Surface cleaning method after carrying out chemical-mechanical polishing (CMP) on lithium niobate wafer in alkalinity

A technology of lithium niobate and the back surface, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as high surface tension, high wafer surface energy, and contamination of metal ions, etc., to achieve Effects of improving uniformity, reducing damaged layers, and improving perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: prepare 2000g lithium niobate crystal water-soluble surface cleaning liquid

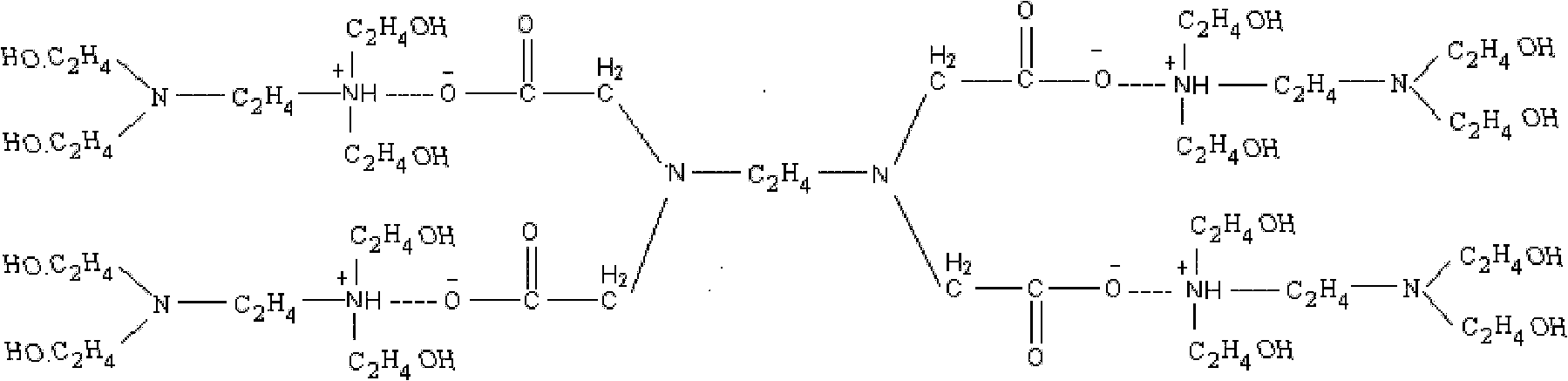

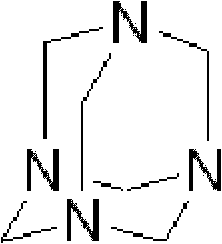

[0026] Take 1800g of deionized water, put in 50g of FA / O surfactant and 40g of FA / O chelating agent while stirring, then weigh 10g of hexamethylenetetramine corrosion inhibitor, dilute it with 100g of deionized water and pour it into the above-mentioned mixture while stirring. liquid. After stirring evenly, 2000g of silicon water-soluble surface cleaning solution is obtained, and the flow rate of 2000g / min is used for water polishing for 60s, and the surface is smooth and free of corrosion.

Embodiment 2

[0027] Embodiment 2: preparation 4000g lithium niobate crystal water-soluble surface cleaning liquid

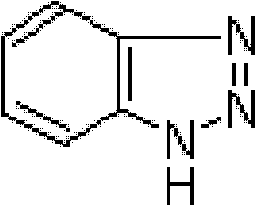

[0028] Get deionized water 3700g, put into Oπ-7 ((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 7 -H) 70g of surfactant, 60g of FA / O chelating agent, and then weigh 70g of benzotriazole corrosion inhibitor, dilute with 100g of deionized water, and pour into the liquid while stirring. After stirring evenly, 4000g of silicon water-soluble surface cleaning solution was obtained. After water polishing at a flow rate of 4000g / min, the surface was smooth and free of corrosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com