Cementing method for gas storage well casing tube

A technology for gas storage wells and casings, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and other directions, can solve the problems of lowering cementing quality, easy corrosion of gas storage well casings 5, and easy loosening of gas storage wells. Achieve the effect of improving cementing quality and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

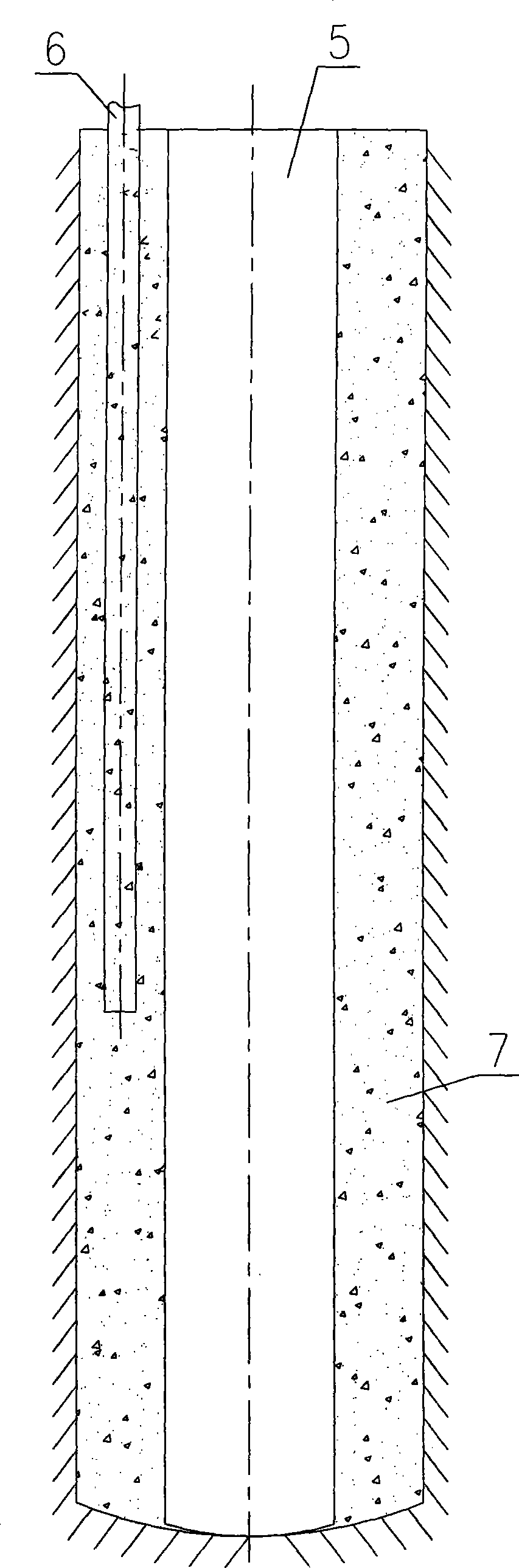

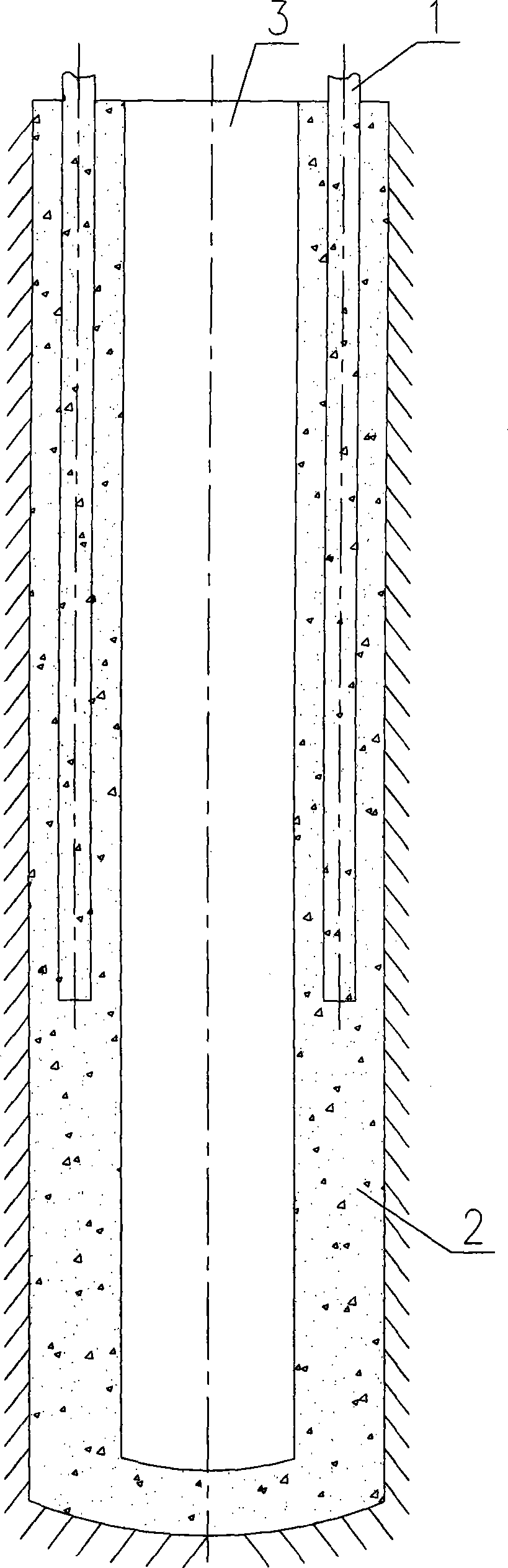

[0010] The well cementing method of gas storage well casing of the present invention, by figure 2 As shown, the following steps are included: 1) two grouting pipes 1 are arranged in the well, and cement slurry 2 is injected to the bottom of the well through the grouting pipes 1. A retarder is added in the cement slurry 2, and the solidification time of the cement slurry 2 needs to be greater than 4 hours; 2) Lower the casing 3 of the gas storage well and make contact with the cement slurry at the bottom of the well. At the same time, continue to inject cement slurry 2 into the well through the grouting pipe 1 until the cement slurry 2 returns from the wellhead, so that the entire well is filled with cement slurry 2, and then stop Grouting, after the cement slurry 2 is solidified, the bottom and surroundings of the gas storage well casing 3 are covered with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com