Method for processing surface of rim and its products

A technology for surface treatment and rims, applied to special surfaces, devices for coating liquid on surfaces, coatings, etc., can solve the problems of uneven thickness, scratches and loss caused by the warping of decorative pieces 53

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

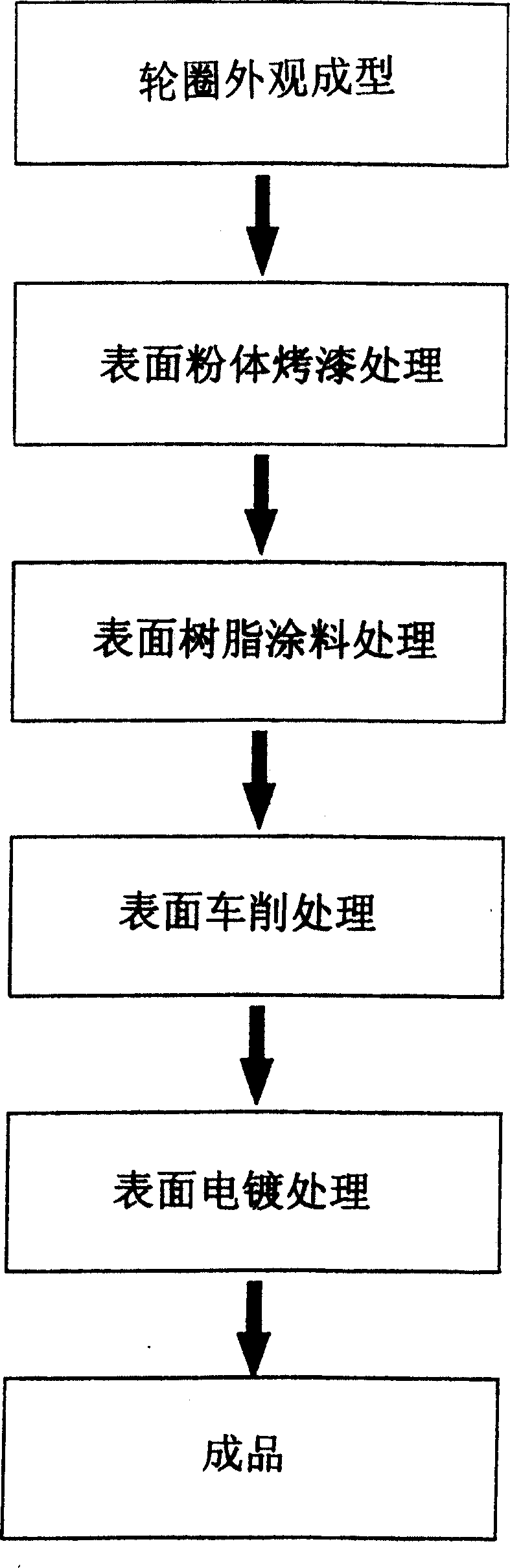

[0036] Please refer to Fig. 1 to Fig. 8, the present invention is a wheel rim surface treatment method and its finished product. The method includes: rim appearance molding, surface powder baking paint treatment, surface resin coating treatment, surface turning treatment and surface Steps such as electroplating treatment, to complete the finished product of the wheel rim of the present invention, wherein;

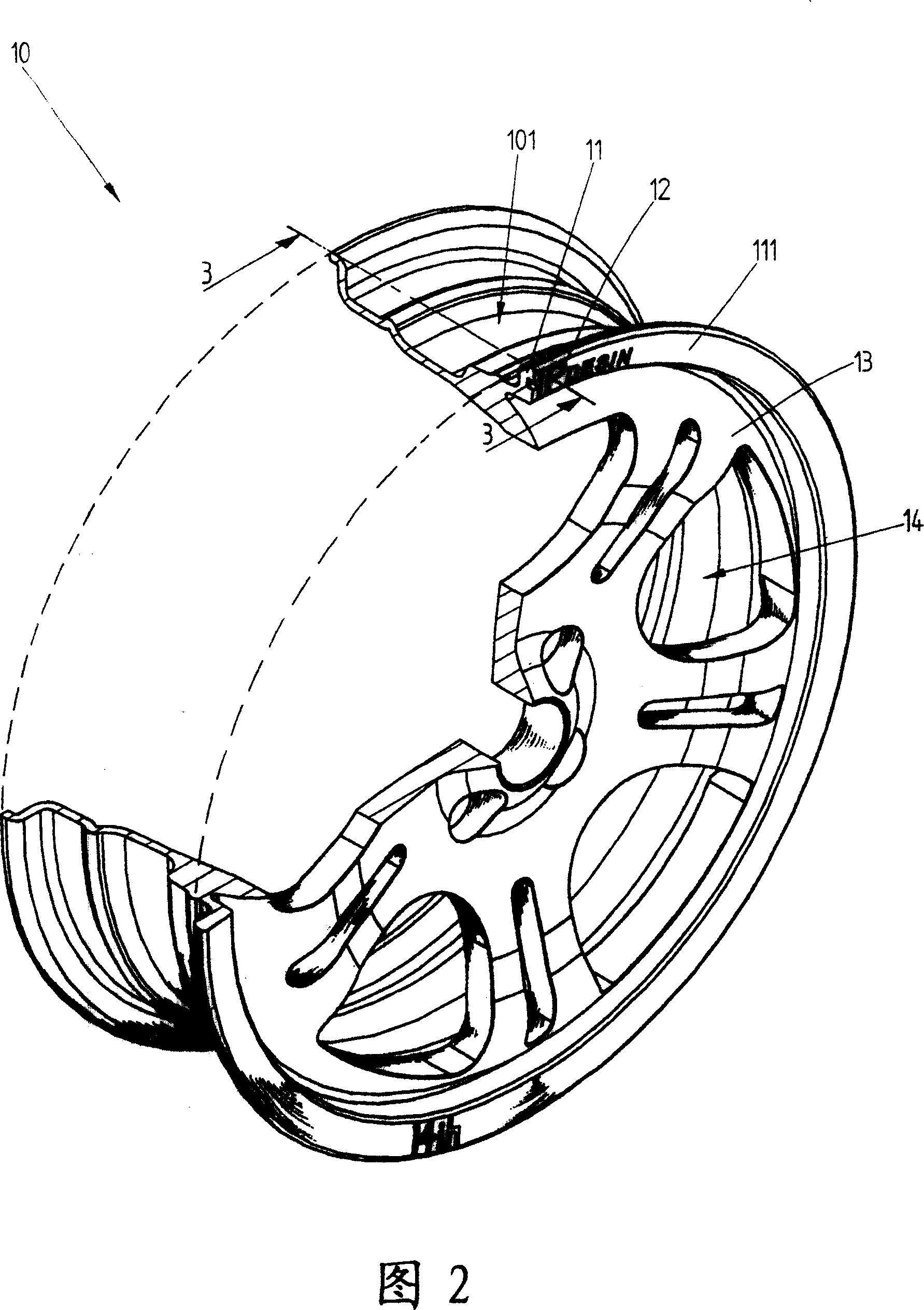

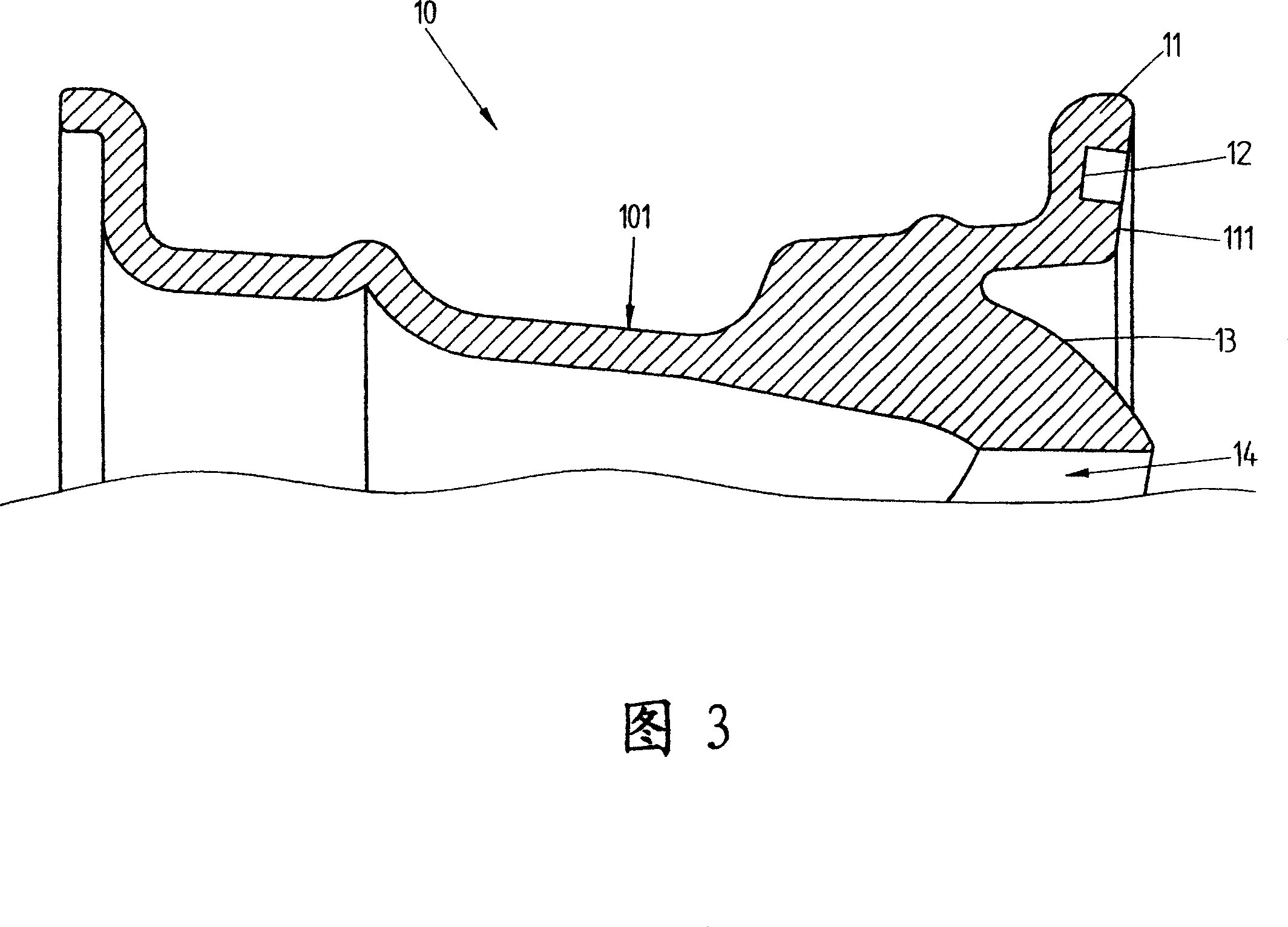

[0037] During the forming step of the rim appearance: please refer to Fig. 2 and shown in Fig. 3, which refers to the manufacture of a rim 10 with a predetermined shape in advance, and the outer edge of the rim 10 is formed with a tire (not shown) sleeve The installation part 101, and one side of the installation part 101 forms a protruding ring 11, and one side of the protruding ring 11 has a mark display part 111, and the predetermined position of the mark display part 111 is provided with a symbol that can represent the size, model, etc. Dimple mark 12, the inner edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com