Box-type substation for dissipating heat by natural wind

A box-type substation and natural wind technology, which is applied in the direction of distribution substation, substation/distribution device shell, substation/switchgear cooling/ventilation, etc., can solve complex structure, increase of air humidity of substation, poor practicability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

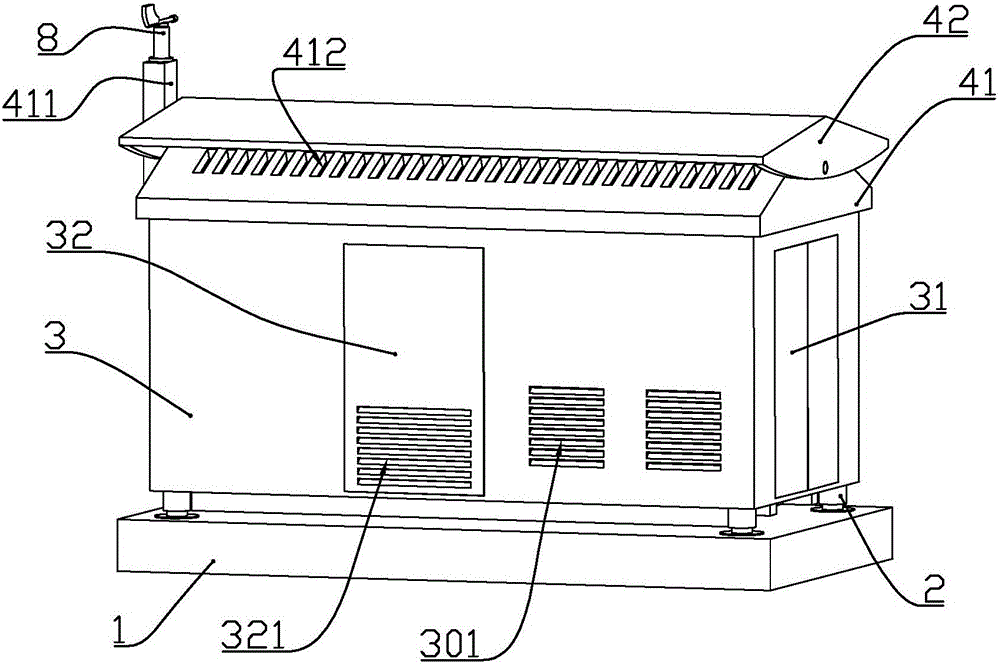

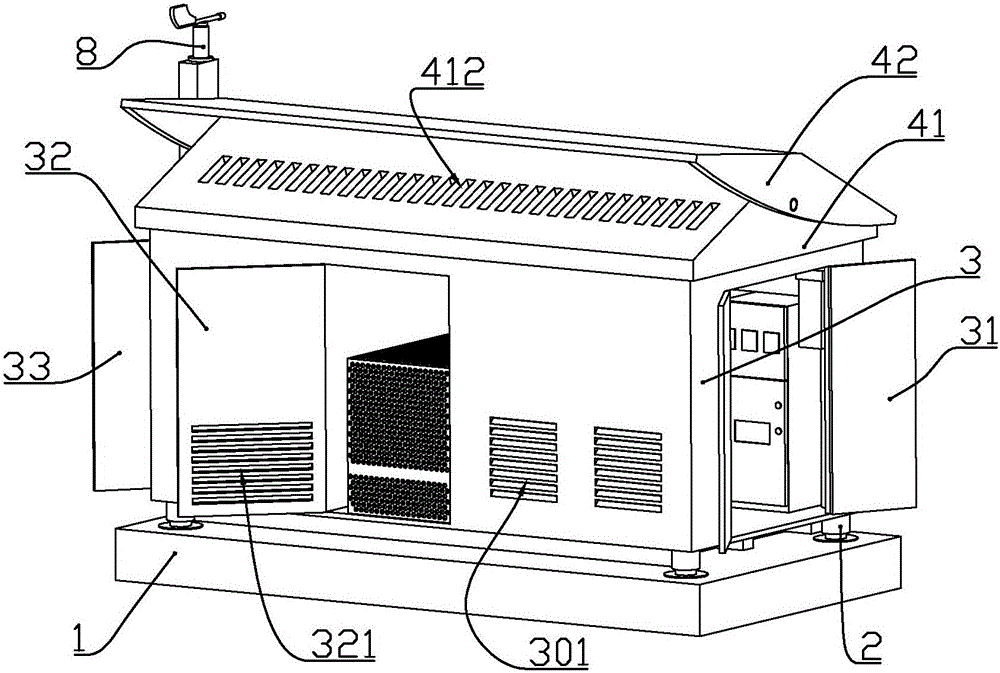

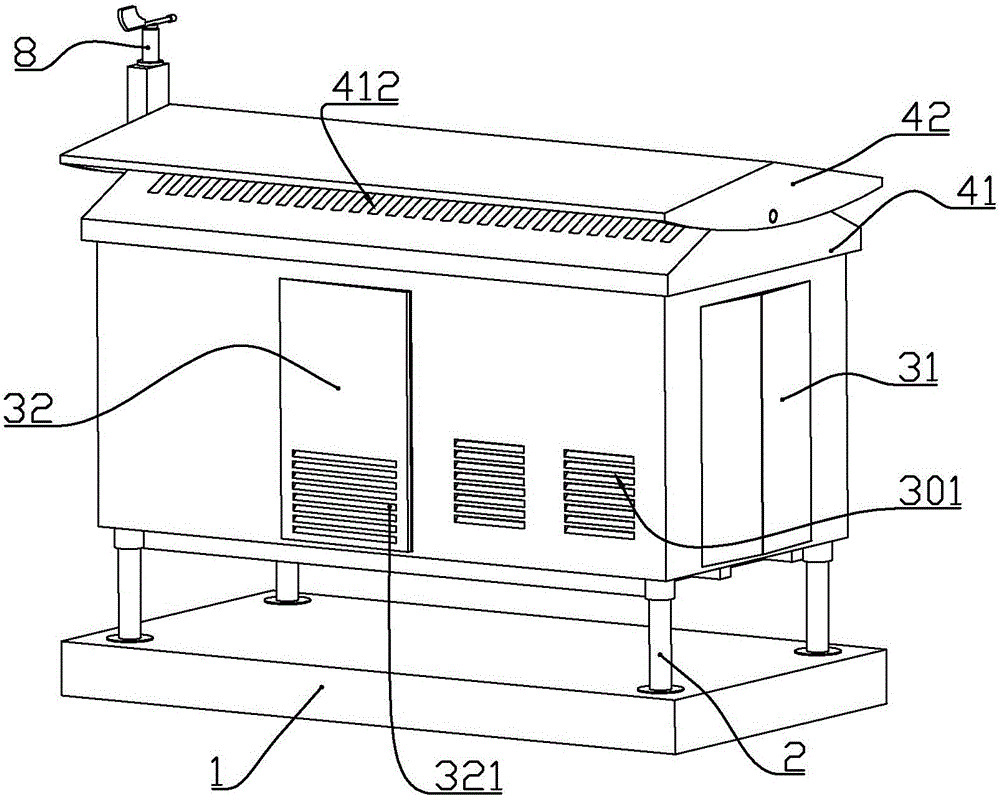

[0081] according to Figure 1 to Figure 15 As shown, this embodiment is a box-type substation utilizing natural wind for heat dissipation, including a base 1 made of reinforced concrete, and a box 3 in the shape of a cuboid arranged above the base.

[0082] An electric push rod 2 arranged vertically is installed near the four vertices in the box, and the output rod of the electric push rod passes downward through the bottom plate at the lower end of the box body and is fixedly connected with the base.

[0083] A liquid level sensor (not shown) is installed on the lower end of the output rod or the base; the liquid level sensor and each electric push rod are respectively electrically connected to a control box, and the control box is installed inside the box.

[0084] When the liquid level sensor detects accumulated water, the control box controls the extension of the electric push rod to lift the tank, and the lifting height of the tank is proportional to the water level detec...

Embodiment 2

[0101] according to Figure 1 to Figure 15 As shown, this embodiment is a box-type substation utilizing natural wind for heat dissipation, including a base 1 made of reinforced concrete, and a box 3 in the shape of a cuboid arranged above the base.

[0102] An electric push rod 2 arranged vertically is installed near the four vertices in the box, and the output rod of the electric push rod passes downward through the bottom plate at the lower end of the box body and is fixedly connected with the base.

[0103] A liquid level sensor (not shown) is installed on the lower end of the output rod or the base; the liquid level sensor and each electric push rod are respectively electrically connected to a control box, and the control box is installed inside the box.

[0104] When the liquid level sensor detects accumulated water, the control box controls the extension of the electric push rod to lift the tank, and the lifting height of the tank is proportional to the water level detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com