Box-type substation having multiple heat radiation modes

A box-type substation, heat dissipation mode technology, applied in the details of substation/switch layout, cooling/ventilation of substation/switchgear, transformer/inductor shell, etc. Leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

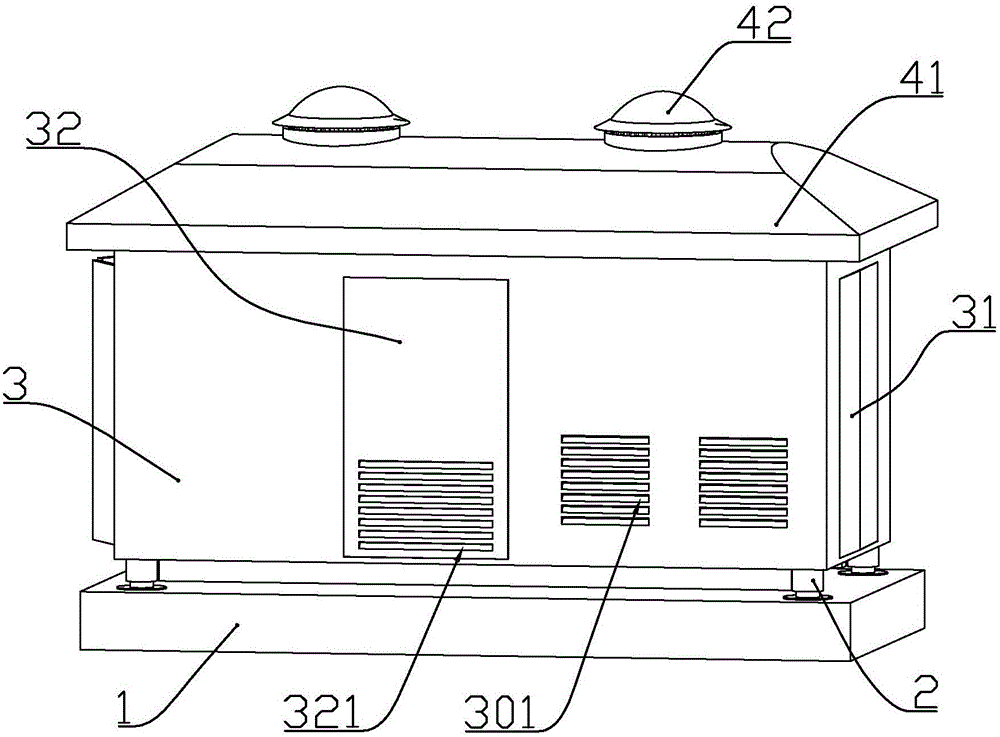

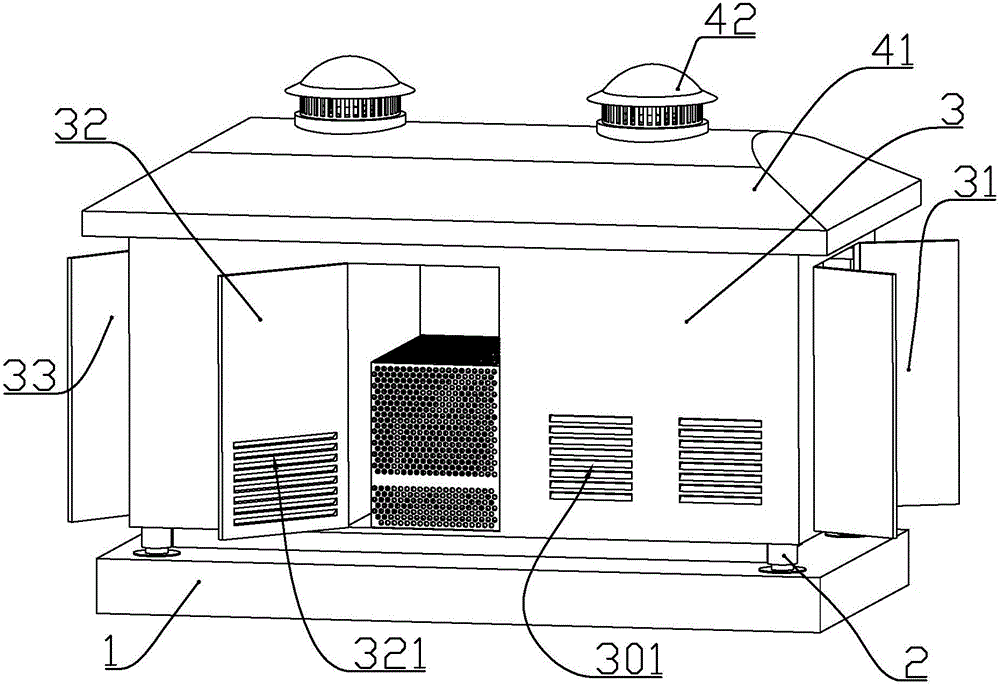

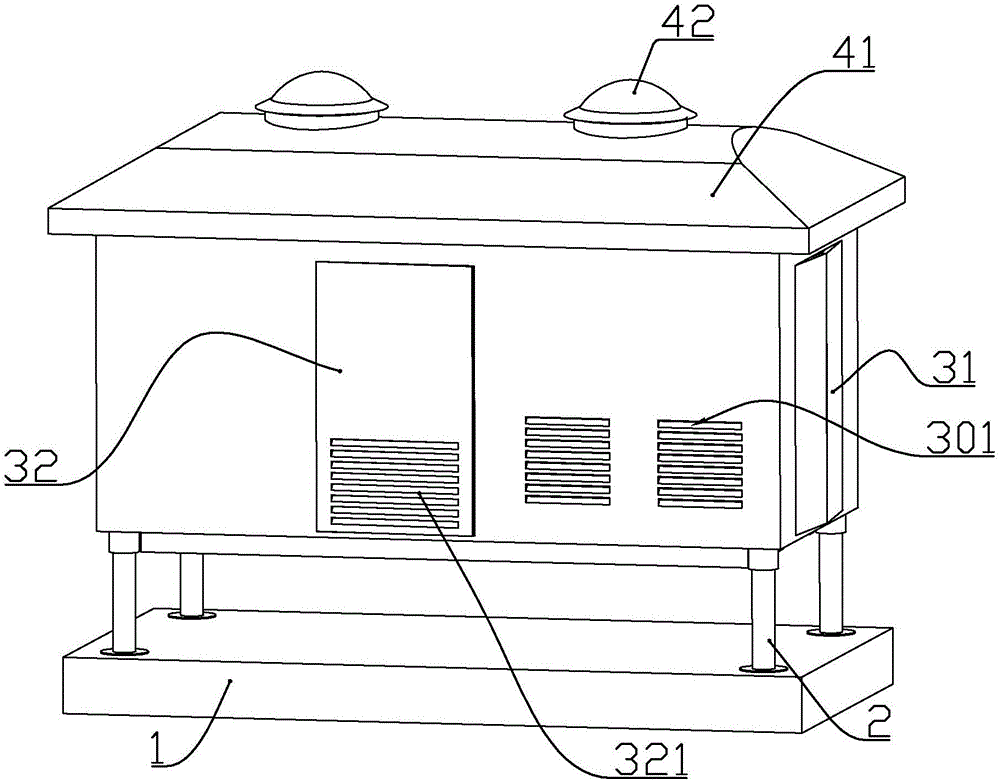

[0070] according to Figure 1 to Figure 12 As shown, this embodiment is a box-type substation with multiple heat dissipation modes, which includes a base 1 made of reinforced concrete and a box 3 in the shape of a rectangular parallelepiped arranged above the base.

[0071] A longitudinally arranged electric push rod 2 is installed in the position close to the four vertices in the box, and the output rod of the electric push rod passes downward through the bottom plate at the lower end of the box and is fixedly connected to the base.

[0072] A liquid level sensor (not shown in the figure) is installed on the lower end of the output rod or the base; the liquid level sensor and each electric push rod are respectively electrically connected with a control box, and the control box is installed inside the box.

[0073] When the liquid level sensor detects the accumulation of water, the control box controls the extension of the electric push rod to raise the tank, and the lifting height o...

Embodiment 2

[0085] according to Figure 1 to Figure 12 As shown, this embodiment is a box-type substation with multiple heat dissipation modes, which includes a base 1 made of reinforced concrete and a box 3 in the shape of a rectangular parallelepiped arranged above the base.

[0086] A longitudinally arranged electric push rod 2 is installed in the position close to the four vertices in the box, and the output rod of the electric push rod passes downward through the bottom plate at the lower end of the box and is fixedly connected to the base.

[0087] A liquid level sensor (not shown in the figure) is installed on the lower end of the output rod or the base; the liquid level sensor and each electric push rod are respectively electrically connected with a control box, and the control box is installed inside the box.

[0088] When the liquid level sensor detects the accumulation of water, the control box controls the extension of the electric push rod to raise the tank, and the lifting height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com