Patents

Literature

161results about How to "Won't corrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

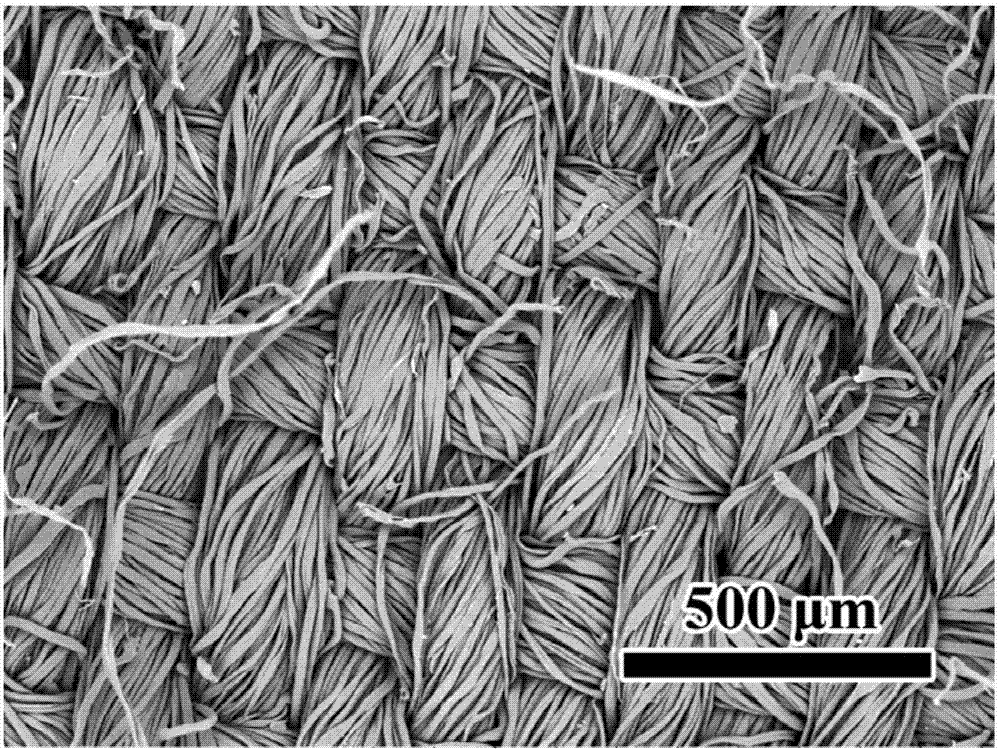

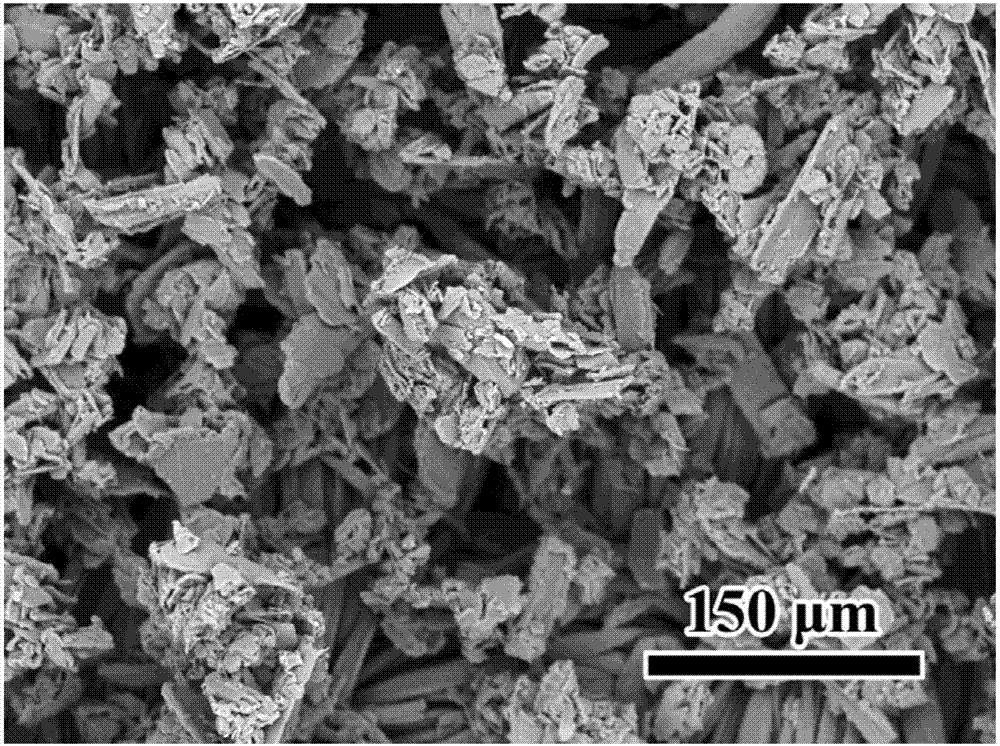

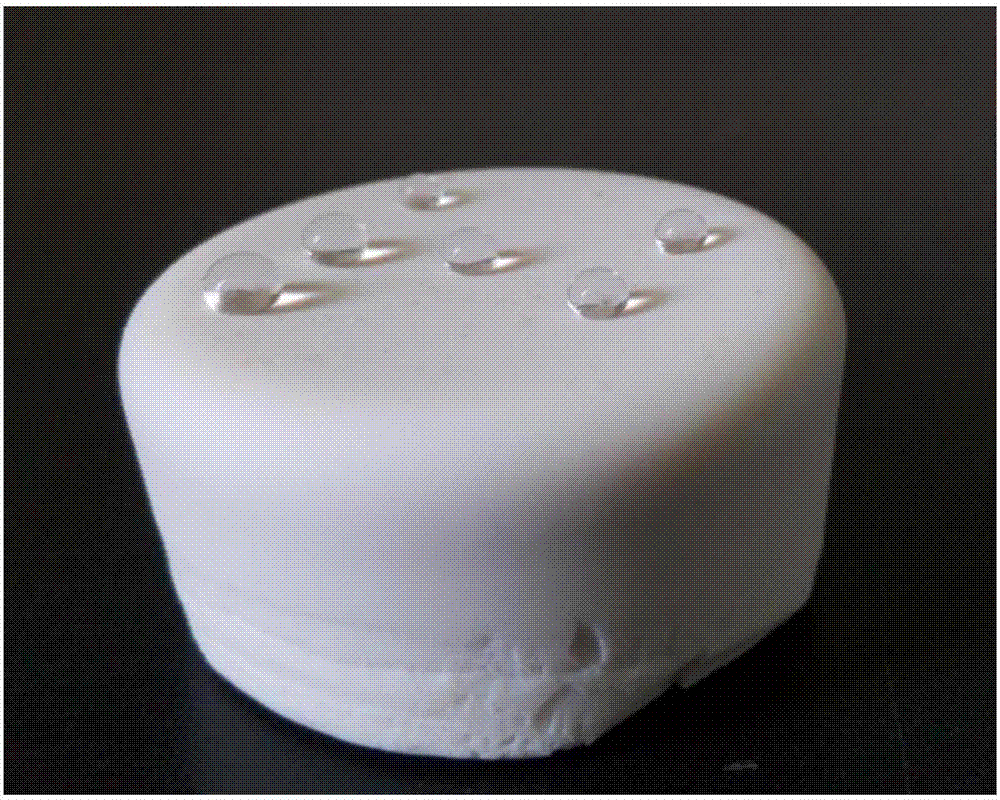

Preparation method of underwater ultraoleophobic and under-oil ultrahydrophobic membrane, and method of continuously separating light-oil/water/heavy-oil mixture therewith

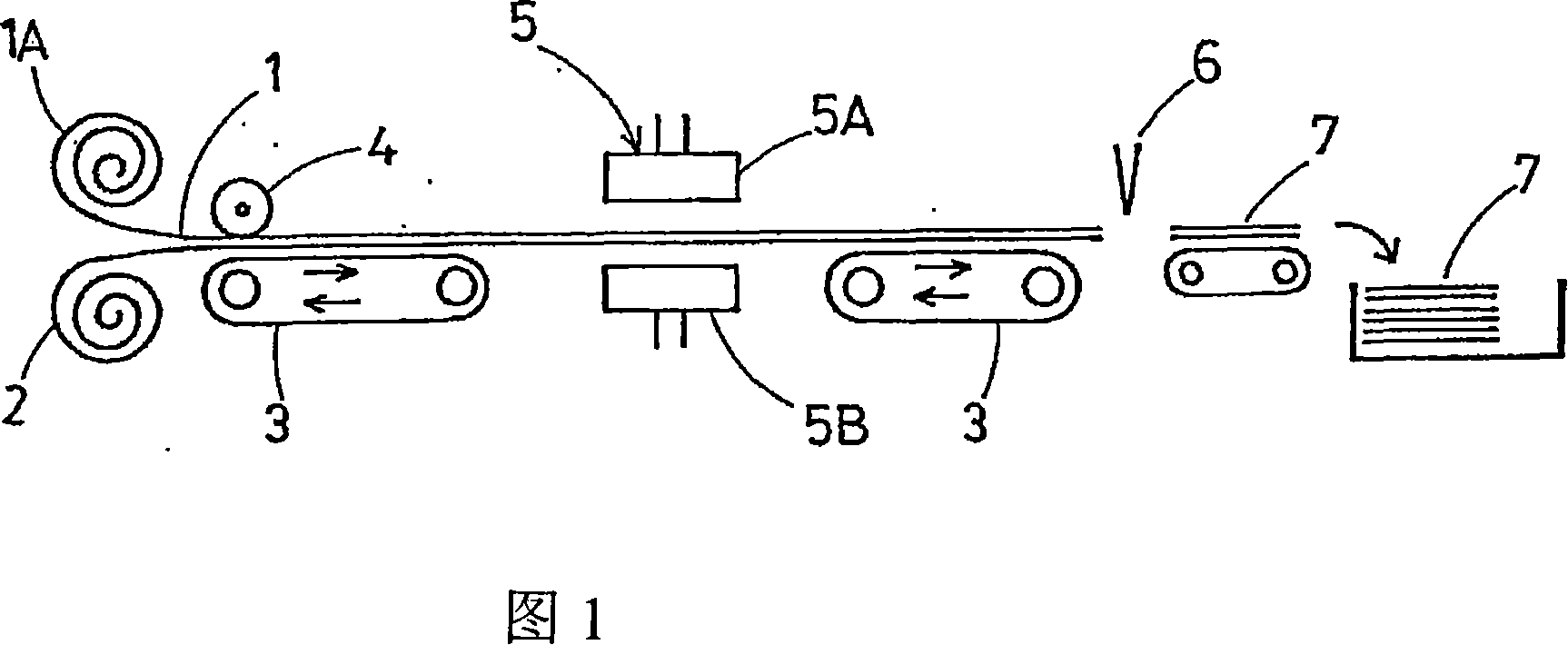

ActiveCN107096391ASimple methodRaw materials are easy to getSemi-permeable membranesMembranesSpray coatingOil water

A preparation method of an underwater ultraoleophobic and under-oil ultrahydrophobic membrane and a method of continuously separating a light-oil / water / heavy-oil mixture therewith. The invention relates to a preparation method of oil-water separation membrane and is direct at solving the problems that a membrane product in the prior art cannot be used for continuously separating a light-oil / water / heavy-oil three-phase mixture by single membrane through gravity, is high in preparation cost, has complex process, has disadvantage on industrial production and has poor chemical stability. The preparation method includes the steps of: 1) preparing a net-shaped base material; 2) preparing a coating dispersion liquid; and 3) performing spray coating. The method of separating the light-oil / water / heavy-oil mixture includes the steps of: 1) pre-wetting; and 2) continuous separation of the light-oil / water / heavy-oil mixture. The invention provides the preparation method of the underwater ultraoleophobic and under-oil ultrahydrophobic membrane and the method of continuously separating the light-oil / water / heavy-oil mixture therewith.

Owner:NORTHEAST FORESTRY UNIVERSITY

Cap agent with light alkaline particle steel coating

InactiveCN1778493AAvoid secondary oxidationSecondary oxidation will notProcess efficiency improvementChemical reactionRefractory

A light-weight alkaline particle used as the covering agent of steel ladle contains siO2 (18-26 Wt%), CaO (26-34), MgO (6-12), Al2O3 (5-8), Fe2O3 (0.5-2.0), and stabilized C (18-26). Its advantages are low specific bulk weight, high insulating performance, and high effect to prevent oxidization of molten steel and decrease the corrosion to refractory of ladle.

Owner:上海宝谊保温材料有限公司

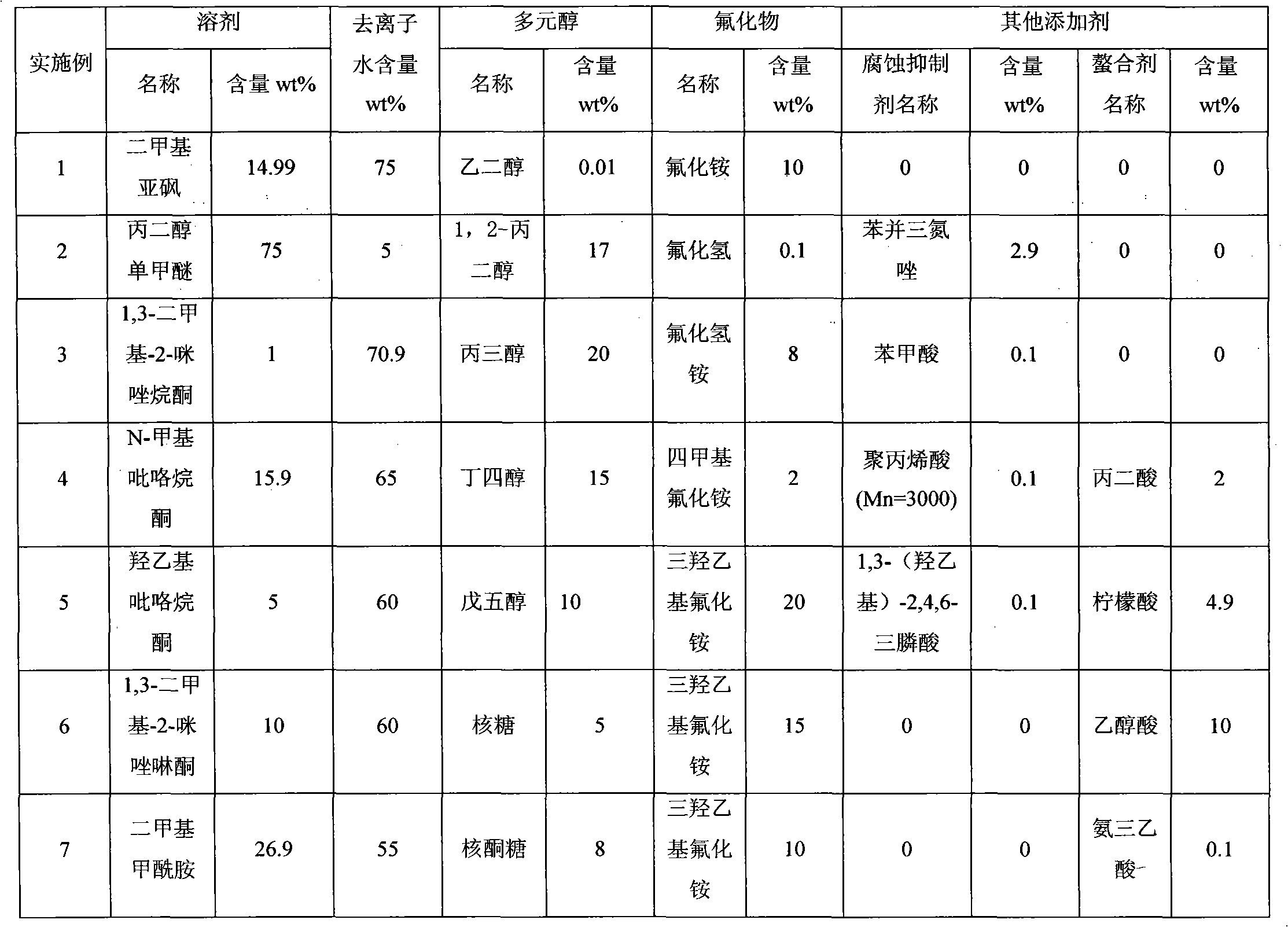

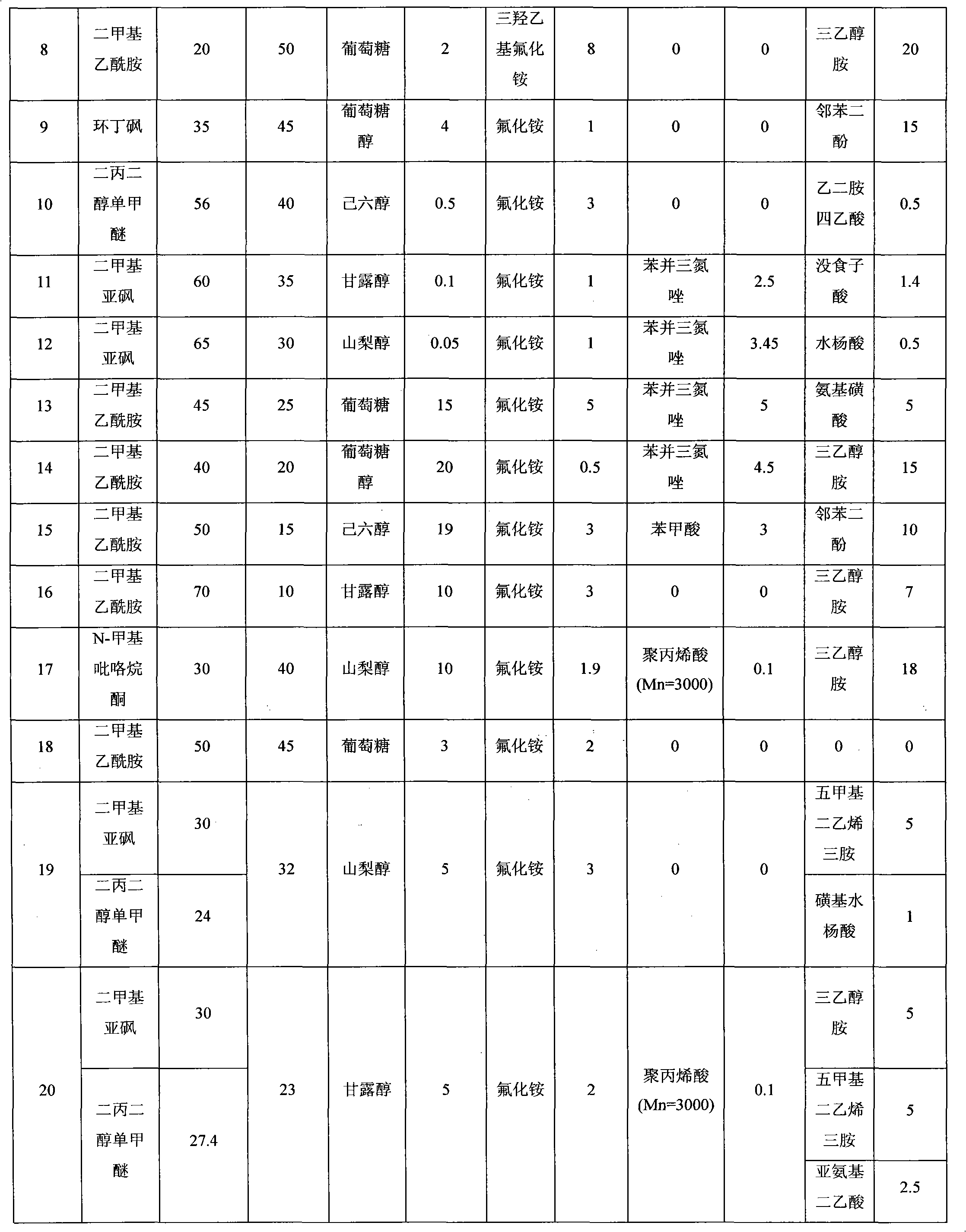

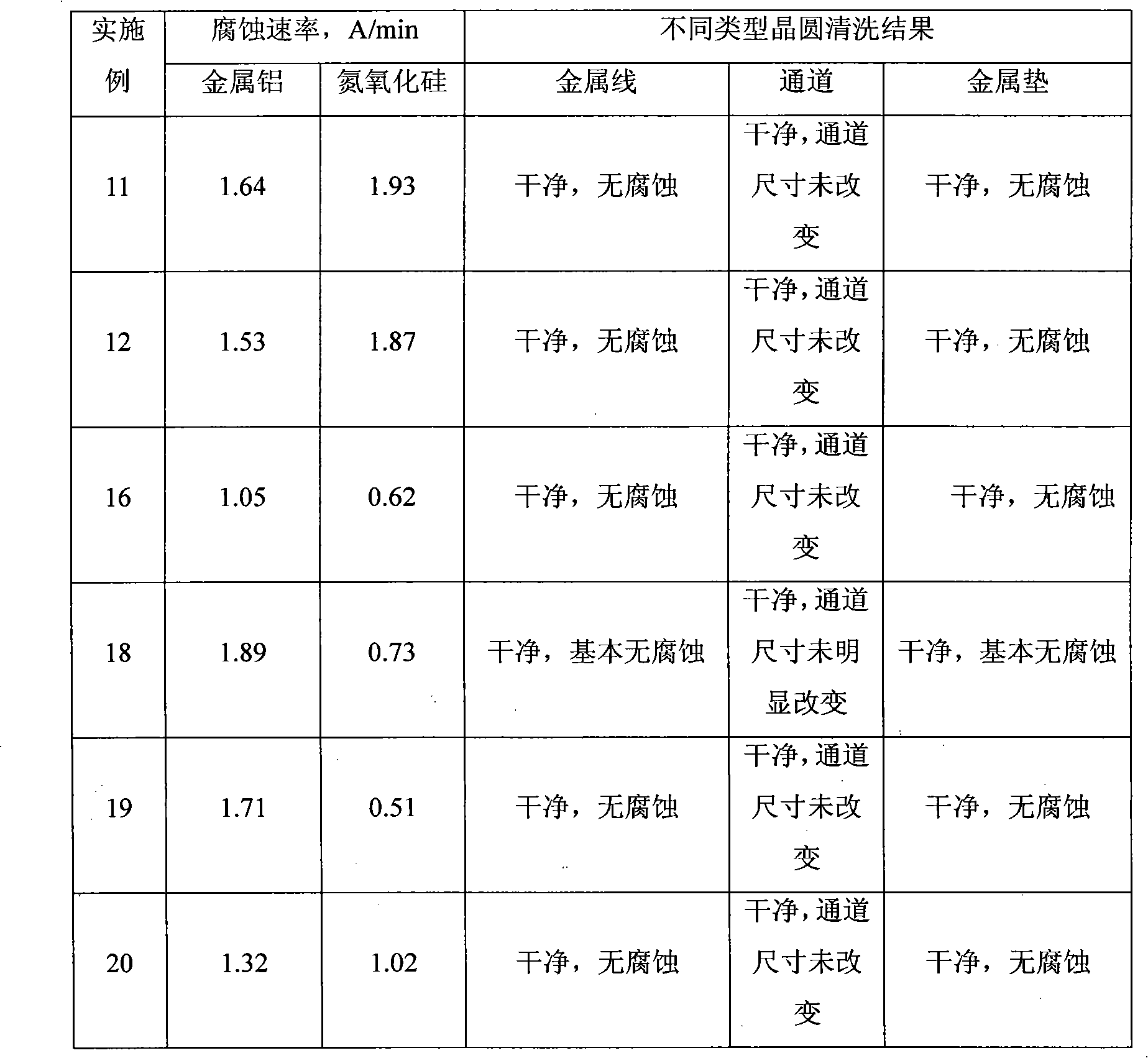

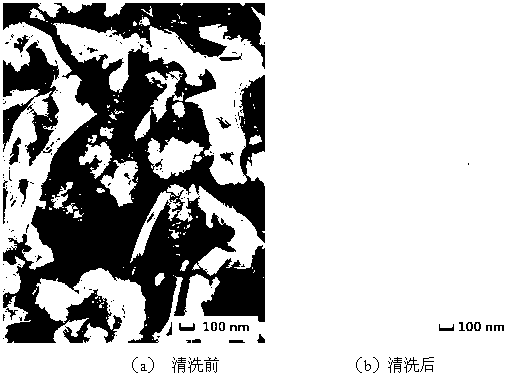

Fluorine-containing cleaning solution

ActiveCN102399648ASmall etch rateWon't corrodeDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventIon

The invention discloses a fluorine-containing cleaning solution with a low silicon oxynitride etching rate and for semiconductor industry use. The cleaning solution composition contains: a) 0.1%-20% of a fluoride, b) 0.01%-20% of polyols, c) 5%-75% of water, d) 1%-75% of a solvent, and e) 0-20% of other additives. The cleaning solution composition of the invention can effectively clean plasma etching residues during a semiconductor manufacturing process, and simultaneously has a low etching rate to base materials such as low dielectric materials (SiO2, PETEOS) and some metal substances (like Ti, Al, Cu) etc., and especially has a low silicon oxynitride etching rate. Therefore, the cleaning operation window of fluorine-containing cleaning solutions can be expanded, the service life of fluorine-containing cleaning solutions can be further enhanced, and the operation cost of semiconductor factories can be reduced. Thus, the fluorine-containing cleaning solution provided in the invention boasts good application prospects in microelectronic fields like semiconductor chip cleaning.

Owner:宁波安集微电子科技有限公司

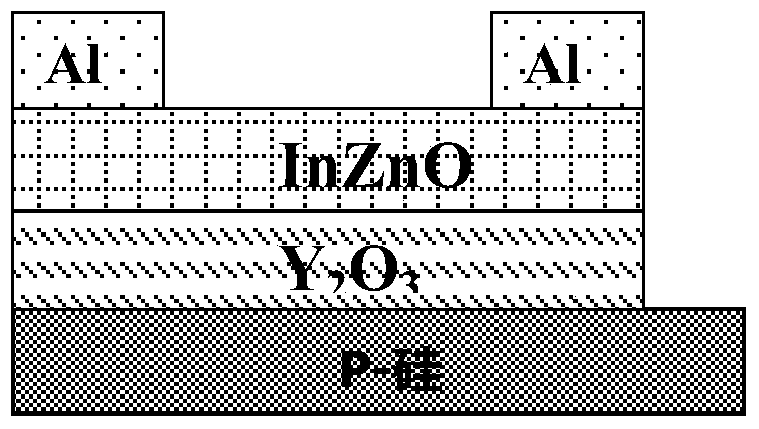

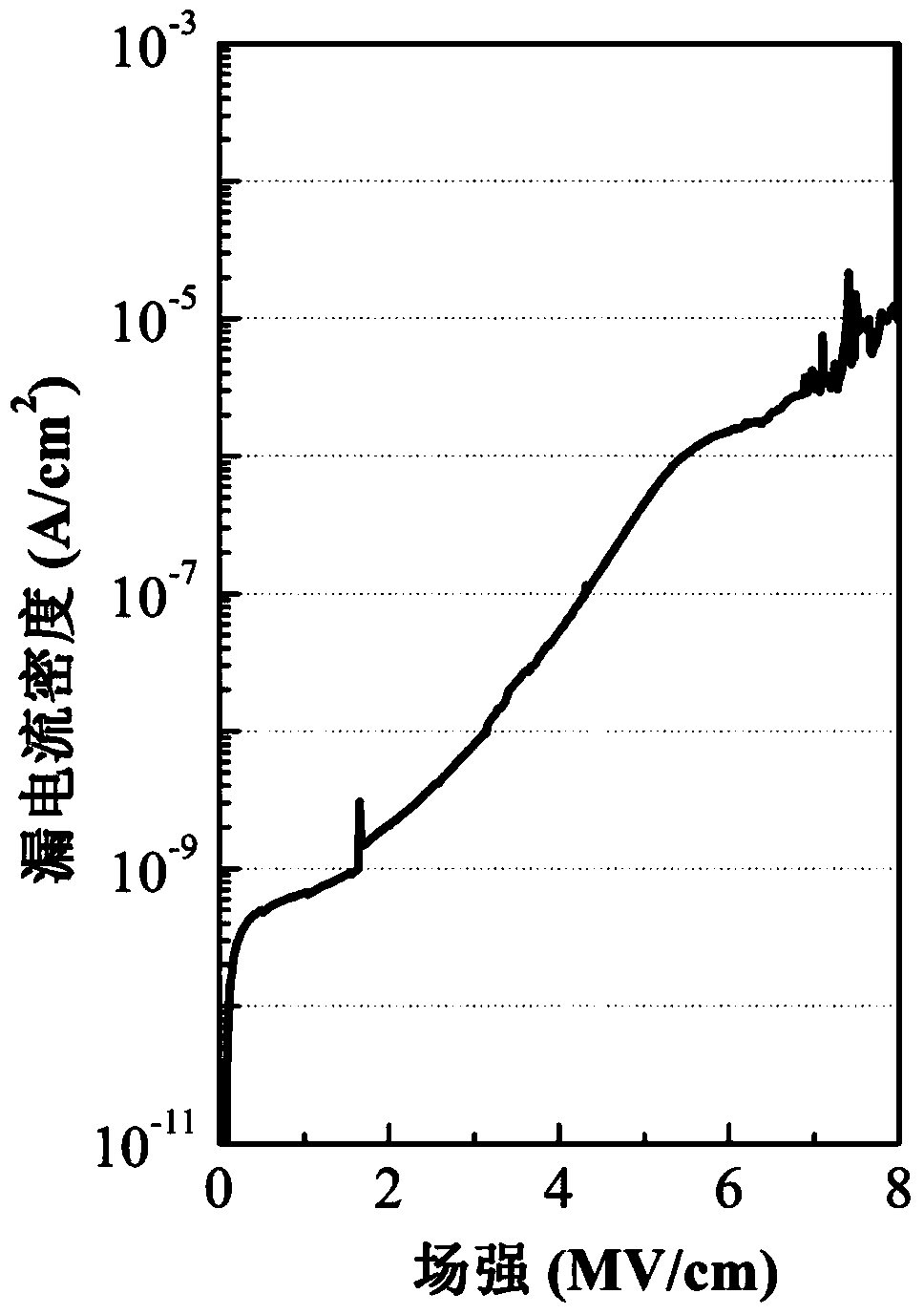

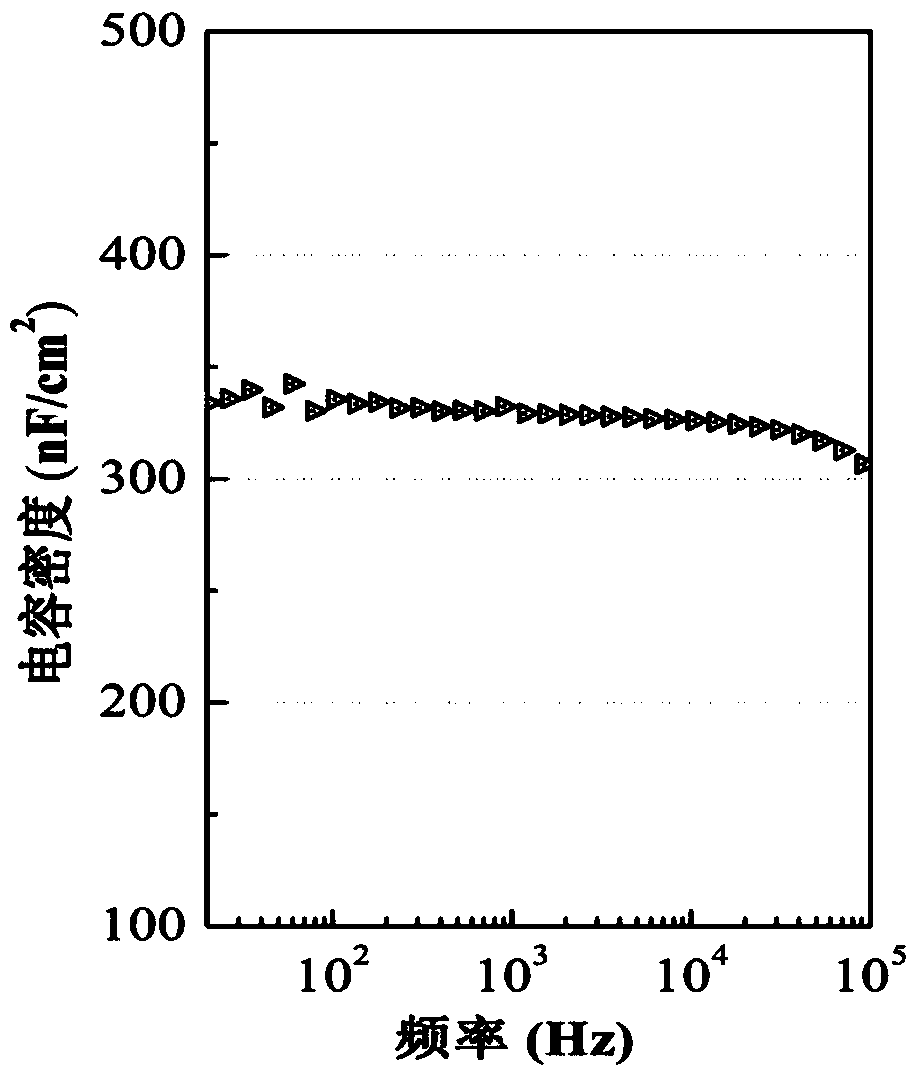

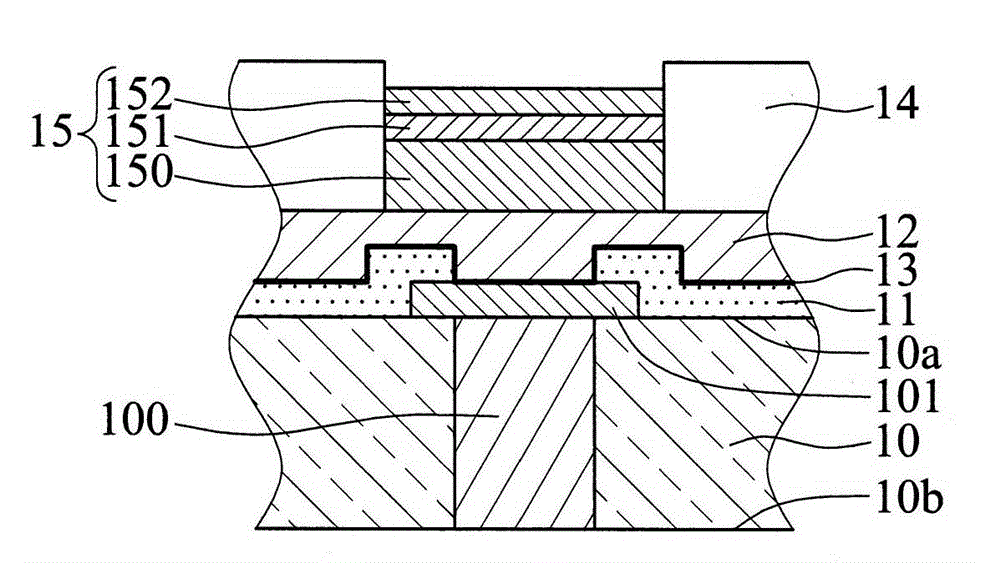

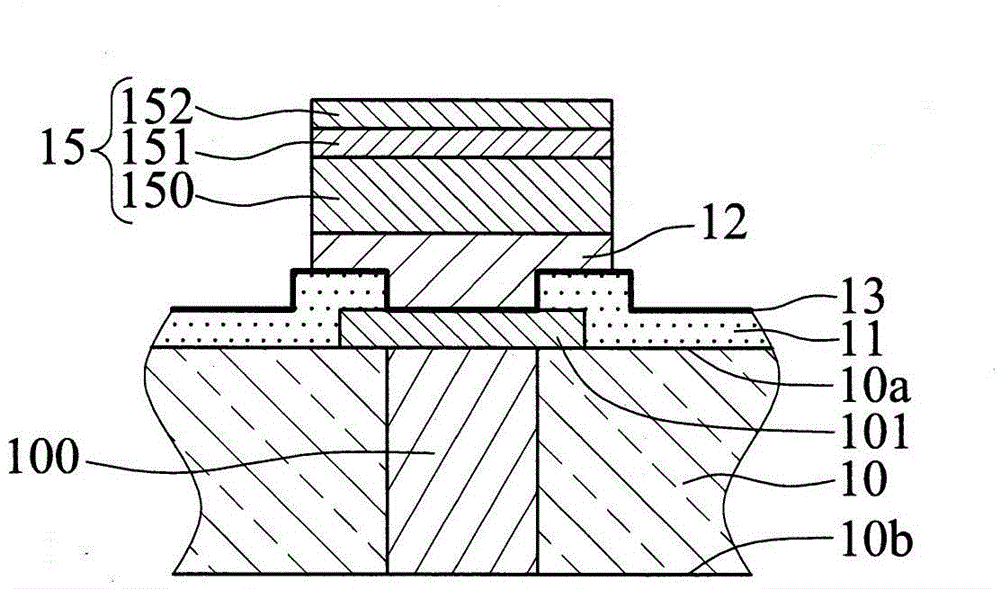

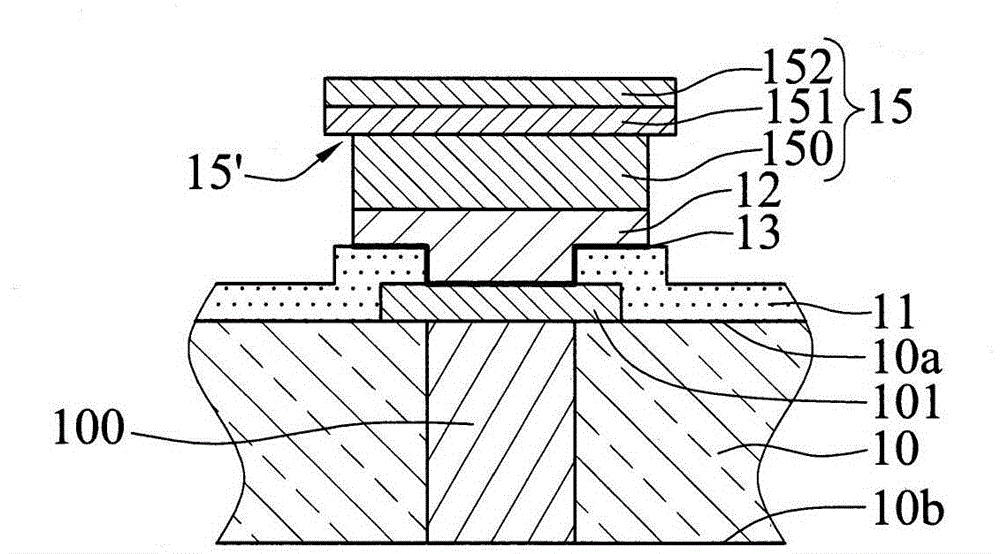

Preparation method for water solution thin film transistor

InactiveCN104201112ALow costAvoid high temperature impuritiesMaterial nanotechnologySemiconductor/solid-state device manufacturingIonYttrium

The invention belongs to the technical field of semiconductor thin film transistor preparation, and relates to a preparation method for a water solution thin film transistor. Firstly, yttrium nitrate is dissolved in deionized water, and a zirconia precursor solution is formed by magnetic force mixing; then, the surface of a low resistance silicon base is cleaned, and is coated with the precursor solution in a rotation manner; a Y2O3 film sample is obtained through baking and low temperature annealing; zinc nitrate and indium nitrate are respectively dissolved in deionized water, and an IZO water solution is formed through mixing; the Y2O3 film surface is coated with the IZO water solution in a rotation manner, is subjected to solidification treatment and low temperature annealing, so that an IZO gutter channel layer is obtained; finally, the vacuum thermal evaporation technology is adopted to prepare a metal source and an electric leakage pole on the IZO gutter channel layer, and the water solution thin film transistor based on ultrathin Y2O3 and high K dielectric layer is obtained. The overall embodiment is low in price; the technology is simple, the principle is reliable, the product performance is good, the preparation is environment-friendly, and the application prospect is wide.

Owner:QINGDAO UNIV

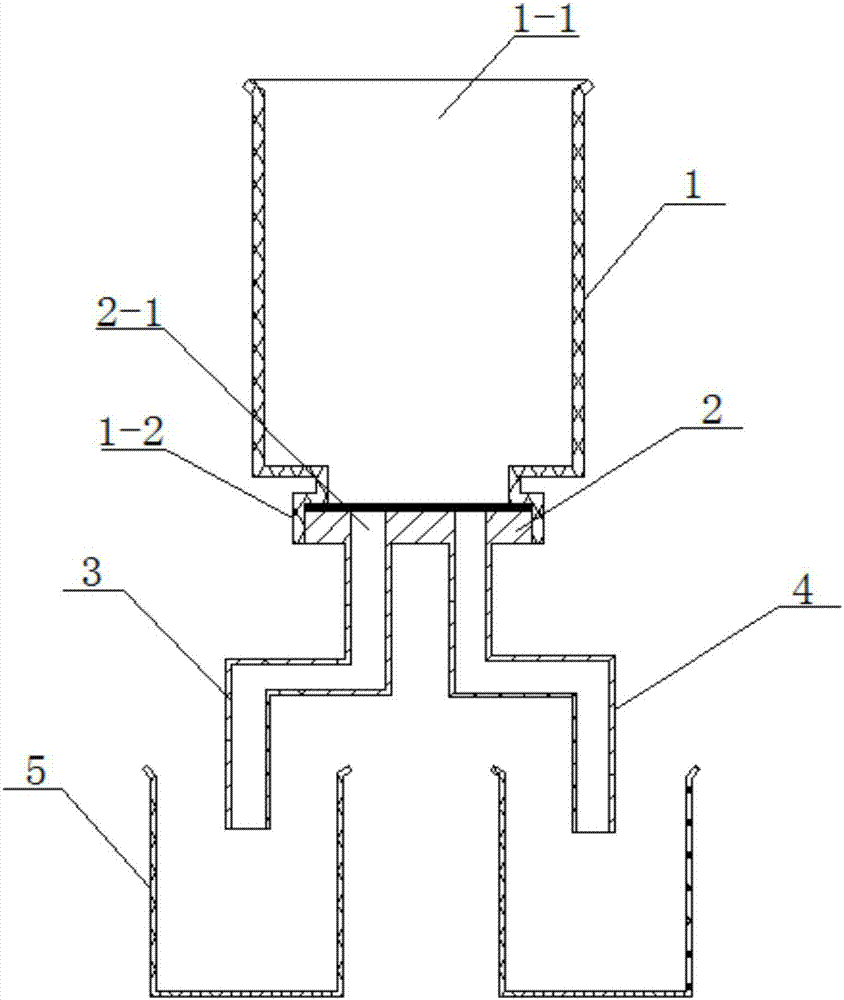

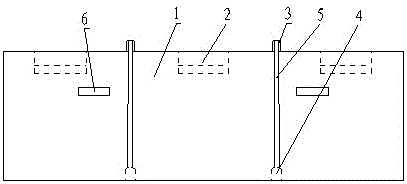

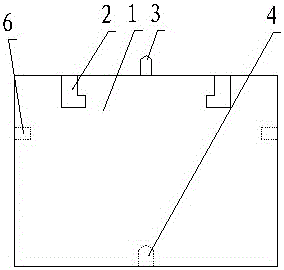

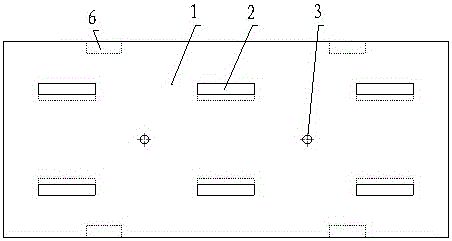

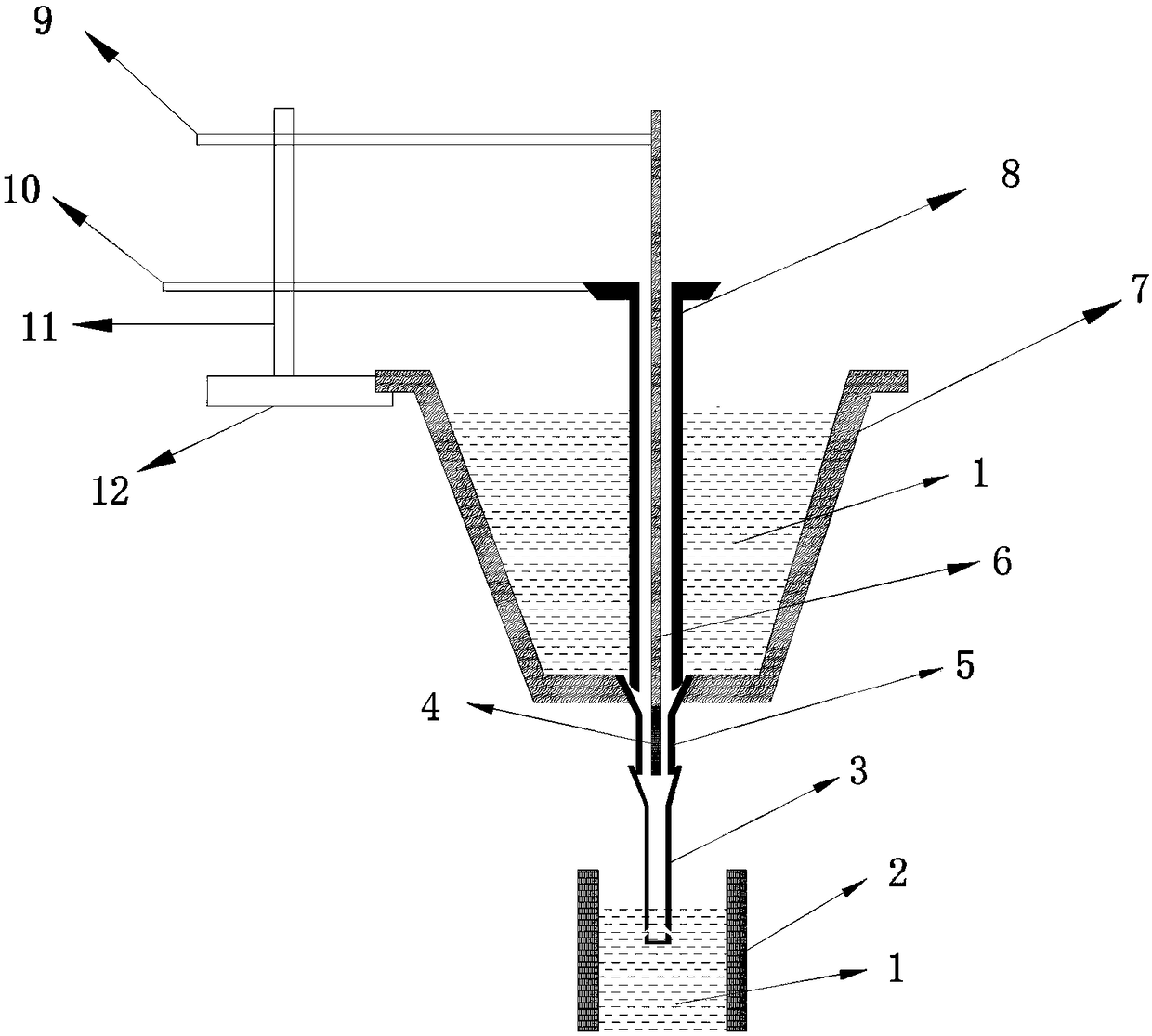

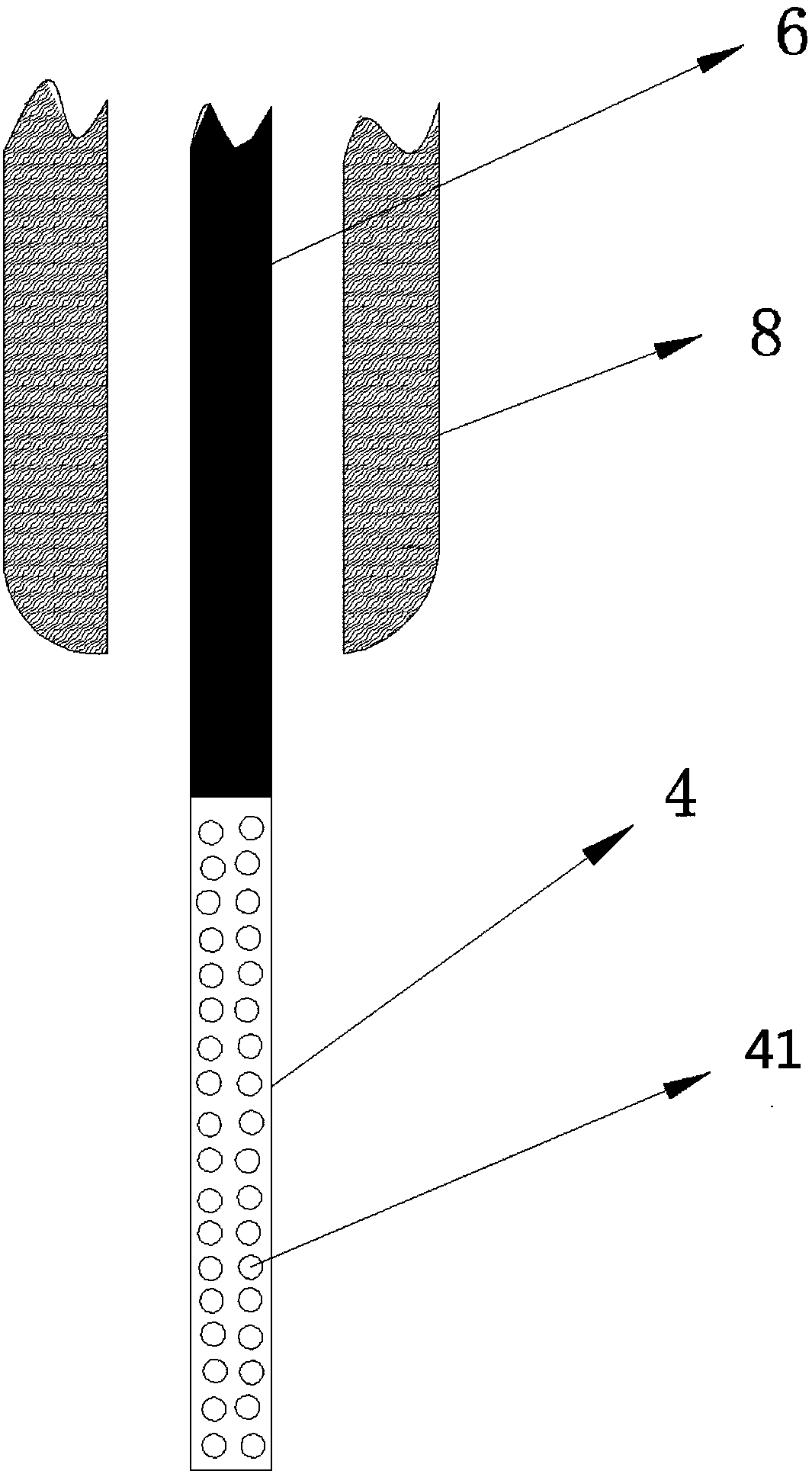

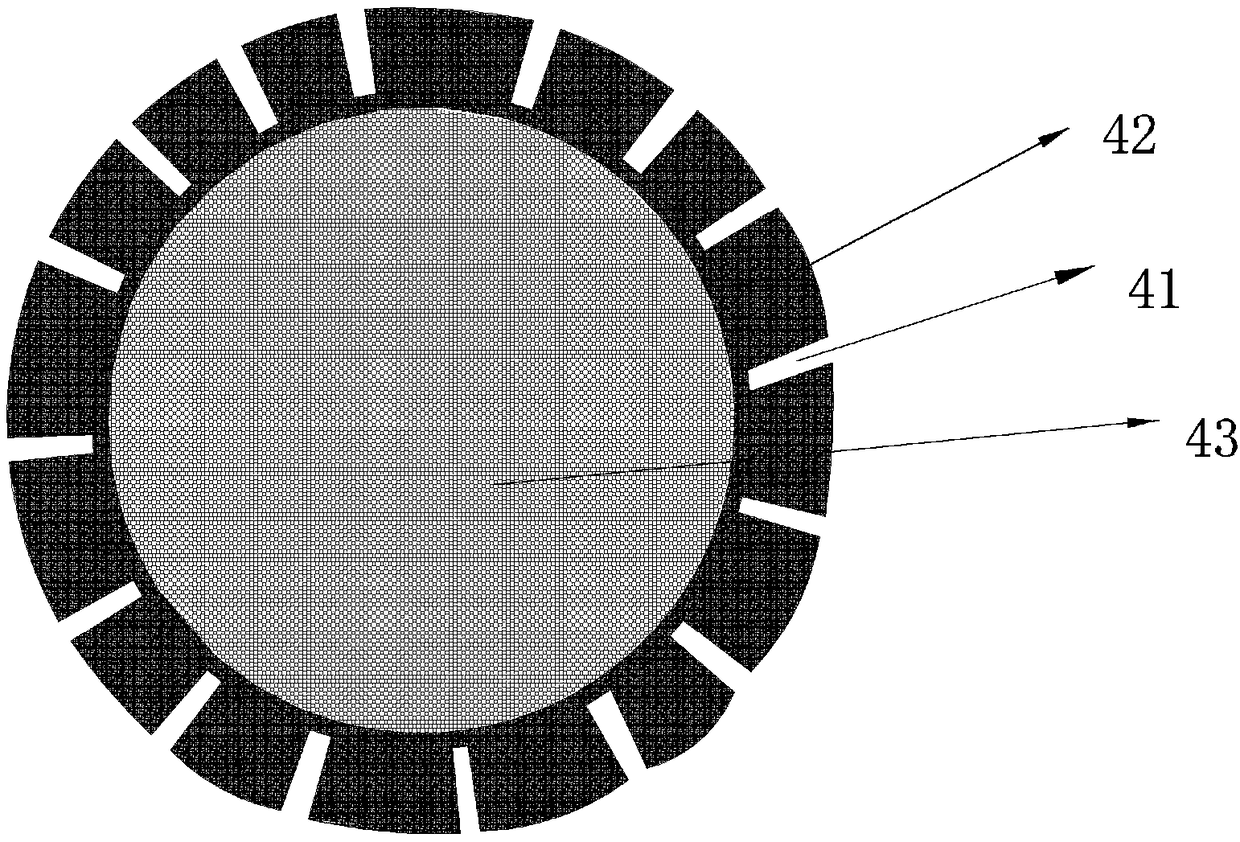

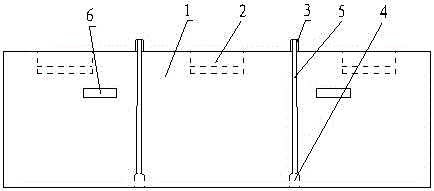

Aluminum electrolysis continuous production method and structure adopting prebaked anode

The invention discloses an aluminum electrolysis continuous production method and structure adopting a prebaked anode. The aluminum electrolysis continuous production method is characterized in that connection grooves (2) are formed in the upper portion of a carbon block body (1) of the anode and connected with a steel claw (7); and when the carbon block body (1) in an electrolytic cell needs to be connected, a new carbon block body (1) is placed above the old carbon block body (1), the new carbon block body (1) and the old carbon block body (1) are connected through fixing protruding heads (3) arranged at the tops of the carbon block bodies (1) needing to be connected and fixing grooves (4) formed in the bottoms of the connected carbon blocks (1) needing to be connected, and the new carbon block body (1) and the old carbon block body (1) are fixed together by filling gaps between the fixing protruding heads (3) and the fixing grooves (4) with sintering feed or pouring materials. According to the aluminum electrolysis continuous production method and structure adopting the prebaked anode, prebaked anode carbon blocks can be produced without anode scraps, the difference between an anode carbon block structure and an existing anode carbon block is not large, and the transformation on a production system is small. The transformation on an existing electrolytic cell is also small, only the connecting steel claw needs to be transformed, auxiliary hooks need to be additionally arranged, and transformation can be achieved without cell shutdown.

Owner:周俊和 +1

Device and method for cleaning tundish upper water gap nodules

ActiveCN108176844AImprove continuous casting outputReduce production lossMelt-holding vesselsEngineeringSteel bar

The invention belongs to the technical field of steel metallurgy and particularly relates to a device and method for cleaning tundish upper water gap nodules. In the continuous casting process, when the tundish upper water gap nodule phenomenon appears, the opening degree of a plug bar is turned down, the pulling speed is reduced to 20-30% of the normal pulling speed, a segment of round steel barcontaining a calcium core is inserted into the tundish upper water gap from the hollow plug bar, steel shells at concave points or concave lines are molten by steel liquid, concave holes or gaps appear in the surface of the periphery of the round steel bar, the calcium core inside the round steel bar is heated to be a gaseous state, the gaseous calcium is sprayed out from the concave holes or thegaps to Al2O3 nodules inside the tundish upper water gap, and the calcium reacts with the Al2O3 nodules. By means of the device and method for cleaning the tundish upper water gap nodules, the cleaning time for the Al2O3 nodules is just 1-5 minutes which is far less than the time for continuous casting order replacement, the improvement of continuous casting production quantity is facilitated, thecaused production loss is far less than that caused by the replacement of a tundish, the plug bar will not be eroded, and the service life of the plug bar will not be shortened.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

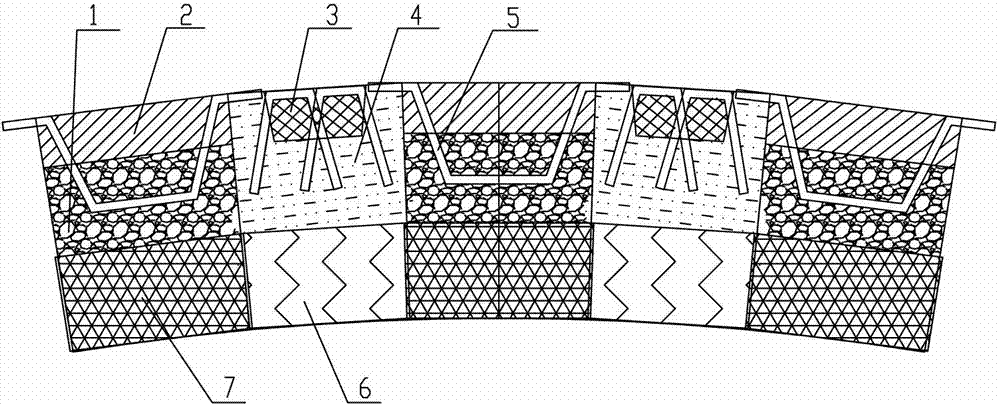

Method for preventing fireproof material of rotary kiln from falling down

The invention relates to the technical field of chain grate machine rotary kilns, and in particular relates to a method for preventing a fireproof material of a rotary kiln from falling down. According to the method, an annular fireproof material protection layer consisting of a prefabricated brick band arranged along an axial direction of the rotary kiln, a pouring band staggered from the prefabricated brick band and a kiln body anchoring nail is involved; a kiln head side and a kiln tail side of the inner surface of the annular fireproof material protection layer are low-temperature regions, and the middle of the annular fireproof material protection layer is a high-temperature region; and the prefabricated brick band is built by prefabricated bricks. The method is characterized by comprising the following steps of: arranging fiber paper in a working region around the prefabricated bricks, wherein the fiber paper is 100 to 120 mm high and 1 to 2 mm thick; arranging an expansion slit in the working region of the pouring band at every 1 to 2 m; arranging an expansion board in each expansion slit, wherein the expansion board is 100 to 120 mm high and 4 to 6 mm thick; and smearing two layers of asphalt on the surface of the kiln body anchoring nail, so that the expansion board is matched with the expansion slit. By the method, thermal stress caused by expansion inconsistency of the fireproof material and a steel structure is eliminated; and the fireproof material can be prevented from falling down.

Owner:NORTHERN ENG & TECH CORP MCC

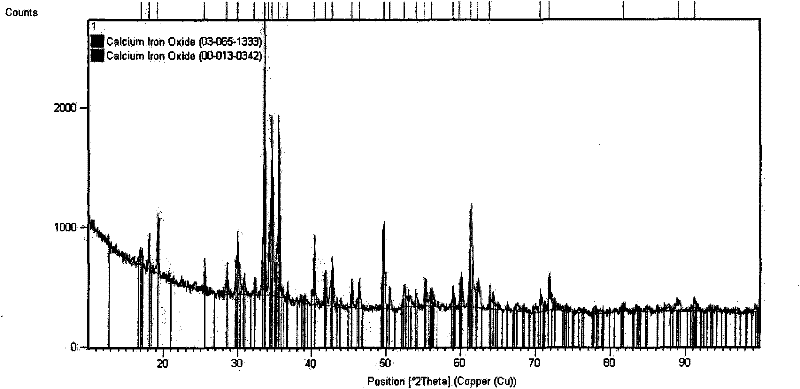

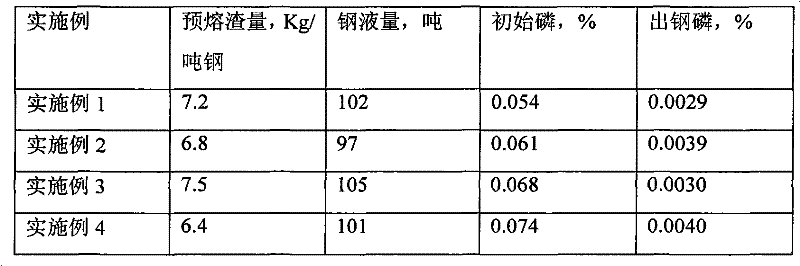

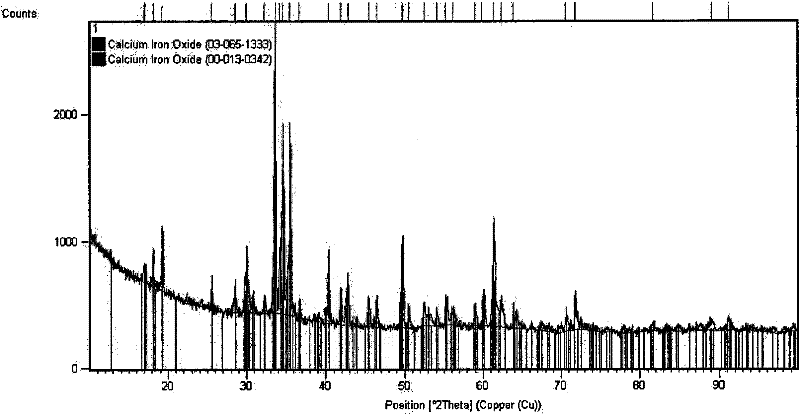

A new type of premelted dephosphorization agent for steelmaking and its preparation method

InactiveCN102296153AUniform compositionNo pollution in the processManufacturing convertersSteelmakingGranularity

The present invention is a novel premelted dephosphorization agent for steelmaking and its preparation method, the purpose of which is to provide a high-efficiency premelted dephosphorization agent suitable for steelmaking to overcome the defects of the above-mentioned various converter steelmaking dephosphorization materials . The composition and mass percentage of the pre-melted dephosphorization agent of the present invention are: CaO: 25%-40%, Fe2O3: 45%-65%, BaO: 0.1-10% Other impurities (MgO\Al2O3\SiO2)≤5.0 %. The sum of the mass percentages of the above components is 100%; the particle size of the pre-melted slag material is 1-100 mm. The composition of the pre-melted slag of the present invention is uniform and stable, has a low melting point (1210°C-1260°C), suitable viscosity (at 1400°C, 0.01-0.05Pa·S), good fluidity, and fast melting speed; creating a fluorine-free melting point Low and efficient dephosphorization and stable dephosphorization materials for steelmaking, the terminal phosphorus can reach below 0.004%.

Owner:LIAONING TIANHE TECH

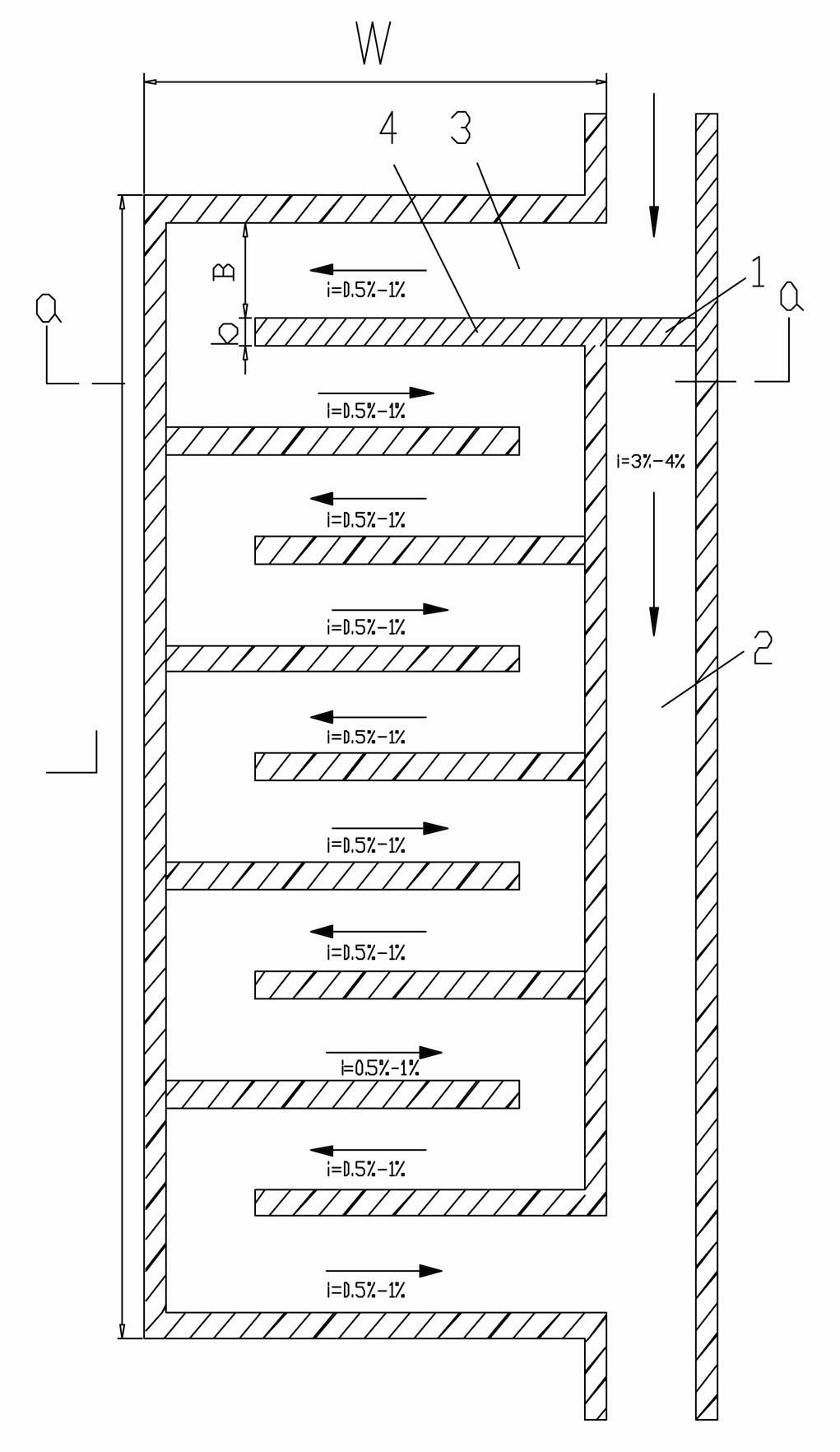

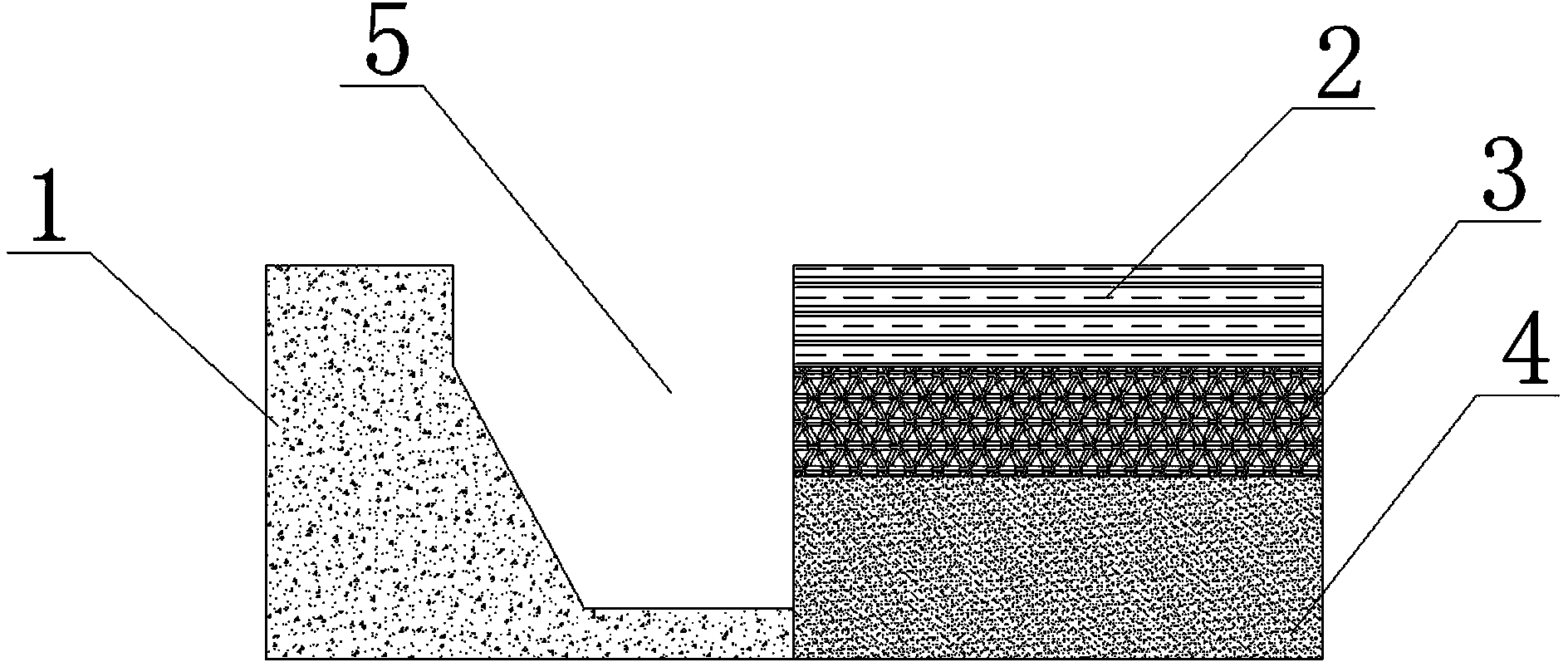

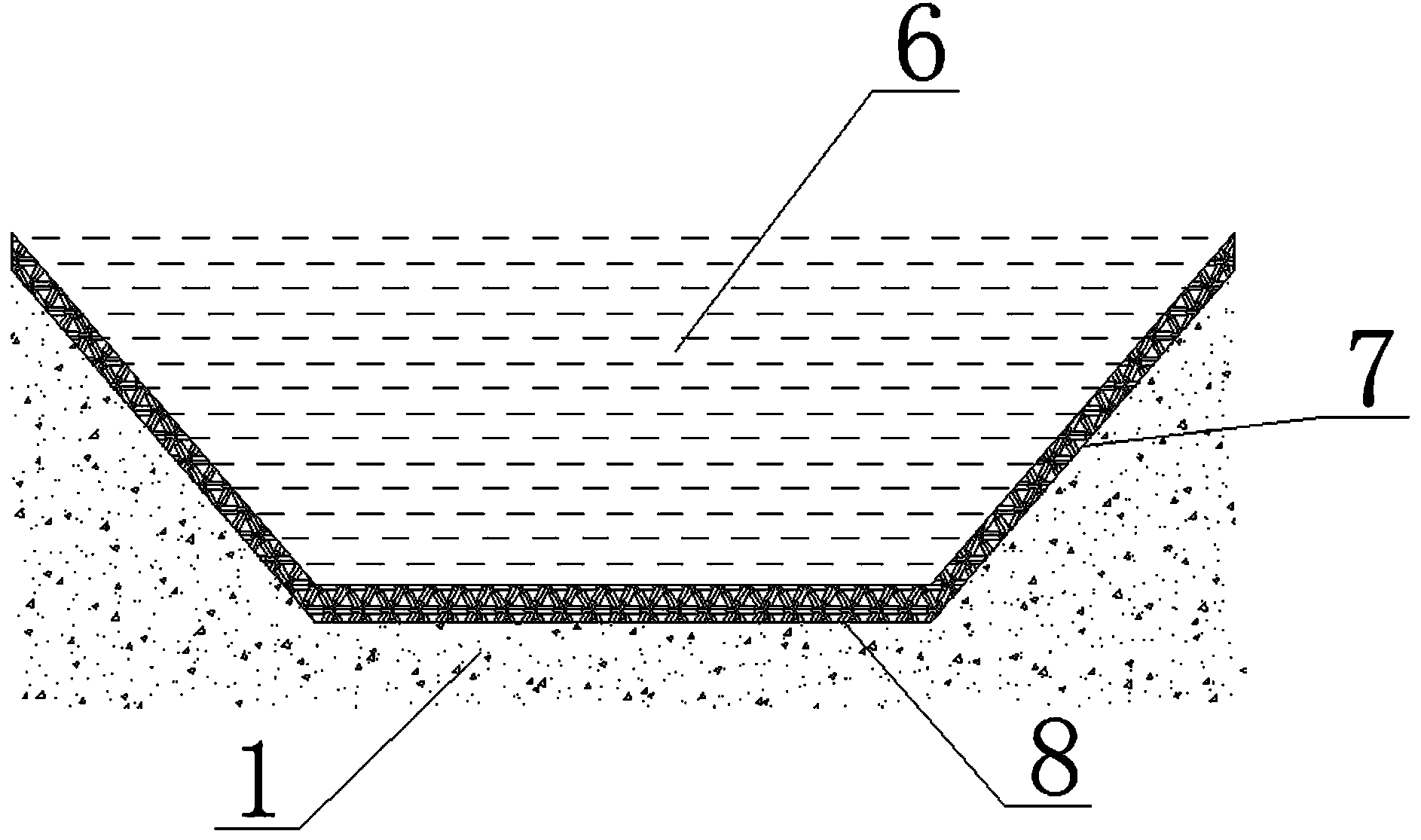

Water drainage open channel for treating and controlling runoff of rainwater of residential areas in baffling manner

InactiveCN102505750AStrong enough to handle heavy rainWon't corrodeClimate change adaptationSewage drainingEngineeringStorm water runoff

The invention discloses a water drainage open channel for treating and controlling runoff of rainwater of residential areas in a baffling manner, which comprises a water drainage open channel body arranged under a green space of a residential area or / and beside a road. The top of the water drainage open channel body is rectangular while the bottom of the water drainage open channel body is inclined, a water inlet is arranged at a short edge of the water drainage open channel body, and a water outlet is arranged on another short edge of the water drainage open channel body. The water drainage open channel is characterized in that an external water drainage ditch is arranged in the water drainage open channel body along a long edge; and a plurality of baffling galleries which are perpendicular to the external water drainage ditch and are connected end to end are disposed in the water drainage open channel body. The baffling type water drainage open channel which is coordinated with a water drainage ditch of the residential area is designed besides green buildings, green spaces and roads of the residential area, so that a rainwater runoff path is elongated, emergence time of rainwater flow peak of the residential area is delayed, the time for the rainwater to flow into an urban rainwater pipe network is delayed, flood drainage pressure of the urban rainwater pipe network when in storm days is reduced, and possibility of urban waterlogging is reduced.

Owner:CHONGQING UNIV

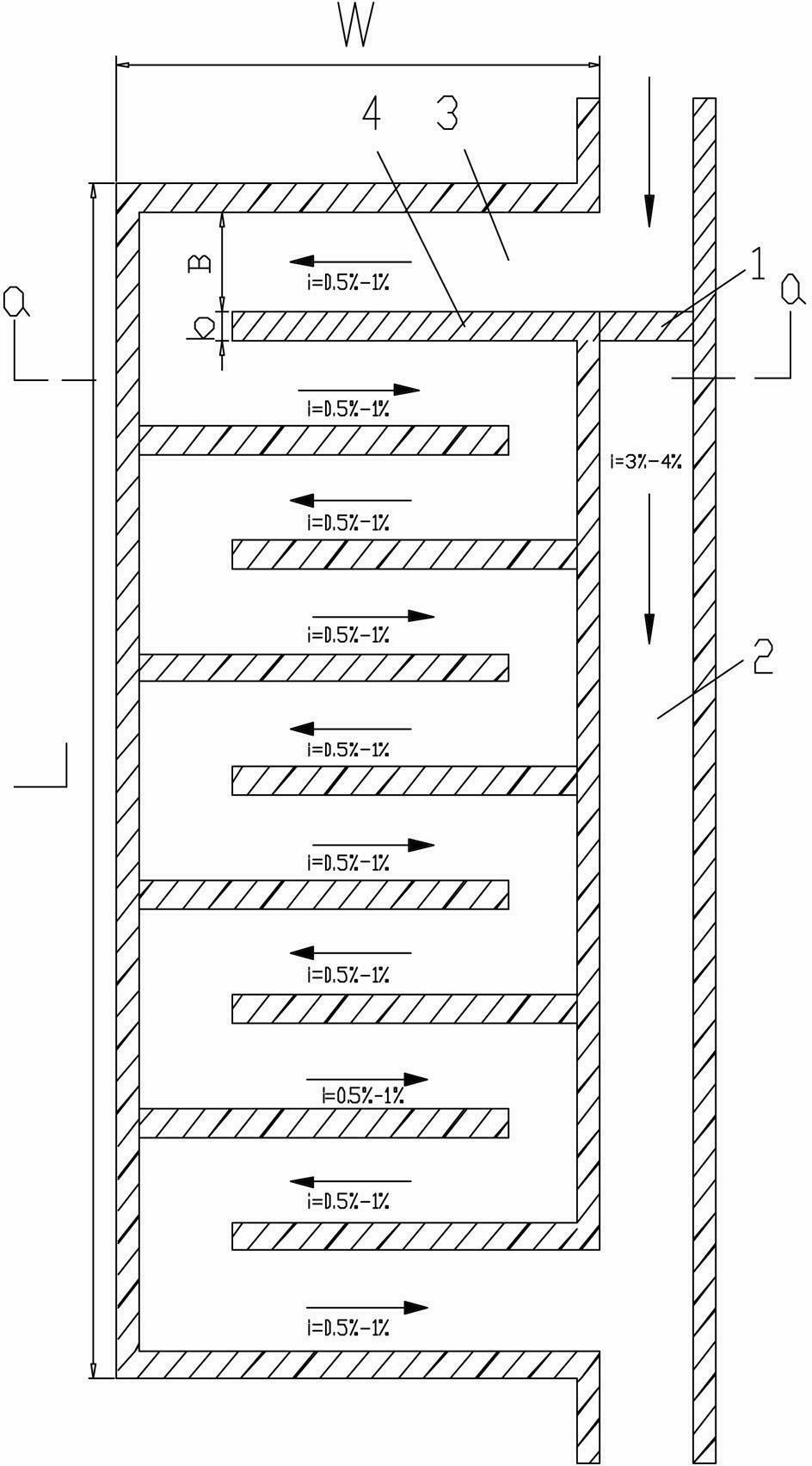

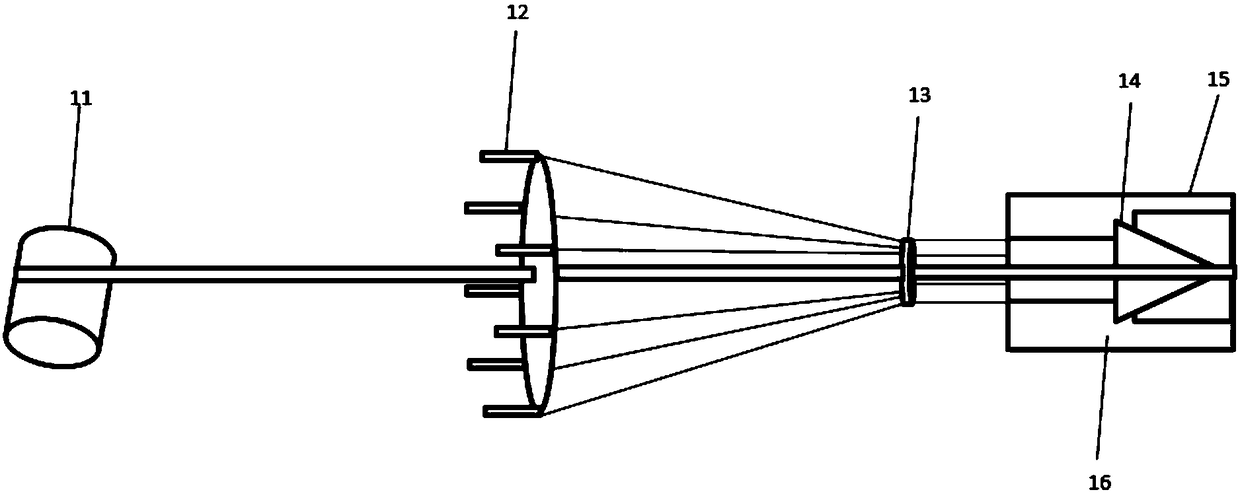

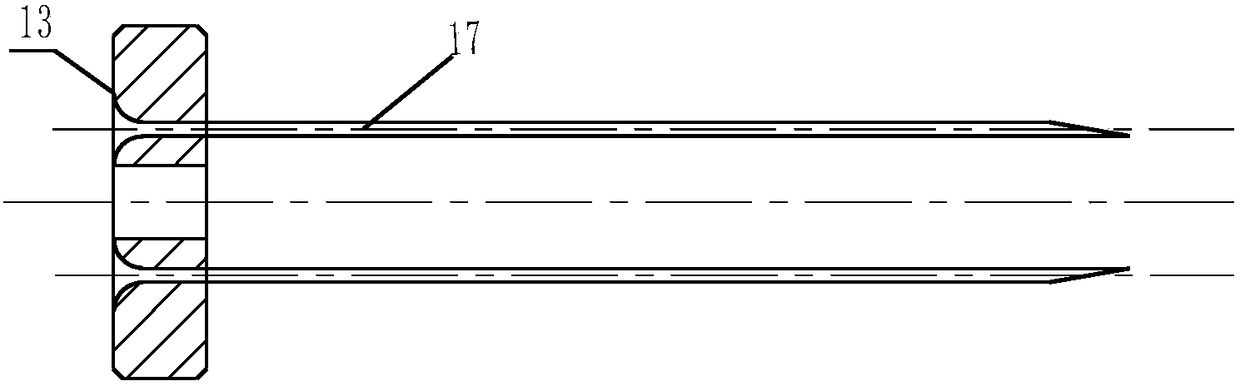

Tiny hole cleaning method

ActiveCN103008293AAvoid recontaminationWon't corrodeCleaning processes and apparatusSurface oxidationCleansing Agents

The invention discloses a tiny hole cleaning method. Plasma is generated through a laser shock target material; a tiny hole is arranged in a plasma plume; the included angle between a connecting line of a laser shock point and a tiny hole axis as well as an incident laser direction is 30-60 degrees; the length of the plasma plume is larger than the length of the tiny hole, and the width of the plasma plume is larger than the width of the tiny hole. With the adoption of the tiny hole cleaning method, the tiny hole is cleaned by adopting a manner that the plasma plume is shocked by a laser, so that secondary pollution generated by a cleaning agent can be avoided, and the tiny hole cleaning method can play a role on the surface of an inner wall of the tiny hole and cannot corrode the inner part of the tiny hole, therefore impurities and surface oxidation can be effectively removed.

Owner:JIANGSU UNIV

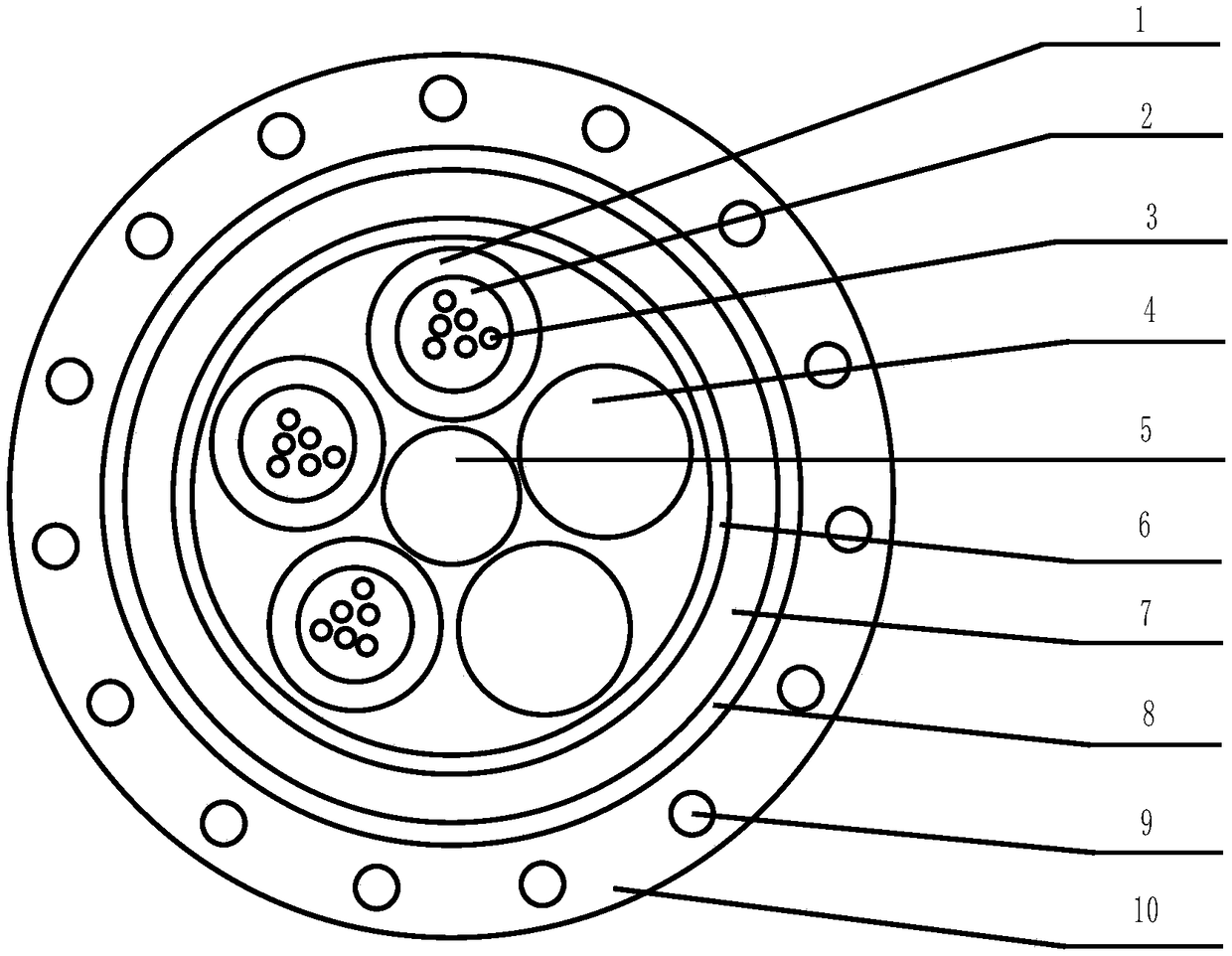

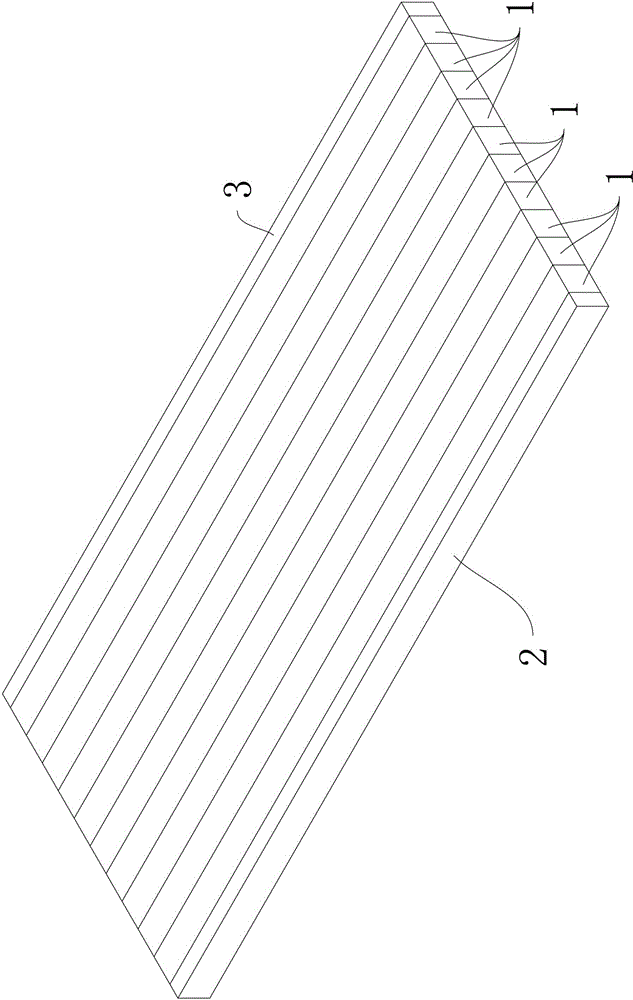

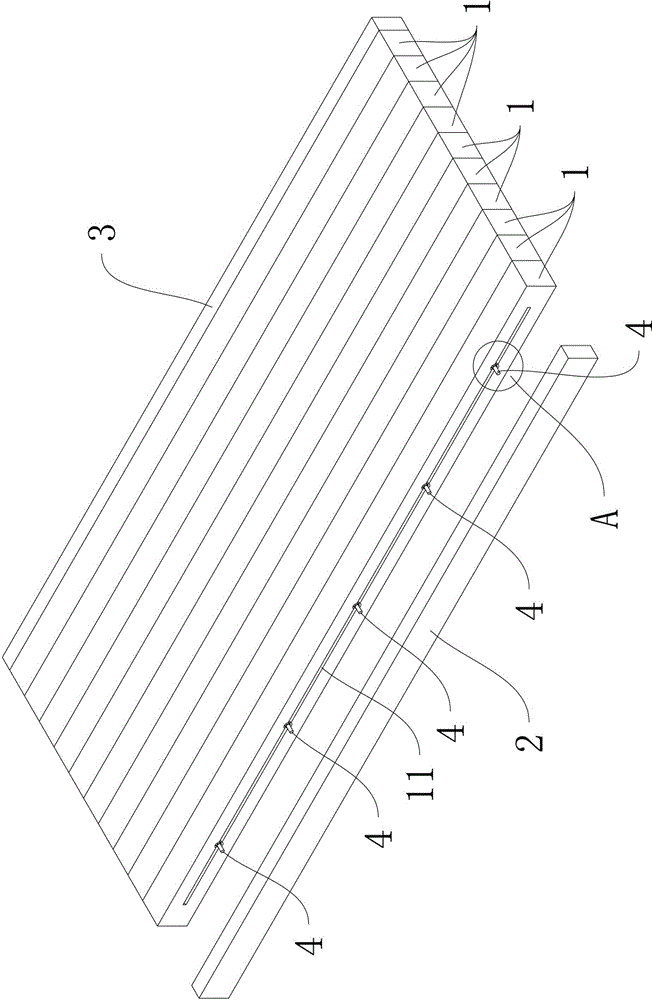

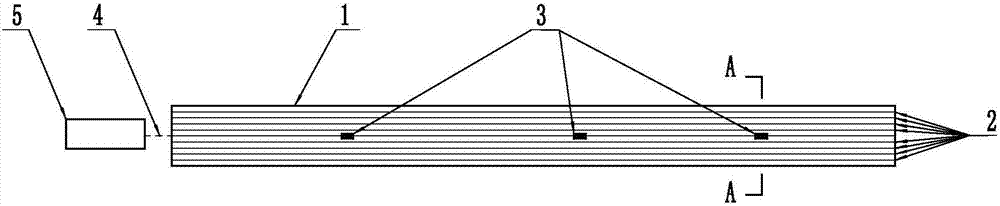

Non-metal yarn inlaid ratproof optical cable and manufacturing method thereof

InactiveCN108363152ARound appearancePrevent destructionFibre mechanical structuresBlocking layerYarn

The invention discloses a non-metal yarn inlaid ratproof optical cable and a manufacturing method thereof. The optical cable comprises an optical cable outer sheath and an optical cable inner sheath.A stainless steel belt armor layer is arranged in the inner sheath. Glass fiber yarn is inlaid in the outer sheath. The outer sheath and the inner sheath are separated by a water blocking layer. A cable core formed by SZ stranding a central reinforcing member and a PBT loose sleeve is arranged in the stainless steel belt armor layer. The PBT loose sleeve contains at least two or more colored optical fibers. The colored optical fibers are surrounded by a sleeve filler. The method comprises the steps of optical fiber coloring, cable core manufacturing through PBT optical fiber oil-filled loose sleeve stranding, stainless steel belt armor polyethylene inner sheath manufacturing, water blocking belt longitudinal wrapping, water-blocking glass fiber yarn manufacturing and glass fiber yarn inlaying in the polyethylene outer sheath, namely non-metal yarn inlaid ratproof optical cable molding. The optical cable has the advantages of good bending performance and light weight, is soft, and is prevented from the damage of rats and environmental erosion. The structure of the optical cable is stable during the service life thereof.

Owner:FURUKAWA ELECTRIC XIAN OPTICAL COMM

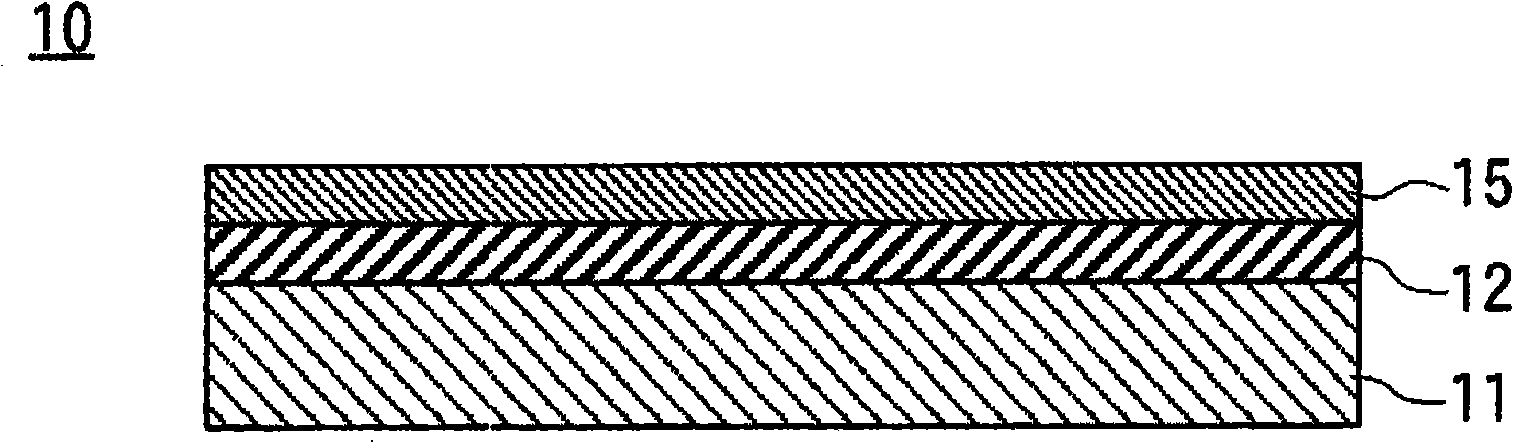

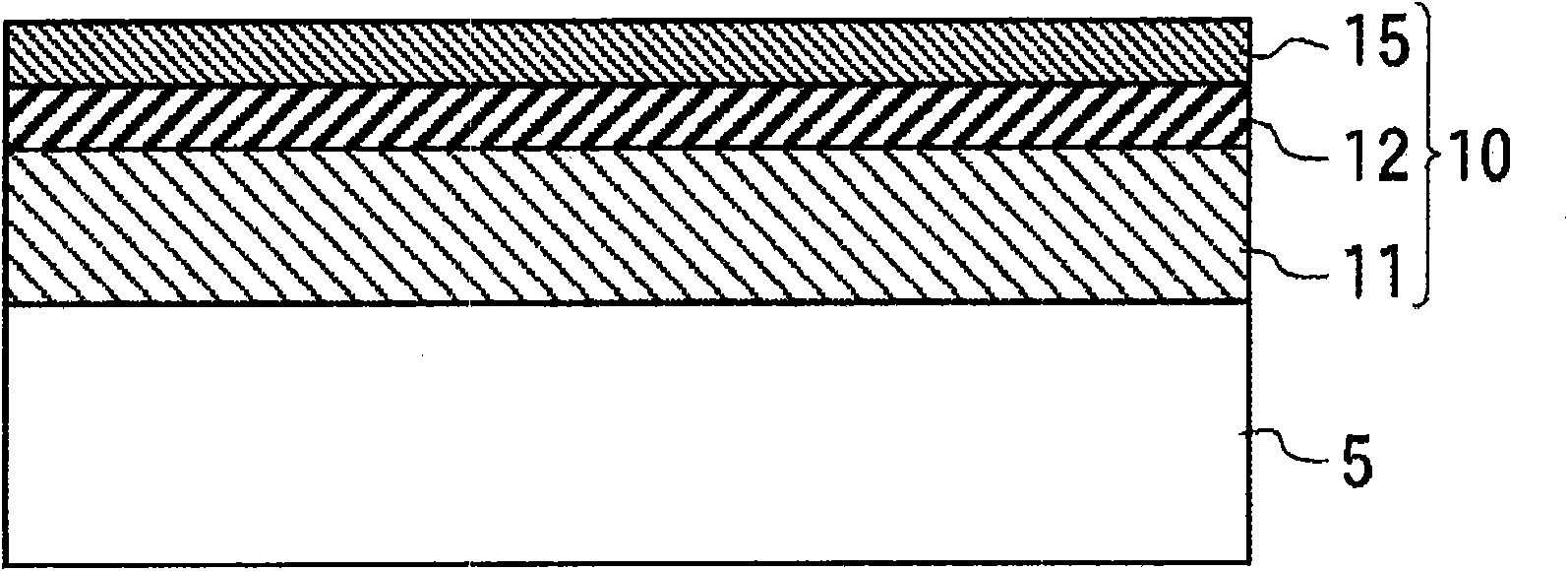

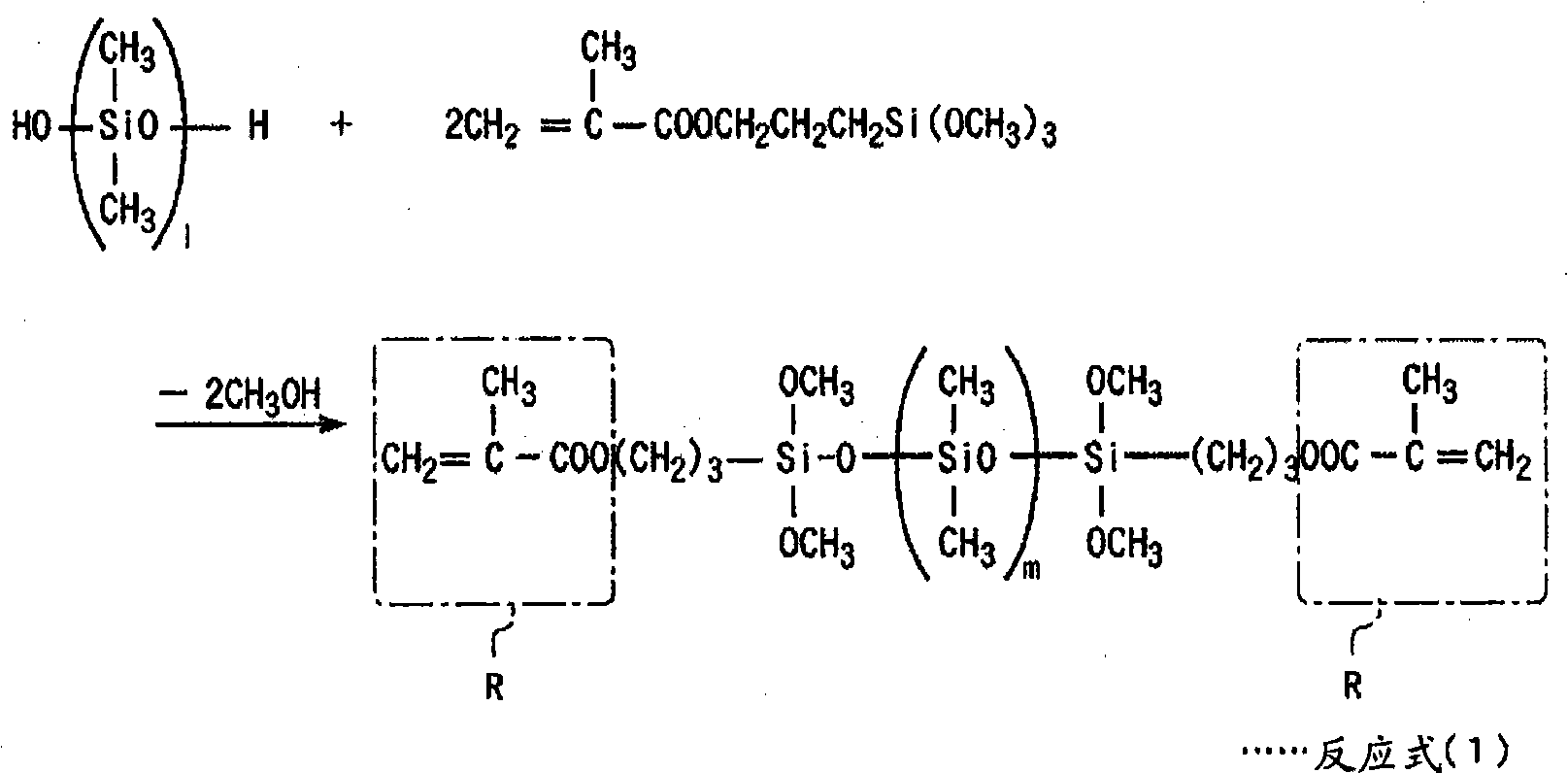

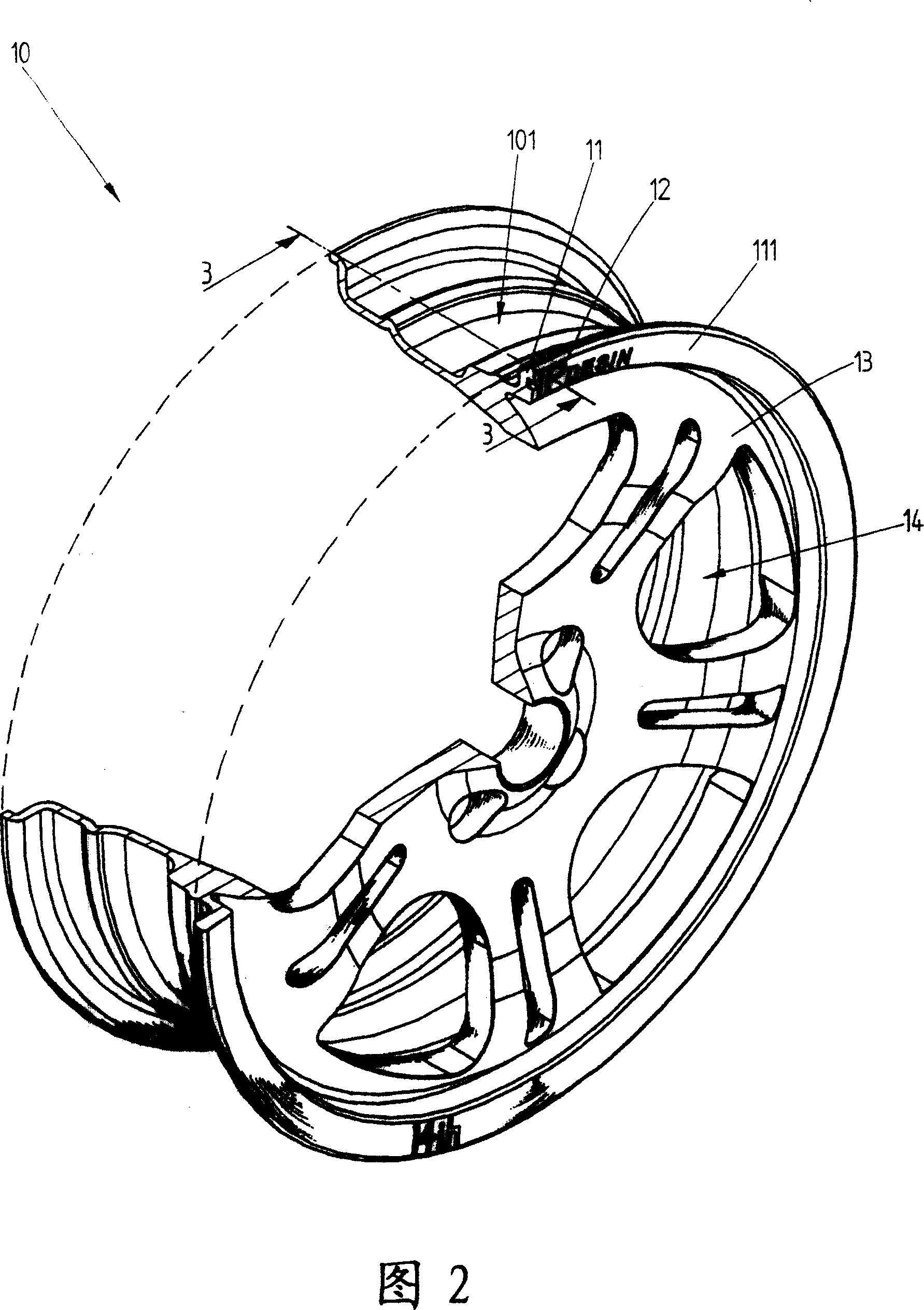

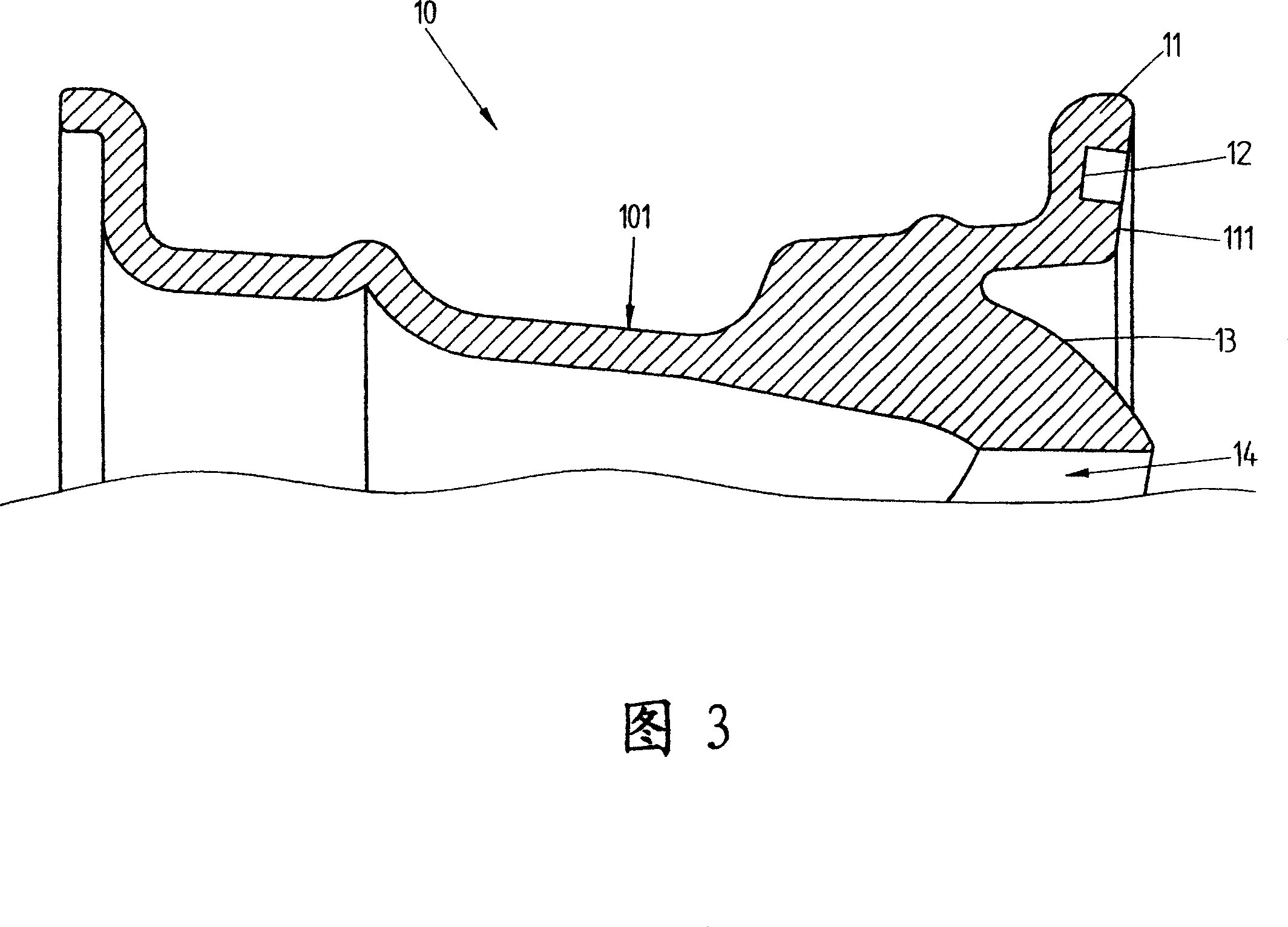

Antireflection film

ActiveCN101784916ALow refractive indexWon't corrodeSynthetic resin layered productsAnti-reflective coatingsSilica particleMeth-

Disclosed is an antireflection film having high antifouling property. Specifically disclosed is an antireflection film (10) comprising a transparent base (11), a high refractive index layer (12) and a low refractive index layer (15). The low refractive index layer (15) is made of a cured product of a polymerizable composition which contains hollow fine particles such as hollow silica particles, a modified silicone compound, and a second resin component such as a polyfunctional (meth)acrylate.

Owner:DEXERIALS CORP

Cleaning liquid composition for plasma etching residues in semi-conductor industry

InactiveCN101126053AImprove corrosion inhibitionApplicable environment is goodOrganic detergent compounding agentsDetergent mixture composition preparationSolventPolymer

The invention discloses a cleaning liquid combination used for removing plasma-etching residue in semiconductor industry. The cleaning liquid comprises amount of solvent used for effectively washing, buffer aqueous solution, fluoride, antifreeze agent, polymer inhibitor. The cleaning liquid combination of the invention can effectively clean plasma-etching residue in semiconductor industry without eroding SiO2, PETEOS, silicon, low medium material and some metals such as Ti, Al and Cu.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

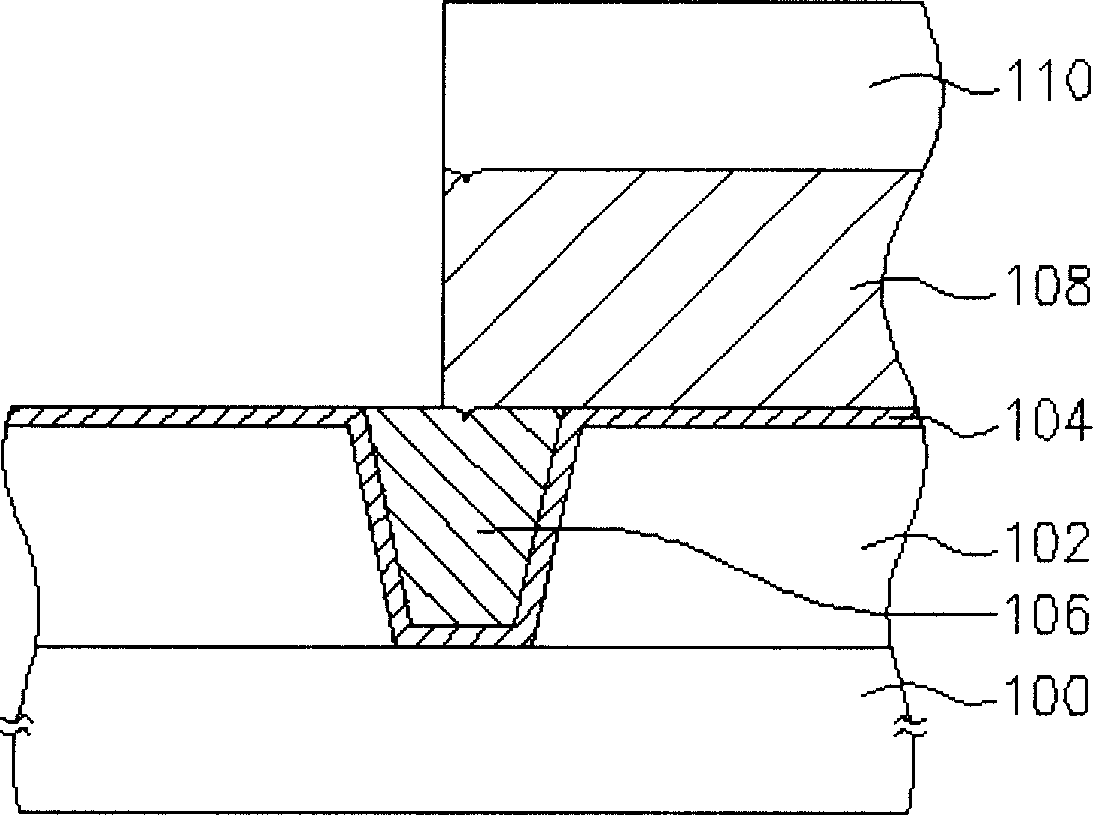

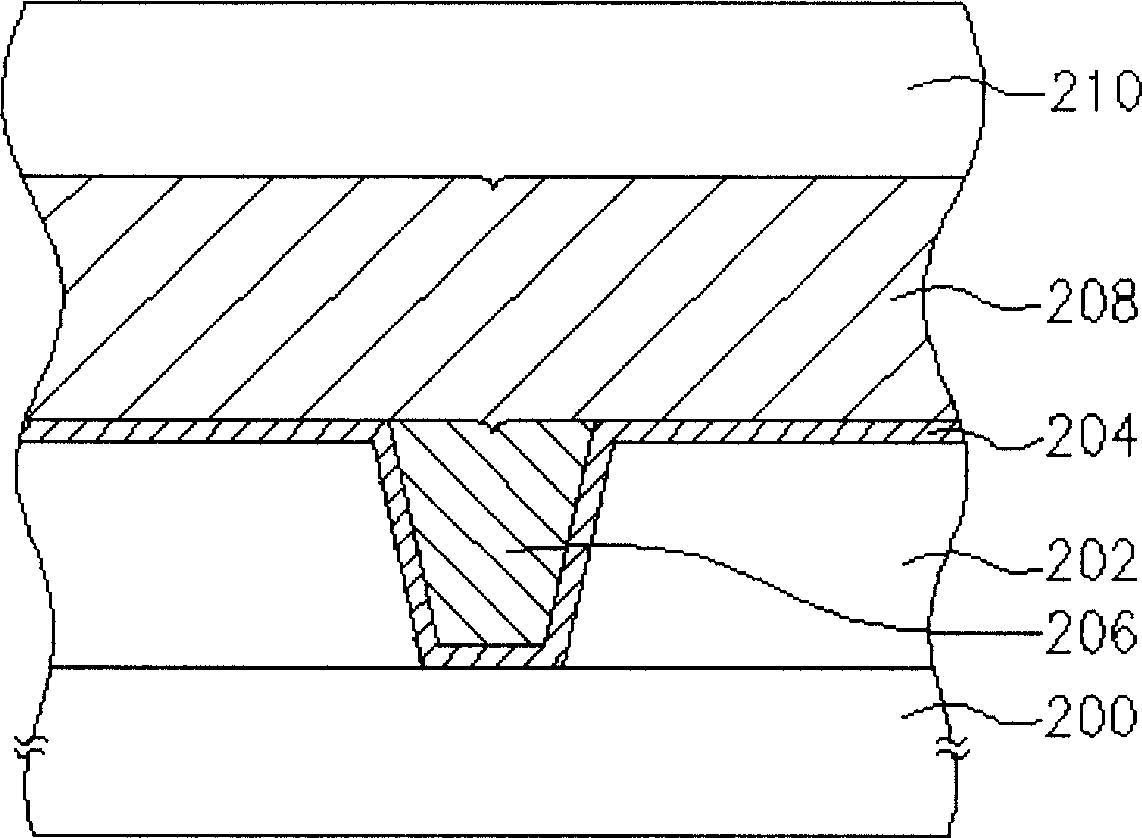

Substrate having electrical interconnection structure and fabrication method thereof

ActiveCN105023906AWon't corrodeAvoid over etchingSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsInterconnection

A method for fabricating a substrate having an electrical interconnection structure is provided, which includes the steps of: providing a substrate body having a plurality of conductive pads and first and second passivation layers sequentially formed on the substrate body and exposing the conductive pads; forming a seed layer on the second passivation layer and the conductive pads; forming a first metal layer on each of the conductive pads, wherein the first metal layer is embedded in the first and second passivation layers without being protruded from the second passivation layer; and forming on the first metal layer a second metal layer protruded from the second passivation layer. As such, when the seed layer on the second passivation layer is removed by etching using an etchant, the etchant will not erode the first metal layer, thereby preventing an undercut structure from being formed underneath the second metal layer.

Owner:SILICONWARE PRECISION IND CO LTD

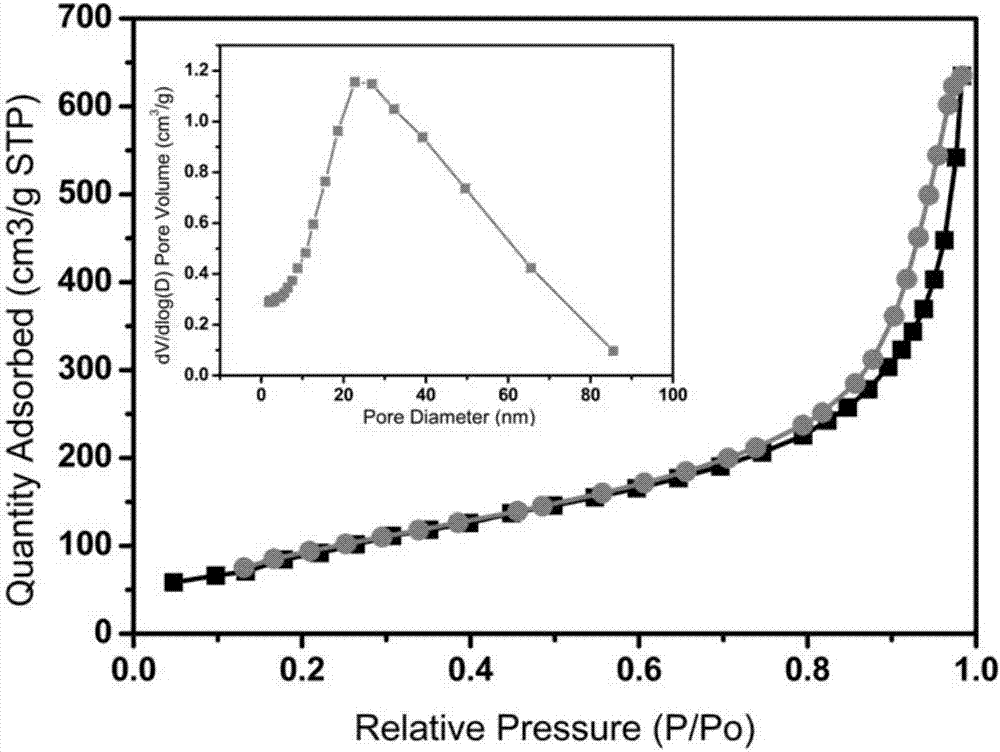

High temperature-resistant mullite type aerogel composite material and preparation method thereof

The invention relates to a high temperature-resistant mullite type aerogel composite material and a preparation method thereof. The preparation method comprises the following steps: 1, respectively hydrolyzing a silicon source, an aluminum source and a titanium source to obtain silica sol, alumina sol and titanium sol; 2, compounding the silica sol, alumina sol and titanium sol according to a preset volume ratio to form composite soil; and carrying out standing gelling on the composite soli to obtain composite gel, and drying the composite gel to obtain the aerogel material; or impregnating a fiber coil or a prefabricated component in the composite sol, carrying out standing gelling to obtain a wet gel composite material, and drying the wet gel composite material to obtain the aerogel material. The silicon-aluminum-titanium ternary composite sol is prepared, the formula is flexibly blended through a single-component stable sol system, all functional components are obtained through compounding active nano-sol particles, and the sols and the gel have homogenous properties and have no phase separation phenomenon.

Owner:北京华夏特材科技发展有限公司

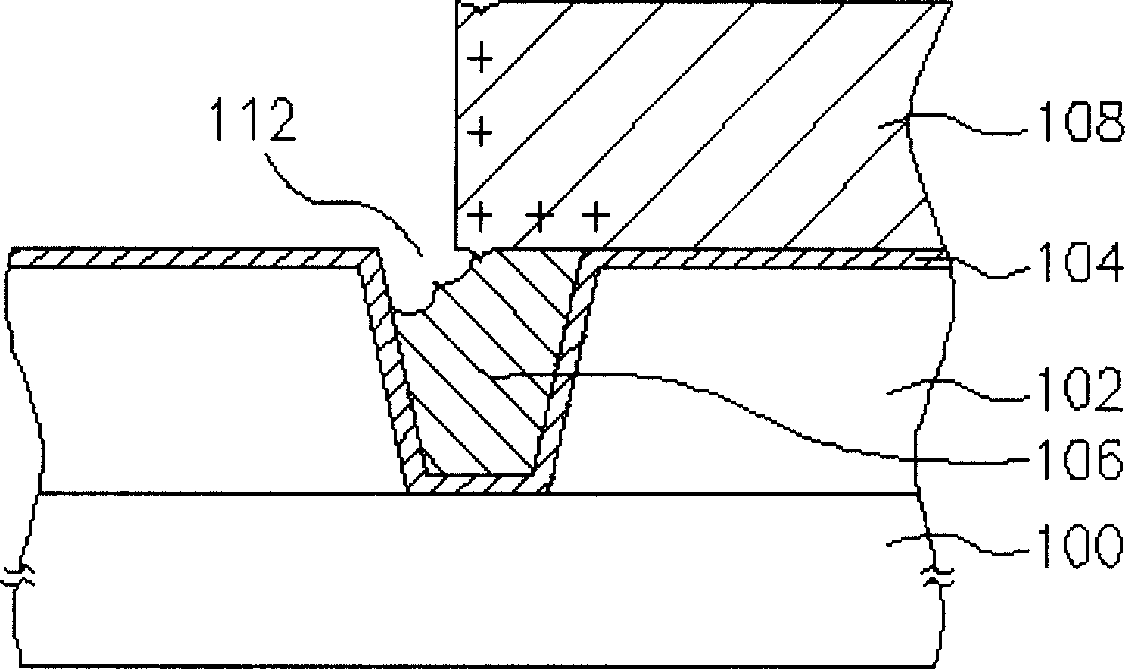

Method for preventing tungsten plug corrosion

InactiveCN1516262AAvoid Galvanic CorrosionDecrease in electrochemical potentialSemiconductor/solid-state device manufacturingTungstenMaterials science

The invention provides a method to prevent wolfram (W) plug from corroding in the semiconductor component making technique, wherein the W plug has been formed on the substrate and coupled with the lead wire formed on the substrate. Then, it uses discharger to process the substrate, eliminating the charges accumulated on the lead wire surface in the lead wire etching making technique. Then, it makes wet cleaning.

Owner:MACRONIX INT CO LTD

Pure log spliced board and aluminum-wood composited spliced board device using same

InactiveCN105113702AWon't swellWon't archConstruction materialCovering/liningsAdhesiveMechanical engineering

The invention relates to a pure log spliced board and an aluminum-wood composited spliced board device using the same. The pure log spliced board comprises a plurality of pure log boards, a first pure log side board, a second pure log side board, a plurality of screws and a plurality of nuts, each pure log board is made to have a splicing lateral side, an extensible groove slit and multiple screw holes are formed in each splicing lateral side, an adhesive is coated on each splicing lateral side, the pure log boards are arranged, spliced and pressed to form an integrated pure log spliced board body, each screw is penetratingly nested in the corresponding screw hole of the corresponding pure log board, two ends of each screw are tightened and locked by using the nuts, and the pure log side boards are arranged on the splicing lateral sides on two sides of the pure log spliced board body respectively to hide the ends of the screws and the nuts in the spliced board. The pure log spliced board is simple in structure, convenient to assemble and easy to realize, unfavorable factors like material cracking and deforming caused by thermal expansion and cold contraction of pure log are prevented effectively, and a log product is more attractive, more environment friendly and longer in service life.

Owner:彭志军

Nano carbon tube composited contact material

InactiveCN1725561AImprove conductivityImproved arc characteristicsCoupling contact membersElectrophoretic coatingsAlloyNano carbon

This invention relates to an nm carbon tube composite electric contact material. The component and its weight percentage are: nm carbon tube: 0.02-5%, the rest is the parent metal. Said nm carbon tube is a multi-wall one with the diameter of 20-100nm or a single wall nm carbon tube with the limited diameter of 1-3nm and length of 1-2mum. Said parent metal refers to the metal prepared by electric deposition reaction and its alloy. This invention applies the carbon nm tube with advanced mechanical and conductive characters as the enhancement substance to replace the traditional substances of CdO, SnO2, MoSz, WCSiC, La2O3 and diamond dust to keep fine conductivity of the parent metal and overcome the Ge pollution.

Owner:SHANGHAI JIAO TONG UNIV

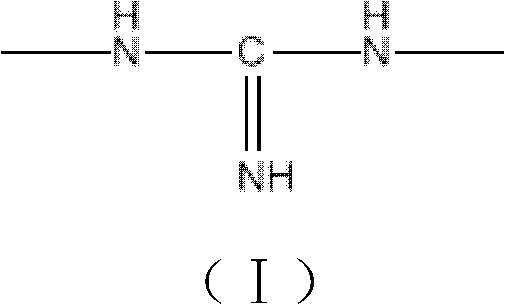

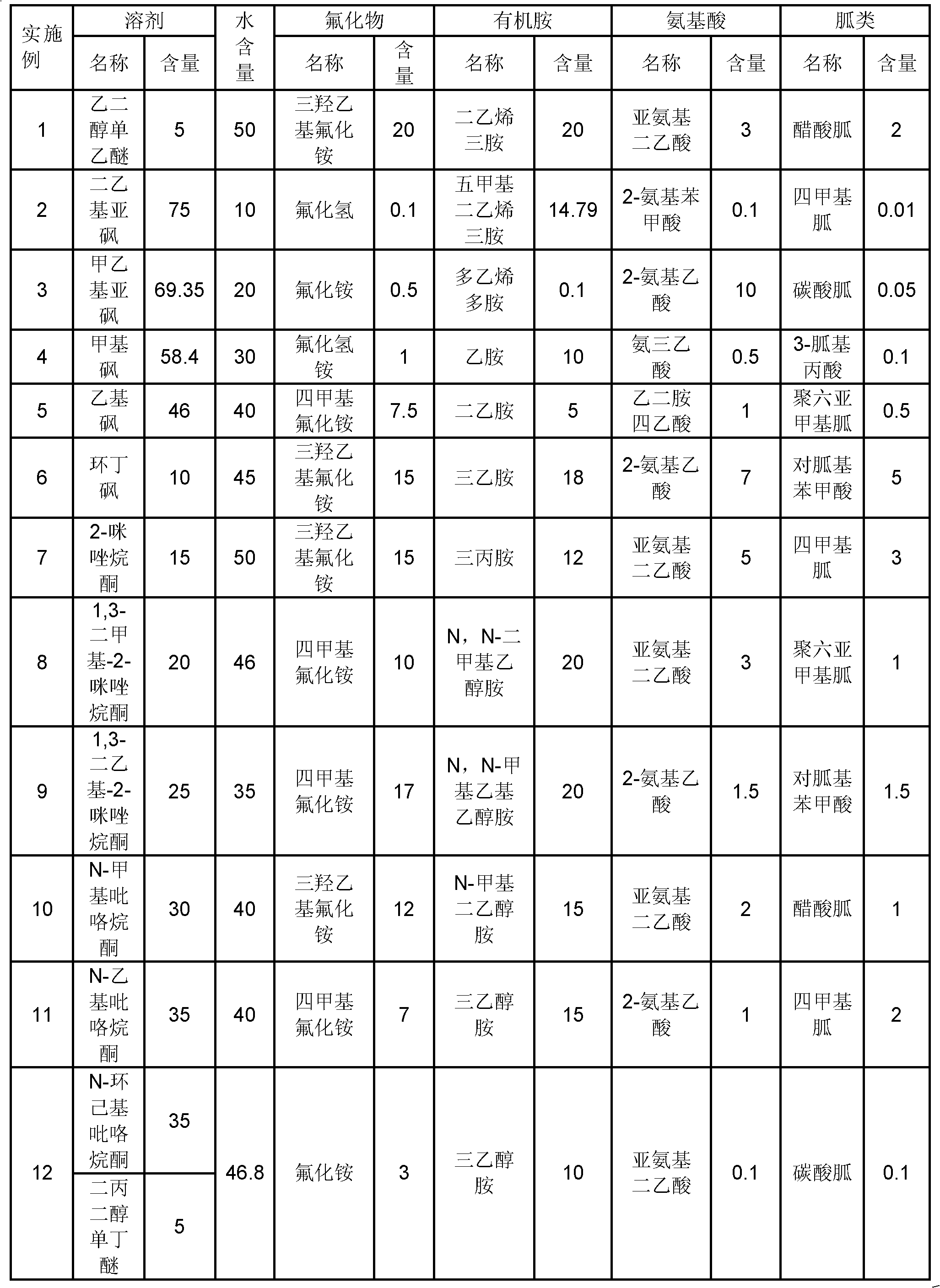

Plasma etching residue cleaning fluid

InactiveCN102827708AInhibition of Galvanic CorrosionLarge rinse windowOrganic non-surface-active detergent compositionsPhotosensitive material processingSemiconductor chipSemiconductor industry

The invention discloses a fluorine-containing plasma etching residue cleaning fluid in the semiconductor industry. The cleaning fluid composition contains 5-75% of organic solvent, 10-50% of water, 0.1-20% of fluoride, 0.1-20% of organic amine, 0.1-10% of amino acid, and 0.01-5% (preferably 0.05-2%) of carbamidines. The cleaning fluid composition can effectively clean plasma etching residues in a semiconductor manufacturing process, has lower etching rate on a base material such as a low-dielectric material (SiO2 and PETEOS (plasma-enhanced tetraethoxysilane)) and some metal (such as Ti, Al and Cu), simultaneously has the capability of inhibiting galvanic corrosion of aluminum-copper alloy, and has excellent application prospects in the semiconductor chip cleaning and other micro-electronic fields.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

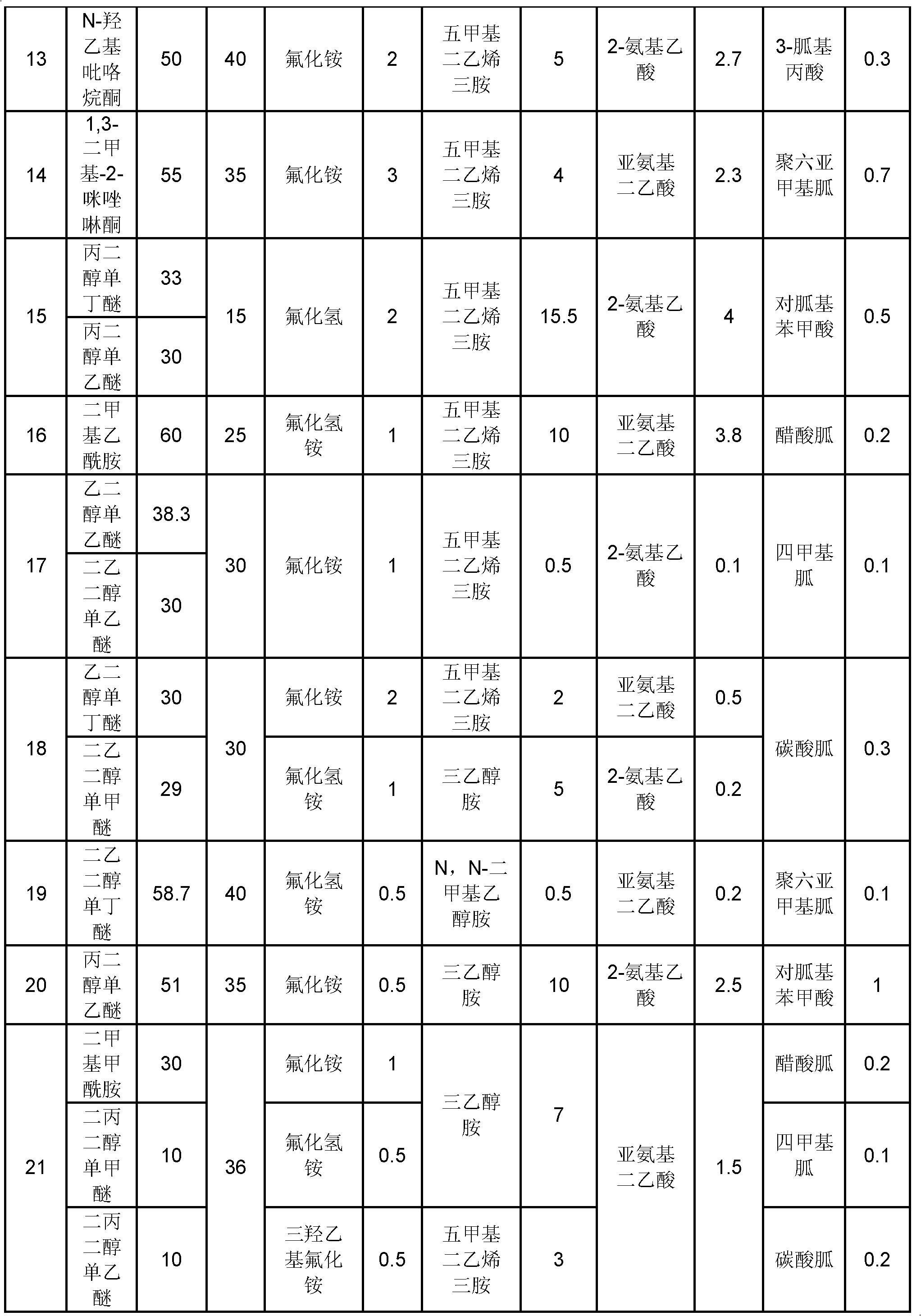

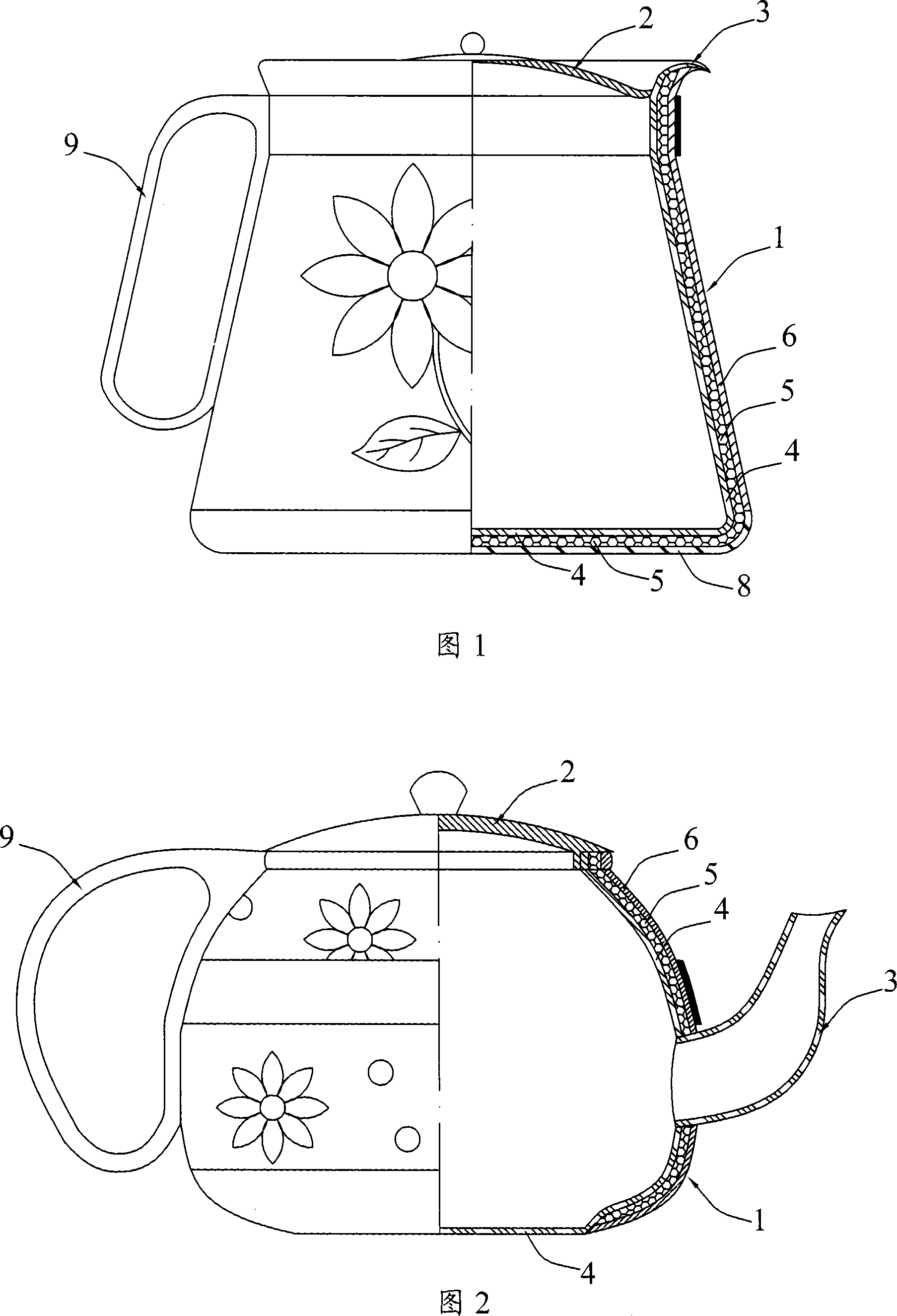

Thermos kettle

InactiveCN101019730AGood insulation performancePrevent heat dissipationCooking-vessel materialsDomestic vesselsFilling materialsMetallic materials

The present invention relates to liquid insulating device, and is especially one kind of thermos kettle with high heat insulating performance, simple structure and fine decoration. The structure of the thermos kettle includes at least one kettle body, one kettle cover and one kettle spout extending outwards from the kettle body. The kettle body in improved structure is one three-layer structure comprising inner container of metal material, filler layer of heat insulating material and outer casing of ceramic material.

Owner:GUANGZHOU YANSHENG INDAL

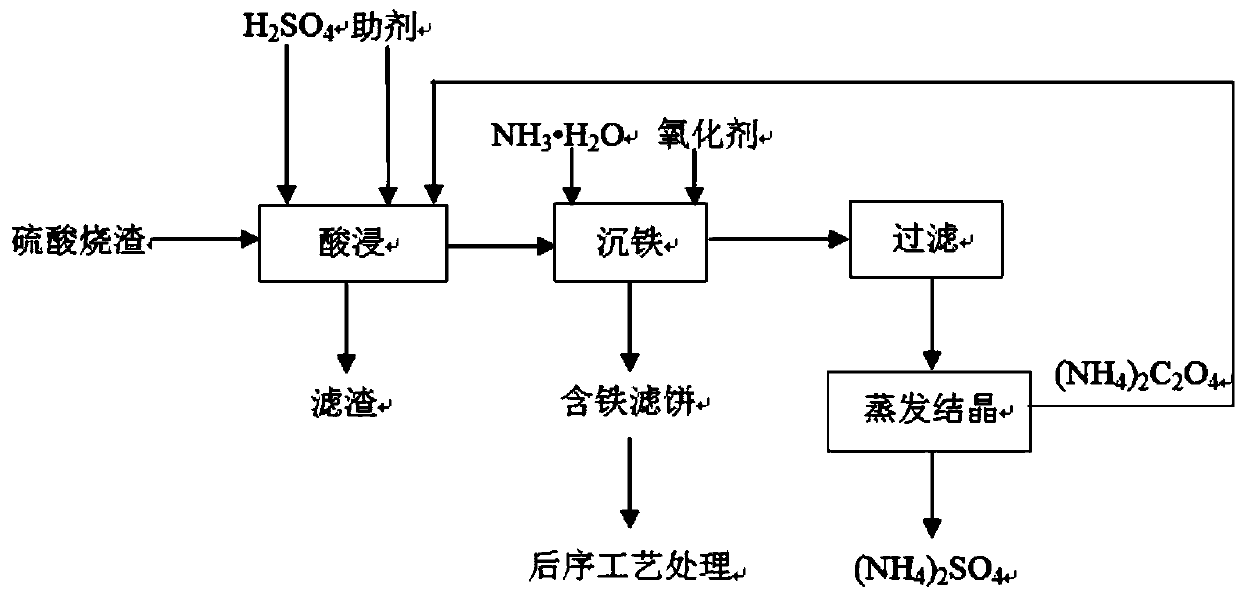

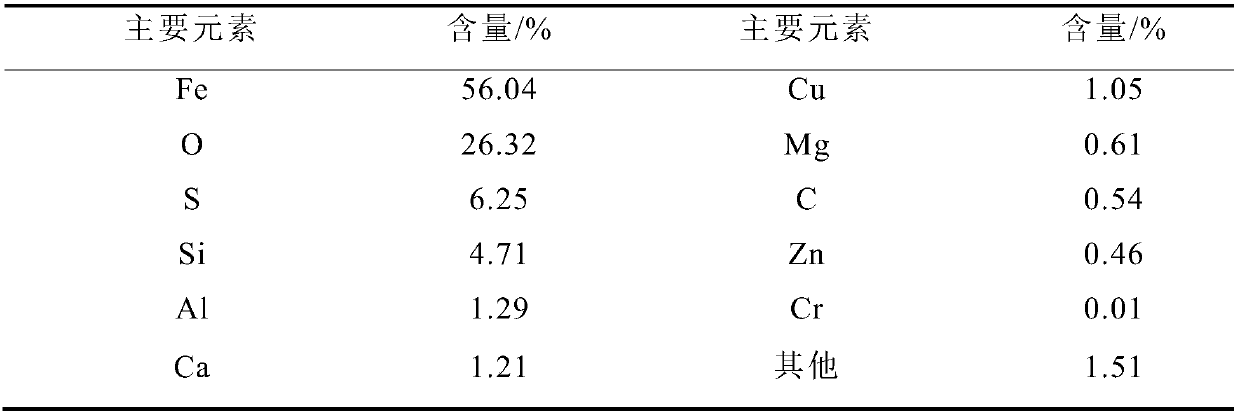

Process for extracting iron in sulfuric-acid slag through auxiliary-strengthening acid leaching method

The invention discloses a process for extracting iron in sulfuric-acid slag through an auxiliary-strengthening acid leaching method. The process for extracting iron in sulfuric-acid slag through the auxiliary-strengthening acid leaching method comprises the steps that sulfuric-acid slag and an auxiliary are evenly mixed in a certain proportion and are placed into a normal-pressure reaction kettle,a sulfuric acid solution with the mass concentration of 30%-50% is added in a certain solid-liquid ration, and heating and stirring are conducted for a reaction; and solid-liquid separation is conducted after the acid leaching reaction is completed, iron deposition is conducted on acid-leaching filtrate containing iron ions, oxalate ions and the like, impurities in an iron-deposited filter cake are removed for preparing an iron product, and the filtrate containing (NH4)2C2O4 is returned to the acid leaching procedure to be reused. Compared with an existing method for extracting iron in sulfuric-acid slag, the process for extracting ion in sulfuric-acid slag through the auxiliary-strengthening acid leaching method has the advantages that the acid leaching temperature is relatively low, theiron leaching rate is high, the quantity of slag is small, and the cost of the auxiliary is low.

Owner:HEFEI UNIV OF TECH

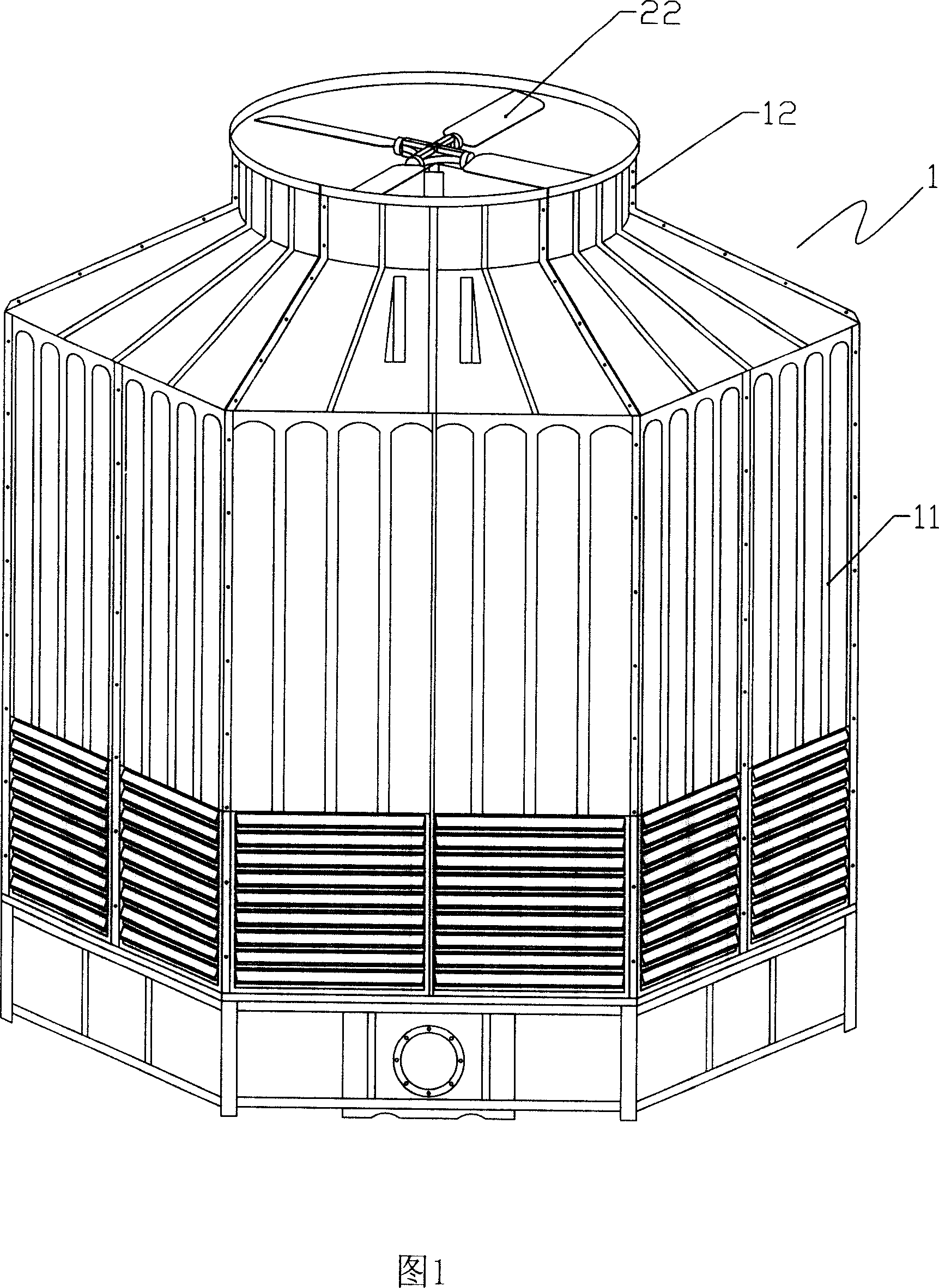

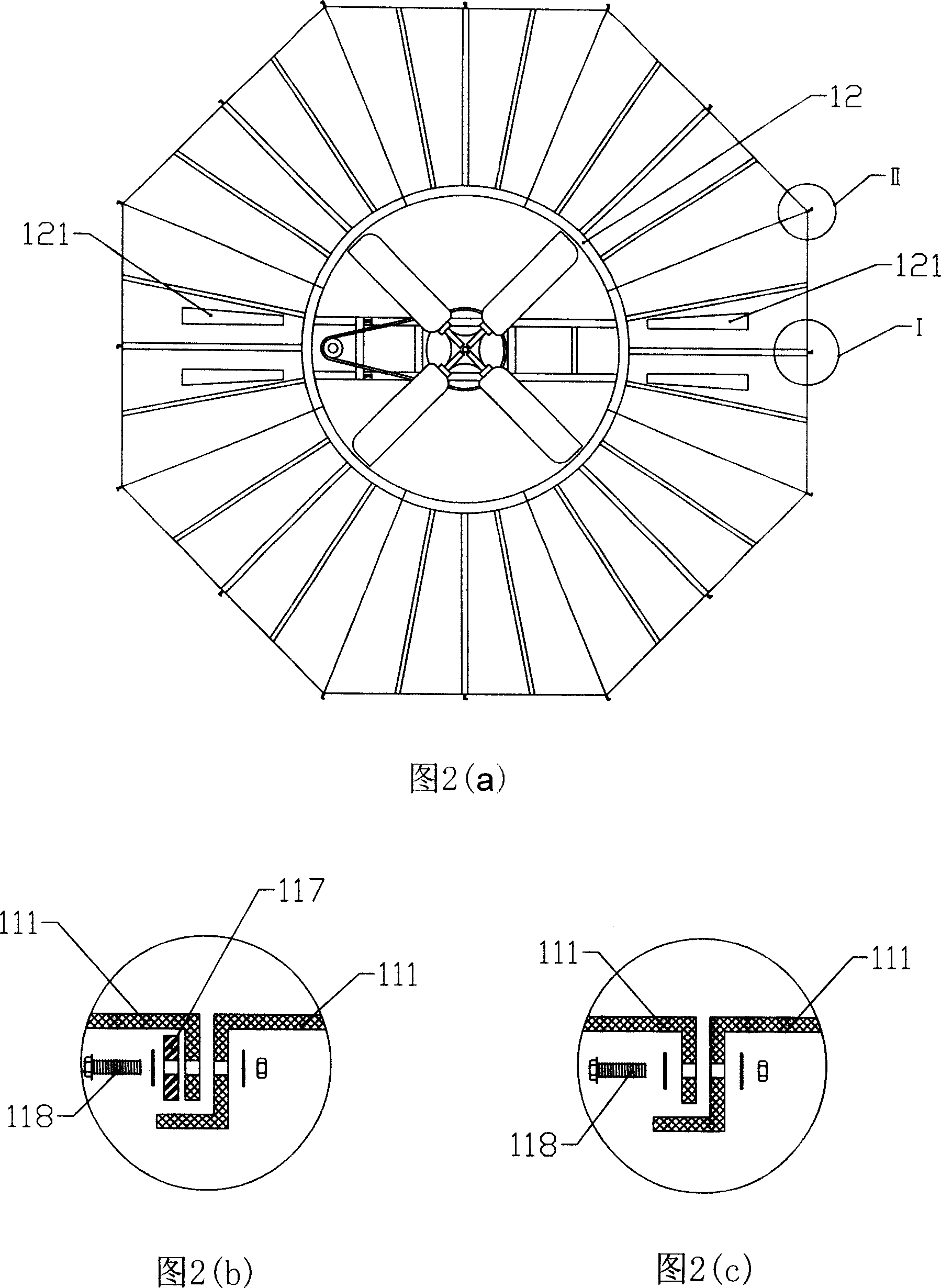

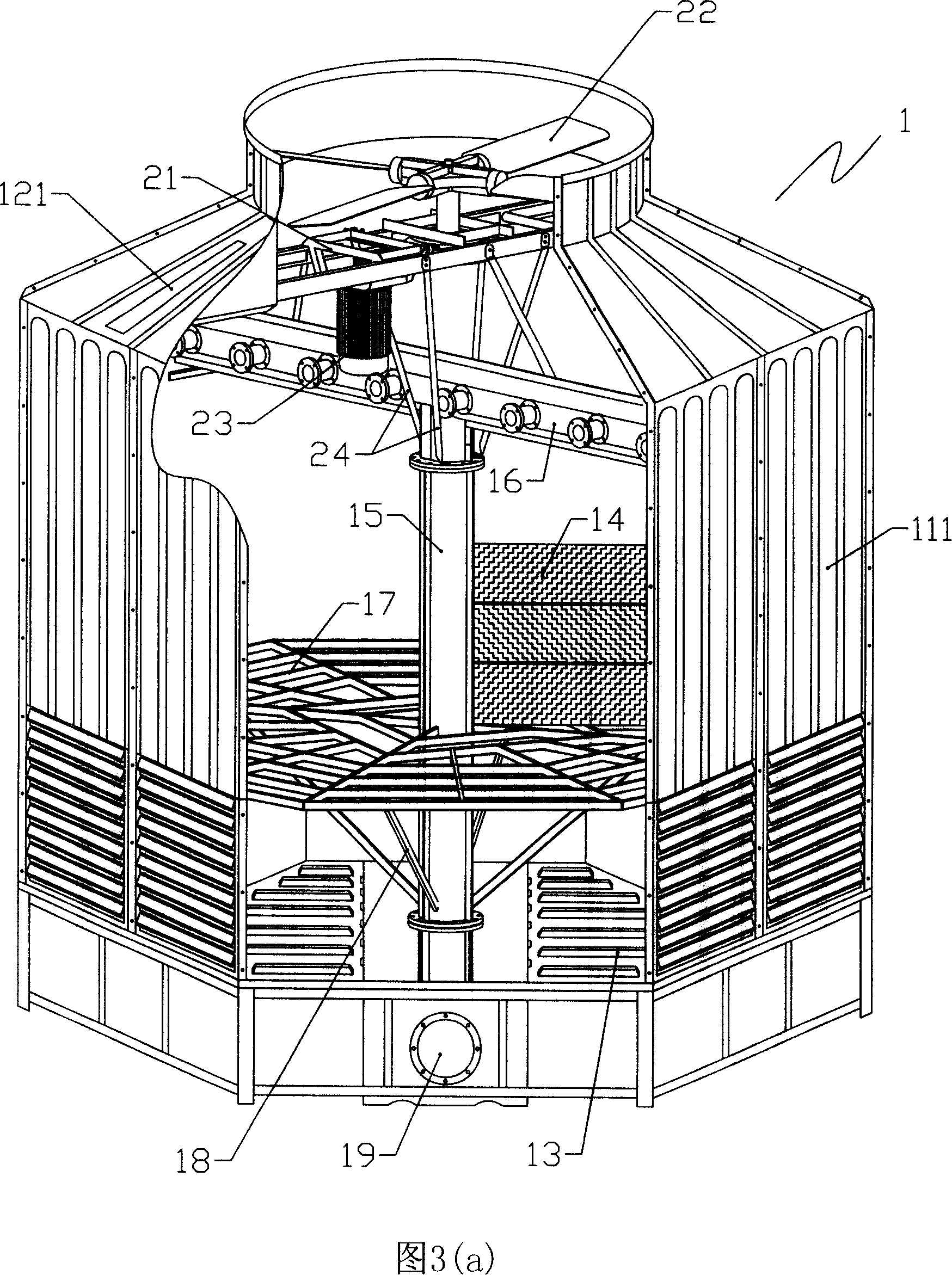

Polygonal counterflow type cooling tower

ActiveCN101021389AImprove corrosion resistanceSave metal materialStationary conduit assembliesGlass fiberWater storage

The invention discloses a polygonal counter flow cooling tower including the tower body which is made up of the body, the wind canister connected to the body top and the water storage basin connected to the body bottom. The wind canister is installed with the fan and the motor device. The tower body is set with the central throat and the water sowing device which the below is the filling. The tower body is the polygon prism structure connected by the glass fiber. The invention has changed the structure of the traditional cooling tower; such as it has save the steel shelf structure, so it can save much steel and bolt, screw. It has the low cost and simple assembly.

Owner:东莞明新玻璃纤维工程有限公司

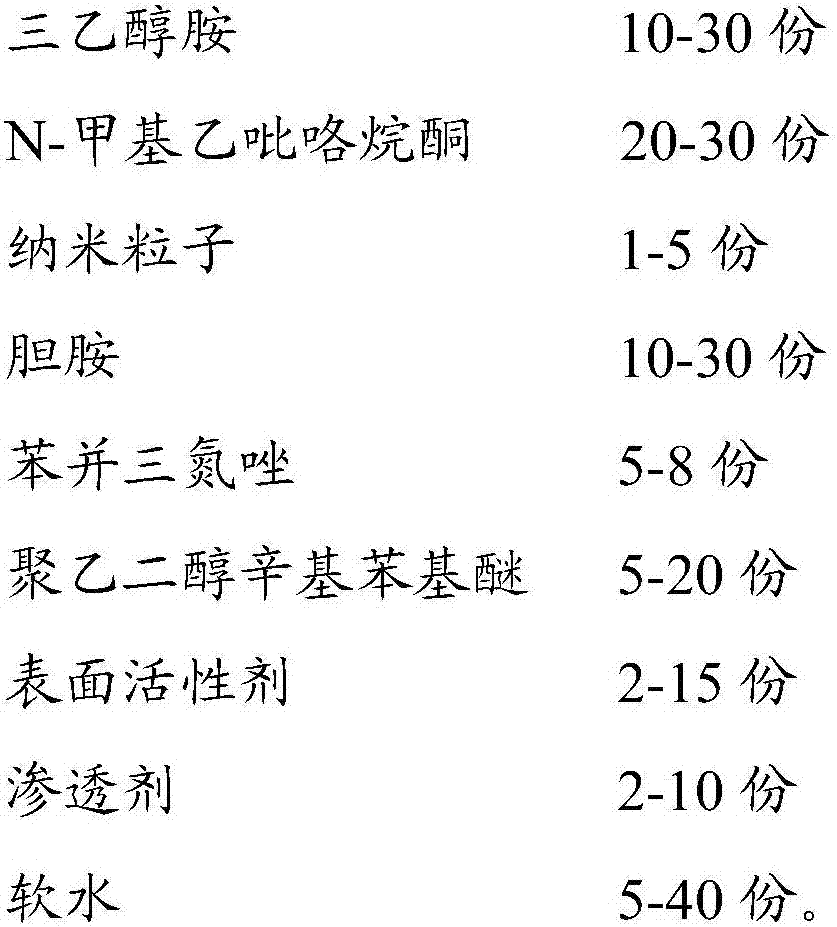

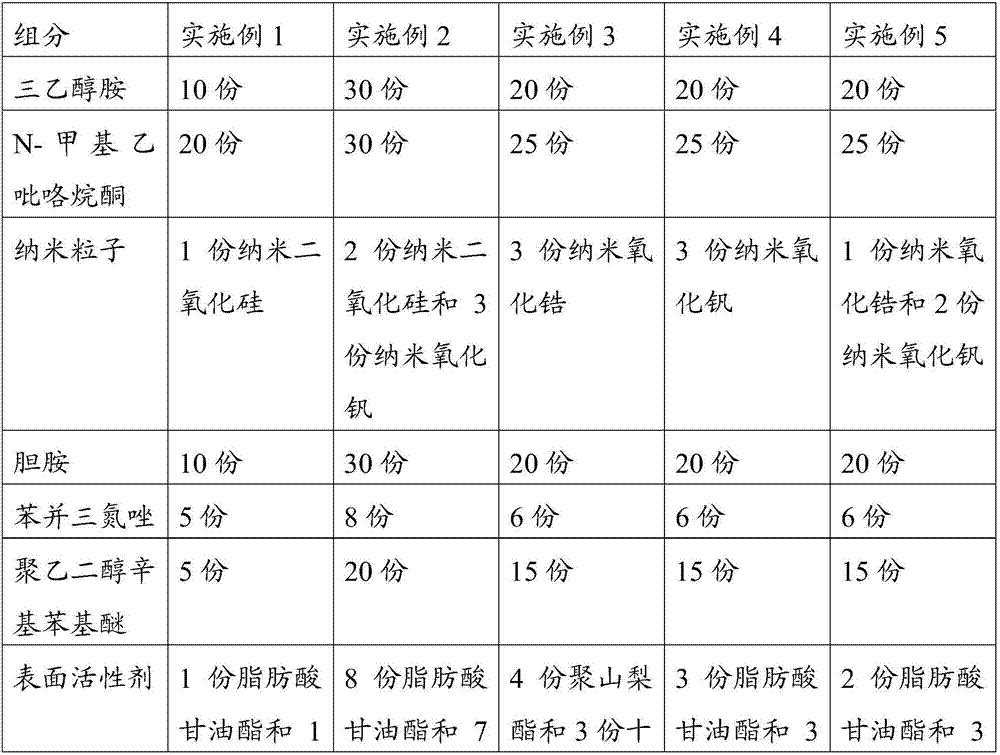

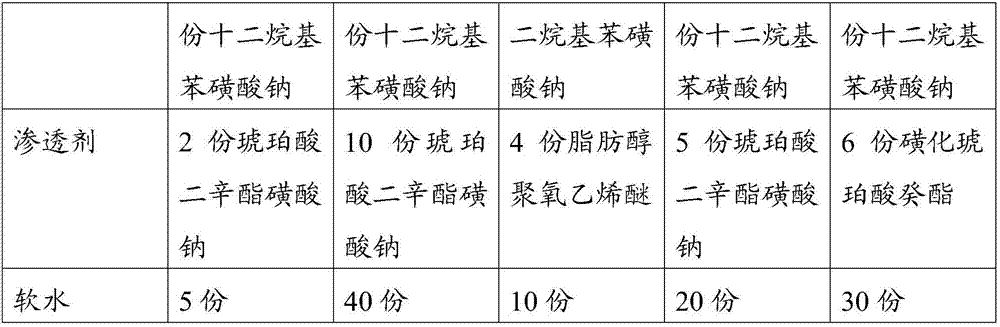

Novel high efficient aqueous printing ink cleaning agent and preparation method thereof

InactiveCN107353700AImprove cleaning efficiencyImprove cleanlinessChemical paints/ink removersSoft waterPolyethylene glycol

The invention provides a novel high efficient aqueous printing ink cleaning agent and a preparation method thereof. The cleaning agent comprises the following components in parts by weight: 10 to 30 parts of triethanolamine, 20 to 30 parts of N-methyl pyrrolidone, 1 to 5 parts of nano particle, 10 to 30 parts of cholamine, 5 to 8 parts of benzotriazole, 5 to 20 parts of polyethylene glycol octyl phenol ether, 2 to 15 parts of surfactant, 2 to 10 parts of osmotic agent, and 5 to 40 parts of soft water. The preparation method comprises the following steps: adding a surfactant and an osmotic agent into soft water according to the formula, stirring 3 to 5 minutes to evenly mix the components; then adding nano particles, stirring for 5 to 10 minutes at a rotation speed of 500-1000 r / min; carrying out ultrasonic dispersion for 10 to 30 minutes at a temperature of 20 to 40 DEG C, then adding triethanolamine, N-methyl pyrrolidone, cholamine, benzotriazole, and polyethylene glycol octyl phenol ether in sequence, stirring, and evenly mixing. The cleaning agent has a strong performance on removing dirt such as printing ink, the cleaning efficiency is high, at the same time, the base material will not be damaged, the cleaning agent is safe to use, the toxicity is little, and the quality is the same after long term storage.

Owner:GUANGDONG REDSUNSTAR IND

Formable sheet and interior finishing material

ActiveCN101166779APrevent dry stateFull stretchSynthetic resin layered productsThin material handlingSynthetic resinHumidity

The invention provides a formable sheet which exhibits good formability even after the storage at low temperature and humidity. A formable sheet obtained by coating or impregnating a porous material with a synthetic resin, which sheet is further impregnated with a water-retaining agent. The water-retaining agent serves to make the sheet retain a suitable amount of water, whereby the sheet can keep good formability.

Owner:NAGOYA OIL CHEM CO LTD

Anti-hydrophobic soil stabilizer as well as preparation method and application thereof

ActiveCN104293354AImprove bearing capacitySpeed up the petrochemical processBuilding constructionsOrganic fertilisersStone carvingSoil stabilization

The invention discloses an anti-hydrophobic soil stabilizer and a preparation method thereof. The preparation method of the anti-hydrophobic soil stabilizer comprises the following steps in parts by weight: dissolving 3 parts by weight of oleamide and 6 parts by weight of triisopropanolamine in alcohol to obtain a mixture; then, reacting the mixture with 5 parts by weight of carbolic acid and adding water into a reaction kettle to synthesize the anti-hydrophobic soil stabilizer. The anti-hydrophobic soil stabilizer is applied to paving a road, performing phosphogypsum environment-friendly treatment, performing slope treatment and performing stone carving artwork repair. The anti-hydrophobic soil stabilizer disclosed by the invention can be used for improving a soil granule structure, lowering the soil particle interface activity, enabling the original cohesion inside the soil particles to recombine to produce irreversible cohesion, blocking soil mass gaps to enable the soil particles to lose capillary water absorption, directly mixing with the natural soil and lowering the consumption and saving over 50% of the energy resources by enabling a weight ratio of the anti-hydrophobic soil stabilizer to natural soil to be smaller than and equal to 0.1%, and can not cause pollution on the natural environment after being mixed into the soil.

Owner:敬启培

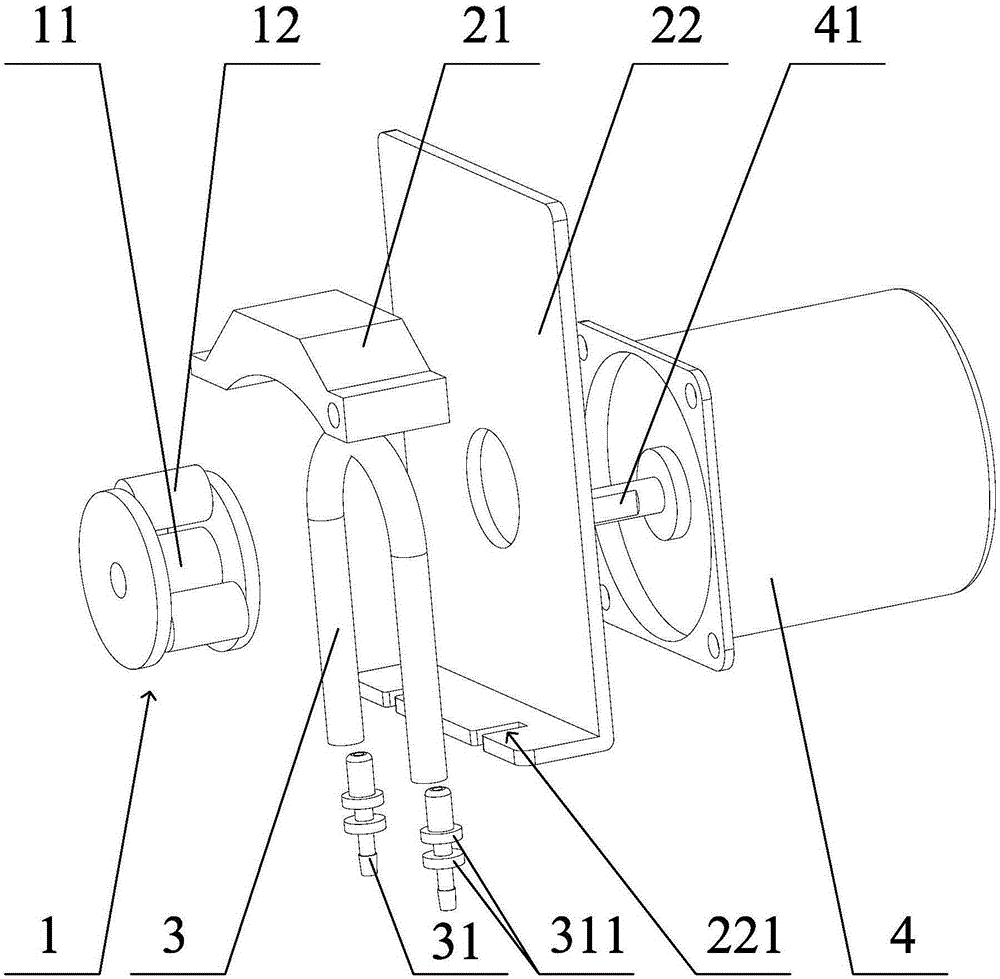

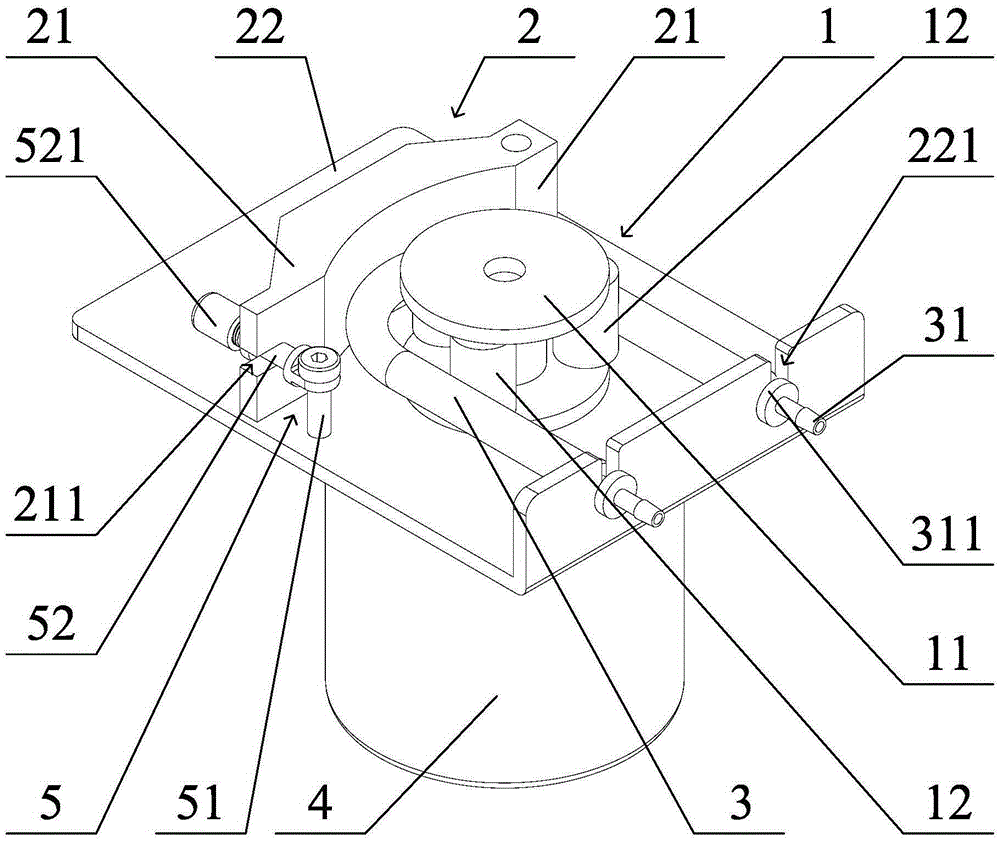

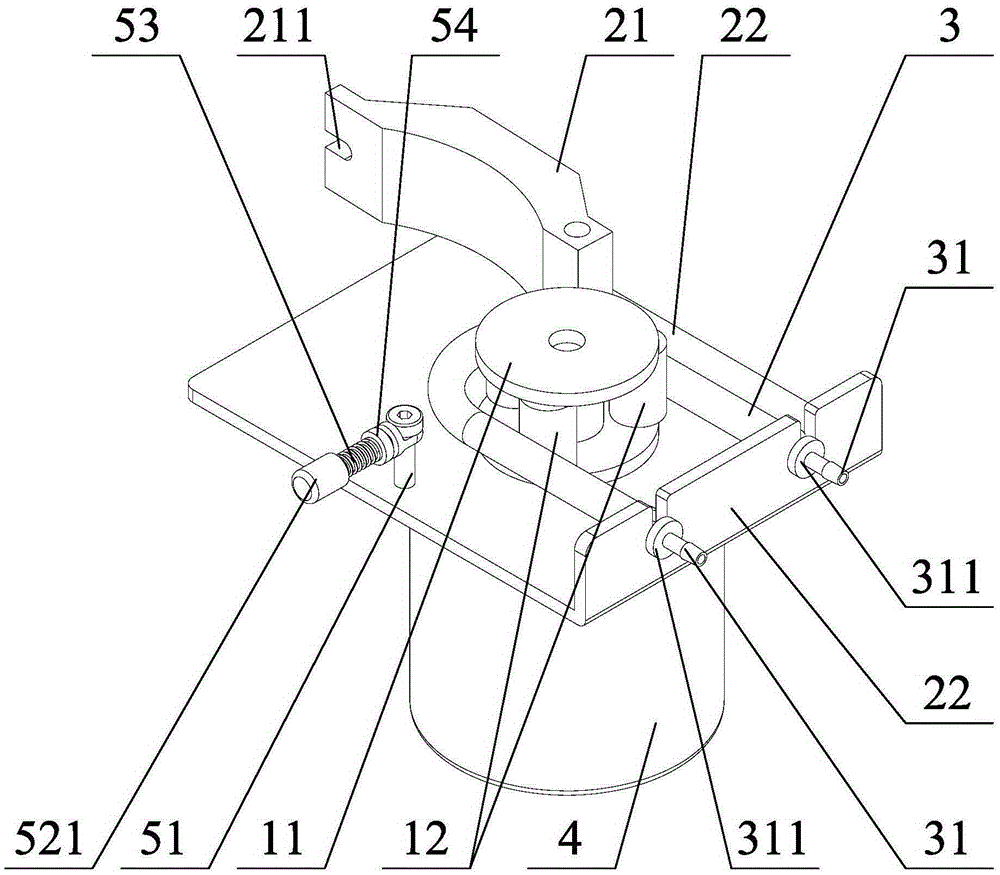

Peristaltic pump

InactiveCN105257519AWon't corrodeLow failure rateFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

The invention relates to the technical field of fluid pumping and injection and provides a peristaltic pump. The peristaltic pump comprises a hose, a driver, a limiting part and a rotary squeezing part, wherein the driver is arranged on the limiting part; an output shaft of the driver is connected with the rotary squeezing part and used for driving the rotary squeezing part to rotate; the hose is arranged on the rotary squeezing part in an eracting manner, and the position of the rotary squeezing part is fixed through the limiting part. The rotary squeezing part squeezes and pushes the hose by rotation, and therefore pumping and injection of fluid are realized. By adopting the structure, the fluid is guided through the hose and makes no contact with a pump body, and therefore the fluid does not corrode the peristaltic pump. The failure rate of the peristaltic pump is lowered, repairing expenses are reduced, and the fluid is not polluted and keeps batter purity.

Owner:GUANGDONG WEICHUANG TECH DEV

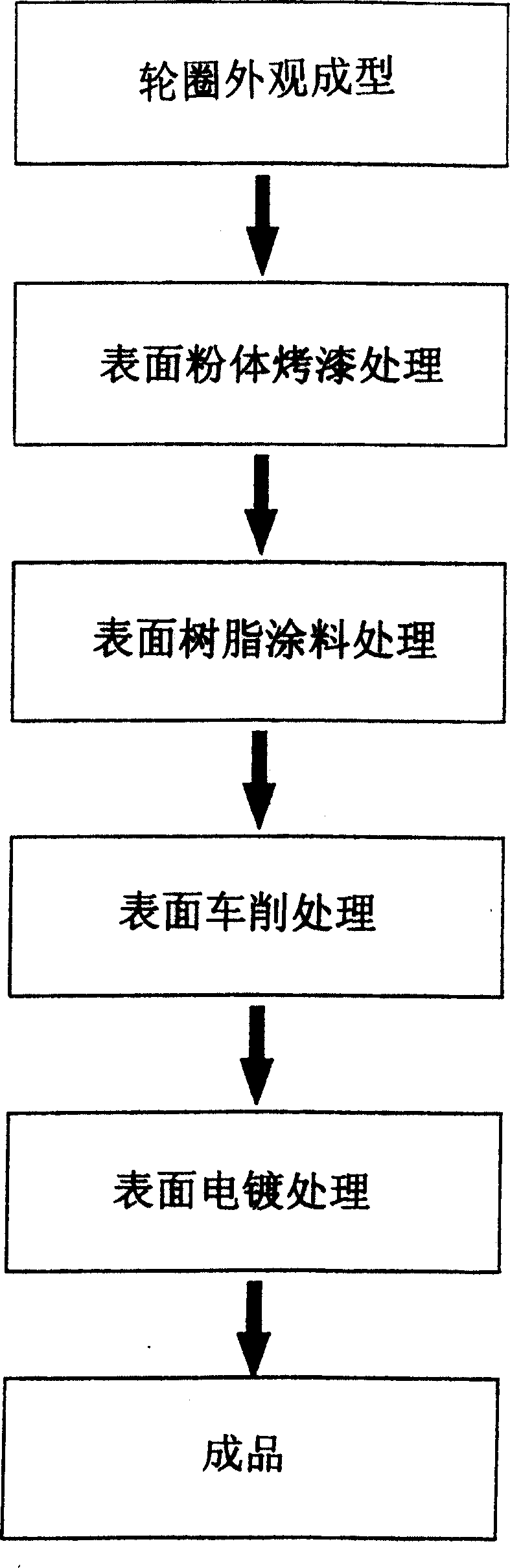

Method for processing surface of rim and its products

A technology for treating the surface of wheel rim includes such steps as manufacturing a wheel rim, machining concave markers about its specifications, applying the varnish powder on its surface, baking to form a layer of color paint, coating resin to form a protective layer, turning to remove the paint layer and protective layer from the predefined position, and electroplating. Its advantages are mirror effect and high resistance to friction, scraping, corrosion, acid and alkali.

Owner:PROTECH WHEEL IND

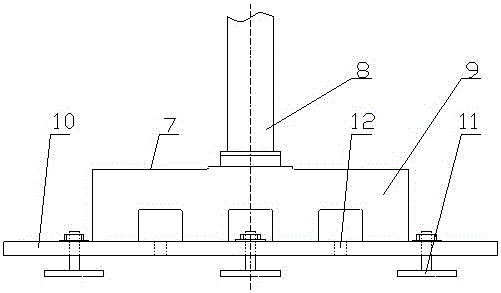

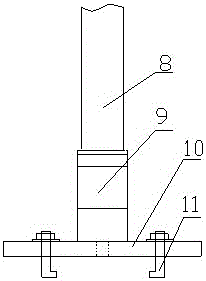

Aluminum electrolysis steel claw for prebaked anode

The invention discloses an aluminum electrolysis steel claw for a prebaked anode. The aluminum electrolysis steel claw is characterized in that the steel claw (7) comprises an electric conducting rod (8); the electric conducting rod (8) is connected with an electric conducting bridge type support (9) which is connected with an electric conducting positioning steel plate (10); and the electric conducting positioning steel plate (10) is provided with connecting locking parts (11). The electric conducting rod of the steel claw is connected with the bridge type support, the bridge type support is connected with the positioning steel plate, the size of the positioning steel plate is equal to or larger than the size of the upper surface of a carbon block body, the steel claw not only can be used for being connected with the carbon block body, but also can cover the upper surface of the carbon block body, and therefore it is ensured that the upper surface of the carbon block body can be clean and flat. The positioning steel plate is connected with the carbon block body through the connecting locking parts, the carbon block body can wrap the connecting locking parts inside, an electrolyte is prevented from making contact with the connecting locking parts to ablate an interlocking mechanism so that an old anode carbon block can be burnt out as much as possible, the weight of the old anode carbon block is reduced, and the height of the oil carbon block is reduced.

Owner:周俊和 +1

Ladle covering agent prepared through utilizing blast furnace slag

ActiveCN103173592AImprove reducibilityNo carbon increaseProcess efficiency improvementSlagSolid particle

The invention provides a ladle covering agent prepared through utilizing blast furnace slag. The ladle covering agent is composed of 30-40 parts by weight of blast furnace slag, 26.7-40 parts by weight of limestone, 15-20 parts by weight of vermiculite and 5-15 parts by weight of fluorite, wherein the total weight part of the above raw materials is 100. The main raw materials of the ladle covering agent have the advantages of low cost, suitable melting point, short fusing time and good spreadability; and limestone decomposes at 800-1200DEG C, foams and expands, vermiculite expands at a high temperature, and the friction force among solid particles is lower than the inner friction force among powders, so the spreadability and the heat insulating property are good. The ladle covering agent can prevent the secondary oxidation and too large temperature decrease of molten steel, and has a certain impurity adsorption and inclusion capability to purify the molten steel because of the appropriate alkalinity. The ladle covering agent has no carbon, does not carburize the molten steel, and is in favor of the component control of the production process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

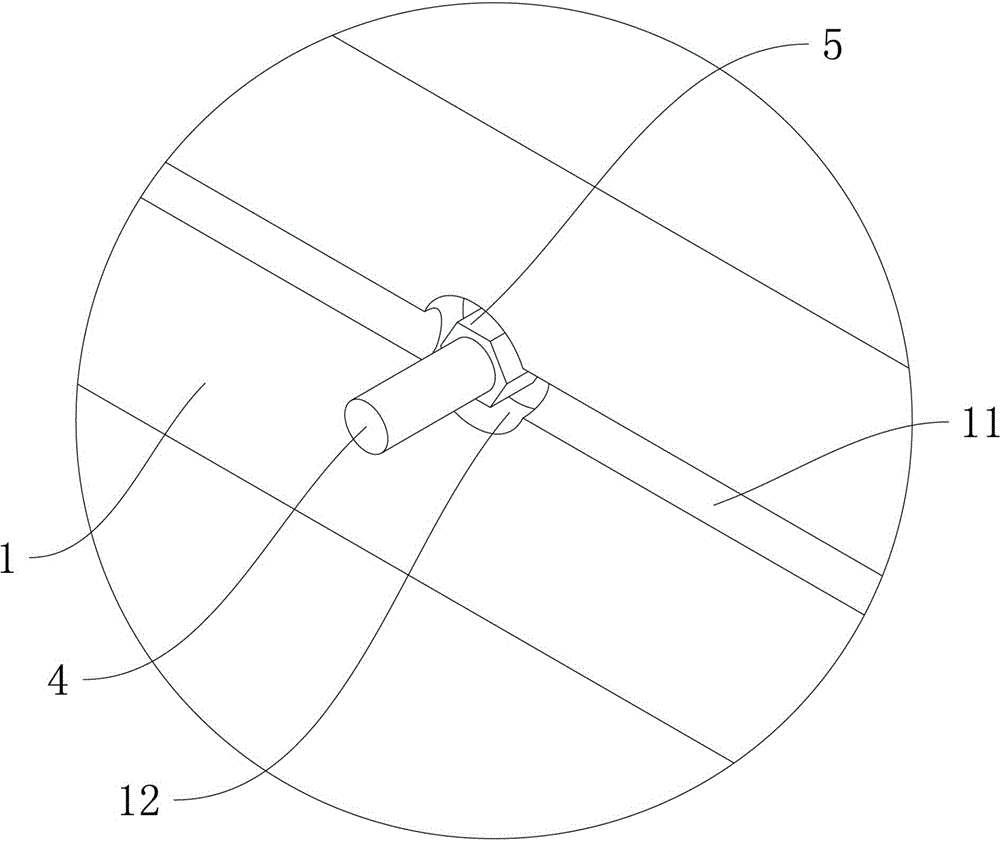

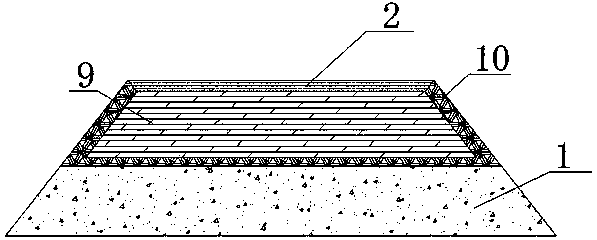

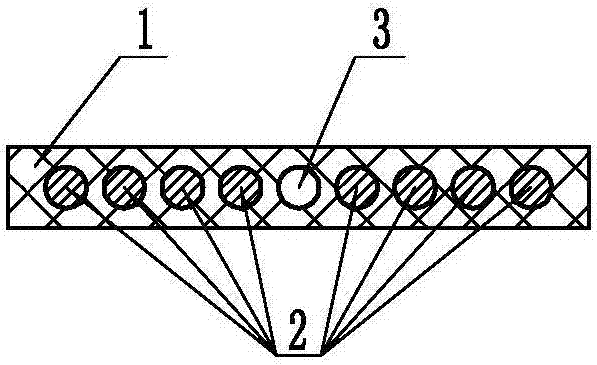

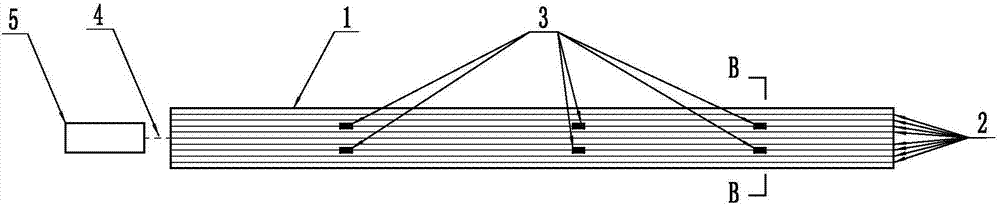

Mixed intelligent carbon fiber board

InactiveCN107956292AWon't corrodeImprove shear resistanceConstruction materialBuilding repairsEpoxyYarn

A mixed intelligent carbon fiber board comprises carbon fiber reinforced plastic, high-strength steel wires embedded in the carbon fiber reinforced plastic and an optical fiber grating sensor, whereinthe carbon fiber reinforced plastic is composed of carbon fiber yarn and matrix resin, and the matrix resin is epoxy resin or vinyl ester resin; the optical fiber grating sensor is connected with anoptical fiber grating demodulator through a test jumper. The tensile strength of the high-strength steel wires axially embedded in the carbon fiber reinforced plastic is not smaller than 1500 MPa, thenumber of the high-strength steel wires is m*n, m is the number of rows of the high-strength steel wires, n is the number of the high-strength steel wires in each row, m is an integer larger than orequal to 1 and smaller than or equal to 5, and n is an integer larger than or equal to 1 and smaller than or equal to 50; the optical fiber grating sensor is composed of x single-mode optical fibers written into y optical fiber gratings, x is an integer larger than or equal to 1 and smaller than or equal to 5, and y is an integer larger than or equal to 1 and smaller than or equal to 10. The mixedintelligent carbon fiber board can monitor a reinforced structure and is low in cost, economical and practical.

Owner:LIUZHOU OVM STRUCTURE INSPECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com