Alkaline cleaning solution for removing particles on surface of copper wafer and inhibiting galvanic corrosion

A technology of surface particle and galvanic corrosion, applied in the field of cleaning liquid composition, can solve the problems of surface residue of cleaning agent, non-uniform surface corrosion, etc., and achieve the effect of preventing copper corrosion, improving service performance and improving perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of alkaline cleaning solution of the present invention is:

[0046] 1) Accurately weigh each component;

[0047] 2) Add the weighed multi-component surfactant and inhibitor into the beaker, add different multiples of deionized water to dilute, and stir to make it completely dissolve;

[0048] 3) Add the chelating agent that has been weighed, stir evenly, add a pH regulator, measure the pH value and electrical conductivity of the solution, set the volume to a certain volume, and filter to obtain an alkaline cleaning solution.

[0049] The effect that the present invention adopts method is:

[0050] The surfactant used in the copper cleaning solution has wetting properties, which can effectively reduce the surface tension of the solution, and then hold up and wrap the particles by the penetration of the penetrant. The active agent molecules with strong penetrability can penetrate deep into the surface of the copper sheet and the adsorbate, and dev...

Embodiment 1

[0052] Step 1: The multi-component surfactant obtained after mixing and stirring the alkylphenol polyoxyethylene ether and the secondary alkyl sodium sulfonate at a mass ratio of 1:1; the multi-component surfactant, 1,2,4- Stir after triazole and deionized water mix, then add chelating agent ethylenediaminetetraacetic acid tetrakis (tetrahydroxyethylethylenediamine), finally use potassium hydroxide solution (concentration is 10g / L) as the pH agent adjustment solution The pH value is 12, and the alkaline cleaning solution is obtained. Wherein, the mass ratio is multiple surfactants: 1,2,4-triazole: EDTA tetrakis(tetrahydroxyethylethylenediamine): water=1:0.1:0.2:1000;

[0053] Step 2: Use the above-mentioned cleaning solution on the cleaning machine to clean the copper light sheet. The cleaning conditions are cleaning fluid flow rate 1000ml / min, rotation speed 200rpm, brush spacing -1.25mm, cleaning time 100s, deionized water rinse time 150s, deionized water flow rate 500ml / mi...

Embodiment 2

[0057] Step 1: the multi-component surfactant obtained after mixing and stirring sorbitan oleic acid ester and sodium laureth sulfate at a mass ratio of 1:10; the multi-component surfactant, mercaptobenzothiazole as inhibitor and After the ionic water is mixed, stir, then add the chelating agent citric acid, and finally use triethanolamine as the pH agent to adjust the pH value of the solution to 11 to obtain the alkaline cleaning solution.

[0058] Wherein, mass ratio is multiple surfactant: mercaptobenzothiazole: citric acid: water=10:0.5:1:1000

[0059] Step 2: Use the above-mentioned cleaning solution on the cleaning machine to clean the copper light sheet. The cleaning conditions are cleaning fluid flow rate 300ml / min, rotation speed 150rpm, brush spacing -0.75mm, cleaning time 55s, deionized water flushing time 80s, deionized water flow rate 1000ml / min, drying time 100s, nitrogen blow dry The time is 60s.

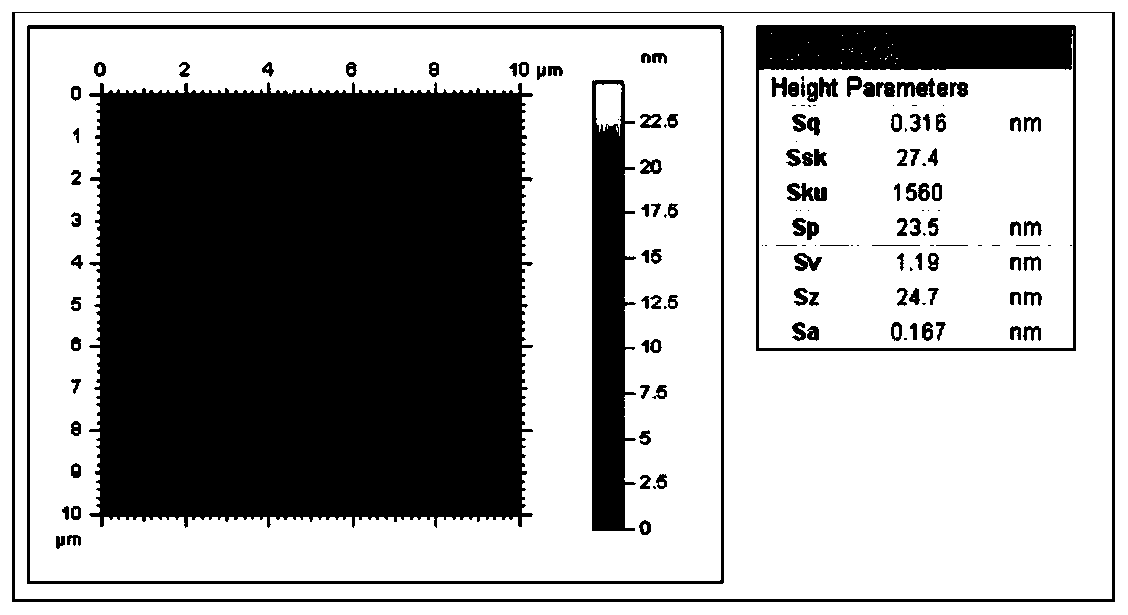

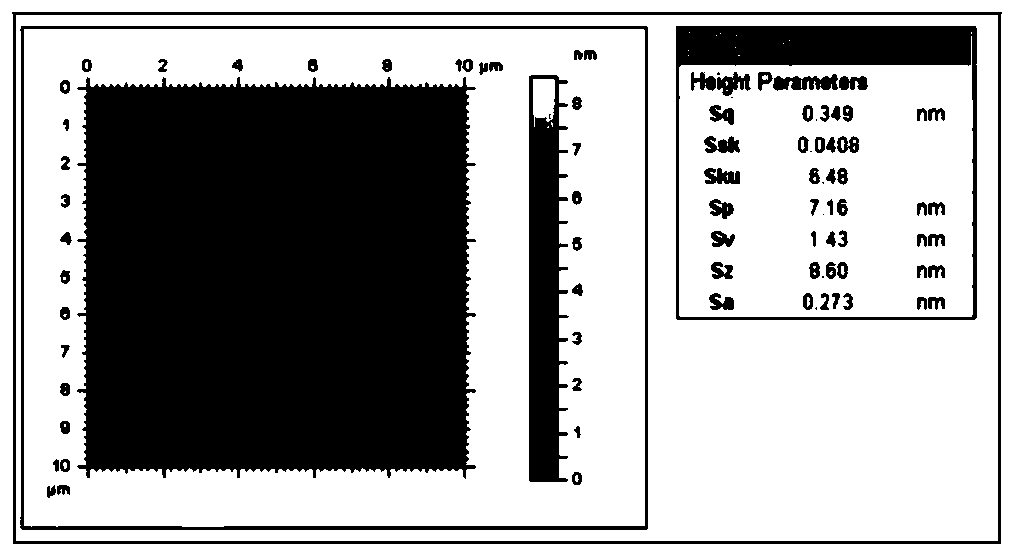

[0060] image 3 It is the AFM figure that obtains in the embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com