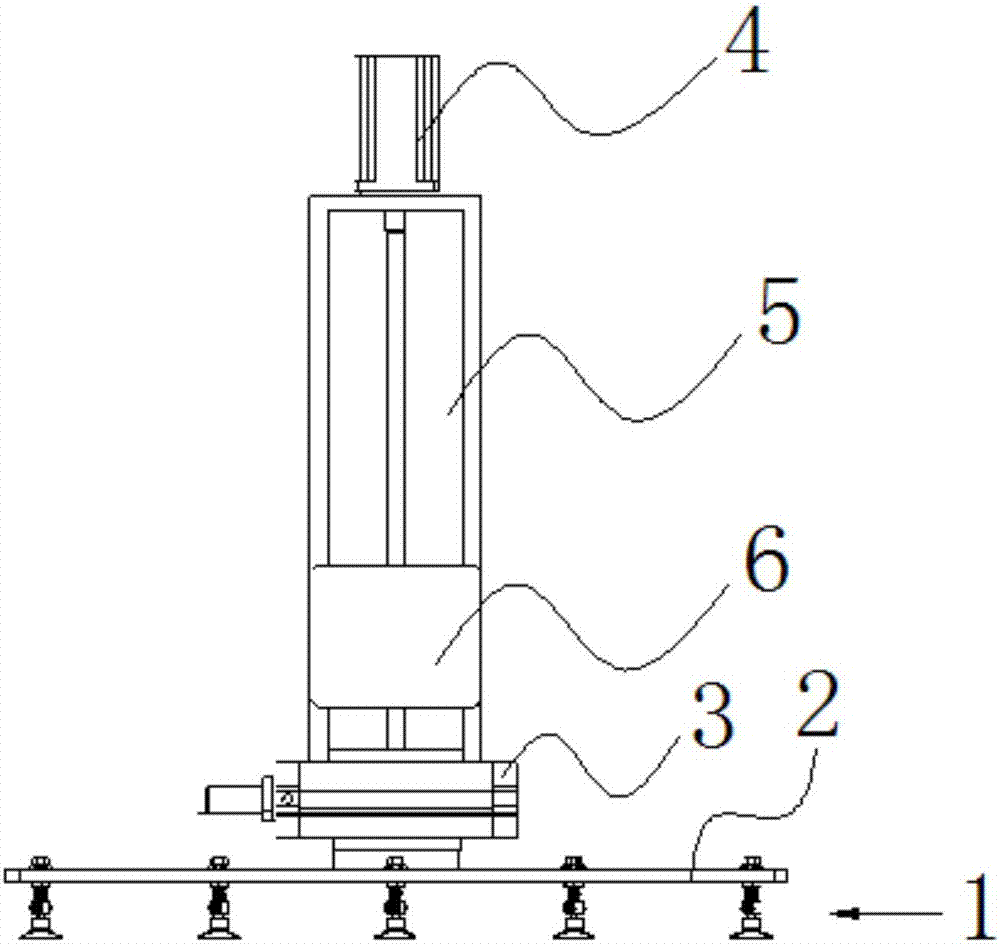

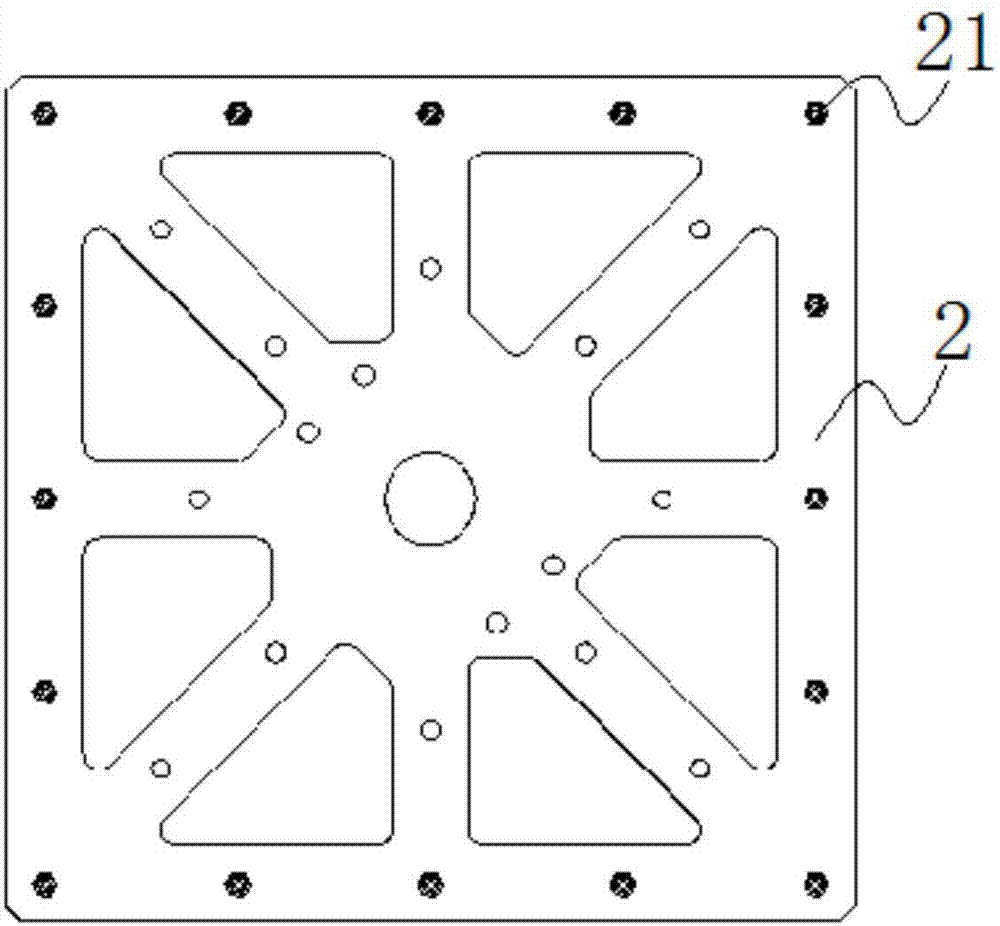

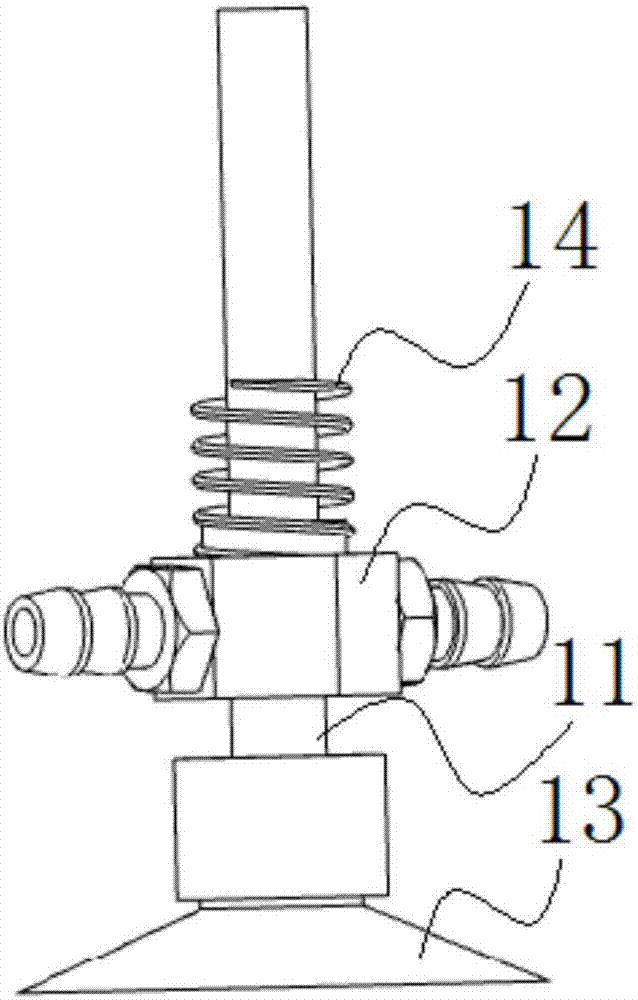

Conveying device based on vacuum suction cups

The invention discloses a conveying device based on vacuum suction cups. The conveying device comprises a vacuum suction cup assembly and a conveying assembly, wherein the vacuum suction cup assemblycomprises a plurality of vacuum suction cup supporting parts and a suction cup frame; a plurality of fixing holes are distributed in the suction cup frame; the upper ends of the vacuum suction cup supporting parts are detachably connected with the fixing holes; the conveying assembly comprises a horizontal rotary mechanism and a vertical moving mechanism; the horizontal rotary mechanism comprisesa rotary cylinder capable of driving the suction cup frame to circumferentially rotate in the horizontal direction; and the vertical moving mechanism comprises a motor, a lead screw and a sliding block capable of moving along the lead screw vertically, one end of the lead screw is connected with an output shaft of the motor, the other end of the lead screw is connected with the rotary cylinder, and the sliding block is fixedly connected with a connection arm. The conveying device is simple in structure, stable in absorption force, and capable of conveniently and rapidly absorbing and conveyingmaterials and improving the work efficiency.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

Tree protection device for keeping humidity and warm during transplantation in winter and usage method of device

InactiveCN107182647AHas acid and alkali resistanceHigh strengthProtective equipmentSynthetic resin layered productsIsolation layerInsect pest

The invention provides a tree protection device for keeping humidity and warm during transplantation in winter and a usage method of the device. The protection device comprises at least one transparent protective isolation layer for keeping humidity and warm to a transplanted tree, wherein each protective isolation layer respectively wraps the tree. The tree protection device is simple in structure and low in cost, has a good blocking function, retains moisture of the tree, also effectively avoids insect pests and improves the survival rate of the tree.

Owner:广东凯天骏景观艺术有限公司

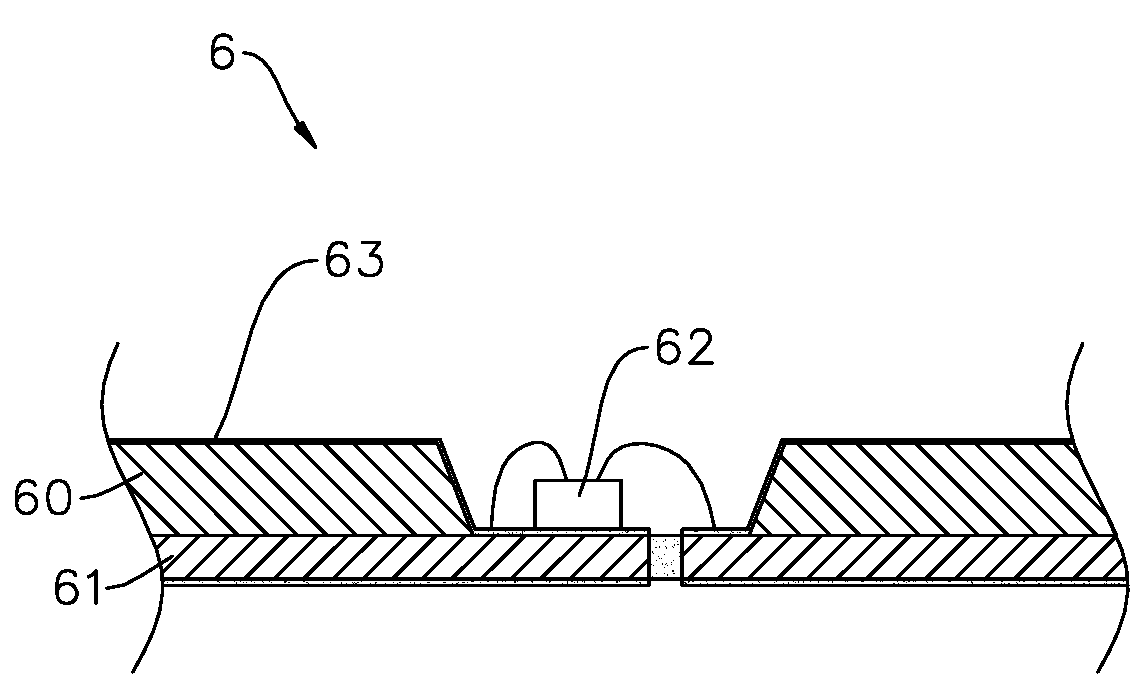

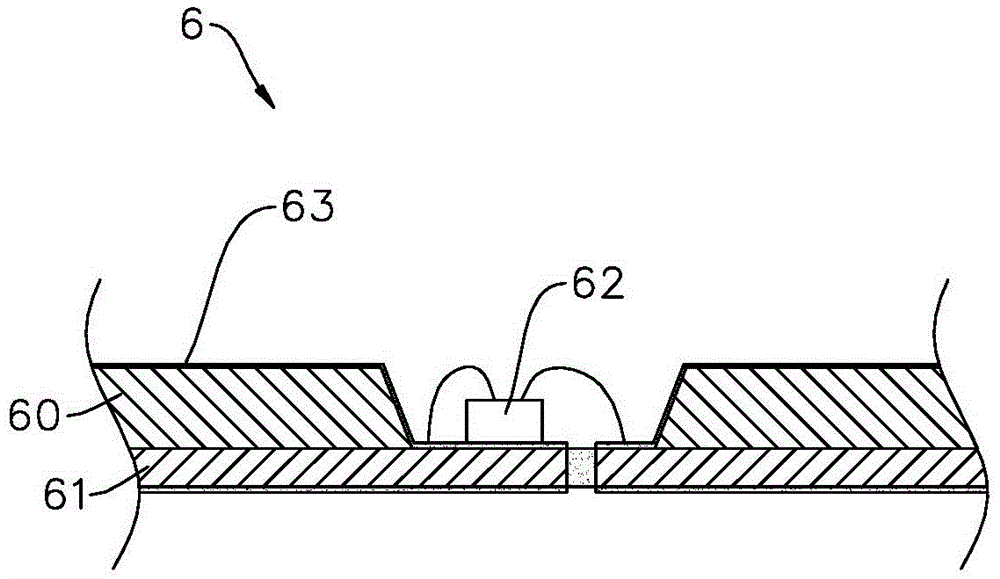

Pre-manufacturing method and pre-manufactured structure for LED package

InactiveCN103682059AStrong jointIncrease contact areaSolid-state devicesSemiconductor devicesInsulation layerHeat conducting

The invention discloses a pre-manufacturing method and a pre-manufactured structure for an LED package. The pre-manufactured structure of the LED package is manufactured mainly through the steps of stamping, coarsening, mold sealing, sticking, electroplating and the like. The pre-manufactured structure comprises a reflection cup rack, an insulation layer and a wire frame which are stuck together in sequence from the top down, wherein the reflection cup can resist high temperature generated by an LED in long-term operation, provides the superexcellent effects of heat conducting and extracting, and prolongs the service life of the LED; besides, the high-temperature-resist insulation layer ensures that the pre-manufactured structure can resist heat and is less susceptible to cracking and embrittling, thereby reducing the damage rate and use cost of the pre-manufactured structure of the LED package.

Owner:CHANG WAH ELECTROMATERIALS INC +1

Composite material for water pipes and preparation method thereof

InactiveCN109021385AImprove corrosion resistanceImprove temperature resistanceAntioxidantShock resistance

The invention discloses a composite material for water pipes and a preparation method thereof and relates to the field of water pipe materials. The composite material comprises, by weight, 50-60 partsof polypropylene, 15-20 parts of natural rubber, 10-15 parts of ultrafine calcium carbonate, 8-15 parts of modified bamboo charcoal, 3-7 parts of nanometer zinc oxide, 3-6 parts of N-phenyl maleimide, 5-10 parts of glass fibers, 5-10 parts of graphite powder, 2-5 parts of a plasticizer, 1.5-2.5 parts of an antioxidant, 1-3 parts of a silane coupling agent and 1.8-2.8 parts of a heat stabilizer. Through synergism of water pipe components, the composite material has good corrosion resistance, temperature resistance, anti-aging properties, excellent mechanical shock resistance, high strength andembrittlement resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

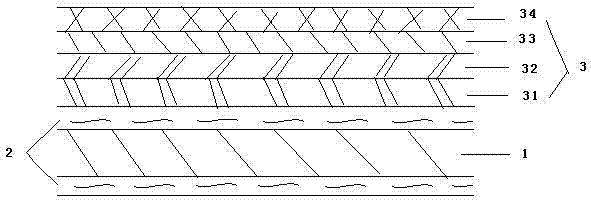

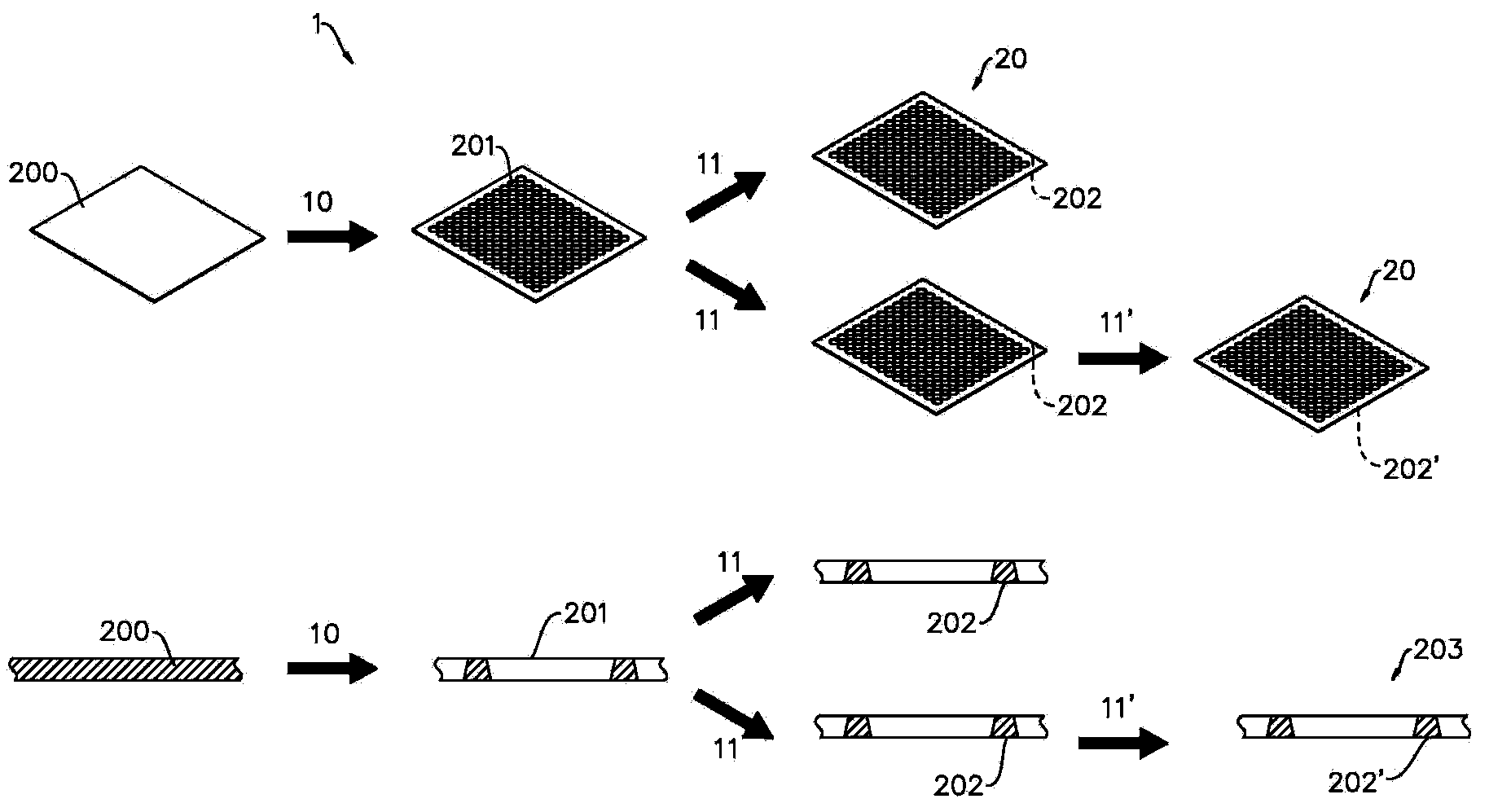

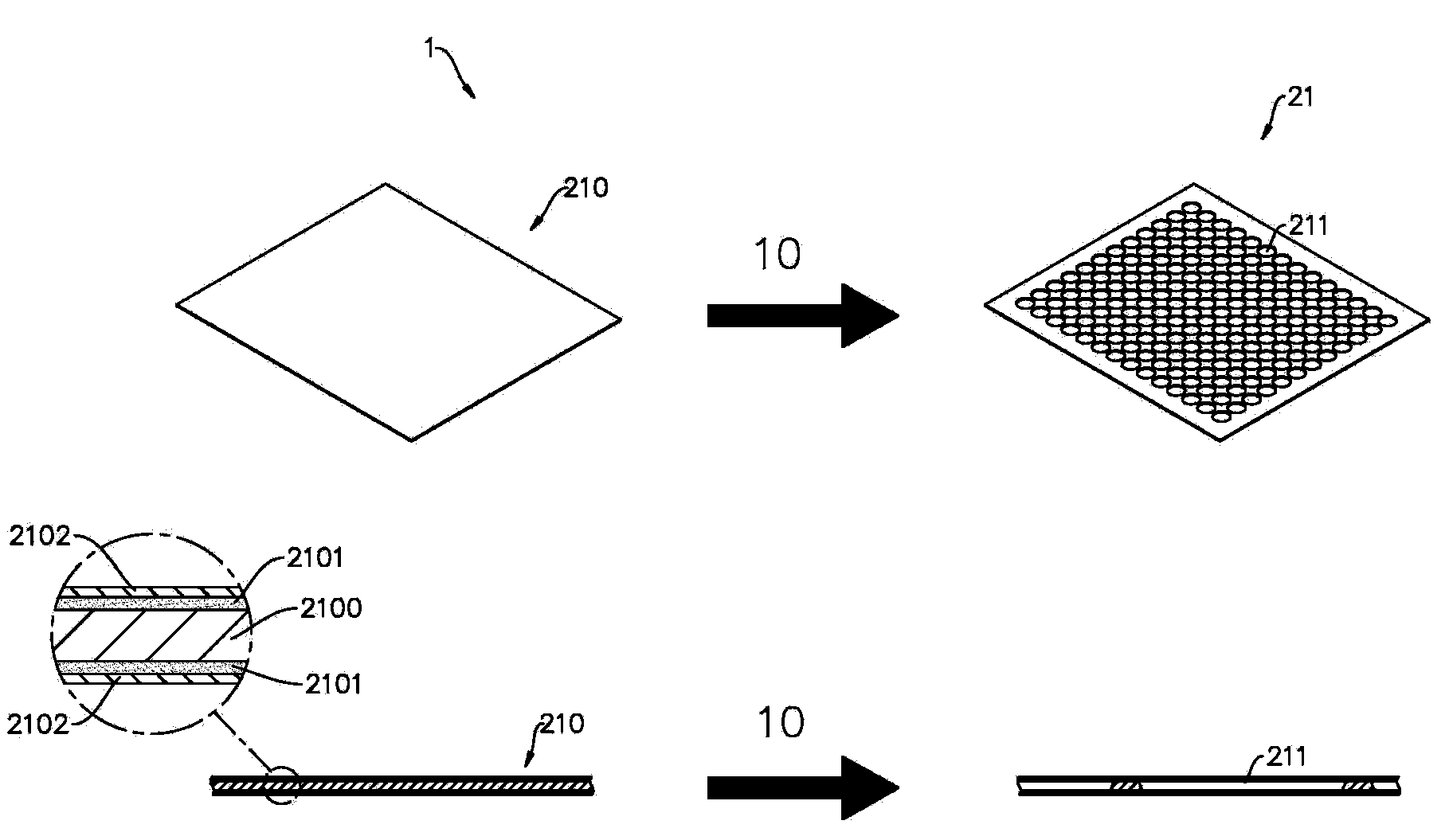

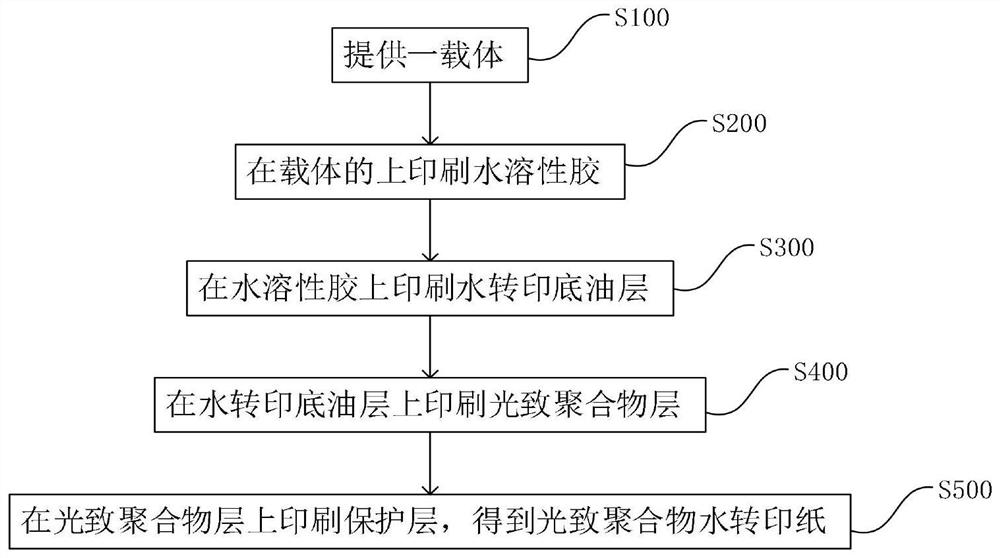

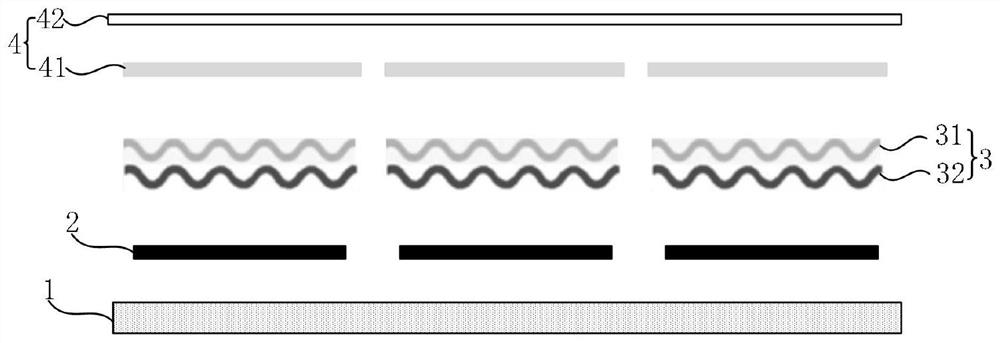

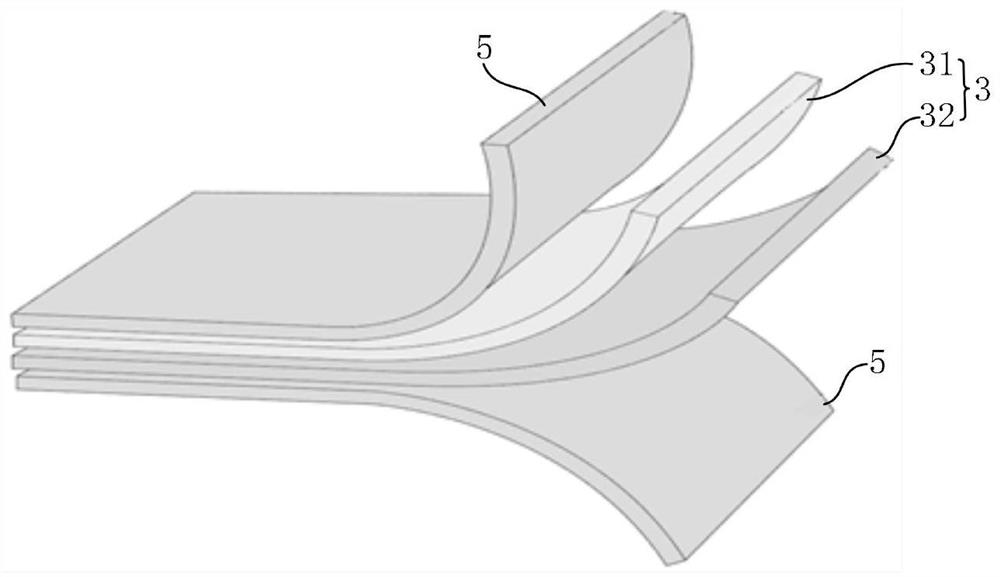

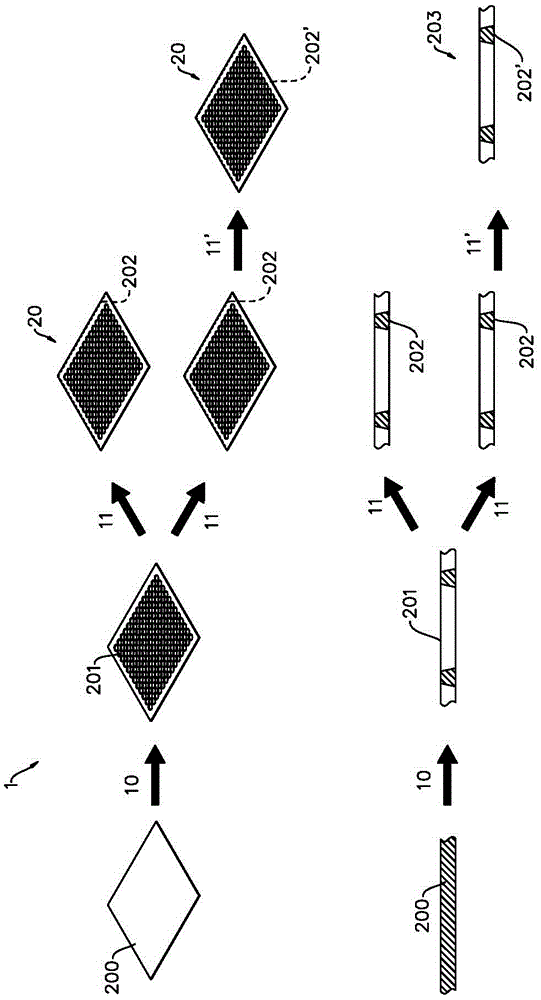

Photopolymer water transfer printing paper manufacturing method, water transfer printing paper and application method

ActiveCN112757800ANot easy to damageNot easy to fall offSpecial paperPattern printingComposite materialCorrosion resistant

The invention discloses a photopolymer water transfer printing paper manufacturing method, water transfer printing paper and an application method. The photopolymer water transfer printing paper manufacturing method comprises the steps that a carrier is provided; water-soluble glue is printed on the carrier; a water transfer printing bottom oil layer is printed on the water-soluble glue; a photopolymer layer is printed on the water transfer printing bottom oil layer; and a protective layer is printed on the photopolymer layer to obtain the photopolymer water transfer printing paper. According to the photopolymer water transfer printing paper manufactured through the photopolymer water transfer printing paper manufacturing method, a release film does not need to be used as the carrier and the protective layer, that is, the influence of the expansion rate of an original release film does not need to be considered, a photopolymer can be approximately fused into a whole and fixed to various products to be attached, the application range is large, and after a long time, falling off is not easy to happen; and the surface of the photopolymer is protected by the protective layer, so that wear resistance and corrosion resistance are achieved, pattern information is not easy to damage, and embrittlement is not easy to happy after a long time.

Owner:沈柏仲 +1

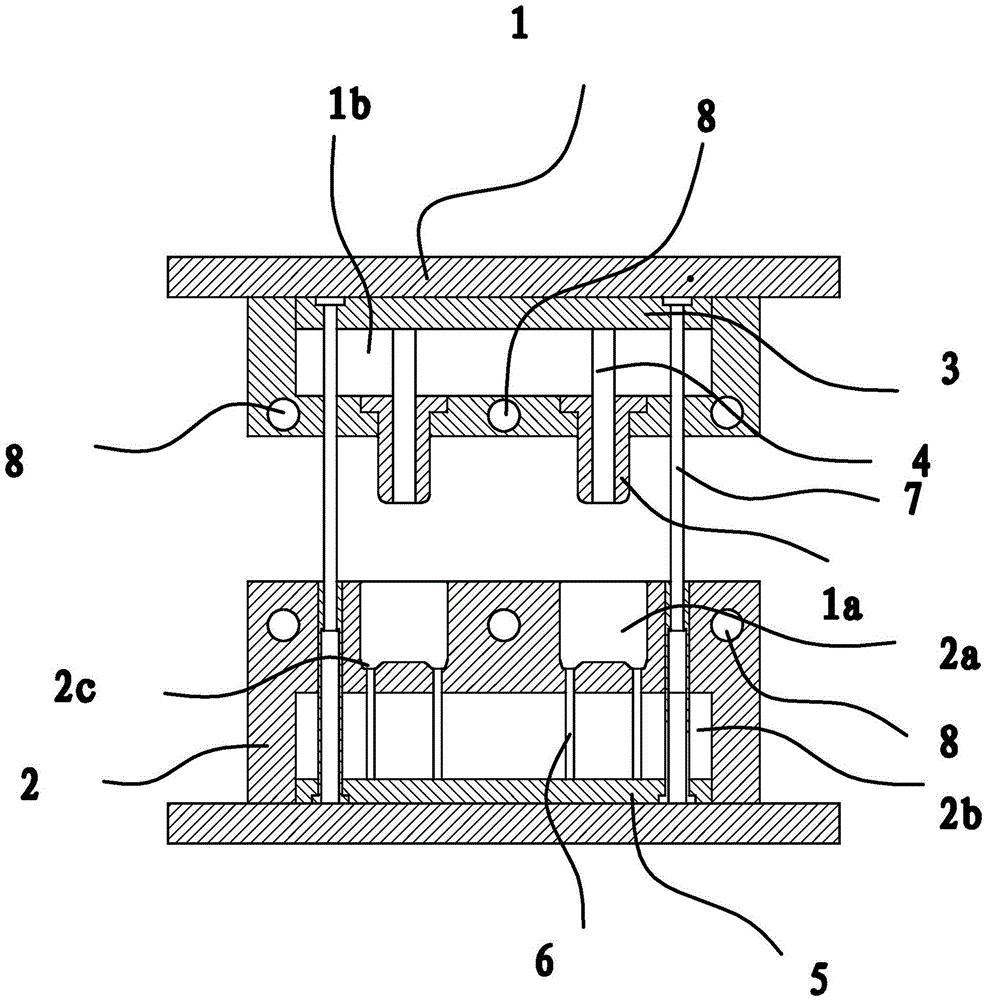

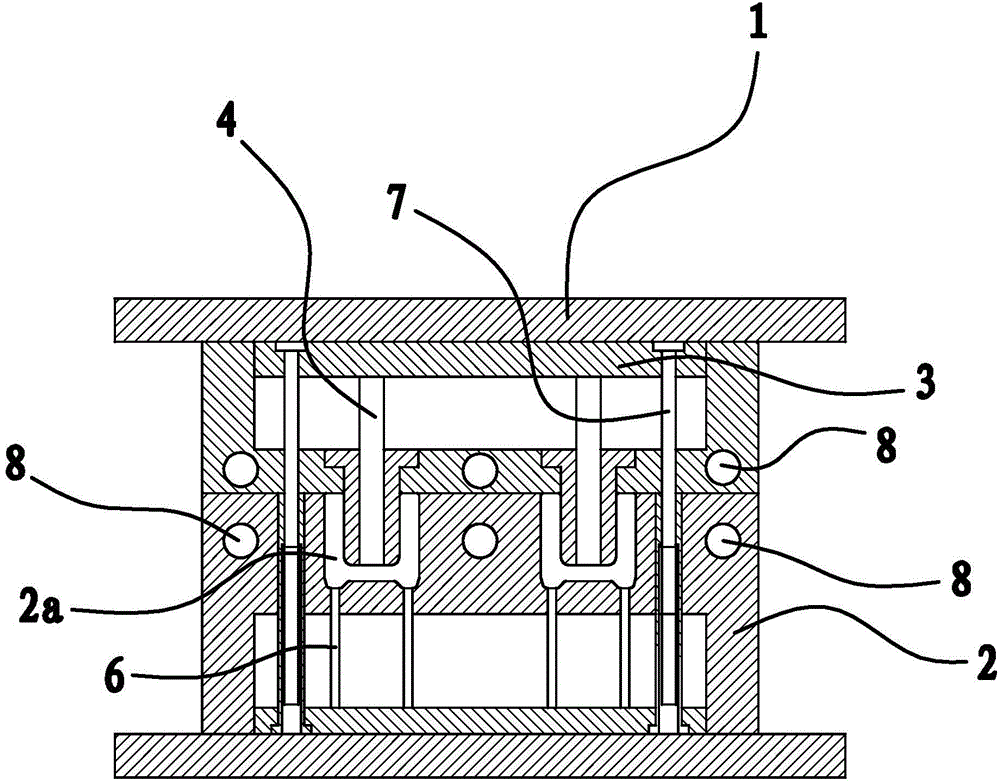

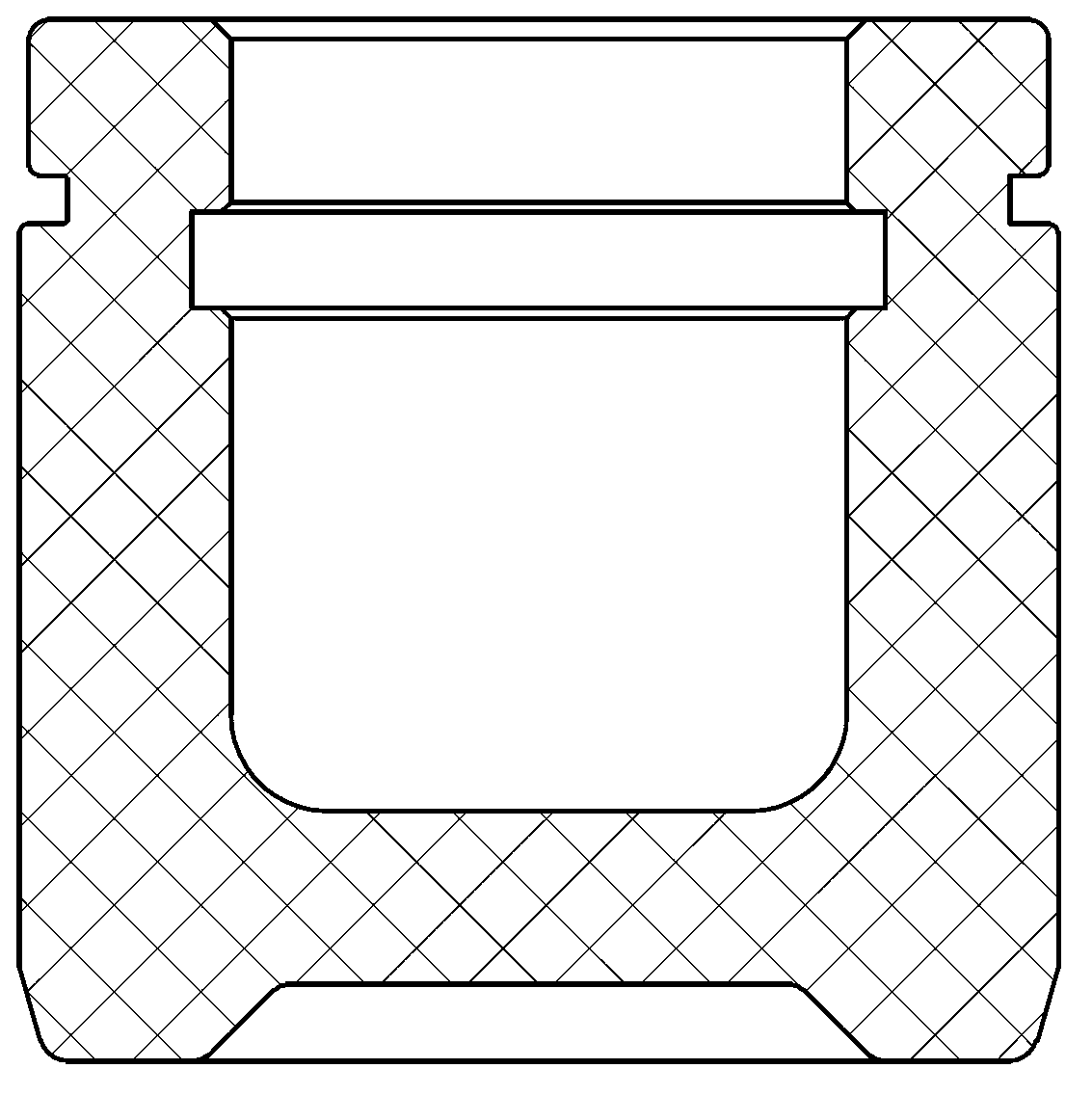

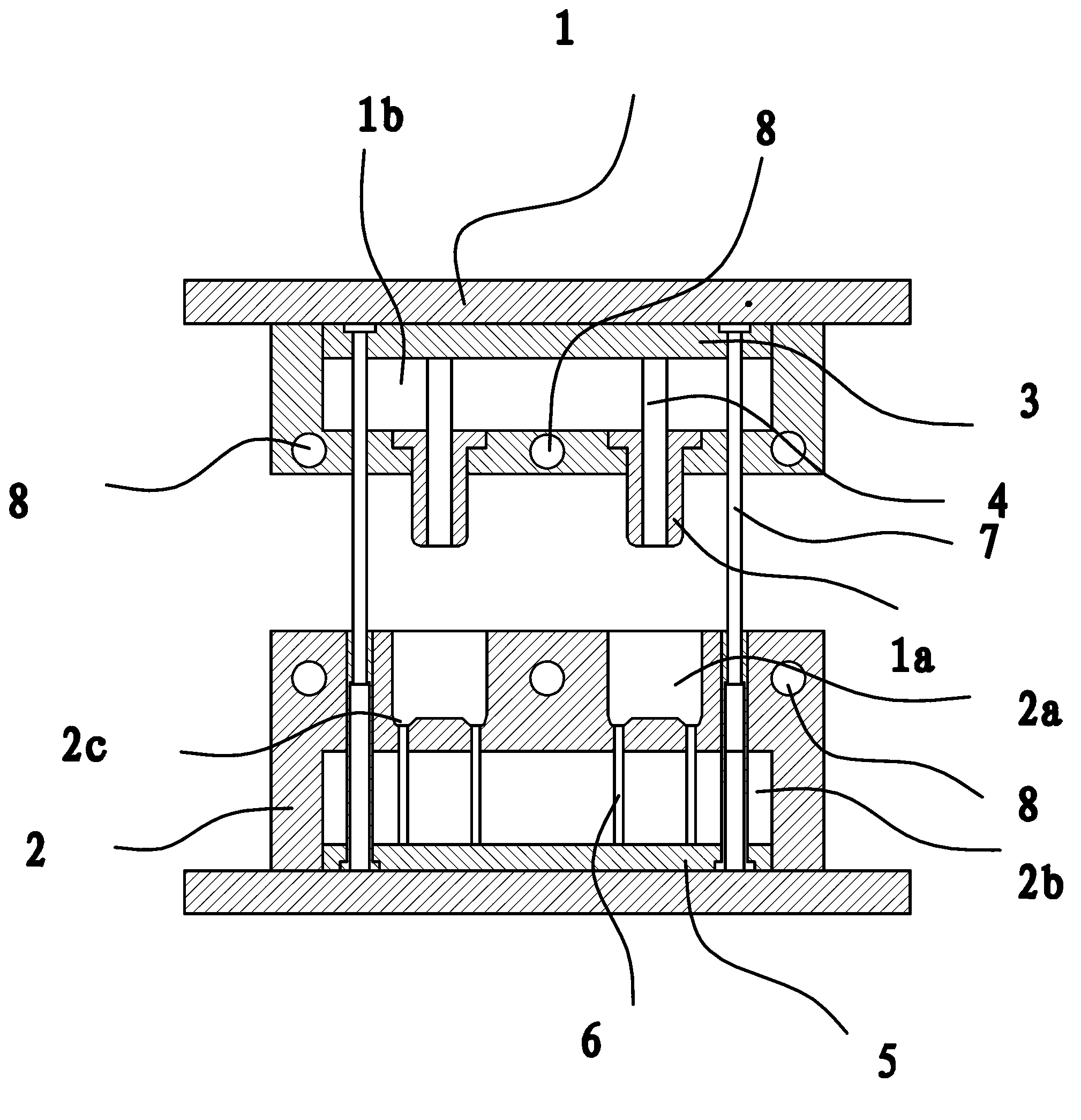

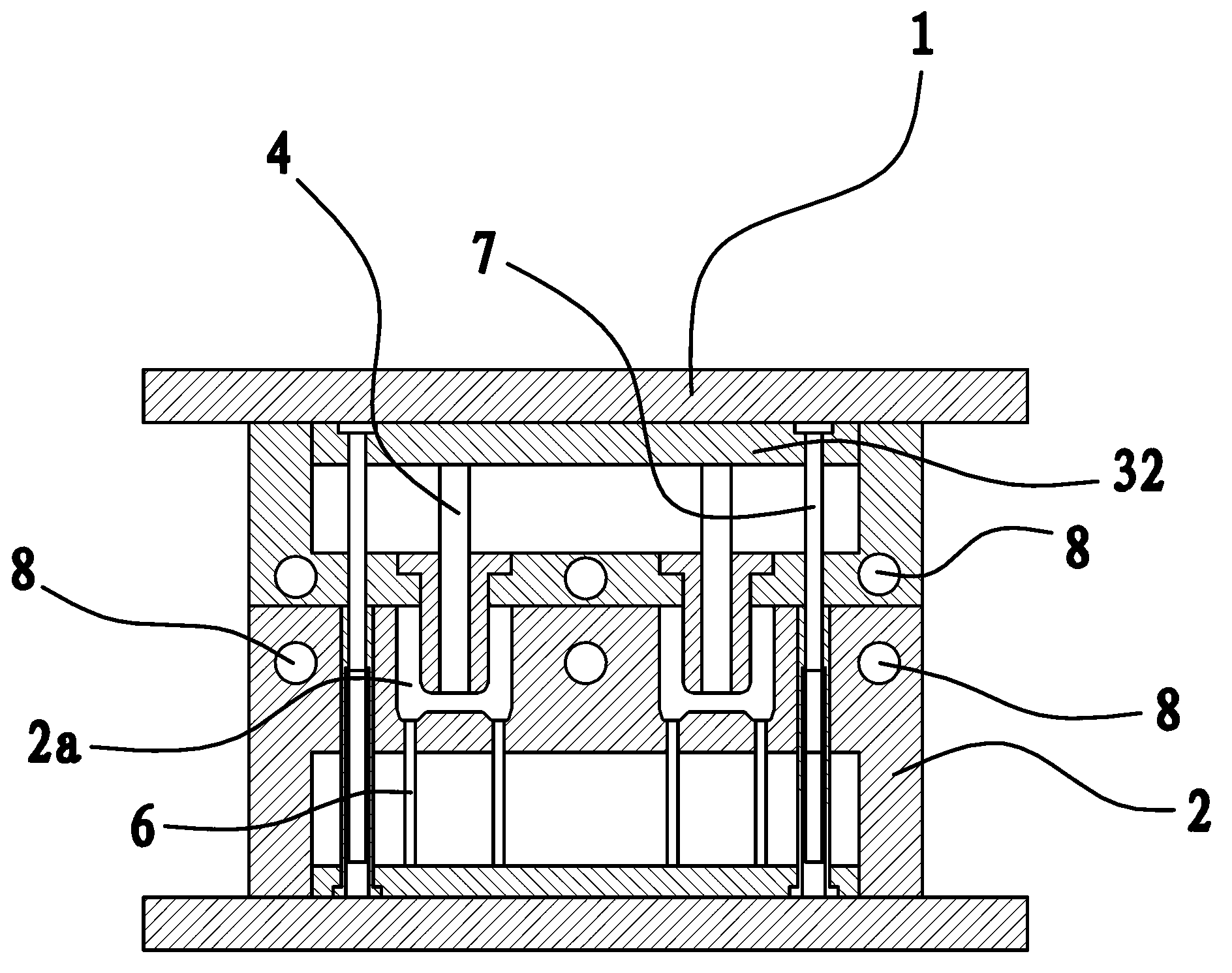

Die of phenolic piston and manufacture method of phenolic piston

The invention provides a die of a phenolic piston and a manufacture method of the phenolic piston, and belongs to the technical field of dies, which solves the problem of poor quality of the existing phenolic piston finished product. The die of the phenolic piston comprises an upper die body and a lower die body, wherein a plurality of heating holes are formed in the upper die body and the lower die body, and are used for directly carrying out electric heating. The upper die body and the lower die body are respectively provided with a material stripping piece, so the phenolic piston is prevented from being adhered on the die, and the stripping stability is high. The manufacture method comprises the following steps of punching cakes, heating the die, closing the die and baking, wherein the upper die body and the lower die body are directly heated, after a blank of the phenolic piston is formed, and temperature is maintained by baking, so the internal performance of the phenolic piston is further improved, the strength is higher, and the phenolic piston is not easy to brittle.

Owner:TAIZHOU WANZHOU MASCH CO LTD

Antistatic flame-retardant PE pipe and preparation method thereof

The invention discloses an antistatic flame-retardant PE pipe and a preparation method thereof. The PE pipe is prepared from 4-6% of fire retardant, 0.5-1.5% of auxiliary flame retardant, 4-6% of antistatic agent and 86-91% of PE base material. The auxiliary components in the formula are concentrated first to prepare dual-resistance master batch, then the master batch is mixed with body resin in proportion, and then the materials are extruded and granulated through a twin-screw extruder. The PE pipe has the advantages of being good in ageing resistance and not prone to embrittlement, having good toughness and impact energy absorption, and being good in rapid crack resistance and corrosion resistance, free of scaling, smooth in inner wall and capable of improving the conveying capacity by 30%.

Owner:SANTEH PIPE & FITTINGNANTONG CO LTD

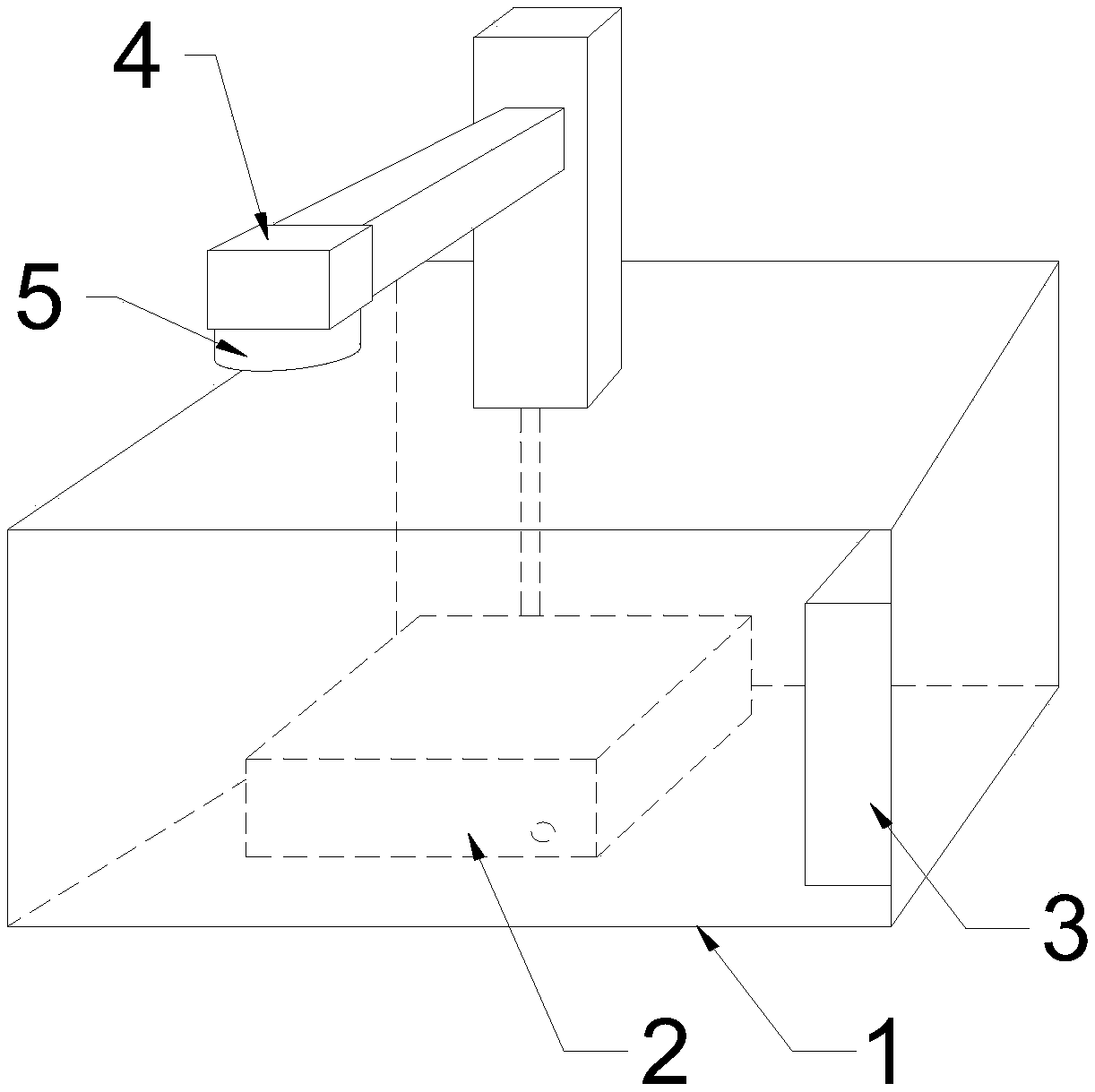

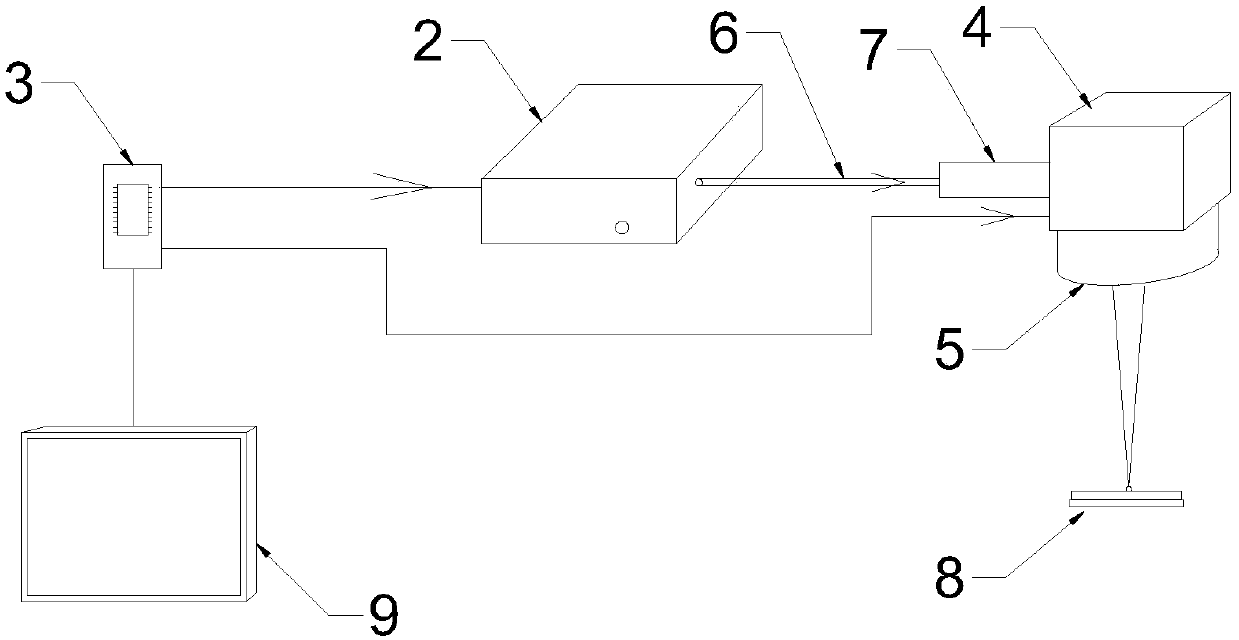

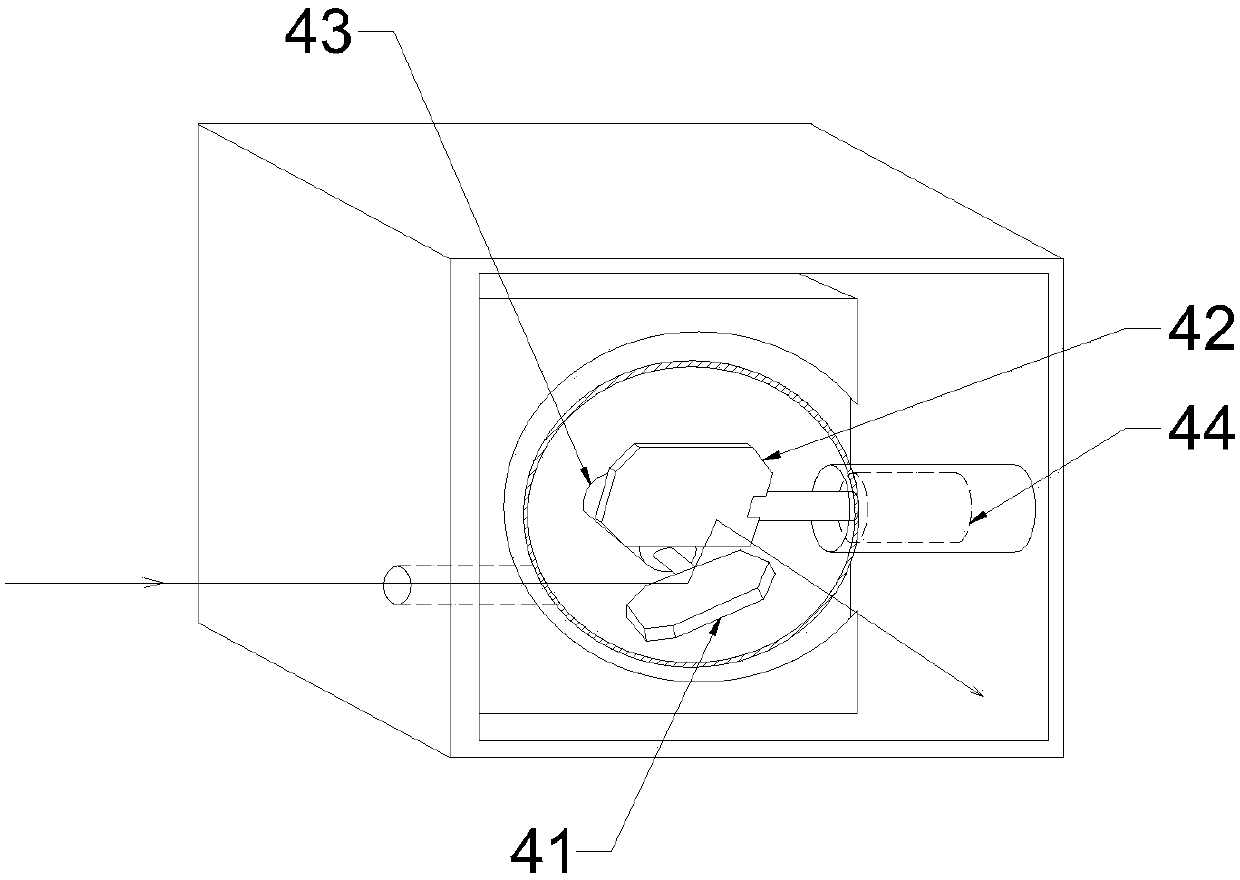

Picosecond pulse laser welding machine

PendingCN109604828AShorten the timeNot easy to embrittleLaser beam welding apparatusPicosecond pulsed laserGalvanometer

The invention provides a picosecond pulse laser welding machine which comprises a machine box. A picosecond pulse laser device and a control board card are arranged in the machine box, a galvanometerand a field lens are sequentially arranged above the machine box through a support, the field lens is connected to the bottom of the galvanometer, the picosecond pulse laser device is connected with the galvanometer through an optical fiber, the galvanometer comprises an X-axis lens and a Y-axis lens, the X-axis lens is connected with an X-axis motor, the Y-axis lens is connected with a Y-axis motor, a laser beam emitted by the picosecond pulse laser device sequentially passes through the X-axis lens, the Y-axis lens and the field lens to be focused on a workpiece to be welded, the signal output end of the control board card is respectively connected to the picosecond pulse laser device, the X-axis motor and the Y-axis motor, and the motion trajectory of the laser beam on the workpiece isa spiral trajectory. High-speed welding can be carried out on the workpiece to form fine welding spots in the spiral trajectory, and the tens of thousands of welding spots are arranged into a spiral welding pattern. When the welding machine is used for welding, two metal materials are not likely to be embrittled, and the welding strength is high.

Owner:苏州镭扬激光科技有限公司

Pressure-proof sealing rubber material for pneumatic telescopic cylinder of security equipment

The invention relates to the technical field of rubber materials, in particular to a pressure-proof sealing rubber material for a pneumatic telescopic cylinder of security equipment. The rubber material includes the following components: butadiene-acrylonitrile rubber, modified natural rubber, a thermoplastic elastomer, a pressure resistant filler, a reinforcing agent, trioctyl trimellitate, a coupling agent, an accelerant, sulfur and an antistatic agent, wherein the thermoplastic elastomer comprises one of a SBS elastomer, a SEPS elastomer, a SEBS elastomer and a SIS elastomer; the pressure resistant filler contains nano-silica, nano-silicon carbide, nano-white corundum and nano-zinc oxide; the antistatic agent contains one or a mixture of any of the four lithium salt components of LiClO4, LiAsF6, LiBF4 and LiPF6. The rubber material has excellent gas tightness, good elasticity, outstanding pressure resistance and wear resistance, high cycle number of pressure recovery, and long service life.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

Owner:ANSHENG SCI & TECH DEP

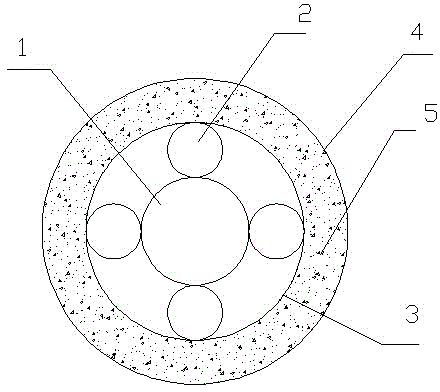

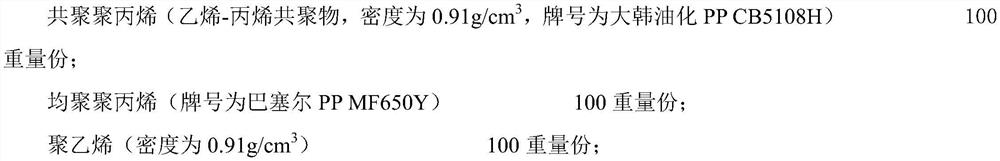

Basalt fiber composite guy cable

ActiveCN104060537AImprove fatigue strengthWill not be corrodedBridge structural detailsGlass fiberCarbon fibers

The invention discloses a basalt fiber composite guy cable, which comprises a center composite rib, peripheral composite ribs, an inner protective sleeve, a filler and an outer protective sleeve, wherein the center composite rib is positioned in the center position; the peripheral composite ribs are wound on the center composite rib; the center composite rib and the peripheral composite ribs are wrapped in the inner protective sleeve; the filler is filled between the outer protective sleeve and the inner protective sleeve and is an elastic filler; the center composite rib is formed by compounding continuous basalt fiber and glass fiber through a resin matrix; the peripheral composite ribs are formed by compounding carbon fiber and aramid fiber through the resin matrix. The basalt fiber composite guy cable is high in strength, acid and alkaline corrosion resistant, and high in fatigue resistance, can be exposed and used in the open air for a long time, is long in service life and eliminates the potential safety hazard of fracture during use.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

High-polymerization degree polyvinyl chloride (PVC) door/window strip seal and preparation method thereof

InactiveCN103242598APromote absorptionInhibit photooxidationSealing arrangementsPlasticizerPolyvinyl chloride

The invention discloses a high-polymerization degree polyvinyl chloride (PVC) door / window strip seal. The strip seal comprises the following ingredients in parts by mass: 100 parts of PVC, 40-80 parts of a plasticizer, 40-70 parts of a filler, 4-6 parts of a thermal stabilizer, 0.5-5 parts of a lubricant, 2.5-6 parts of acrylic copolymer (ACR), 0.2-1 part of an ultraviolet light absorber and 1-6 parts of carbon black. The product has a good ultraviolet light absorption effect, can inhibit photoxidation and optical ageing and is hardly embrittled; the strip seal has shore hardness of 55, the tensile strength of 9.5MPa, the elongation at break of 355% and the tear strength of 25KN / m; the strip seal is low in manufacturing cost, is cold-resistant, has the brittle temperature of -35 DEG C, can be widely used and can continuously replace a conventional material.

Owner:苏州市德莱尔建材科技有限公司

Die of phenolic piston and manufacture method of phenolic piston

The invention provides a die of a phenolic piston and a manufacture method of the phenolic piston, and belongs to the technical field of dies, which solves the problem of poor quality of the existing phenolic piston finished product. The die of the phenolic piston comprises an upper die body and a lower die body, wherein a plurality of heating holes are formed in the upper die body and the lower die body, and are used for directly carrying out electric heating. The upper die body and the lower die body are respectively provided with a material stripping piece, so the phenolic piston is prevented from being adhered on the die, and the stripping stability is high. The manufacture method comprises the following steps of punching cakes, heating the die, closing the die and baking, wherein the upper die body and the lower die body are directly heated, after a blank of the phenolic piston is formed, and temperature is maintained by baking, so the internal performance of the phenolic piston is further improved, the strength is higher, and the phenolic piston is not easy to brittle.

Owner:TAIZHOU WANZHOU MASCH CO LTD

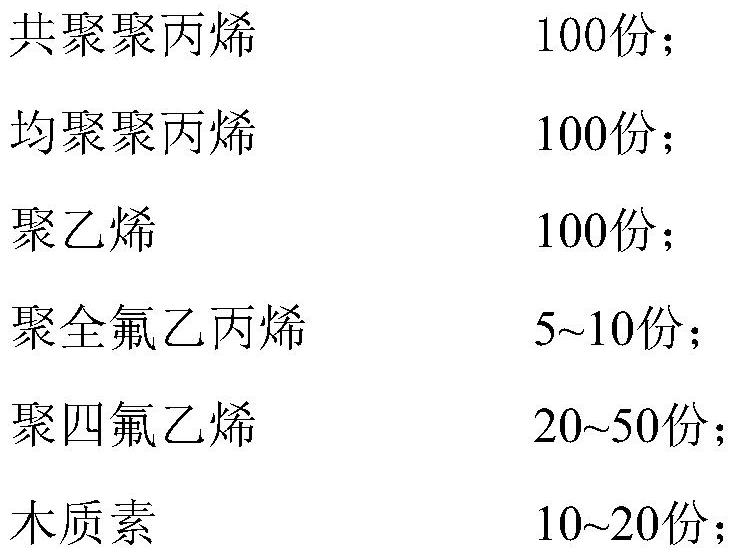

Low-temperature-impact-resistant stress-whitening-resistant polypropylene material and preparation method thereof

The invention relates to a low-temperature-impact-resistant stress-whitening-resistant polypropylene material and a preparation method thereof. The preparation method comprises the following steps: mixing, by weight, 5-10 parts of a tetrafluoroethylene-hexafluoropropylene copolymer and 20-50 parts of polytetrafluoroethylene in a mixer to obtain a mixture A; mixing 100 parts of co-polypropylene (namely an ethylene-propylene copolymer, wherein the melt index of the ethylene-propylene copolymer under the test conditions of 230 DEG C and 2.16 kg is 5-12 g / 10 min), 100 parts of homo-polypropylene (with a melt index of 1500-1900 g / 10 min under the test conditions of 230 DEG C and 2.16 kg), 100 parts of polyethylene and 10-20 parts of lignin in the mixer to obtain a mixture B; and finally, addingthe mixture A from a first-section cylinder of a double-screw extruder, laterally feeding the mixture B from a sixth-section of the double-screw extruder, and carrying out extrusion granulation to obtain the low-temperature-impact-resistant stress-whitening-resistant polypropylene material. The falling ball stress whitening performance of the finally prepared material is 1.0-1.6 delta L, and notch impact strength at a temperature of 20 DEG C and notch impact strength at a temperature of 40 DEG C are 68-75 J / M and 40-50 J / M respectively. The method is simple and easy to implement, and the prepared material is excellent in performance and wide in application prospects.

Owner:上海日之升科技有限公司

Basalt fiber composite cable

ActiveCN104060537BImprove fatigue strengthWill not be corrodedBridge structural detailsGlass fiberCarbon fibers

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Fresh polygonatum odoratum freeze-dried decoction pieces and preparation method thereof

The invention discloses a fresh polygonatum odoratum freeze-dried decoction piece and a preparation method thereof, and relates to the field of traditional Chinese medicine, the fresh polygonatum odoratum is cleaned to remove impurities, the cleaned fresh polygonatum odoratum is cut into thick pieces, the thick pieces are placed in an acidic soak solution containing vegetable oil for ultrasonic impregnation, and the thick pieces are taken out and dried to obtain a first crude product; the first crude product is put into fermentation liquor containing oxalate decarboxylase to be fermented, and a second crude product is obtained after fermentation is finished; the second crude product is subjected to freeze drying under the vacuum condition, and a third crude product is prepared. According to the fresh polygonatum odoratum freeze-dried decoction piece, the content of calcium oxalate in the fresh polygonatum odoratum freeze-dried decoction piece is reduced, and meanwhile the dried decoction piece is not prone to embrittlement and easy to store.

Owner:江西纳弗堂制药有限公司

Novel modified PA66 (polyamide 66) material and preparation method thereof

The invention relates to a novel modified PA66 (polyamide 66) material. The novel modified PA66 material comprises the following components in parts by weight: 50-80 parts of PA66, 20-30 parts of nano calcium carbonate, 0.2-0.3 part of liquid paraffin oil, 0.2-0.3 part of titanate coupler TC-114, 20-30 parts of toughening agent, 1-2 parts of crosslinking sensitizer, 0.5-1 part of crosslinking auxiliary, 0.5-0.8 part of main antioxidant, 0.3-0.5 part of auxiliary antioxidant and 1-2 parts of lubricating agent; and the preparation method of the novel modified PA66 material sequentially comprises a preparation process of active nano calcium carbonate, a preparation process of mixed material granules, a drying process, an injection moulding process and an irradiation modification process, wherein irradiation dose of an electron accelerator in the irradiation modification process is 5-8Mrad. The modified PA66 material prepared by the invention has stronger toughness and heat resistance, hardly tenders at low temperature and is lower in water absorption ratio and moulding shrinkage; besides, complete modification can also be realized when an irradiated material is thicker.

Owner:HANCHUN SMALL SHENLONG BABY PROD

Pre-process method and structure of light-emitting diode packaging

InactiveCN103682059BStrong jointIncrease contact areaSolid-state devicesSemiconductor devicesInsulation layerHeat conducting

Owner:CHANG WAH ELECTROMATERIALS INC +1

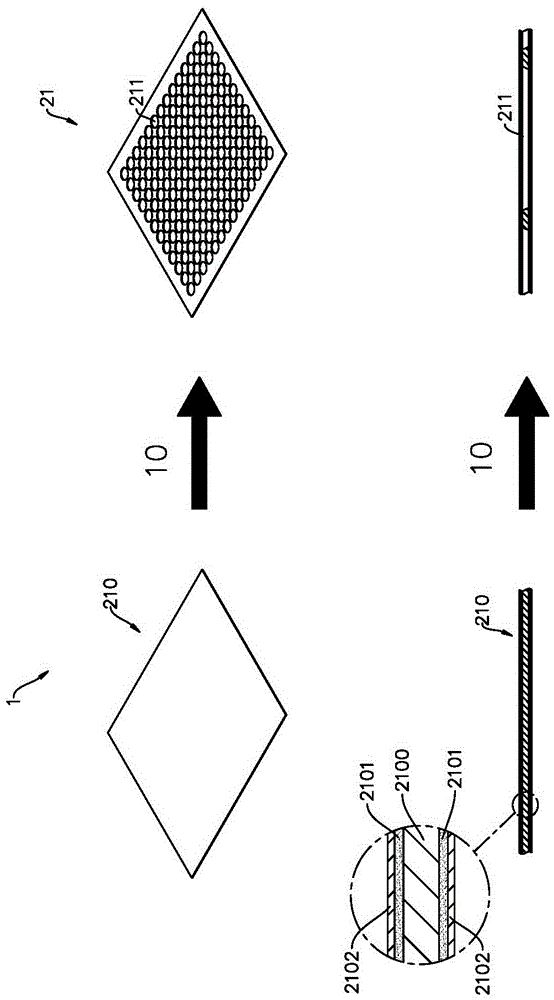

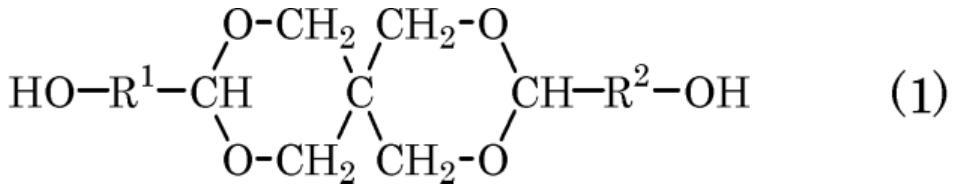

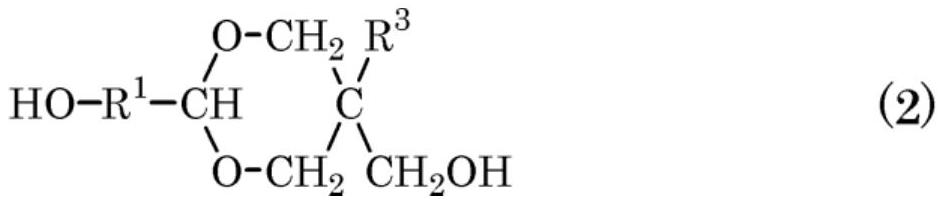

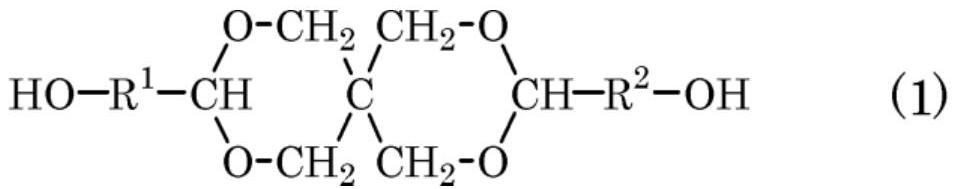

A kind of high-hardness polyurethane hot-melt adhesive and preparation method thereof

ActiveCN104212403BHigh modulusIncrease elasticityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyol

The invention relates to the technical field of polyurethane hot-melt adhesives, in particular to a high-hardness polyurethane hot-melt adhesive and a preparation method thereof. The polyurethane hot-melt adhesive of the present invention is composed of 50-70 parts by weight of polyester polyol, 8-25 Parts of diisocyanate, 0-5 parts of chain extender, 5-35 parts of filler additives; the hardness of the high-hardness polyurethane hot-melt adhesive of the present invention can reach more than 55D, with high modulus, high resilience, The advantages of not being brittle are mainly due to the use of different types of engineering plastics and inorganic additives, which are added during the production of polyurethane to achieve the effect of good compatibility and not being brittle, and the melting point can also be controlled according to requirements, overcoming the The defects of polyurethane hot-melt adhesive products on the market; the preparation method of the present invention is simple and mature, has high production efficiency, and is conducive to popularization and application.

Owner:东莞宏石功能材料科技有限公司

Polyester resin composition, polyester injection-molded article, polyester extrusion-molded article, polyester foam, polyester container, polyester bottle, polyester tableware, and polyester feeding bottle

Owner:MITSUBISHI GAS CHEM CO INC

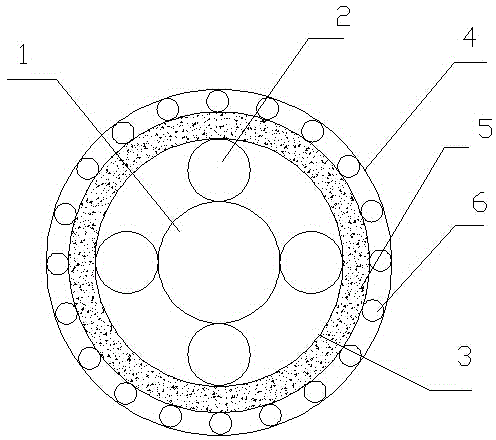

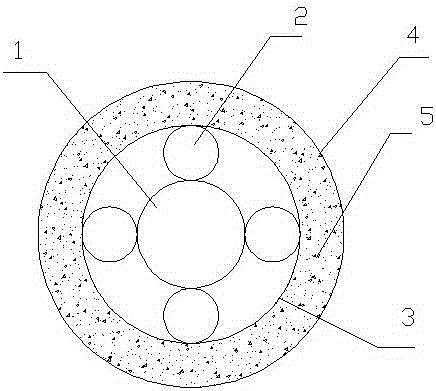

A composite cable containing continuous basalt fibers

ActiveCN104060538BImprove fatigue strengthWill not corrodeLoad-supporting elementsBridge structural detailsGlass fiberCarbon fibers

The invention relates to a compound inhaul cable containing continuous basalt fiber. The compound inhaul cable comprises three centre compound ribs, twelve peripheral compound ribs, a centre stainless steel pipe, an inner sheath, a filling material and an outer sheath, wherein the three centre compound ribs form a triangle; the centre stainless steel pipe is positioned in the centre of the triangle; each centre compound rib is twined with four peripheral compound ribs; the inner sheath wraps the centre compound ribs and the peripheral compound; the part between the outer sheath and the inner sheath is filled with the filling material; the filling material is the elastic filling material; the centre compound ribs are compounded from the continuous basalt fibers and glass fibers through resin matrix; the peripheral compound ribs are compounded from carbon fibers and aramid fibers through the resin matrix. The compound inhaul cable is high in strength, acid corrosion resistant, alkaline corrosion resistant and strong in anti-fatigue performance, can be exposed outdoors for use in long term, is long in service life, and eliminates potential safety hazard of being broken when in use.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

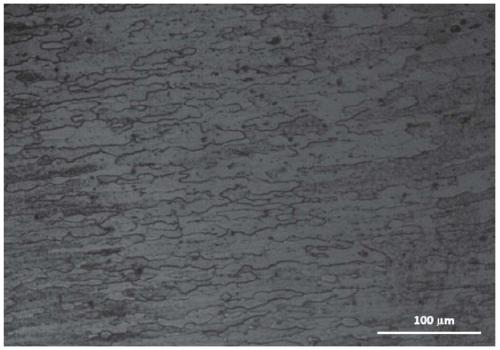

Novel heating element

InactiveCN101772225BReduce distortionSolution to short lifeOhmic-resistance heatingMoisture absorptionAlloy

The invention discloses a heating element, which belongs to range of heating components. The middle of the heating element is a plate core formed by covering high-temperature resistant heat-conduction insulating ceramic materials onto high-quality alloy wire heater; both side surface of the plate core are provided with a heating element skeleton which is composed of metal oxide, carbon materials and high-temperature resistant heat-conduction insulating inorganic binder, the outer side surface of the heating element skeleton is provided with stainless steel metal meshes in a clinging way, the outer side surface of the stainless steel metal meshes is provided with nano far-infrared material and high-temperature resistant moisture-proof covering. The advantages of the invention are as follows: the heater provided by the invention has small deformation, long the service life, hard brittleness, no power recession; the heat of the heating core plate not only can be fully discharged, but also can overcome the defect of degradation of electrical insulation performance during using due to moisture absorption when the electric heater is not used; the thermal efficiency can reach up to 99% or more, the radiation area is large, the radiation cooling is strong, and the comfort is good.

Owner:北京桑普电器有限公司

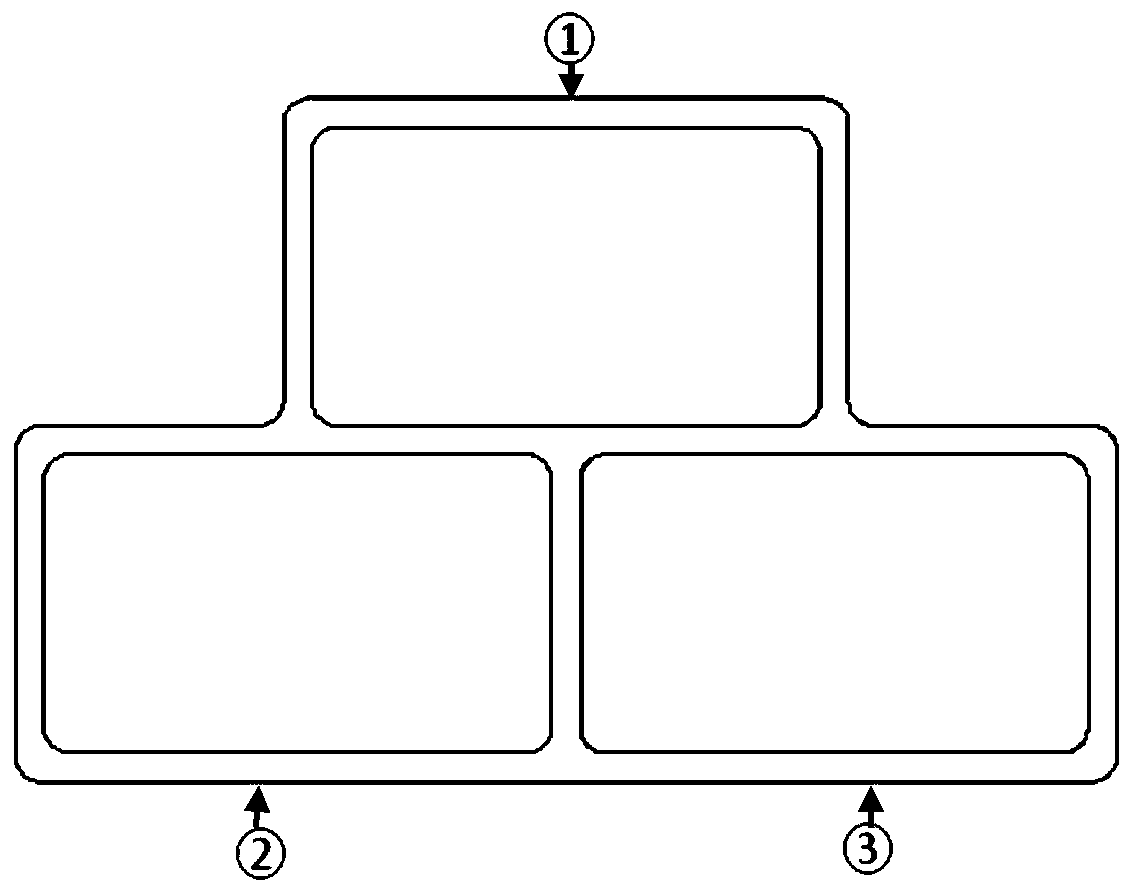

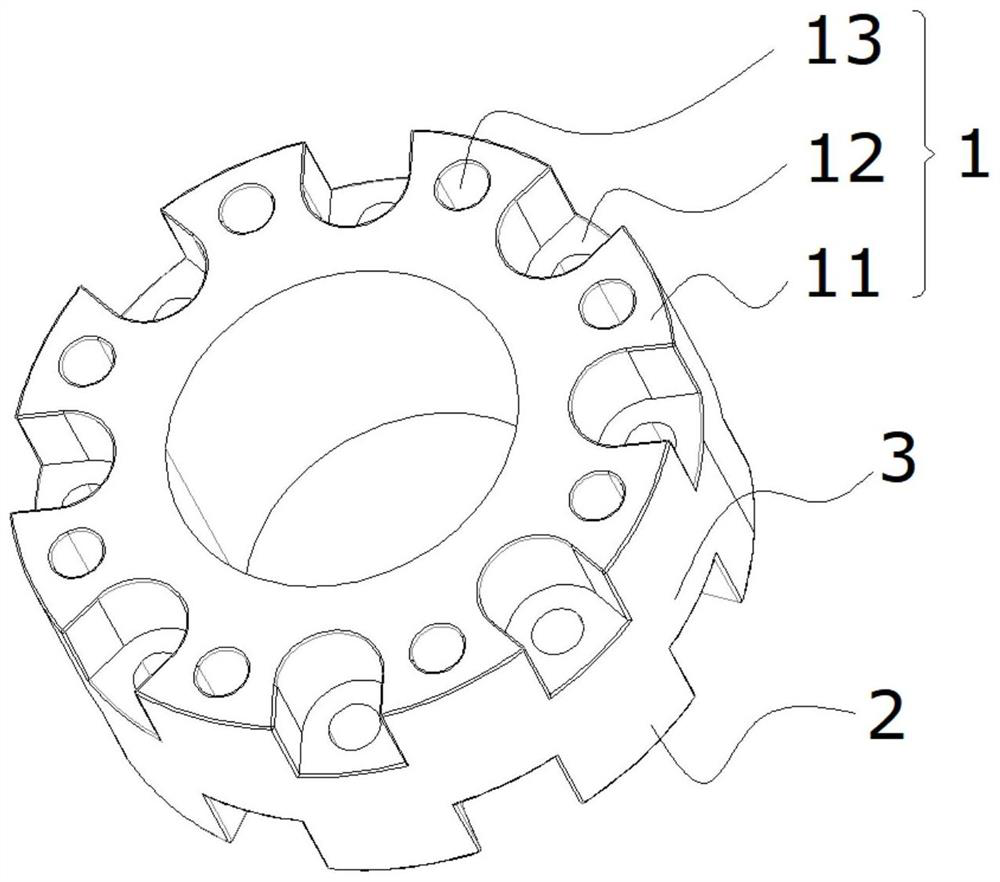

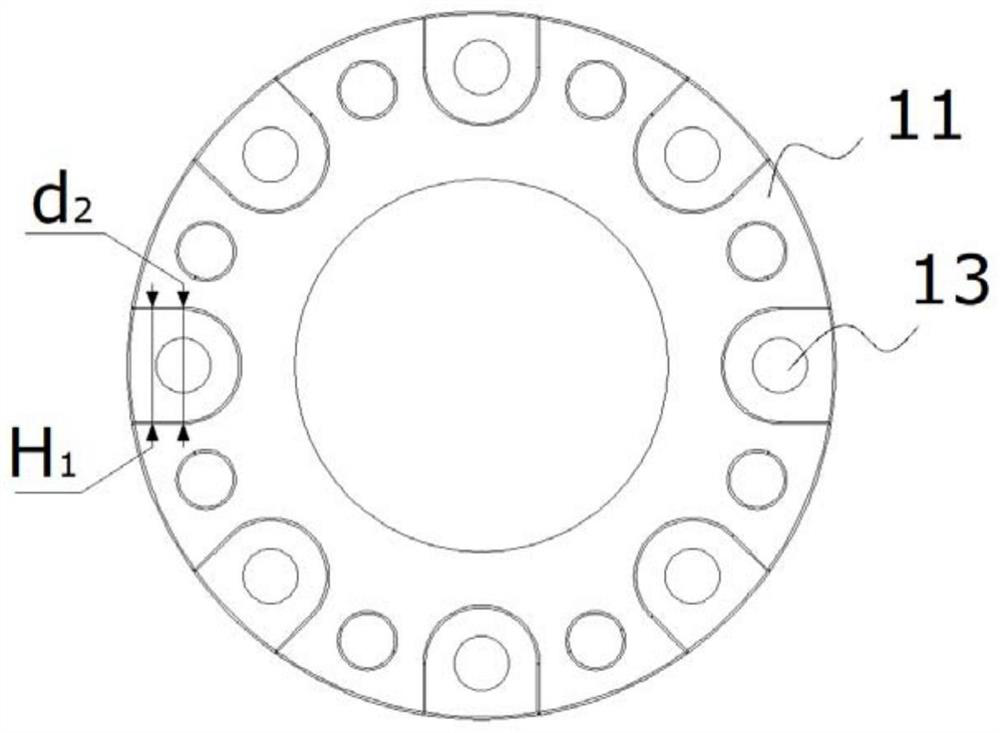

Novel insulating flange

PendingCN112815165ANo gapReduced insulation performanceFlanged jointsMaterials sciencePolytetrafluoroethylene

A novel insulating flange is detachably arranged on a connector of a pipeline and comprises an integrally-formed flange plate, and the flange plate comprises an upper flange plate body, a lower flange plate body and a connecting part arranged between the upper flange plate body and the lower flange plate body. The upper flange plate body comprises a plurality of mounting parts arranged at intervals and open grooves, and threaded through holes penetrating through the upper flange plate body and the connecting part are formed in the mounting parts. The lower flange plate body and the upper flange plate body are the same in structure. The upper flange plate body and the lower flange plate body are arranged in a staggered mode, the mounting parts of the upper flange plate body correspond to the open grooves of the lower flange plate body, and the open grooves of the upper flange plate body correspond to the mounting parts of the lower flange plate body. The flange plate is made of low-temperature-resistant insulating plastic, and the low-temperature-resistant insulating plastic is one or a composite material of UPE (Unplasticized Polyethylene) or PTFE (Polytetrafluoroethylene).

Owner:厦门市卓励石化设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com