Aluminum electrolysis steel claw for prebaked anode

A pre-baked anode and aluminum electrolysis technology, applied in the field of steel claws, can solve the problems of increased heat loss, increased power consumption rate, and stable operation of the electrolytic cell, and has the effect of reducing weight and height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

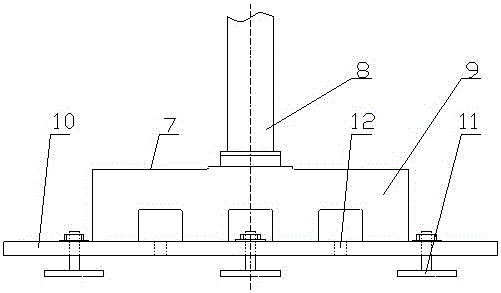

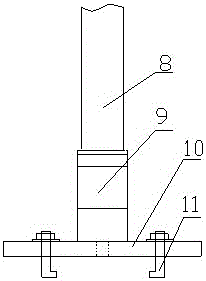

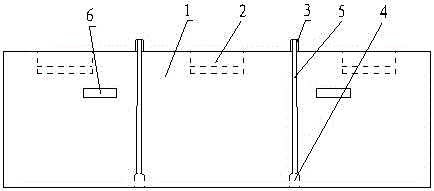

[0016] Example 1. A prebaked anodized aluminum electrolytic steel claw such as Figure 1-2 As shown, the steel claw 7 includes a conductive rod 8, the conductive rod 8 is connected to a conductive bridge-shaped bracket 9, and the bridge-shaped bracket 9 is connected to a conductive positioning steel plate 10, and the positioning steel plate 10 is provided with a connecting locking part 11.

[0017] The cross-section of the coupling locking part 11 is L-shaped, and the coupling locking part 11 is connected with the coupling groove 2 of the carbon block body 1 .

[0018] The connecting locking part 11 has an L-shaped cross-section, and the upper part is a screw rod. The connecting locking part 11 is locked with the positioning steel plate 10 and the carbon block body 1 through the upper nut and washer.

[0019] The positioning steel plate 10 is provided with a hole 12 for placing the fixing protrusion 3 .

[0020] The anode carbon blocks used in conjunction with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com