Patents

Literature

112results about How to "Will not be corroded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite coal slurry dispersant used in coal chemical engineering field

The invention discloses a composite coal slurry dispersant used in the coal chemical engineering field. The composite coal slurry dispersant is composed of the following components in percentage by weight: 35 to 65% of dispersant main agent, 5 to 25% of viscosity reducer, 0.5 to 5% of surface modifier, 0.5 to 2.5% of metal ion chelating agent, 0.2 to 2% of corrosion inhibitor, and 0.5 to 58.8% of water; wherein the dispersant main agent is one or more of naphthalene sulfonate formaldehyde condensate, acrylic acid-allyl polyoxyethylene ether-sodium styrene sulfonate ternary copolymer, naphthalene sulfonic acid-styrene-maleic acid ternary copolymer, sodium lignin sulfonate, and modified polymethacrylate copolymer, the viscosity reducer is one or more of tannic acid, sulfonated tannin, sulfonated phenolic resin, and sodium nitrohumate, the surface modifier is one or more of dodecyl dimethyl benzyl ammonium chloride, OP-10, AEO-20, SP-40, and TWEEN-60, the metal ion chelating agent is one or more of polyacrylic acid, dihydroxyethyl glycine, and EDTA, and the corrosion inhibitor is benzotriazole and / or thiourea. The coal slurry dispersant is nontoxic, safe, and environment-friendly, and has a wide temperature and application range and good slurry-forming property.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

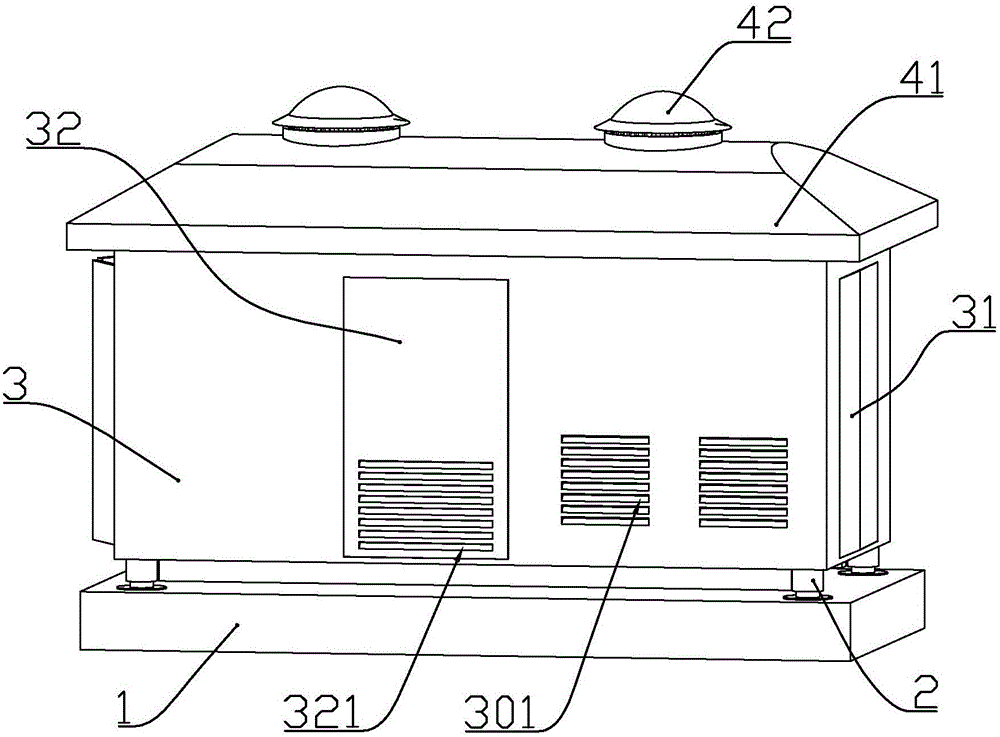

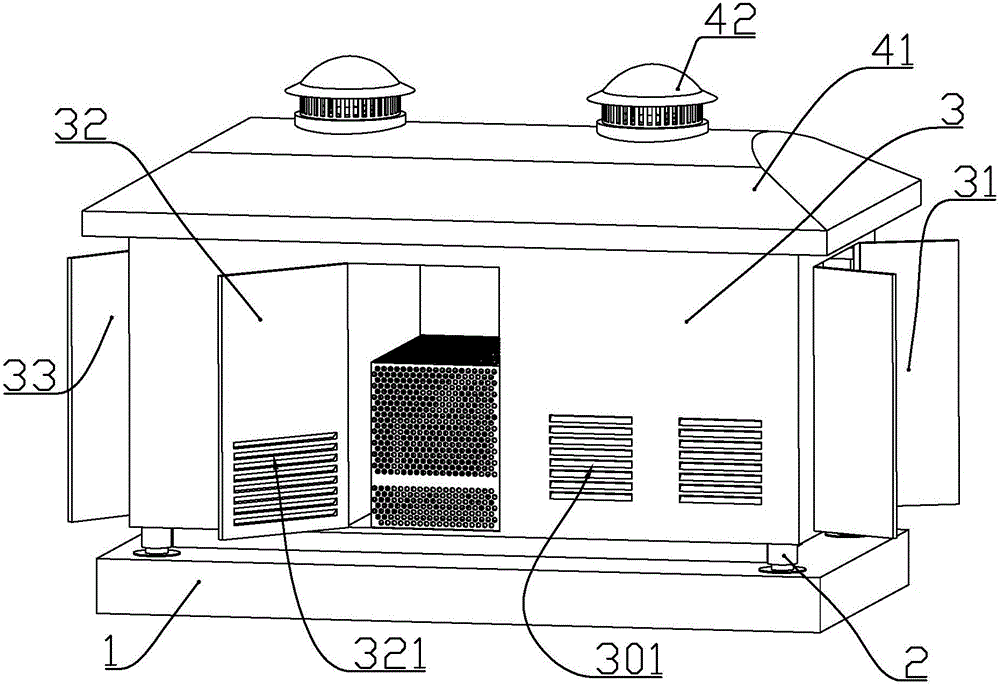

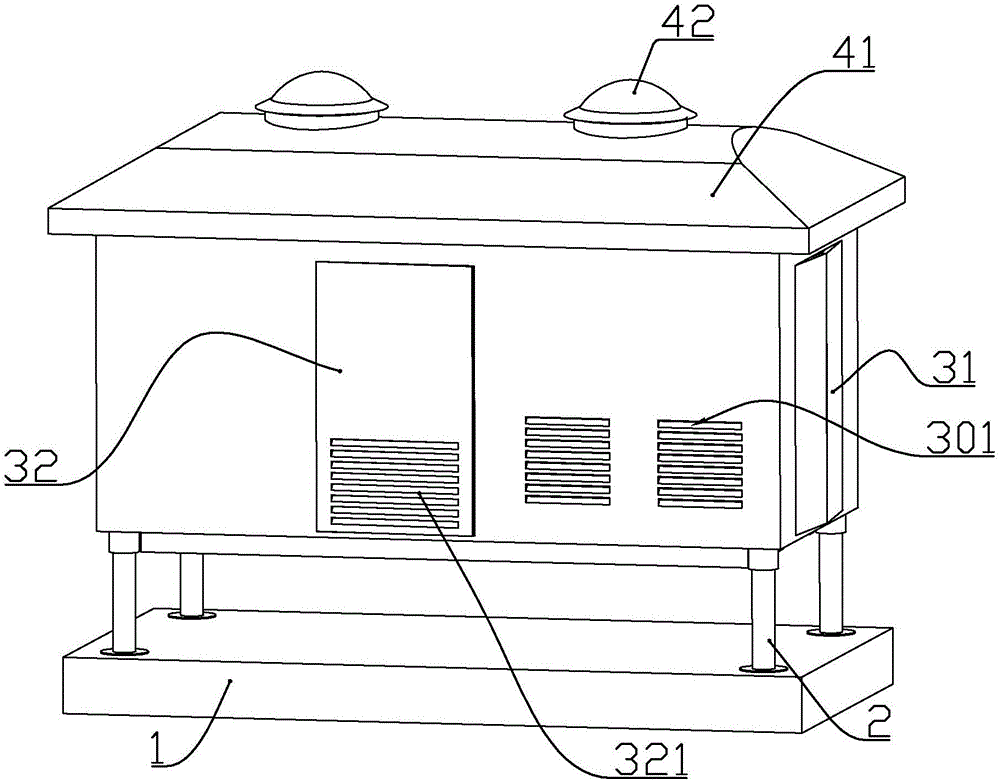

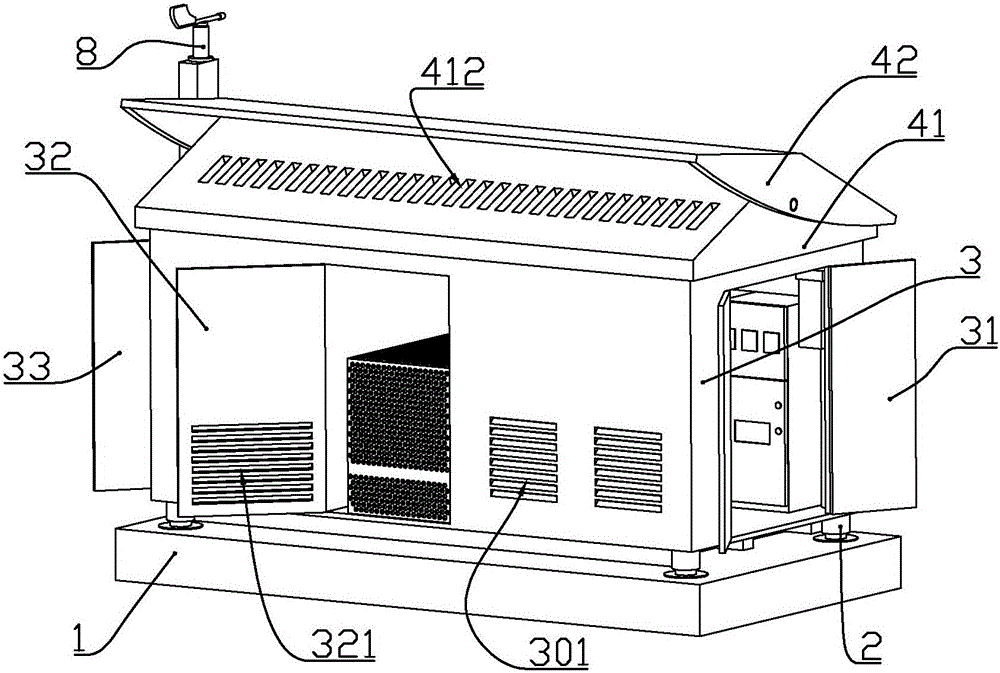

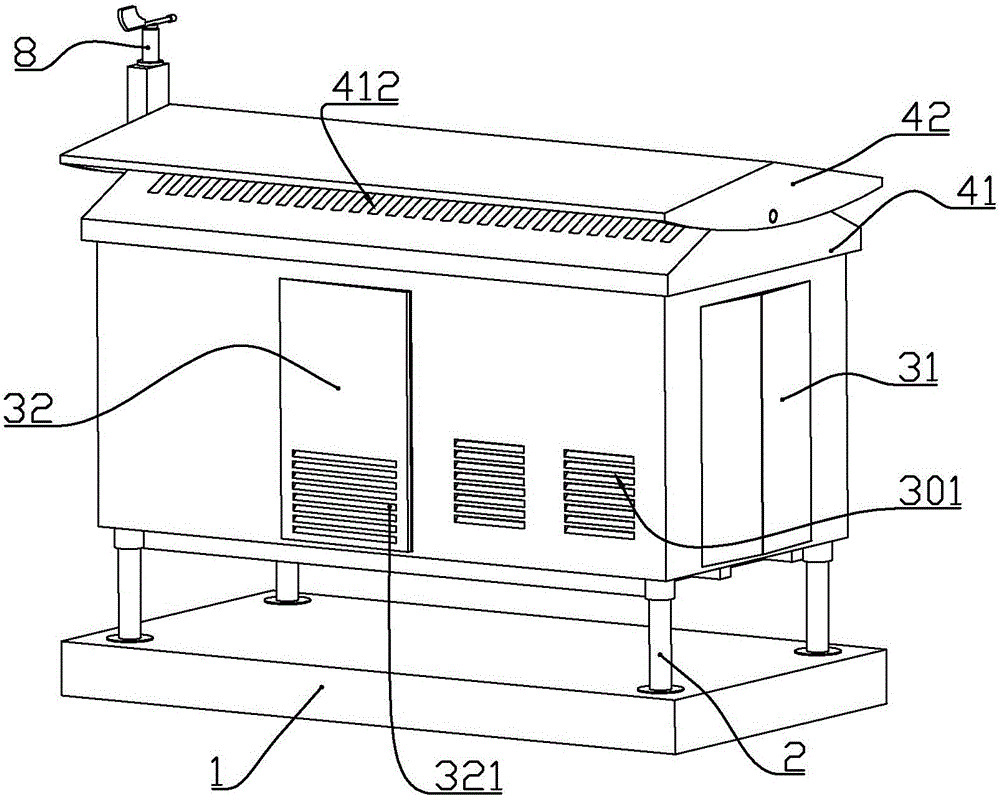

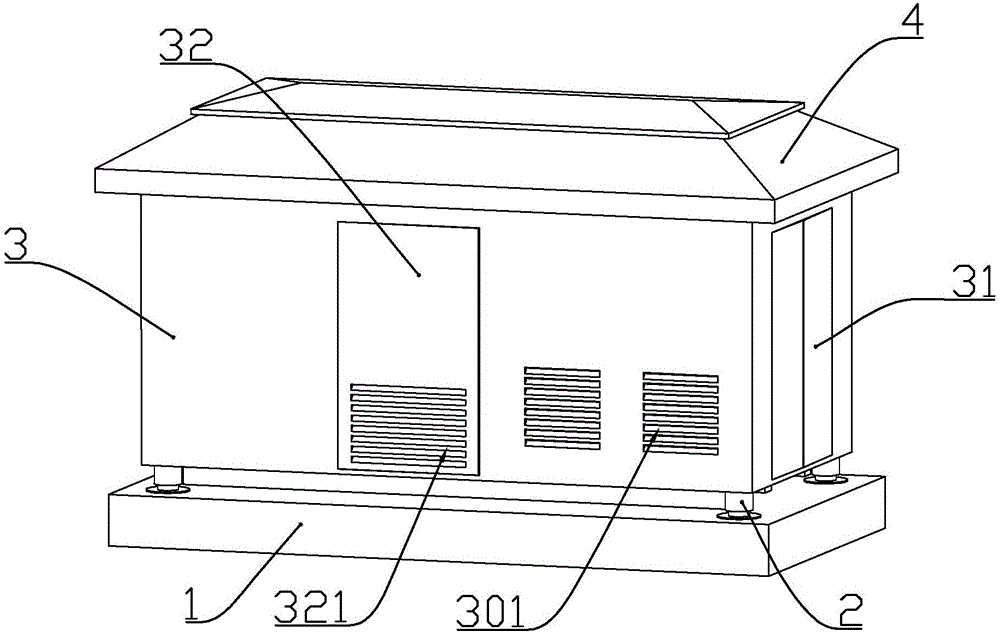

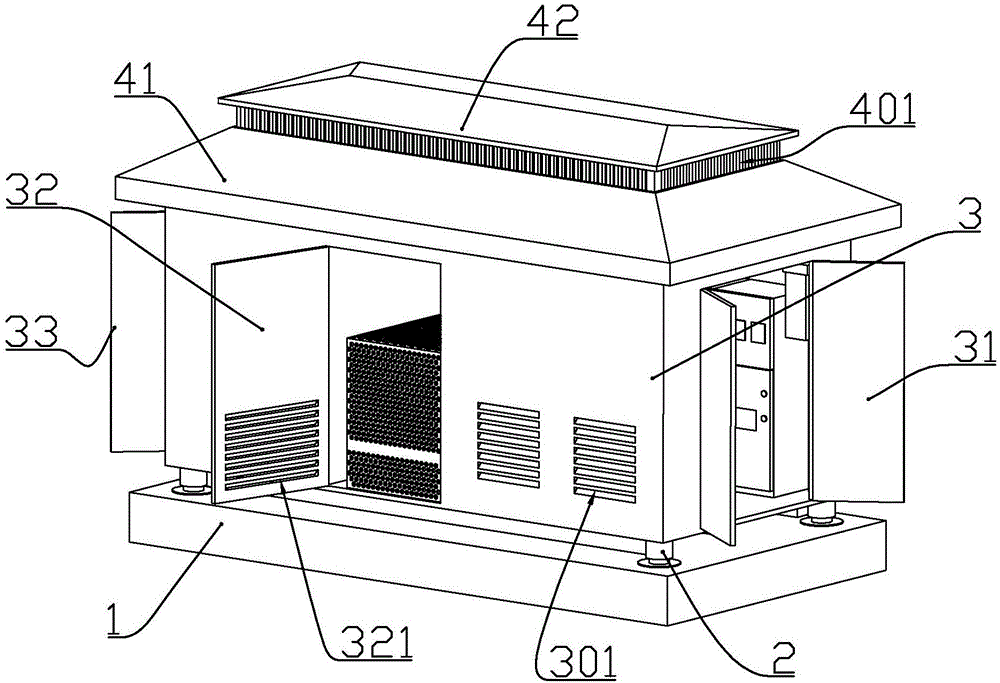

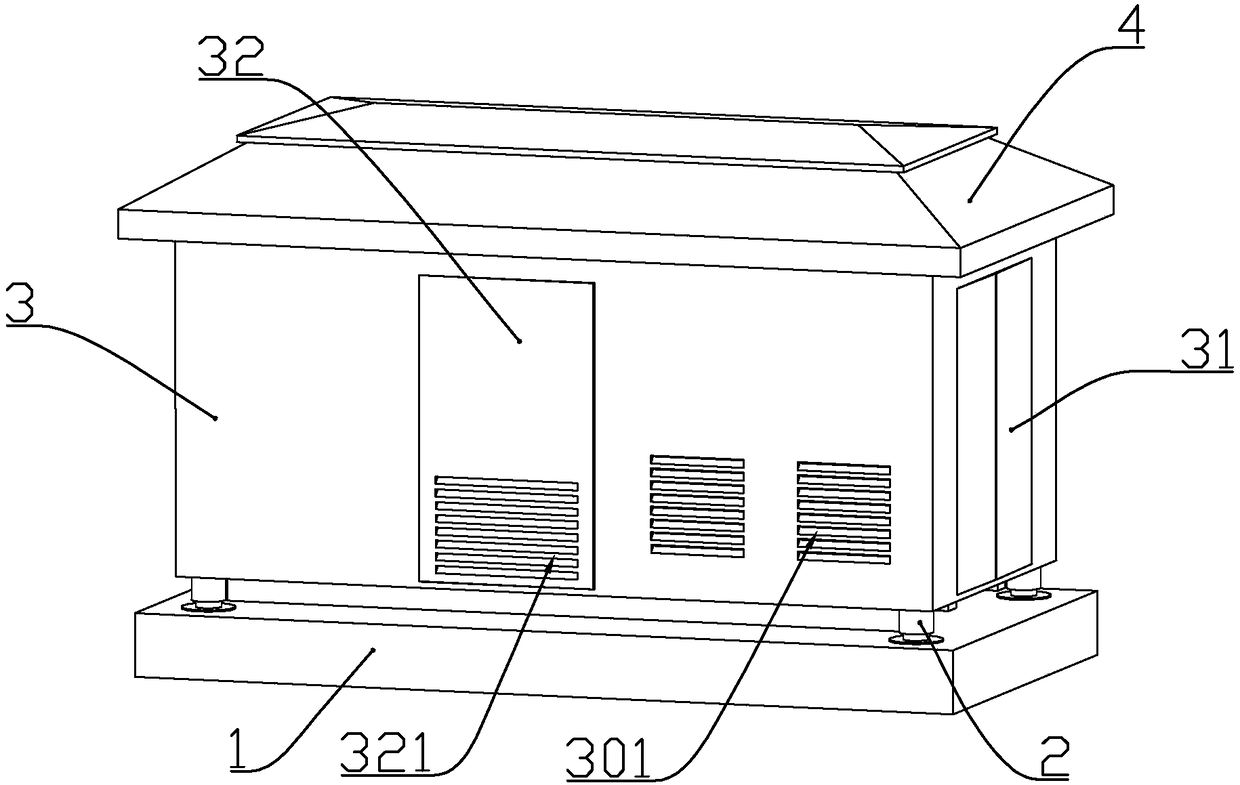

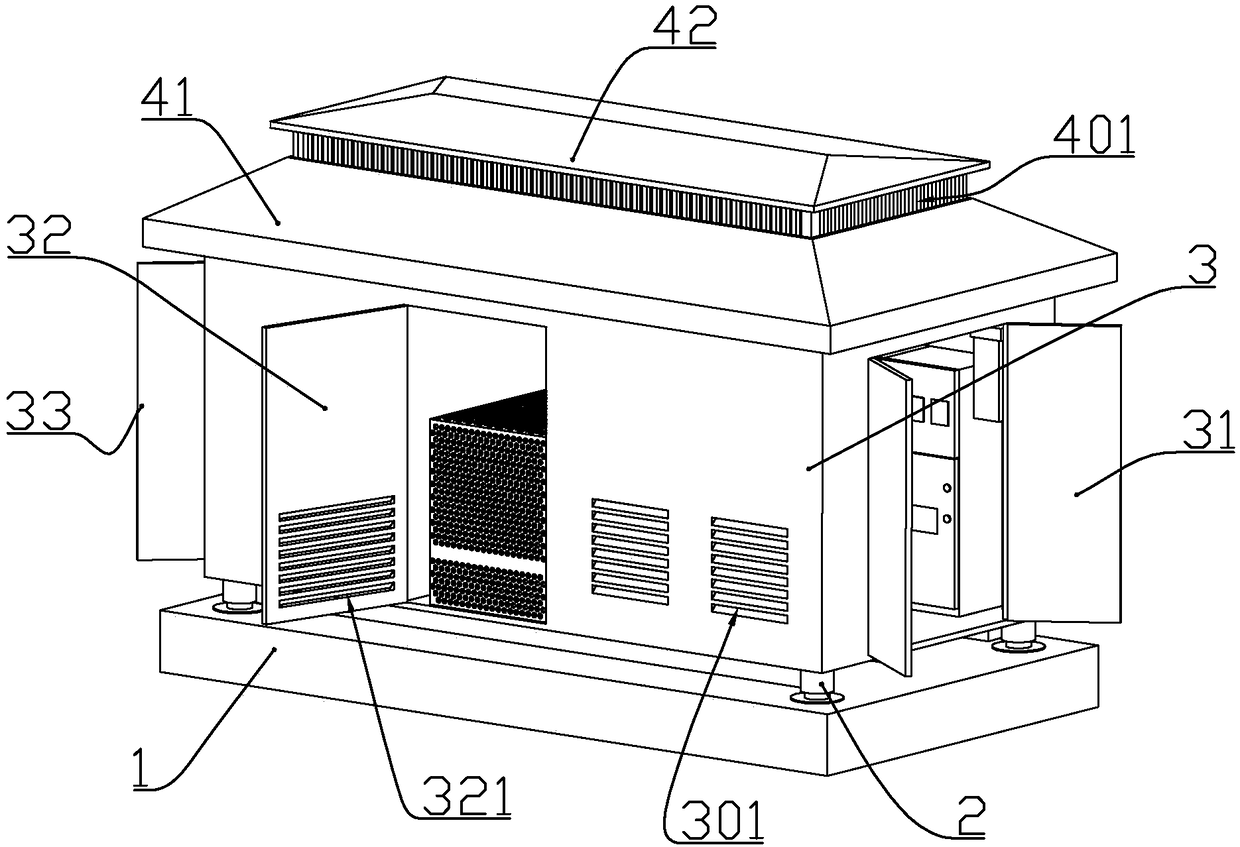

Box-type substation having multiple heat radiation modes

ActiveCN105977837AEasy to buildWill not corrodeTransformers/inductances coolingTransformers/inductances casingsTransformerRadiation mode

The invention discloses a box-type substation having multiple heat radiation modes. The box-type substation includes a pedestal and a box body which is arranged above the pedestal. The box body is connected to a top cover thereabove. The top cover is provided with two cylindrical upper air outlets at the places corresponding to a transformer chamber and a low-pressure chamber. Each upper air outlet is provided with an exhaust hood. A ventilation wall of the exhaust hood is evenly molded into exhaust openings thereon. The exhaust openings assume longitudinally-arranged bar shaped. The exhaust hood is provided with a centrifugal fan therein, and a lower part of the exhaust hood is provided with longitudinally arranged top cover push rod. According to the invention, the box-type substation has compact structure, reasonable design, easy construction, and excellent heat radiation effects.

Owner:保定市柯必达电气设备制造有限公司

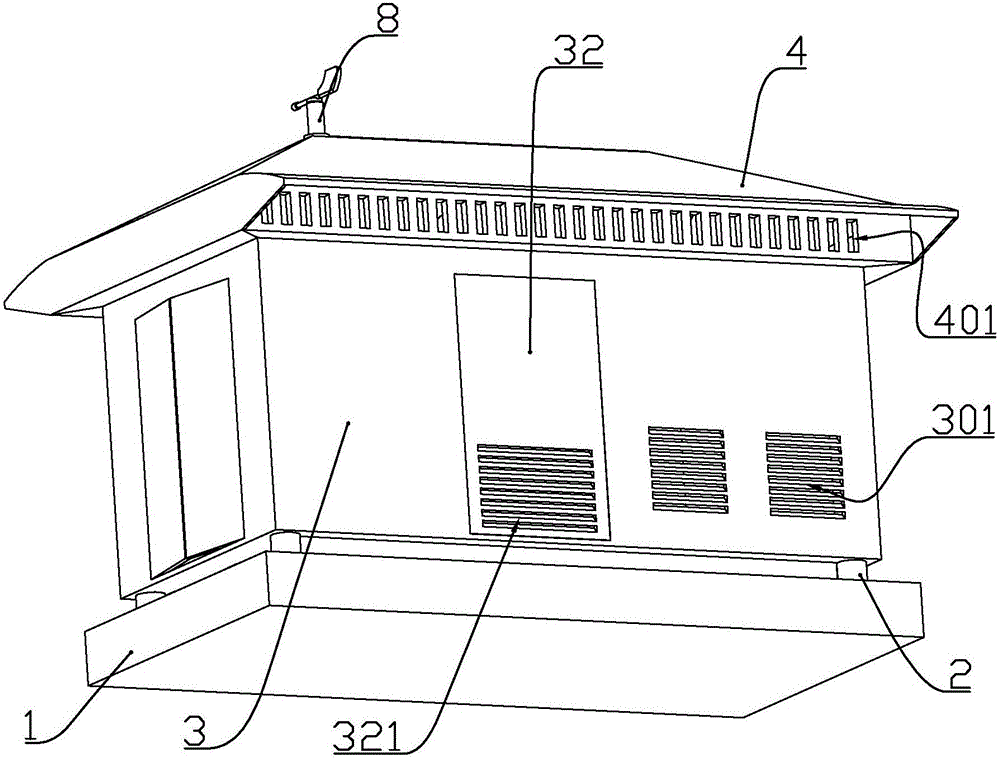

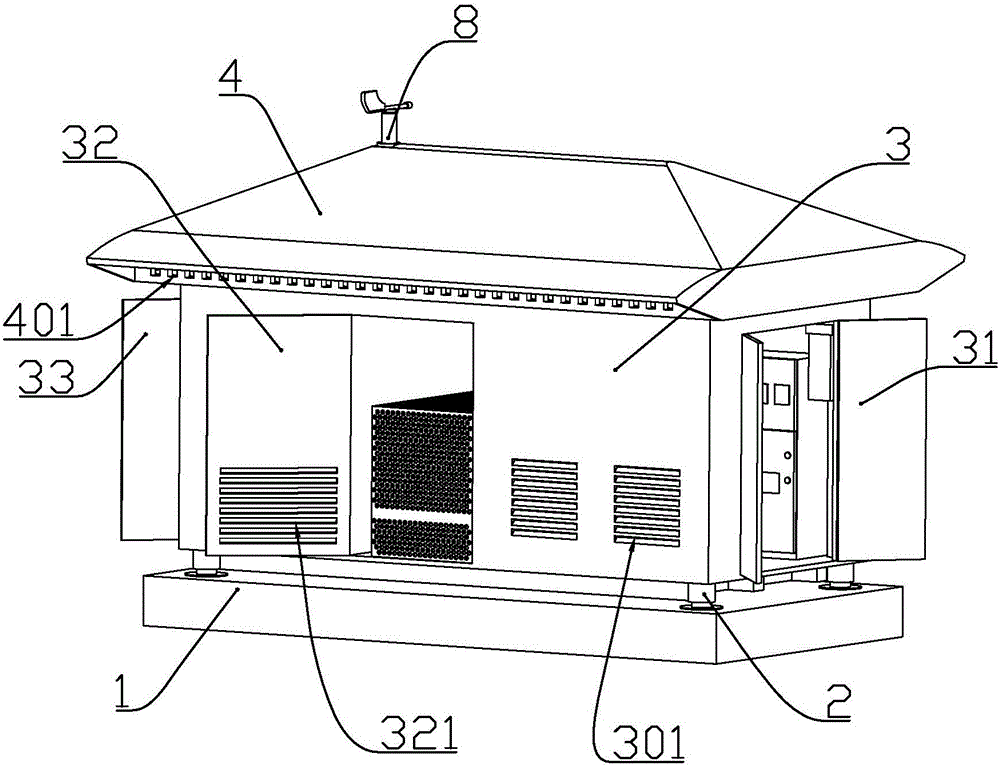

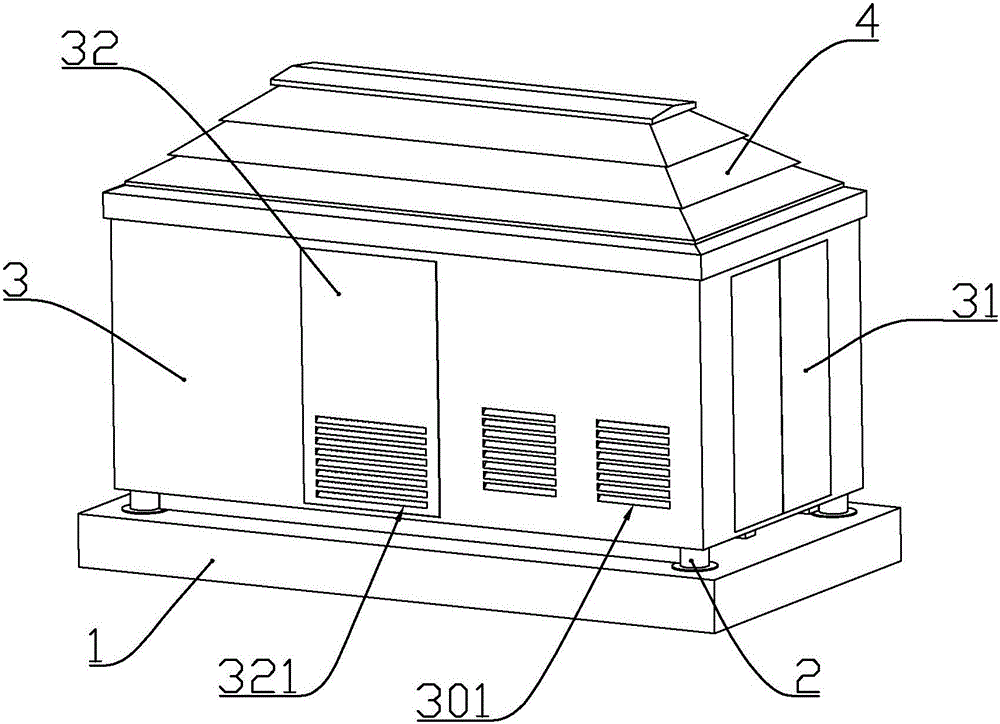

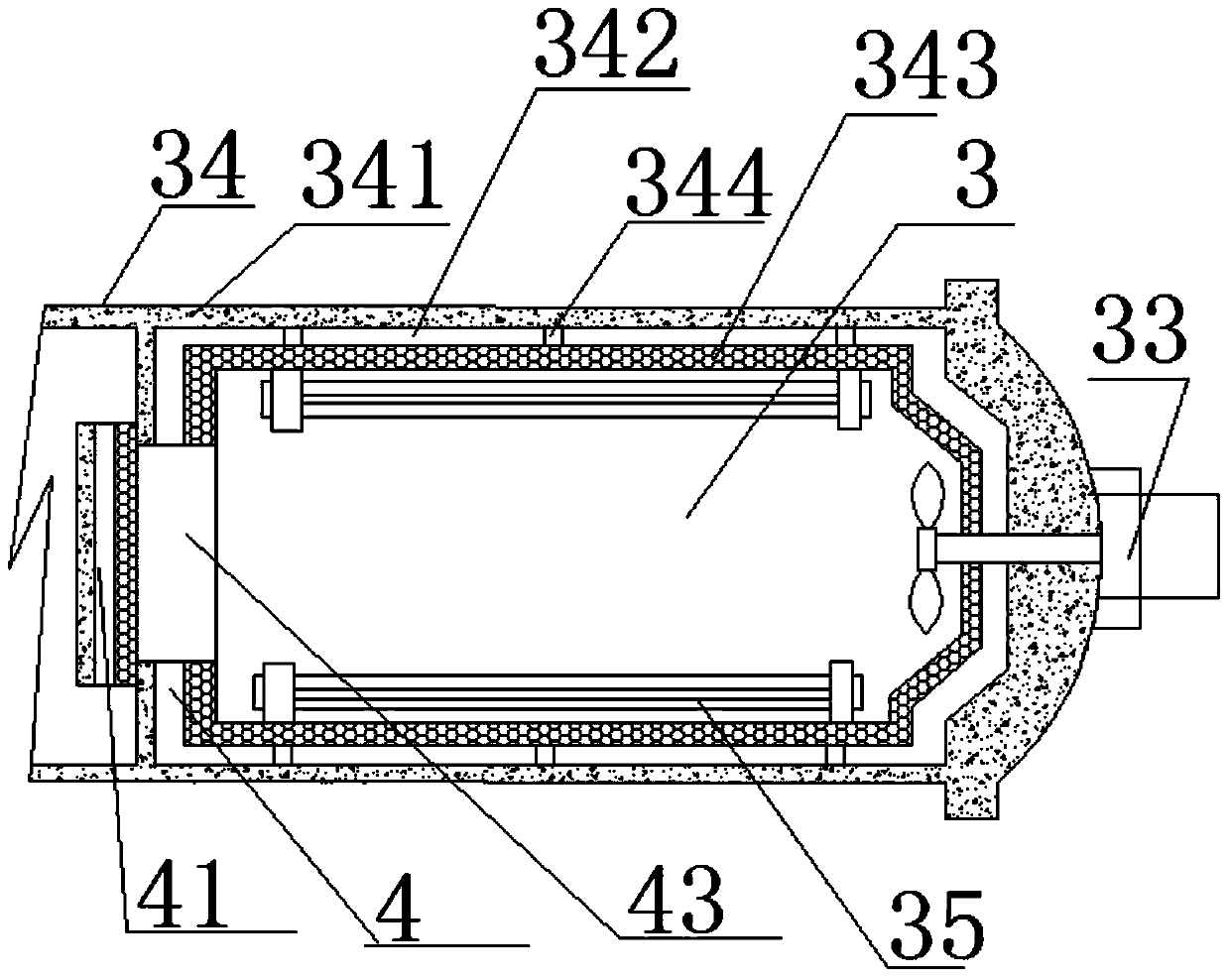

Adjustable box-type substation

ActiveCN106129829AEasy to buildWill not corrodeTransformers/inductances coolingEnclosed substationsCooling effectEngineering

The invention discloses an adjustable box-type substation, which comprises a base and a box body arranged at the upper part of the base, wherein the upper part of the box body is connected with a head cover; the head cover comprises longitudinal walls and slope walls; the lower parts of the longitudinal walls are fixedly connected with horizontally arranged transverse walls; exhaust outlets are uniformly formed in two groups of longitudinal walls, along the length direction, of the head cover; slide chute sockets are formed in the positions, corresponding to the exhaust outlets, of the transverse walls; wind grid plates are connected to the inside of the slide chute sockets in a sliding manner; grid plate openings which are used in fit with the exhaust outlets are formed in the corresponding wind grid plates; grid plate push rods are arranged on the inner walls of the transverse walls, along the width direction, of the head cover; an output rod of each grid plate push rod is fixedly connected with the end part of the corresponding wind grid plate; and a wind direction sensor is also arranged at the upper end of the head cover. The adjustable box-type substation is compact in structure, reasonable in design, convenient to construct and good in cooling effect.

Owner:山东恒东实业集团有限公司

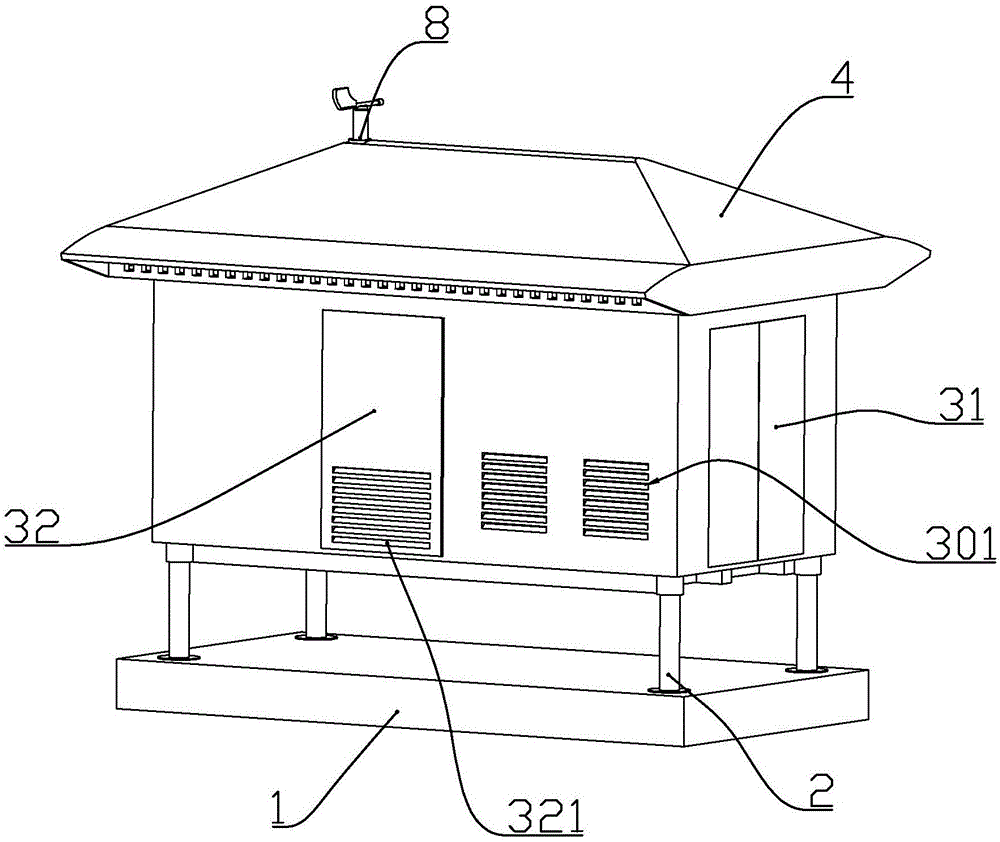

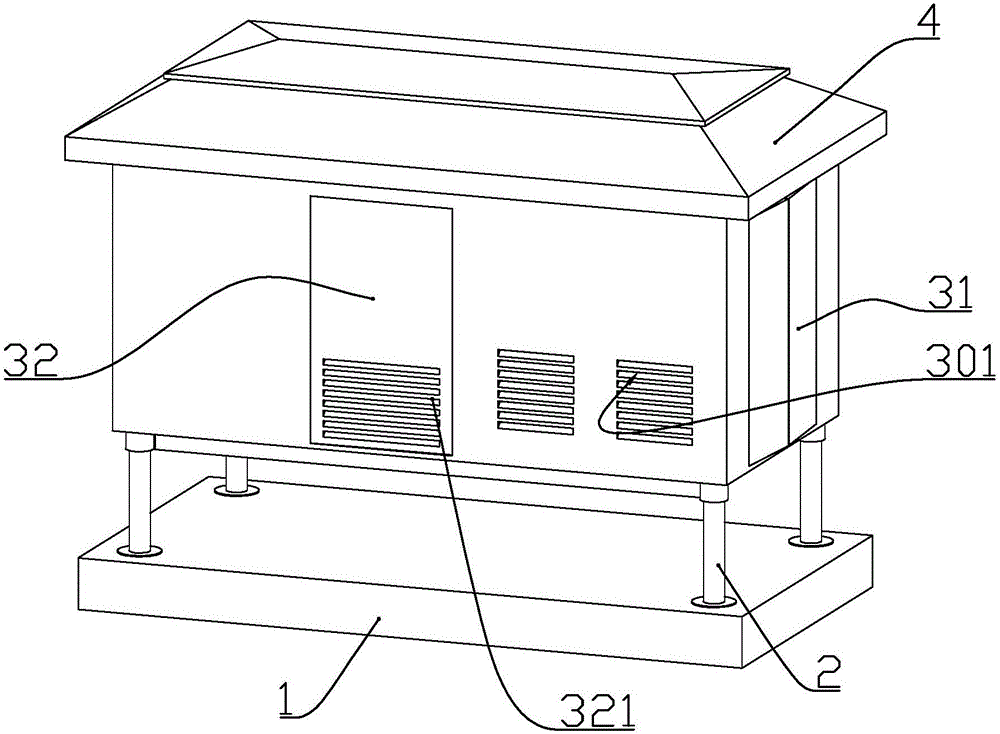

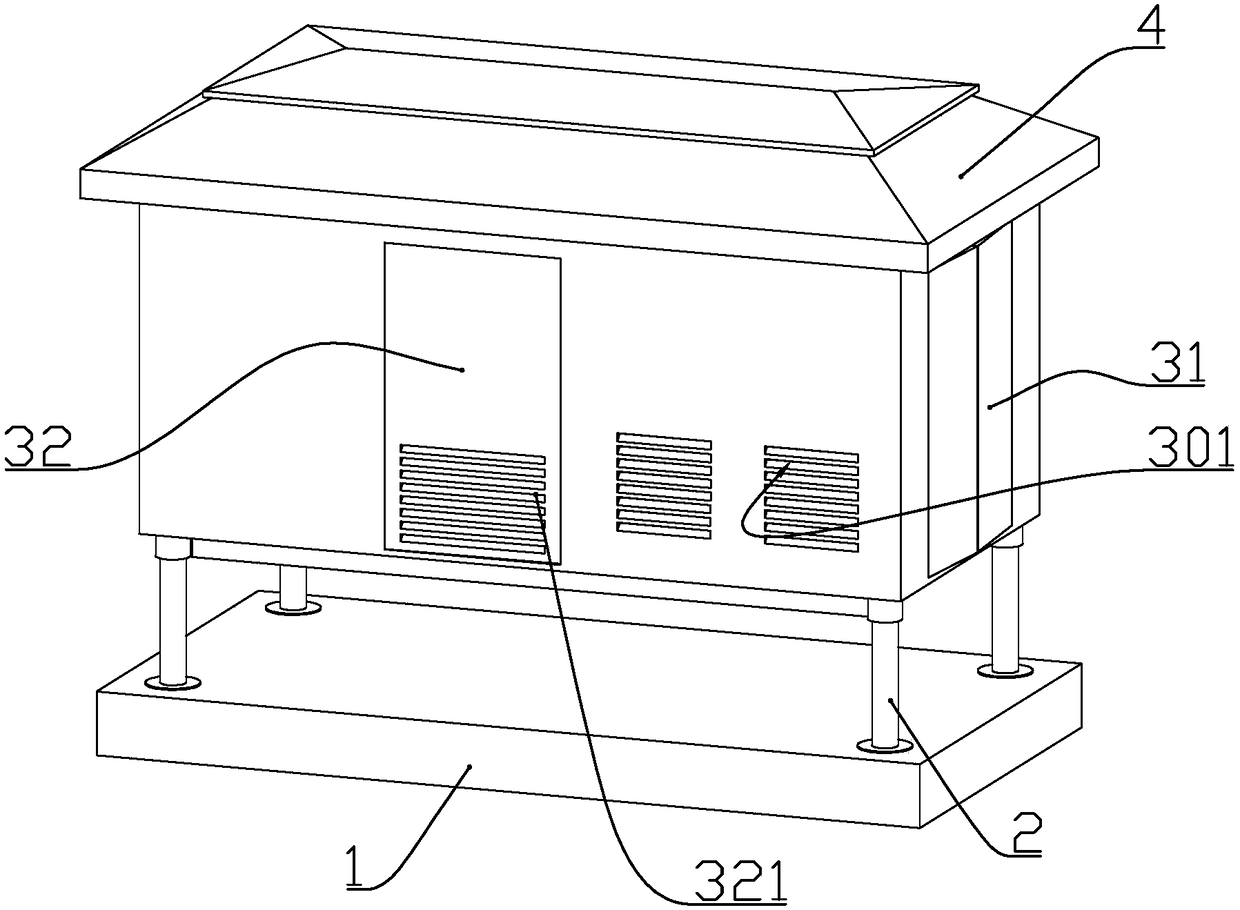

Box-type substation for dissipating heat by natural wind

ActiveCN105914631AEasy to buildWill not corrodeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringWind direction

The invention discloses a box-type substation for dissipating heat by natural wind. The box-type substation comprises a base and a box body, wherein the box body is arranged at the upper part of the base; the upper part of the box body is connected with a head cover; the head cover comprises longitudinal walls and slope walls; the lower part of each longitudinal wall is fixedly connected with a horizontally arranged transverse wall; air outlets are evenly formed in two groups of longitudinal walls, along the length direction, of the head cover; sliding chute sockets are formed in the positions, corresponding to the air outlets, on the transverse walls; wind grid plates are connected with the inside of the sliding chute sockets in a sliding manner; grid plate openings which are matched with the air outlets for use are formed in the wind grid plates respectively; a grid plate push rod is arranged on the inner wall of each transverse wall, along the width direction, of the head cover; an output rod of each grid plate push rod is fixedly connected with the end part of the corresponding wind grid plate; and a wind direction sensor is also arranged at the upper end of the head cover. The box-type substation is compact in structure, reasonable in design, convenient to construct and good in heat dissipation effect.

Owner:ZTT ELECTRICAL TECH CO LTD

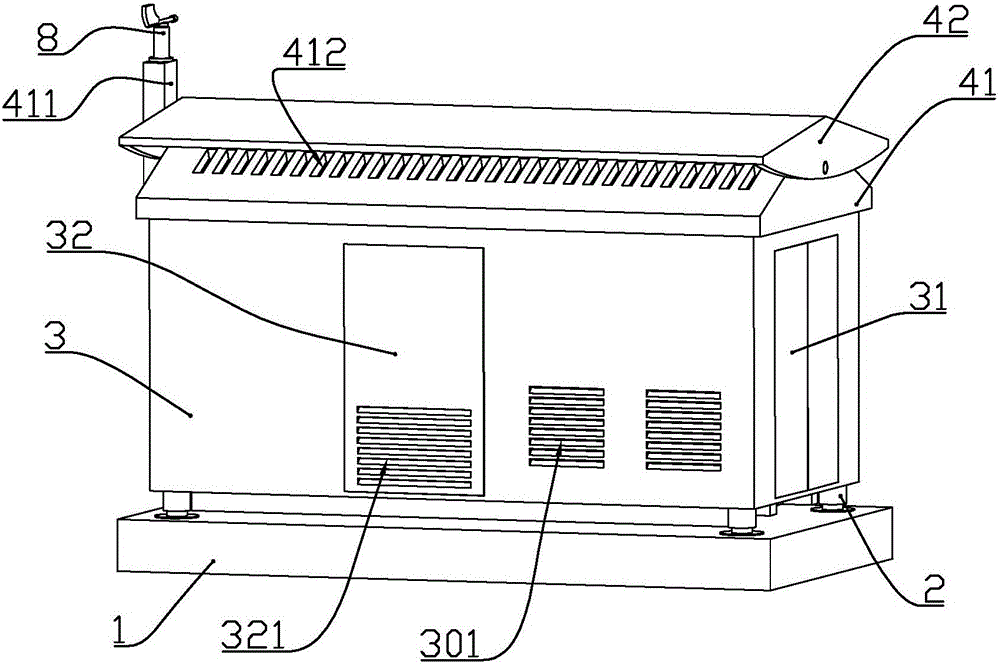

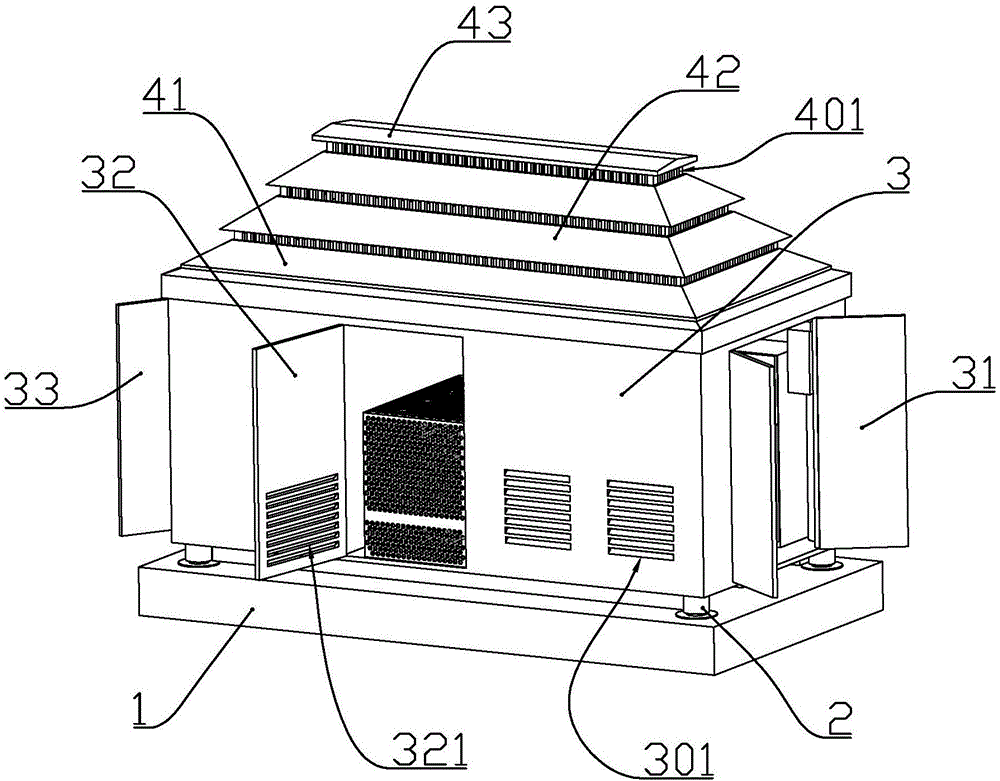

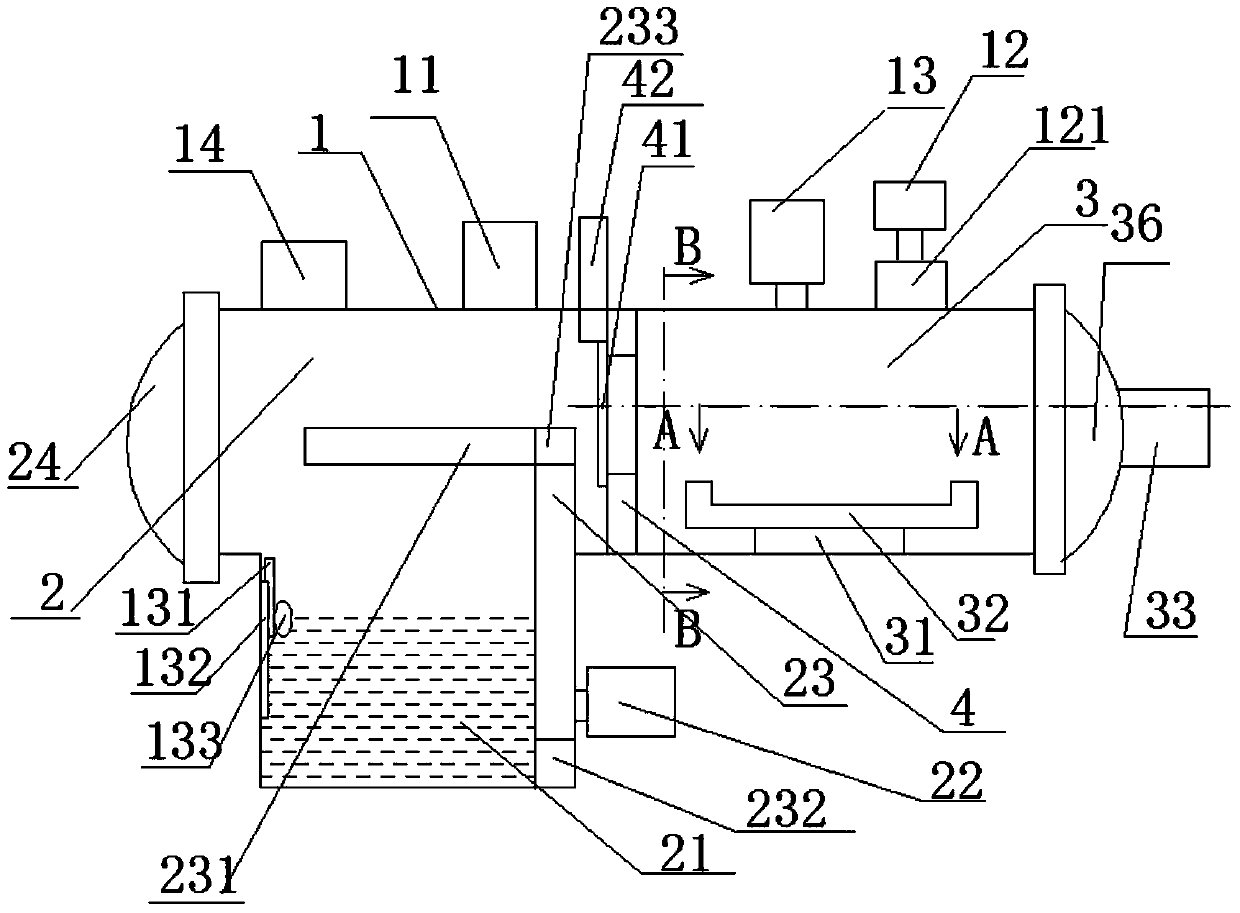

Box-type transformer substation

ActiveCN105958355AEasy to buildWill not corrodeTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationEngineeringTransformer

The invention discloses a box-type transformer substation. The box-type transformer substation comprises a substrate and a box body, wherein the box body is arranged above the substrate; a top cover is connected above the box body; the top cover comprises a lower top cover fixedly connected above the box body, and an upper top cover installed on the lower top cover; the lower top cover comprises a longitudinal wall, and a slope wall fixedly connected with an upper end of the longitudinal wall; an external end of the slope wall is formed into an extension wall positioned outside the longitudinal wall; the upper top cover comprises a ventilating wall having a rectangular frame form, and an upper sealing plate fixedly connected with the upper end of the ventilating wall; the external end of the upper sealing plate is formed into the extension wall outside the ventilating wall; air vents are uniformly formed in the ventilating wall; axial flow fans are installed at positions, corresponding to a transformer chamber and a low voltage chamber, above the box body; top cover pushing rods which are longitudinally arranged are further installed at the positions, corresponding to two end portions of the upper sealing plate, above the top cover; and output rods of the top cover pushing rods are fixedly connected with the upper sealing plate of the upper top cover. The box-type transformer substation disclosed by the invention is compact in structure, reasonable in design, convenient in construction and good in heat dissipation effect.

Owner:HANGZHOU GUANGYIN POWER EQUIP IND CO LTD

Waterproof box-type substation

ActiveCN106129828AEasy to buildWill not corrodeTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationCooling effectStructural engineering

The invention discloses a waterproof box-type substation, which comprises a base and a box body, wherein the box body is arranged at the upper part of the base; the upper part of the box body is connected with a head cover; the head cover comprises a lower head cover fixedly connected with the upper part of the box body and an upper head cover arranged on the lower head cover; the lower head cover comprises a longitudinal wall in a rectangular frame shape and a slope wall fixedly connected to the upper end of the longitudinal wall; the lower end part of the longitudinal wall is fixedly connected with a horizontally arranged transverse cover wall; a limiting bayonet is formed in the lower surface of the upper end of the slope wall; the inner end of the transverse cover wall tightly abuts on the upper edge of the box body; the transverse cover wall is fixedly connected with the box body through a bolt; the transverse cover wall is provided with a plurality of strip-shaped lower exhaust outlets in the wall surface of the outer side of the upper edge of the box body; and the lower exhaust outlets are horizontally arranged along the transverse cover wall at equal intervals. The waterproof box-type substation is compact in structure, reasonable in design, convenient to construct and good in cooling effect.

Owner:山东恒东实业集团有限公司

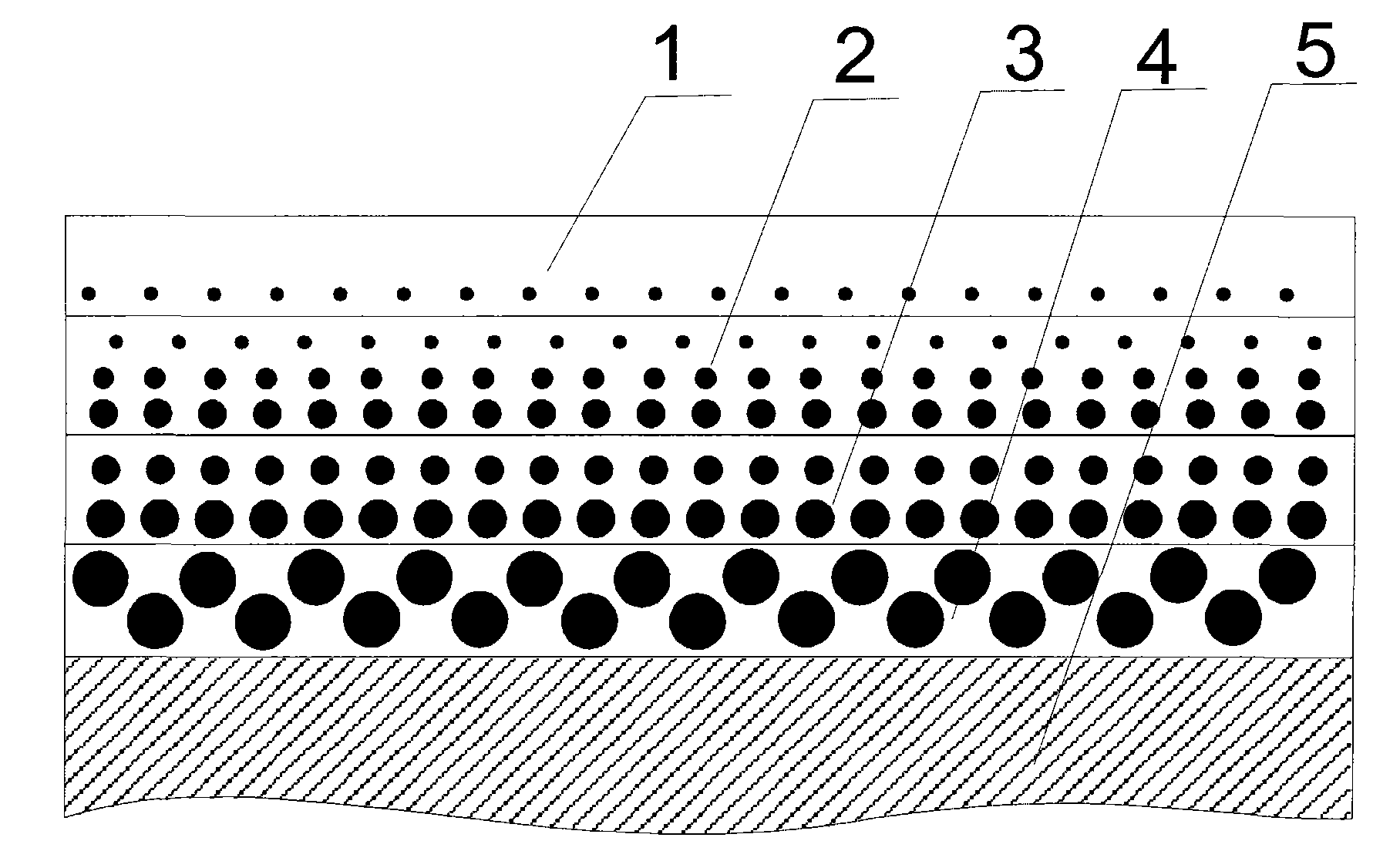

Selective coating for absorbing solar light and heat

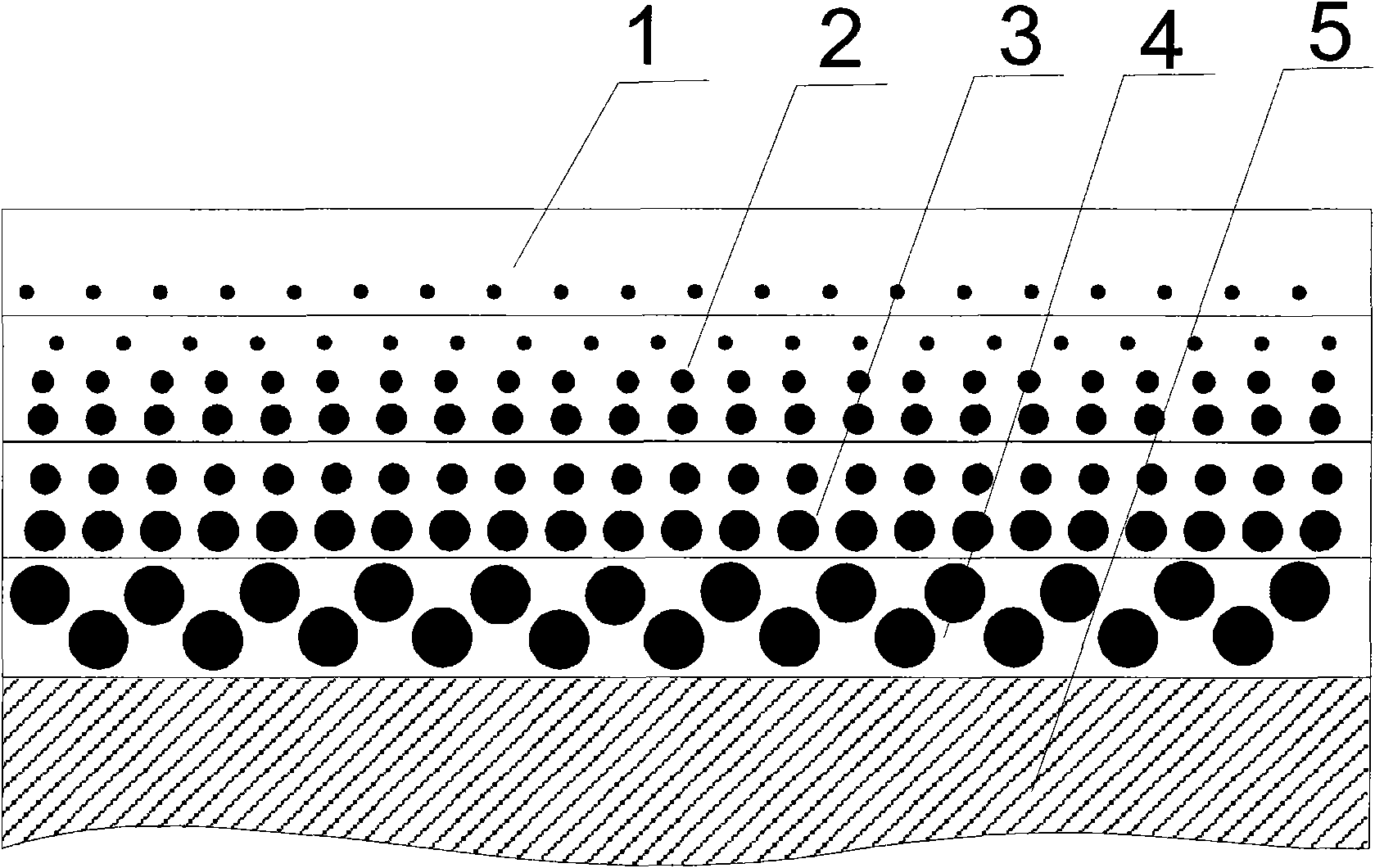

InactiveCN101769648AReduce thermal emissivityGood weather resistanceSolar heat devicesVacuum evaporation coatingCompound aSolar light

The invention discloses a selective coating for absorbing solar light and heat which belongs to field of solar energy equipment, particularly, relates to a selective absorbing coating which is used on the surface of the flat-plate solar collector and is used for absorbing and utilizing solar energy. The selective coating for absorbing solar light and heat is formed by compounding a plurality of layers of metal and non-metal, the selective solar energy is attached on a metal flat plate; the characteristics are as follows: the attachment sequence of the coating on the metal flat plate is as follows: a bottom layer-aluminum nitride composite layer-aluminum nitride composite layer- aluminum oxide (wherein, after the second layer of aluminum reacts with N2, whether new aluminum nitride composite material is generated). The invention provides a selective absorbing film with excellent selective absorption characteristic of solar energy and firm film, which is provided with high binding strength, good weatherability, as well as high production efficiency in production.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

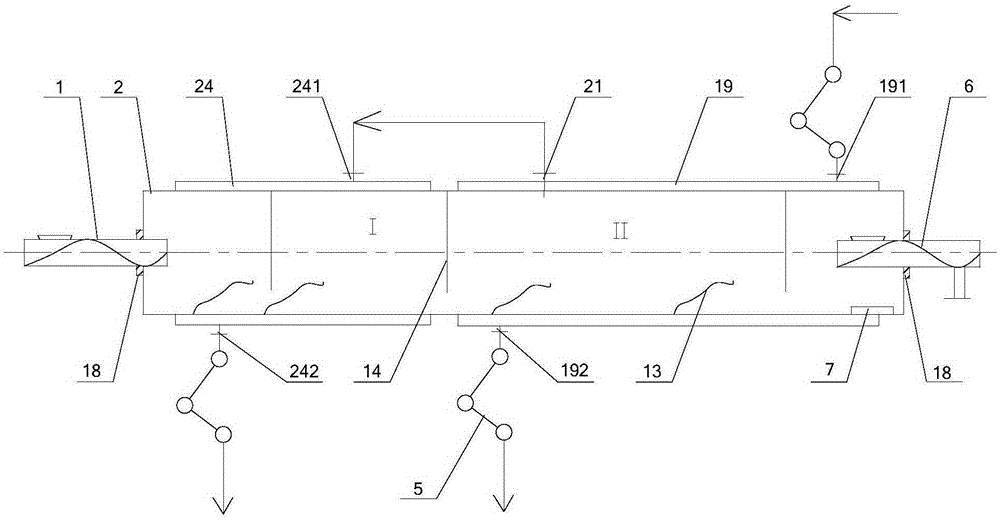

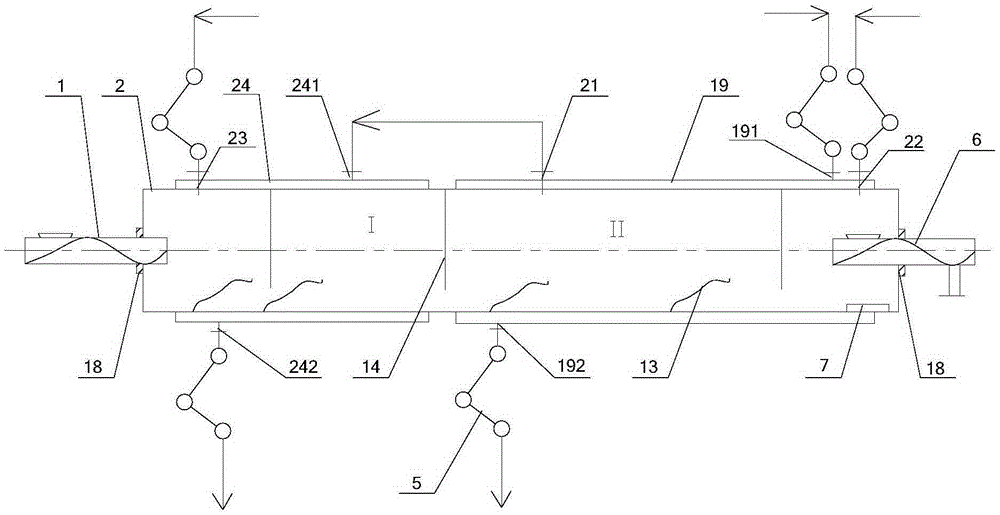

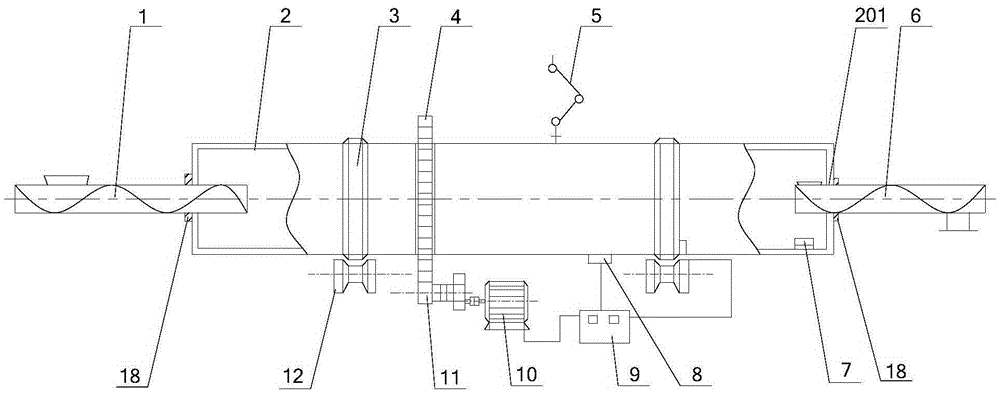

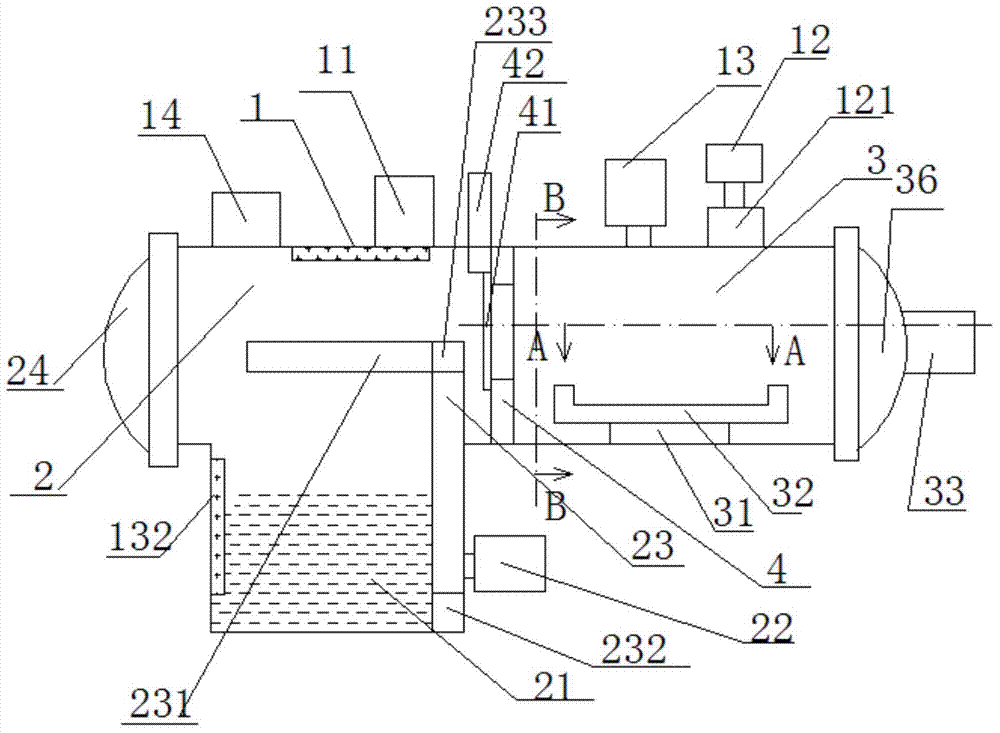

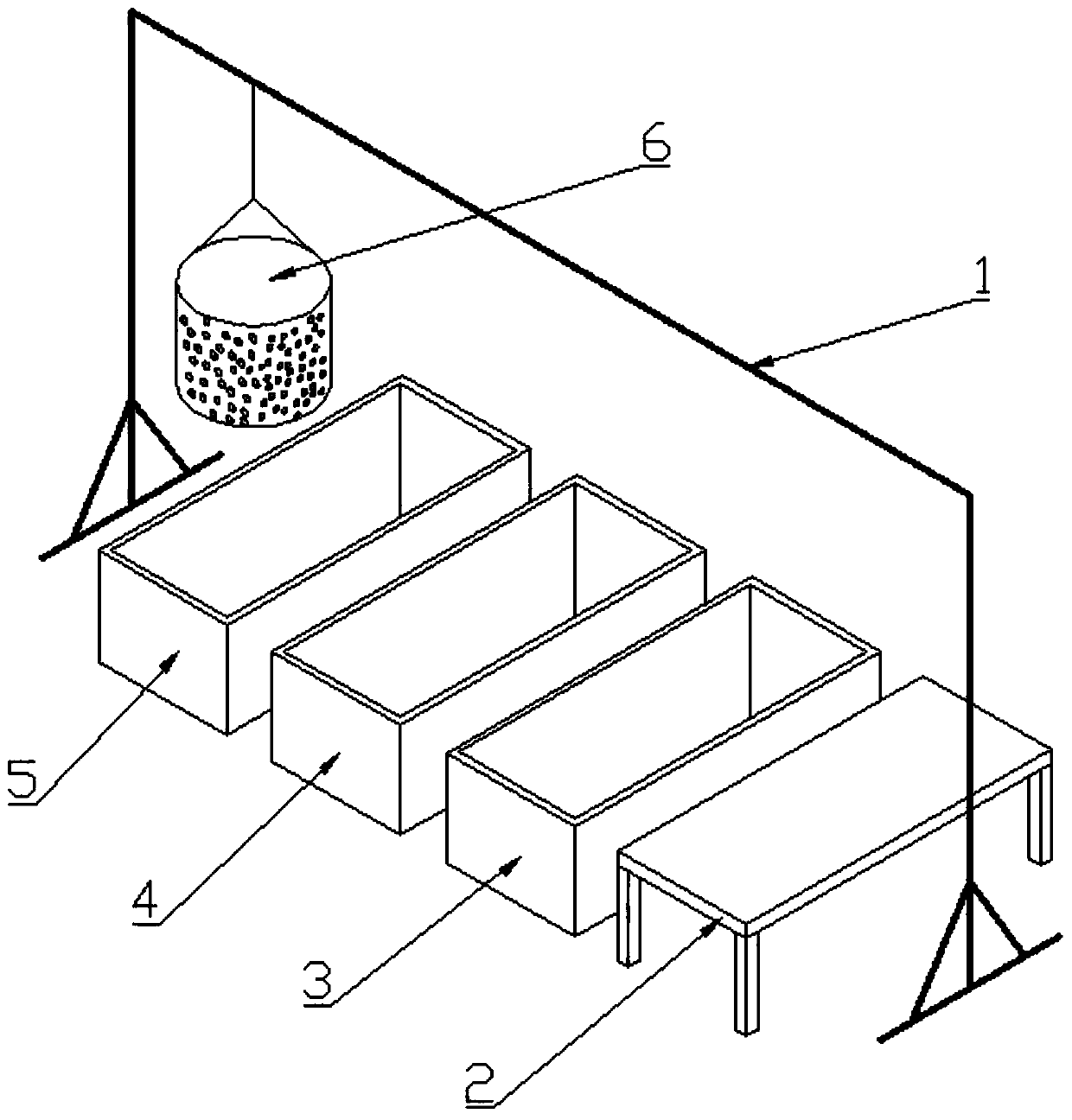

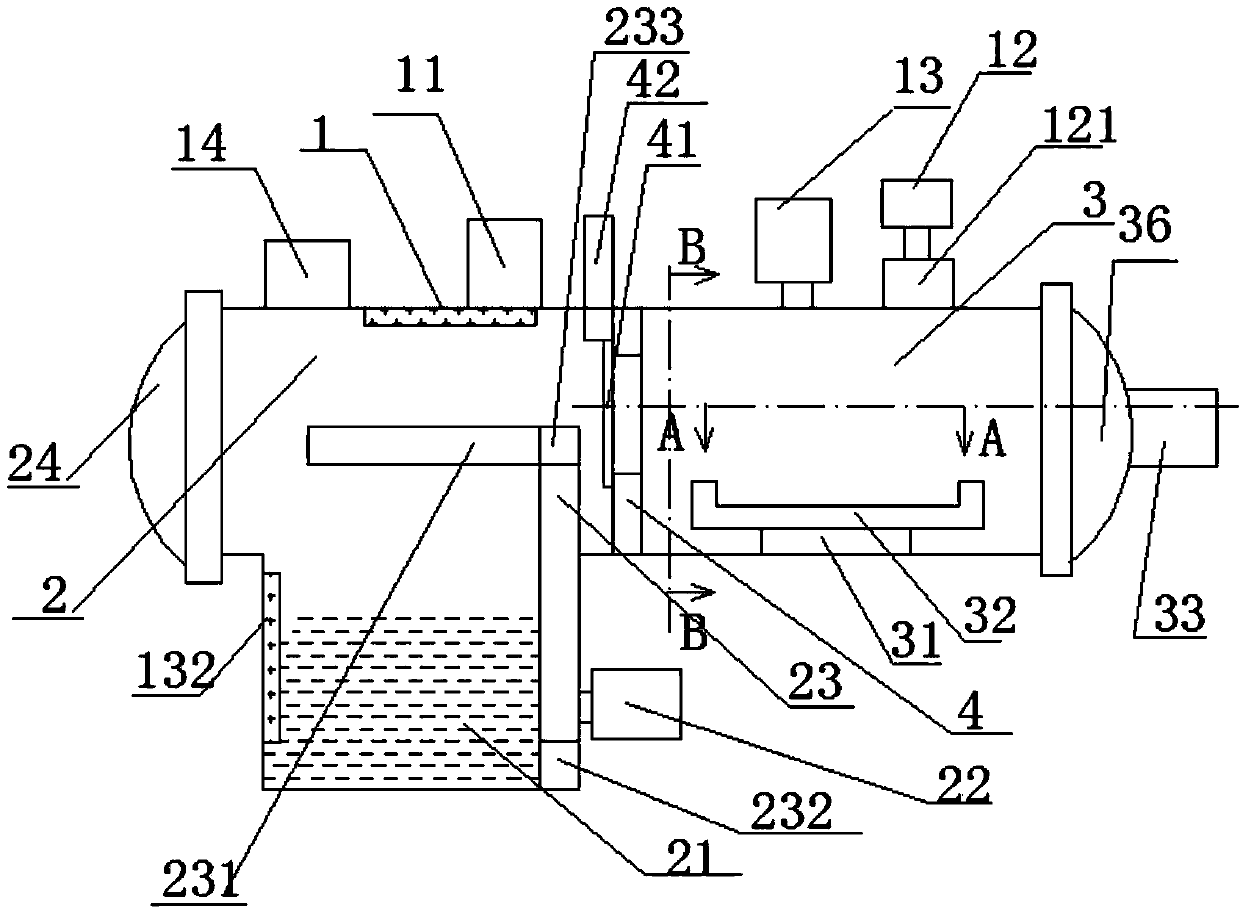

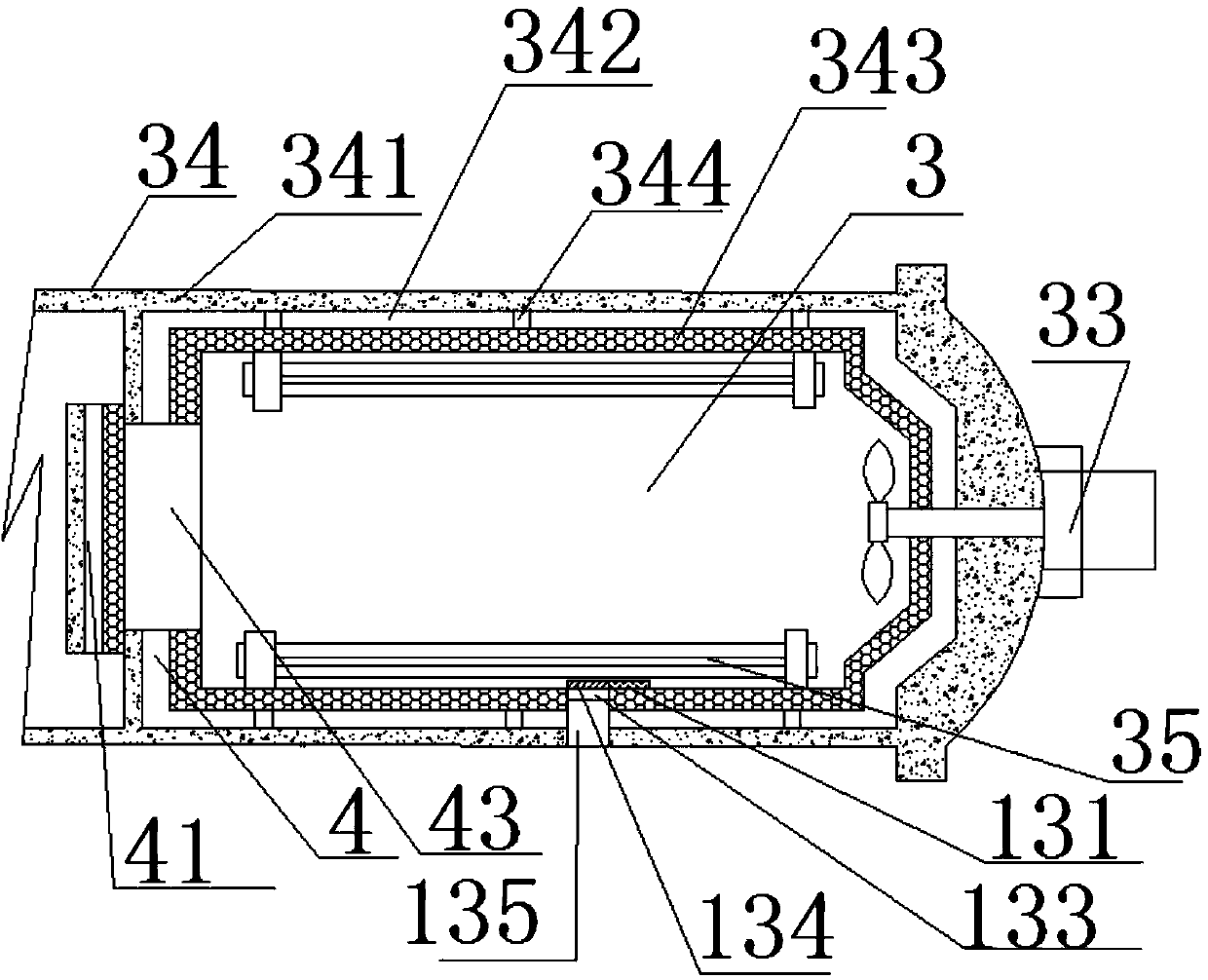

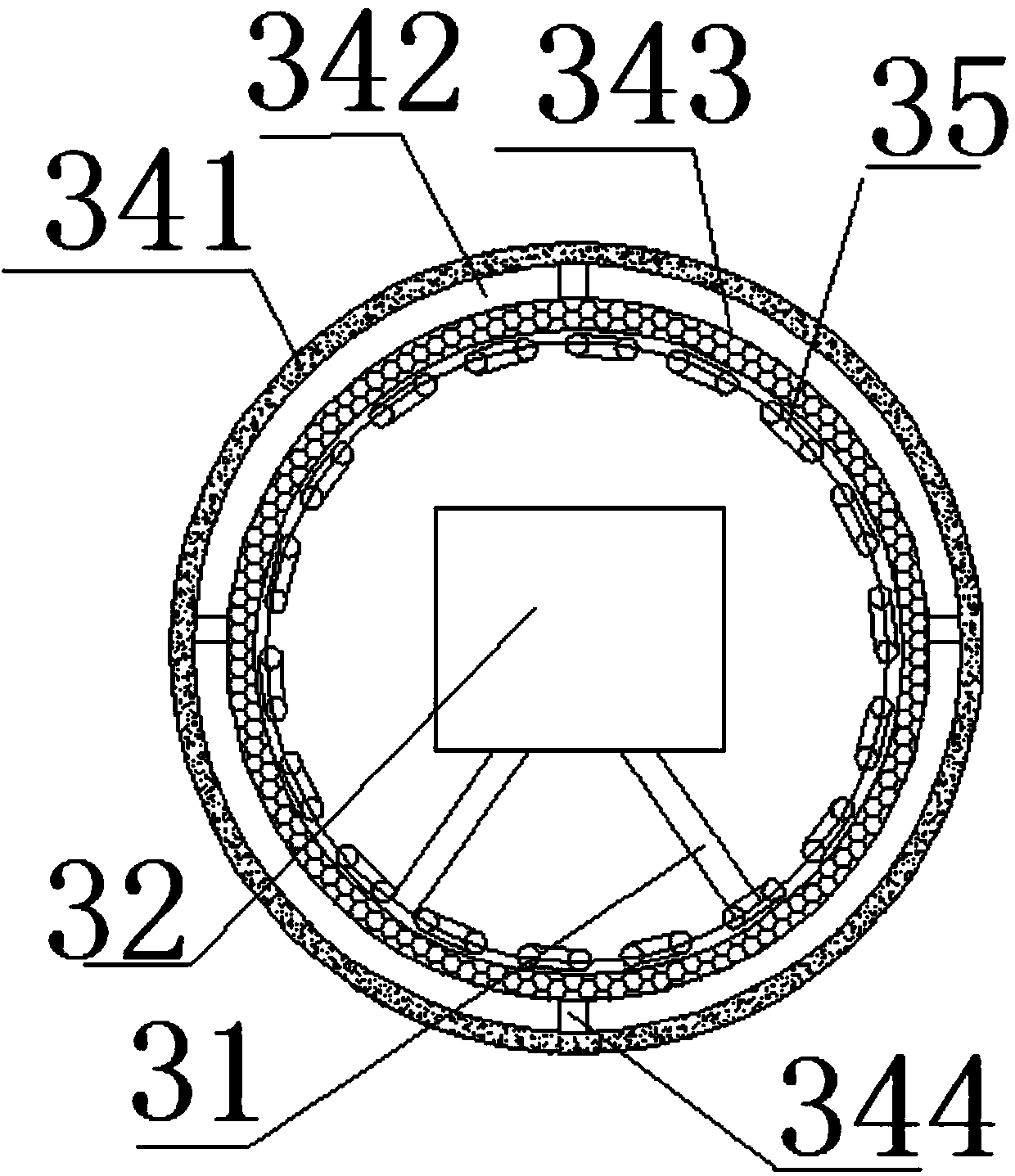

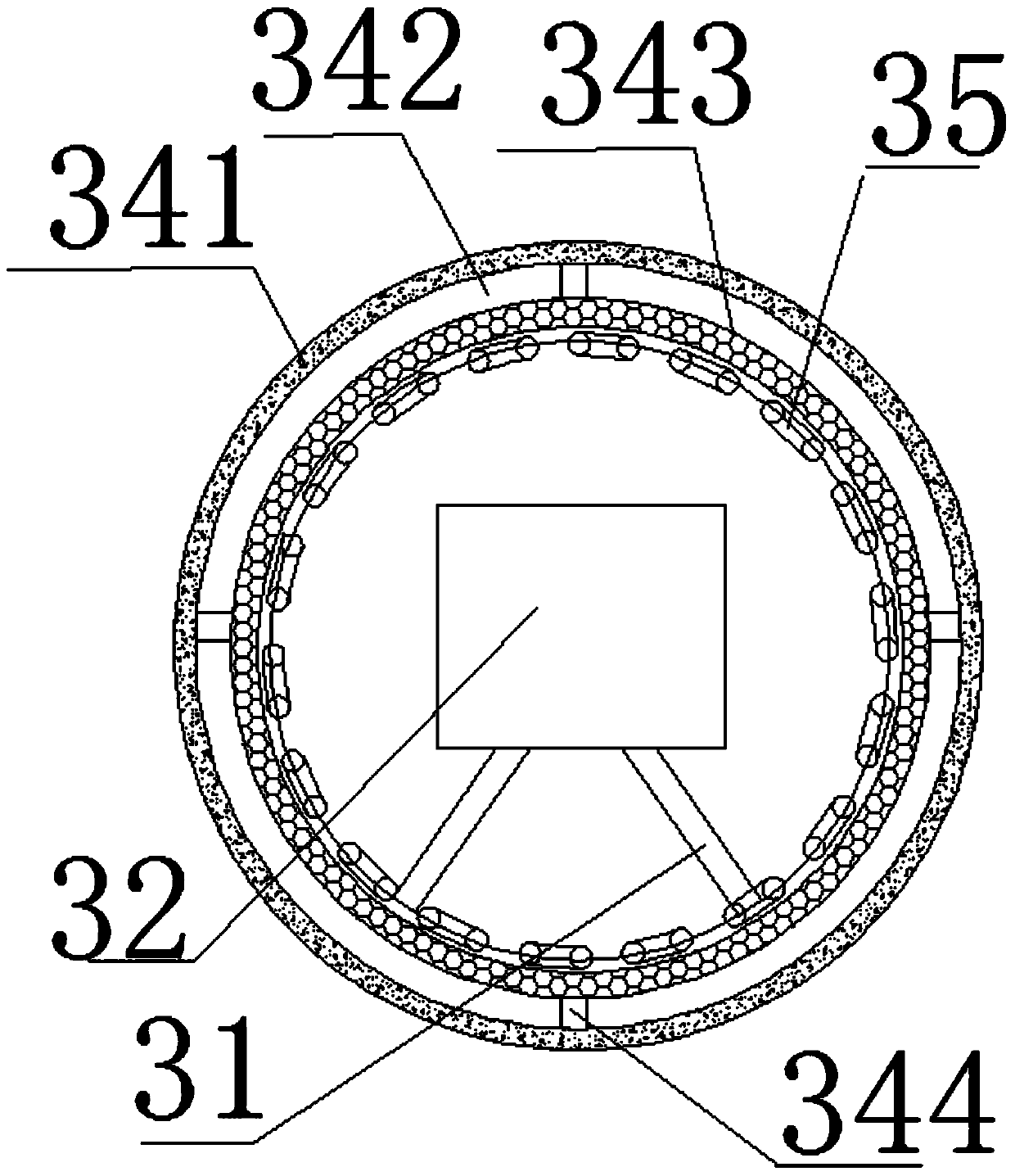

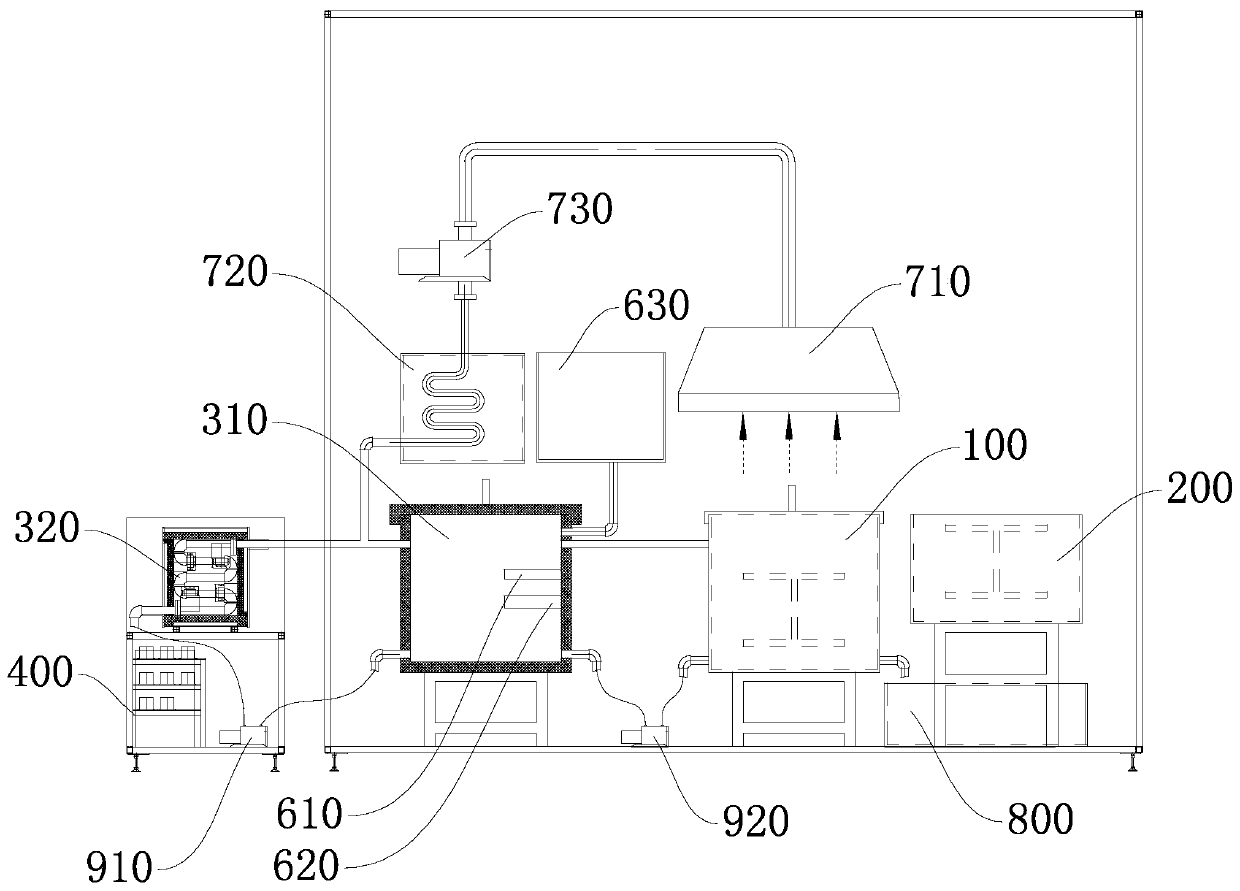

Rotary drying device and drying technology

ActiveCN105910414ASave energyHigh thermal efficiencyDrying solid materials with heatDrying gas arrangementsFailure rateDry structure

The invention discloses a rotary drying device, comprising a swing-type rotary furnace. The swing-type rotary furnace comprises a rotary drum, a driving device and a supporting device, a control device, and a heating jacket and / or dry hot gas inlet and outlet. The rotary drum is internally provided with a drying section. The cylinder wall of the vapor phase region of the drying section is provided with a steam outlet. The driving device and the supporting device are arranged out of the rotary drum, and are used to drive and support the rotary drum to swing back and forth around a rotating axis. The control device is connected with the driving device through a wire, and is used to control operation of the driving device. The heating jacket is arranged on the cylinder wall of the drying section. The heating jacket is provided with a hot medium inlet and a hot medium outlet which are connected with an external pipe through a moveable conduit assembly. Since the rotary drying device uses the swing-type rotary furnace, the rotary drum just swings back and forth in certain radian, and the cylinder wall of the rotary drum is provided with the heating jacket and the dry hot gas inlet and outlet. Compared with an existing built-in drying structure, the device is simple in structure, reduced in failure rate, and convenient in maintenance. The invention also discloses a drying technology.

Owner:HUNAN DINGJIU ENERGY & ENVIRONMENT TECH LTD

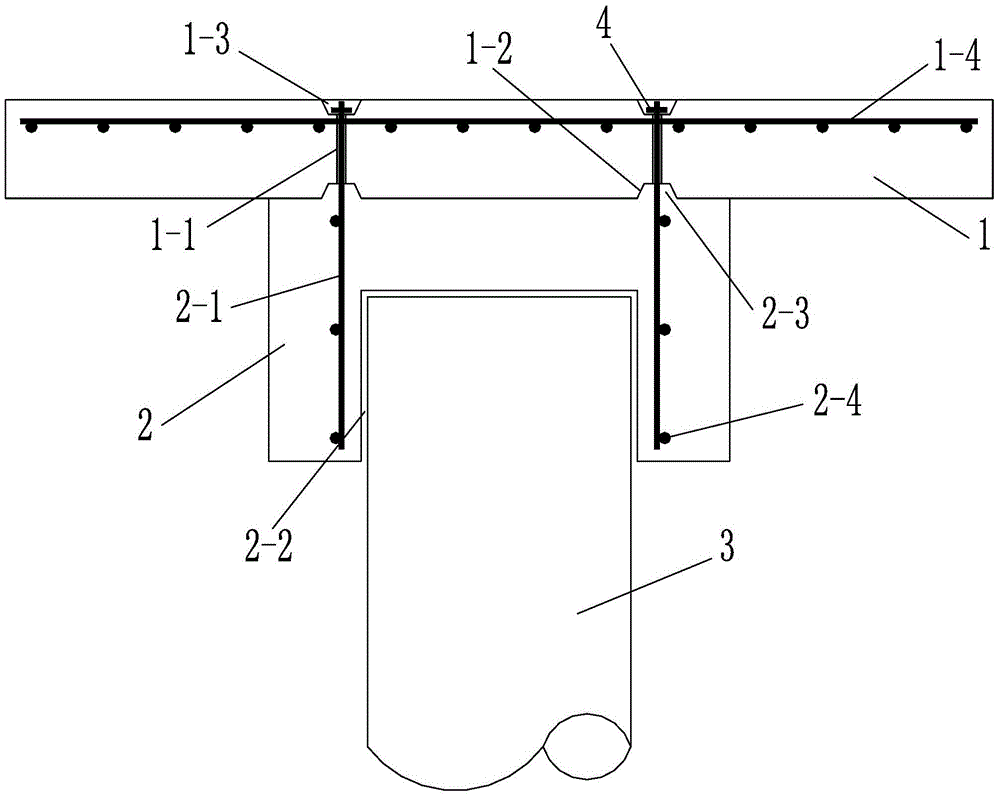

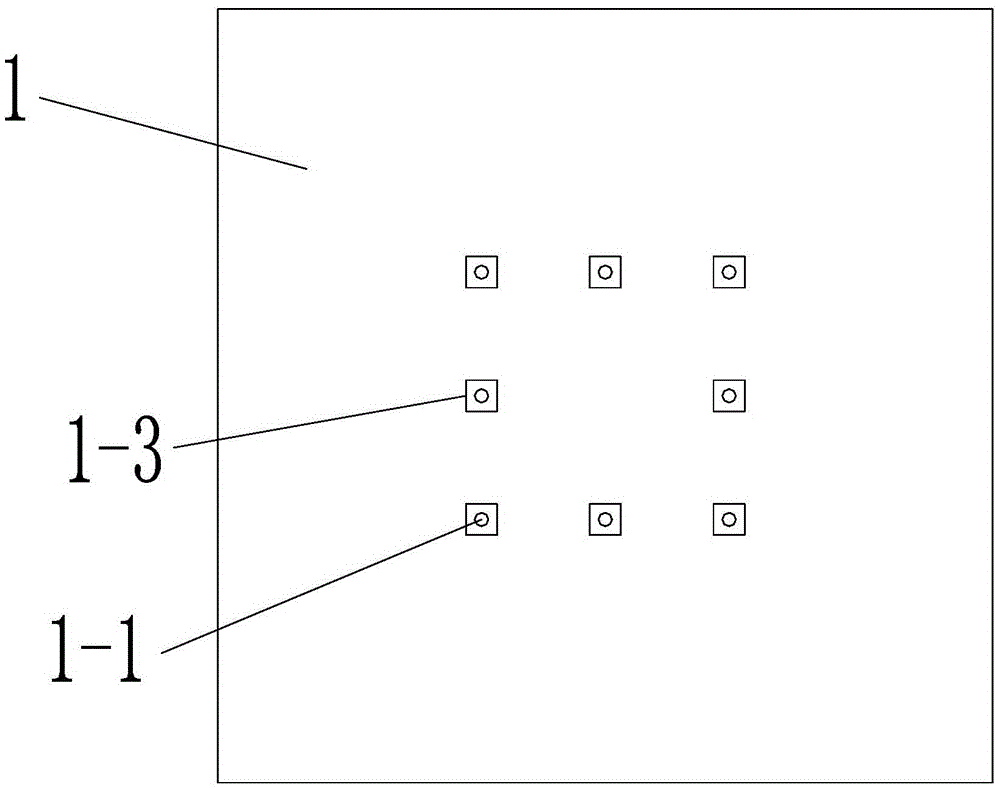

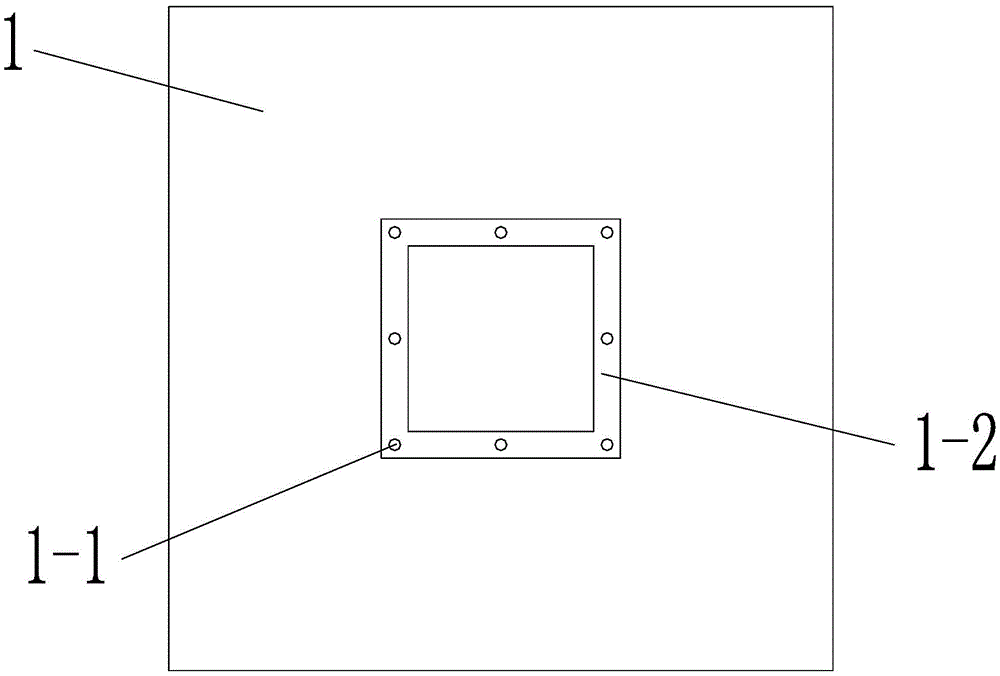

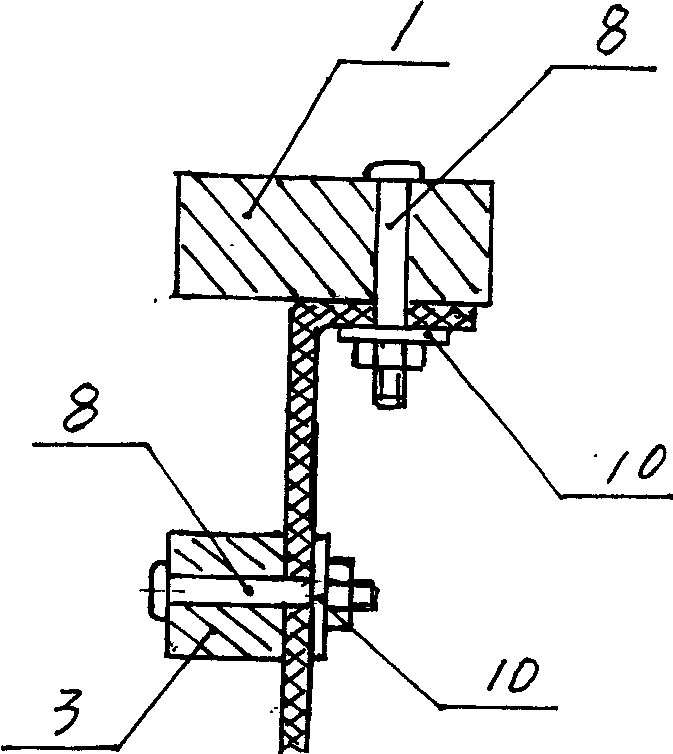

Prefabricated pile cap for composite foundation

The invention relates to a prefabricated pile cap for a composite foundation. The prefabricated pile cap comprises a top plate and a fixing sleeve connected onto the lower side surface of the top plate, wherein a plurality of locking rods are vertically distributed in the fixing sleeve and extend out of the upper end surface of the fixing sleeve, and a blind hole for sleeving a prefabricated pile is formed in the lower end of the fixing sleeve; locking through holes allowing the locking rods to penetrate through are correspondingly formed in the top plate, the top plate and the fixing sleeve are fixedly connected by the aid of locking nuts, and the locking nuts are rotationally arranged on the locking rods penetrating through the upper side surface of the top plate. With the adoption of the prefabricated pile cap for the composite foundation, the engineering construction speed and quality can be effectively increased, and the cost can be reduced. The prefabricated pile cap for the composite foundation has the advantages as follows: 1, the prefabricated pile cap for the composite foundation can be disassembled into the top plate and the fixing sleeve, so that all components cannot be overweight, construction is facilitated, and the rent of machinery can be reduced.

Owner:ARCHITECTURAL DESIGN INST FUKIEN PROV

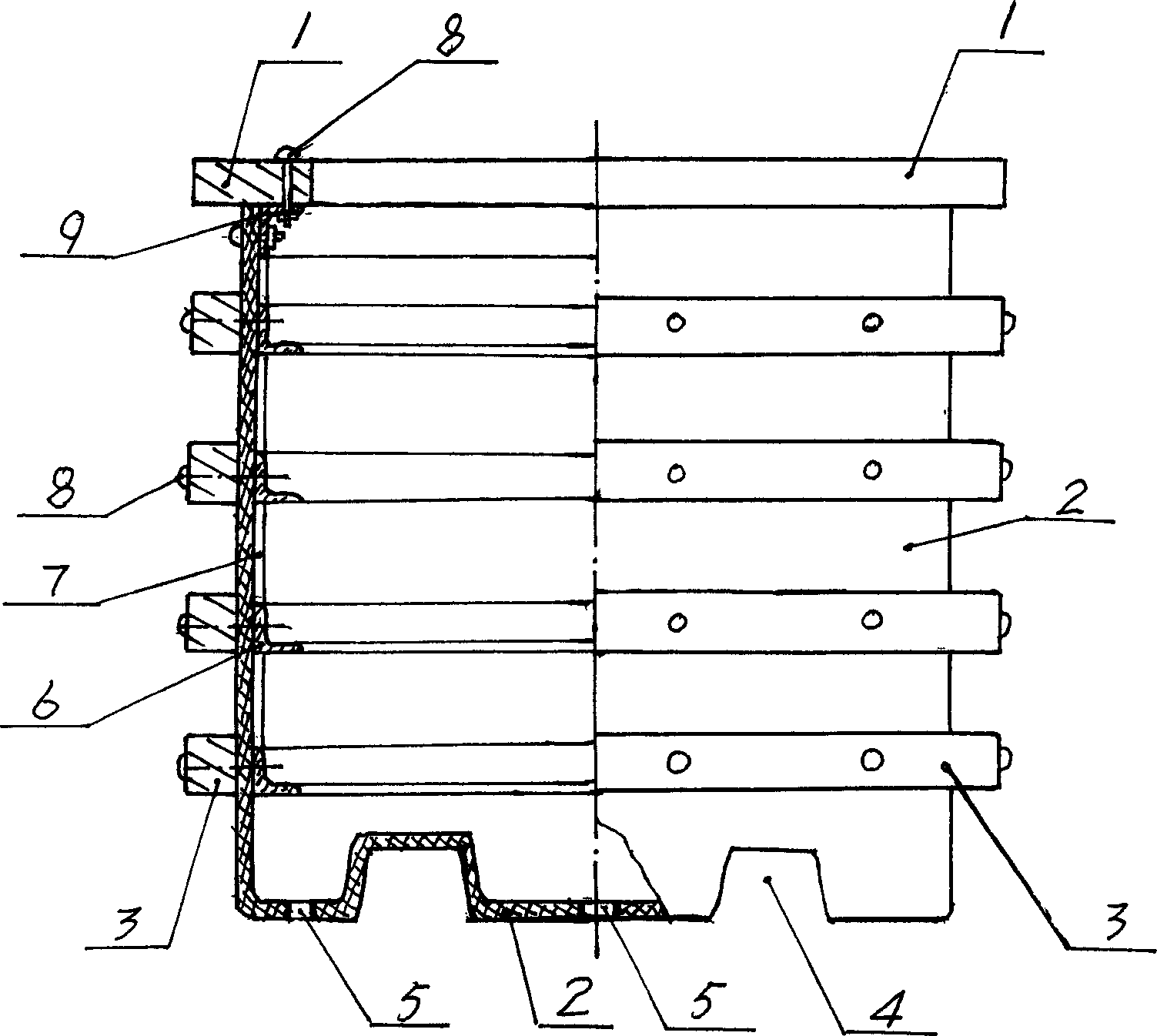

Wood/glass reinforced plastic combined decoration flowerpot

A solid wood / glass reinforced plastic composite potter landscape, comprising: glass reinforced plastic inner container, potter mouth solid wood strip, potter wall solid wood strip, potter mouth supporting cradle, metal connecting component and corner angle connecting component, the potter mouth solid wood strip is fixed in the upper mouth of the glass reinforced plastic potter inner container, the potter wall strip is fixed on the all-around outer surface in space, notch facilitate for mechanical carrying is equipped in the bottom of the inner container, a water outlet is equipped in the lowest part of the inner container. The potter landscape is characterized by the beautiful appearance, anti-rot property, strong intensity, long durability and facilitate for mechanical carrying. The solid wood consumption is 1 / 4-2 / 1 times as mush as that of current potter landscape, and because the solid wood strip is assembled on the inner container, the potter mouth solid strip, potter wall solid wood strip, glass reinforced plastic inner container, potter mouth supporting cradle, metal connecting board, corner angle connecting board and flat head bolt can be batch processed individually, and then for batch packing.

Owner:曹树春

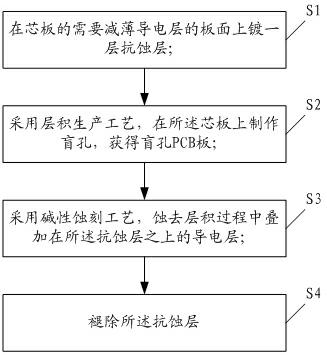

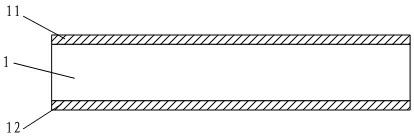

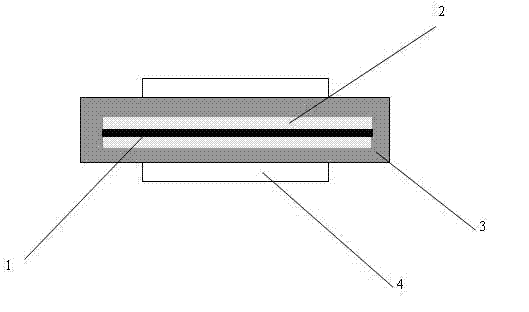

Machining method of blind hole PCB (Printed Circuit Board)

ActiveCN102427673AUniform thicknessWill not be corrodedMultilayer circuit manufactureNon-metallic protective coating applicationEngineeringPrinted circuit board

The invention discloses a machining method of a blind hole PCB (Printed Circuit Board), which comprises the steps of: S1, plating a corrosion-resisting layer on the board surface where a conductive layer needs to be thinned of a core board; S2, by adopting a lamination production process, manufacturing a blind hole on the core board to obtain the blind hole PCB; S3, by adopting an alkali etching process, etching the conductive layer overlapped on the corrosion-resisting layer in the lamination process; and S4, fading the corrosion-resisting layer. The embodiment of the invention ensures that the thinned conductive layer is distributed uniformly while the conducive layer laminated on the surface of the blind hole PCB is thinned so that multiple blind hole boards with minimum line width or spacing of outer layers are possibly produced by adopting the lamination process.

Owner:GCI SCI & TECH

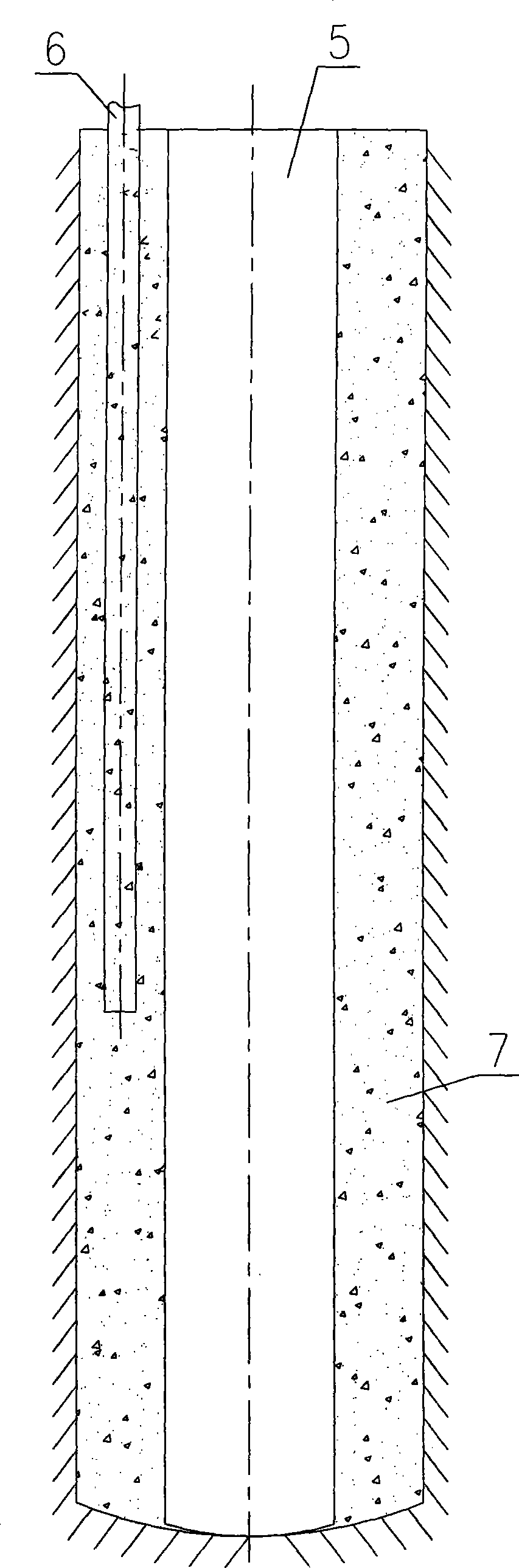

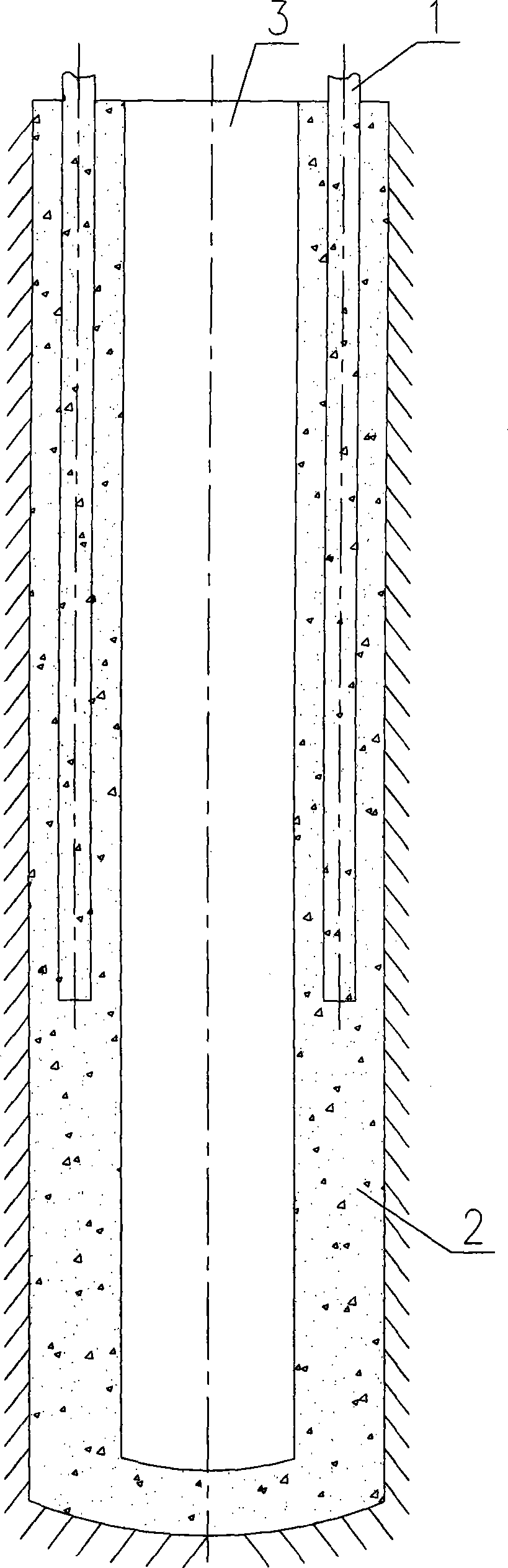

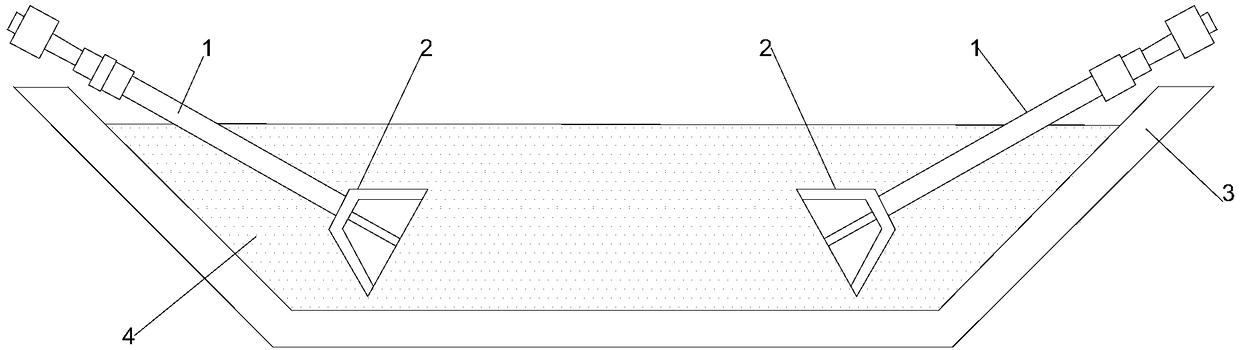

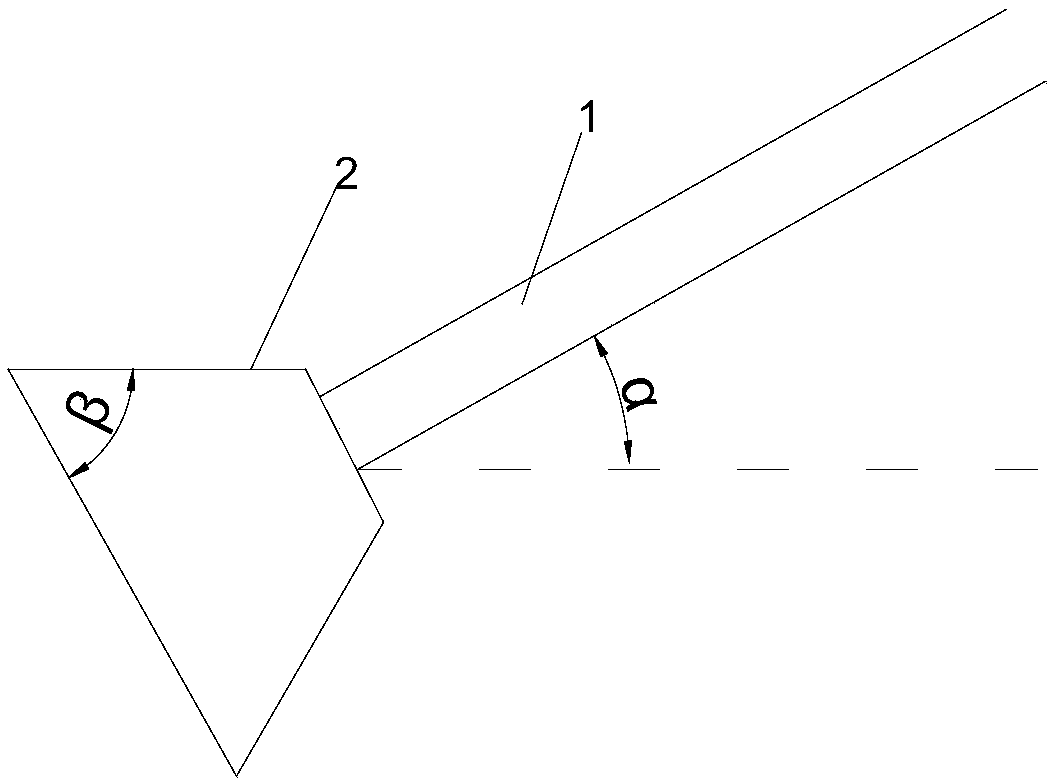

Cementing method for gas storage well casing tube

InactiveCN101503944ANot easy to looseAvoid contactDrilling machines and methodsWell cementingCement slurry

The invention discloses a method for cementing a sleeve pipe of a gas storage well, which is characterized by comprising the following steps: (1) arranging one or more slurry filling pipes in the well, and filling cement slurry into the well bottom through the slurry filing pipes, wherein the cement slurry is added with a retarding agent; and (2) putting down the sleeve pipe of the gas storage well to touch the cement slurry at the well bottom, simultaneously continuing filling the cement slurry into the well through the slurry filling pipes until the cement slurry returns from the mouth of the well so as to ensure that the whole well is filled with the cement slurry, then stopping filling the slurry, and achieving the aim of completely cementing the well after the cement slurry solidifies. The method can guarantee that the bottom and the circumference of the sleeve pipe of the gas storage well are both covered by the cement and prevent the bottom of the sleeve pipe of the gas storage well from contacting with the ground floor, has the advantages of no easy loosening of the gas storage well and no corrosion of the bottom of the sleeve pipe of the gas storage well, and improves the well cementing quality.

Owner:SICHUAN PETROLEUM & NATURAL GAS SCI & TECH CORP

Cladding glass for acid soluble method flexible optical fiber image transmitting beam

The invention discloses the composition of a cladding glass for flexible optical fiber image-transmission bundle, which is characteristic in: (1) well numerical aperture; (2) well chemical reliability; (3) well resistance to separate crystal for good technical match, and without impregnation phenomenon with the material glass.

Owner:EAST CHINA UNIV OF SCI & TECH +1

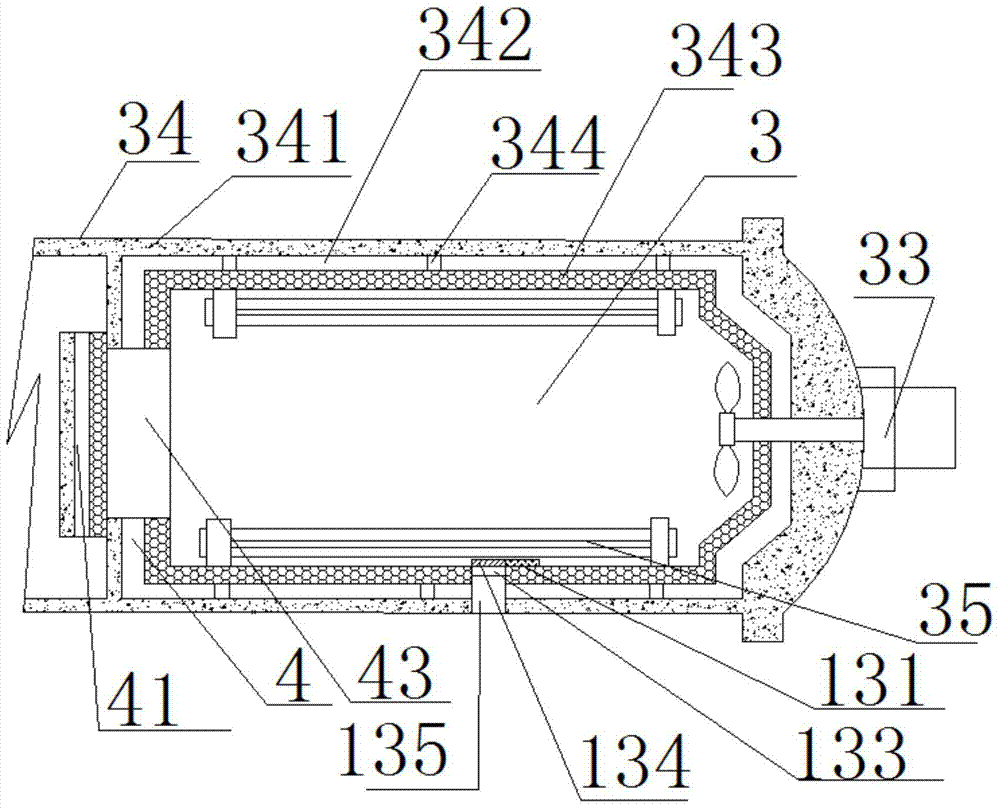

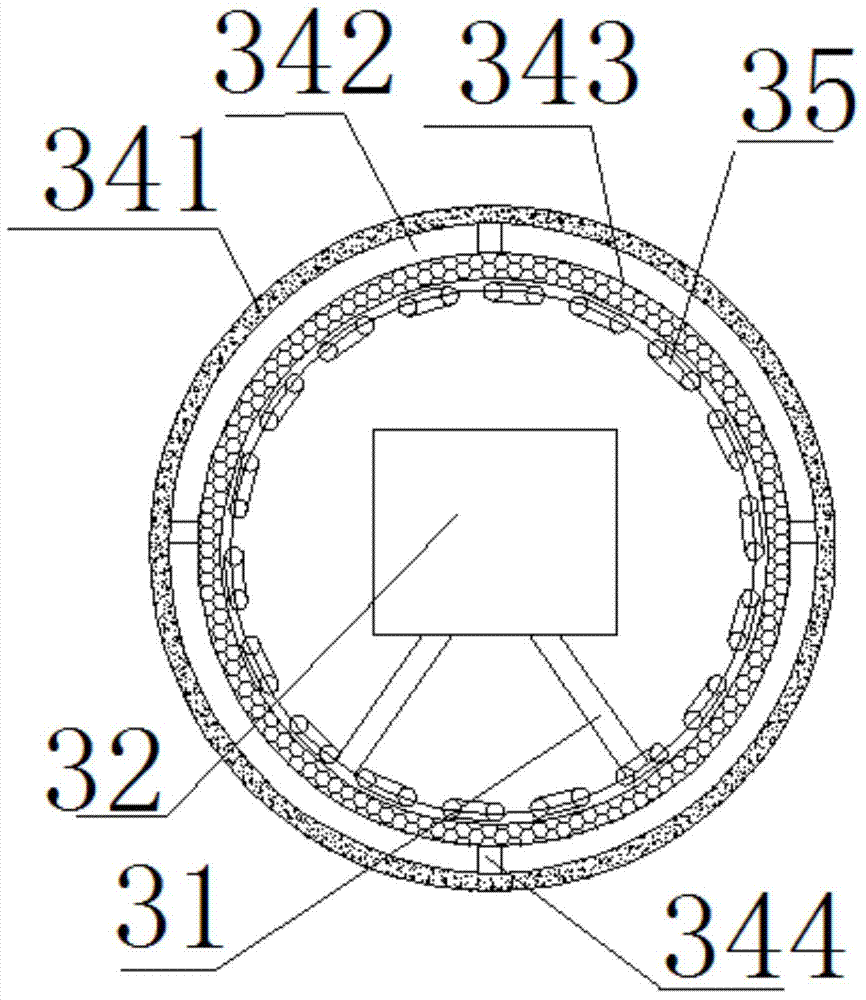

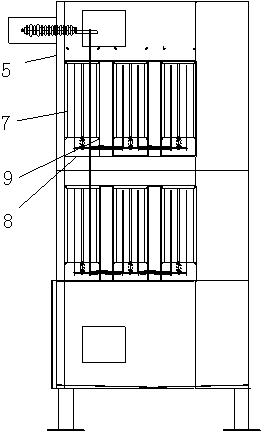

Anticorrosive vacuumizer pollution-discharge spraying-purification operation-observing/monitoring vacuum furnace

The invention relates to an anticorrosive vacuumizer pollution-discharge spraying-purification operation-observing / monitoring vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

Two-piece type self-cleaning ball valve adopting floating seal

The invention discloses a two-piece type self-cleaning ball valve adopting floating seal, and belongs to the field of ball valves. Self-cleaning of the floating ball valve can be achieved, as a ball body is mounted in a ball body seat, impurities can be prevented from being massively accumulated between the ball body and the inner wall of a valve seat, and the ball body is protected against corrosion of the impurities; and as cleaning scraper blades are arranged on the two sides of the ball body, when the ball body rotates, the impurities settling on the outer surface of the ball body can be scraped off through the cleaning scraper blades, a deformation plate is further arranged on the inner wall of the ball body seat, an arch face is formed on the inner wall of the ball body seat, thus, the probability that the impurities scale on the inner wall of the ball body seat can be greatly reduced, the impurities settling on the deformation plate can be vibrated off through the vibration effect of deformation restoration of the deformation plate, the impurities are taken away by media, thus, self-cleaning of the ball body is achieved, long-time stable work of the ball valve is guaranteed,in addition, cleaning balls similar to lotus leaf surface structures are further arranged in a passageway of the ball body to prevent the impurities from being left, and the self-cleaning effect of the ball valve is further improved.

Owner:ZHEJIANG WANSHITONG VALVE CO LTD

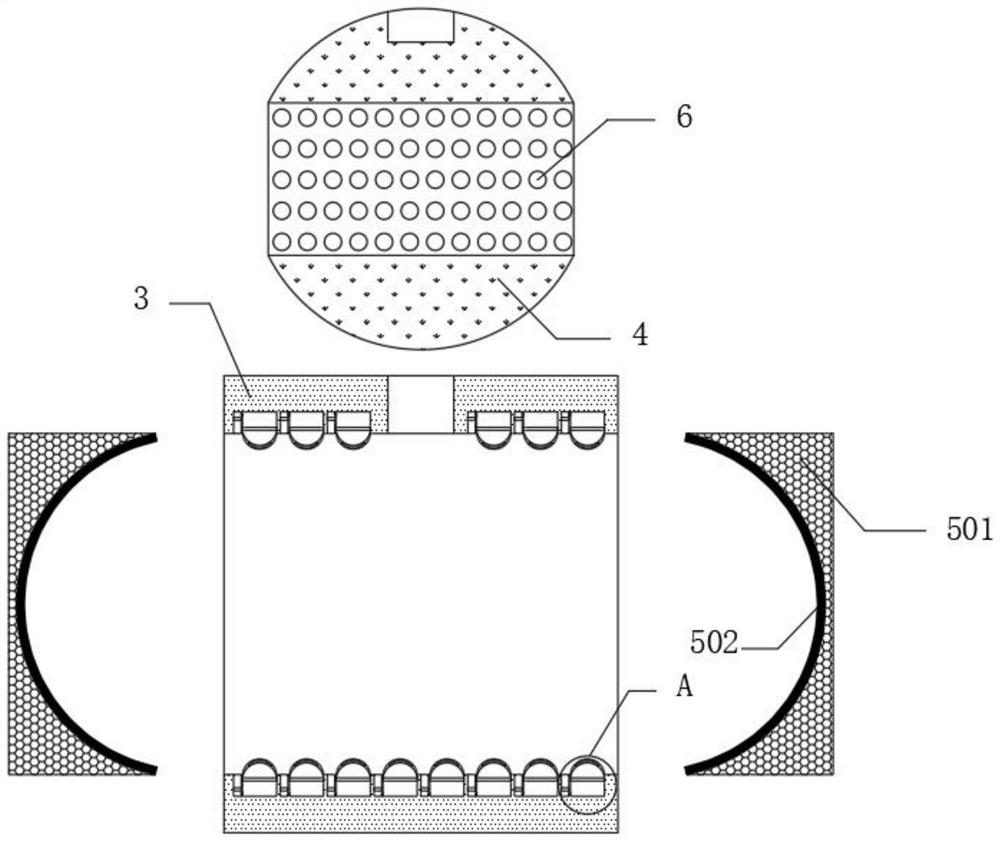

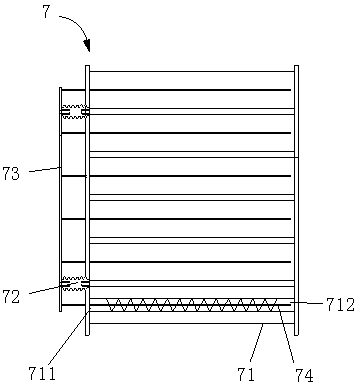

Wire rod conveying device for quenching tank

ActiveCN108251613AImprove reliabilityWill not be corrodedFurnace typesHeat treatment furnacesWire rodEngineering

The invention provides a wire rod conveying device for a quenching tank, relates to the technical field of salt bath heat treatment, and solves the problem that the conveying difficulty of wire rods is large when the wire rods are fed into or conveyed out of a salt bath tank. The device comprises a driving device and a plurality of cantilevered rollers, wherein the plurality of cantilevered rollers are in transmission connection with the driving device; the plurality of cantilevered rollers are symmetrically distributed on the two sides of the quenching tank in the length direction of the quenching tank; the bottom end of each of the cantilevered rollers is fixedly connected with a corresponding stepped pulley; the stepped pulleys are in a frustum cone shape; each row of stepped pulleys are formed into concave-shaped roller ways between an inlet of the quenching tank and an outlet of the quenching tank; a corresponding concave-shaped roller way comprises a downslope section, a horizontal section and an upslope section; the wire rods can be placed on the conical surfaces of the stepped pulleys; and when the cantilevered rollers are driven by the driving device to be rotated, the stepped pulleys are driven to be rotated, the wire rods can enter into the quenching tank from the downslope section along the two concave-shaped roller ways, are subjected to quenching treatment at thehorizontal section and then are conveyed out of the quenching tank through the upslope section, so that the wire rods can be easily fed into or conveyed out of the quenching tank.

Owner:北京勤泽鸿翔冶金科技有限公司

High-specific-gravity tungsten-nickel-iron alloy for balancing weight of golf club and preparation method thereof

The invention discloses a high-specific-gravity tungsten-nickel-iron alloy for a balancing weight of a golf club and a preparation method thereof, and belongs to the technical field of alloy. The method comprises the following steps: (1) preparing materials, wherein the used metal powder is reduced tungsten powder, hydroxyl nickel powder and hydroxyl iron powder; (2) preparing powder, namely, weighing sieved tungsten powder, iron powder and nickel power with corresponding weight according to the required weight ratio under a clean working environment, wherein the tungsten, nickel and iron in percentage by weight are that 62-80% of W, 7-15% of Ni, and 10-23% of Fe; (3) initially mixing, namely, initially mixing the tungsten powder, nickel powder and iron powder obtained in step (2) through a stainless steel plate, wherein the bottom layer is tungsten powder, the middle layer is nickel powder, and the top layer is iron powder during the initial mixing; and (4) mixing, namely, transferring the initially mixed alloy powder into a mixer to mechanically mix, and then adding an adhesive to obtain the mixed metal powder. According to the high-specific-gravity tungsten-nickel-iron alloy for the balancing weight of the golf club, the ratio of nickel to iron is adjusted, so that the cost can be decreased, and the yield is increased; in addition, the corrosion is avoided, and moreover, the requirement of a ball head can be met.

Owner:袁汝明

Protective film removal chemical liquid for LED aluminum surface

The invention provides a protective film removal chemical liquid for an LED aluminum surface. The film removal chemical liquid comprises the following components in parts by weight: 10-15 parts of hydrogen peroxide, 10-15 parts of sodium hydroxide, 5-10 parts of potassium hydroxide, 5-10 parts of lauryl sodium sulfate, 5-10 parts of ammonium molybdate, 5-10 parts of sodium molybdate, 1-5 parts ofcorrosion inhibitor, 1-5 parts of accelerant, 1-5 parts of oxidant, 1-5 parts of corrosion inhibitor and 70-80 parts of water. The film removal chemical liquid is a film removal chemical liquid developed with regard to film removal for the LED aluminum surface, does not attack the aluminum surface, keeps the glossiness of the original metal aluminum surface, and is simple to operate, easy to clean, and residual-free; and during use, an aluminum substrate do not cover a protection film, and meanwhile, the aluminum surface cannot be corroded.

Owner:TAICANG HE S CIRCUIT BOARD CO LTD

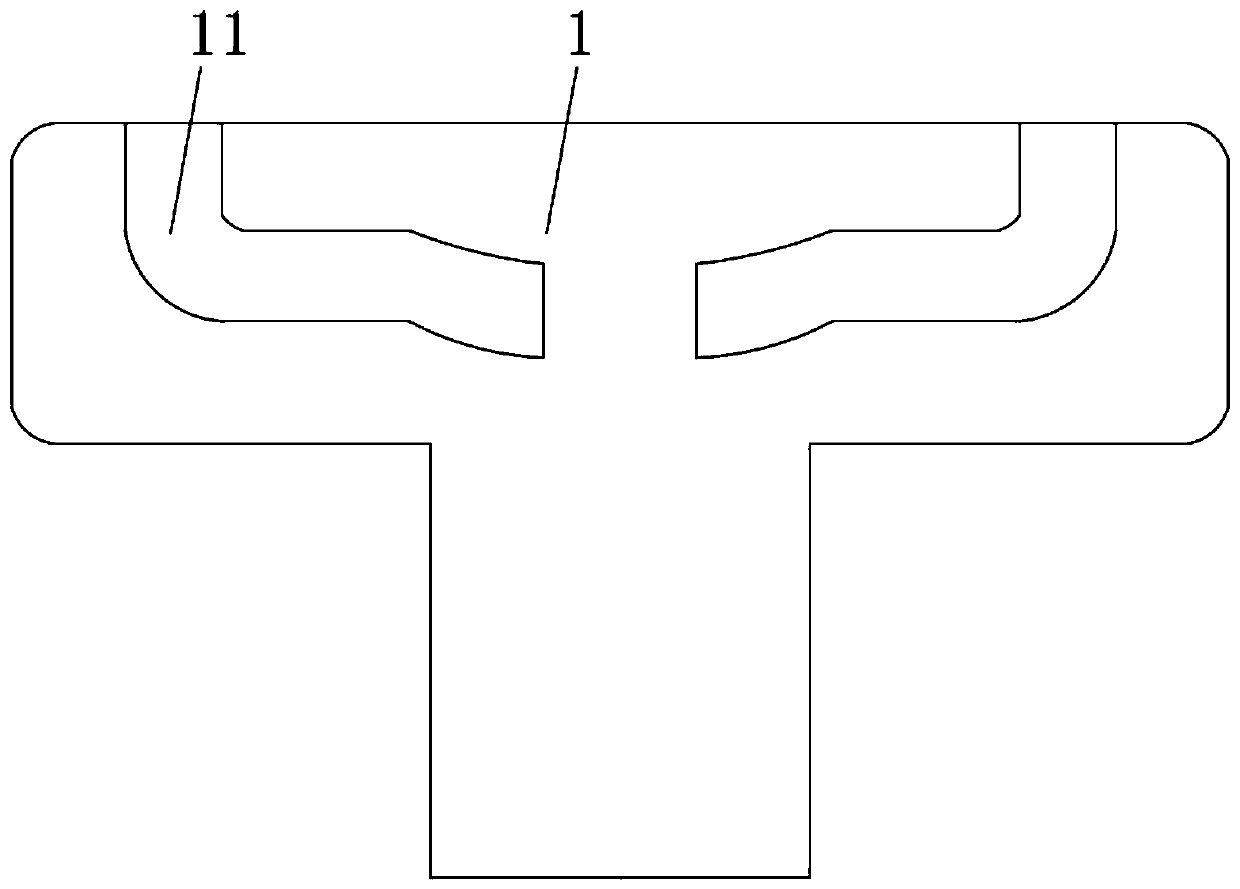

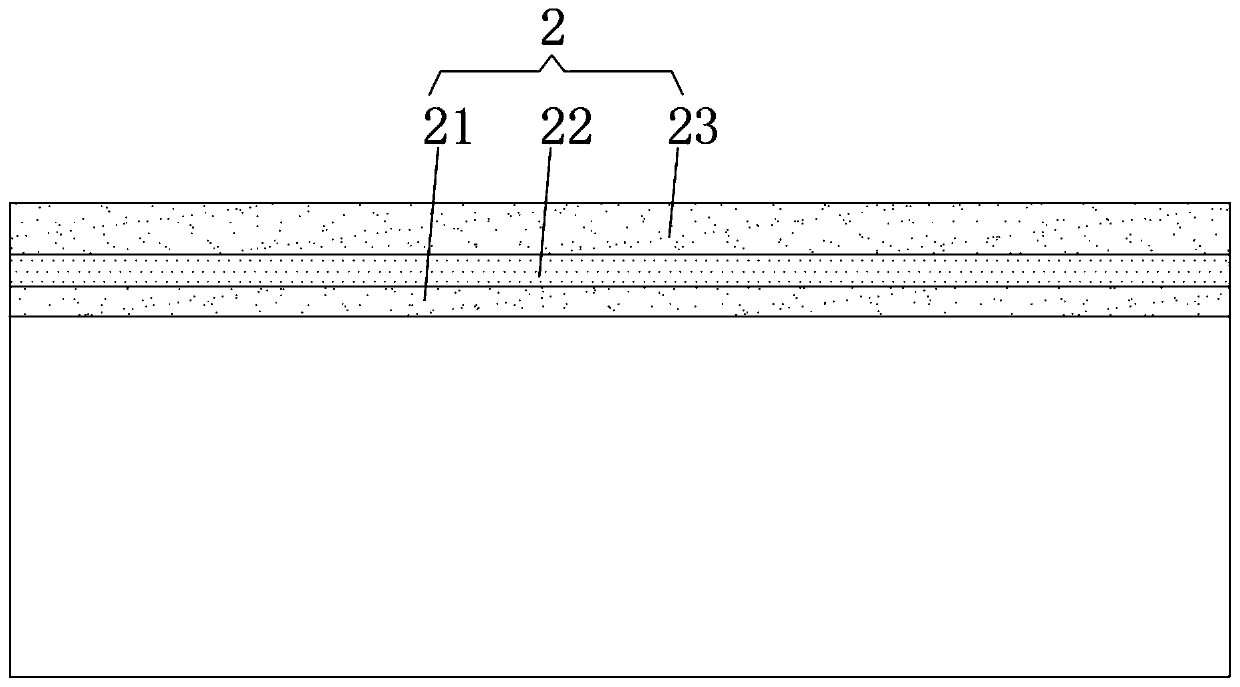

3D printing PVD mold and method thereof

InactiveCN110216815AImprove cooling effectIncrease productivityAdditive manufacturingIncreasing energy efficiencyHardnessVolumetric Mass Density

The invention discloses a 3D printing PVD mold, and relates to the technical field of 3D printing. The 3D printing PVD mold comprises a mold body, the mold body is T-shaped, the surfaces of the two sides of the mold body are provided with conformal water paths, and a coating is arranged on the surface of the mold body. The invention further discloses a printing method of the 3D printing PVD mold.The printing method comprises the following steps of A, establishing a model; B, carrying out additive manufacturing; C, polishing; D, carrying out surface treatment; and E, coating. According to the3D printing PVD mold, the changeable water paths can be designed according to the shape of the mold, the newest 3D printing technology is adopted instead of a conventional drilling process, the product can achieve the most effective cooling in a short time, the production efficiency is greatly improved, and the product cost is reduced; and the prepared mold is high in precision, low in roughness,high in density, higher in hardness than a forged piece, and the tensile strength is superior to that of a casting.

Owner:JIMEI UNIV

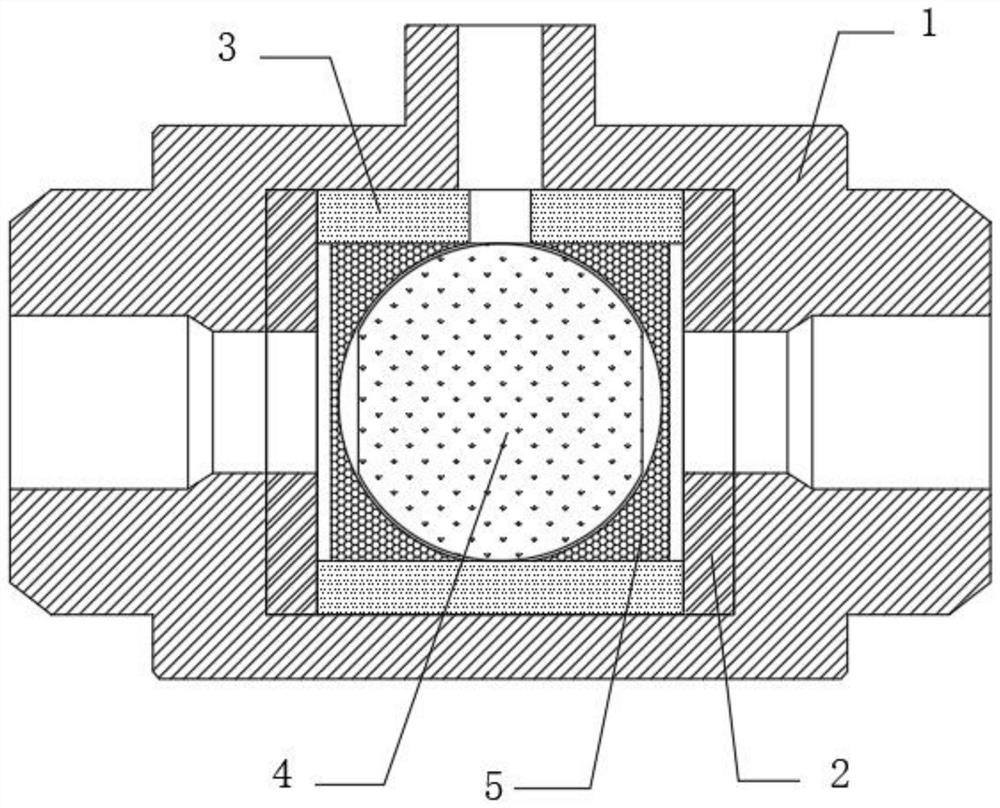

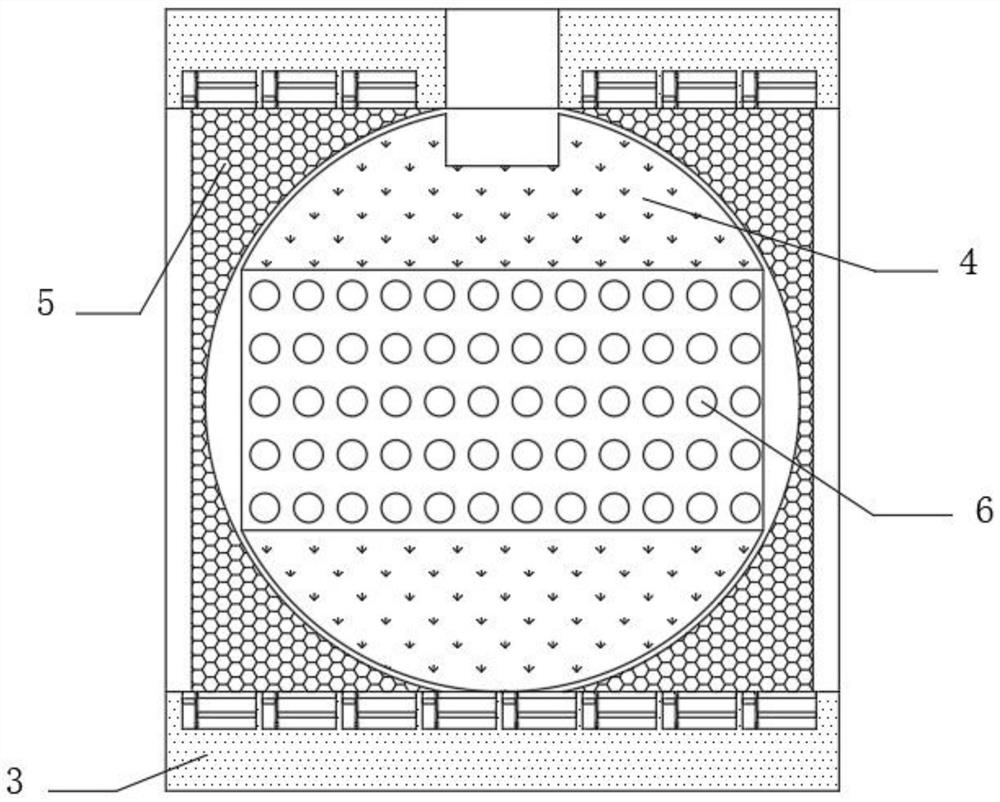

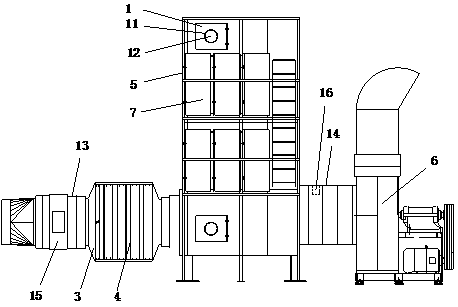

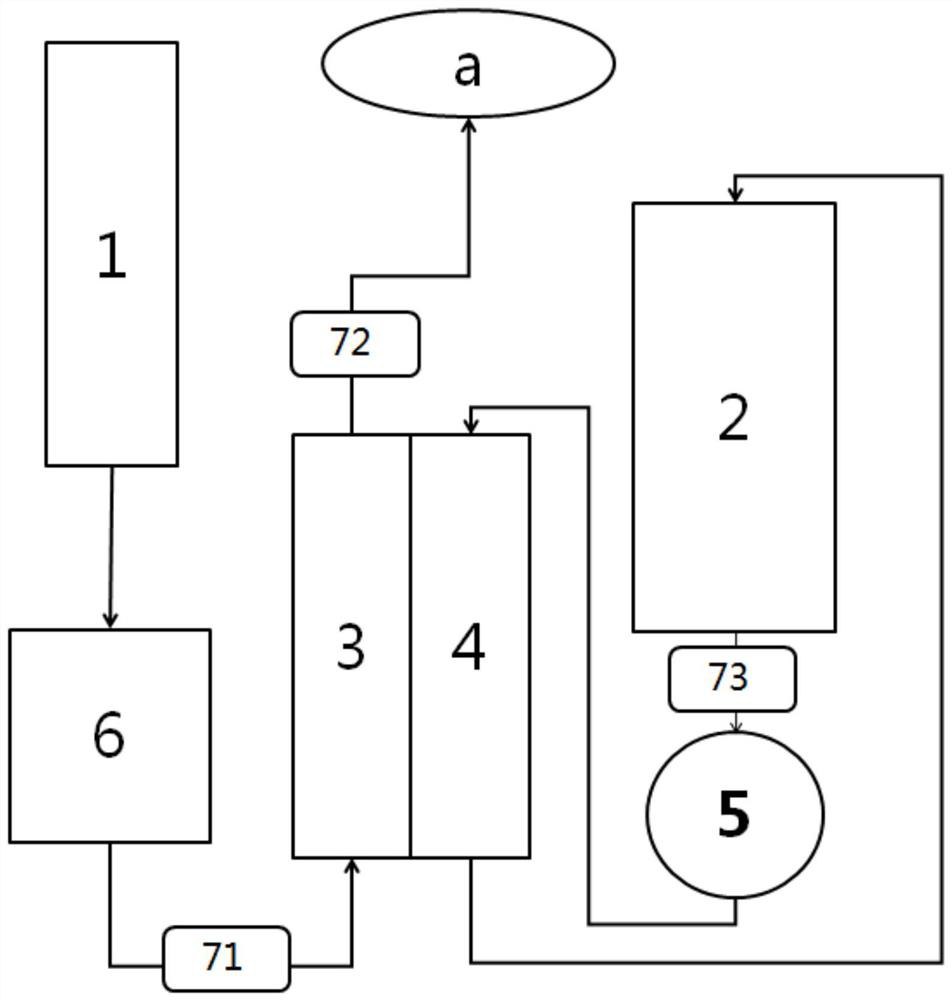

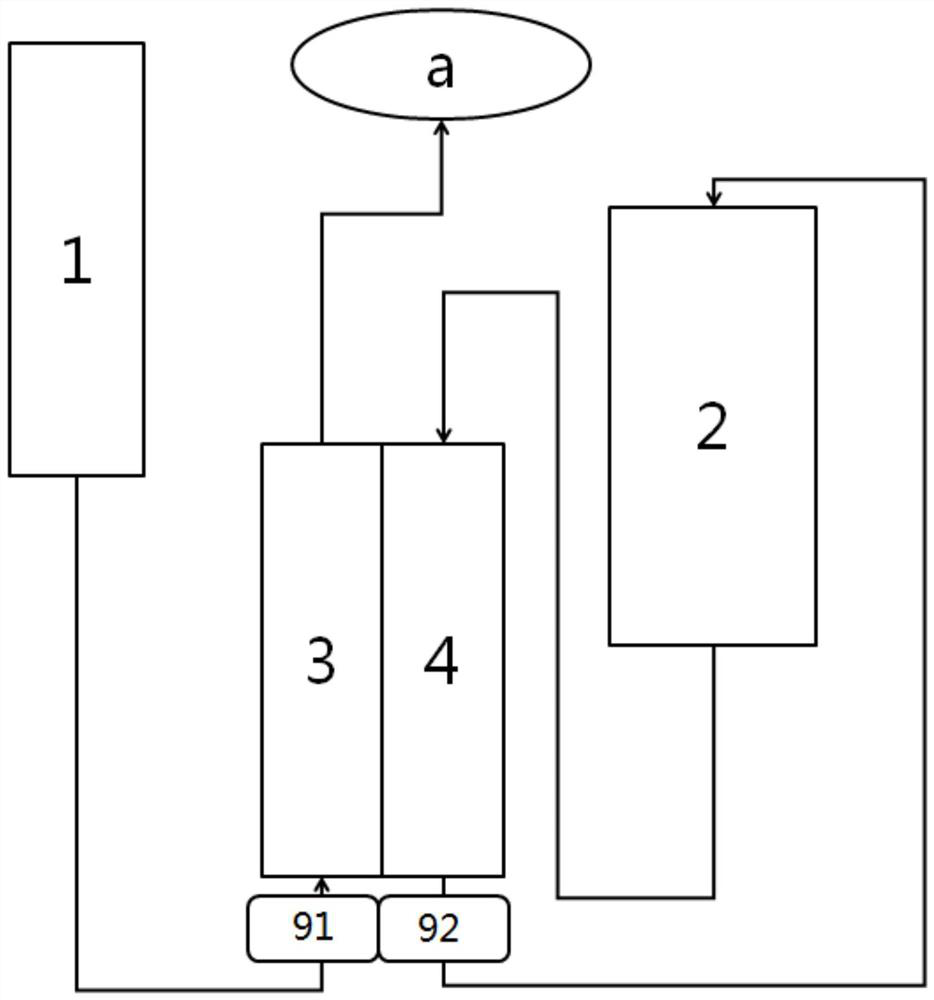

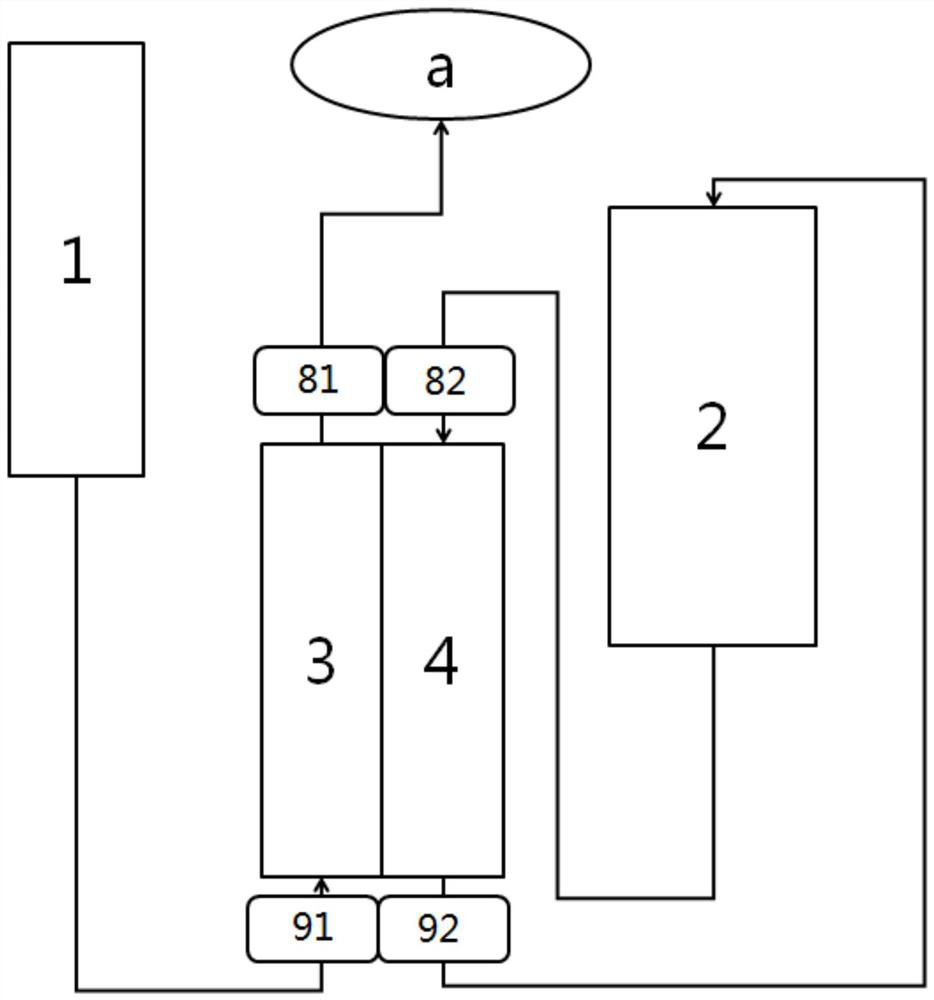

Dioctyl phthalate recycling equipment

ActiveCN103736590AAvoid short circuitUniform ionizationExternal electric electrostatic seperatorElectric supply techniquesEngineeringHigh pressure

The invention discloses dioctyl phthalate recycling equipment. The dioctyl phthalate recycling equipment comprises a high-voltage power supply, a controller, a filter, a cooler, an electrostatic recycling device and a fan, wherein the filter, the cooler, the electrostatic recycling device and the fan are sequentially connected; a plurality of high-voltage electrostatic generators, which are connected with one another, are arranged in the electrostatic recycling device; each high-voltage electrostatic generator comprises m anode cylinders, n insulators and an electric field frame; m and n are natural numbers, and m is greater than n; the m anode cylinders are arranged on the electric field frame in parallel; a cathode pin is arranged in each anode cylinder; one end of each anode cylinder is the inlet end, and the other end of each anode cylinder is the outlet end; the n insulators are arranged at the inlet ends of the m anode cylinders; the cross section of each anode cylinder is circular; each cathode pin is a screw rod; each insulator is a porcelain bottle; the high-voltage power supply is connected with the controller; each cathode pin is connected with the high-voltage power supply. According to the dioctyl phthalate recycling equipment, an air uniformizing system is not needed, oil fume can be uniformly ionized and decomposed in an electric field, and the phenomenon of short circuit of positive and negative poles is unlikely to be caused.

Owner:苏州巨联环保有限公司

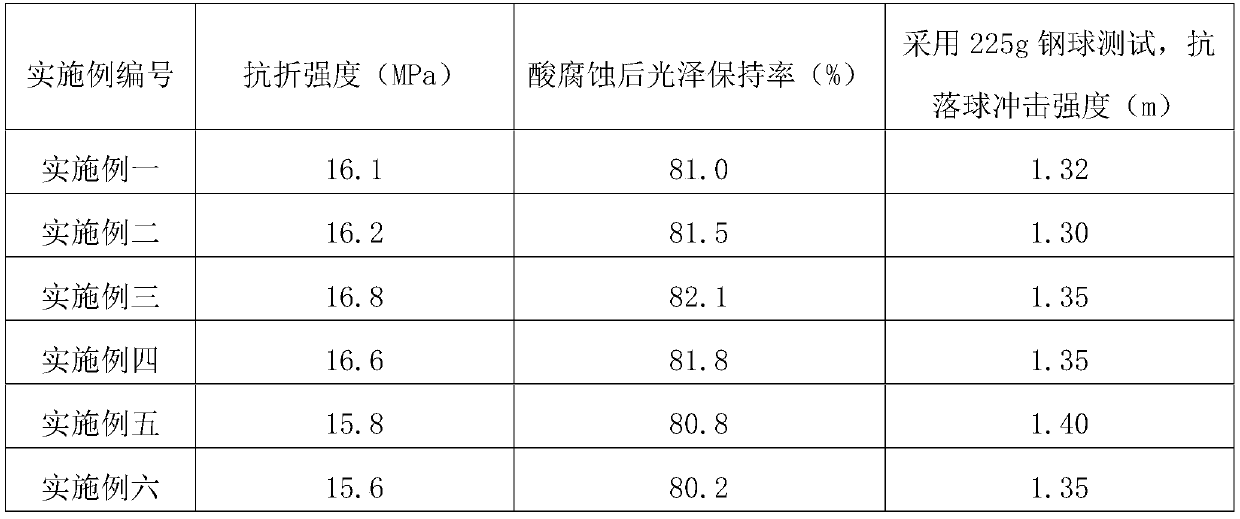

Geopolymer crack-resisting artificial stone and preparation method thereof

InactiveCN110002801ALow raw material costRealize resource utilizationCeramic shaping apparatusCement productionSlagReducing agent

The invention relates to an artificial stone and a preparation method thereof, in particular to a geopolymer crack-resisting artificial stone and a preparation method thereof. The geopolymer crack-resisting artificial stone is prepared from the following raw material components in parts by weight: 100 parts of nickel iron slag, 35 to 50 parts of a geopolymer, 7 to 15 parts of water, 0.35 to 1.0 part of a water reducing agent, 0.07 to 0.1 part of a plasticizer, 0.7 to 1.5 parts of an anti-cracking agent and 0.01 to 2 parts of pigment. The preparation method of the geopolymer crack-resisting artificial stone comprises the following steps: firstly, stirring and mixing raw materials; secondly, carrying out compression moulding; thirdly, curing; fourthly, polishing. The geopolymer crack-resisting artificial stone disclosed by the invention has the advantages of better acid and alkali resistance characteristics, capability of being used outdoors, good weather resistance and relatively high breaking strength; the preparation method of the geopolymer crack-resisting artificial stone disclosed by the invention adopts simple process steps and strictly controls process parameters of all the steps, so that the final quality of a finished artificial stone product is ensured.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Cold pickling device for steel ball production and using method thereof

The invention discloses a cold pickling device for steel ball production and a using method thereof. The cold pickling device comprises a supporting hopper frame, an anti-rust pool, a deacidificationcleaning pool and a pickling pool, wherein the supporting hopper frame, the anti-rust pool, the deacidification cleaning pool and the pickling pool are sequentially arranged, a light rail travelling crane is erected above the supporting hopper frame, the anti-rust pool, the deacidification cleaning pool and the pickling pool, and an acid ball filter hopper is mounted on the light rail travelling crane. The device is simple in structure, the flow of the cold pickling appearance process in the steel ball manufacturing industry can be greatly simplified by utilizing the acid ball filter funnel capable of accommodating a whole disc of steel balls through the five procedures of material preparation, pickling, deacidification, rust prevention and detection, the labor intensity of workers is greatly reduced, and operation can be achieved by only one person; and the device is simple in structure and easy to implement, and meanwhile, in the pickling process, only the light rail travelling craneneeds to be manually operated without direct contact with liquid, so that corrosion is avoided, and the safety is ensured.

Owner:合肥力和机械有限公司

Aluminizing method of alloy base material

InactiveCN101781747BFlat surfaceHigh surface finishSolid state diffusion coatingMegasonic cleaningAlloy

The invention relates to an aluminizing method of an alloy base material, which is an aluminizing method. The aluminizing method solves the problems that the aluminizing on shaped work pieces and tube inner walls in the alloy base materials is incomplete or can not be realized, aluminized sheet work pieces are easily deformed, and the micro-area aluminizing can not be carried out on work pieces in the traditional aluminizing process. The aluminizing method comprises the following steps of: (1) pregrinding the alloy base material, cleaning with ultrasonic waves, and coating AlCl3 powder or NH4Cl powder to the surface of the alloy base material to obtain a test piece; (2) wrapping the test piece with aluminum foil, and carrying out aluminizing treatment to finish aluminizing. Alternatively,the aluminizing method comprises the following steps of: (1) cleaning the alloy base material with the ultrasonic waves to obtain the test piece; (2) wiping the aluminum foil by using HCl, wrapping the test piece with the aluminum foil, and carrying out aluminizing treatment to finish aluminizing. The base material aluminized by the invention can not deform, the size of the base material is unlimited, and the aluminizing on the shaped work pieces and the tube inner walls in the alloy base materials can be realized, micro-area aluminizing can be carried out to specific areas of the test piece,and the surface of the aluminized alloy base material is smooth and is not sticky to the aluminum foil.

Owner:HARBIN INST OF TECH

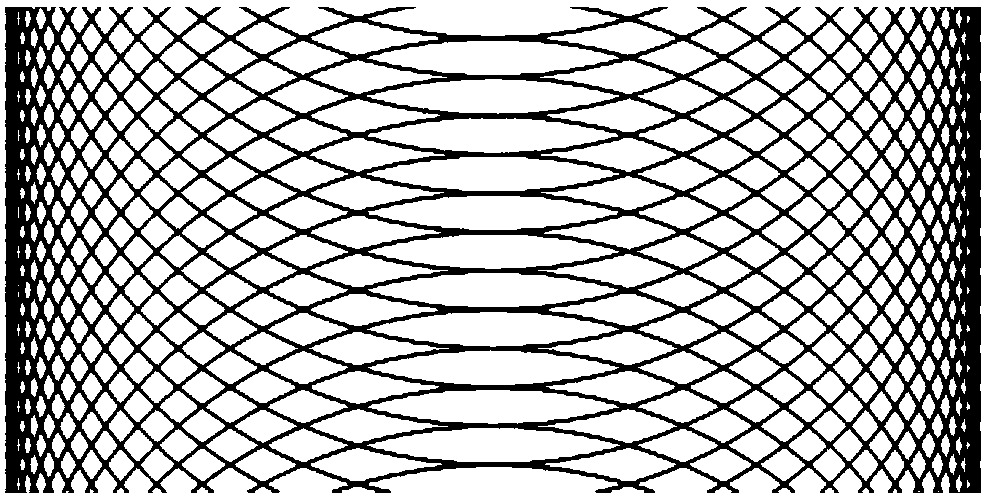

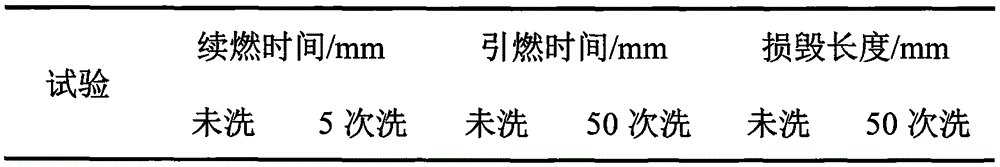

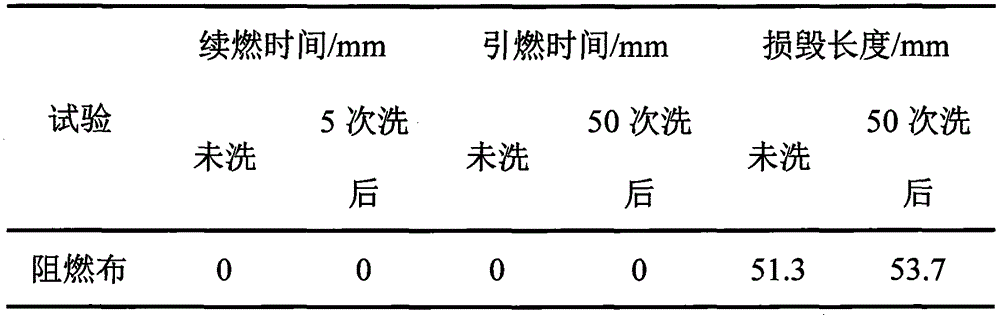

A kind of 320~340 ℃ refractory cloth and its preparation method

The invention relates to fire-resistant cloth for resisting a temperature of 320-340 DEG C and a preparation method thereof, and belongs to the technical field of textile materials and fire prevention. Warp is prepared from, by mass, 30-70% of polyphosphamide fiber and 30-70% of aramid fiber, and weft is prepared from, by mass, 1-30% of long stapled cotton, 29-70% of polyphosphamide fiber and 29-70% of alginate fiber. The warp is formed by blending polyphosphamide fiber and aramid fiber, the weft is formed by blending long stapled cotton, polyphosphamide fiber and alginate fiber, and the warp and the weft are combined and woven into fire-resistant cloth with certain density through a staggered weaving method; after leaving a fire source, the cloth can automatically flame out without producing molten drops, the cloth is curled at the temperature of 352 DEG C and is carbonized at a high temperature without combusting, and the permanent effect is achieved. The fire-resistant cloth woven through the method has the advantages of being durable, resistant to high temperature, good in breathability, high in strength, good in hand feeling, good in dyeing and finishing performance, comfortable to wear and the like.

Owner:深圳市名仕度服饰有限公司

Anticorrosive vacuumizer pollution-discharge liquid-purification observation-monitoring-operation vacuum furnace

InactiveCN103740908AEvenly heatedNot easy to splashFurnace typesHeat treatment process controlInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification observation-monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Instant water heater and control method thereof

PendingCN114151960AWater flow controlWater flow control to meet the actual hot water temperature controlWater heatersControl of fluid heatersTap waterWater source

The invention provides an instant water heater. The instant water heater comprises a shell and a heating module. The heating module comprises a cold water channel, a hot water channel and a hot water tank; the cold water channel is connected with the tap water source; a water inlet of the hot water channel is communicated with a water outlet of the hot water tank, and a water outlet of the hot water channel is connected with a water inlet of the hot water tank; heat exchange is realized between the cold water channel and the hot water channel; and a heat exchange starting device for starting the heating module on the basis of water flow in the cold water channel is further arranged. The invention further provides a control method of the instant water heater. Through the structure and the method, control over the hot water outlet flow of the hot water tank is achieved through the method, the actual hot water temperature requirement is met, and regulation and control over the outlet water temperature of the instant water heater are achieved.

Owner:GUANGDONG LIZI TECH CO LTD

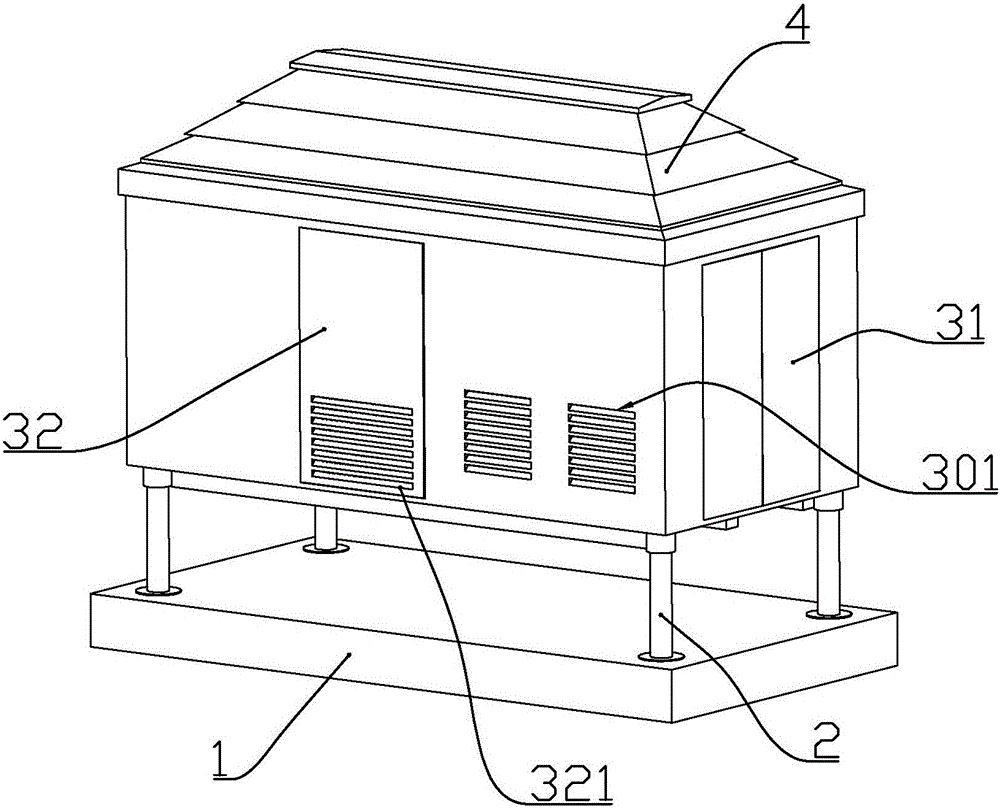

A waterproof box-type substation

ActiveCN106129828BEasy to buildWill not corrodeTransformers/inductances coolingEnclosed substationsCooling effectStructural engineering

The invention discloses a waterproof box-type substation, which comprises a base and a box body, wherein the box body is arranged at the upper part of the base; the upper part of the box body is connected with a head cover; the head cover comprises a lower head cover fixedly connected with the upper part of the box body and an upper head cover arranged on the lower head cover; the lower head cover comprises a longitudinal wall in a rectangular frame shape and a slope wall fixedly connected to the upper end of the longitudinal wall; the lower end part of the longitudinal wall is fixedly connected with a horizontally arranged transverse cover wall; a limiting bayonet is formed in the lower surface of the upper end of the slope wall; the inner end of the transverse cover wall tightly abuts on the upper edge of the box body; the transverse cover wall is fixedly connected with the box body through a bolt; the transverse cover wall is provided with a plurality of strip-shaped lower exhaust outlets in the wall surface of the outer side of the upper edge of the box body; and the lower exhaust outlets are horizontally arranged along the transverse cover wall at equal intervals. The waterproof box-type substation is compact in structure, reasonable in design, convenient to construct and good in cooling effect.

Owner:山东恒东实业集团有限公司

Anti-breakage and anti-corrosion cable sheath material

InactiveCN108264699AExtended service lifeWill not be corrodedPlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses an anti-breakage and anti-corrosion cable sheath material. The material is characterized by being prepared from, by weight, 50-90 parts of polyvinyl chloride resin, 40-70 partsof III type resin, 30-50 parts of EVA resin, 20-45 parts of ethylene propylene diene monomer, 15-30 parts of foamed rubber, 5-15 parts of chlorinated polyethylene, 3-10 parts of magnesium oxide, 10-25 parts of polyolefin, 15-20 parts of polypropylene, 2-5 parts of potassium pyrophosphate, 4-7 parts of antimonous oxide, 2-6 parts of titanate coupling agent, 1-4 parts of sulfanilamide, 2-7 parts ofmelamine cyanurate, 1-4 parts of stearic acid, 10-20 parts of microencapsulated red phosphorus, 4-8 parts of nanometer kaolin, 10-17 parts of talcum powder, 0.5-1 part of white carbon black, 5-15 parts of bentonite, 5-13 parts of nylon, 1-4 parts of antioxidant, 0.4-1 part of lubricant and 1-5 parts of epoxidized soybean oil. The material has the advantages of preventing breakage and corrosion, resisting stretching and being long in service life; a cable cannot be corroded even after being placed for a long time, and the structural strength of the cable is improved; the anti-breakage strengthand structural strength of the cable are enhanced.

Owner:HUAIBEI TIANXIANG CABLE

Anticorrosive vacuumizer pollution-discharge liquid-purification monitoring-operation vacuum furnace

ActiveCN103740910AEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:NANTONG FEIBEN MACHINERY

Macrostructure hot acid etching device

PendingCN110595858AHeating safetyAvoid direct contactPreparing sample for investigationAcid etchingMicrowave

The invention discloses a macrostructure hot acid etching device which comprises an acid etching tank, a workpiece cleaning pool, an acid etching liquid supply device and a microwave heating device for heating acid etching liquid in the acid etching liquid supply device, and the acid etching liquid supply device is communicated with the acid etching tank. A microwave heating mode is adopted, so that the heating device is prevented from direct contact with the acid etching liquid, and the purpose of safely and reliably heating the acid etching liquid is achieved; microwave heating is high in temperature rising speed and heating efficiency, energy loss can be greatly reduced, and the production cost is reduced; the microwave heating device, the acid etching liquid supply device and the acidetching tank are all independent equipment units, and electrified elements and circuits are not in direct contact with acid etching liquid and cannot be corroded by the acid etching liquid. The acid etching liquid in the acid etching tank is not directly heated by microwaves, but flows into the acid etching tank after being heated by the acid etching liquid supply device, so that the potential hazard that a workpiece of the conventional equipment is possibly exploded due to direct contact with the heated acid etching liquid is solved, and the safety is high.

Owner:湖南华冶微波科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com