A kind of 320~340 ℃ refractory cloth and its preparation method

A technology of fire-resistant cloth and polyphosphoramide, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of low heating temperature of fire-resistant cloth, poor coloring rate of Nomex, melting dripping, etc., and achieve simple process and significant economic benefits and social benefits, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

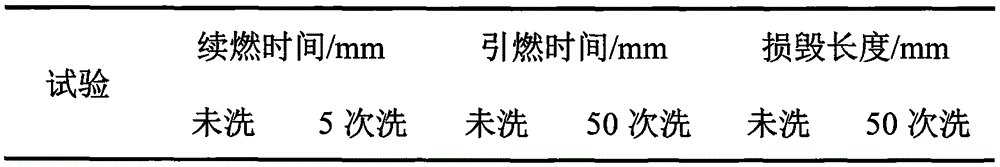

[0028] Get 650kg polyphosphoramide fibers and 350kg aramid fibers in the HXF-1 type reciprocating carding machine and mix them uniformly in the mixing machine; spin into 45, 55 and 65 yarns through the spinning machine, the broken The strength is 363.2cN, the breaking strength is 22.3cN / tex, and it is used as the warp yarn when weaving; take 250kg of long-staple cotton, 520kg of polyphosphoramide fiber and 230kg of seaweed fiber, and loosen them in the HXF-1 reciprocating carding machine and pass through Mix evenly in the mixing machine; spun into 40, 60 and 80 yarns by the spinning machine, the breaking strength is 321.6cN, and the breaking strength is 20.4cN / tex, which is used as the weft yarn when weaving; in WF-II type The loom is controlled by computer, using 12 warp fibers and 9 weft fibers, using a 3×3 T-shaped interlaced weaving method, and the density of the woven refractory fabric is 289.6g / m 2 , with a total area of 5594m 2 . Its mechanical properties are that t...

Embodiment 2

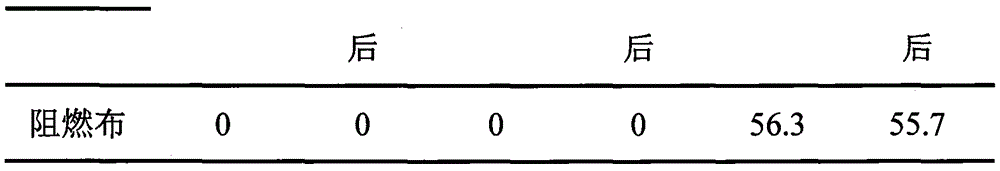

[0034] Get 550kg polyphosphoramide fibers and 450kg aramid fibers in the HXF-1 reciprocating carding machine and mix them uniformly in the mixing machine; spin into 30, 45 and 65 yarns through the spinning machine, and the broken The strength is 334.7cN, the breaking strength is 21.3cN / tex, and it is used as the warp yarn when weaving; take 200kg of long-staple cotton, 550kg of polyphosphoramide fiber and 250kg of seaweed fiber, and loosen them in the HXF-1 reciprocating carding machine and pass through Mix evenly in the mixing machine; spun into 20, 60 and 90 yarns by the spinning machine, the breaking strength is 331.3cN, and the breaking strength is 22.5cN / tex, which is used as the weft yarn when weaving; in WF-II type The loom is controlled by a computer, using 3 warp fibers and 6 weft fibers, using a 3×3 T-shaped interlaced weaving method, and the density of the refractory fabric woven is 239.0g / m 2 , with a total area of 6778.3m 2 . Its mechanical properties are that...

Embodiment 3

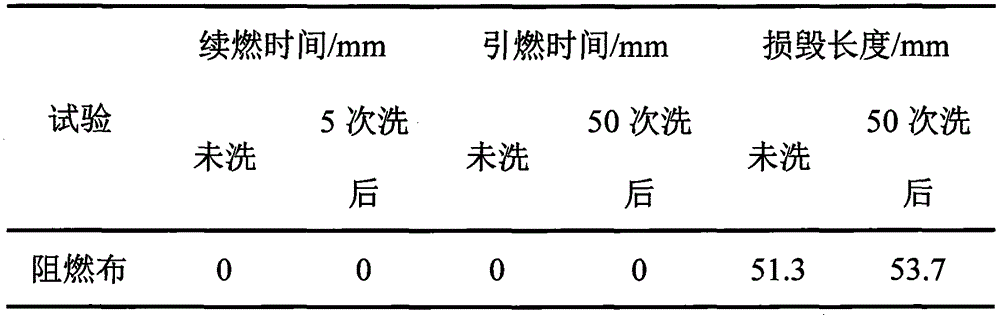

[0039] Get 70kg polyphosphoramide fiber and 30kg aramid fiber in the HXF-1 reciprocating carding machine and mix them evenly in the mixing machine; spin into 45, 55 and 65 yarns through the spinning machine, the broken The strength is 354.7cN, the breaking strength is 25.1cN / tex, and it is used as the warp yarn when weaving; take 30kg of long-staple cotton, 45kg of polyphosphoramide fiber and 35kg of seaweed fiber, and loosen them in the HXF-1 reciprocating carding machine and pass through Mix evenly in the mixing machine; spun into 40, 60 and 80 yarns by the spinning machine, the breaking strength is 322.4cN, and the breaking strength is 21.3cN / tex, which is used as the weft yarn when weaving; in WF-II type Computer control is adopted on the loom, with 6 warp fibers and 9 weft fibers, and a 3×3 T-shaped interlaced weaving method, and the prepared fabric is 262.1g / m 2 , with a total area of 618m 2 ; Its mechanical properties are transverse fracture strength of 61.6cN / tex, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com