Patents

Literature

63results about How to "Improve perfection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

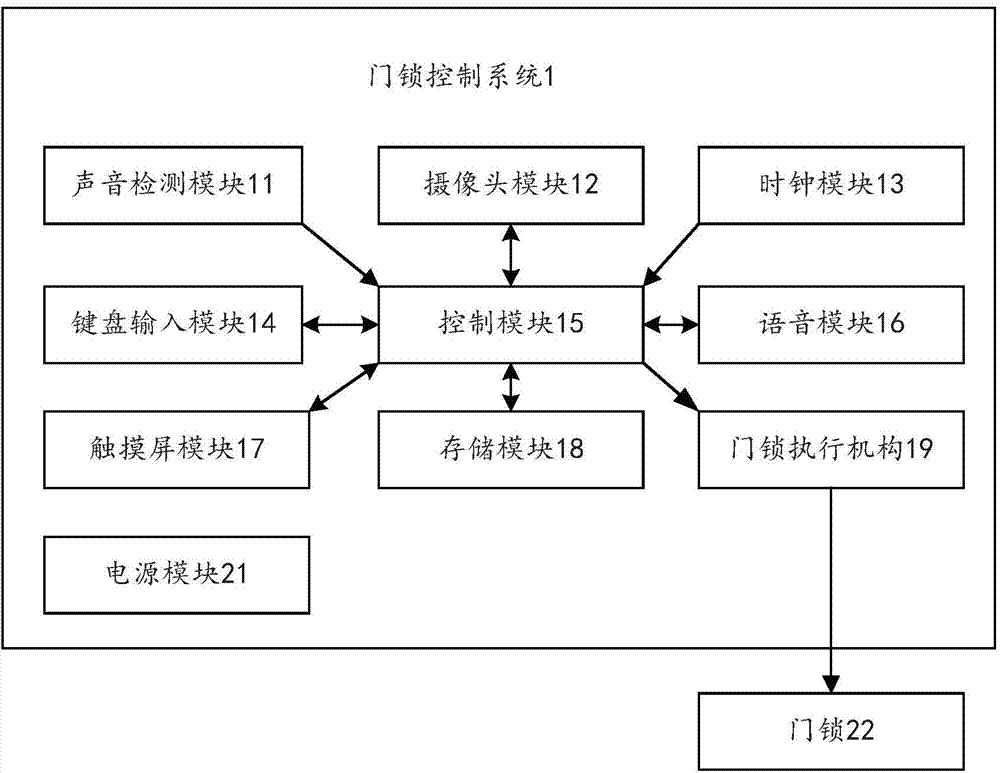

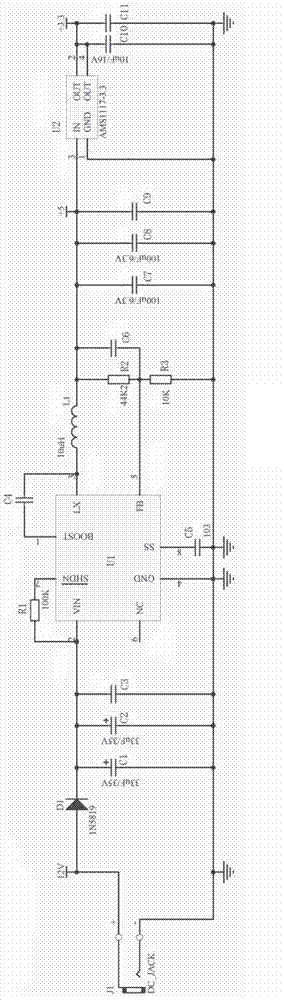

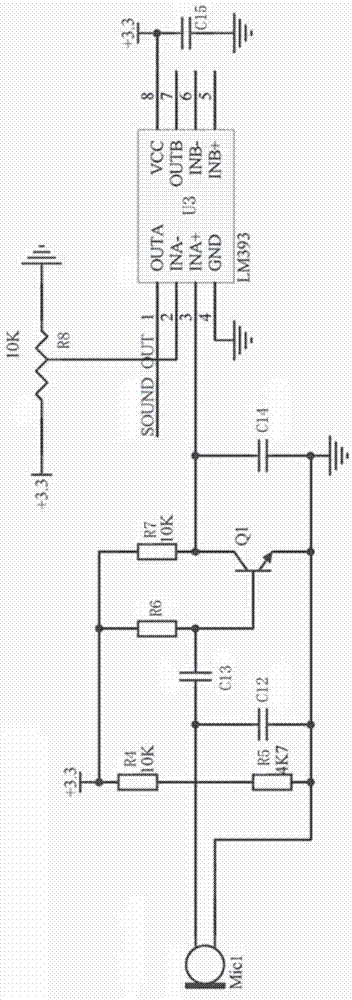

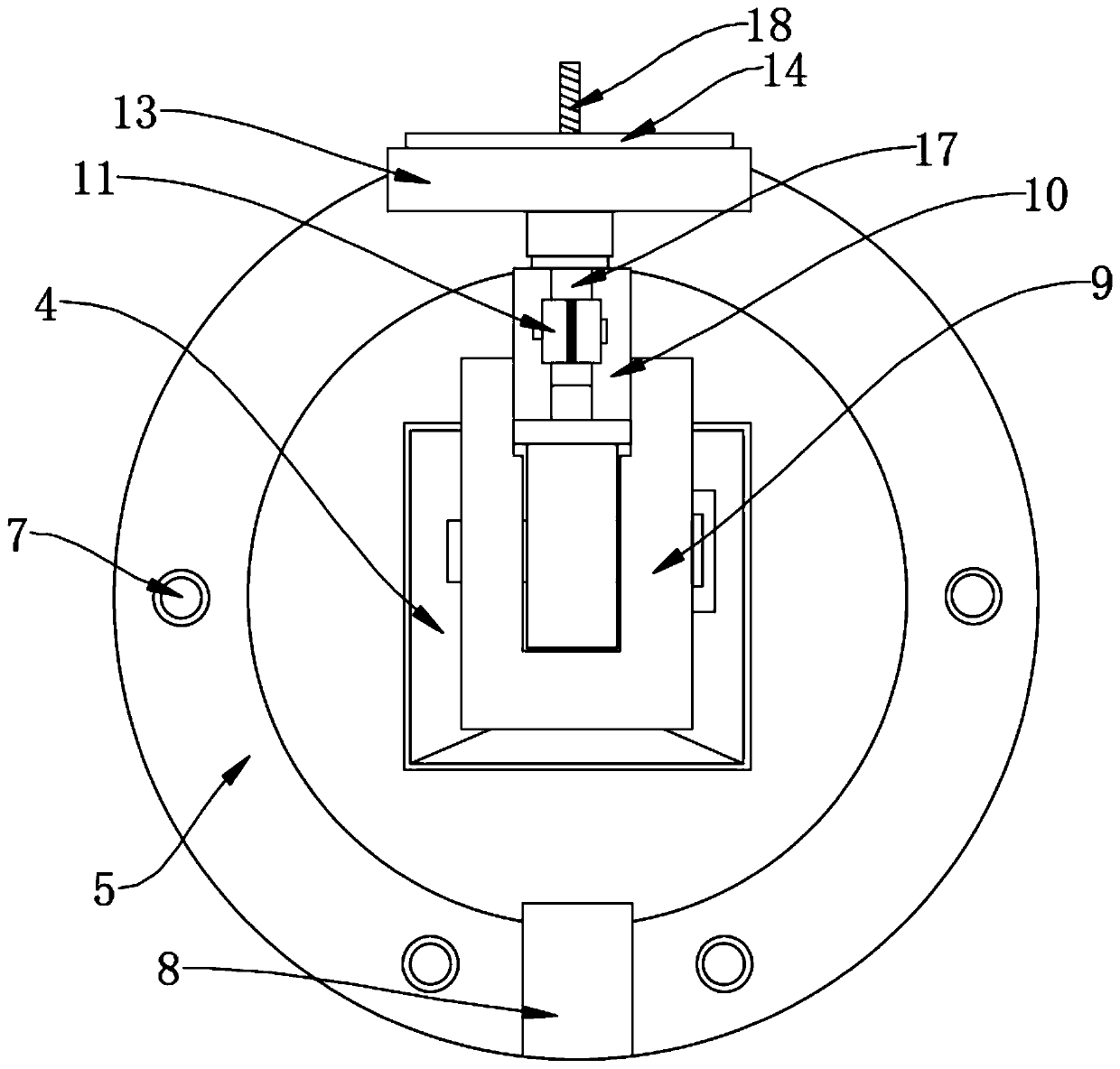

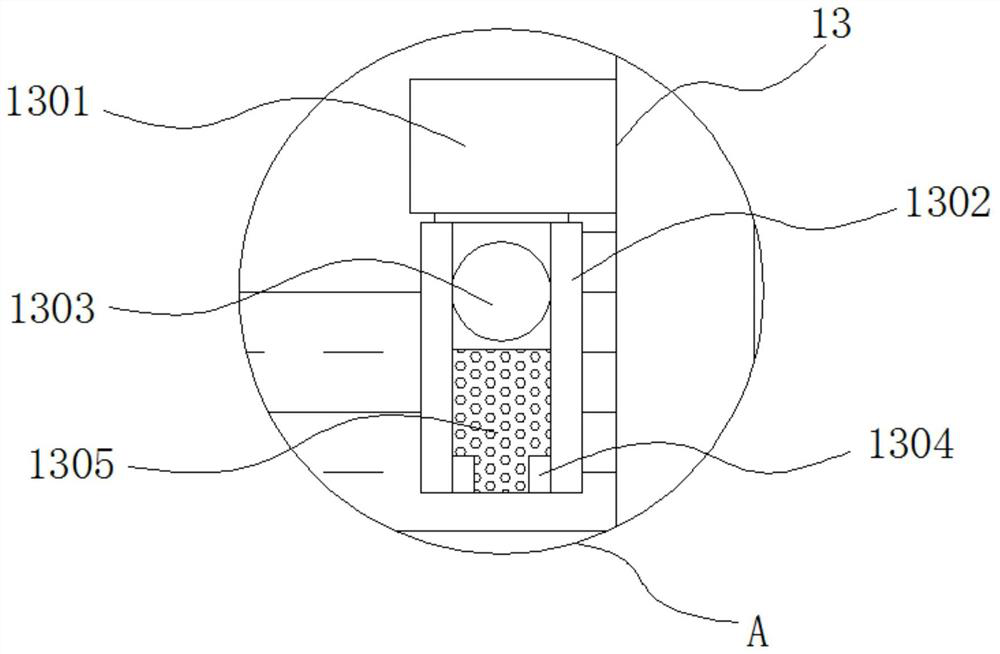

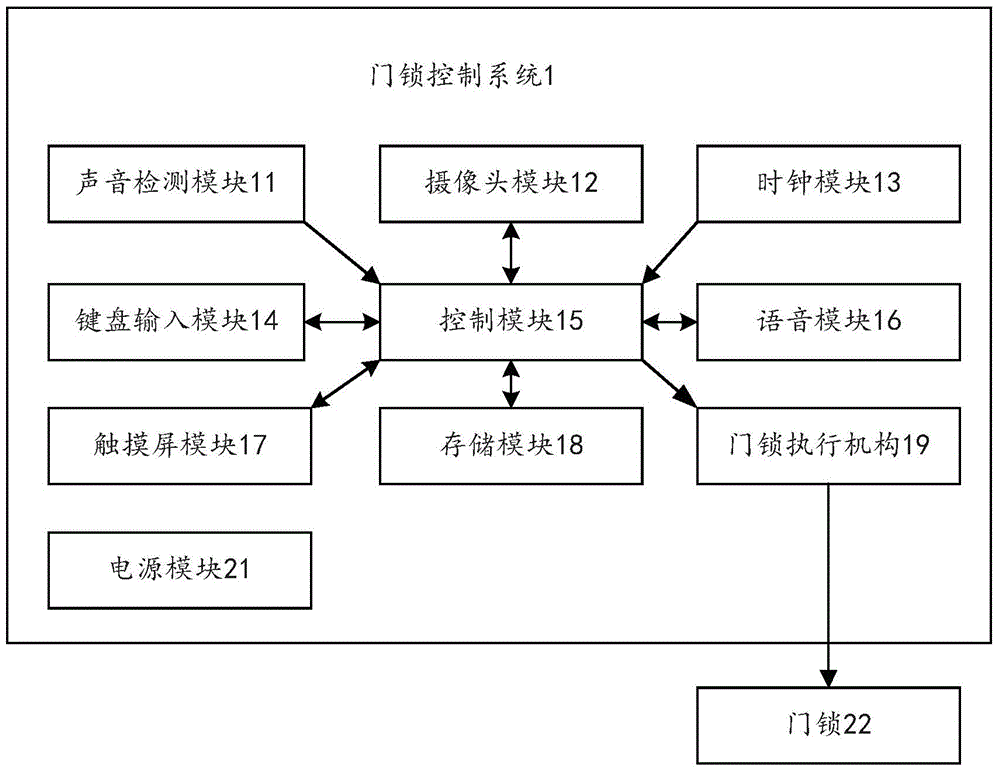

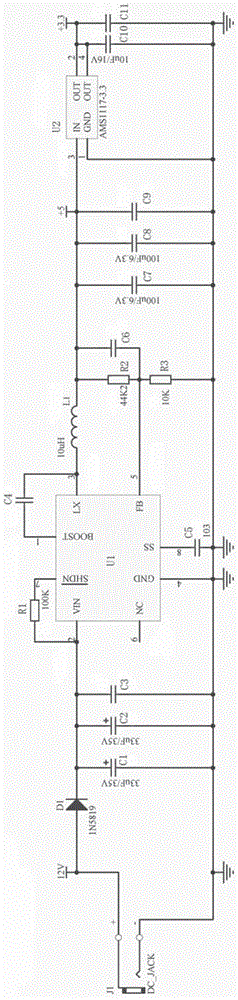

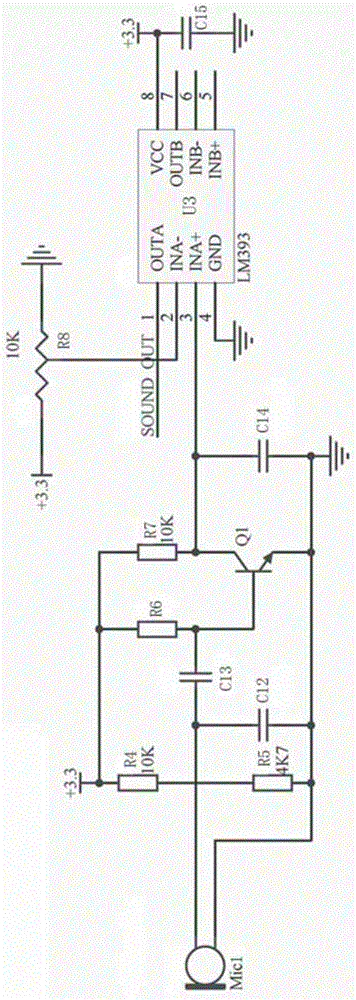

Door lock control system and control method

ActiveCN104299296AImprove perfectionAvoid wastingIndividual entry/exit registersSound detectionControl system

The invention provides a door lock control system and a door lock control system control method, the door lock control system comprises a door lock actuator, a control module, a power supply module, a sound detection module, a camera module, a keyboard input module, a touch screen module, a voice module, a storage module and a clock module, the sound detection module is used for detecting sound and outputting a feedback signal to the control module, the camera module is used for obtaining an image signal and outputting the image signal to the control module, the keyboard input module is used for inputting a first cipher signal to the control module, the touch screen module is used for receiving a display signal outputted by the control module and inputting a second cipher signal to the control module, the voice module includes a first microphone and a sound production module, the first microphone is used to obtain a voice signal and store in the voice module, and the sound production module is used for receiving a voice control signal outputted by the control module and producing a sound. The door lock control system control method is conductive to saving resources and providing a user a more convenient and safer door lock.

Owner:GUANGZHOU HORIZONTAL INFORMATION TECH

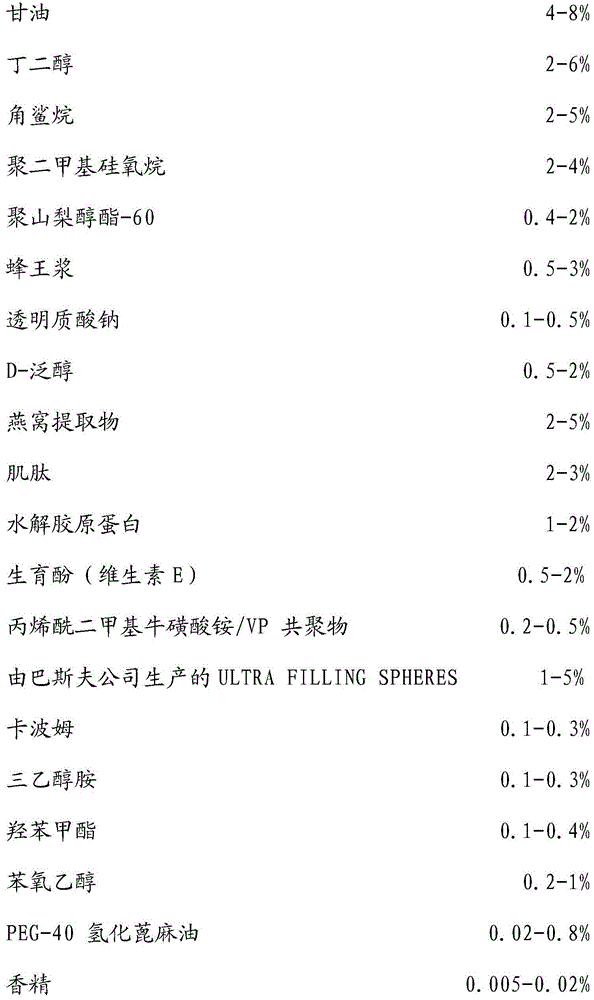

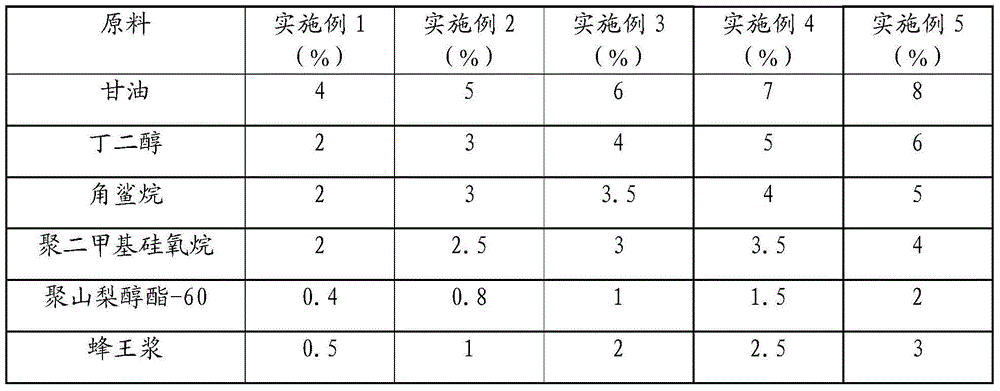

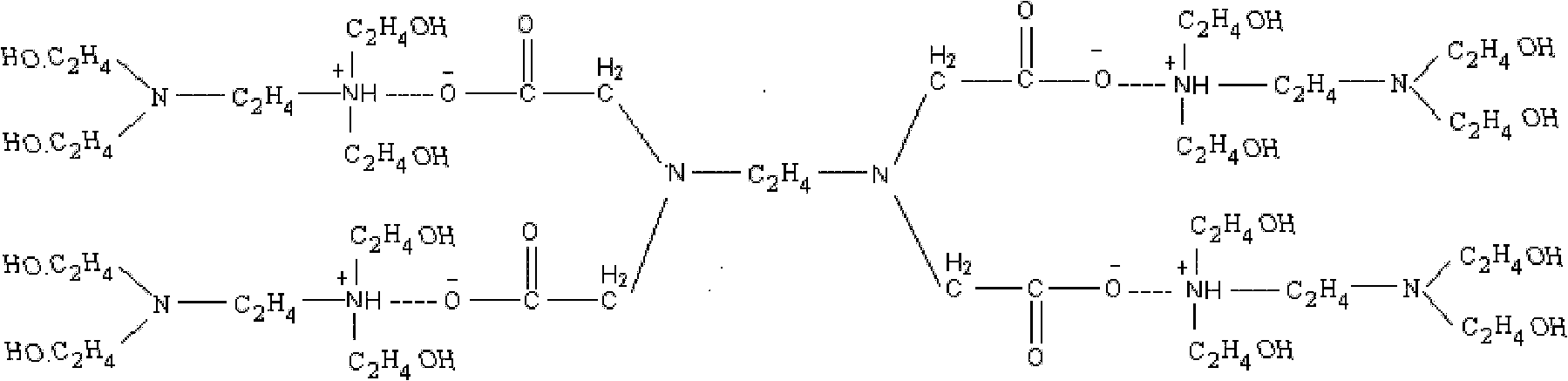

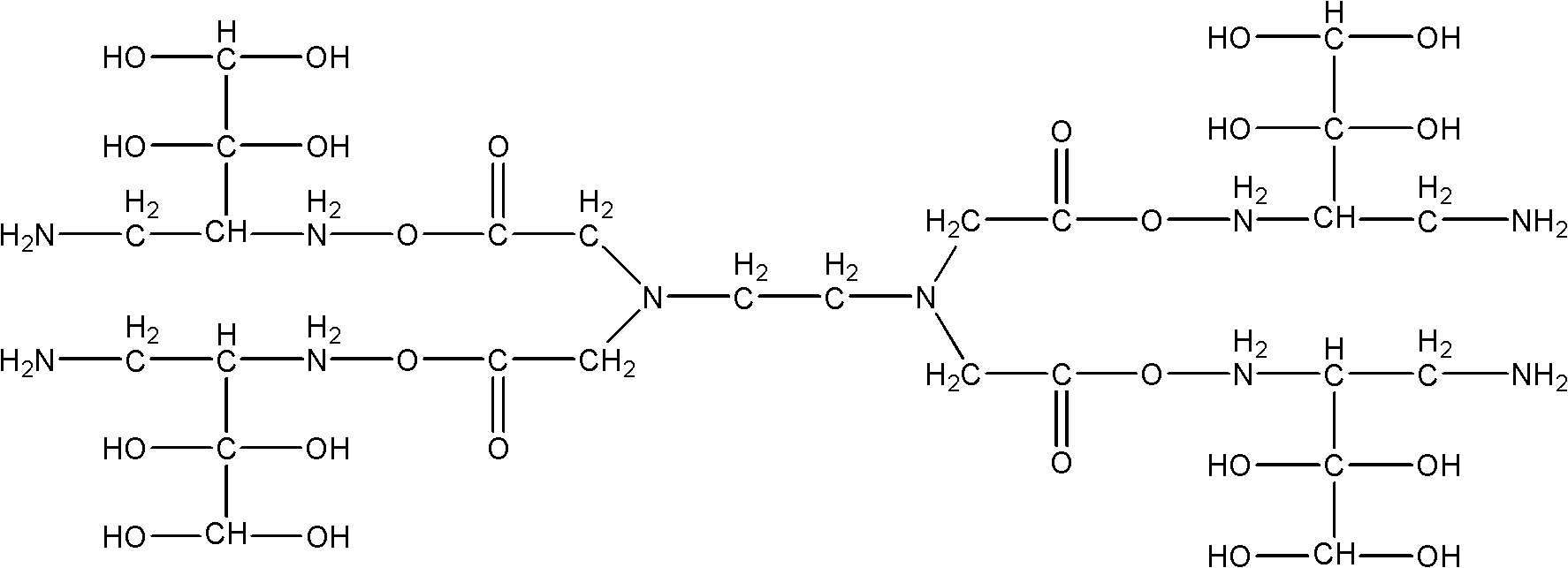

Skin-tightening mask and production method thereof

InactiveCN104546650AImprove firmnessImprove perfectionCosmetic preparationsToilet preparationsWater useSolvent

The invention discloses a skin-tightening mask and a production method thereof. The mask is prepared from water used as a solvent, glycerin, butylene, squalane and sodium hyaluronate which are used as moisturizers, polydimethylsiloxane and polysorbate-60 which are used as emulsifiers, tocopherol, D-panthenol and carnosine which are used as emollients, methylparaben and phenoxyethanol which are used as preservatives, an ammonium acryloyldimethyltaurate / VP copolymer and carbomer which are used as thickeners, royal jelly, a bird's nest extract, hydrolysis collagen and Ultra Filling Spheres which are used as skin conditioners, triethanolamine used as a PH regulator, PEG-40 hydrogenated castor oil used as a solubilizer as well as essence. The mask can reduce looseness caused by skin dryness after makeup, tighten facial skin, shrink pores, delay aging, fade dry and thin winkles, supplement the skin with required nutrition and moisture, keep the healthy function of the skin and keep the skin moistened and transparent all day.

Owner:广州市洁新化妆品有限公司

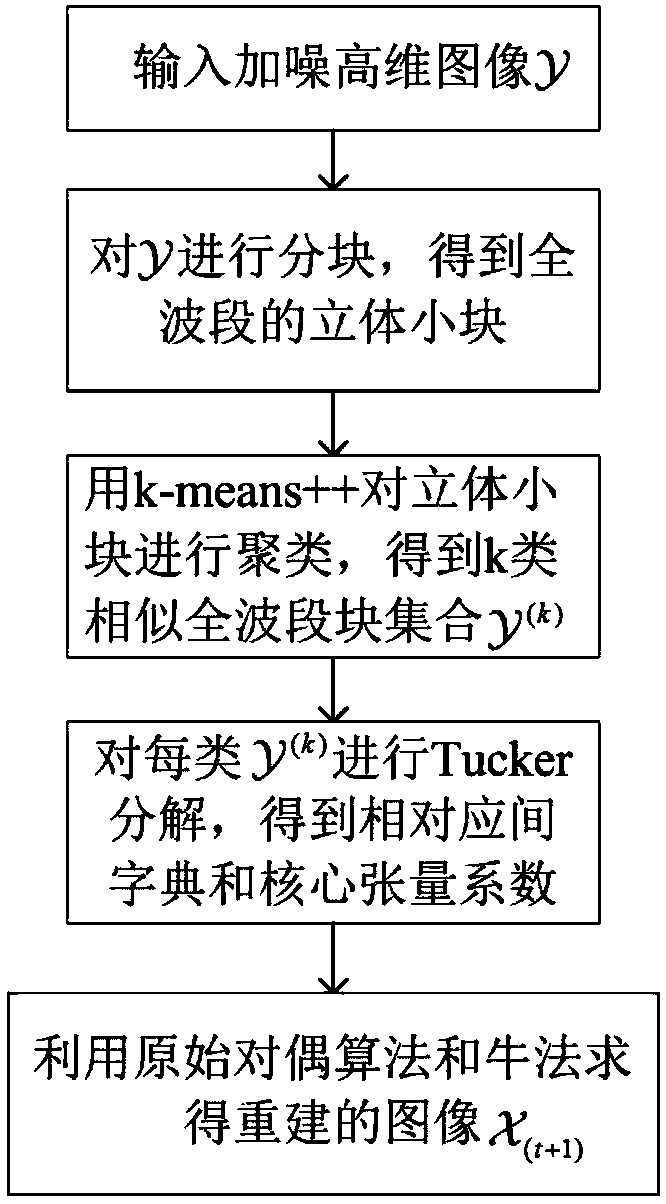

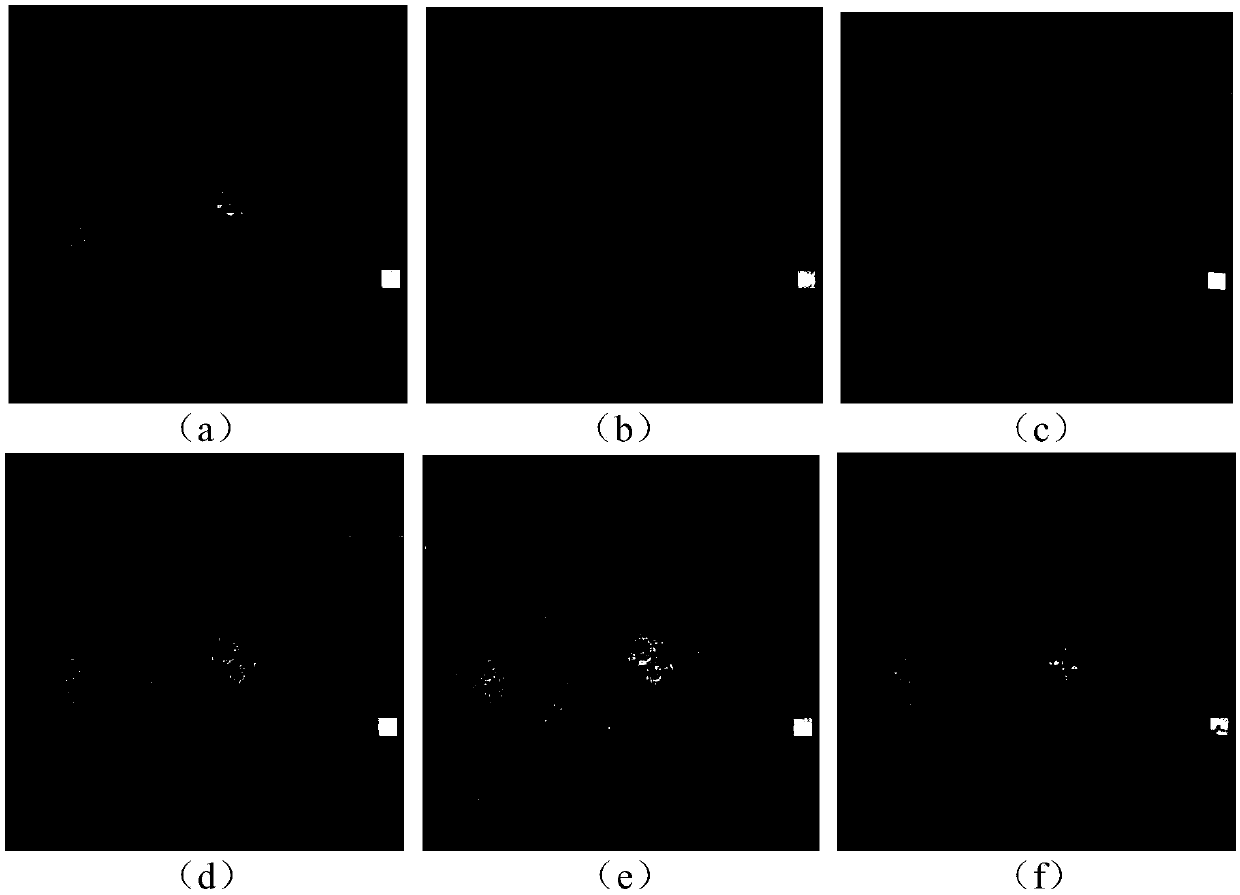

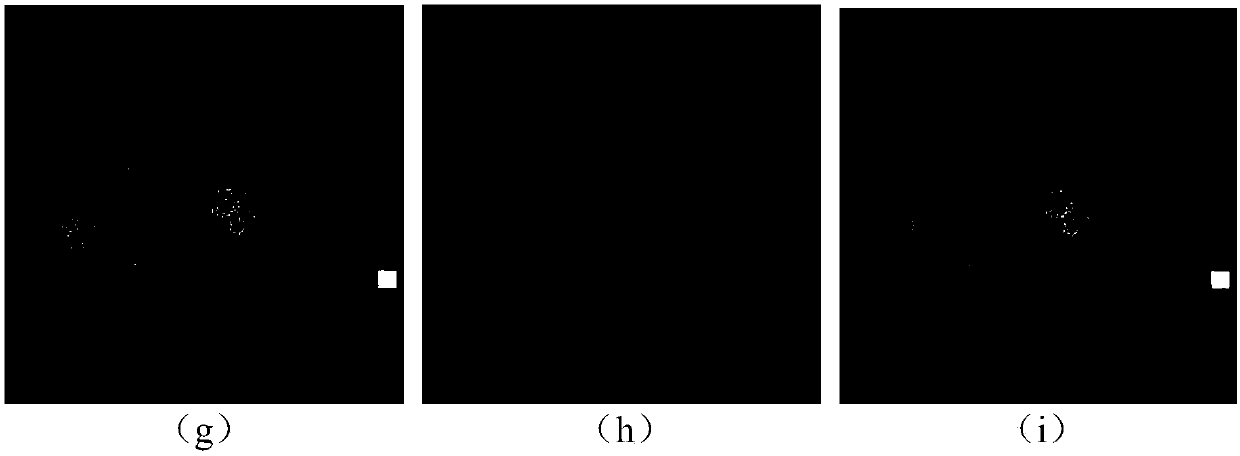

High-dimensional image de-noising method based on tensor dictionary and total variation

ActiveCN108399608AImprove perfectionImprove clarityImage enhancementImage analysisWave bandDe noising

The invention discloses a high-dimensional image de-noising method based on a tensor dictionary and total variation. Based on the study of high-dimensional image processing, the tensor dictionary learning combines a total variation regular term, a high-dimensional image de-noising model combing the tensor dictionary learning with a TV regular term is provided, and then the model is solved by usingan alternate iterative method to obtain a reconstructed MSI image after iteratively updating. The high-dimensional image de-noising method based on the tensor dictionary and the total variation has the advantages that a high-dimensional image is regarded as a tensor entirety, stereochemical structure information cannot lose, the correlation among wave bands is also considered, and the accuracy ofan algorithm is improved through a tensor dictionary learning mode; under the premise without losing a high-dimensional image space structure, a high-order TV regular term is adopted, more complete edge information is well preserved, and a good reconstruction effect is obtained; the experimental result achieves a better effect in both subjective vision and objective evaluation indexes, and more texture information and contour information can be retained.

Owner:GUILIN UNIV OF ELECTRONIC TECH

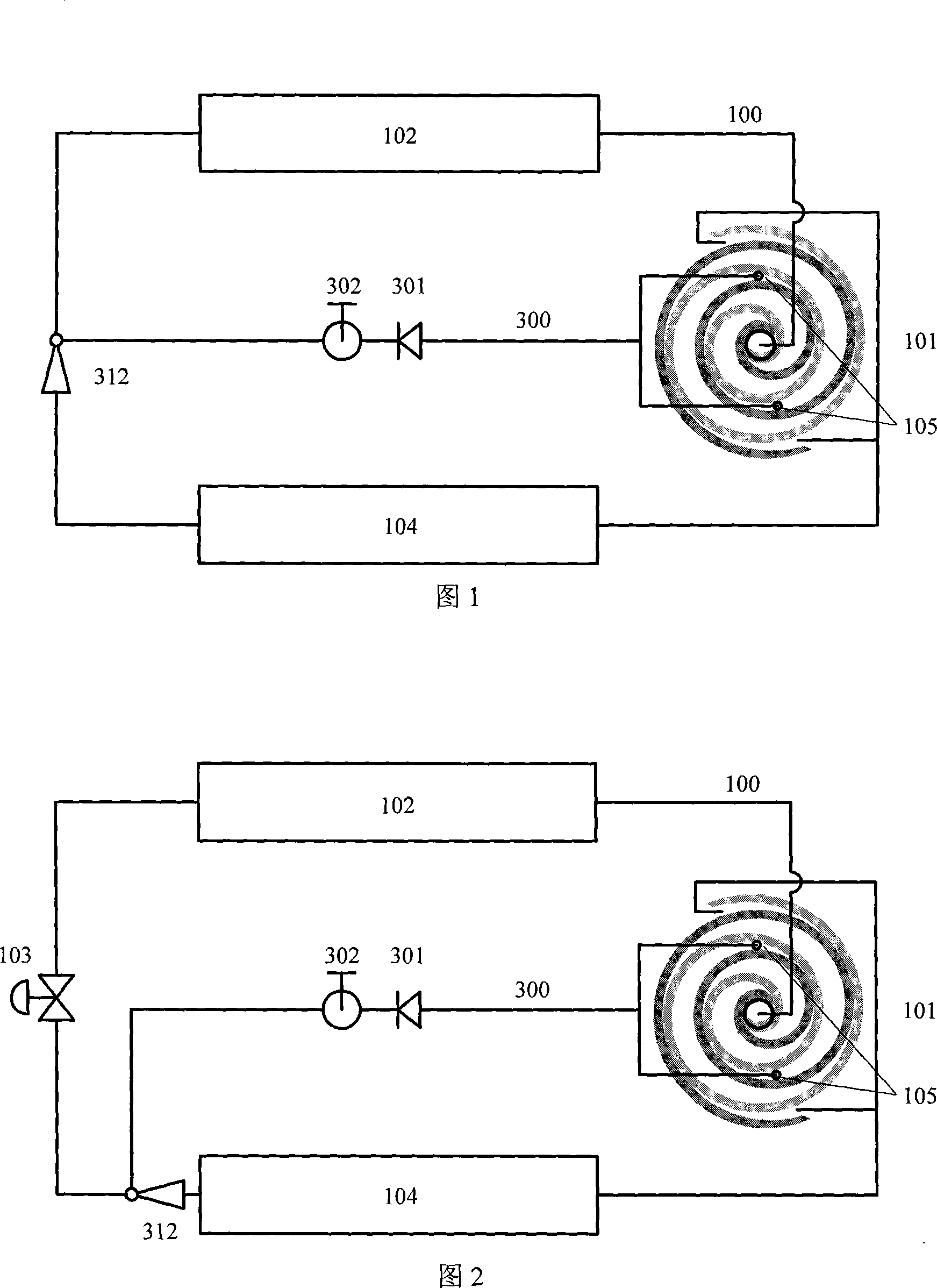

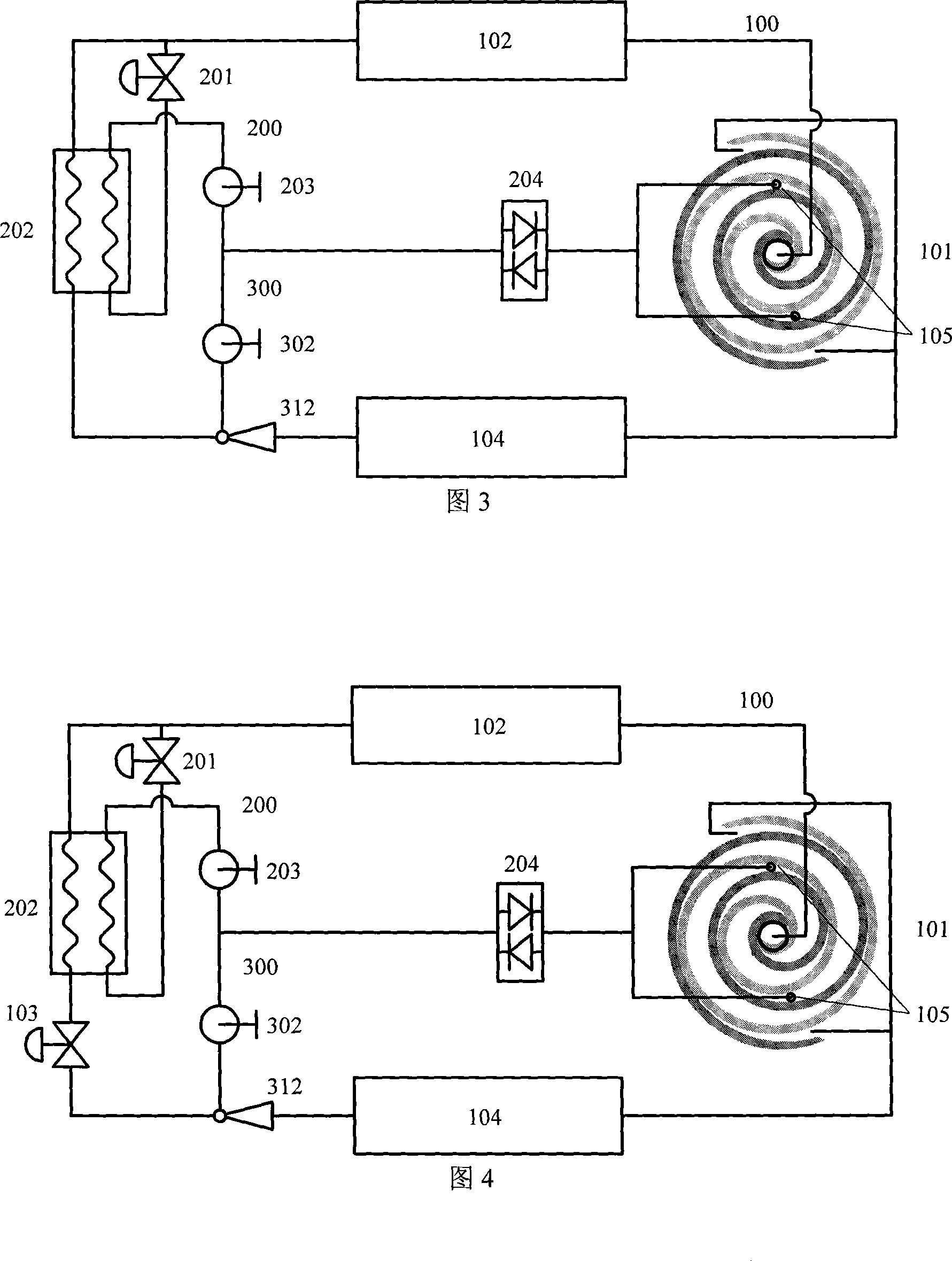

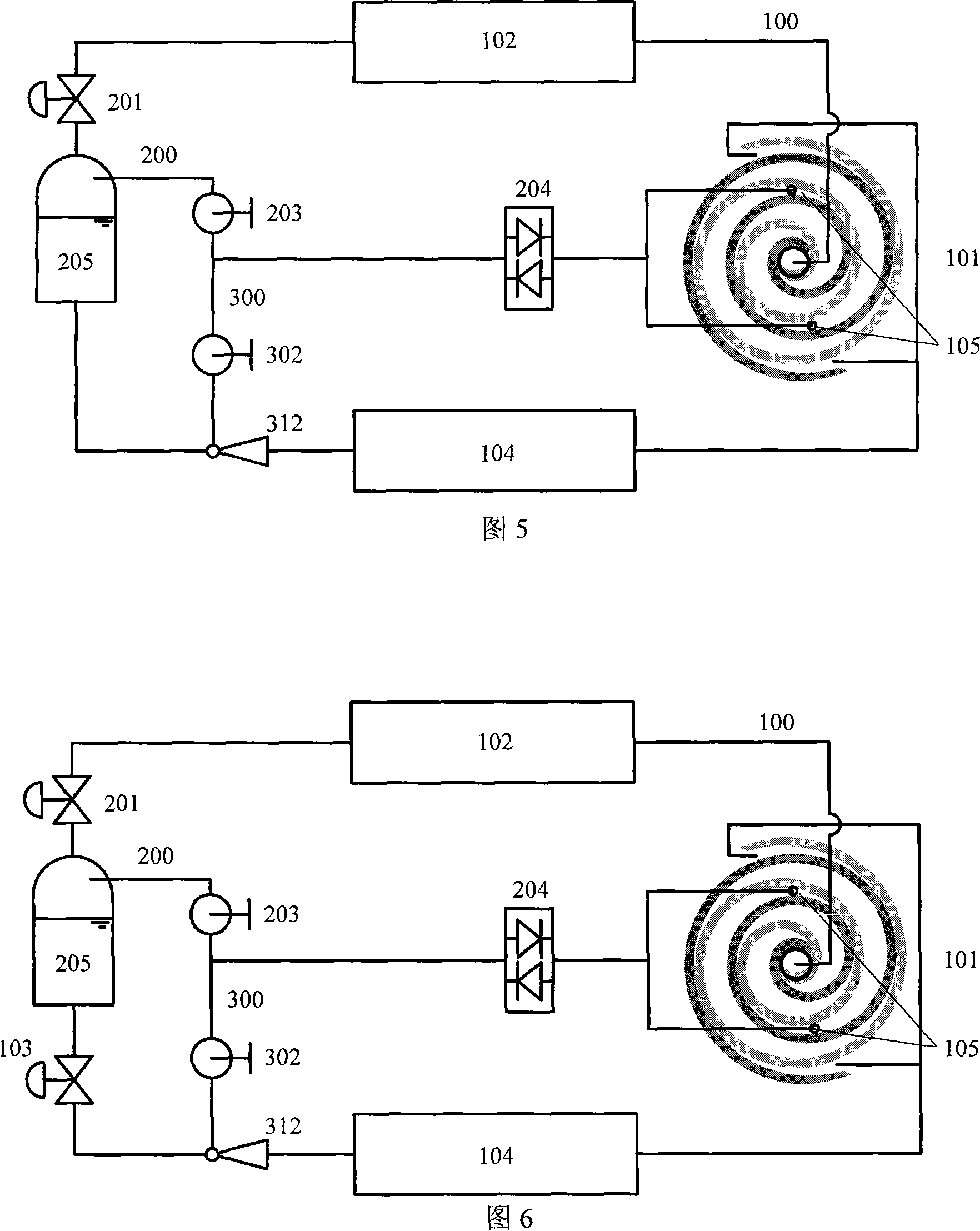

Capacity adjustable vortex compressor refrigeration system with main return loop installed with ejector

InactiveCN101169291ALess investmentImprove adaptabilityCompression machines with non-reversible cycleFluid circulation arrangementSystem capacityAir conditioning

The invention relates to a whirl compressor cooling system which has a main loop provided with an ejector and the capacity adjustable, belonging to the cooling and air conditioning field. The ejector is arranged between the condenser and an evaporator in the system loop. The refrigerant is released from the middle section of the compressor to the low-pressure side by utilizing the high-low pressure differential reinforcing whirl compressor cooling system so as to improve the unloading capability of the whirl compressor. Meanwhile, the reinforced refrigerant release technique is combined with the refrigerant ejection technique so that the whirl compressor has the capacity change from the largest to the lowest greatly improved. The technique can be applied to the air conditioner cooling field with the cooling / heat pump system, thereby the efficiency, the system capacity and the performance of the compressor can be effectively changed, the highly efficient work of the system in larger work area can be achieved, and then the applicability of the system in large and changeable work condition is improved.

Owner:TSINGHUA UNIV

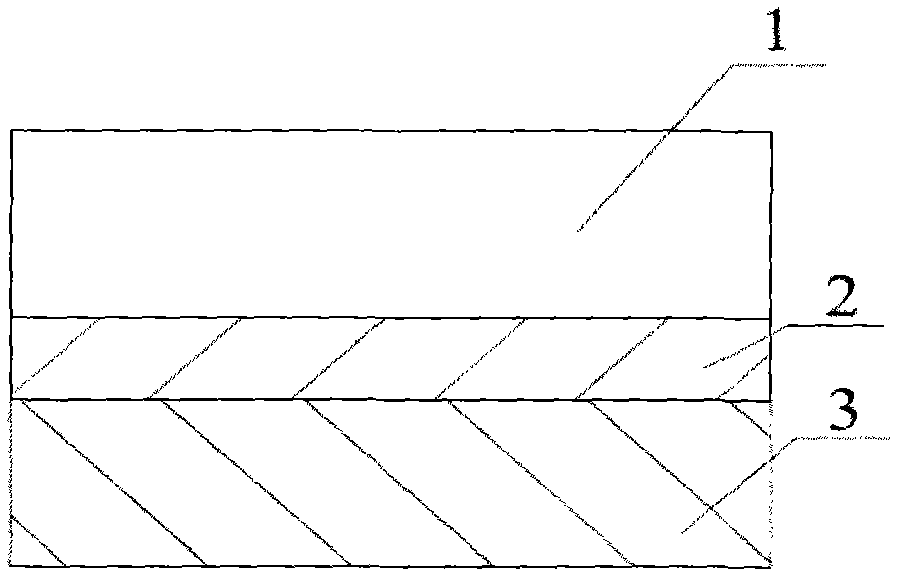

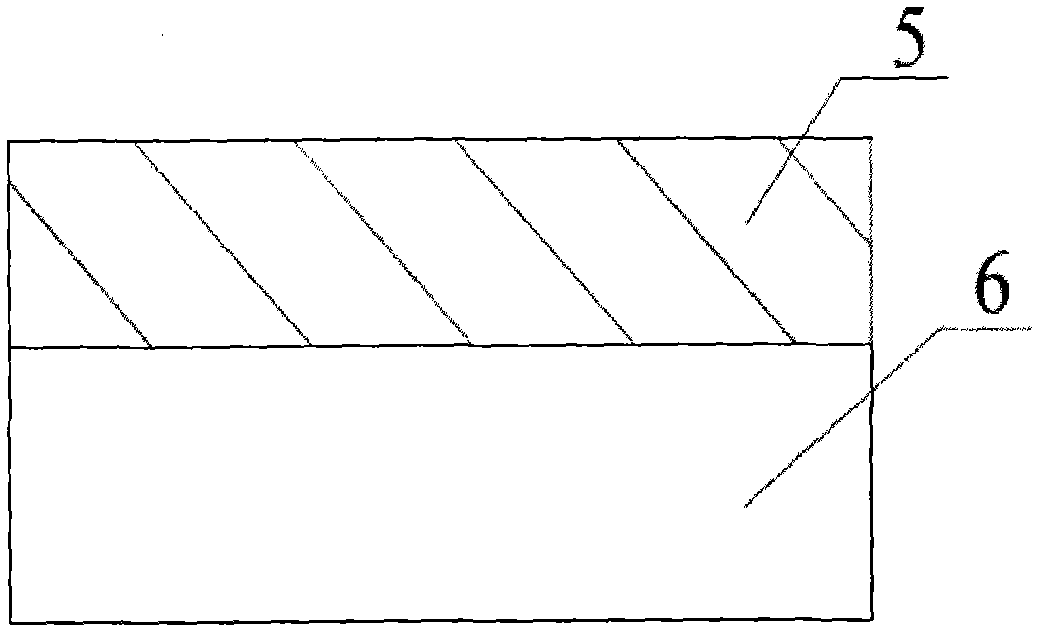

Method for carrying out bonding epitaxial wafer and silicon wafer by indium (In)

InactiveCN102569031AImprove performanceLow melting pointSemiconductor/solid-state device manufacturingIndiumWafer bonding

The invention discloses a method for carrying out epitaxial wafer and silicon wafer bonding by indium (In). The method comprises the steps as follows: an indium (In) layer is deposited on the silicon wafer where a gold (Au) layer is evaporated, and the gold (Au) layer is evaporated on the epitaxial wafer where a reflecting mirror layer is deposited; the two wafers (the indium (In) layer in the middle) face relatively and are put into a bonding machine for bonding, so as to prepare an LED (light-emitting diode) device with the advantages of high efficiency, high brightness, low resistance and steady performance. The epitaxial wafer and silicon wafer bonding is carried out by the method, the bonding area is compact and hole-free, the bonding strength is high, and the bonding rate can reach above 98%. The bonding area of a prepared substrate slice has no pollution layer, polycrystalline layer or oxide layer, so that the performance of the prepared light-emitting diode device is greatly improved.

Owner:BEIJING TIMES HAODING TECH

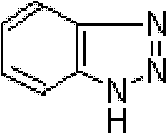

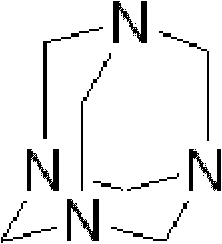

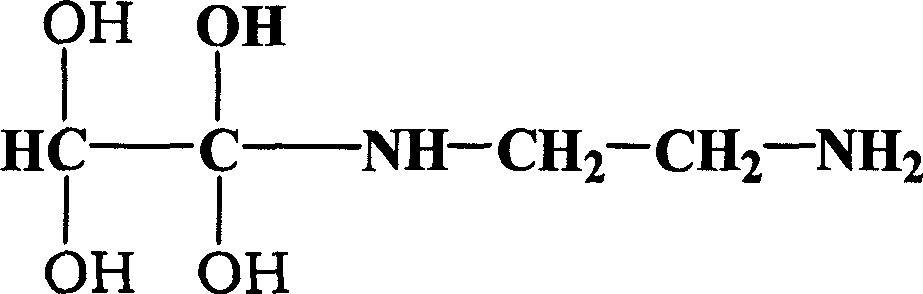

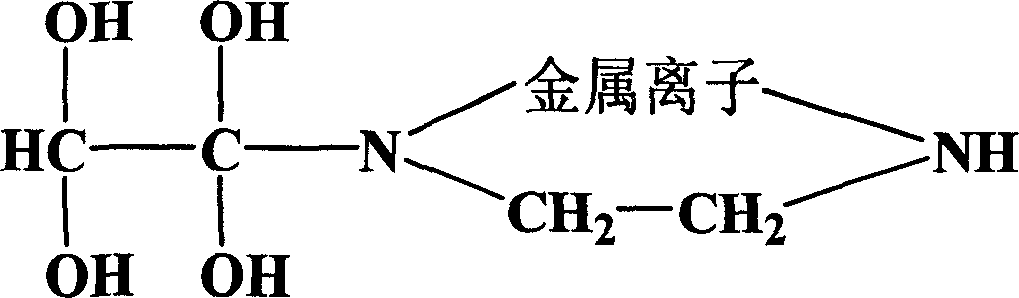

Method for cleaning back surface of tungsten plug CMP for integrated circuit in ultra-large scale

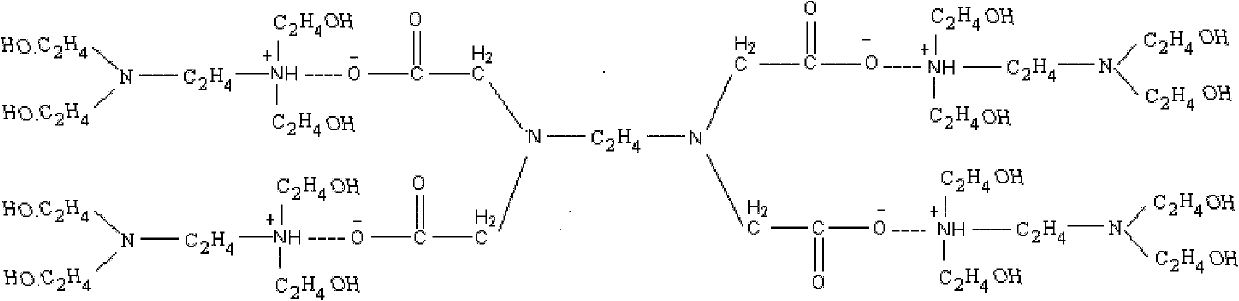

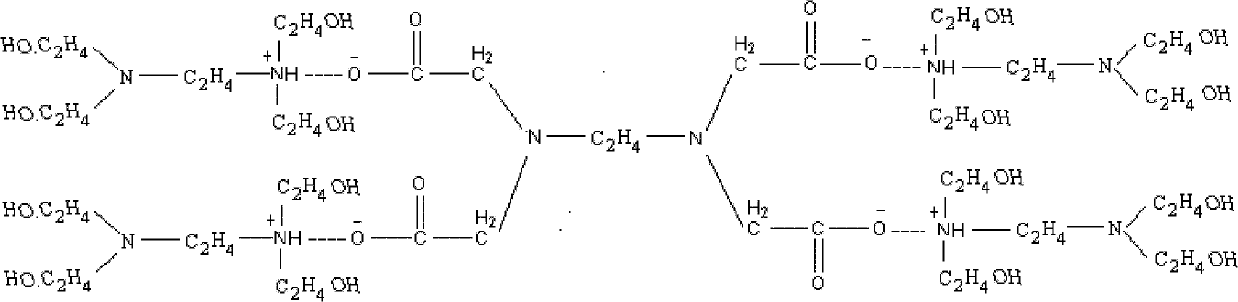

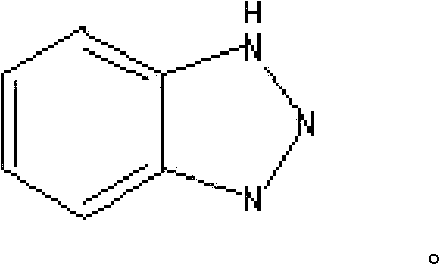

InactiveCN101908502AReduce surface tensionImprove uniformityDetergent mixture composition preparationSemiconductor/solid-state device manufacturingEngineeringMachining process

The invention relates to a method for cleaning the back surface of a tungsten plug CMP in the high-precision machining process of the surface of the tungsten plug for an integrated circuit in an ultra-large scale. A water polishing solution of an alkaline medium is utilized, and the water polishing solution comprises an activator, a chelator and a corrosion inhibitor. After an alkaline polishing process is just finished, the water polishing solution is added immediately, and a large-flow water polishing method is adopted, so that the residual polishing solution can be washed away, substances which can be cleaned easily are absorbed, the surface tension is quickly lowered, the reaction is prevented from continuing (physical adsorption state), a monomolecular passivating film is formed, and metal ions can form soluble chelates, thereby obtaining a clean and perfect polished surface. Moreover, the water polishing solution has the advantages of low cost, no pollution on the environment and no corrosion on the equipment.

Owner:HEBEI UNIV OF TECH

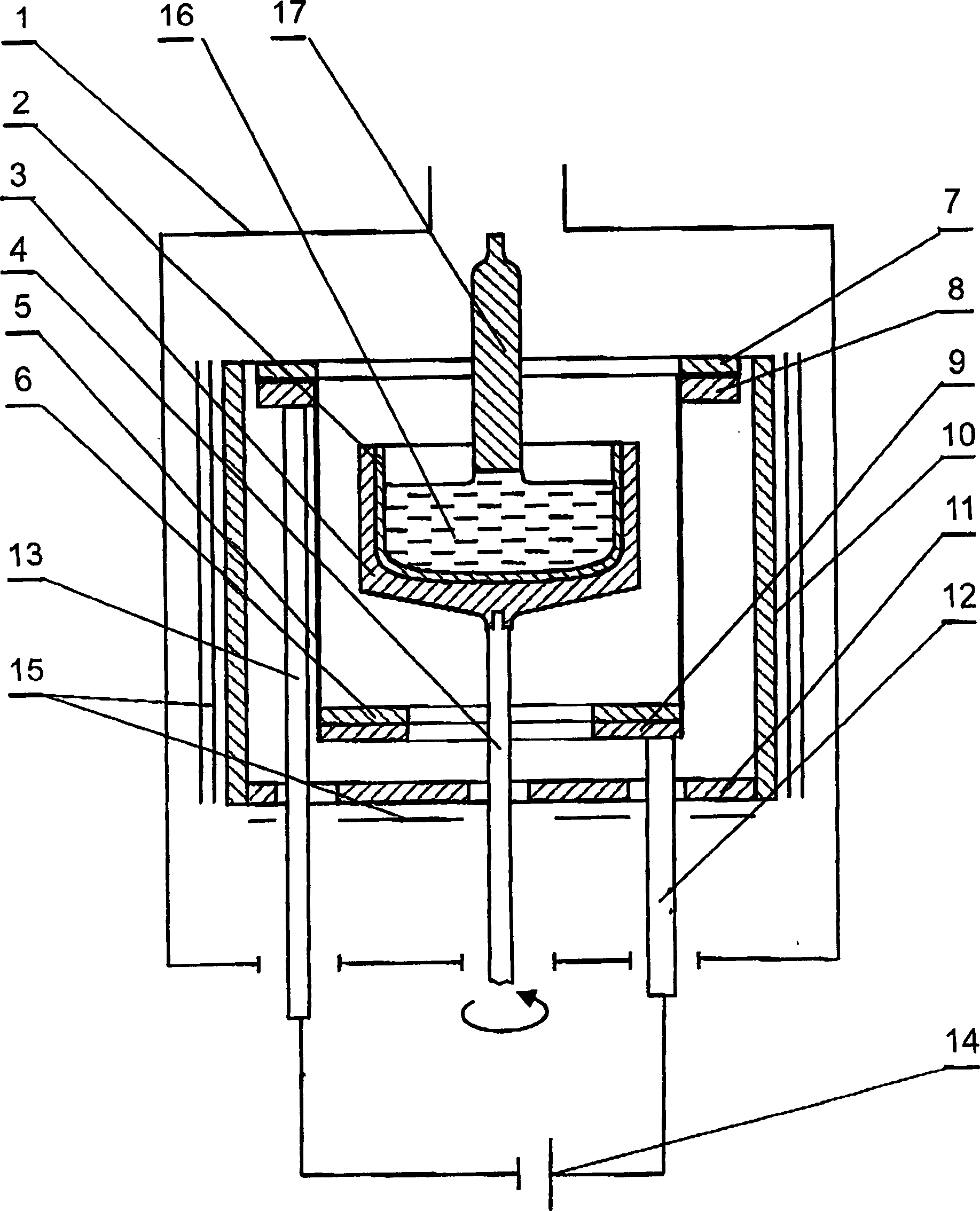

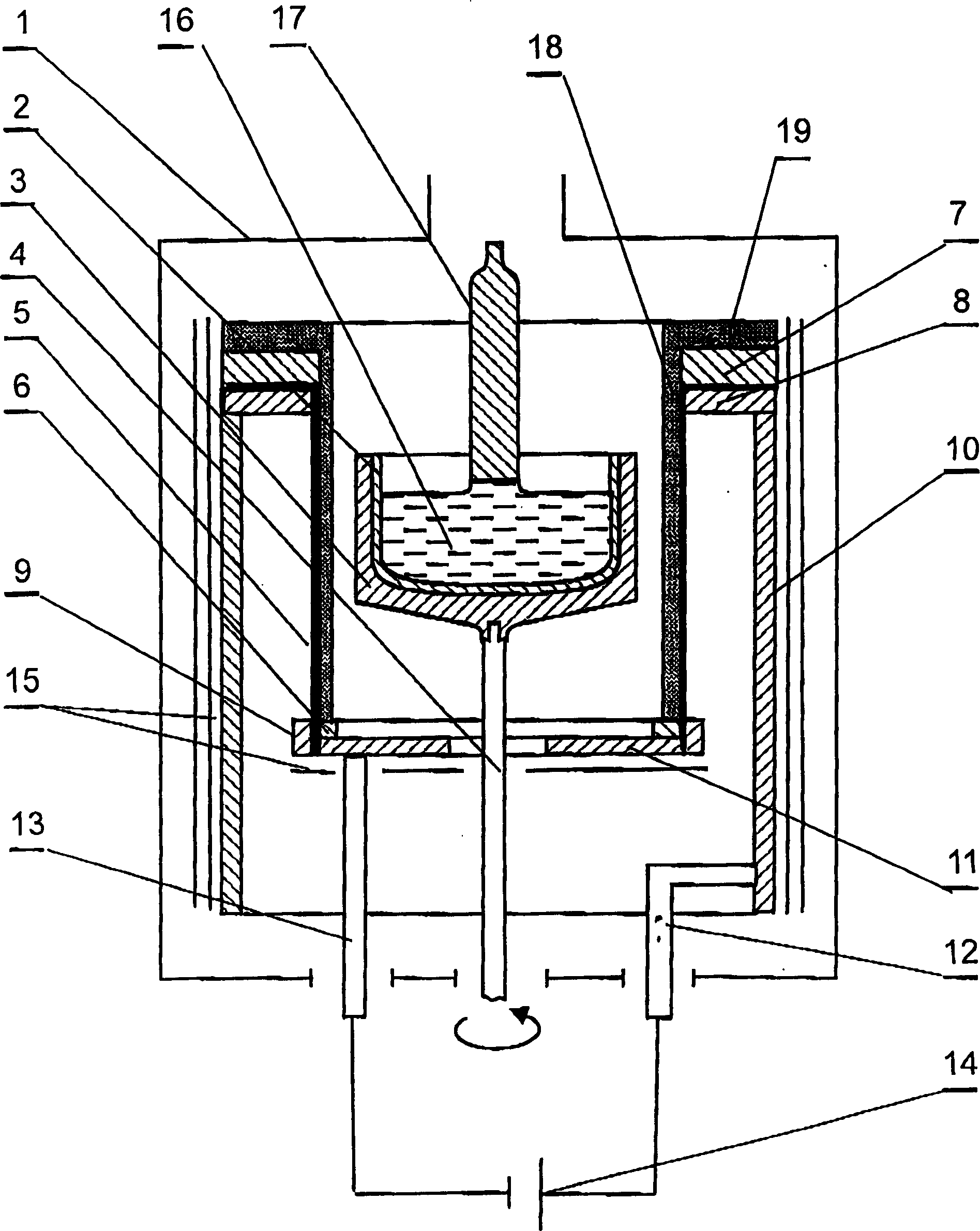

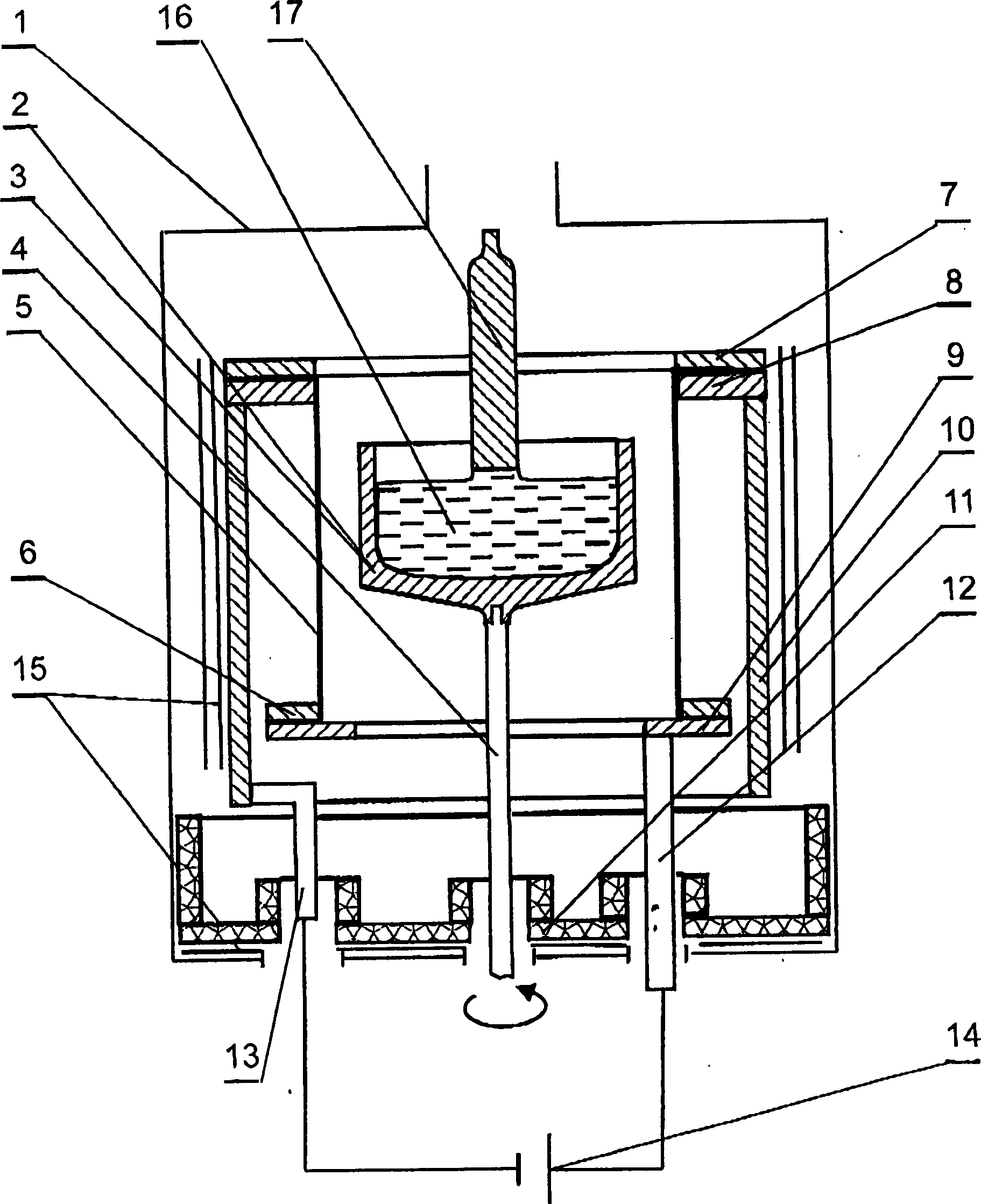

Device for pulling monocrystals

InactiveCN1656258ASolve operational problemsLight in massAfter-treatment apparatusPolycrystalline material growthCrucibleWorking temperature

The device comprises a crucible with a support, a heater and at least one heat-insulating screen, wherein, according to the invention, the heater is made of a starting flexible carbon-bearing material in the form of a cylinder whose ends are fixed between coaxially arranged rigid rings of carbon material that are connected to a power supply. And, the heater is made so that the wall thereof has its thickness determined from the relationship: delta . rho - c = 500 to 8500 J / m<2>. K, where: <> delta - heater wall thickness, m; rho - density of the material the heater is made of, kg / m<3>; and c - specific heat of the material the heater is made of (at working temperature), J / kg.K.

Owner:弗拉基米尔・弗拉基米罗维奇・科斯京 +1

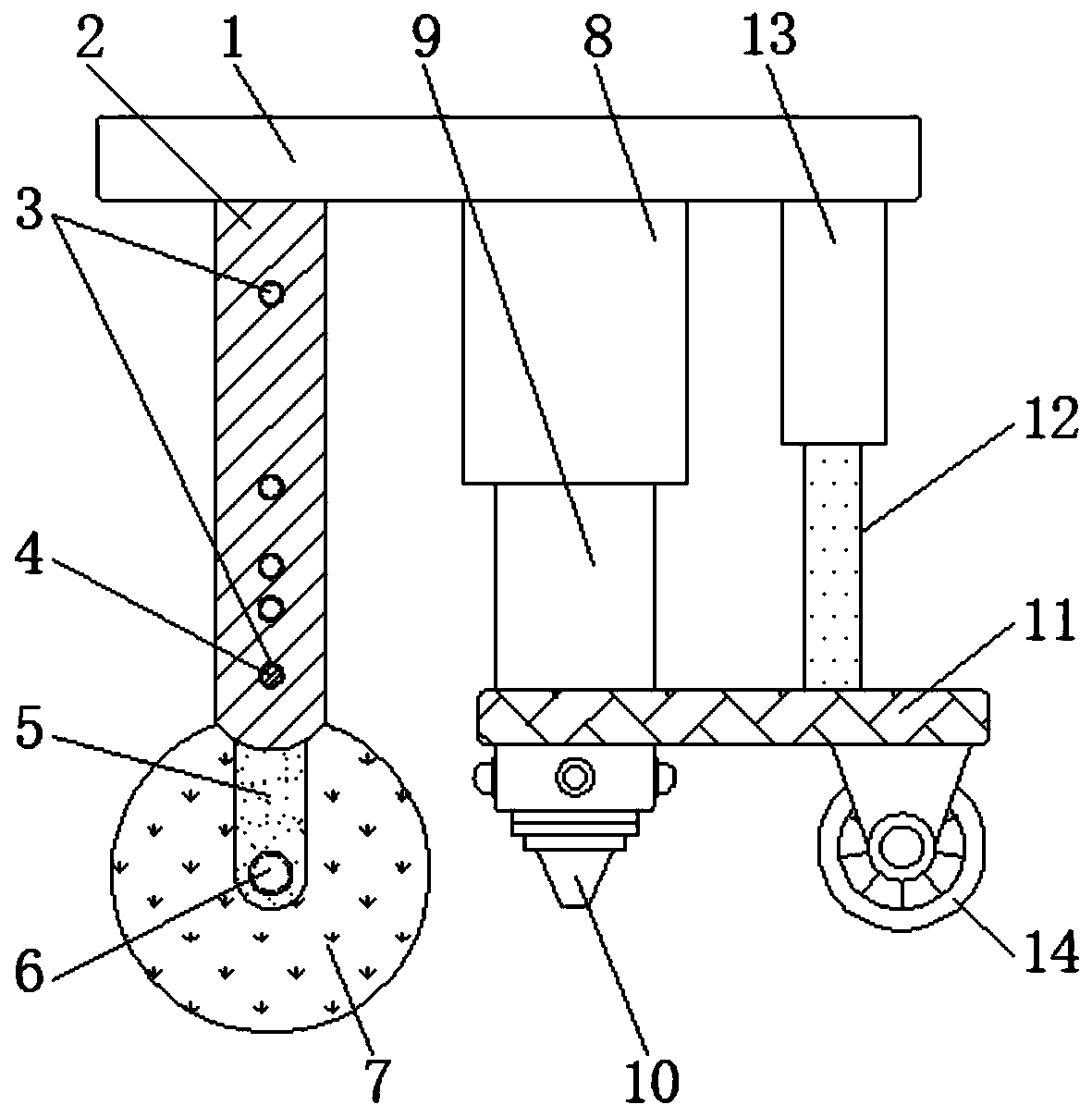

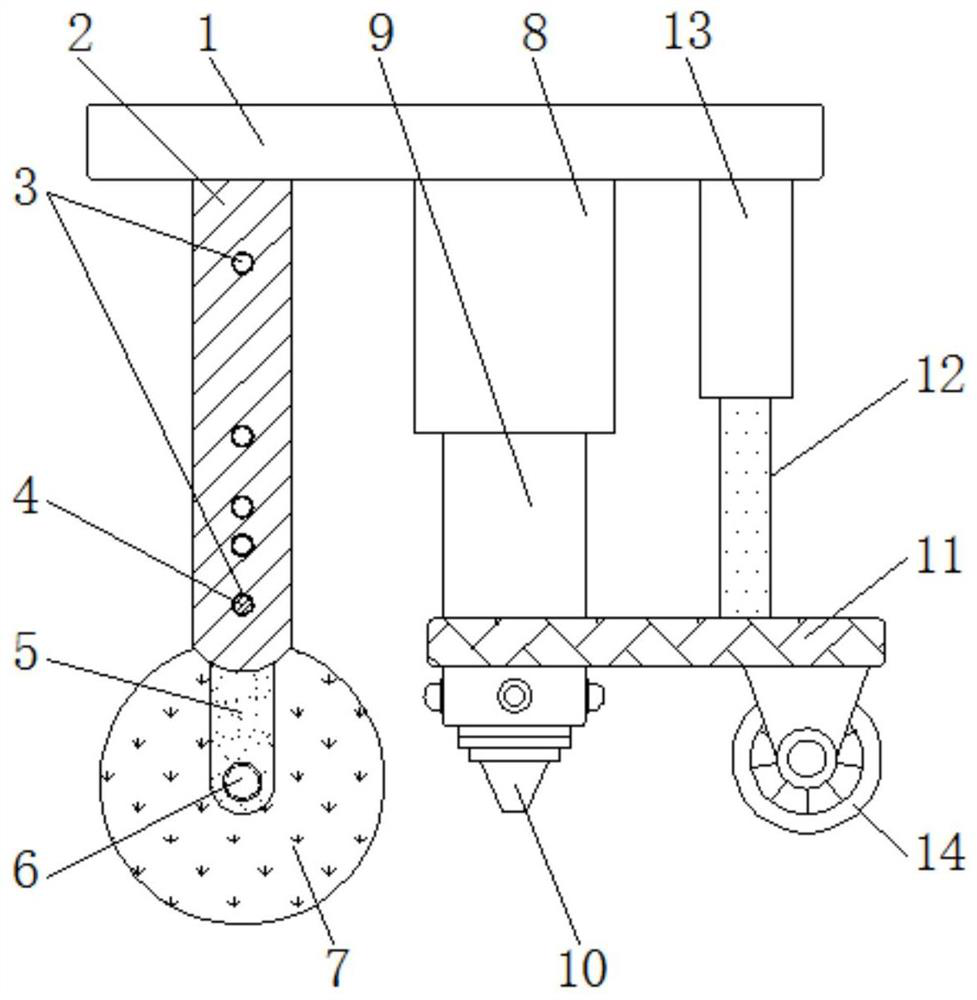

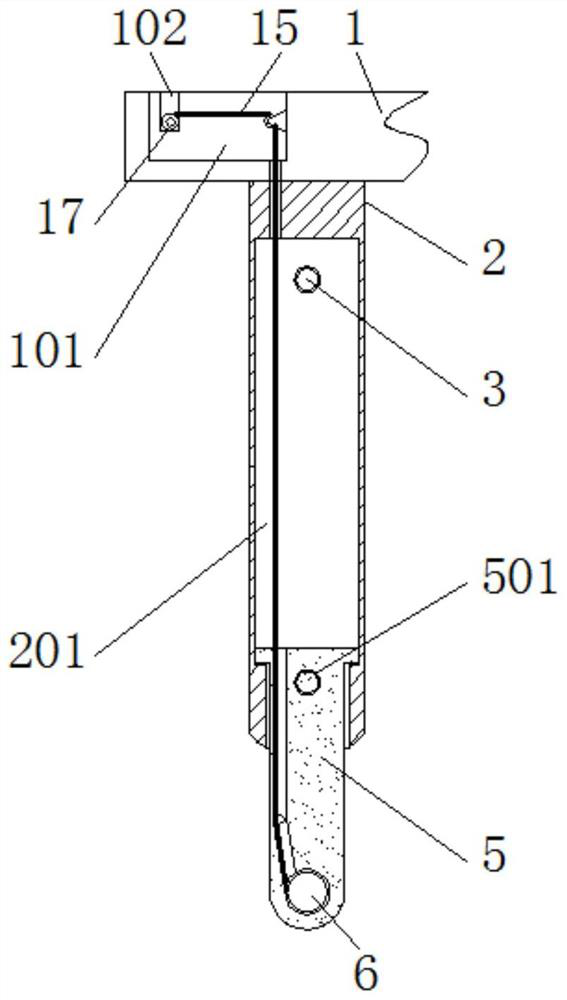

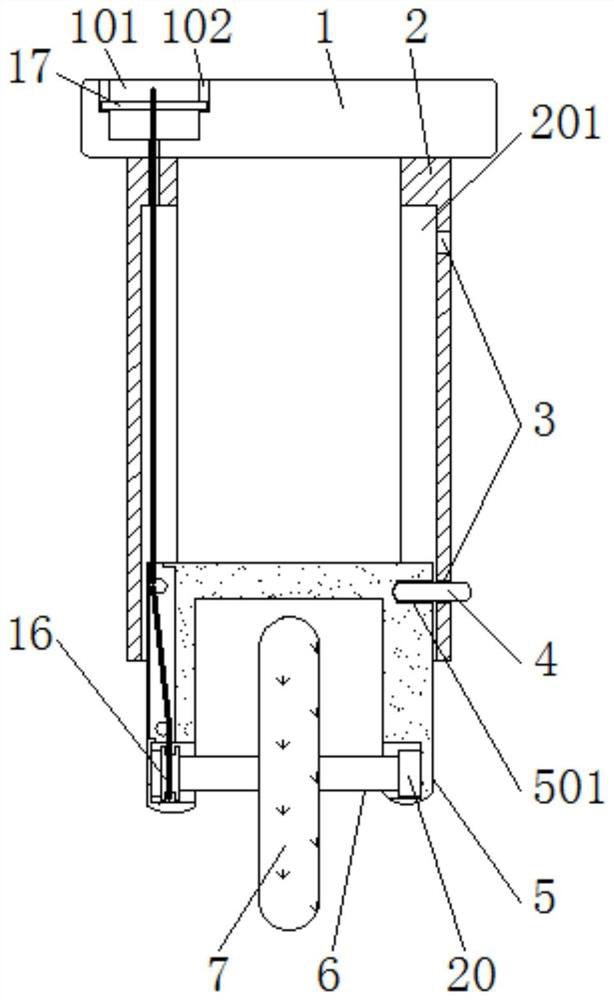

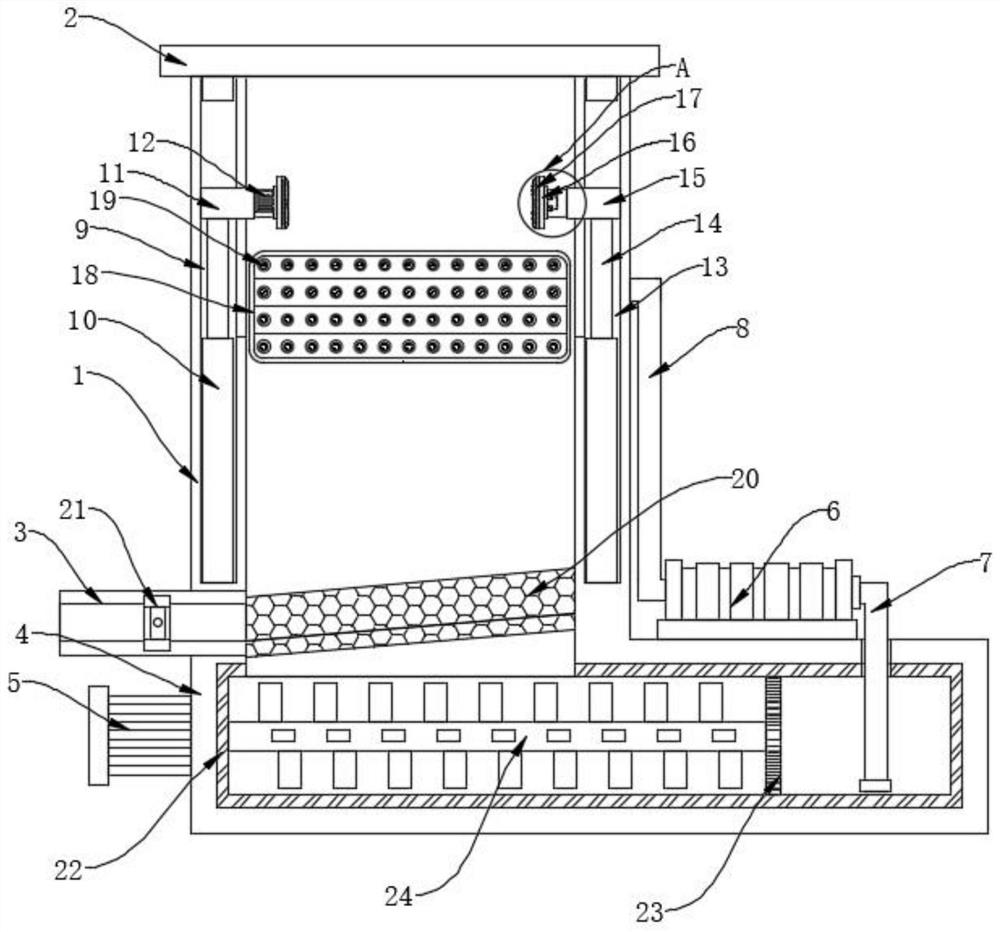

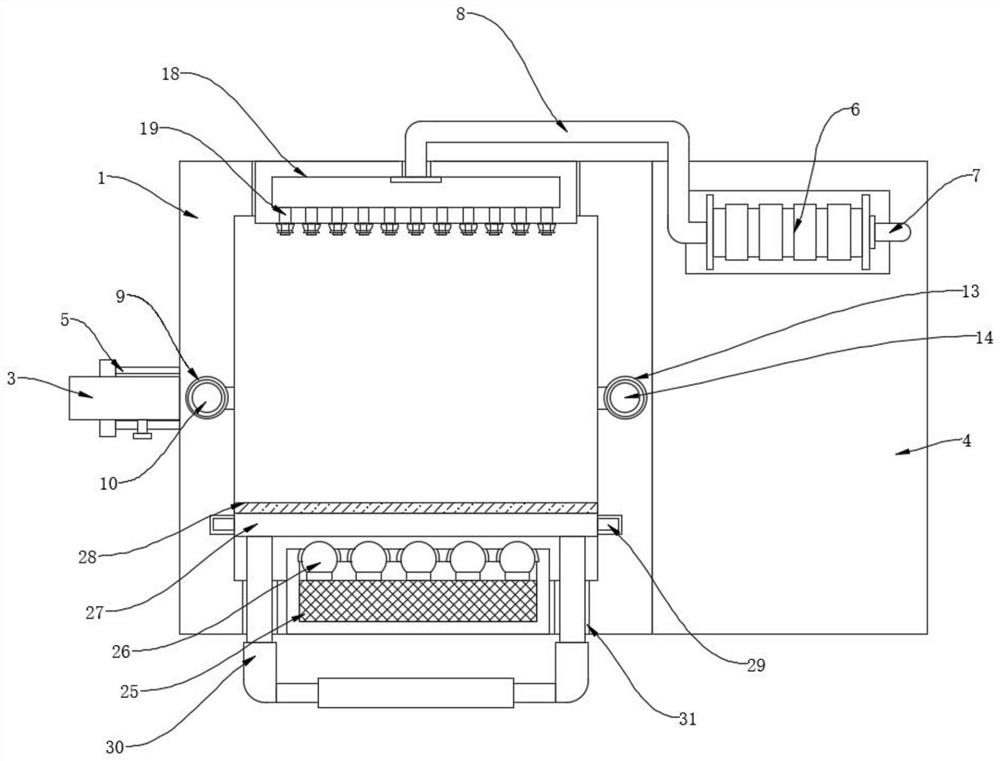

Laser cutting head for conducting smoothing processing on burrs of cutting surface during cutting

ActiveCN110549011AAvoid contactReduce manufacturing costOther manufacturing equipments/toolsLaser beam welding apparatusSpray nozzleLaser cutting

The invention discloses a laser cutting head for conducting smoothing processing on burrs of a cutting surface during cutting. The laser cutting head comprises a main mounting plate body, a main lasercutting head body and a spraying nozzle; a supporting plate is fixed to the left side of the bottom of the main mounting plate body, mounting holes are formed in the front side face of the supportingplate, a supporting frame is installed on the inner side wall of the supporting plate, and mounting pillars are in threaded connection with the interiors of the mounting holes. The laser cutting headfor conducting smoothing processing on the burrs of the cutting surface during cutting is provided with a levelness measuring wheel, the levelness measuring wheel at the right side can be driven to move when the whole laser cutting head moves rightwards on a guide rail, and then walks on the surface of a workpiece, when meeting a bulging face during walking, the levelness measuring wheel can moveupwards, thus a fixed plate drives the main laser cutting head body to move upwards, the situation that the spraying nozzle at the bottom of the main laser cutting head body is in contact with the bulging face of the workpiece is avoided, and then the spraying nozzle is protected.

Owner:重庆茂和兴科技有限公司

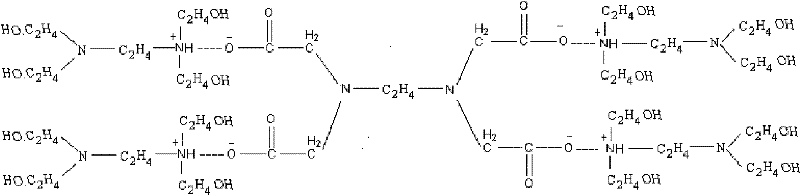

Method for cleaning chip surface after polishing aluminum wire in super large scale integrated circuit

InactiveCN101901783ASpread evenlyReduce tensionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingVery large scale integrated circuitsCompound (substance)

The invention relates to a method for cleaning a chip surface after polishing an aluminum wire in a super large scale integrated circuit, which is characterized by comprising the following steps of: preparing a water polishing liquid; weighing deionized water in weight percentage, adding 0.5-5% of surfactant, 0.1-5% of FA / O chelant type II and 0.01-5% of FA / O rust inhibitor type II while uniformly stirring, and preparing into a neutral water polishing liquid after uniform stirring; and after the chemical mechanical polishing (CMP) of the aluminum wire, immediately polishing the workpiece by using the neutral water polishing liquid in a high flow method so as to clean the surface. The invention has the advantage that water polishing is used before a polishing disk stops rotating after CMP, high flow water polishing is used to clean the chip surface, and no corrosion on equipment is produced; non-uniformly distributed polishing liquid and large particles remaining on the chip surface can be washed away quickly, so that a clean and perfect polishing surface can be obtained.

Owner:HEBEI UNIV OF TECH

Surface cleaning method of polished silicon substrate material

The invention relates to a surface cleaning method of a polished silicon substrate material, which is characterized by comprising the following concrete steps of: taking 0.5-5 parts of nonionic surfactant, 0.1-5 parts of FA / OII type chelating agent, 0.1-5 parts of FA / O II type compound corrosion inhibitor and the balance of deionized water in parts by weight, and uniformly stirring to prepare a water-soluble surface cleaning solution with the pH value of 6.5-7.6; carrying out polishing cleaning on a silicon substrate material subjected to alkaline chemical-mechanical polishing by using the cleaning solution obtained in the step 1 under the conditions of less than 4000Pa of low pressure and 400-5000ml / minute of large flow, wherein the polishing cleaning time is at least 30 seconds-3 minutes, so that the surface of the silicon substrate material is clean. The invention has the advantages that low-pressure large-flow cleaning is carried out on the silicon substrate material by immediately using the cleaning solution after the polishing process in a CMP (Chemical-Mechanical Polishing) working procedure, and a clean and perfect polished surface can be obtained.

Owner:HEBEI UNIV OF TECH

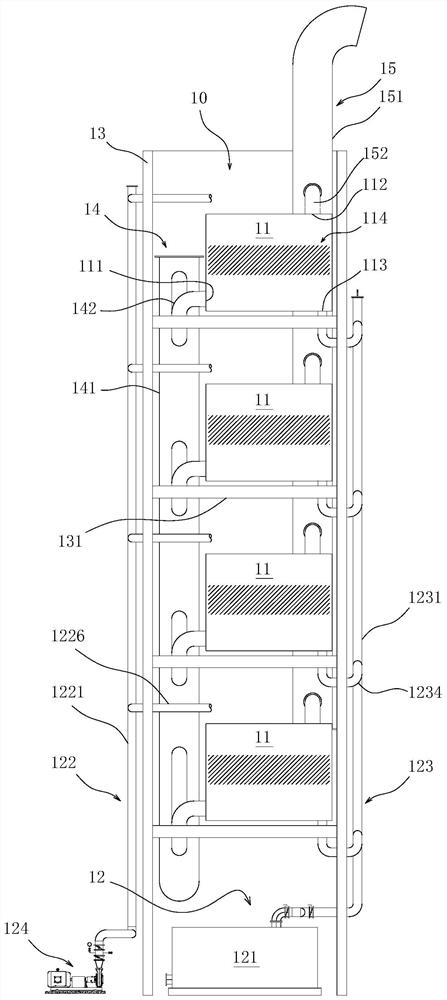

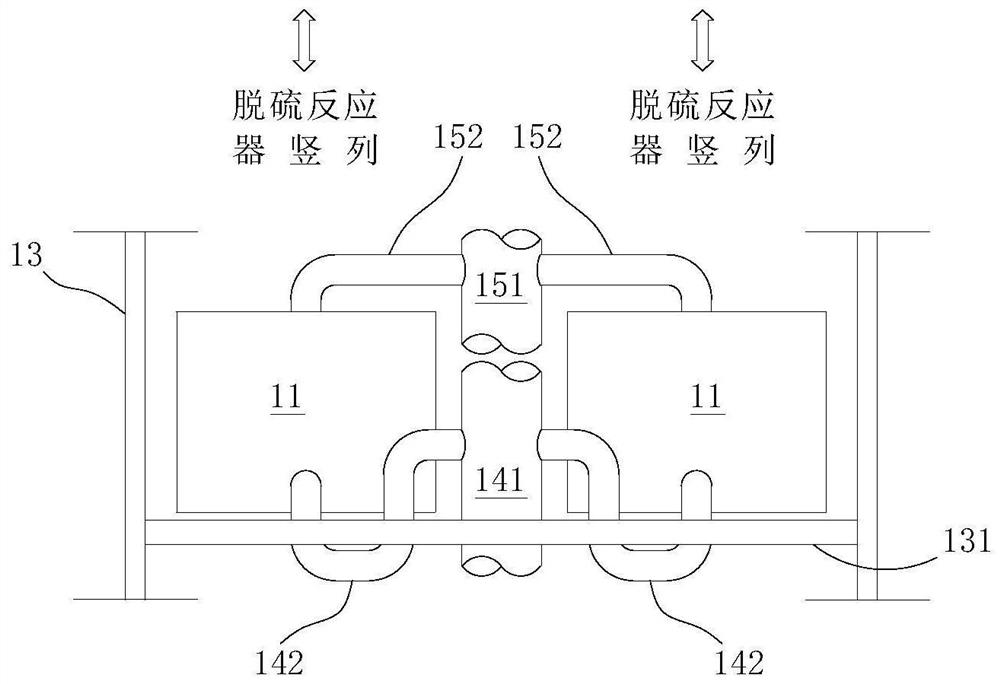

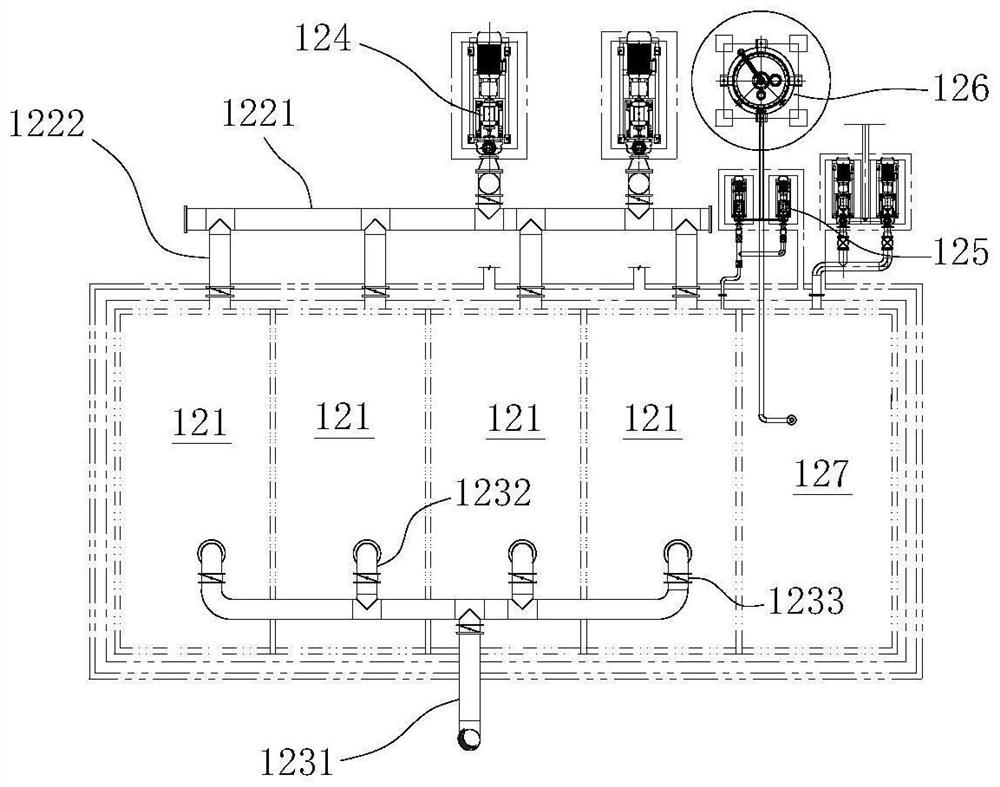

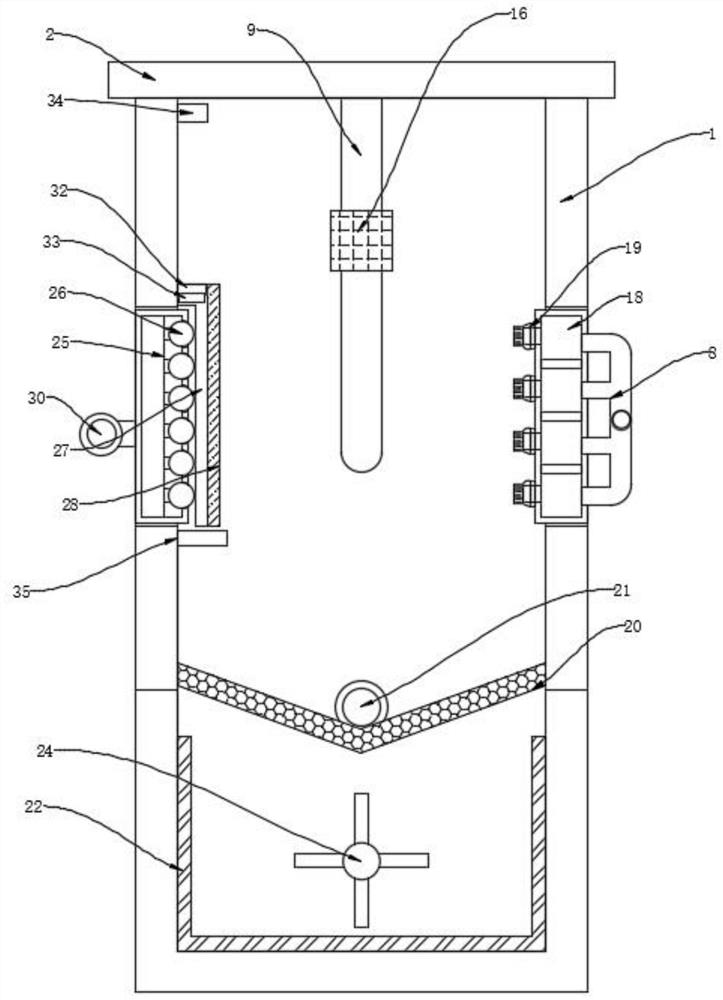

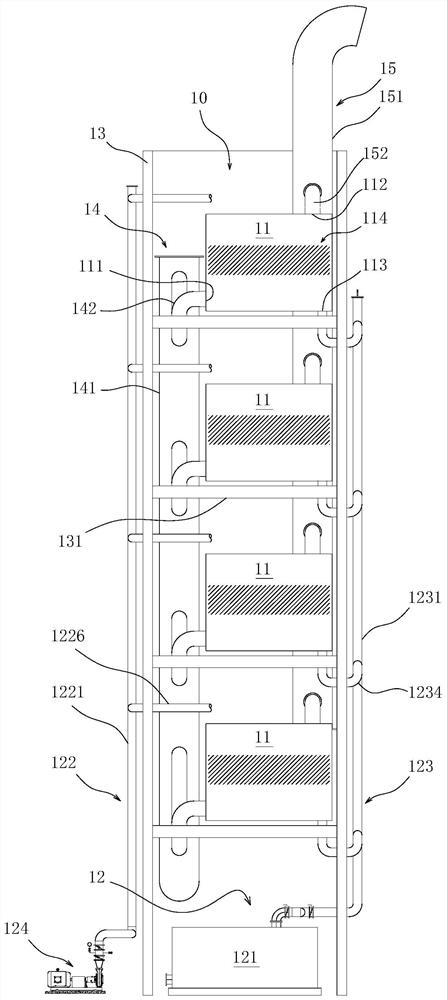

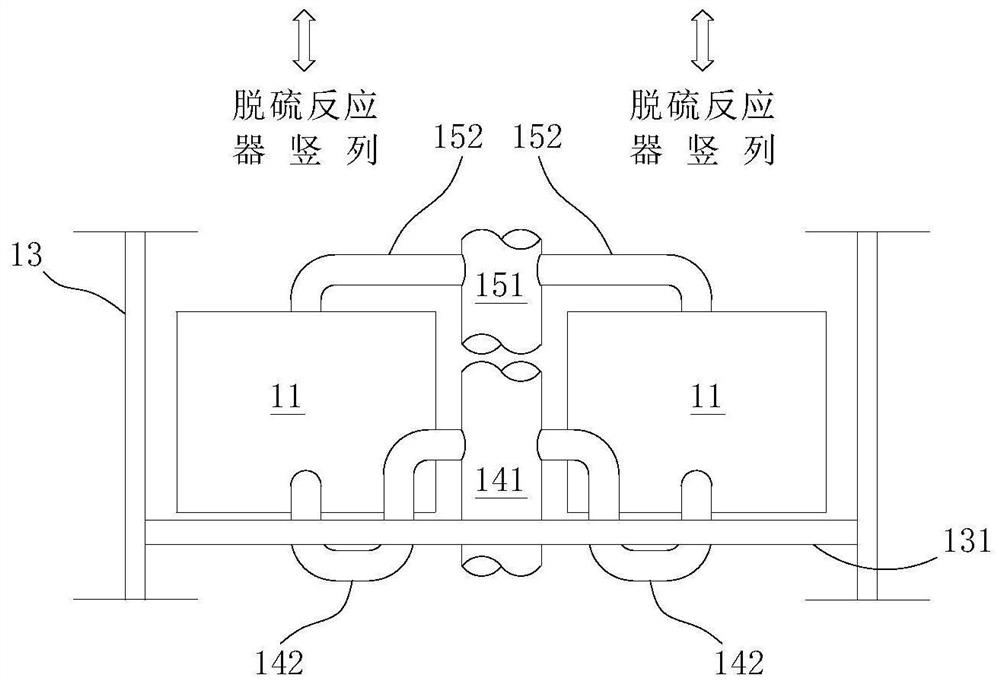

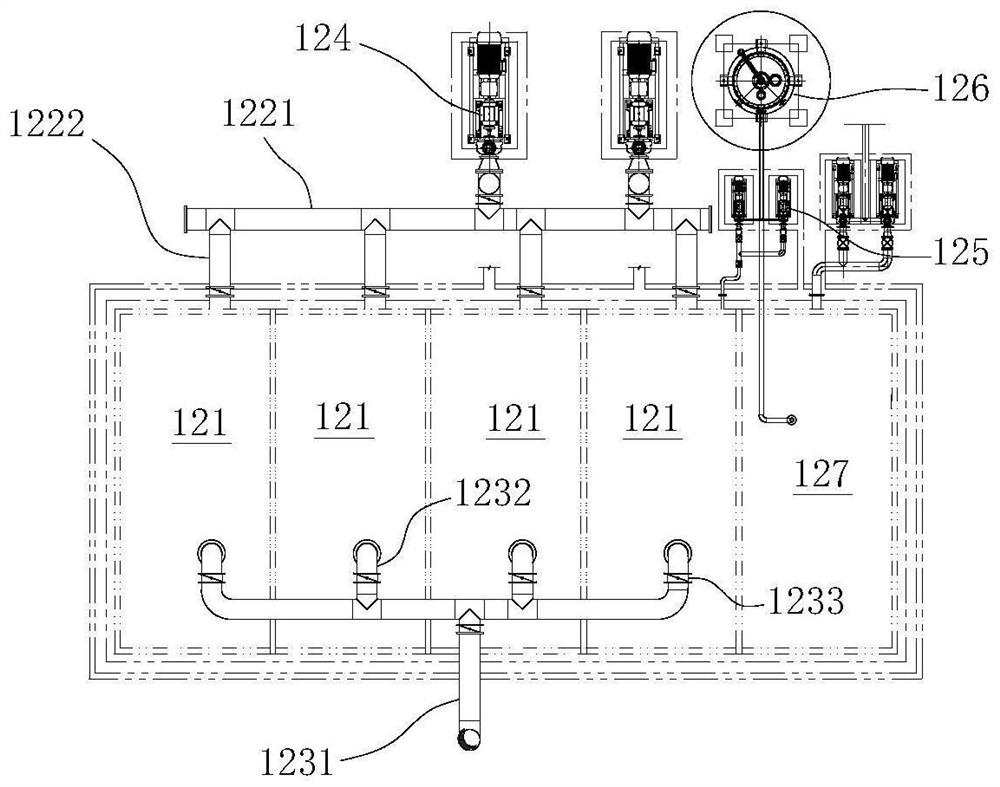

Catalytic flue gas desulfurization tower

PendingCN114653202AImprove perfectionGas treatmentDispersed particle separationThermodynamicsCatalytic method

The invention discloses a catalytic flue gas desulfurization tower, which performs flue gas desulfurization through desulfurization reactors, and comprises a left desulfurization reactor vertical column, a right desulfurization reactor vertical column, a left desulfurization reactor vertical column and a right desulfurization reactor vertical column, the right side desulfurization reactor vertical column comprises at least two desulfurization reactors; an air inlet pipe network, an exhaust pipe network and a regeneration liquid circulation system; the outline of the desulfurization reactor forms a first rectangular body, and the vertical overall outline of the left desulfurization reactor and the vertical overall outline of the right desulfurization reactor respectively form a second rectangular body; and the overall outline of the desulfurization tower main body consisting of the left side desulfurization reactor vertical column, the right side desulfurization reactor vertical column and the frame type supporting structure forms a third rectangular body. The whole desulfurization tower main body is more attractive, and meanwhile, the space occupied by the whole catalytic flue gas desulfurization tower is more sufficiently distributed to the desulfurization reactor, so that the waste of the peripheral space of the desulfurization reactor is reduced.

Owner:成都达奇科技股份有限公司

Nano SiO2 grinding material polishing fluid for electronic glass

InactiveCN1861724AImprove chemical performanceReduce surface tensionPolishing compositions with abrasivesPlane surface grinding machinesNano sio2Organic base

The invention relates to a nanometer SiO2 abradant polishing fluid of the electronic glass which the weight ratio is the abradant and the SiO2 hydrosol 20-45%, the composite alkali 0.5-5.5%, the penetrant 1.0-10%, the surface active agent 1.0-10%, the de-ionized water residuum. The polishing fluid uses the SiO2 hydrosol as the base abradant and adjust the pH to 10.5-13.5 by the composite alkali formed by the KOH and the organic base. So the SiO2 has the good stability.

Owner:HEBEI UNIV OF TECH

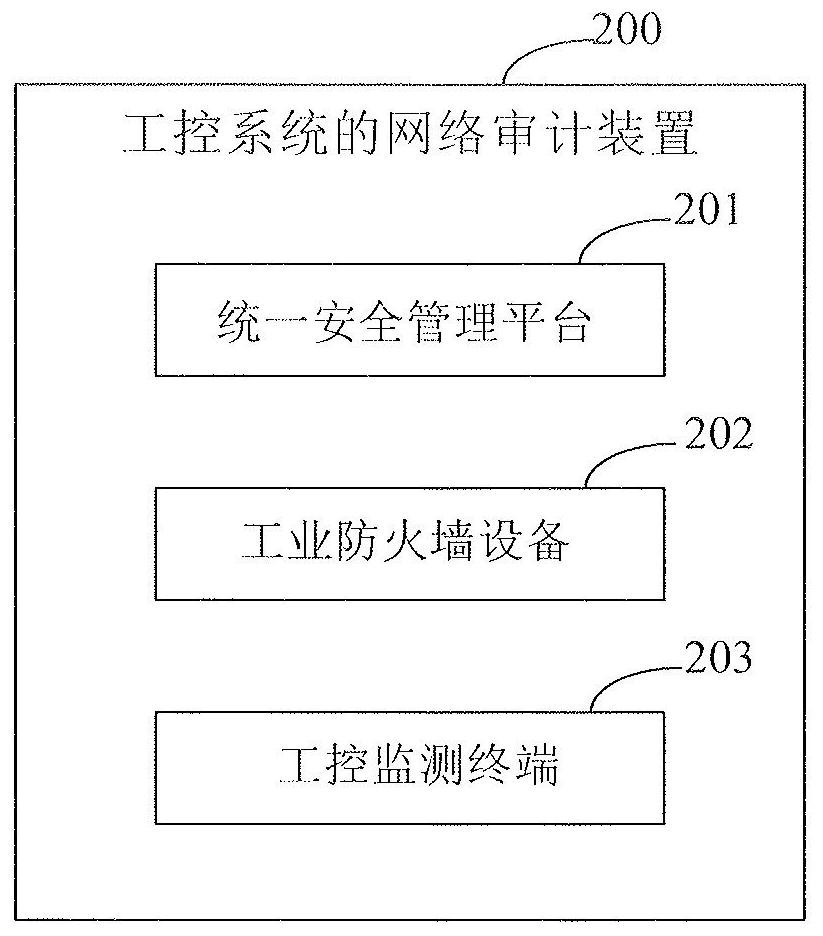

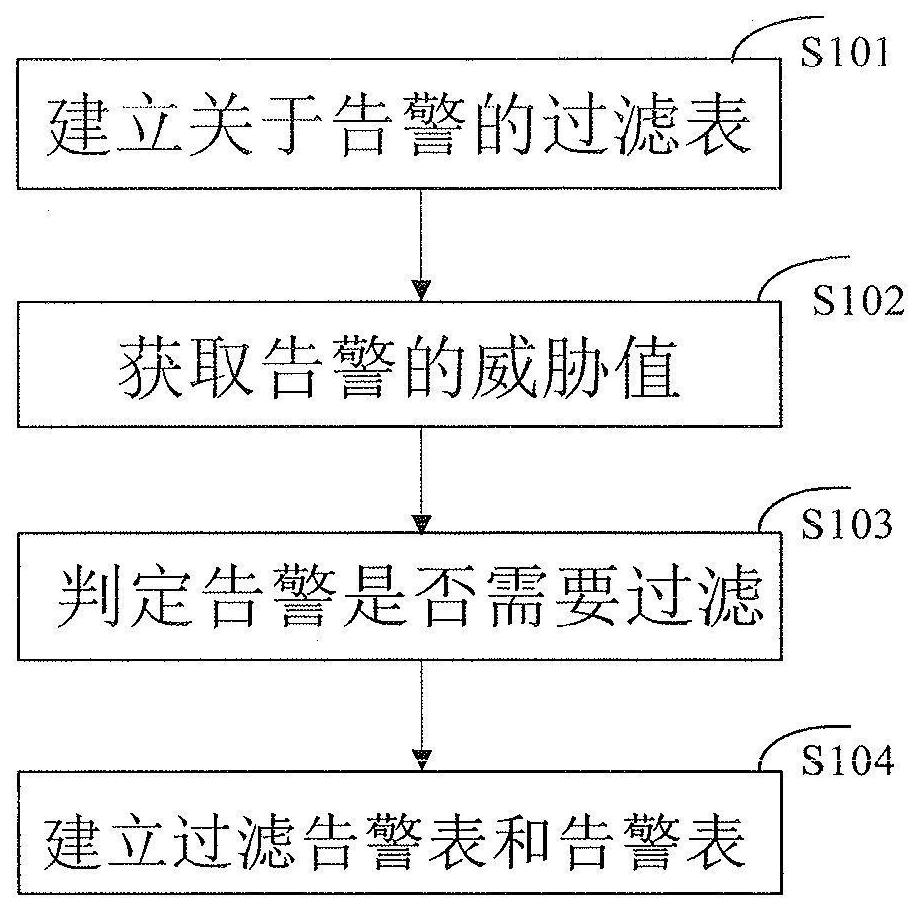

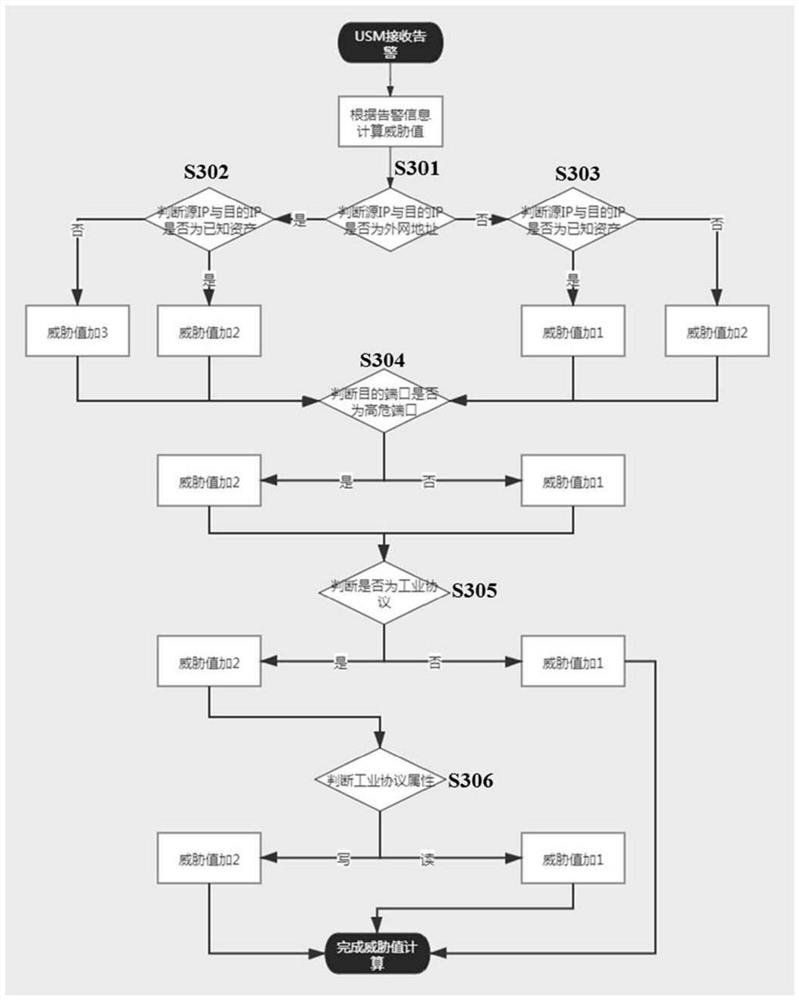

Network auditing method and device of industrial control system

The invention discloses a network auditing method and device of an industrial control system, and relates to the technical field of industrial automation control. One specific embodiment of the methodcomprises the following steps: industrial firewall equipment and an industrial control monitoring terminal being used for identifying and alarming, putting the identified alarms into a filter table,receiving each alarm in the filter table by a unified security management platform, and for each alarm, obtaining a total threat value of each alarm according to a threat value list pre-stored in theunified security management platform; and determining the threat level of each alarm based on the acquired total threat value of each alarm, and determining the display of the alarm according to the determined threat level. According to the embodiment, high-risk alarm identification can be carried out on the alarm information generated by violation of the white list rule, a large number of high-risk alarms caused by incomplete white list learning data are avoided, the number of the high-risk alarms is reduced, and a user can process the high-risk alarms conveniently and preferentially.

Owner:GUIZHOU QIANYUAN POWER CO LTD +1

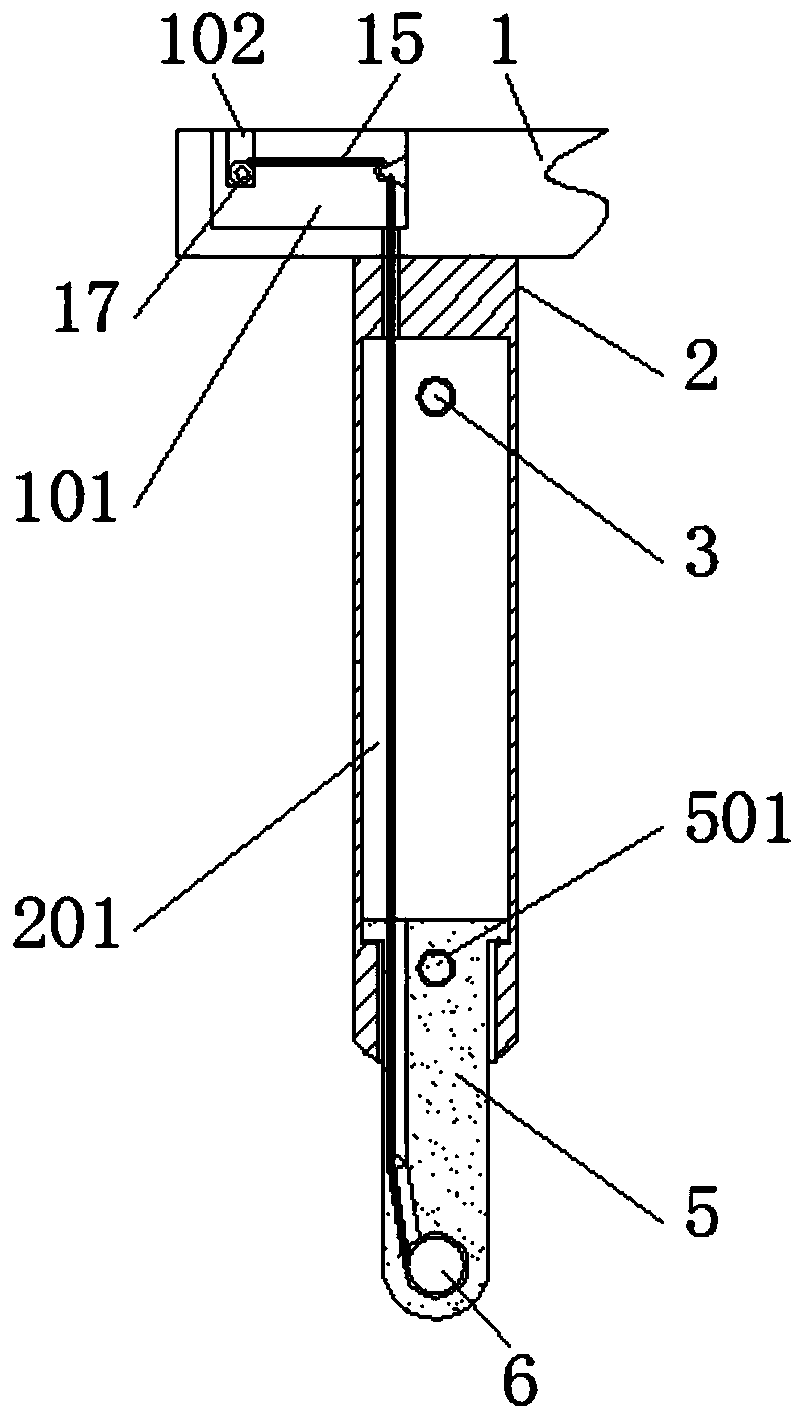

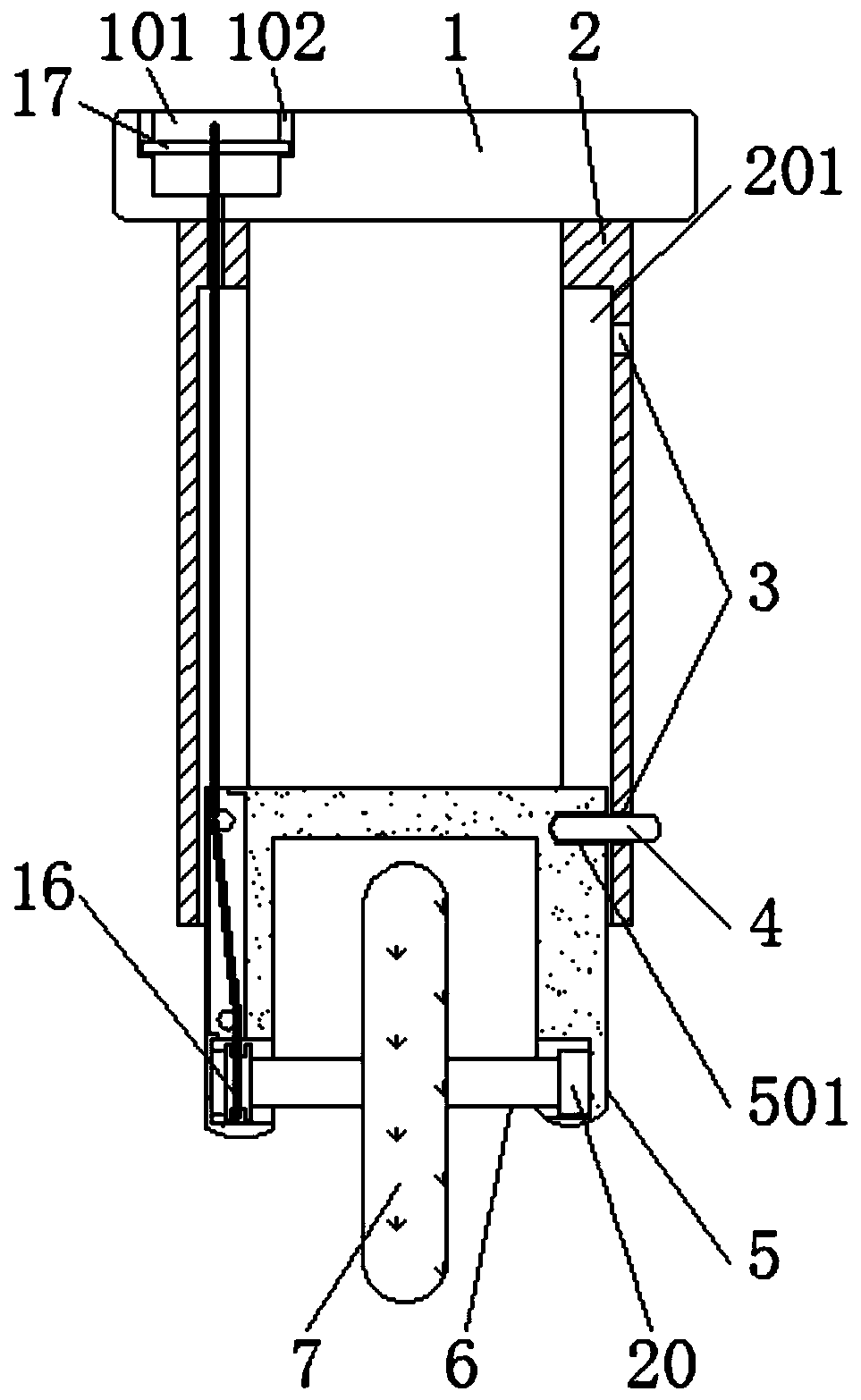

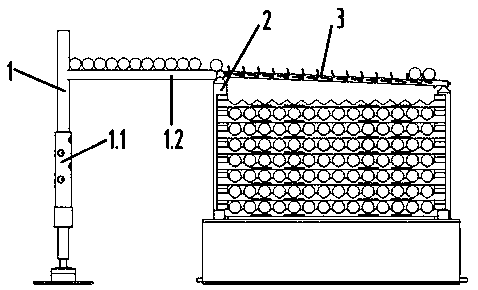

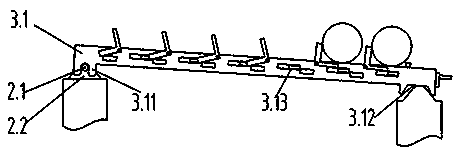

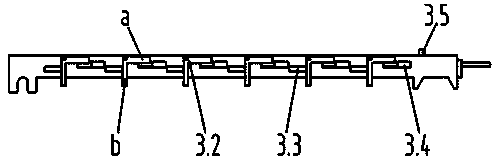

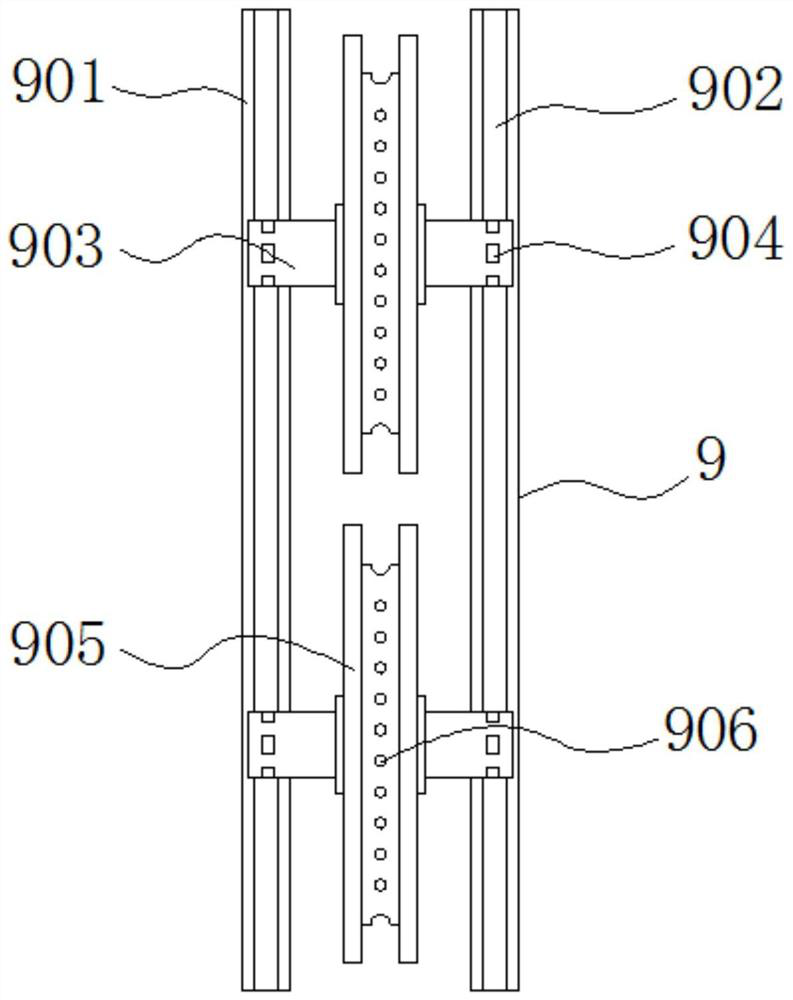

Device and method for transferring oil pipes in batches

PendingCN111042748AImprove perfectionImprove efficiencyDrilling rodsDrilling casingsStructural engineeringMechanical engineering

The invention discloses a device and method for transferring oil pipes in batches. The device comprises at least two sets of lifting stand columns, wherein each set of lifting stand columns comprisestwo lifting stand columns of the same structure, namely the left lifting stand column and the right lifting stand column; the top end of each left lifting stand column and the top end of the corresponding right lifting stand column jointly bear a pipe rotating cross arm; each pipe rotating cross arm comprises a cross arm rod, a pipe arranging shifting tooth and a fixing stop block; each pipe arranging shifting tooth is of a bent structure and is hinged to the front side face of the corresponding cross arm rod through a center shaft at the bent position; each fixing stop block is fixed to the front side face of the corresponding pipe rotating cross arm; each pipe arranging shifting tooth of the bent structure comprises a first edge and a second edge, wherein the weight of the first edge inthe pipe arranging shifting tooth is larger than that of the second edge; the first edge is positioned at the lower part in the natural state; and the first edge is limited by the fixing stop block atthe lower portion. According to the device and method, the oil pipes on pipe rows can be rapidly collected through the mechanical batch transferring device when the oil pipes are replaced, meanwhile,the transferred new oil pipes are arranged on the cross arms in order, and the batch pipe rotating procedure is reliable and efficient.

Owner:CHINA PETROLEUM & CHEM CORP +1

A laser cutting head for smoothing cutting surface burrs during cutting

ActiveCN110549011BAvoid contactReduce manufacturing costOther manufacturing equipments/toolsLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a laser cutting head for smoothing the burrs on the cutting surface during cutting, which comprises a mounting plate main body, a laser cutting head main body and a nozzle, a support plate is fixed on the left side of the bottom of the mounting plate main body, and the support plate A mounting hole is opened on the front side of the support plate, and a support frame is installed on the inner side wall of the support plate, and the internal thread of the mounting hole is connected with a mounting column. The laser cutting head that smoothes the burrs on the cutting surface during cutting is provided with a leveling wheel. When the entire laser cutting head moves to the right on the guide rail, it will drive the leveling wheel on the right side to move, so that the leveling wheel on the right side The flat wheel walks on the surface of the workpiece. If the level measuring wheel encounters a protruding surface when walking, the level measuring wheel will move upwards, thereby driving the main body of the laser cutting head to move upward through the fixed plate, thereby preventing the nozzle at the bottom of the main body of the laser cutting head from colliding with the The convex surfaces of the workpieces are in contact, thereby protecting the nozzle.

Owner:重庆茂和兴科技有限公司

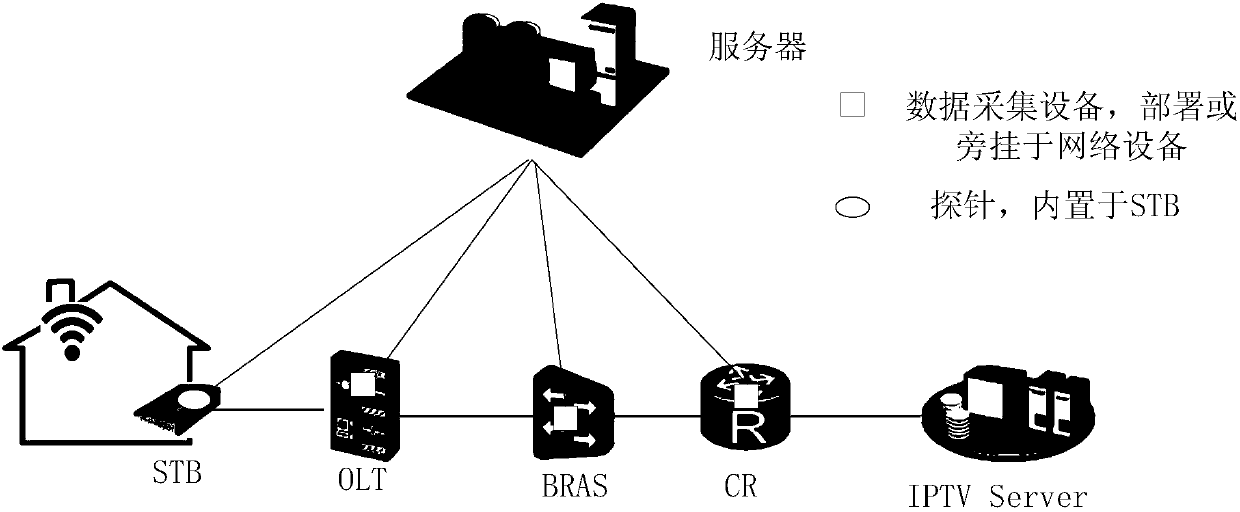

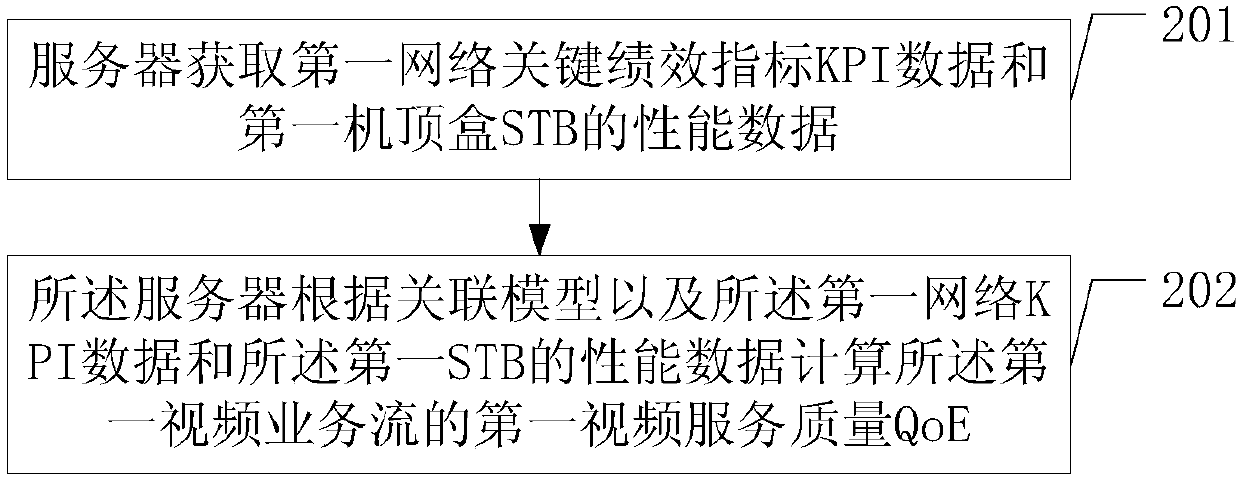

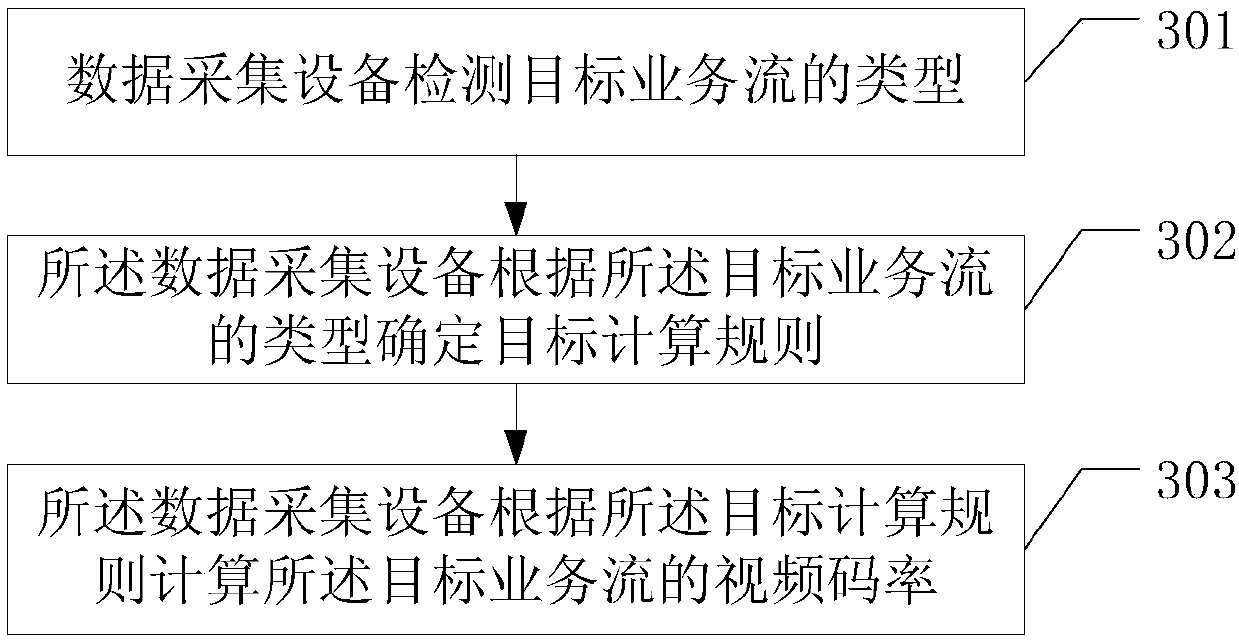

Data processing method, server and data acquisition device

ActiveCN110139167AReduce the burden onLow costSelective content distributionData switching networksService flowAssociation model

The embodiment of the invention discloses a data processing method, a server and a data acquisition device, which are used for calculating a first video QoE of a first video service flow by the serveraccording to first network KPI data and performance data of a first STB, so as to reduce the burden of the STB. The method comprises the steps that a server obtains first network key performance index (KPI) data and performance data of a first set top box (STB), the first network KPI data are network KPI data of a first video service flow, and the first STB is an STB for receiving the first videoservice flow; the server calculates first video quality of service QoE of the first video service flow according to an association model, the first network KPI data and the performance data of the first STB, wherein the correlation model is a model obtained through training according to historical data, and the correlation model is used for the server to calculate the video QoE according to the network KPI data and the STB performance data.

Owner:HUAWEI TECH CO LTD

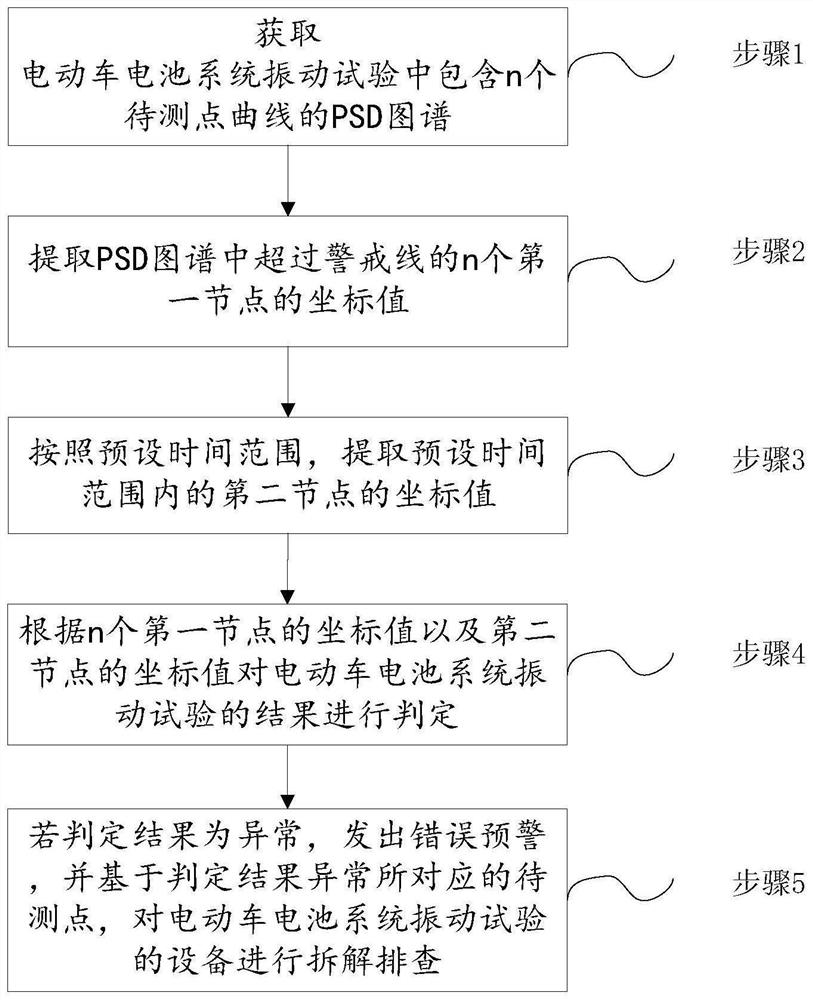

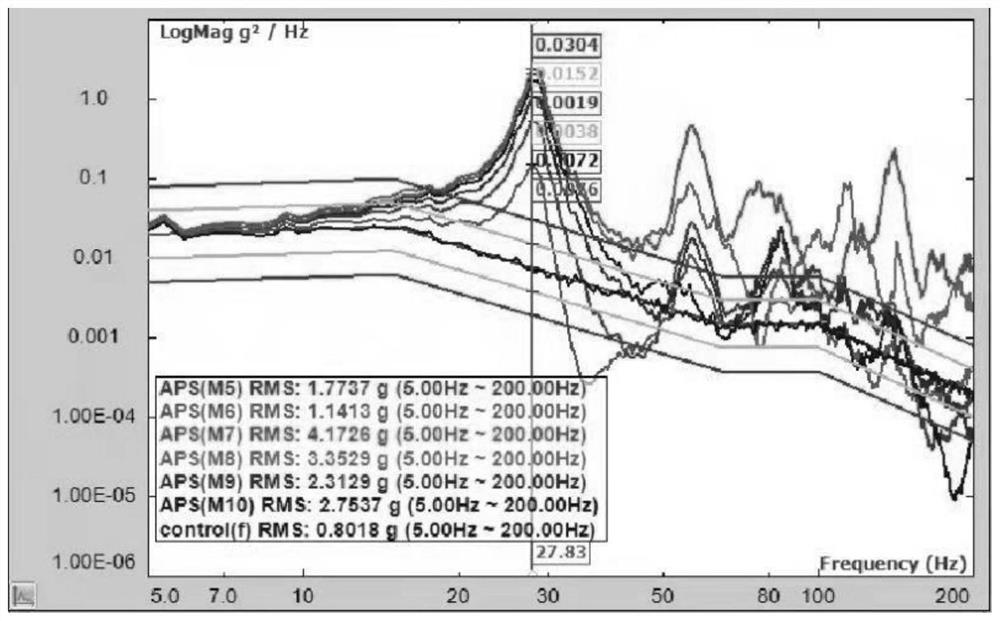

Judgment method and system for electric vehicle battery system vibration test and storage medium

ActiveCN112710446AImprove securityImprove reliabilityVibration testingElectric-vehicle batteryElectrical battery

The invention discloses a judgment method and system for an electric vehicle battery system vibration test and a storage medium, and relates to the field of battery vibration tests. The method comprises the following steps: step 1, obtaining a PSD map containing n to-be-tested point curves in an electric vehicle battery system vibration test; step 2, extracting coordinate values of n first nodes exceeding a warning line in the PSD map; step 3, according to a preset time range, extracting a coordinate value of a second node in the preset time range; step 4, judging the result of the vibration test of the electric vehicle battery system according to the coordinate values of the n first nodes and the coordinate values of the second nodes; and step 5, if the judgment result is abnormal, sending out an error early warning, and based on the to-be-tested point corresponding to the abnormal judgment result, disassembling and checking the equipment for the vibration test of the electric vehicle battery system. The problem that the failure position cannot be accurately judged can be solved, and the effects of improving the safety and reliability of the battery system while accurate positioning is achieved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

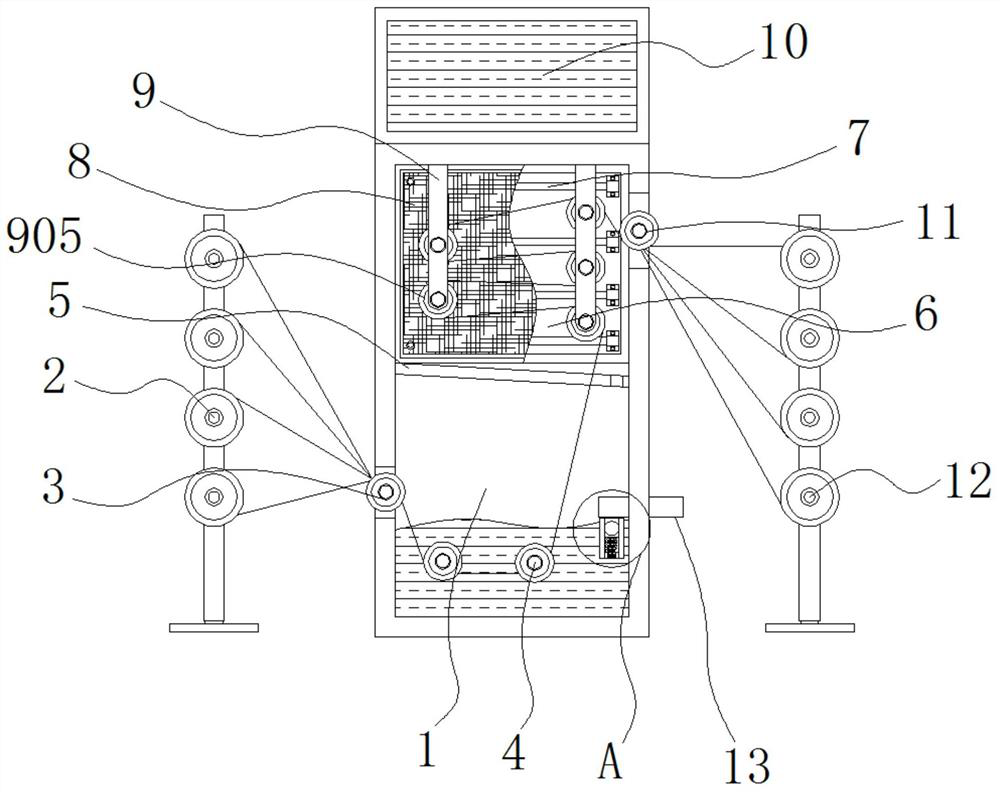

Flexible printing process for corrugated cartons

InactiveCN111959144AAvoid erosionAvoid shellingOther printing apparatusPrinting press partsCartonPrinting press

The invention discloses a flexible printing process for corrugated cartons, relates to the technical field of flexible printing, and aims to solve the problems that performance of an existing flexibleprinting process for corrugated cartons is not perfect enough and the working efficiency is low. The process comprises the steps that S1, a plate cylinder is cleaned; S2, a base surface of a photosensitive resin plate is cleaned and dried by using a detergent; S3, a hard board double-sided adhesive tape is pasted to the plate cylinder; S4, a photosensitive resin plate printing plate is pasted onthe plate cylinder, and edge sealing is conducted by using a sealant; S5, an anilox roller is cleaned, and the plate cylinder and an anilox roller plate cylinder are installed separately; S6, a scraper blade is cleaned, and the scraper blade is mounted in a scraper chamber; S7, an ink box is cleaned, the ink box is installed, and then water-based ink is poured into the ink box; and S8, printing iscarried out on a corrugated board by a flexible printing machine.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD

Surface cleaning method after carrying out chemical-mechanical polishing (CMP) on lithium niobate wafer in alkalinity

InactiveCN101972754AReduce surface tensionImprove uniformityCleaning using liquidsActive agentSurface cleaning

The invention relates to a surface cleaning technique after lithium niobate chemical-mechanical polishing liquor is used to precisely finish and polish a lithium niobate wafer. Water polishing is adopted to achieve the clean of the surface, the main chemical components of water polishing liquor comprise an active agent, a chelant, a corrosion resistance agent and deionized water. After alkaline polishing is just completed, the water polishing liquor is immediately used and a method of large flow amount of water polishing is adopted, thereby washing the residual polishing slurry away and simultaneously rapidly reducing surface tension, forming a monomolecular passive film and leading metal ions to form soluble chelate to cleanly and perfectly polish the surface. The water polishing method has the advantages of low cost, no pollution of environment and no corrosion of equipment.

Owner:HEBEI UNIV OF TECH

Method for cleaning surface of magnesium aluminum alloy subjected to chemically mechanical polishing

The invention discloses a method for cleaning the surface of a magnesium aluminum alloy subjected to chemically mechanical polishing, aiming at providing a simple and easy cleaning method capable of reducing the subsequent processing cost of the alkali chemically mechanical polishing of the magnesium aluminum alloy and improving the surface quality of a wafer. The method comprises the steps of: taking ultrapure water with resistance of above 18M omega, stirring and adding a non-ionic surface active agent and an FA / O chelating agent at the same time; adopting an ultrapure water diluting rust inhibitor with resistance of above 18M omega; adding the diluted rust inhibitor into the liquid under the stirring, uniformly stirring to obtain a soluble surface cleaning liquid, rapidly carrying out polishing cleaning on the magnesium aluminum alloy subjected to the chemically mechanical polishing by using the obtained soluble surface cleaning liquid under the condition of large flow and low pressure; and washing by using the ultrapure water with resistance of above 18 M omega under the condition of zero-pressure and large-flow.

Owner:HEBEI UNIV OF TECH

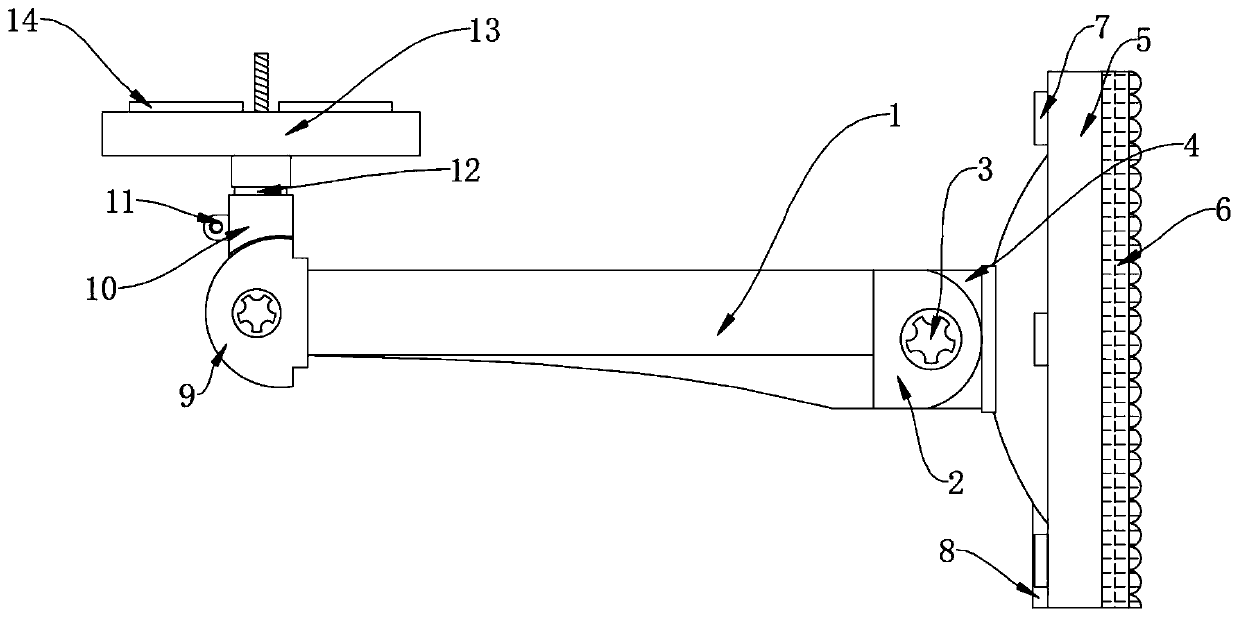

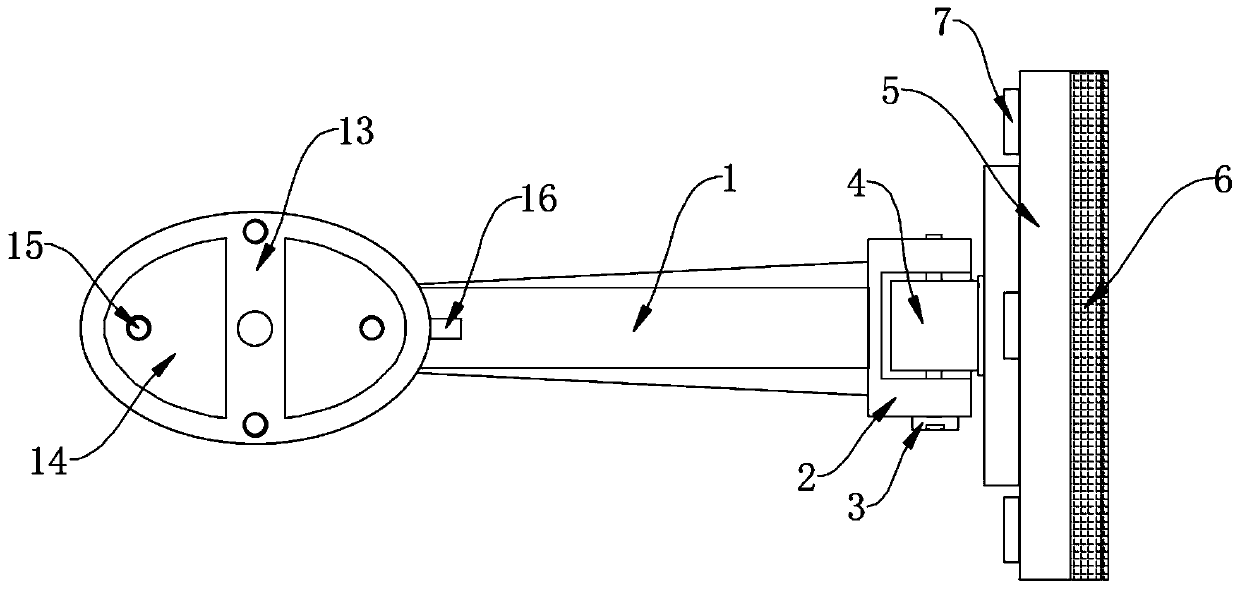

Outdoor mounting support of monitoring device

PendingCN110836311AImprove practicalityEasy to installClosed circuit television systemsStands/trestlesEngineeringMonitor equipment

The invention discloses an outdoor mounting support of a monitoring device, and relates to the technical field of mounting supports. In order to solve the problem that an existing outdoor mounting support for a monitoring device is single in kind, and the mounting direction is not easily transformed, the outdoor mounting support is provided. A first fixed block is arranged on one side of a supporting strip, a twisting bolt is arranged on the front end of the first fixed block, a first connecting block is arranged on the other side of the first fixed block, a fixed chassis is arranged on the other side of the first connecting block, an anti-sliding gasket is arranged on the other side of the fixed chassis, multiple fixed bolts are arranged on one side of the fixed chassis, a wire outlet hole is formed in the lower portion of one side of the fixed chassis, and a second fixed block is arranged on the other side of the supporting strip.

Owner:江苏纵目信息科技有限公司

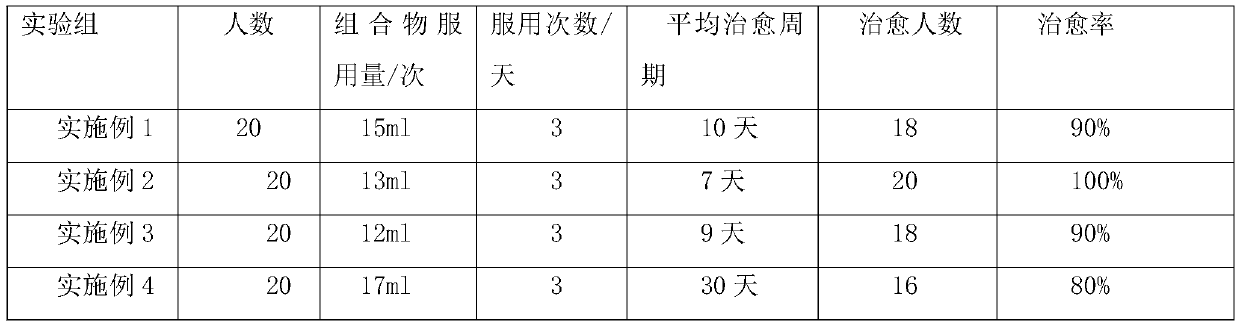

Probiotic composition

PendingCN111567808AImprove perfectionImprove securityYeast food ingredientsTransportation and packagingAloinBlastomycetes

The invention provides a probiotic composition. The composition comprises the following components in percentage by mass: 5.0%-8.0% of saccharomycetes, 5.0-7.0% of probiotic spore bacteria, 4.0%-7.0%of lactobacillus, 3.0%-5.0% of trace minerals, 2.0%-5.0% of edible minerals, 2.0%-4.0% of aloe extract, 2.0%-4.0% of slippery elm bark powder, 1.0%-3.0% of an additive, 1.0%-2.0% of a gastric mucosa repairing preparation and the balance of purified water. A plurality of probiotics such as the saccharomycetes, the probiotics spore bacteria and the lactobacillus are added into the components of theprobiotic composition, and a plurality of groups of elements required by human bodies such as the trace minerals and the edible minerals are added into the probiotic composition, so that the purpose of supplementing trace elements for the human body is achieved. In addition, the aloe extract, the slippery elm bark powder and the gastric mucosa repairing preparation are added into the composition,so that the damaged part of the intestinal tract of the human body can be repaired and maintained while the probiotic composition oral liquid is taken, and the completeness of the intestinal tract ofthe human body is improved.

Owner:上海薄荷健康科技股份有限公司

Surface cleaning method of polished silicon substrate material

The invention relates to a surface cleaning method of a polished silicon substrate material, which is characterized by comprising the following concrete steps of: taking 0.5-5 parts of nonionic surfactant, 0.1-5 parts of FA / OII type chelating agent, 0.1-5 parts of FA / O II type compound corrosion inhibitor and the balance of deionized water in parts by weight, and uniformly stirring to prepare a water-soluble surface cleaning solution with the pH value of 6.5-7.6; carrying out polishing cleaning on a silicon substrate material subjected to alkaline chemical-mechanical polishing by using the cleaning solution obtained in the step 1 under the conditions of less than 4000Pa of low pressure and 400-5000ml / minute of large flow, wherein the polishing cleaning time is at least 30 seconds-3 minutes, so that the surface of the silicon substrate material is clean. The invention has the advantages that low-pressure large-flow cleaning is carried out on the silicon substrate material by immediately using the cleaning solution after the polishing process in a CMP (Chemical-Mechanical Polishing) working procedure, and a clean and perfect polished surface can be obtained.

Owner:HEBEI UNIV OF TECH

Device and technology for improving sizing rate of T16S yarn

ActiveCN111621939AIncrease sizing rateImprove work efficiencyLiquid/gas/vapor removalTextile treatment machine arrangementsYarnProcess engineering

The invention discloses a device and technology for improving the sizing rate of T16S yarn, and relates to the technical field of sizing machines. The device comprises a first sizing box, a winding group and an automatic adding pipe; a discharging cylinder is arranged on one side of the first sizing box in parallel, a sizing wheel is arranged at the bottom of the inner wall of the first sizing box, a drying chamber is arranged above a heat insulating plate, a protective wire screen is arranged on the outer side of an electric heating wire, the winding group is arranged in the drying chamber, the side face of the drying chamber is connected with a second wire wheel, and the automatic adding pipe is arranged at the bottom of the side wall of the first sizing box. According to the device andtechnology for improving the sizing rate of the T16S yarn, sizing in a second sizing box flows out of the surface of a winding wheel through a discharging hole, so that the friction force between theyarn and the winding wheel is reduced, one-side sizing operation is performed on the surface of the yarn again while falling of the sizing on the surface of the yarn is reduced, missing positions generated due to friction are filled, and therefore the integrity of sizing film on the surface of the yarn is improved.

Owner:武汉裕大华纺织有限公司

Surface spraying device for thermal barrier coating material

InactiveCN112317209APlay the role of fixed anti-skidInhibit sheddingPretreated surfacesLiquid spraying apparatusElectric machineryThermal barrier coating

The invention discloses a surface spraying device for a thermal barrier coating material, relates to the technical field of surface spraying devices, and aims at solving the problems that an existingsurface spraying device for the thermal barrier coating material is poor in spraying effect and low in surface drying speed. A sealing cover is installed above a spraying box; an installation pipe isinstalled on one side of the spraying box; a coating box is installed below the spraying box; the spraying box is connected with the coating box in a welded mode; a stirring motor is installed on oneside of the coating box, and a booster water pump is installed on the other side of the upper portion of the coating box; a water pumping pipe is installed on one side of the booster water pump and extends into the coating box; and a flow dividing pipe is installed on the other side of the booster water pump.

Owner:德清恒川新材料科技有限公司

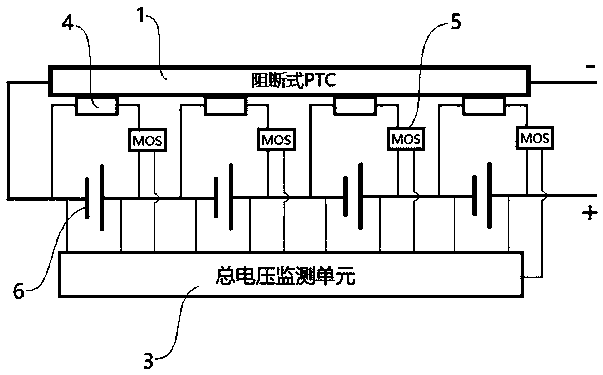

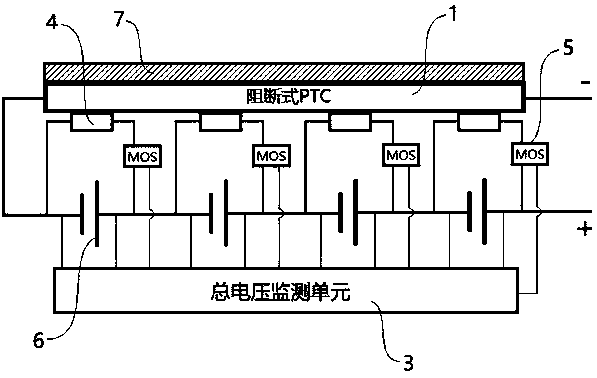

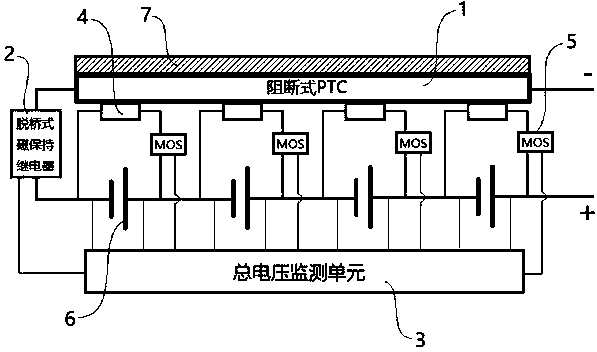

Blocking-type PTC-based battery protection device and method thereof

PendingCN108631413AUniform dischargeLogical fast equalizationCharge equalisation circuitSafety/protection battery circuitsInternal resistanceHigh voltage cathode

The invention discloses a blocking-type PTC-based battery protection device and a method thereof. The device comprises a blocking-type PTC, an equalization unit and a total voltage monitoring unit, wherein the blocking-type PTC is serially connected in a charge and discharge main circuit of a lithium battery pack; the equalization unit internally comprises a plurality of equalization resistors controlled by MOS switches; each equalization resistor is in bridge connection onto two ends of a corresponding cathode mix and is laminated at one side of the blocking-type PTC; and the total voltage monitoring unit is connected with each cathode mix and each MOS switch. In the method, the high-voltage cathode mix is equalized through heating of the bypass equalization resistor, and consistency is equalized; the equalization energy is made full use of to actively heat the blocking-type PTC, the internal resistance is increased dramatically, the charge current is thus suppressed, and overcharge protection is realized. The blocking-type PTC-based battery protection device and the method thereof have the characteristics of simple structure, safety, reliability and low cost, the problems of dynamic consistency and reliability of the lithium battery under safe voltage can be effectively solved, and the life time of the battery is enhanced.

Owner:樊朝晖

Method for cleaning surface after chemically mechanical polishing of tungsten-molybdenum alloy

InactiveCN102074460ALow costWash away quicklySemiconductor/solid-state device manufacturingCleaning using liquidsElectrical resistance and conductanceAlkaline water

The invention discloses a method for cleaning surface after chemically mechanical polishing of a tungsten-molybdenum alloy, aiming to provide a cleaning method which has the beneficial effects of improving the wafer surface quality and reducing the subsequent processing cost of alkaline chemically mechanical polishing of a tungsten-molybdenum alloy material and is convenient to use, simple and practical. The method comprises the following steps: taking ultrapure water with resistance being more than 18MOmega and adding a surfactant and an FA / OII chelating agent while stirring; adopting the ultrapure water with resistance being more than 18MOmega to dilute a corrosion inhibitor; adding the diluted corrosion inhibitor to obtained liquid while stirring and preparing alkaline water polishing liquid with pH value of 7.5-8.5 after uniform stirring; immediately using the alkaline water polishing liquid to carry out water polishing under the conditions of high flow of 1000-5000ml / min and low pressure of 0-0.01 atmosphere after chemically mechanical polishing of the tungsten-molybdenum alloy material; and later using the ultrapure water with resistance being more than 18MOmega to wash the surface under the conditions of zero pressure and flow of 1000-5000ml / min.

Owner:HEBEI UNIV OF TECH

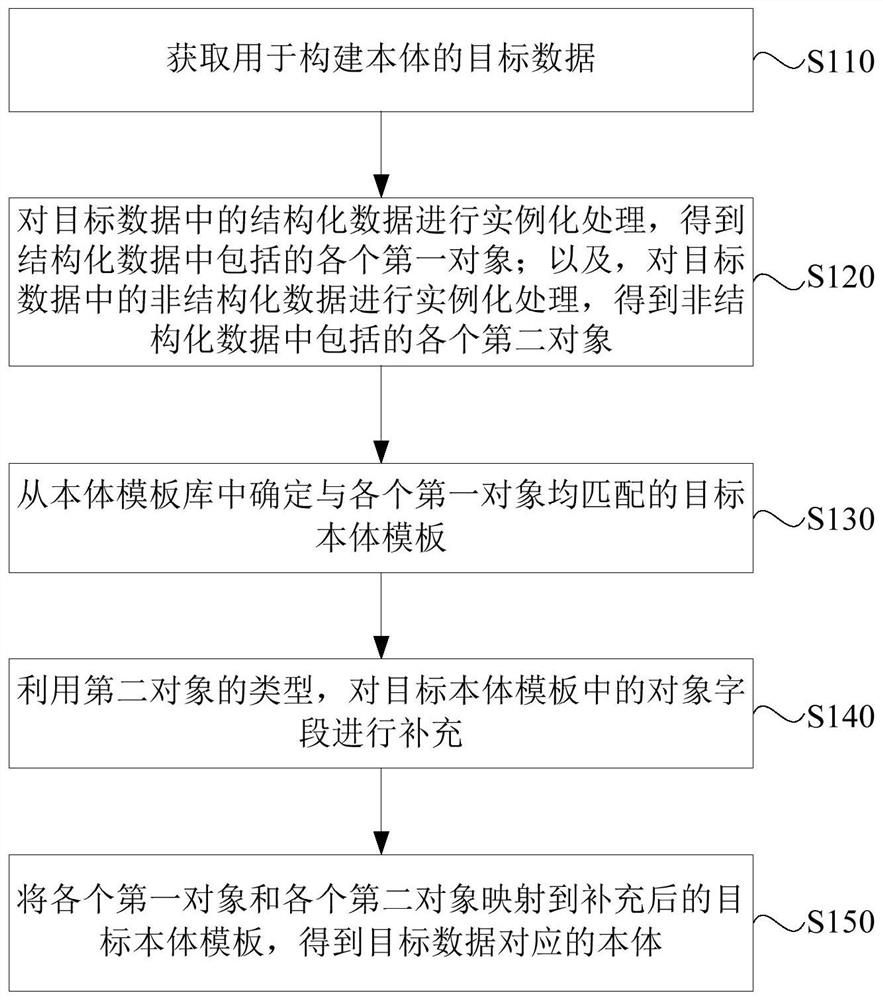

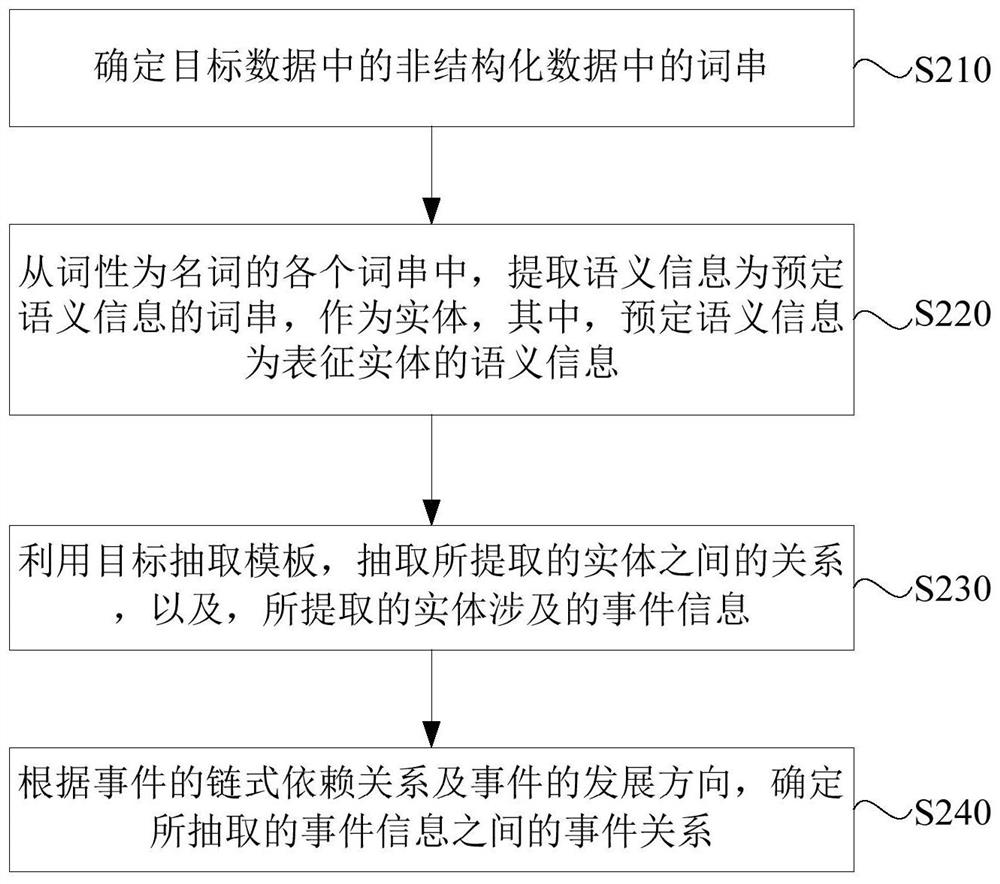

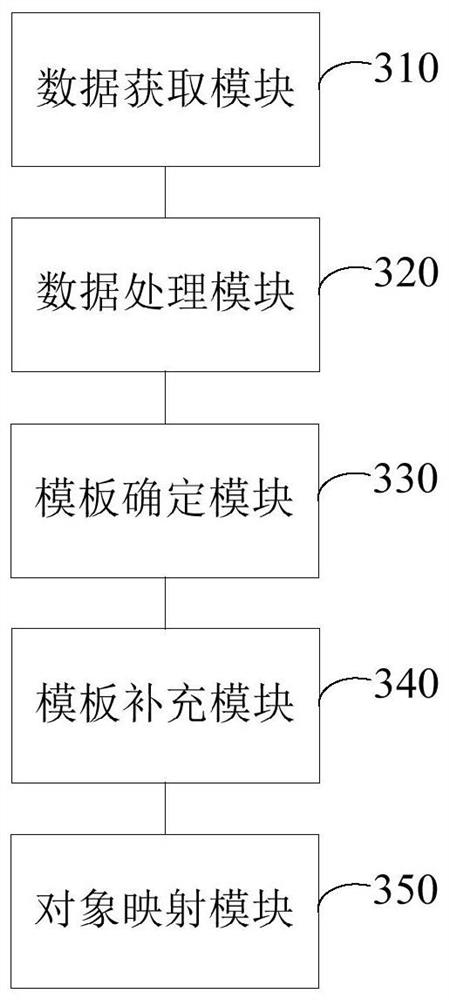

Ontology construction method and device, electronic equipment and storage medium

PendingCN111858948AImprove perfectionSemantic analysisSpecial data processing applicationsSoftware engineeringUnstructured data

The embodiment of the invention provides an ontology construction method and device, electronic equipment and a storage medium, and the method is characterized in that the method comprises the steps:obtaining target data for constructing an ontology; performing instantiation processing on the structured data in the target data to obtain each first object included in the structured data; performing instantiation processing on the unstructured data in the target data to obtain each second object included in the unstructured data; determining a target ontology template matched with each first object from an ontology template library; supplementing an object field in the target ontology template by utilizing the type of the second object; and mapping each first object and each second object to the supplemented target ontology template to obtain an ontology corresponding to the target data. Through the technical scheme provided by the embodiment of the invention, the data completeness of the ontology corresponding to the target data can be improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Catalytic flue gas desulfurization device

PendingCN114653201AImprove perfectionGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention discloses a catalytic flue gas desulfurization device which comprises a desulfurization reactor, the interior of the desulfurization reactor is divided into a flue gas distribution layer, a catalyst placement layer and a flue gas overflow layer from bottom to top, a gas distribution supporting structure is arranged in the flue gas distribution layer, a catalyst is placed in the catalyst placement layer above the gas distribution supporting structure, and the flue gas overflow layer is arranged in the flue gas distribution layer. A catalyst partition plate is arranged above the gas distribution supporting structure in the desulfurization reactor and comprises a main plate and wing plates, wherein the main plate is arranged along the first vertical surface and is used for separating the catalyst placement layer, and the wing plates are arranged along the second vertical surface, are connected to two sides of the main plate and are distributed at intervals along the length direction of the main plate. The main plate can be effectively prevented from toppling due to extrusion of the catalyst, and the impact force on the catalyst partition plate in the vertical direction due to rapid flow when the catalyst is poured into the catalyst placing layer is relieved.

Owner:成都达奇环境科技有限公司

Door lock control system and control method thereof

ActiveCN104299296BImprove perfectionAvoid wastingIndividual entry/exit registersSound detectionControl system

Owner:GUANGZHOU HORIZONTAL INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com