Plasma etching residue cleaning fluid

A technology of etching residue and cleaning solution, which is applied in the field of cleaning solution, can solve the problems of short production and use time of fluorine-based cleaning solution, and achieve the effect of inhibiting galvanic corrosion and large rinsing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

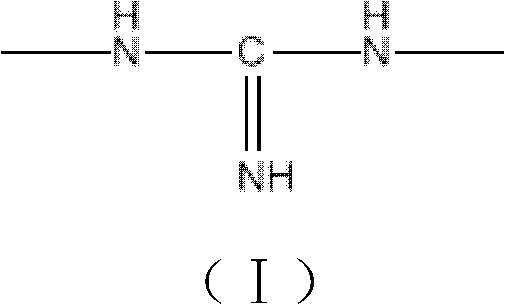

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. The percentages of each composition in the examples are percentages by mass.

[0024] The raw materials of the cleaning solution of the present invention are easy to obtain and easy to make, and each formula can be simply mixed evenly by raw materials.

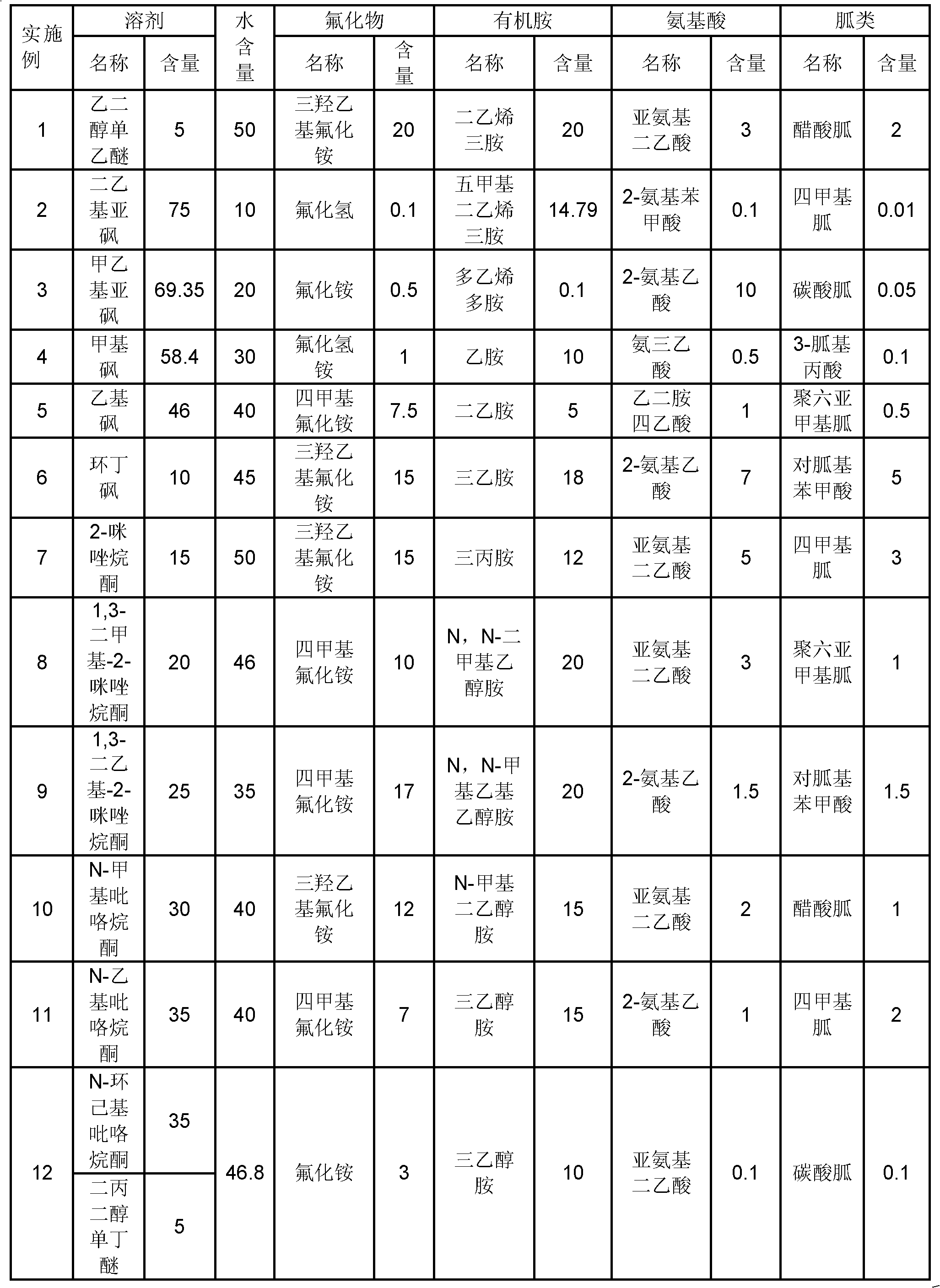

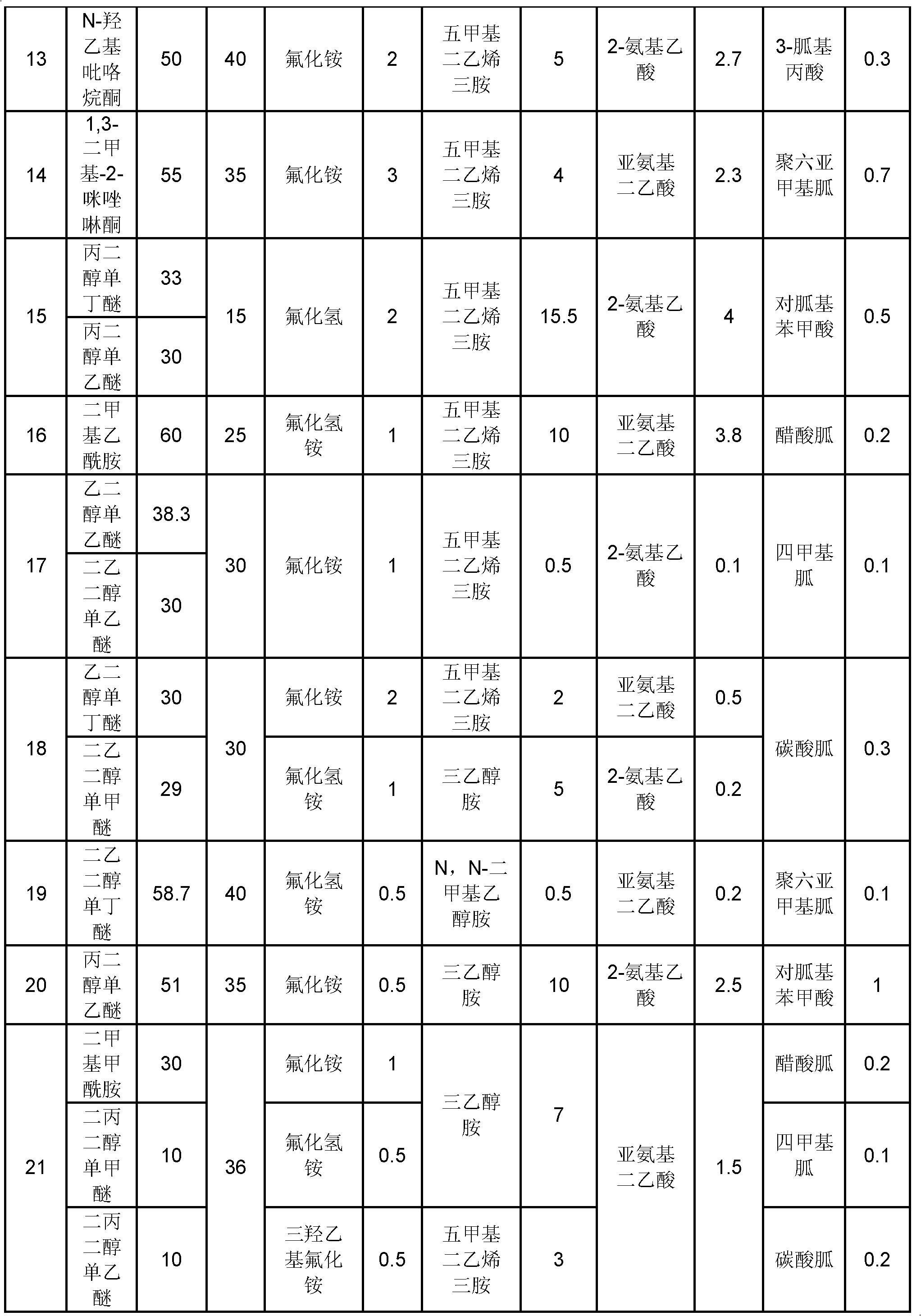

[0025] Table 1: Formulas of light cleaning solution 1-24 of the present invention

[0026]

[0027]

[0028]

[0029] We have selected some embodiments in the above table for performance testing, and the cleaning results are shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com