Die of phenolic piston and manufacture method of phenolic piston

The technology of a phenolic piston and a manufacturing method, which is applied to manufacturing tools, presses and other directions, can solve problems such as poor quality of finished products, and achieve the effects of high yield, not easy to embrittle, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

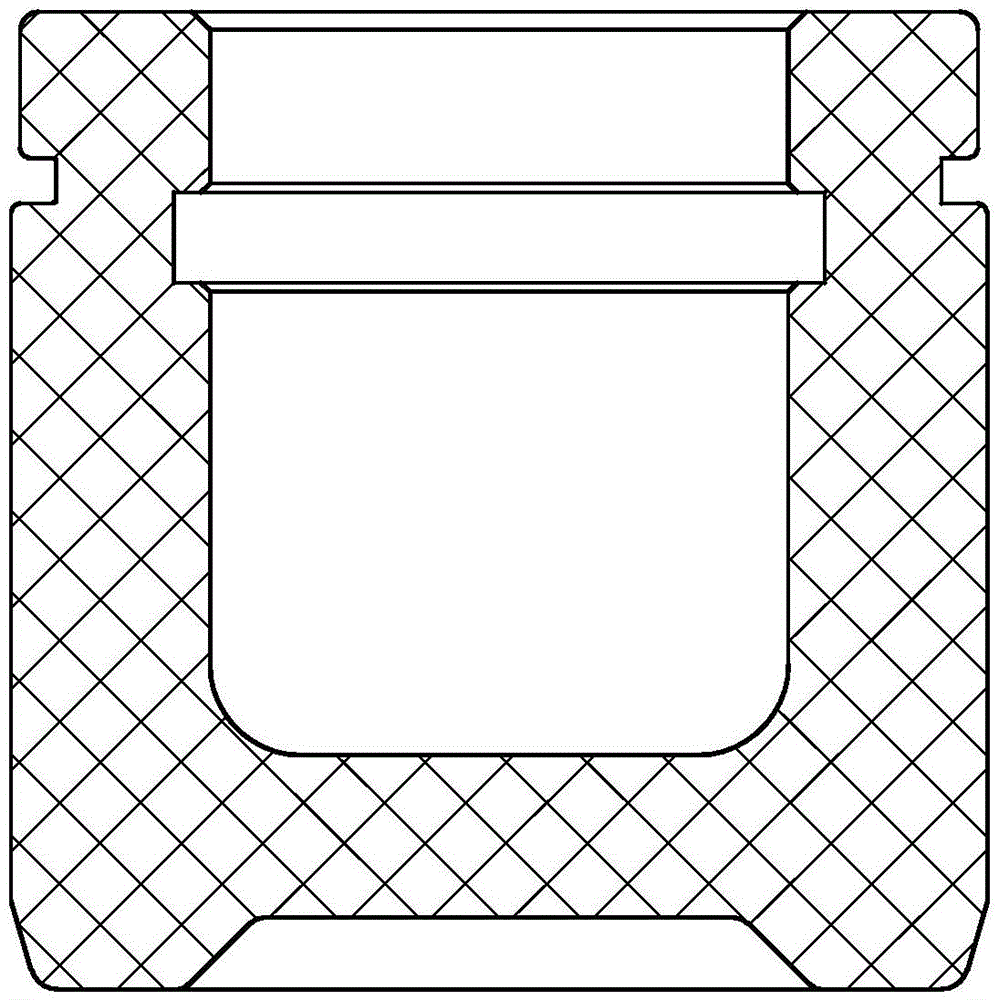

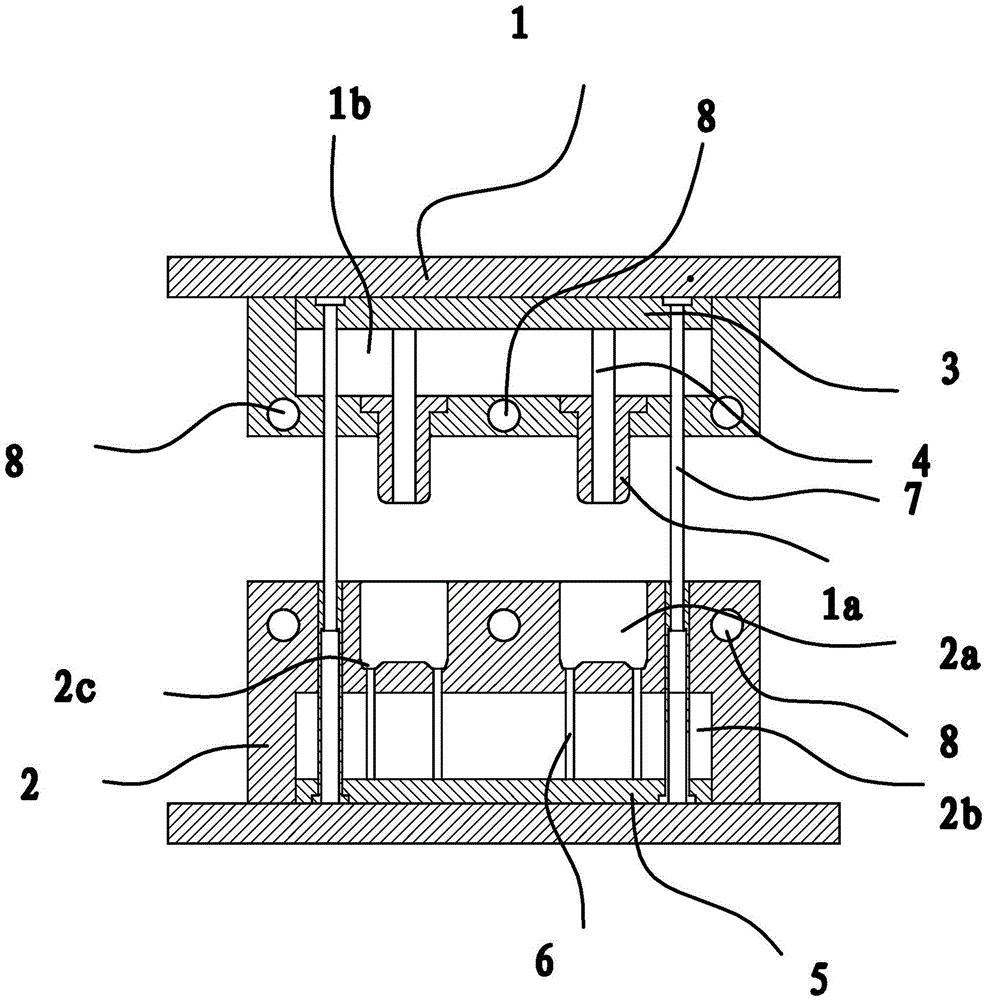

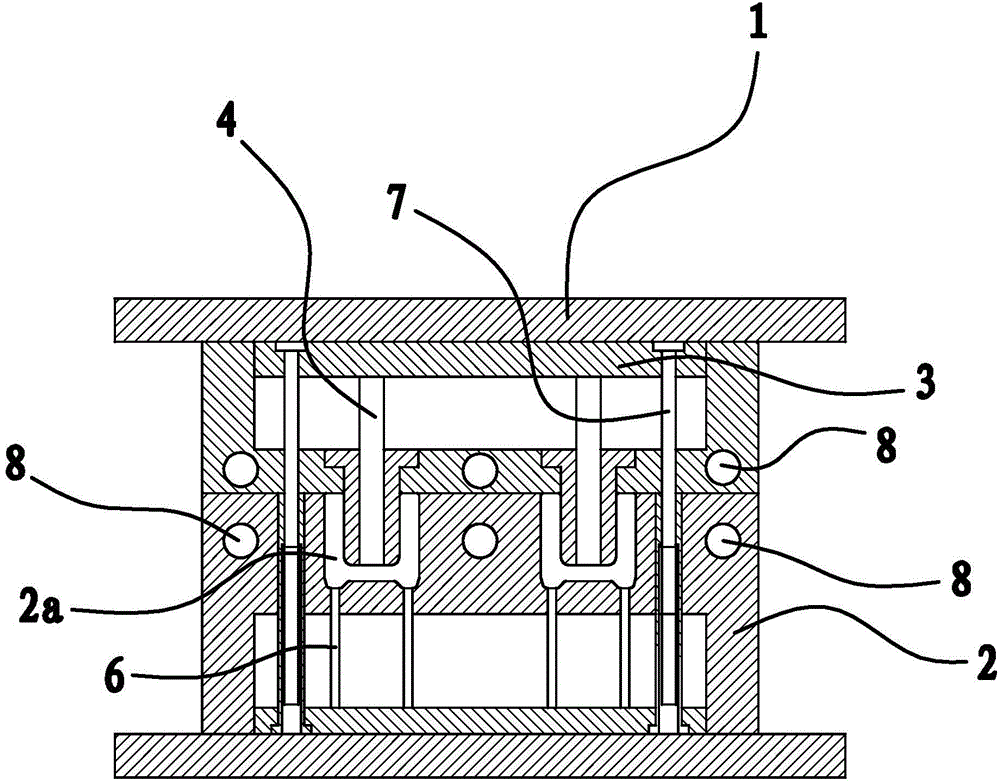

[0042] Such as figure 2 and image 3As shown, the mold of the phenolic piston includes an upper mold body 1 and a lower mold body 2. After the upper mold body 1 and the lower mold body 2 are snapped together, a molding cavity for molding the phenolic piston is formed between the two. On the upper mold body 1, there is a punch 1a that matches the inner cavity of the phenolic piston, on the lower mold body 2, there is a concave mold 2a that matches the outside of the phenolic piston, and on the convex mold 1a, there is a phenolic piston that can be adhered to it. Separate stripping piece 1, the concave mold 2a has a stripping piece 2 capable of separating the phenolic piston adhered therein. Both the upper mold body 1 and the lower mold body 2 have several heating holes 8 .

[0043] The punch 1a is in the shape of a cylinder, and the stripping part 1 includes the guide cavity 1b inside the upper mold body 1, the stripping plate 3 and the stripping rod 4 located in the guide c...

Embodiment 2

[0054] This embodiment is basically the same as the solution of Embodiment 1, the difference is:

[0055] A. Cake making: the granulated phenolic aldehyde is manufactured into a cup-shaped cake by stamping. In this embodiment, the phenolic granules are pressed into a cup-shaped cake with a pressure of 8 tons on a common punch. Then, the cake material was heated to 240°C.

[0056] B. Mold preheating: Both the upper mold body 1 and the lower mold body 2 are heated to 240°C. In this embodiment, the upper mold body 1 and the lower mold body 2 are heated to 240°C by means of electric heating. Then, the above-mentioned cake material at 240° C. is put between the upper mold body 1 and the lower mold body 2 . In this embodiment, the upper mold body 1 and the lower mold body 2 are heated to 240° C. and then kept warm for 15 minutes.

[0057] C. Mold clamping: Place the mold on the punching machine and fasten the upper mold body 1 and the lower mold body 2 with a pressure of 70 tons. ...

Embodiment 3

[0060] This embodiment is basically the same as the solution of Embodiment 1, the difference is:

[0061] A. Cake making: The granulated phenolic formaldehyde is manufactured into a cup-shaped cake by stamping. In this embodiment, the phenolic granules are pressed into a cup-shaped cake with a pressure of 6 tons on a common punch. Then, the cake material was heated to 200°C.

[0062] B. Mold preheating: Both the upper mold body 1 and the lower mold body 2 are heated to 200°C. In this embodiment, the upper mold body 1 and the lower mold body 2 are heated to 200°C by means of electric heating. Then, the above-mentioned 200° C. cake material is put between the upper mold body 1 and the lower mold body 2 . In this embodiment, the upper mold body 1 and the lower mold body 2 are heated to 200° C. and then kept warm for 10 minutes.

[0063] C. Mold closing: place the mold on the punching machine and fasten the upper mold body 1 and the lower mold body 2 through a pressure of 60 ton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com