Process for manufacturing wood grain color coated aluminum plate

A manufacturing process and wood grain technology, which is applied in the manufacturing process of wood grain color-coated aluminum panels, can solve problems such as blurred texture, unsatisfactory fashion pursuit, poor weather resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

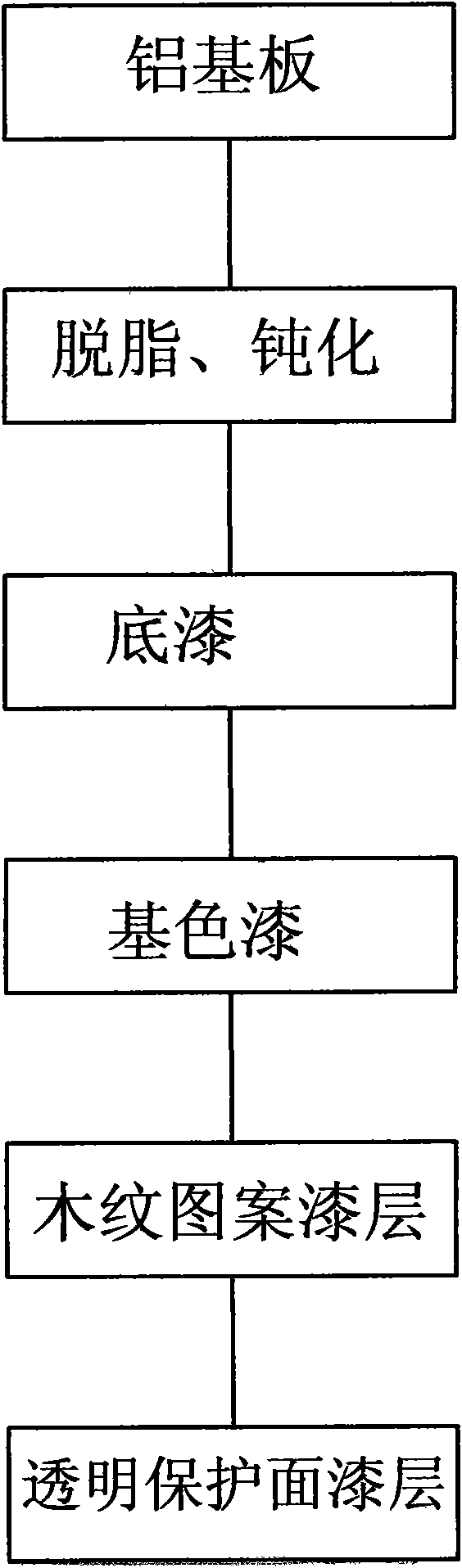

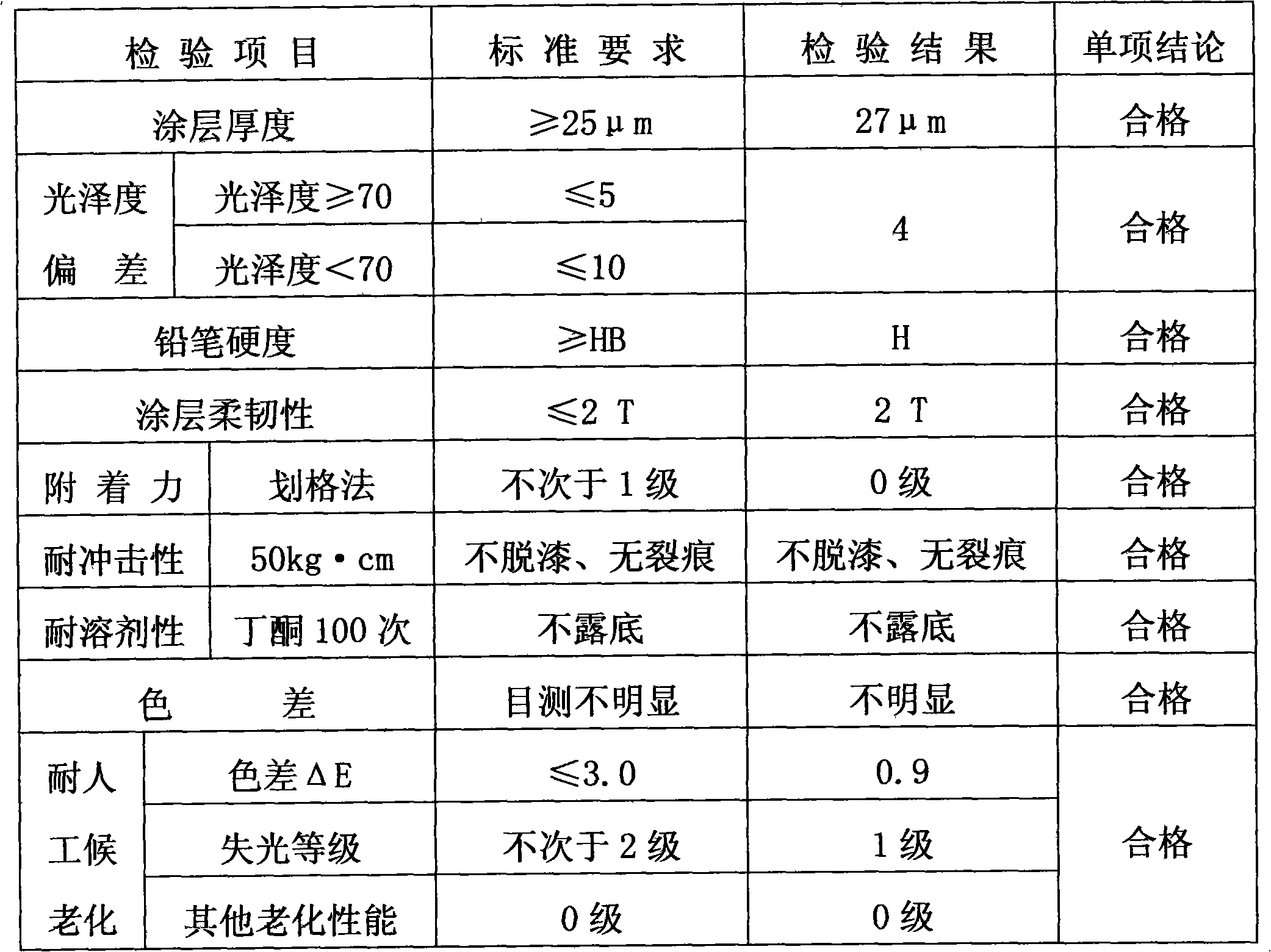

[0019] Embodiment 1: refer to figure 1 Shown, a kind of manufacturing process of wood-grain color-coated aluminum plate, this process comprises the following steps

[0020] (1) Perform pretreatment degreasing and passivation processes on the aluminum substrate 11, so that a passivation film layer is formed on the surface of the aluminum substrate 11;

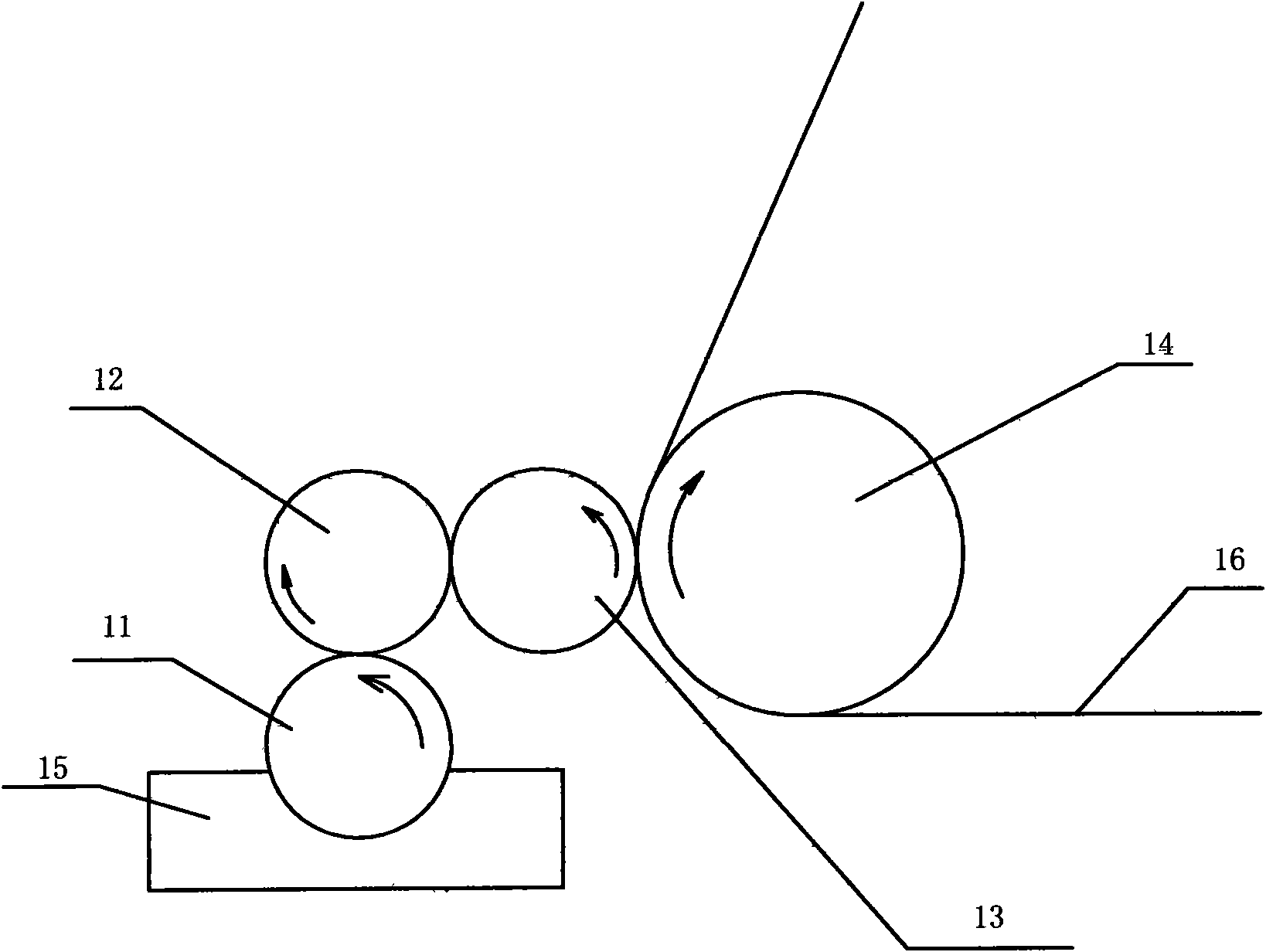

[0021] (2) Coating a layer of polyurethane paint on the passivation film layer, and baking it in an oven, so that the temperature of the aluminum substrate 11 reaches 204 ° C, and forming a film to form a primer after baking for 60 seconds, Then coat a layer of fluorocarbon resin paint on the primer, and bake it in an oven, so that the temperature of the aluminum substrate reaches 232 ° C, after baking for 60 seconds, a film is formed to form a base color paint. Combination constitutes base color primer layer, the coating viscosity of this polyurethane coating is 60 " (4# Ford cup), and the coating viscosity of fluorocarbon res...

Embodiment 2

[0026] Embodiment 2: refer to figure 1 Shown, a kind of manufacturing process of wood-grain color-coated aluminum plate, this process comprises the following steps

[0027] (1) Perform pretreatment degreasing and passivation processes on the aluminum substrate 11, so that a passivation film layer is formed on the surface of the aluminum substrate 11;

[0028] (2) Coating a layer of polyurethane paint on the passivation film layer, and baking it in an oven so that the temperature of the aluminum substrate 11 reaches 208 ° C, and forming a film to form a primer after baking for 53 seconds, Then coat a layer of fluorocarbon resin paint on the primer, and bake it in an oven, so that the temperature of the aluminum substrate reaches 237 ° C, and after baking for 53 seconds, a film is formed to form a base color paint. Combination constitutes base color primer layer, the coating viscosity of this polyurethane coating is 65 " (4# Ford cup), and the coating viscosity of fluorocarbon ...

Embodiment 3

[0032] Embodiment 3: refer to figure 1 Shown, a kind of manufacturing process of wood-grain color-coated aluminum plate, this process comprises the following steps

[0033] (1) Perform pretreatment degreasing and passivation processes on the aluminum substrate 11, so that a passivation film layer is formed on the surface of the aluminum substrate 11;

[0034] (2) Coating a layer of polyurethane paint on the passivation film layer, and baking it in an oven, so that the temperature of the aluminum substrate 11 reaches 216 ° C, and forming a film to form a primer after baking for 45 seconds, Then coat a layer of fluorocarbon resin paint on the primer, and bake it in an oven, so that the temperature of the aluminum substrate reaches 241 ° C, and after baking for 45 seconds, a film is formed to form a base color paint. Combination constitutes base color primer layer, the coating viscosity of this polyurethane coating is 70 " (4# Ford cup), and the coating viscosity of fluorocarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com