Patents

Literature

31results about How to "Avoid shelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

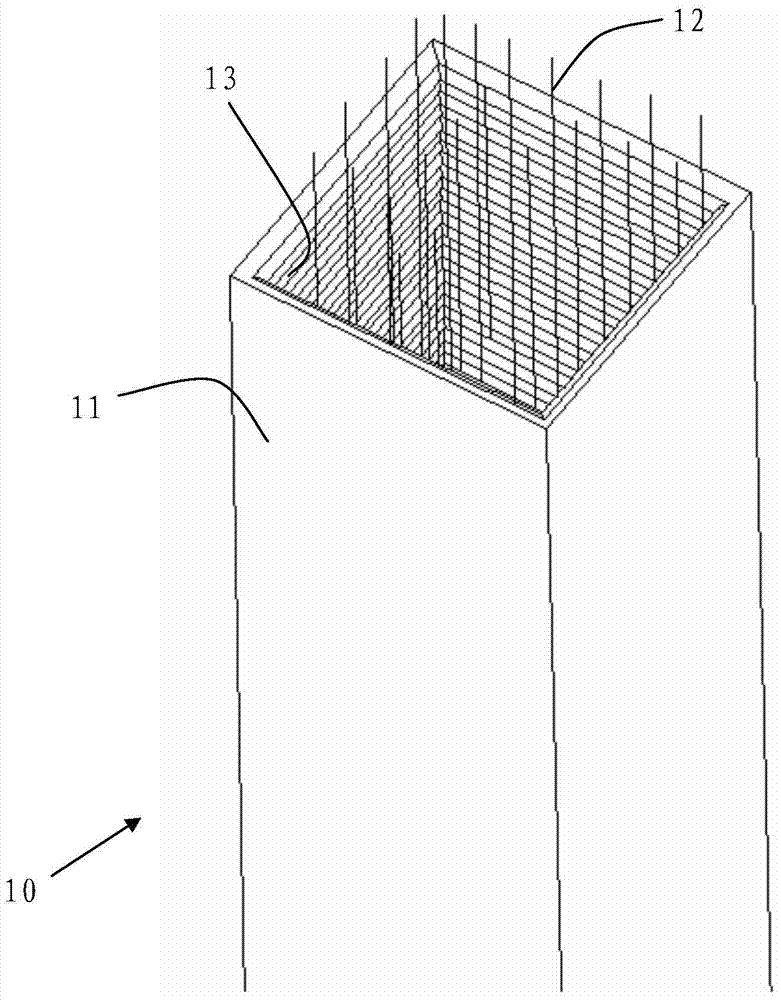

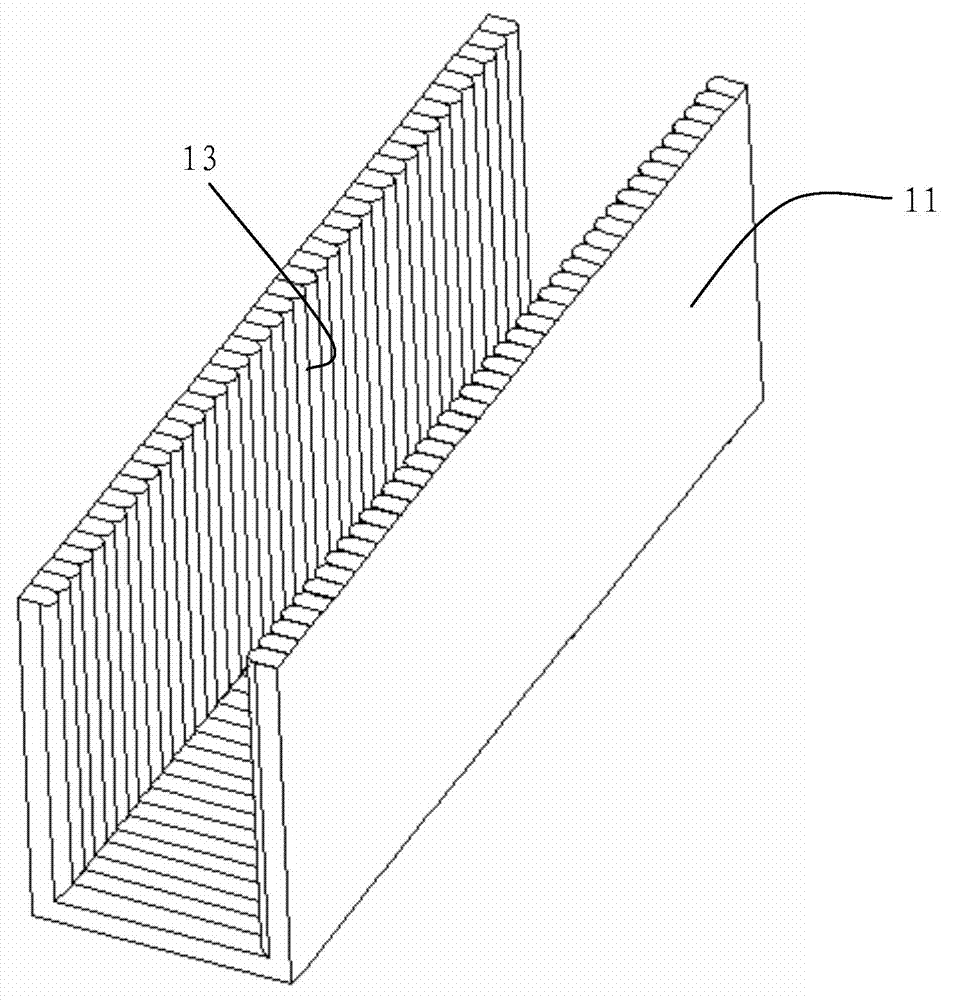

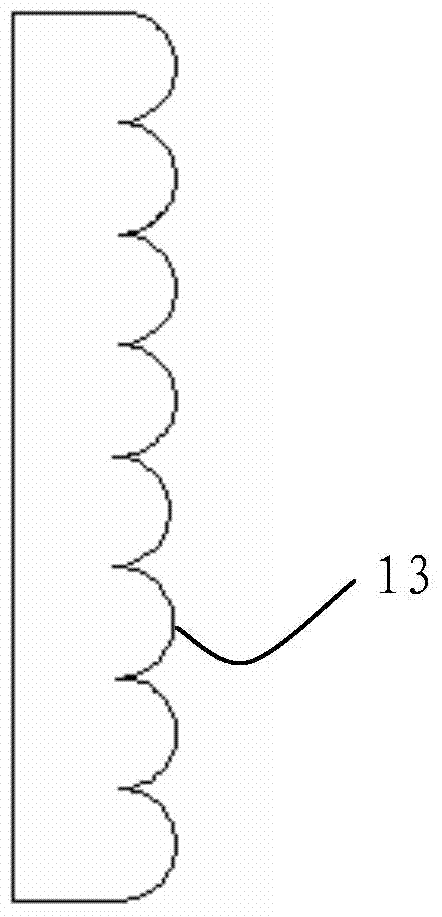

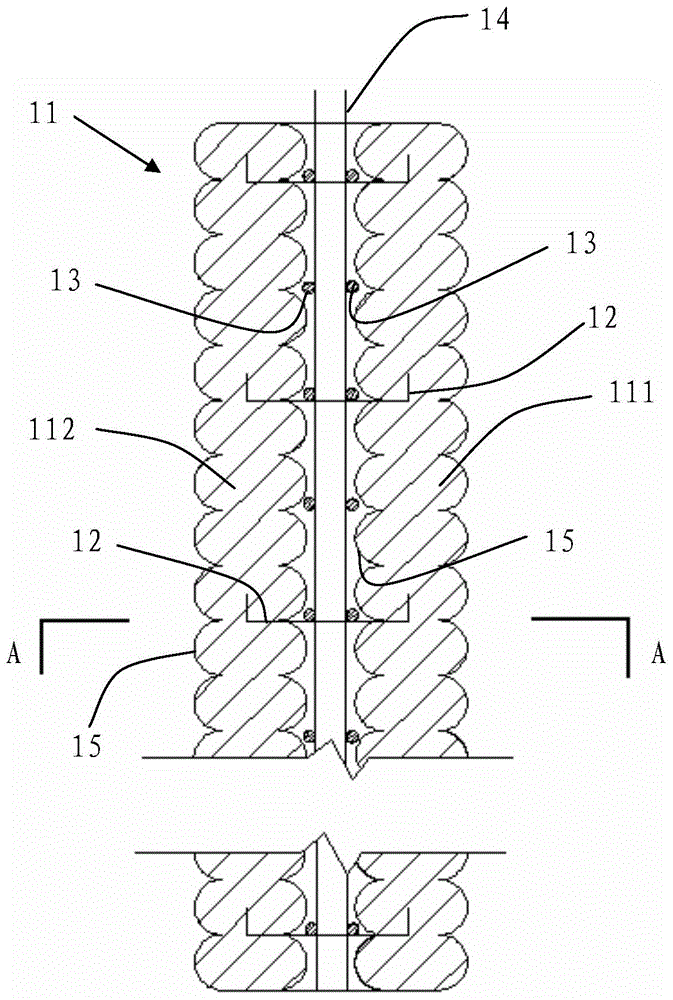

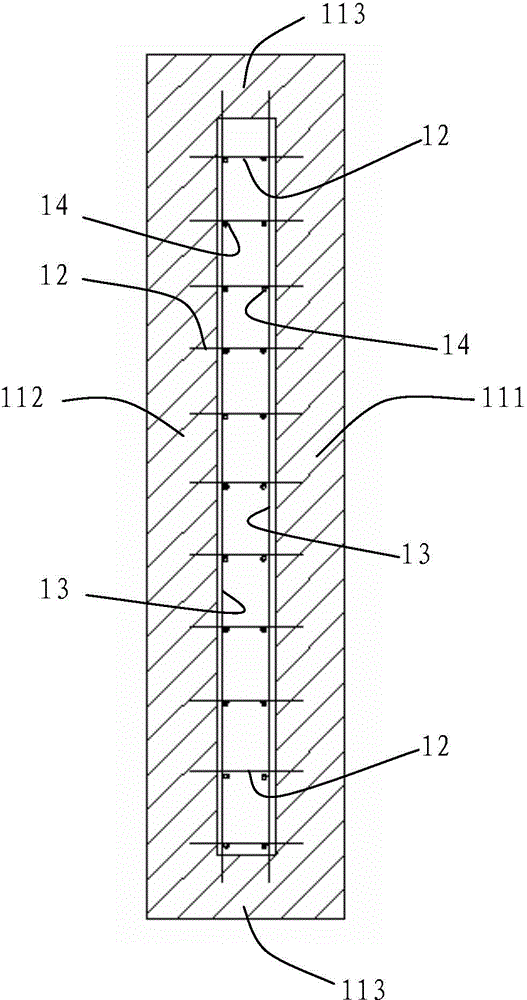

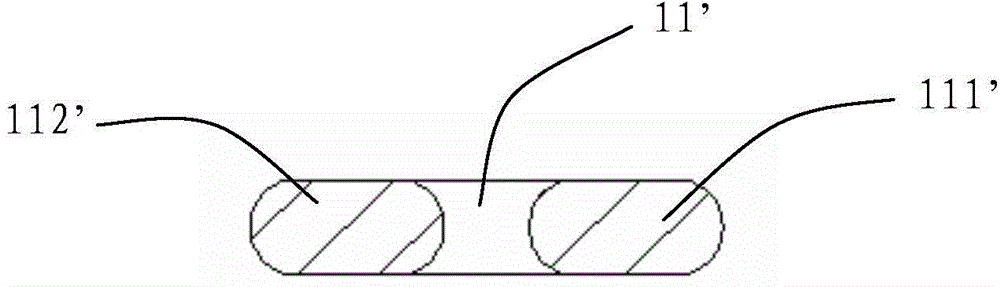

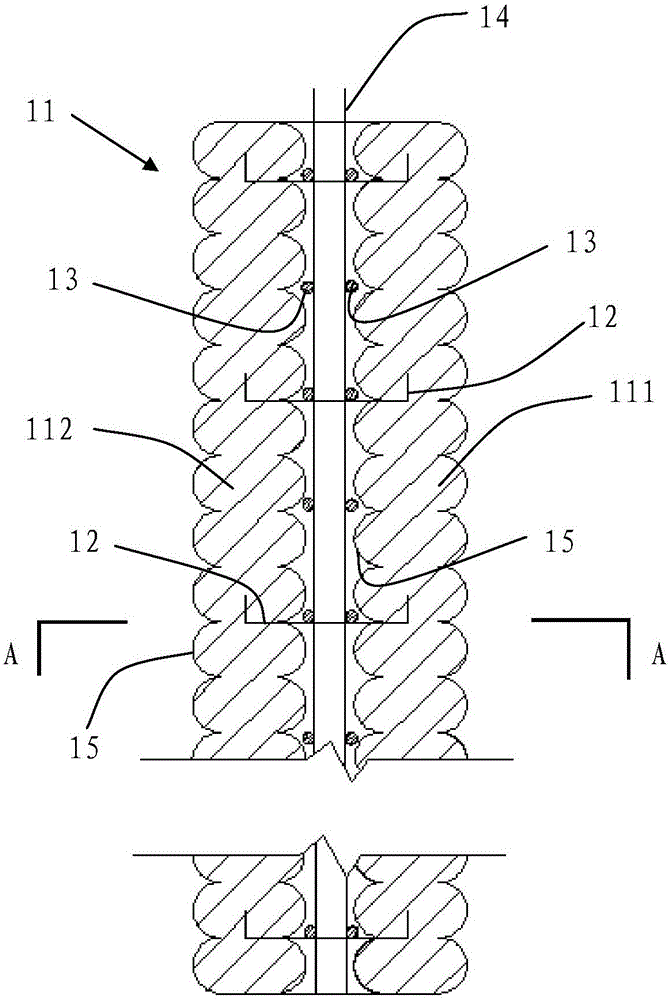

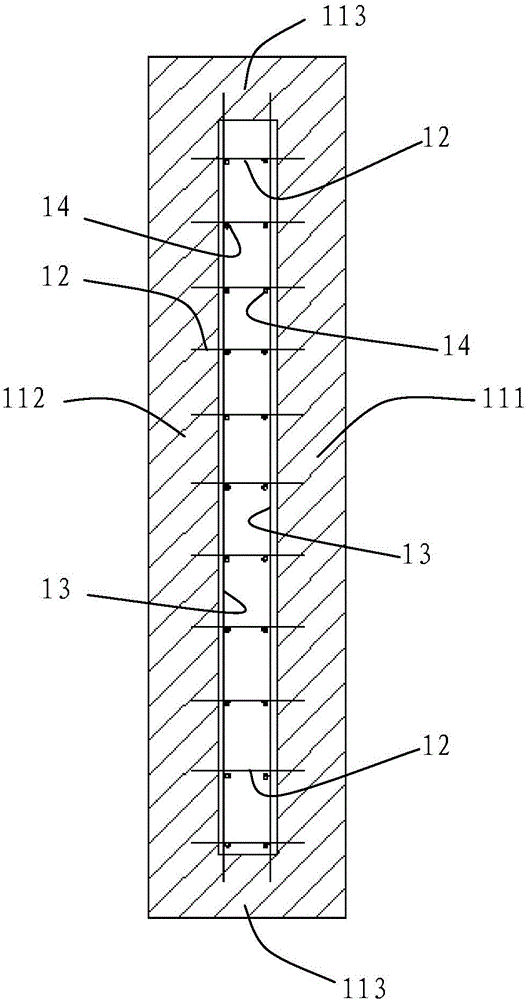

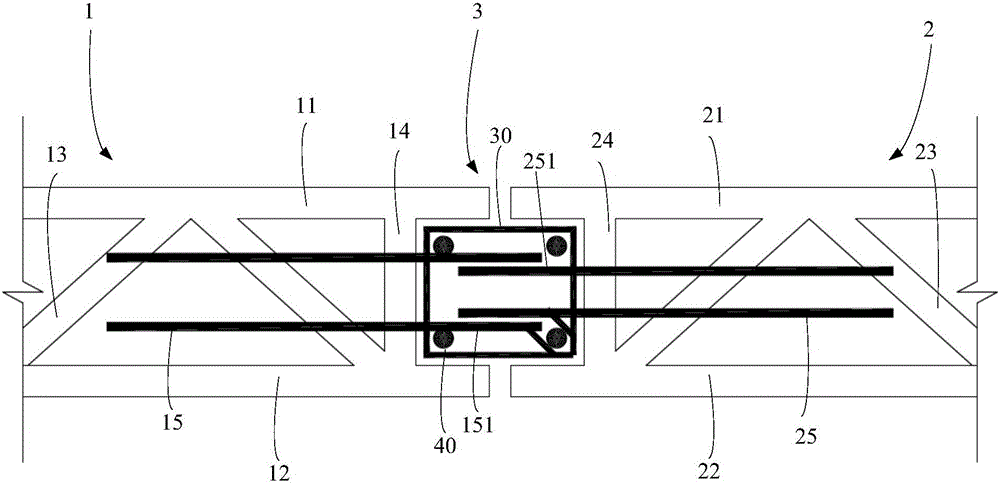

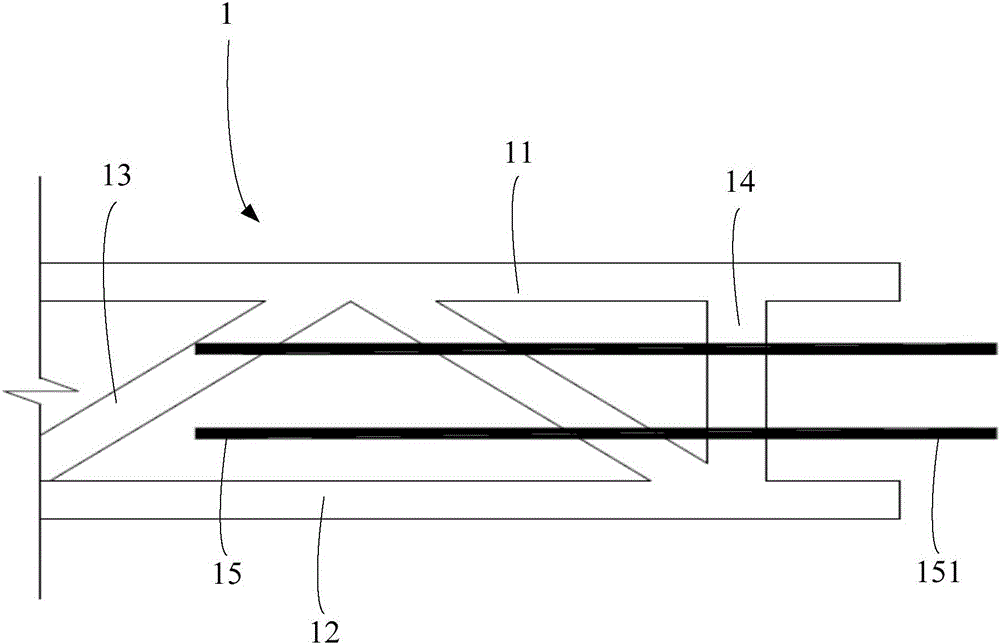

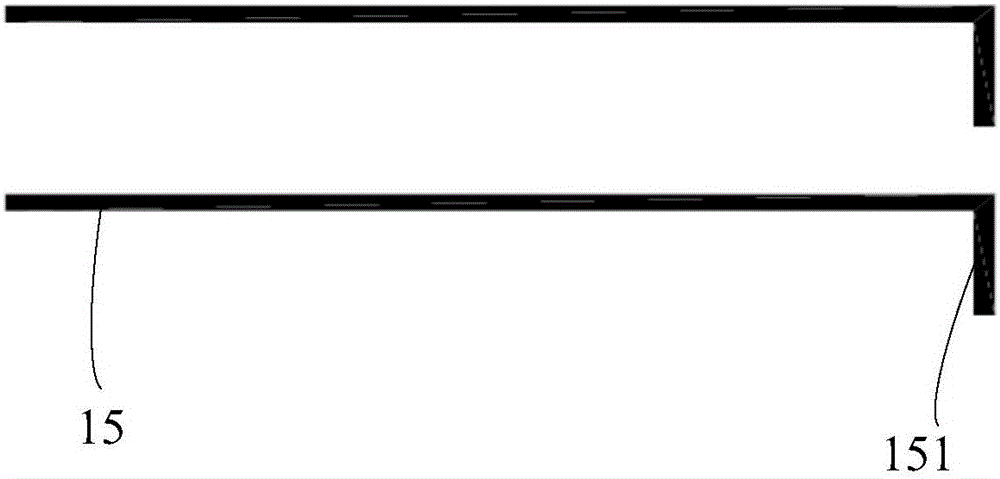

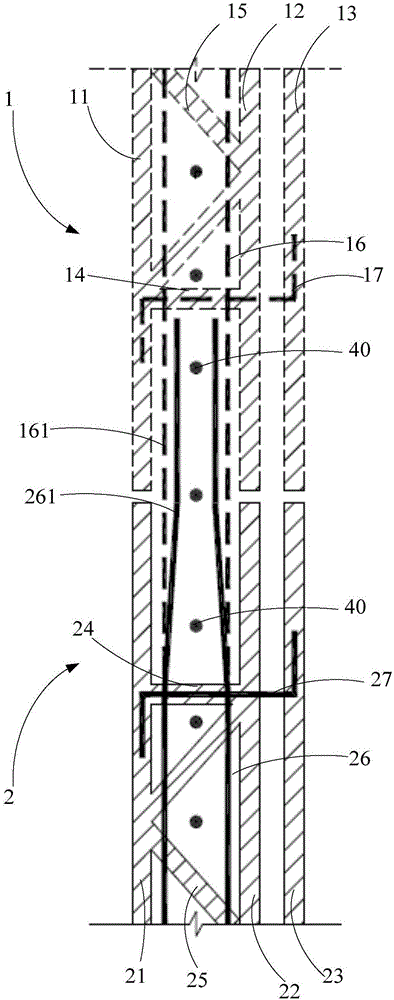

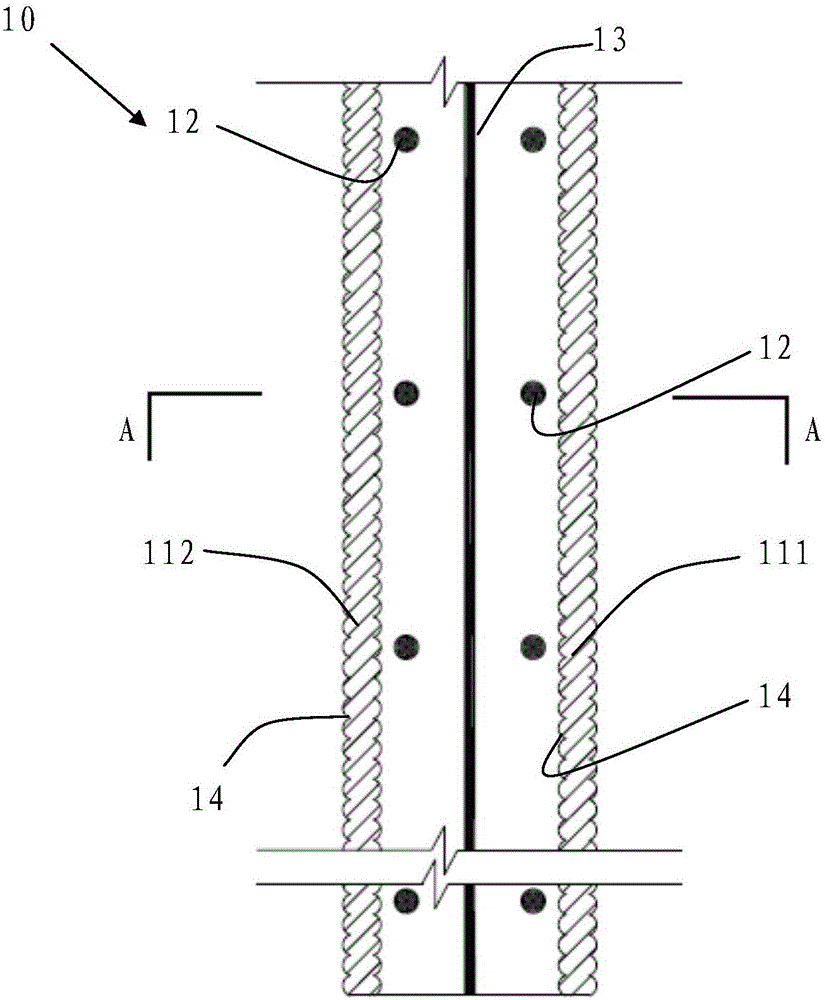

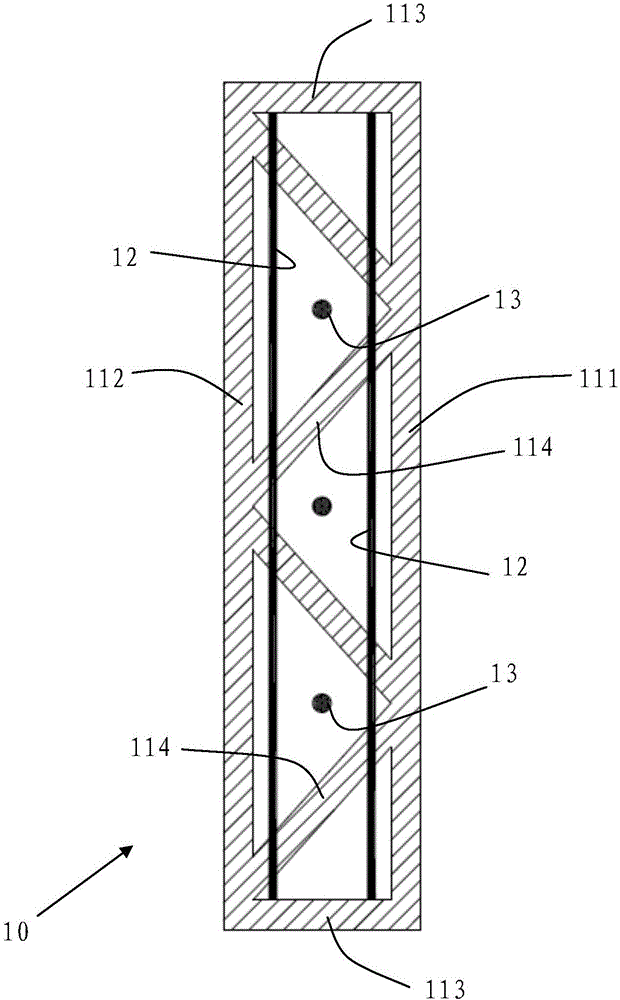

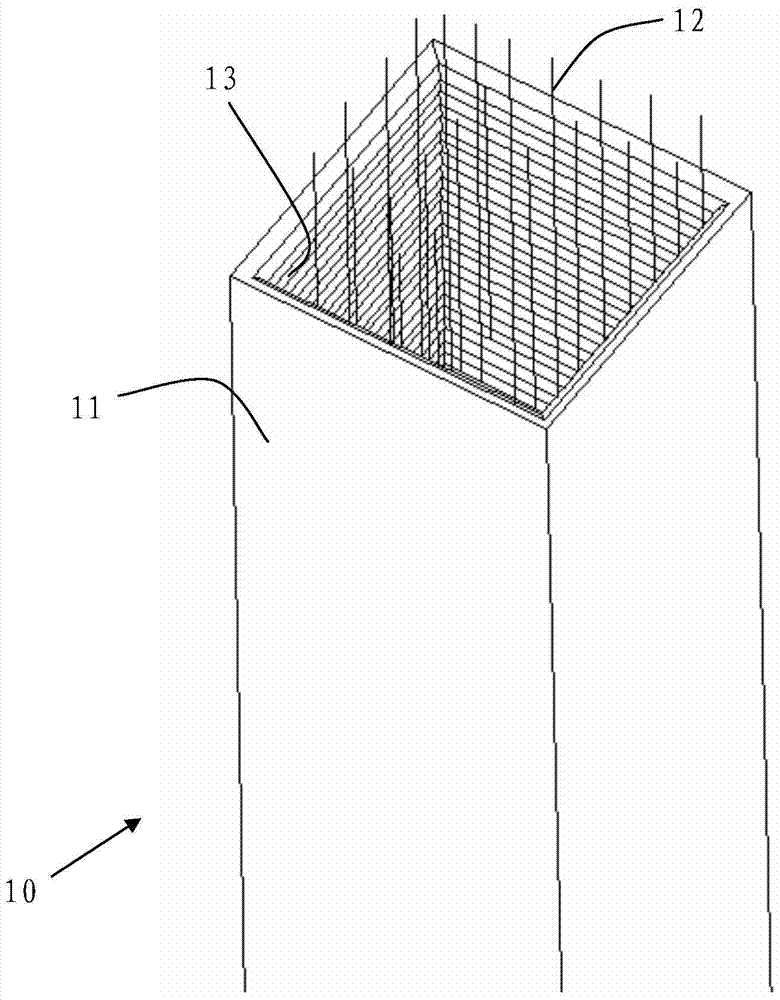

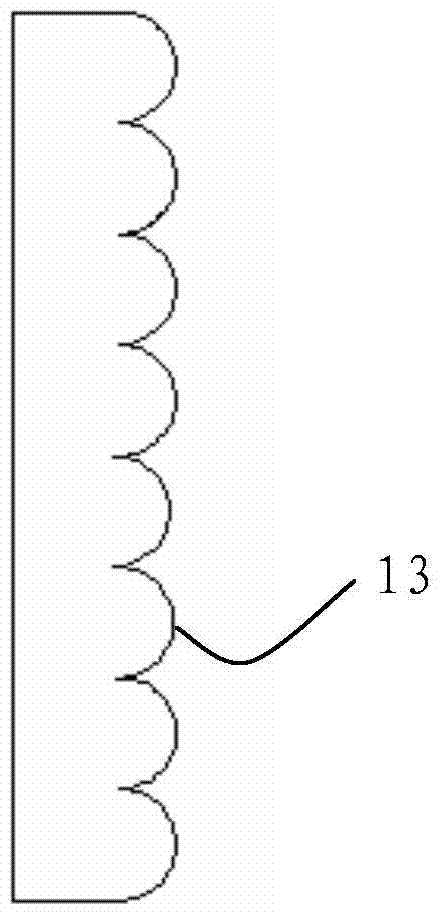

Reinforced concrete structure based on 3D printing and structure construction method

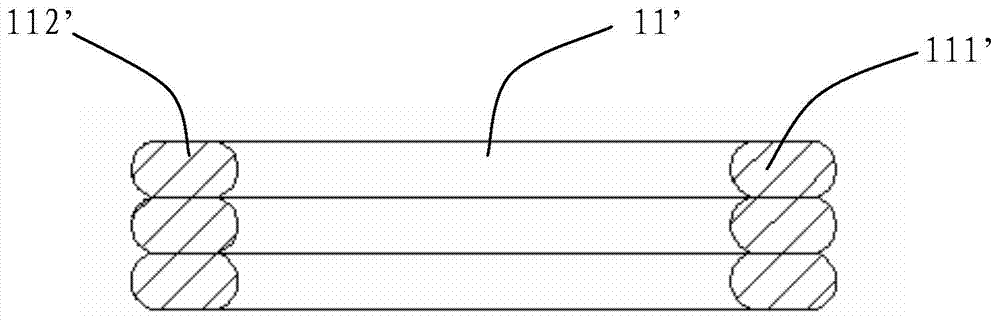

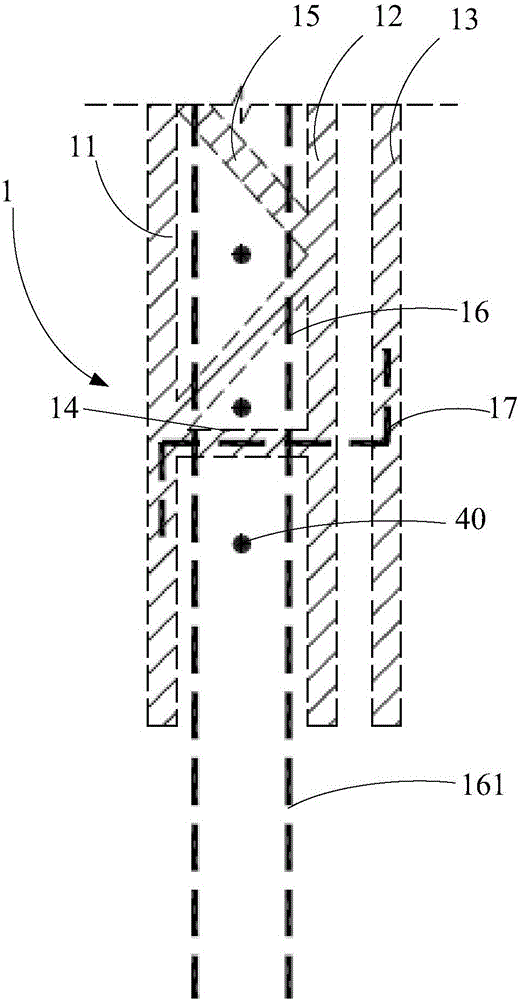

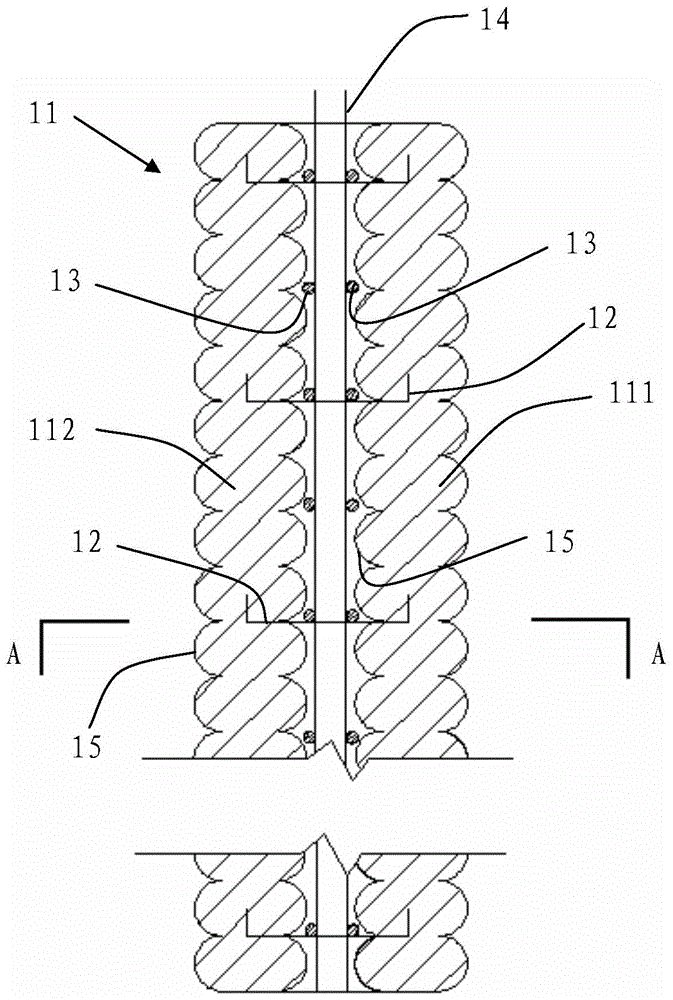

The invention discloses a reinforced concrete structure based on 3D printing and a structure construction method. The method comprises the following steps that a foundation bottom plate is constructed, and a connection section is reserved on the foundation bottom plate; a steel bar structure of a structural column is bound to the connection section; a first prefabricated concrete outer shell is manufactured by adopting 3D printing, and concave-convex lines are formed in the inner surface of the first prefabricated concrete outer shell; the first prefabricated concrete outer shell is arranged on the steel bar structure of the structural column in a sleeved mode; a steel bar structure of a structural beam is bound, and the steel bar structure of the structural beam is bound to the steel bar structure of the structural column; a second prefabricated concrete outer shell is manufactured by adopting 3D printing; the second prefabricated concrete outer shell is mounted on the steel bar structure of the structural beam; concrete is poured in the second prefabricated concrete outer shell, and the structural beam and the structural column are completed. The prefabricated concrete outer shells are formed integrally by adopting a 3D printing technology, the continuous concave-convex lines are formed in the inner surfaces of the prefabricated concrete outer shells, the contact surfaces between the concrete poured in the prefabricated concrete outer shells and the inner surfaces of the prefabricated concrete outer shells are enlarged, compared with a smooth inner surface, friction is increased, bonding strength is improved, and a shell disengagement phenomenon is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

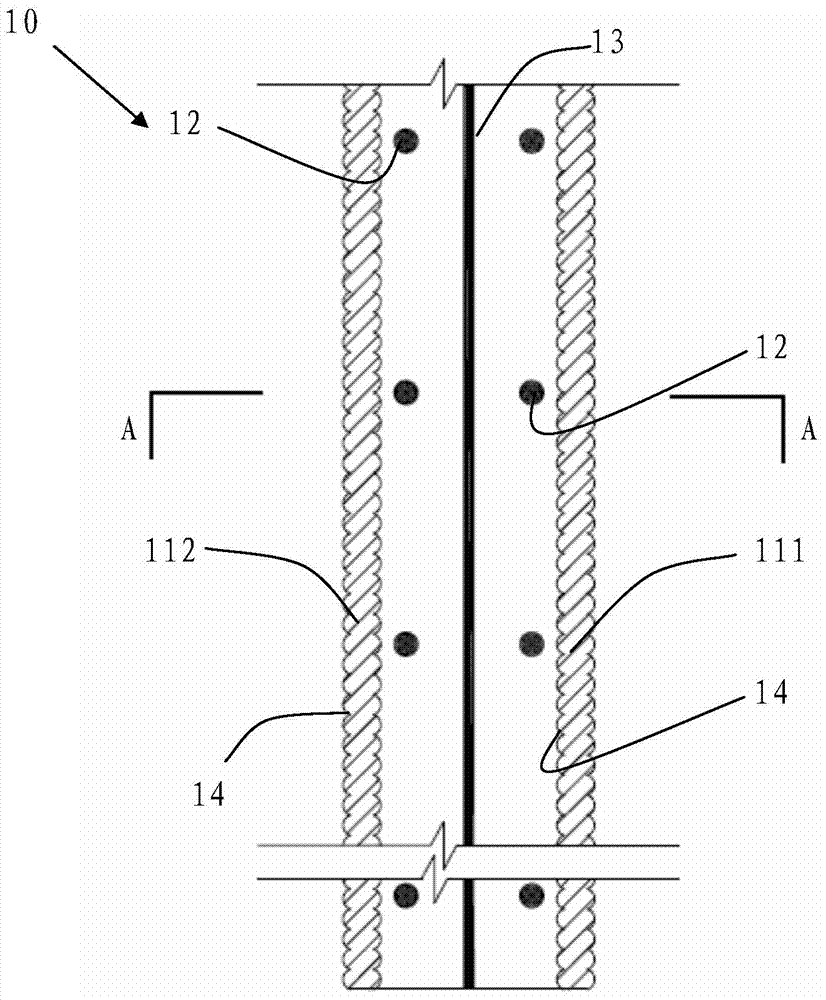

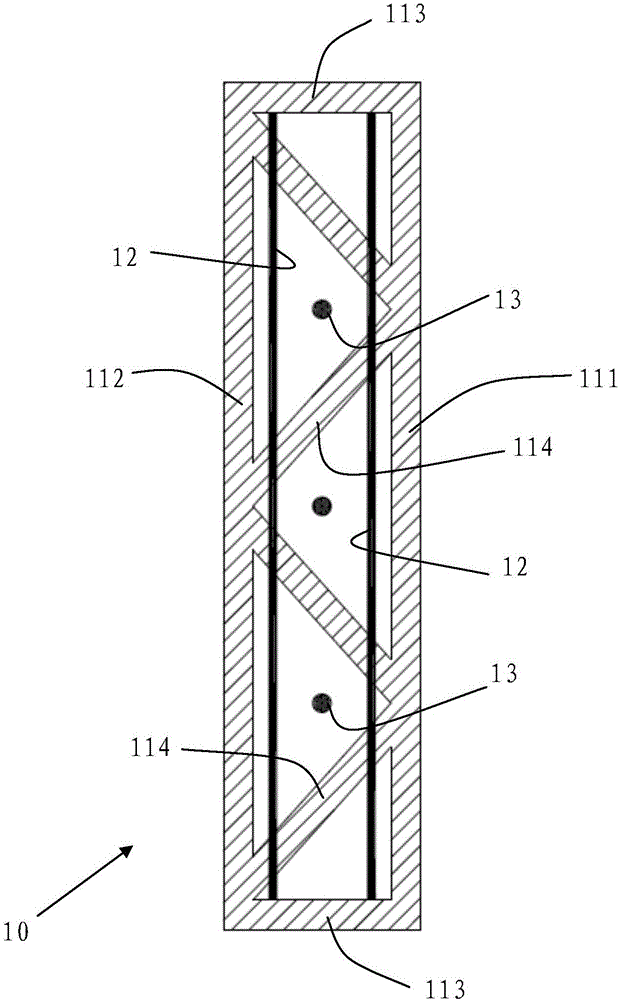

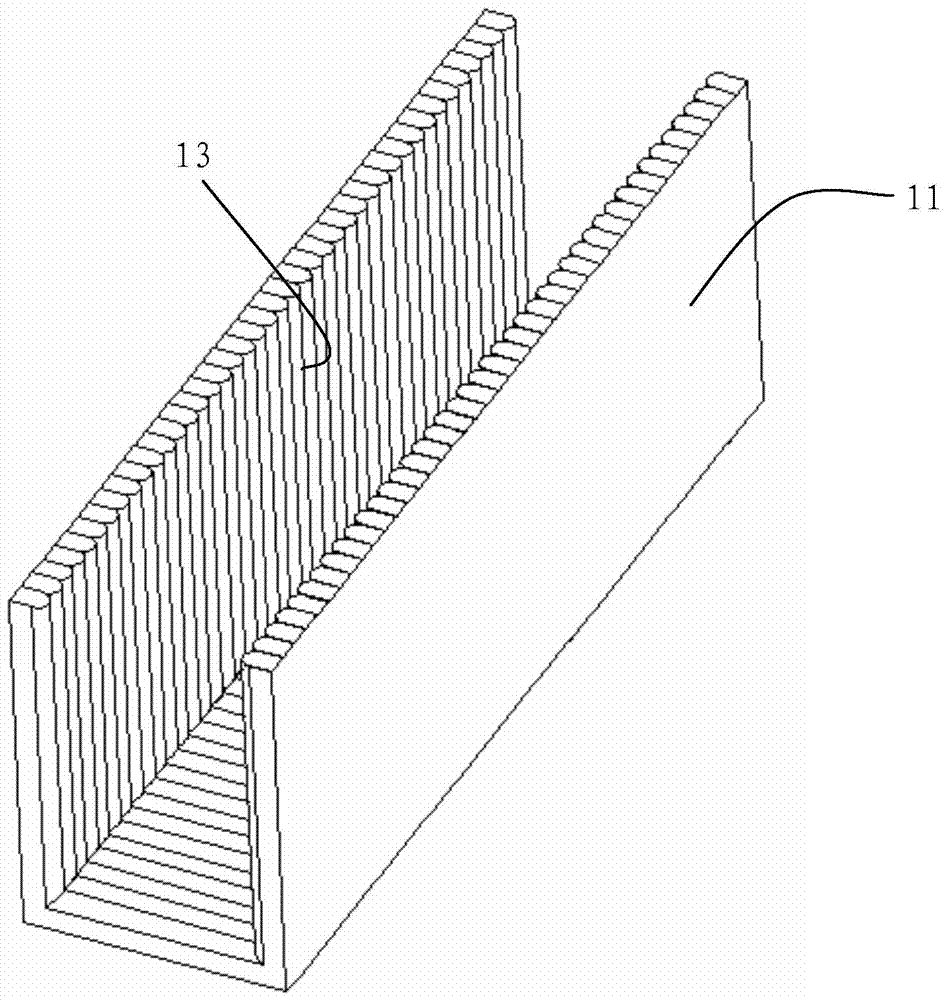

Concrete shear wall structure based on 3D printing and construction method of concrete shear wall structure

ActiveCN104153493AAvoid constructionAvoid demolitionAdditive manufacturing apparatusWallsEngineeringHorizontal bar

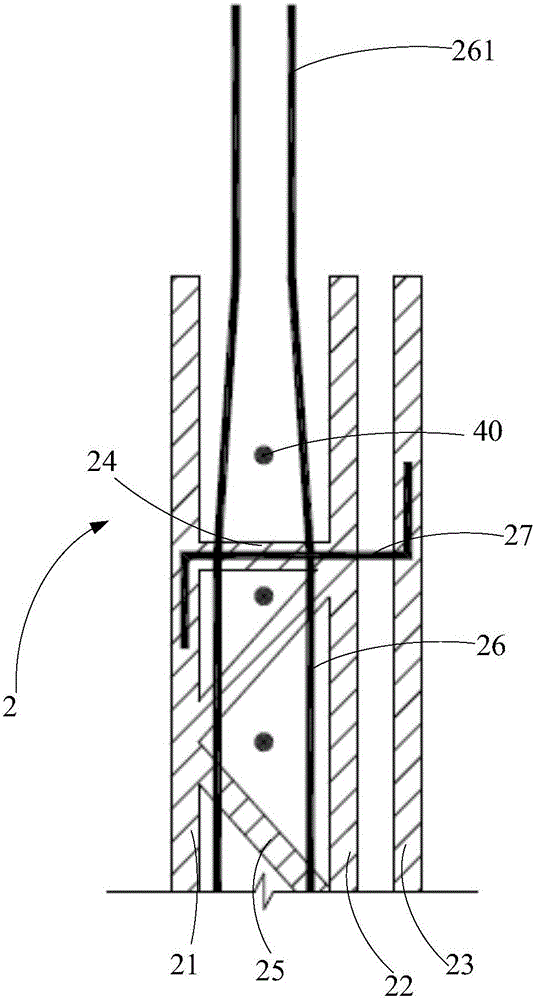

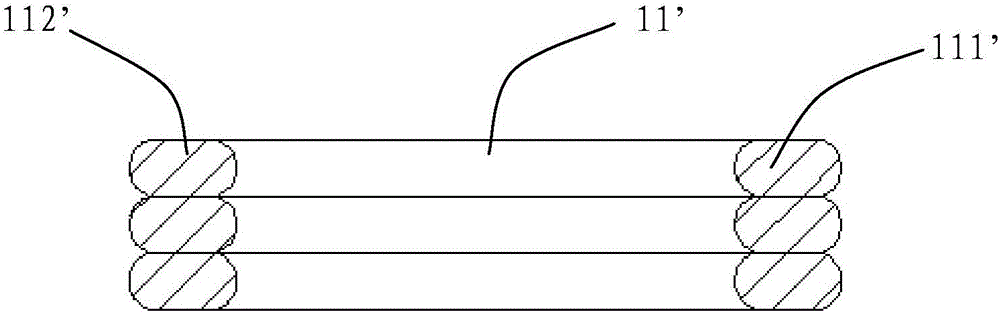

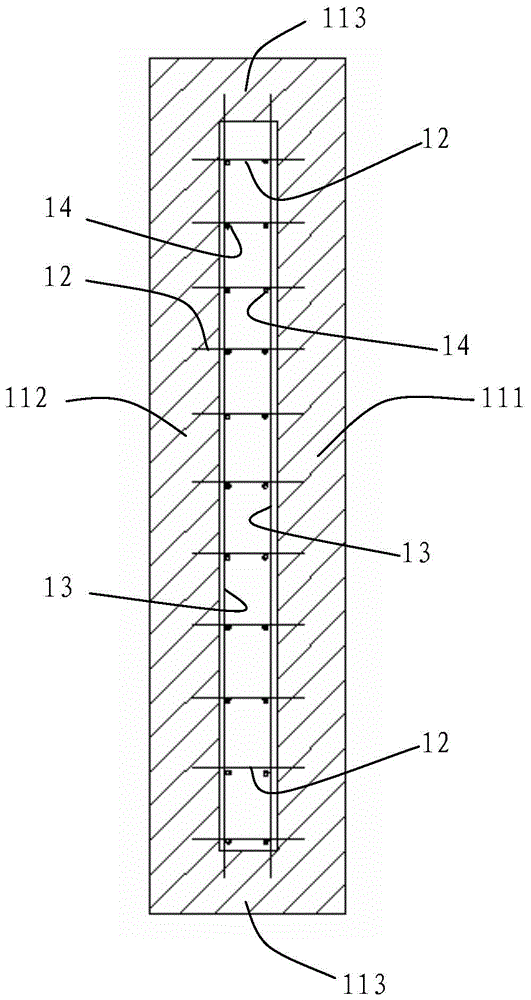

The invention discloses a concrete shear wall structure based on 3D printing and a construction method of the concrete shear wall structure. The construction method comprises the following steps that (a) a first layer of prefabricated concrete shell is manufactured by adopting 3D printing; (b) a first layer of tie bars and / or horizontal bars are arranged on the top of the first layer of prefabricated concrete shell; (c) a second layer of prefabricated concrete shell is manufactured on the top of the first layer of prefabricated concrete shell, and the two ends of the tie bars and / or the horizontal bars are embedded into the prefabricated concrete shells respectively; (d) a second layer of tie bars and / or horizontal bars are arranged on the top of the second layer of prefabricated concrete shell, the step (c) is repeated until the prefabricated concrete shells are completed to reach designed elevation, and concrete is poured. The tie bars are prefabricated between an inner wall faces and an outer wall faces of the prefabricated concrete shells to prevent formwork expansion, the horizontal bars of a shear wall are also embedded between the prefabricated concrete shells, construction inconvenience brought by the horizontal bars in the later mounting process is avoided, and construction is simplified.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

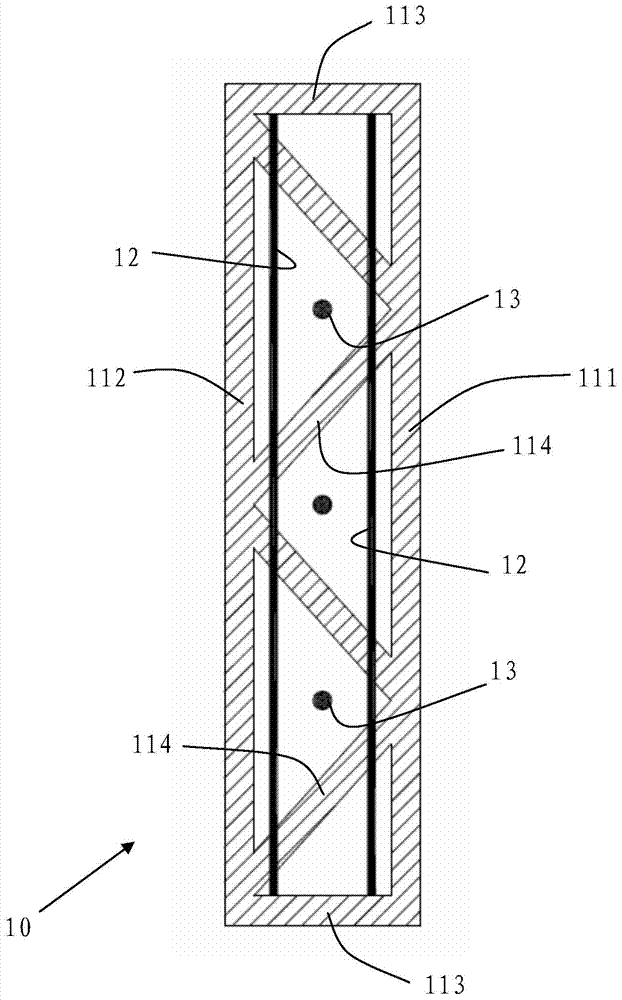

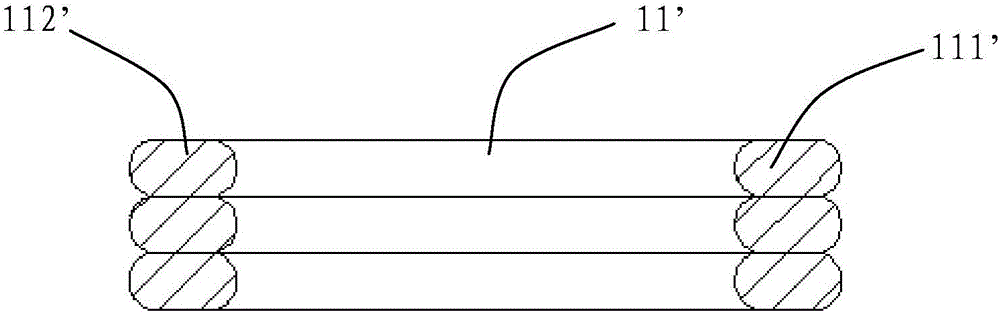

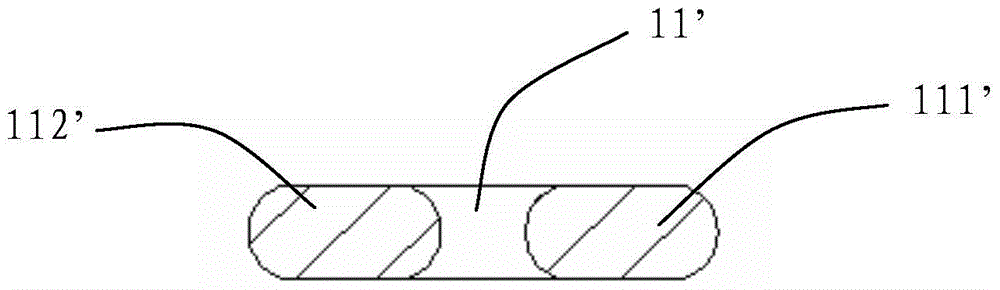

3D printing reinforcement masonry shear wall structure and construction method thereof

ActiveCN104264862ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebarTransverse reinforcement

The invention discloses a 3D printing reinforcement masonry shear wall structure and a construction method thereof. The construction method includes the following steps that a, the 3D printing technology is used for manufacturing a first layer of masonry outer shell to the pre-buried elevation position of transverse reinforcement; b, the transverse reinforcement is arranged on the top of the first layer of masonry outer shell; c, the 3D printing technology is used for manufacturing a second layer of masonry outer shell on the top of the first layer of masonry outer shell, and thus the transverse reinforcement can be laid in the masonry outer shell; d, the step b and the step c are executed repeatedly, so that the masonry outer shell is obtained; e, the step a and the step d are executed repeatedly, so that a plurality of masonry outer shells are obtained, and the masonry outer shells are stacked to the designed elevation of a shear wall; f, vertical reinforcement is mounted in each masonry outer shell; g, concrete is poured, and accordingly the shear wall can be constructed. By the adoption of the 3D printing technology, the masonry outer shells of reinforcement masonry can be integrally formed, original concrete small hollow blocks are replaced, the site construction labor force is greatly reduced, the construction procedures are omitted, the building quality is guaranteed, and thus building industrialization can be facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

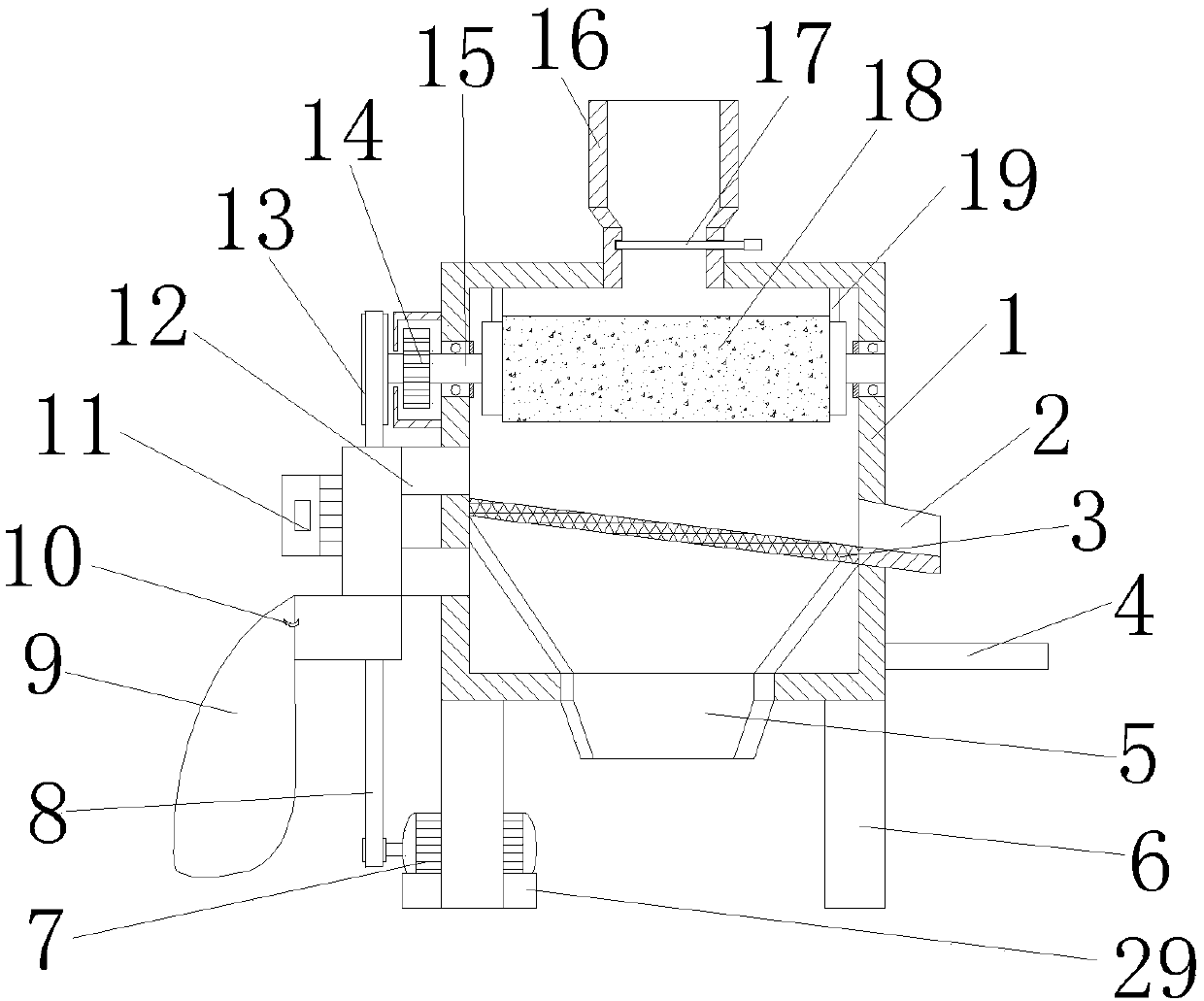

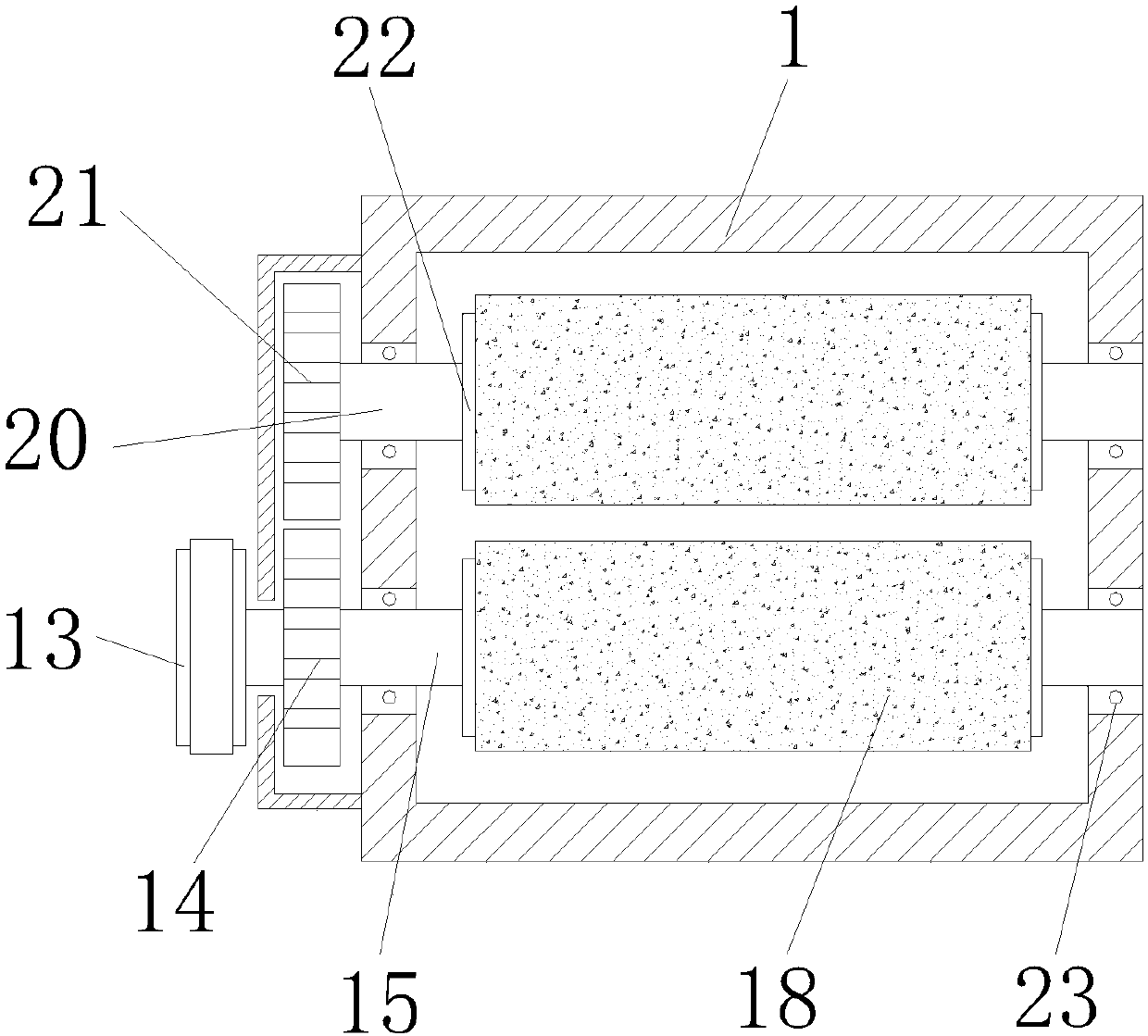

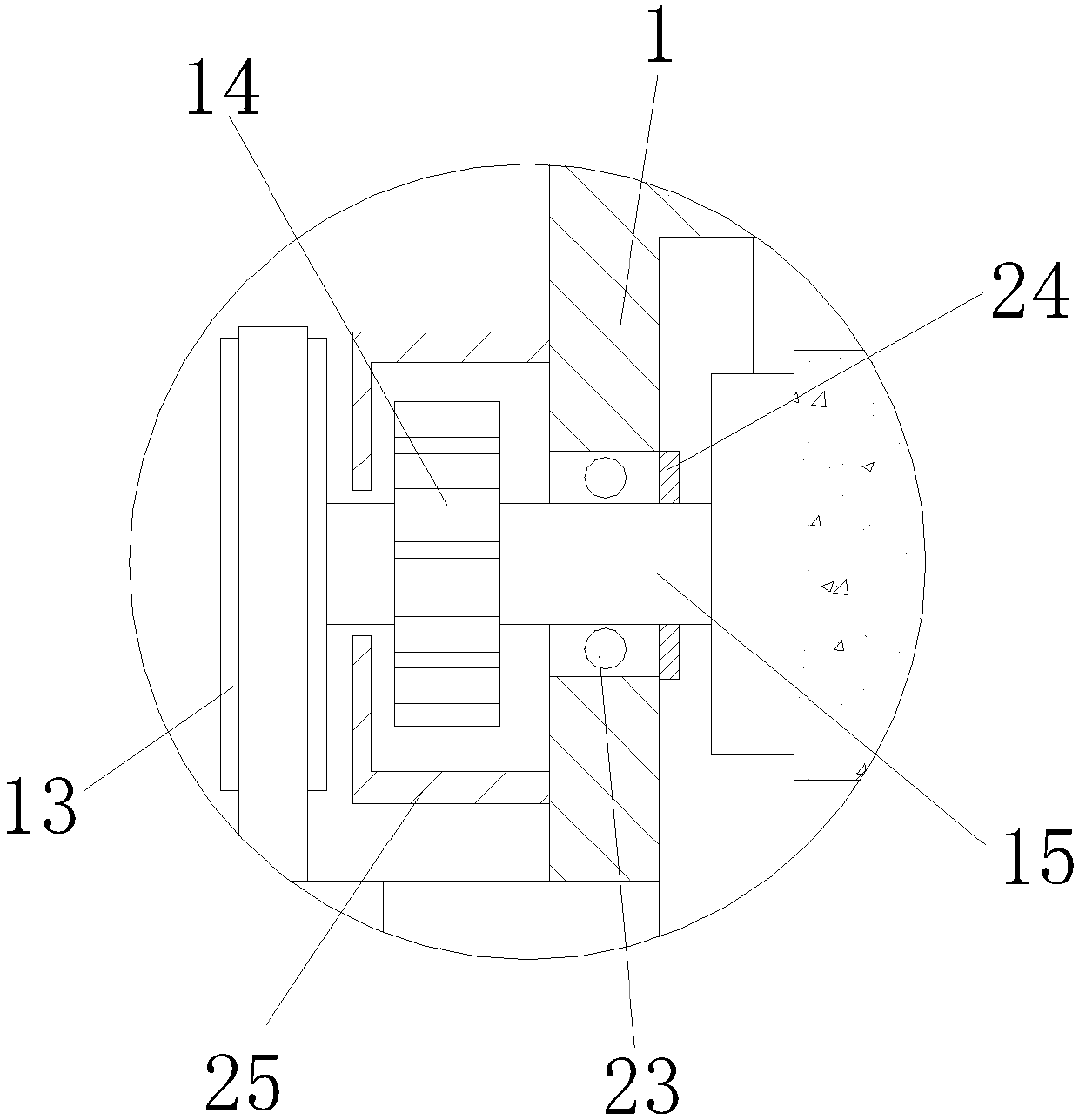

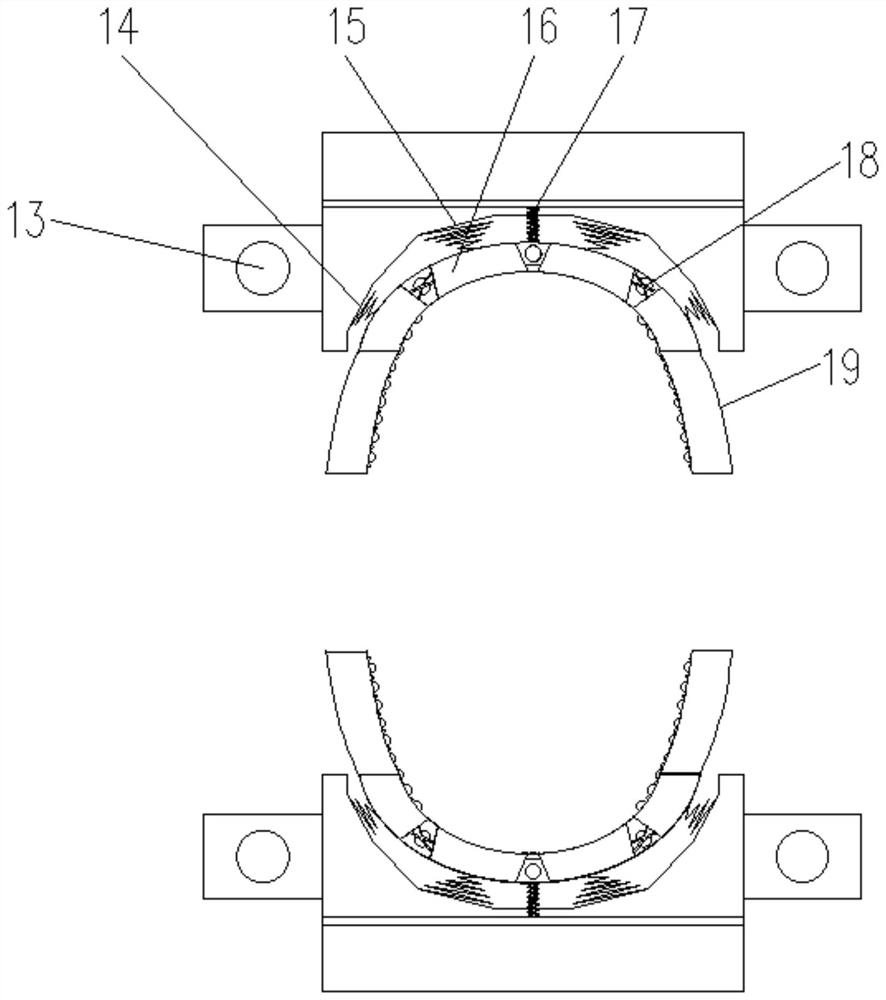

Rice milling device of rice miller

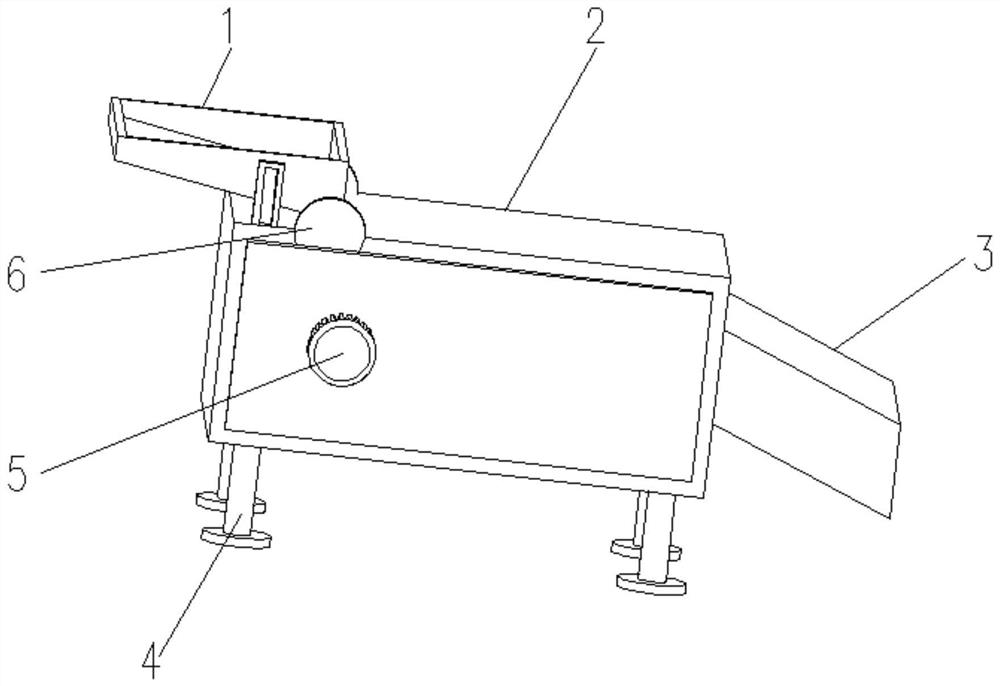

InactiveCN107638896AAvoid shellingFast shelling operationGrain huskingGrain polishingDrive shaftGear wheel

The invention discloses a rice milling device of a rice miller. The rice milling device includes a box body, a hopper is arranged at the top of the box body, a driving shaft is mounted at the front end of the inner side of the box body, a first gear is mounted on the left side of the outer wall of the driving shaft, a belt pulley is mounted on the left side of the driving shaft, a driven shaft ismounted at the rear end of the inner side of the box body, the driven shaft and the driving shaft are connected with the box body through bearings, and milling rollers are mounted on the outer walls of the driven shaft and the driving shaft. According to the rice milling device of the rice miller, when rice hulling is performed, rice is added into the inner side of the hopper, an external power supply of a motor is collected, a rubber sleeve is driven by the milling rollers to rotate, so that the rubber sleeve is in full contact with the rice, hull of the rice is removed, and rice hulling operation is implemented. Thus, it is shown that hulling is performed by friction between the rubber sleeve and the rice, rice pulverization is avoided, hulling operation is completed, the hulling operation speed is quick, and working efficiency is ensured.

Owner:安徽省中日农业环保科技有限公司

Reinforcing structure of 3D printing reinforced masonry shear wall

ActiveCN105908860ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebar3d printed

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

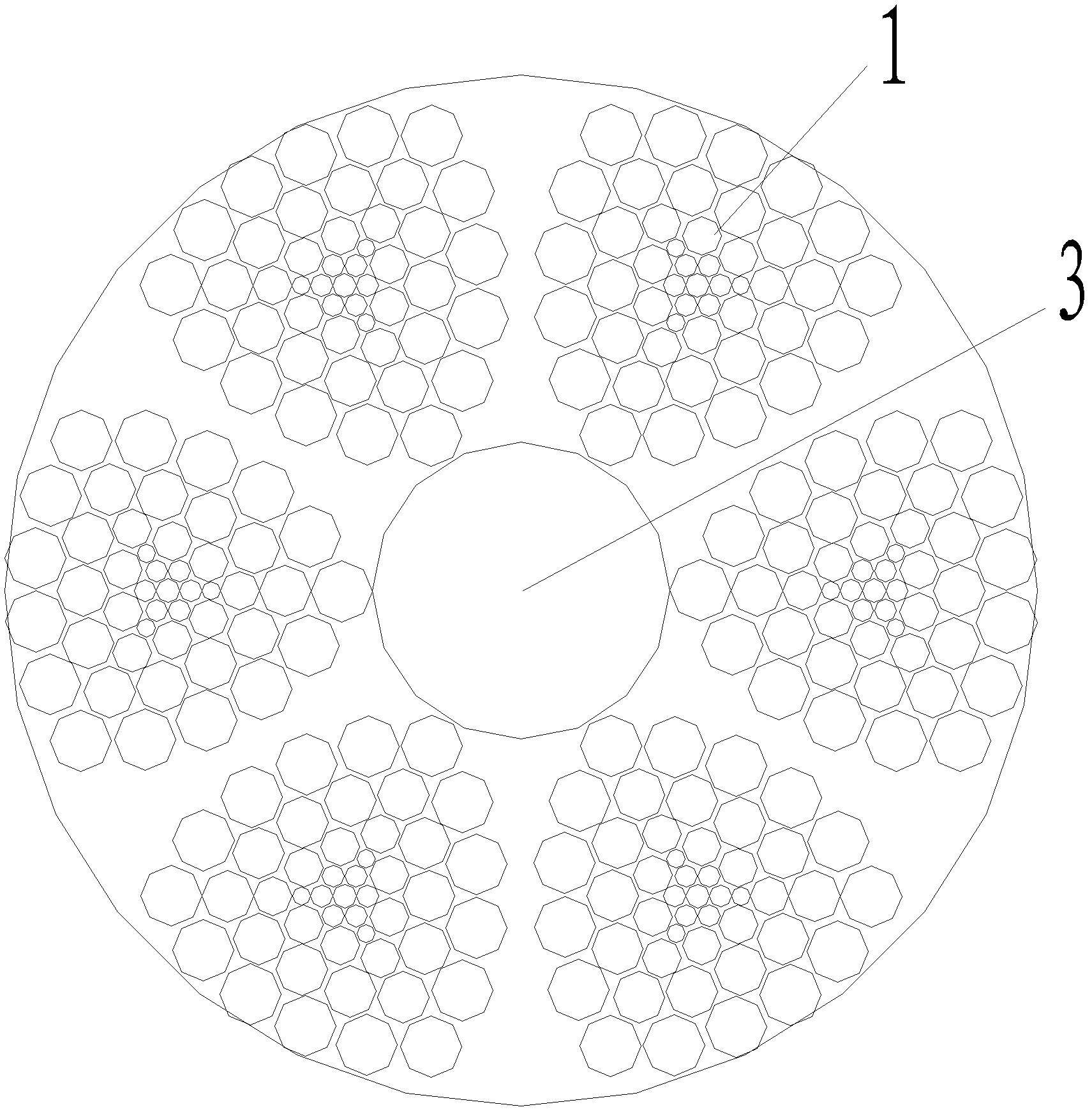

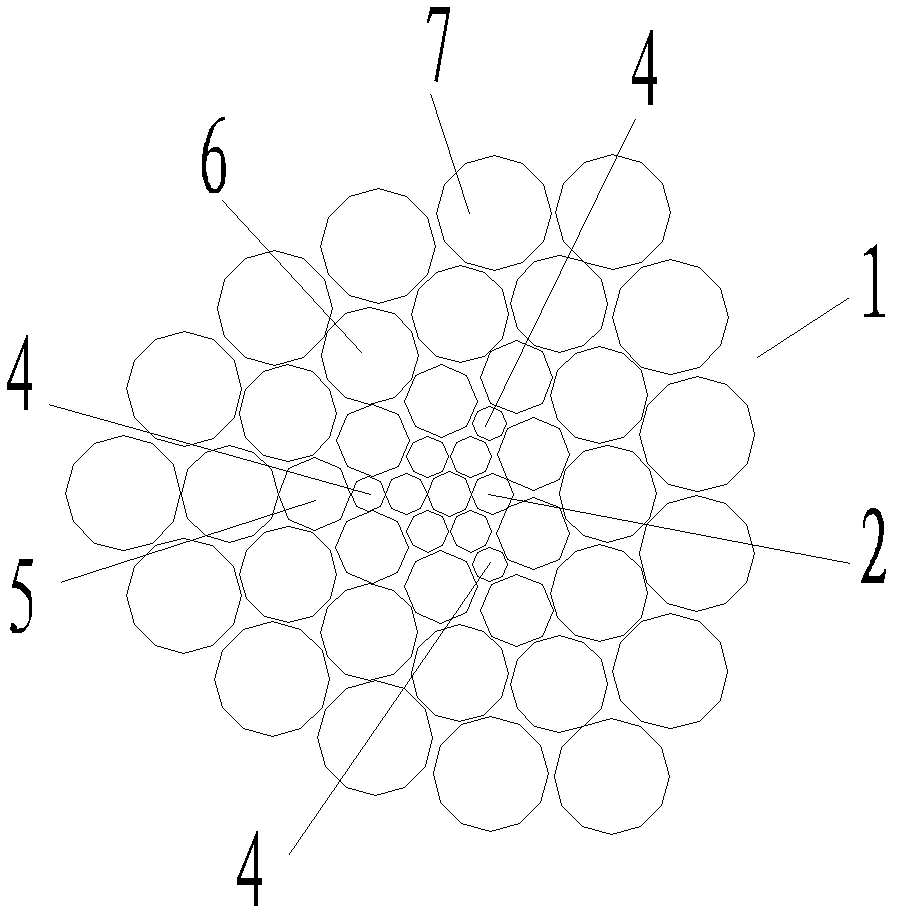

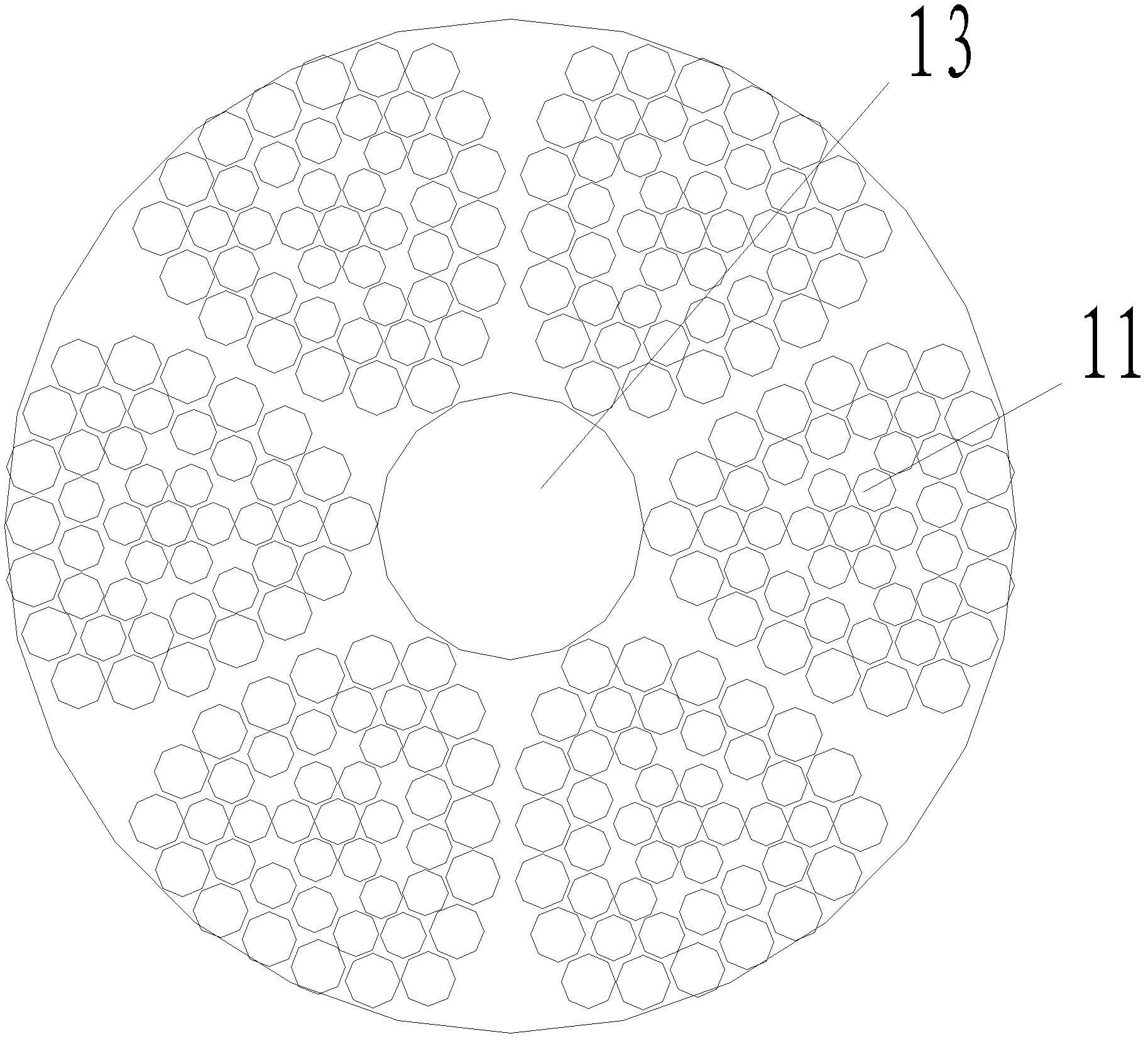

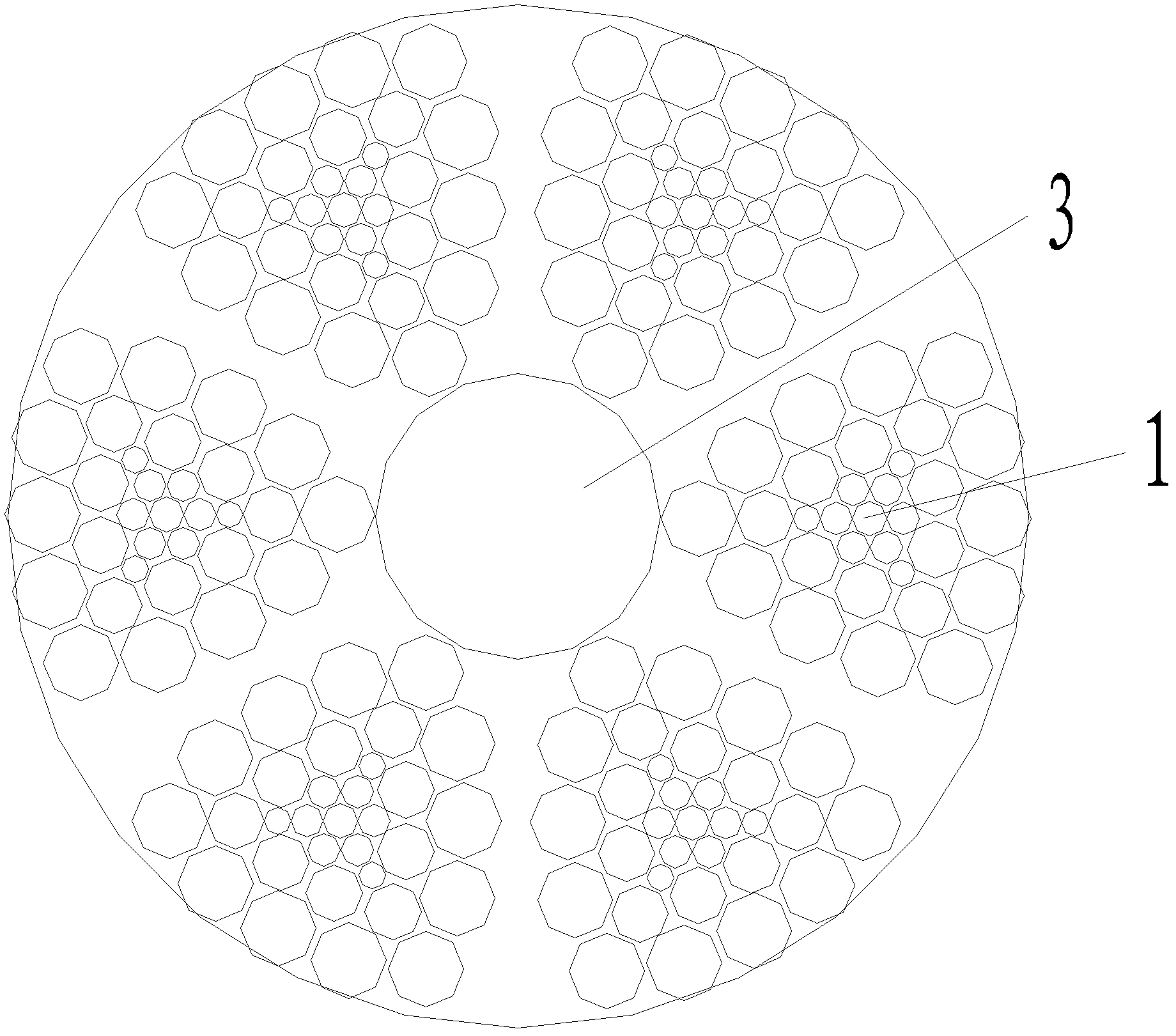

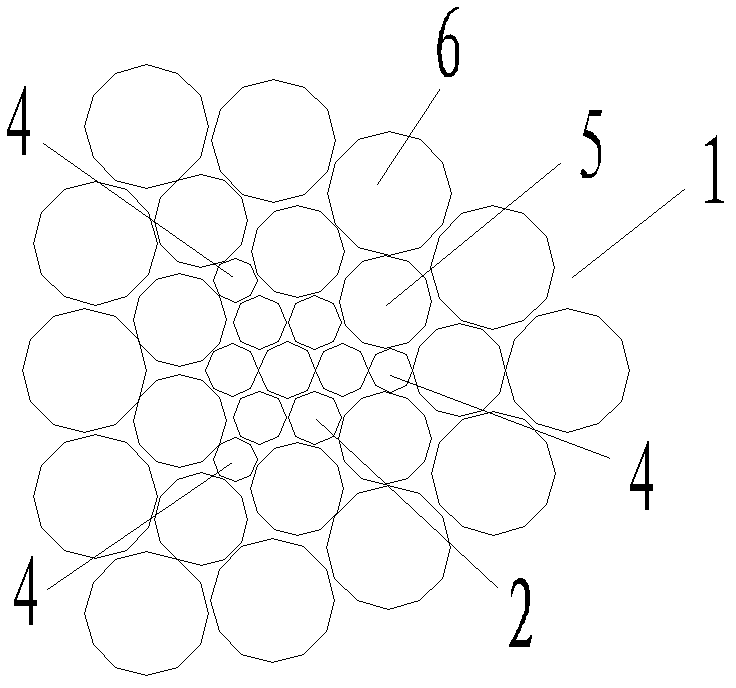

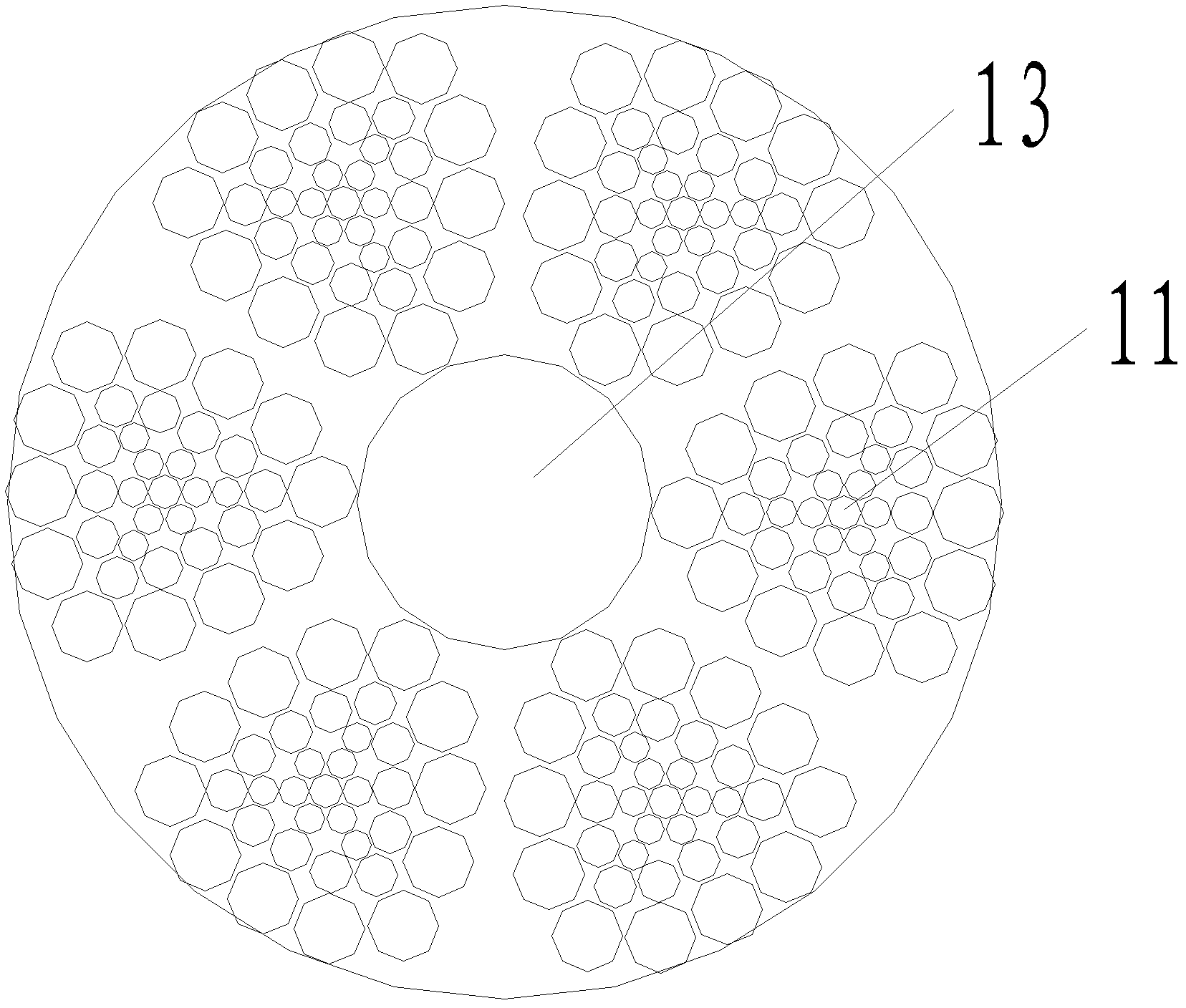

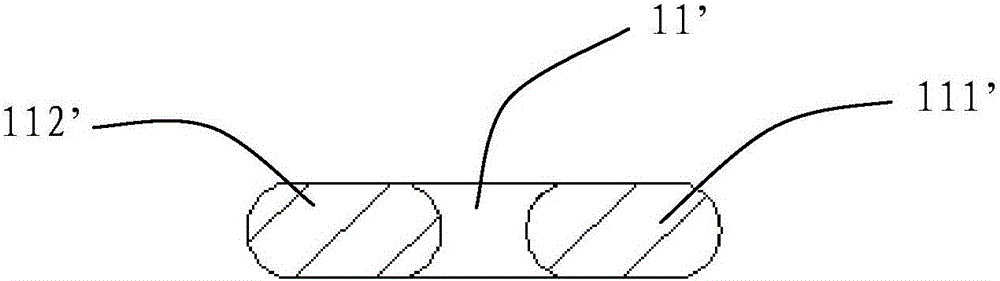

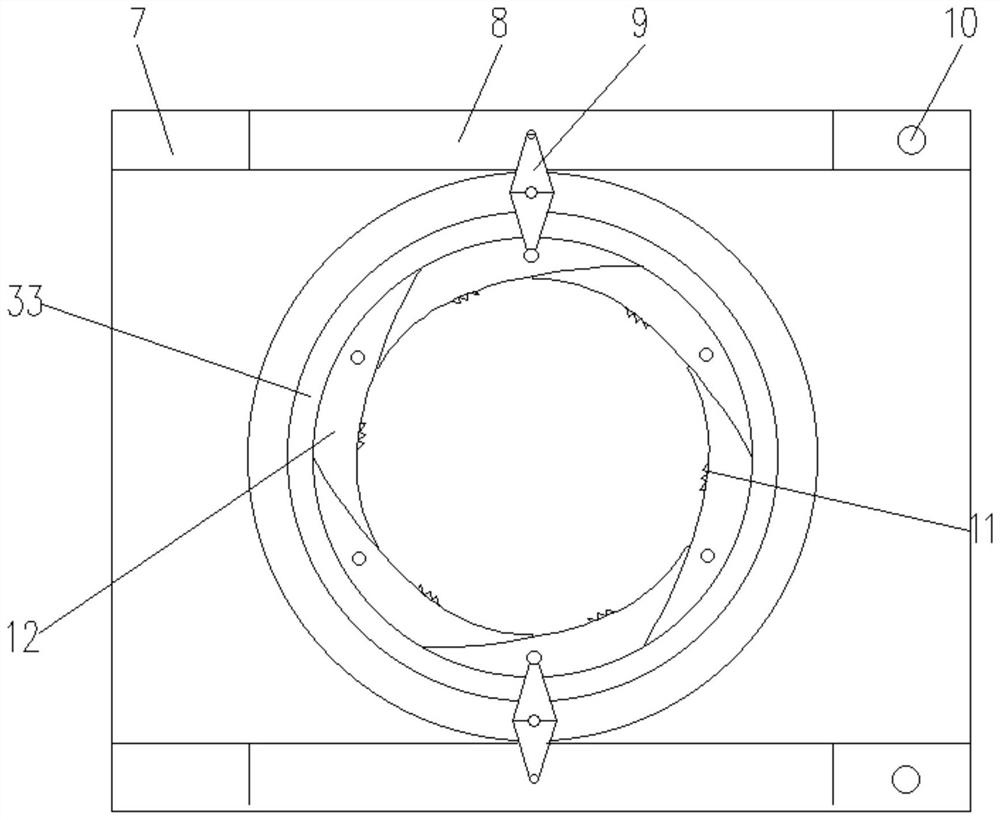

High-performance triangular-strand steel wire rope

The invention discloses a high-performance triangular-strand steel wire rope, which comprises six wire strands and a wire core. The six wire strands are uniformly twisted outside the wire core and arranged by forming 60-degree equant angles, and each wire strand is tangent with the wire core and is approximately triangular and comprises a strand core, three central steel wires, inner steel wires, middle steel wires and outer steel wires. The strand core is a circular steel wire strand formed by a plurality of steel wires, the three central steel wires are arranged on the periphery of the strand core by forming 120-degree equant angles and form a triangle shape with the strand core, the strand core and the central steel wires are wrapped by the inner steel wires, the middle steel wires are twisted on the outer periphery of the inner steel wires, and the outer steel wires are twisted on the outer periphery of the middle steel wires. Each strand core consists of forty six steel wires, and hardly any gaps are reserved among the inner steel wires, the strand core and the central steel wires. By twisting three times, the application range of the diameter of the steel wires and the range of the diameter of the steel wire rope can be maximized and flexibility of the steel wire rope is improved simultaneously.

Owner:JIANGSU SHENWANG GROUP

Triangular strand wire rope

The invention discloses a triangular strand wire rope, which comprises six rope strands and a rope core. The six rope strands are twisted uniformly outside the rope core, each of the rope strand is tangent with the rope core; the six rope strands are arranged according to a uniformly divided angle of 60 DEG; the appearance of the rope strand is substantially triangular, the rope strand comprises a strand core, three central wires, inner wires and outer wires; the strand core is a round wire strand formed by a plurality of wires; the three central wires are arranged according to a uniformly divided angle of 120 DEG, and form a triangle coordinated with the strand core; the inner wires wrap the strand core and the central wires; the outer wires are twisted outside the inner wires; the inner wires are tangent with the central wires and the strand core receptively; the outer wires are tangent with the inner wires. According to the invention, constituent elements have no interspaces between each other, so that the problems of shelling, getting loose and being poor in anti-torsion performance during the working process can be avoided, the high stability, high anit-torsion performance and high reliability of the wire rope can be obtained, and the service life of the product is improved.

Owner:JIANGSU SHENWANG GROUP

Making method of prefabricated concrete casting structure of 3D printing concrete shear wall

ActiveCN105937276AAvoid constructionAvoid demolitionAdditive manufacturing apparatusWallsHorizontal barPrecast concrete

The invention discloses a making method of a prefabricated concrete casting structure of a 3D printing concrete shear wall. The making method comprises the steps that (a) a first layer of prefabricated concrete casting is made by adopting 3D printing; (b) a first layer of binding bars and / or horizontal bars is arranged at the top of the first layer of prefabricated concrete casting; (c) a 3D printing technology is adopted to make a second layer of prefabricated concrete casting at the top of the first layer of prefabricated concrete casting to make two ends of the first layer of binding bars and / or horizontal bars embedded at the connecting position of the first layer of prefabricated concrete casting and the second layer of prefabricated concrete casting; (d) the steps (b) and (c) are repeated till all layer of prefabricated concrete casting are made to reach designed elevation. The formwork swelling is prevented by prefabricating the binding bars between the inner wall face and the outer wall face of the prefabricated concrete casting, the horizontal bars of the shear wall are also embedded in the prefabricated concrete casting, inconvenient construction brought during post-installation of the horizontal bars is avoided, and the construction is simplified.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

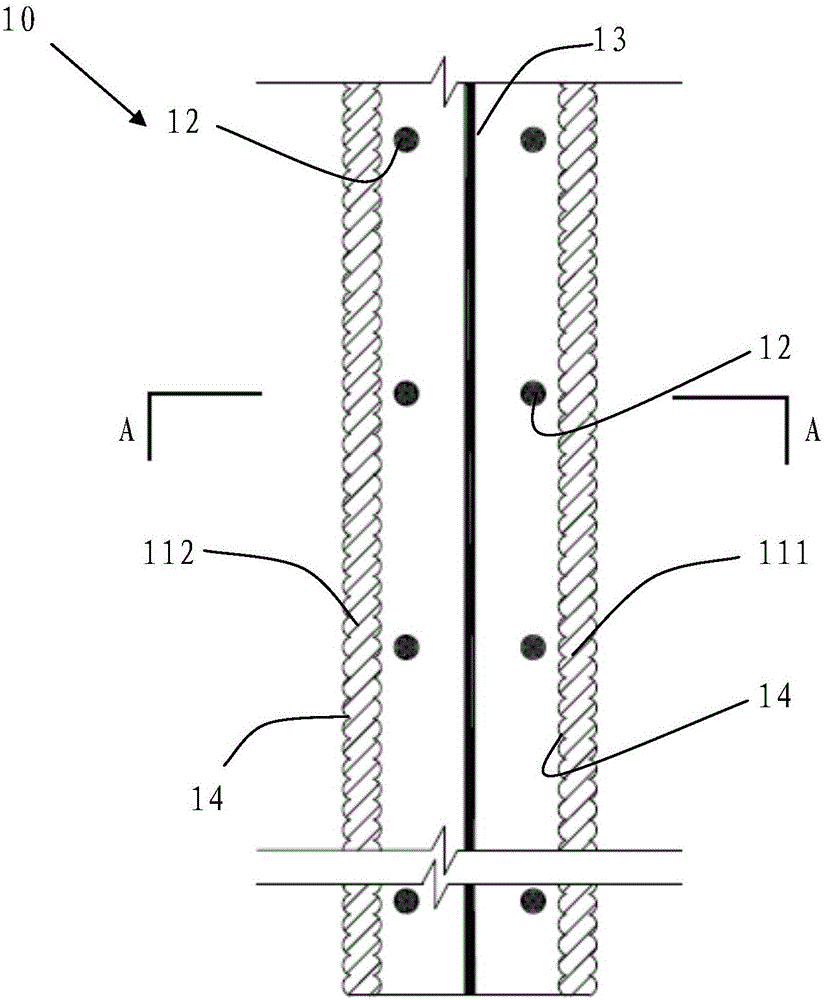

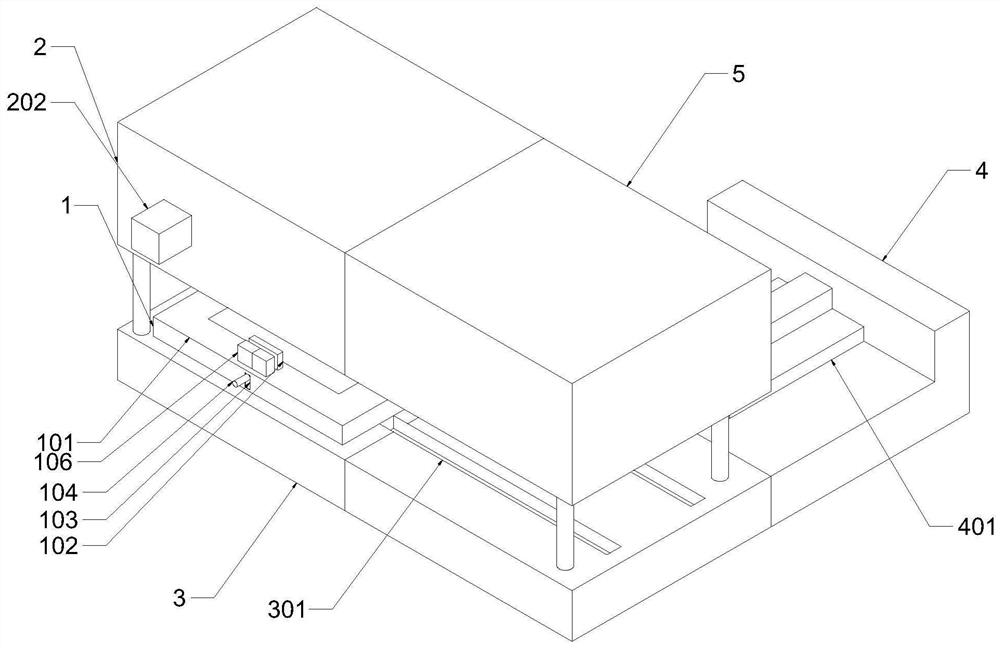

Structural column structure formed based on 3D printed filling wall

ActiveCN105908869AReduce consumptionReduce construction proceduresAdditive manufacturing apparatusWallsEarthquake resistanceButt joint

The invention discloses a connecting method and a connecting structure of a 3D printed filling wall and a structural column. The connecting method comprises the steps that a first wall part and a second wall part of the filling wall are manufactured with the 3D printing technology, wherein butt-joint grooves are formed in the ends of the first wall part and the second wall part, horizontal steel bars are anchored in the first wall part and the second wall part, and one end of each horizontal steel bar protrudes out and forms an anchoring end; the butt-joint grooves of the first wall part and the second wall part are connected in an abutting mode to form a column space, wherein the anchoring ends of the horizontal steel bars are arranged in the column space; vertical steel bars are inserted into the column space and bound with hopping rings; concrete is poured into the column space, and the structural column is formed. Compared with the prior art, the connection of the 3D printed filling wall and the structure column is achieved, the integrity and the earthquake resistance of the filling wall are improved, and the tie force is increased.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Heat insulation structure based on 3D-printed reinforced masonry

ActiveCN106003365AImprove integrityGuaranteed seismic performanceAdditive manufacturing apparatusRoadwaysRebarStructure based

The invention discloses a connecting method and structure based on a 3D-printed reinforced masonry shear wall. The method comprises steps as follows: a first wall body part and a second wall body part of the reinforced masonry shear wall are manufactured respectively with the 3D printing technology, abutting grooves are formed in one end of the first wall body part and one end of the second wall body part, horizontal reinforcing steel bars are anchored in the first wall body part and the second wall body part, one end of each horizontal reinforcing steel bar bulges out, and the horizontal reinforcing steel bars form anchoring ends in the corresponding abutting grooves; the abutting groove of the first wall body part and the abutting groove of the second wall body part are placed in an abutting manner to form abutting space; vertical reinforcing steel bars are inserted in the first wall body part, the abutting space and the second wall body part at intervals; and concrete is poured into the first wall body part, the abutting space and the second wall body part, and the 3D-printed reinforced masonry shear wall is formed. With the connecting method and structure, the overall anti-seismic property and heat insulation performance of a 3D-printed wall body are guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

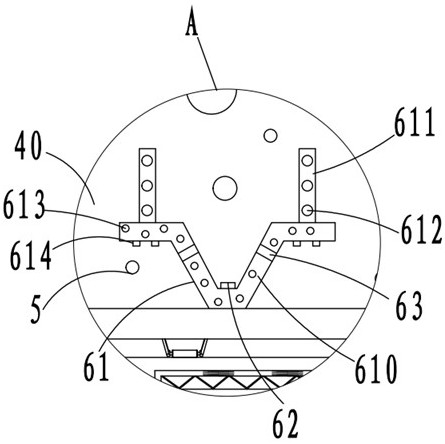

Egg shelling device

The invention provides an egg shelling device, and relates to the field of egg production. The egg shelling device comprises a shelling box, a fixed plate is arranged on the outer wall of the top end of the shelling box, a feeding port is formed in the inner wall of one side of the fixed plate, a discharging port is formed in the outer wall of one side of the shelling box, a base is arranged on the outer wall of the bottom end of the shelling box, a motor is arranged on the outer wall of one side of the shelling box, an output shaft of the motor is connected with a rotating rod through a coupler, an egg fixing frame is arranged on the inner wall of the shelling box, the fixing frame is in transmission fit with the rotating rod through a belt, and mounting plates are arranged on the inner walls of two sides, close to the fixing frame, of the shelling box. According to the egg shelling device, a cracked egg shell is opened through sliding a suction cup, it is avoided that a rubber roller and an impacting mechanism are used for removing shells of eggs, and therefore the problems that the surfaces of the processed eggs are not round and complete enough, the eggs are prone to damage during vacuum packaging, and bacteria are prone to breeding on the damaged surfaces are effectively solved.

Owner:畅新杰

Flexible printing process for corrugated cartons

InactiveCN111959144AAvoid erosionAvoid shellingOther printing apparatusPrinting press partsCartonPrinting press

The invention discloses a flexible printing process for corrugated cartons, relates to the technical field of flexible printing, and aims to solve the problems that performance of an existing flexibleprinting process for corrugated cartons is not perfect enough and the working efficiency is low. The process comprises the steps that S1, a plate cylinder is cleaned; S2, a base surface of a photosensitive resin plate is cleaned and dried by using a detergent; S3, a hard board double-sided adhesive tape is pasted to the plate cylinder; S4, a photosensitive resin plate printing plate is pasted onthe plate cylinder, and edge sealing is conducted by using a sealant; S5, an anilox roller is cleaned, and the plate cylinder and an anilox roller plate cylinder are installed separately; S6, a scraper blade is cleaned, and the scraper blade is mounted in a scraper chamber; S7, an ink box is cleaned, the ink box is installed, and then water-based ink is poured into the ink box; and S8, printing iscarried out on a corrugated board by a flexible printing machine.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD

Plastic packaging method for bulb flowers

The invention relates to the technical field of plant cultivation, and particularly discloses a plastic packaging method for bulb flowers. The plastic packaging method comprises the following steps: (a) selecting proper bulb flowers in a cultivation area; (b) at least spraying a systemic bactericide to the selected bulb flowers in the cultivation area once; (c) digging out the bulb flowers sterilized by the systemic bactericide, drying the bulb flowers in the shade or in the sun, and removing leaves and cutting roots of the bulb flowers dried in the shade or in the sun; (d) carrying out secondary disinfection and sterilization on the bulbs subjected to leaf removal and root cutting treatment; (e) storing the bulbs subjected to secondary disinfection and sterilization in an environment of 0-10 DEG C for more than 35 days; (f) taking out the stored bulbs, and performing third disinfection and sterilization; and (g) wrapping the bulbs disinfected and sterilized for the third time with a thermal shrinkage film. The plastic packaging method has the advantages that the flowering phase can be accurately controlled, recycling can be achieved, a printing function can be achieved, the bulbs cannot be damaged or shaken, and sealing shells cannot be broken.

Owner:何为

Manufacturing method for masonry shells in 3D printing reinforced masonry shear wall

ActiveCN105908862ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebarTransverse reinforcement

The invention discloses a manufacturing method for masonry shells in a 3D printing reinforced masonry shear wall. The method includes the following steps that a, the first layer of masonry shell is manufactured to the pre-buried elevation position of transverse reinforcements through 3D printing; b, the transverse reinforcements are arranged at the top of the first layer of masonry shell; c, the second layer of masonry shell is manufactured at the top of the first layer of masonry shell through a 3D printing technology, so that the transverse reinforcements are buried in the masonry shells; and d, the steps b and c are repeated to complete manufacturing of the masonry shells. By means of the manufacturing method for the masonry shells in the 3D printing reinforced masonry shear wall, the reinforced masonry shells are integrally formed through the 3D printing technology, original concrete small hollow blocks are replaced, the site construction labor force is greatly reduced, the construction processes are reduced, the building quality is guaranteed, and building industrialization is facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

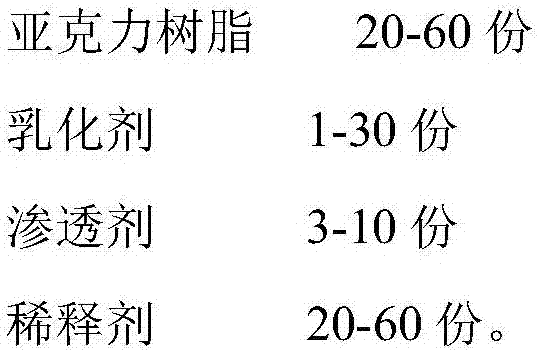

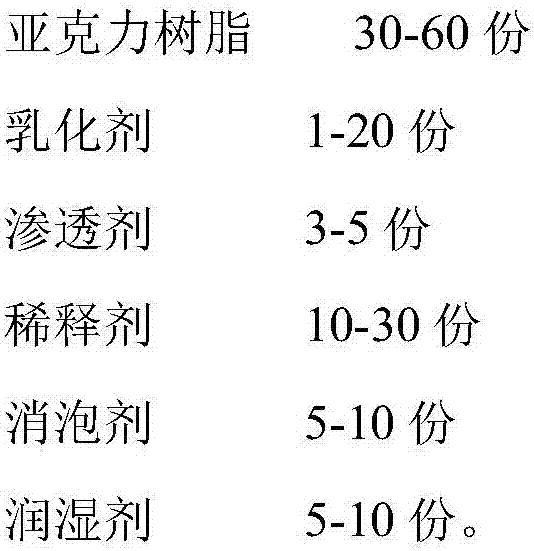

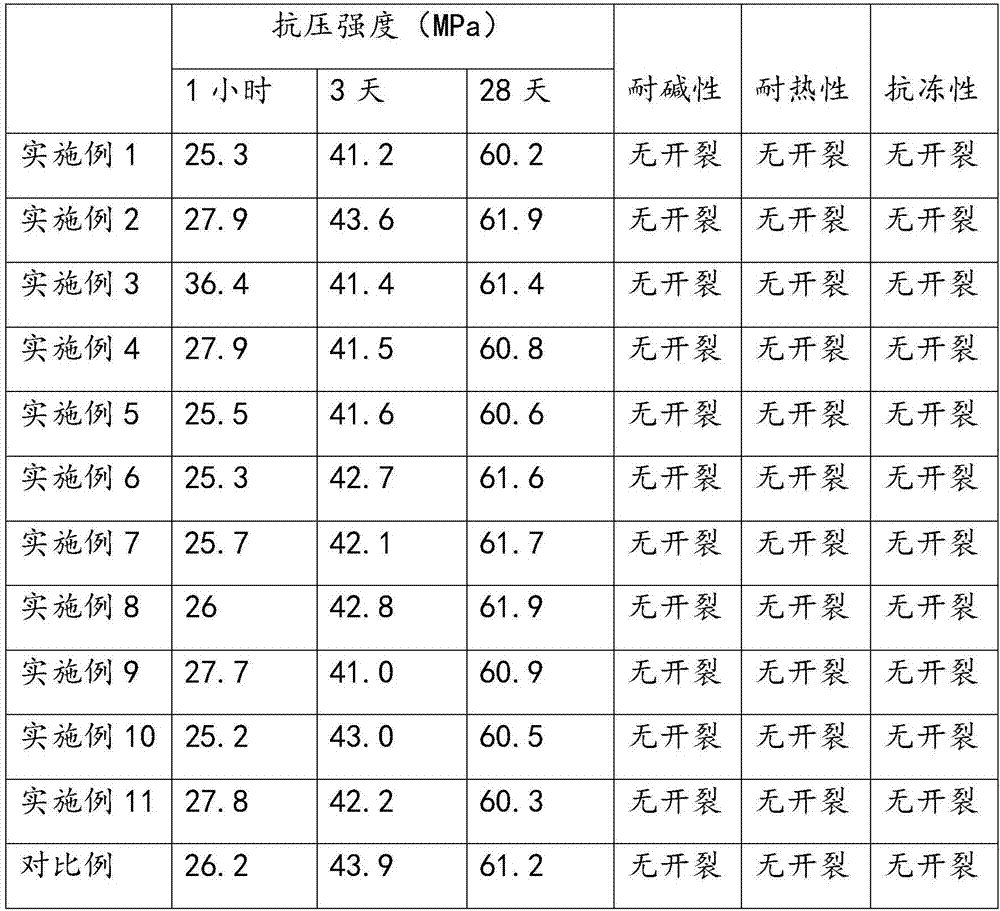

Concrete repair agent and application thereof

The invention relates to a concrete repair agent. The concrete repair agent is prepared from, by weight, acrylic-based resin, an emulsifying agent, a penetrating agent and a diluting agent. The concrete repair agent is commonly known as a concrete solder and is a waterborne environment-friendly agent, and the concrete repair agent is capable of having cross-linking reaction with dust generated ina cement and concrete grinding process to enable re-setting and hardening, and defects of holes, cracks and the like of concrete repaired. By application of the concrete repair agent to new and old concrete combination faces, adhesion firmness of the new and old concrete combination faces can be remarkably improved, and concrete bulging, layering and shedding can be prevented. In addition, the concrete repair agent is simple in operation, early strength of concrete can be quickly improved, an integral construction period is shortened, and concrete compactness is improved to make it easy for grinding and polishing.

Owner:苏州金润新材料科技有限公司

Reinforcing method for 3D printing reinforced masonry shear wall

ActiveCN105908861ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebarTransverse reinforcement

The invention discloses a reinforcing method for a 3D printing reinforced masonry shear wall. The method includes the following steps that a, a first layer of masonry shell is manufactured to the pre-buried elevation position of transverse reinforcements through 3D printing; b, the transverse reinforcements are arranged at the top of the first layer of masonry shell; c, a second layer of masonry shell is manufactured at the top of the first layer of masonry shell through a 3D printing technology, so that the transverse reinforcements are buried in the masonry shells; d, the steps b and c are repeated to complete the masonry shells; e, the steps a to d are repeated to complete multiple masonry shells, and the multiple masonry shells are stacked to the designed elevation of the shear wall; and f, vertical reinforcements are installed in the masonry shells. By means of the reinforcing method for the 3D printing reinforced masonry shear wall, the reinforced masonry shells are integrally formed through the 3D printing technology, original concrete small hollow blocks are replaced, the site construction labor force is greatly reduced, the construction processes are reduced, the building quality is guaranteed, and building industrialization is facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

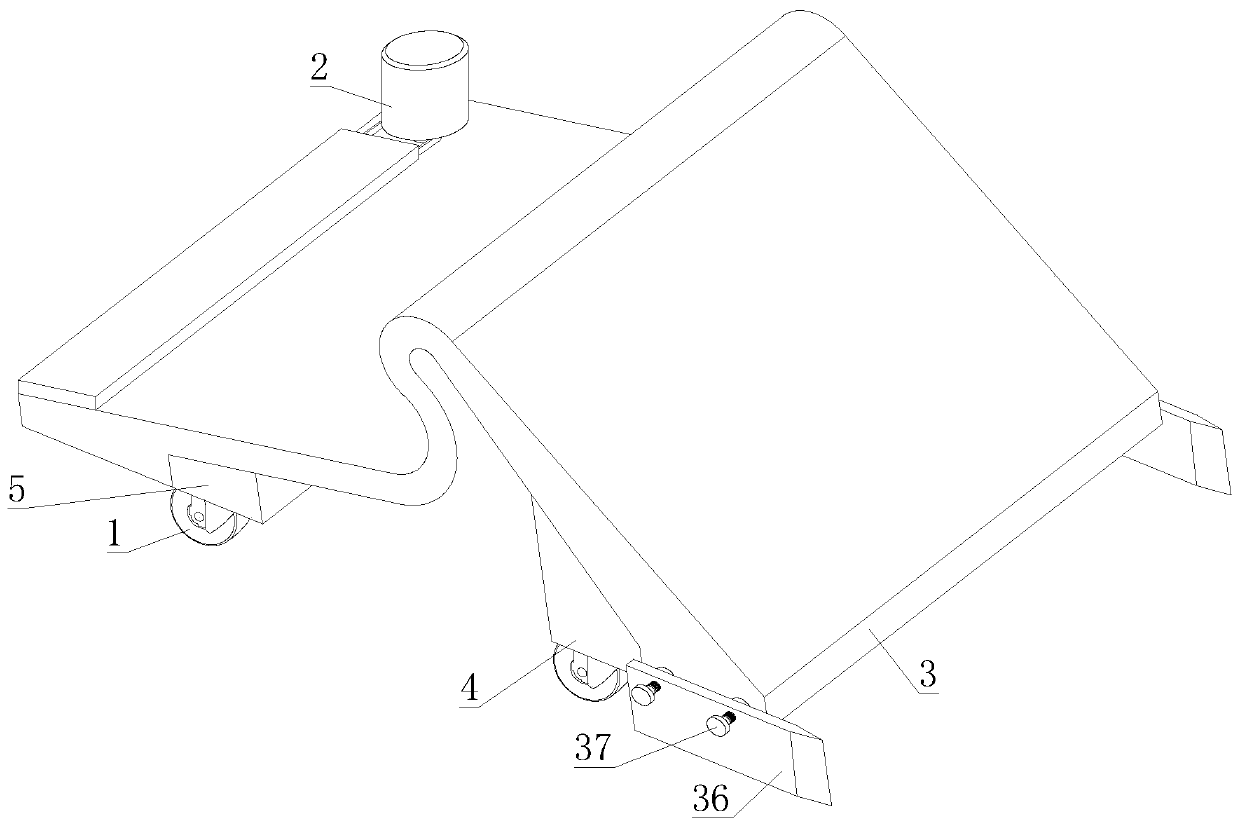

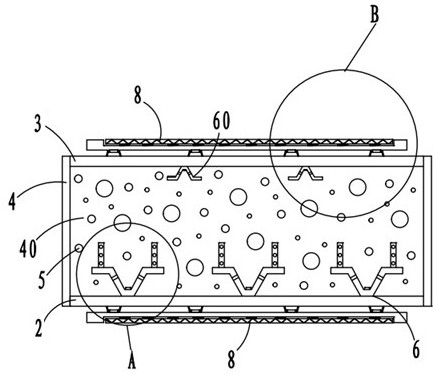

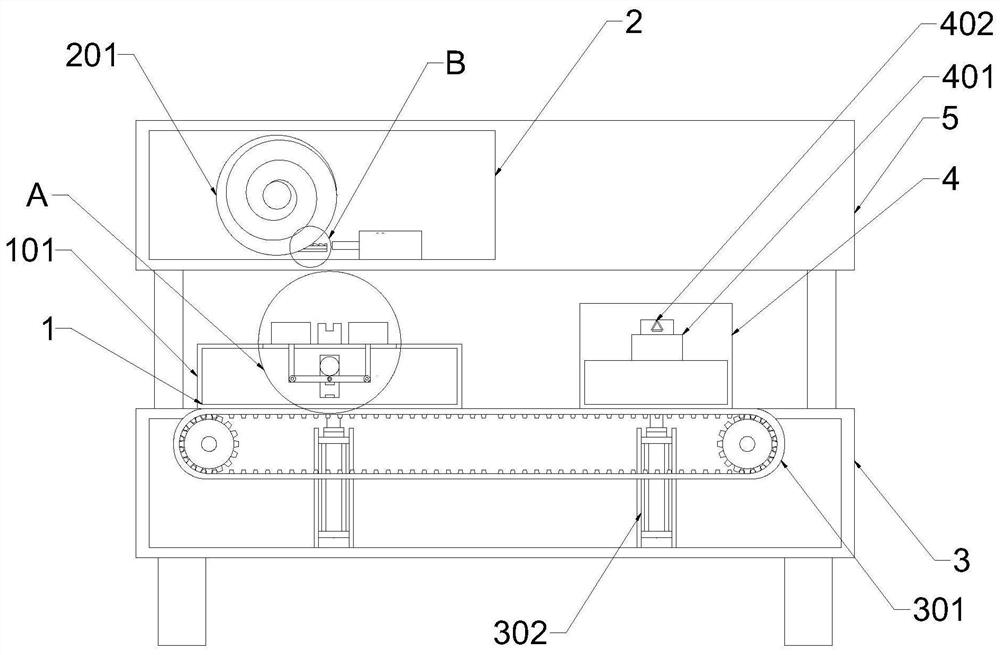

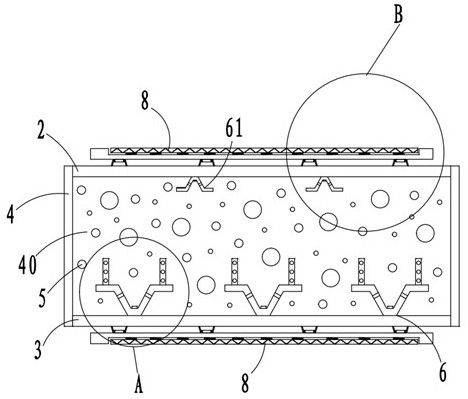

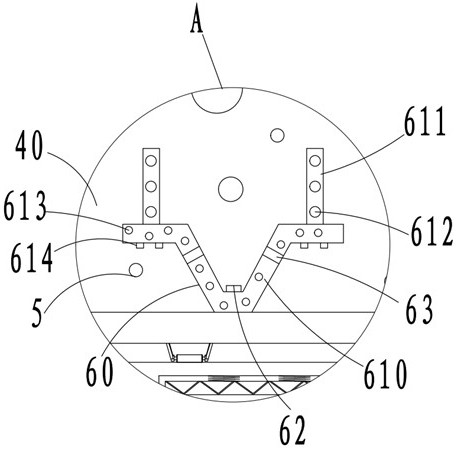

Teding and air drying device for rice

ActiveCN110906729ATurn over to achieveAvoid shellingDrying gas arrangementsDrying chambers/containersAnimal scienceEngineering

The invention discloses a tedding and air drying device for rice. The tedding and air drying device for rice includes a walking mechanism, a suction mechanism, a device main body, a front mounting plate and a rear mounting plate. The lower ends of the front mounting plate and the rear mounting plate are each provided with the walking mechanism. The rear end of the device main body is provided witha suction mechanism. The device main body includes a barrel, an air duct, a feed inlet, a discharge outlet and an electric heating piece. The middle part of the barrel is the air duct, and the air duct is S-shaped. The inner wall of the barrel is provided with a suction mechanism. The rice under the feed inlet is inhaled into the air duct through the suction mechanism, discharged from the discharge outlet through the air duct and returned to the ground. The tedding and air drying device for rice changes the traditional way of tedding, the tedding efficiency is high, the rice is avoided from peeling, and air drying can be accelerated in the tedding process.

Owner:安徽信福乡田生态农业有限公司

Bulb flower wrapping and sealing method

ActiveCN113261411AIncrease soil nutrientsStrong penetrating powerAntifouling/underwater paintsCellulose coatingsBacteriocidesAgronomy

The invention relates to the technical field of plant application, and particularly discloses a bulb flower wrapping and sealing method. The bulb flower wrapping and sealing method comprises the following steps of (a) selecting a proper bulb flower; (b) at least spraying a systemic bactericide once before digging the selected bulb flower; (c) digging out the bulb flower sterilized by the systemic bactericide, drying the bulb flower in the shade or in the sun, and removing leaves and cutting roots of the bulb flower dried in the shade or in the sun; (d) carrying out secondary disinfection and sterilization on the bulb flower subjected to leaf removal and root cutting treatment; (e) placing the bulb flower subjected to secondary disinfection and sterilization in an environment of 0-10 DEG C to be stored for more than 35 days; (f) taking out the stored bulb flower and carrying out third disinfection and sterilization; and (g) wrapping the outer surface of the bulb flower subjected to the third disinfection and sterilization with degradable fiber paste. The bulb flower wrapping and sealing method has the characteristics that the bulb flower wrapping and sealing method is green and environment-friendly, has no pollution to the environment, can increase organic matters in soil and cannot damage and die the bulb flower.

Owner:杭州旺源生物技术有限公司

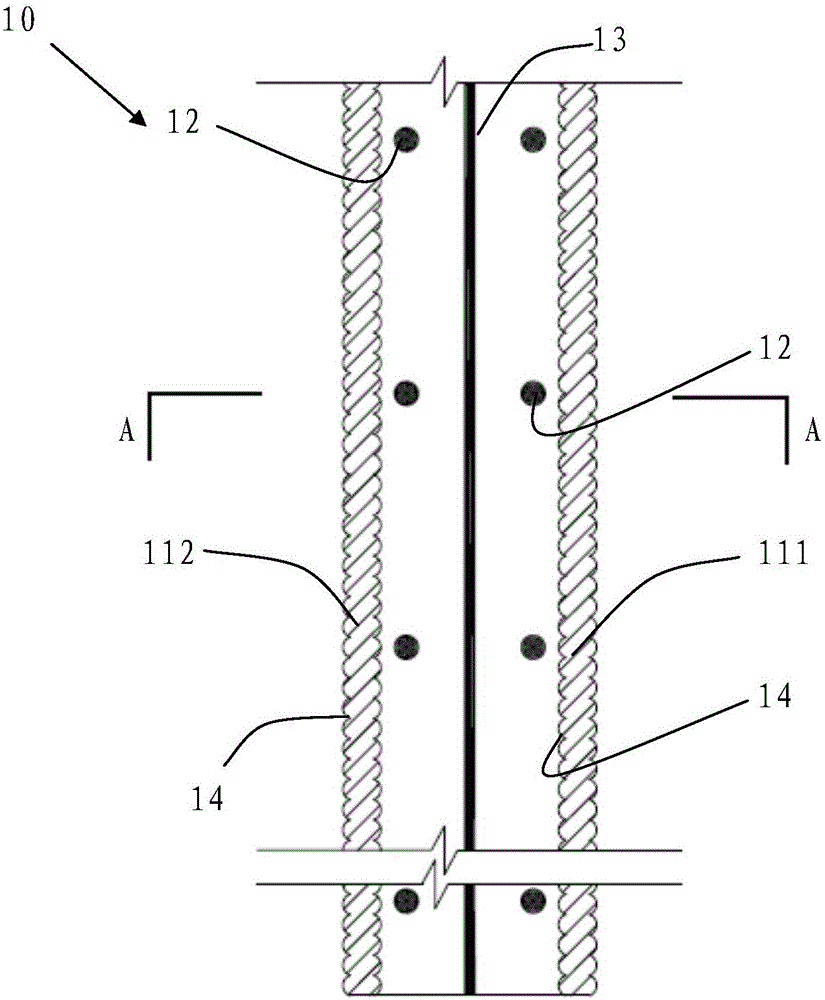

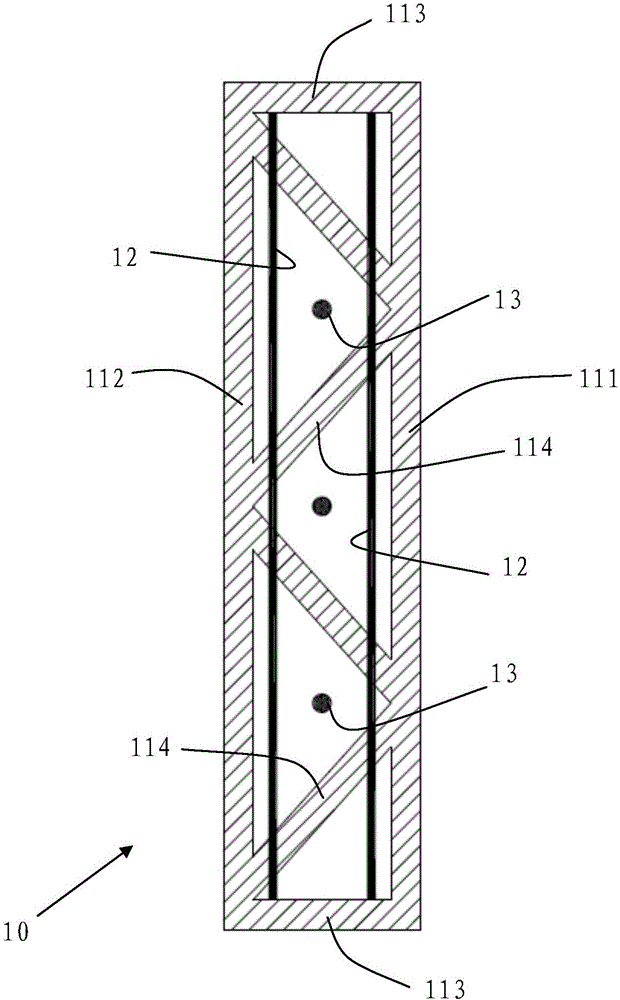

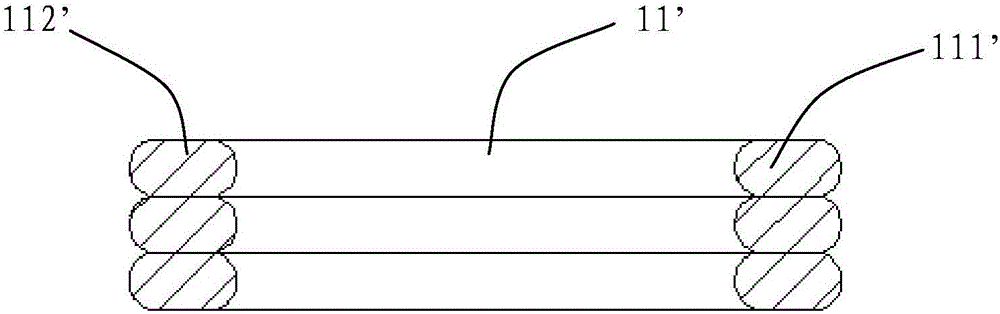

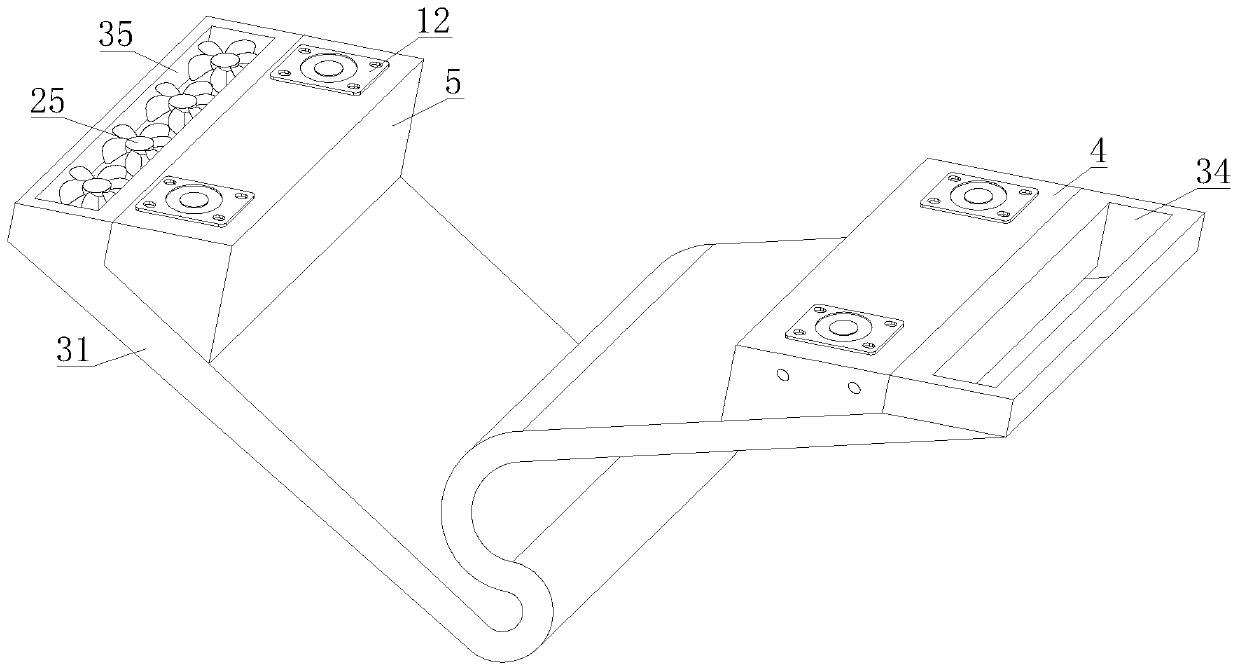

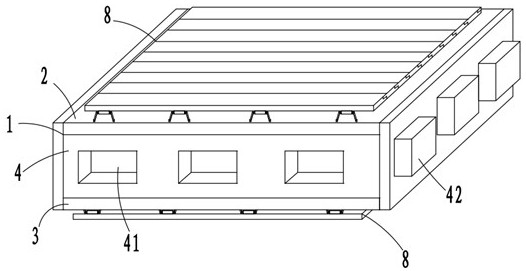

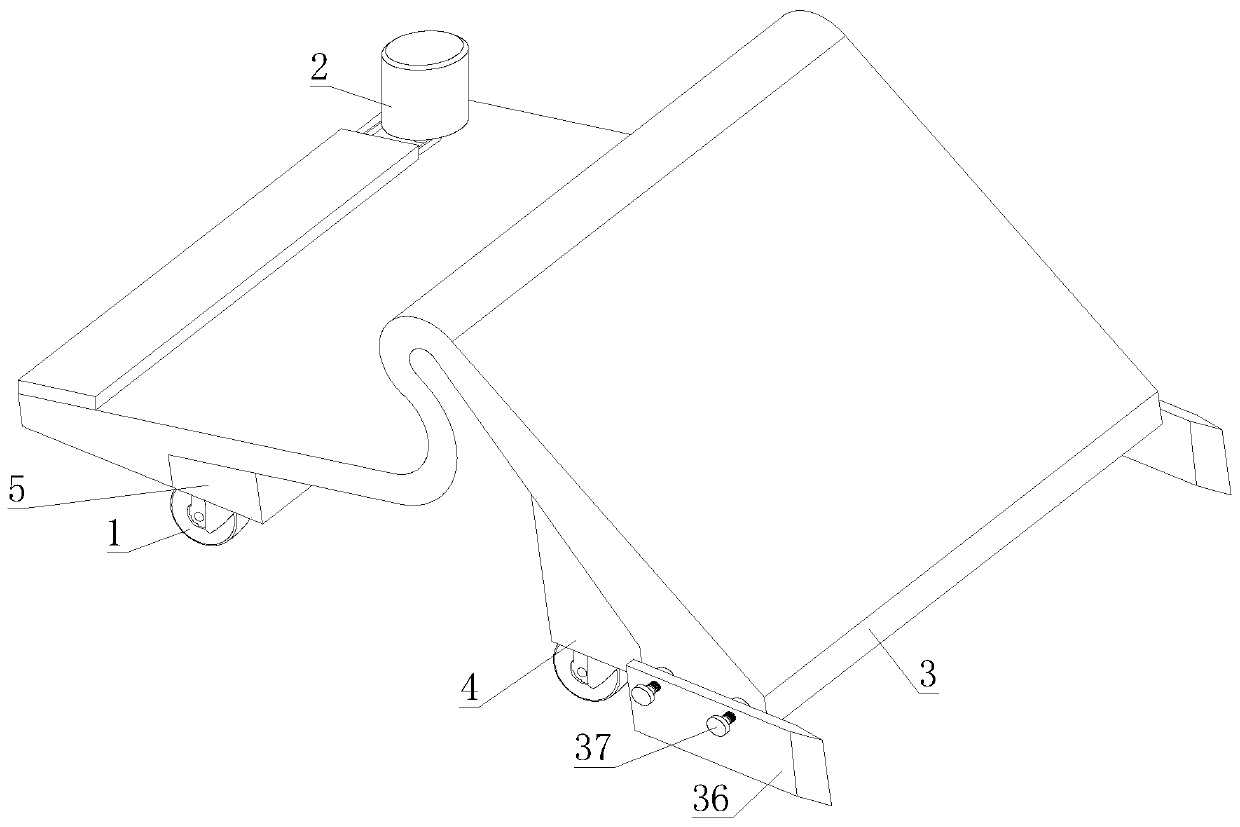

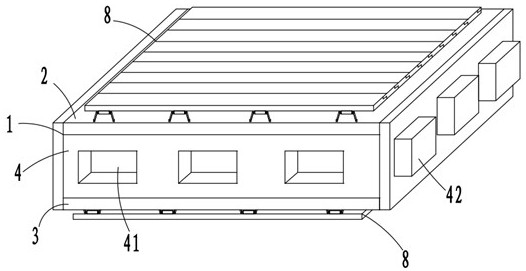

An anti-shelling and non-combustible thermal insulation system for aircraft testing

ActiveCN114575480BHigh bonding strengthAvoid shellingWeight reductionHeat proofingProduction lineThermal insulation

The invention provides an anti-shelling and non-combustible heat preservation system for aircraft testing, which belongs to the technical field of aircraft testing. The thermal insulation system is formed by splicing a plurality of thermal insulation storage boards, and the thermal insulation storage board includes an inner panel, an outer panel, a fastening frame for connecting the inner panel and the outer panel and forming a thermal insulation cavity, and a thermal insulation core arranged in the thermal insulation cavity. In the automatic production process, the inner panel can be placed in the lower position of the production line, which significantly improves the bonding strength between the inner panel and the thermal insulation core material. In the inner panel, the insulation core material is reinforced by reinforcing fasteners, which can further increase the bonding strength between the inner panel and the insulation core material, and avoid shelling of the insulation core material.

Owner:CHINA AIRPLANT STRENGTH RES INST

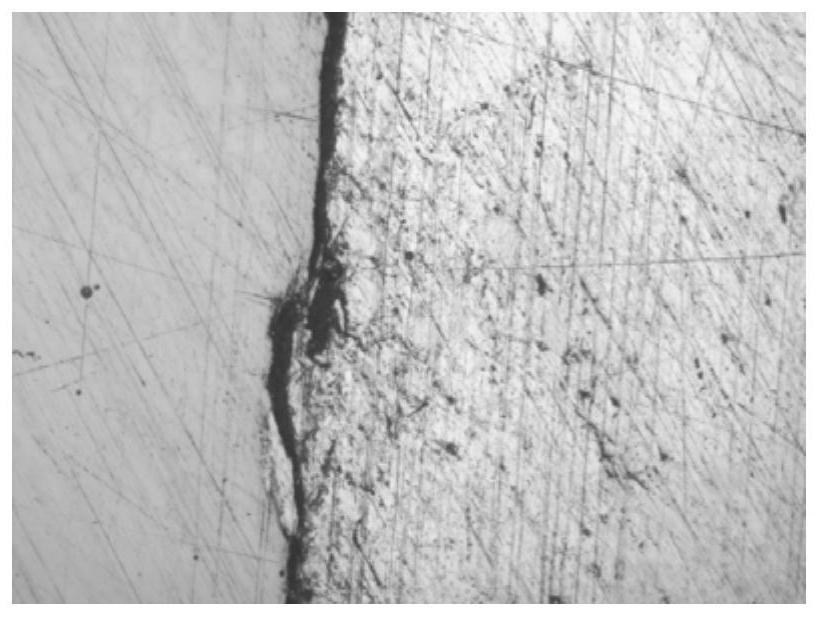

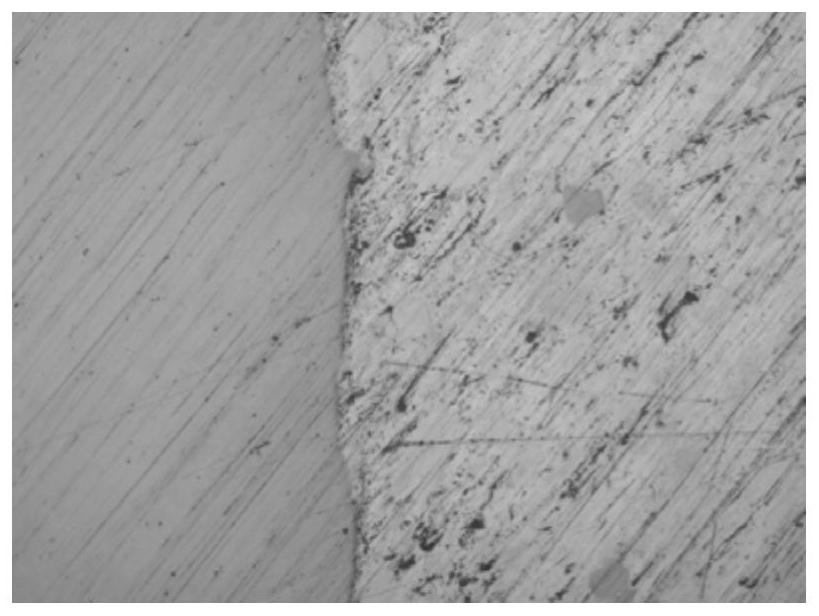

Method for preventing bearing body babbitt metal from shelling after pouring

The invention discloses a method for preventing bearing body babbitt metal from shelling after pouring, and relates to the technical field of alloy pouring. The invention aims to solve the problem that the bonding force between a bearing bush body and a babbitt metal is influenced by oxidation of a tin layer and then a shelling phenomenon is generated when the babbitt metal of a traditional bearing body is poured. The method comprises the following steps: immersing the pouring surface of a pretreated bearing body bearing bush into a tin solution for first tinning, immediately and uniformly spreading anhydrous ammonium chloride powder on the pouring surface of the bearing bush after taking out the bearing bush for 10-15 seconds, then immersing the bearing bush into the tin solution for secondary tinning, immediately and uniformly spreading anhydrous ammonium chloride powder on the pouring surface of the bearing bush after taking out the bearing bush for 10-15 seconds, and finally, pouring the babbitt metal liquid to the pouring surface of the bearing bush to finish the pouring of the babbitt metal of the bearing body. The method for preventing the bearing body babbitt metal from shelling after pouring can be obtained.

Owner:HARBIN TURBINE +2

A reinforced concrete structure and structure construction method based on 3D printing

The invention discloses a reinforced concrete structure based on 3D printing and a structure construction method. The method comprises the following steps that a foundation bottom plate is constructed, and a connection section is reserved on the foundation bottom plate; a steel bar structure of a structural column is bound to the connection section; a first prefabricated concrete outer shell is manufactured by adopting 3D printing, and concave-convex lines are formed in the inner surface of the first prefabricated concrete outer shell; the first prefabricated concrete outer shell is arranged on the steel bar structure of the structural column in a sleeved mode; a steel bar structure of a structural beam is bound, and the steel bar structure of the structural beam is bound to the steel bar structure of the structural column; a second prefabricated concrete outer shell is manufactured by adopting 3D printing; the second prefabricated concrete outer shell is mounted on the steel bar structure of the structural beam; concrete is poured in the second prefabricated concrete outer shell, and the structural beam and the structural column are completed. The prefabricated concrete outer shells are formed integrally by adopting a 3D printing technology, the continuous concave-convex lines are formed in the inner surfaces of the prefabricated concrete outer shells, the contact surfaces between the concrete poured in the prefabricated concrete outer shells and the inner surfaces of the prefabricated concrete outer shells are enlarged, compared with a smooth inner surface, friction is increased, bonding strength is improved, and a shell disengagement phenomenon is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

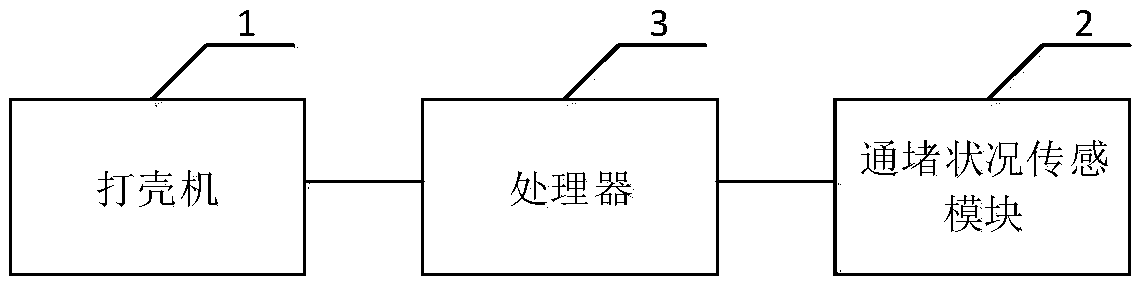

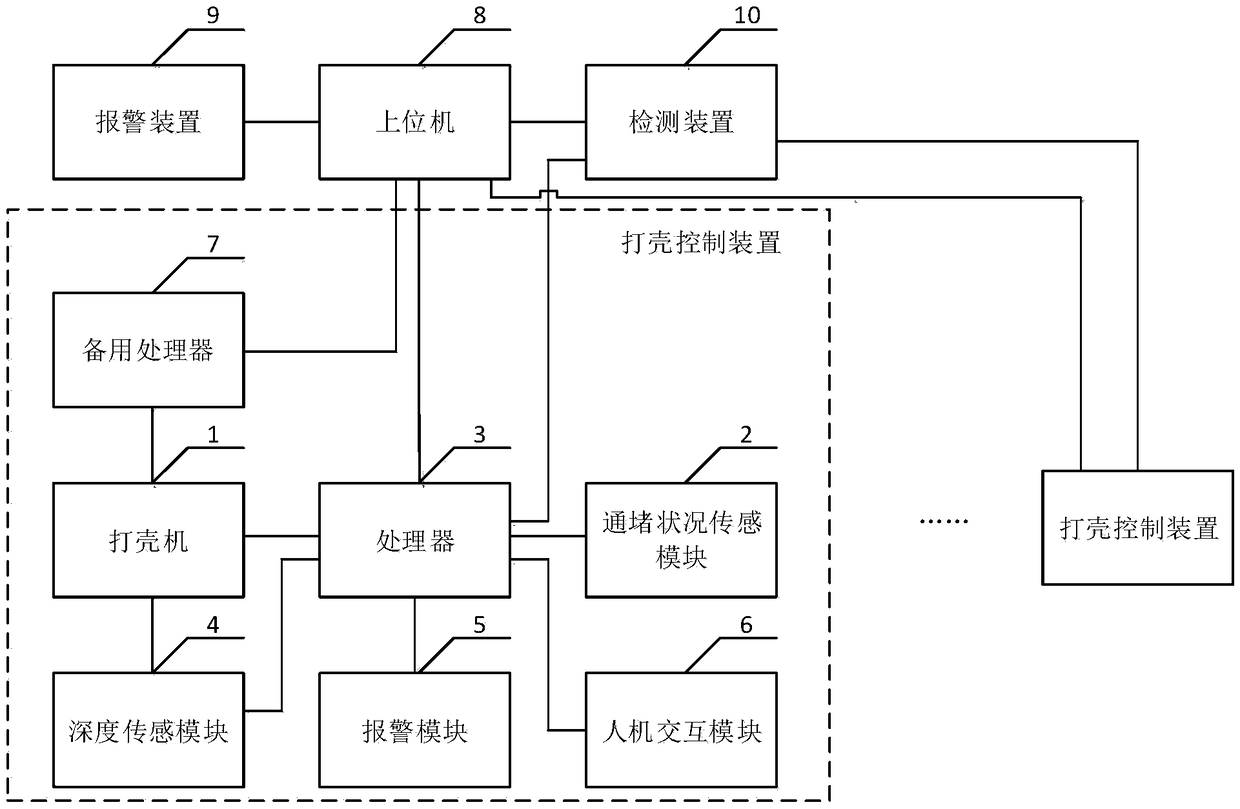

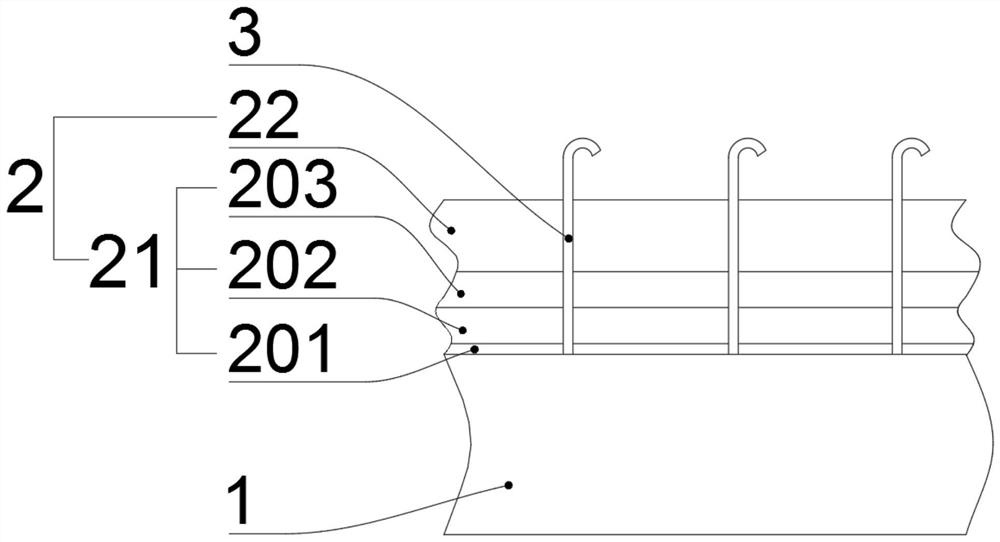

Aluminum electrolysis centralized control system and crust breaking control device thereof

The invention discloses an aluminum electrolysis crust breaking control device which comprises a crust breaking machine, an unblockage-blockage condition sensing module and a treatment device; the unblockage-blockage condition sensing module used for acquiring the unblockage-blockage condition of unblockage and blockage of an unloading hole; and the treatment device is connected with the crust breaking machine and the unblockage-blockage condition sensing module and is used for controlling the crust breaking machine to execute a crust breaking movement before unloading and when the unblockage-blockage condition is blockage only. Seen from that the unblockage-blockage condition sensing module in the aluminum electrolysis crust breaking control device can acquire the unblockage-blockage condition of unblockage and blockage of the unloading hole, and the treatment device can control the crust breaking machine to execute the crust breaking movement before unloading and when the unblockage-blockage condition is blockage only, so that unnecessary crust breaking movement is avoided, use and loss of relative software and hardware are reduced, and the electric quantity is saved at the sametime. The invention also discloses an aluminum electrolysis centralized control system. The aluminum electrolysis centralized control system has the beneficial effects same as the crust breaking control device.

Owner:HENAN KDNEU INT ENG

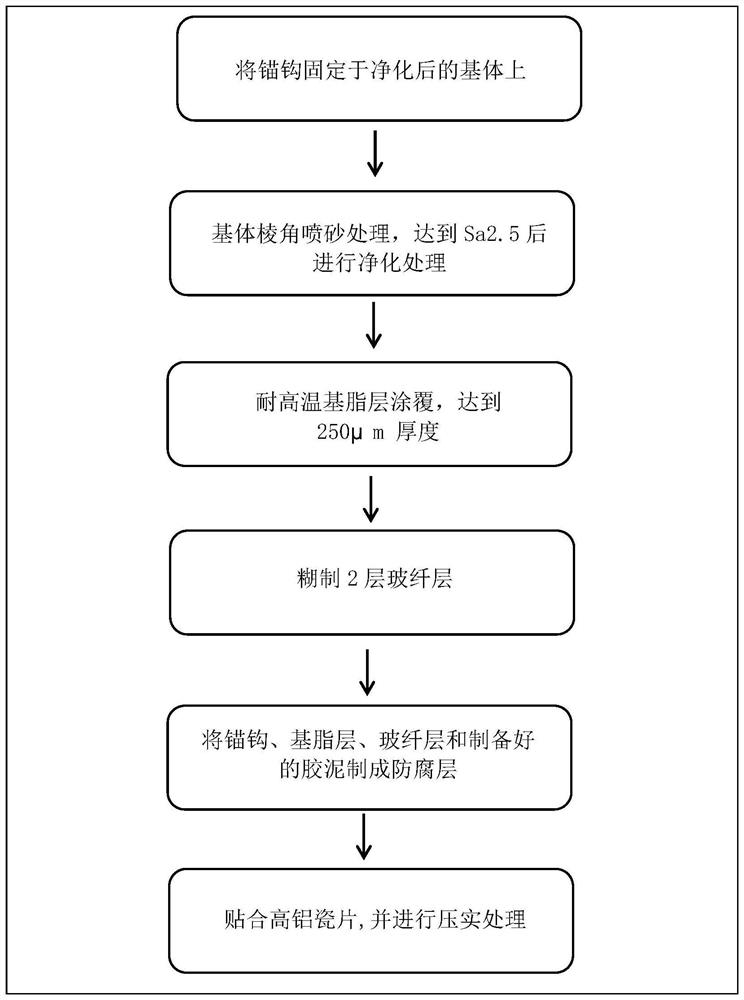

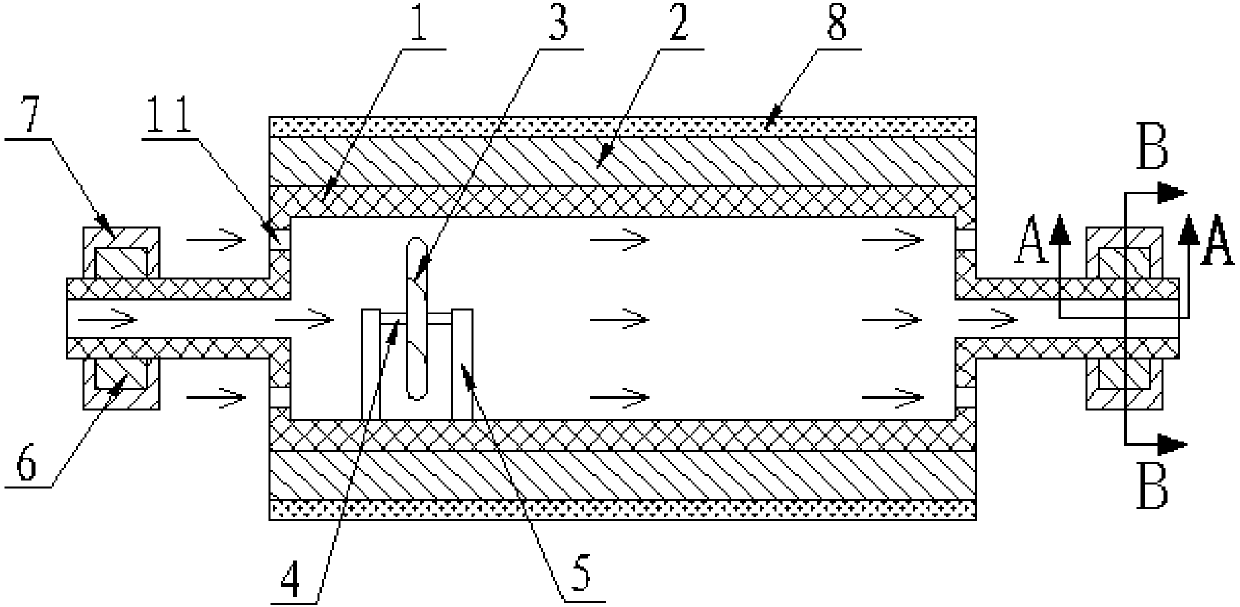

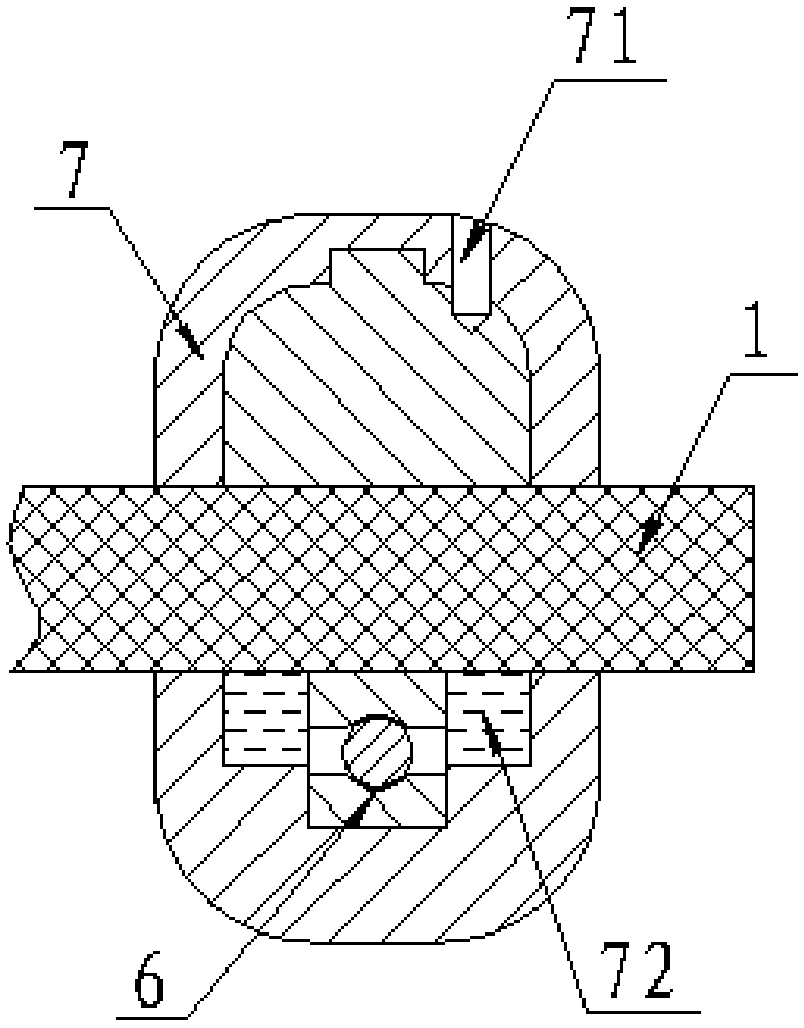

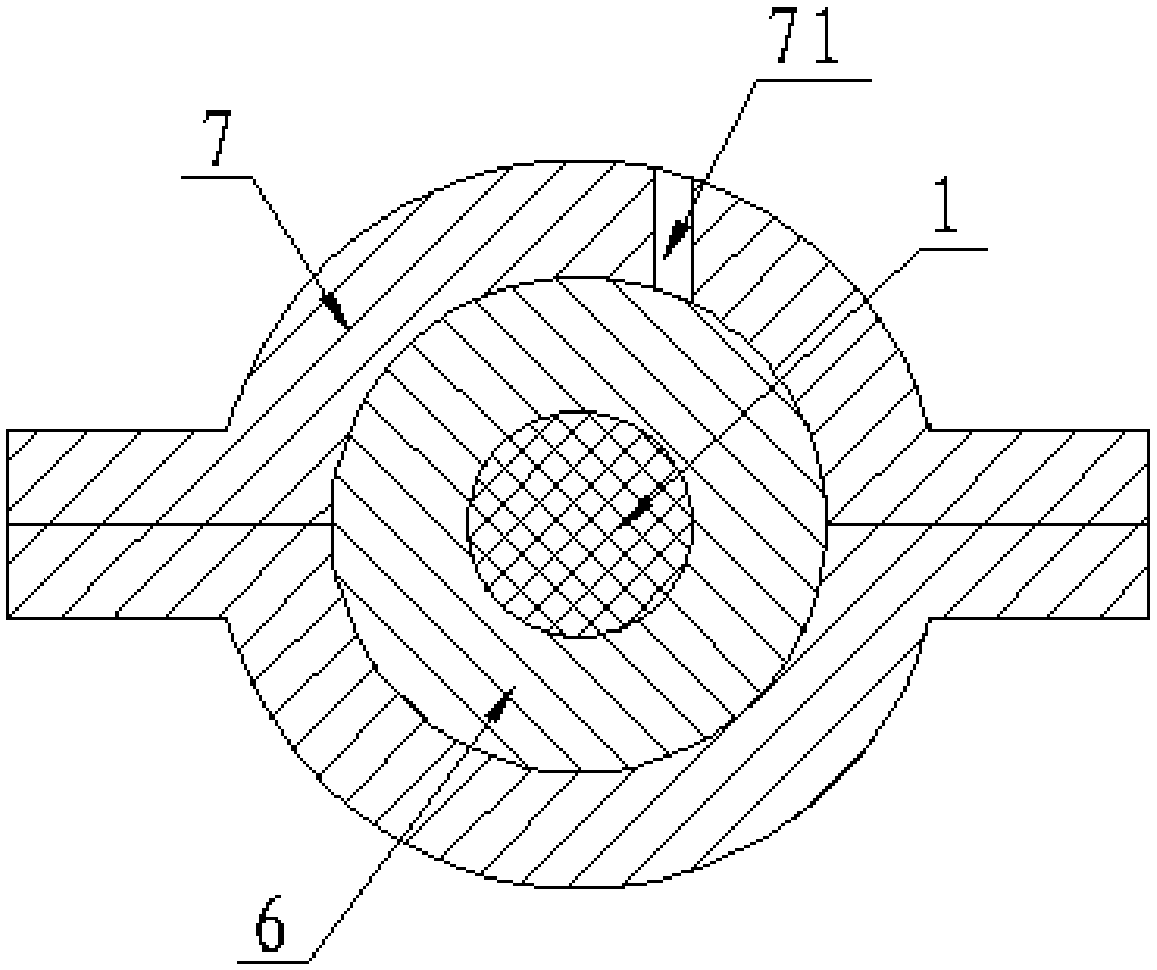

High-temperature anti-corrosion structure and process suitable for severe chemical environment

PendingCN114290768AReduce the temperatureExtended service lifeLaminationLamination apparatusComposite materialCorrosive substance

The invention discloses a high-temperature anti-corrosion structure and process suitable for a severe chemical environment, belongs to the technical field of anti-corrosion processes, and can at least partially solve the problem that in the prior art, an anti-corrosion layer is short in service life under the chemical high-temperature environment of high temperature and a corrosive cavity. The high-temperature anti-corrosion structure suitable for the severe chemical environment comprises a base body and an anti-corrosion structure attached to the base body, the thickness of the anti-corrosion structure ranges from 7 mm to 12 mm, the anti-corrosion structure comprises an anti-corrosion layer, the anti-corrosion layer is attached to the surface of the base body, and the thickness of the anti-corrosion layer is at least 3 mm or above; the anti-abrasion layer is attached to the surface of the anti-corrosion layer, and the anti-abrasion layer is made of a ceramic material; the reinforcing piece is fixed to the surface of the base body and penetrates through the anti-corrosion layer and the anti-abrasion layer.

Owner:安普德泰工程科技有限公司

Coating and method for easy identification of potential safety hazards in a small amount of water seepage, hot and humid roadway

ActiveCN111978805BIntuitive graspAvoid safety accidentsAntifouling/underwater paintsUnderground chambersArchitectural engineeringMechanical engineering

The invention discloses a coating and a method for easily identifying safety hazards of roof caving in a small amount of water seepage, sultry and humid roadway. The coating includes a primer, an intermediate coating and a top coating; the method drills water holes in water seepage cracks and installs aqueducts In order to guide the underground water seepage to the drainage ditch of the roadway; in addition, by spraying the alkali-resistant layer, the quick-drying waterproof layer and the white paint layer on the seepage roadway respectively, the white coating will prevent the safety hazard of the roof from falling. Obvious black burrs and fissures appear on the roadway, and the operators can quickly and intuitively grasp the stability of the surrounding rock of the roadway, and pry the pumice in advance to prevent the occurrence of safety accidents; The problem of ground pressure changes effectively improves the beautification of the underground working environment, and greatly improves the brightness of the roadway lighting; in addition, this method makes the safety hazards of the roof caving in the roadway obvious, and effectively improves the efficiency of roadway inspections.

Owner:YUXI DAHONGSHAN MINING

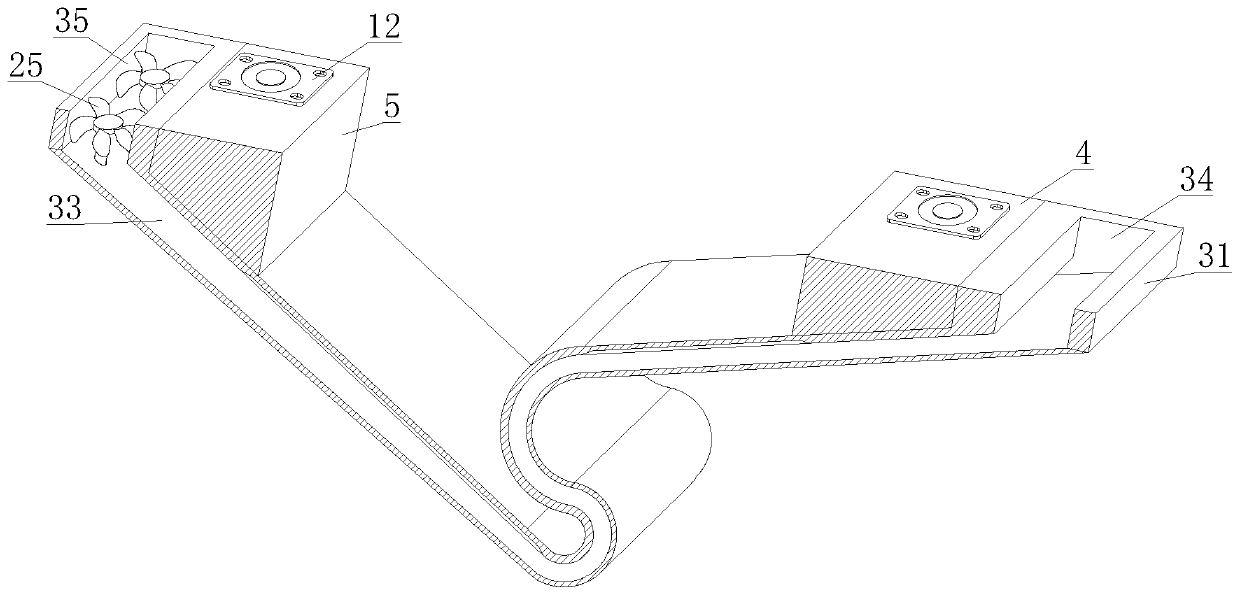

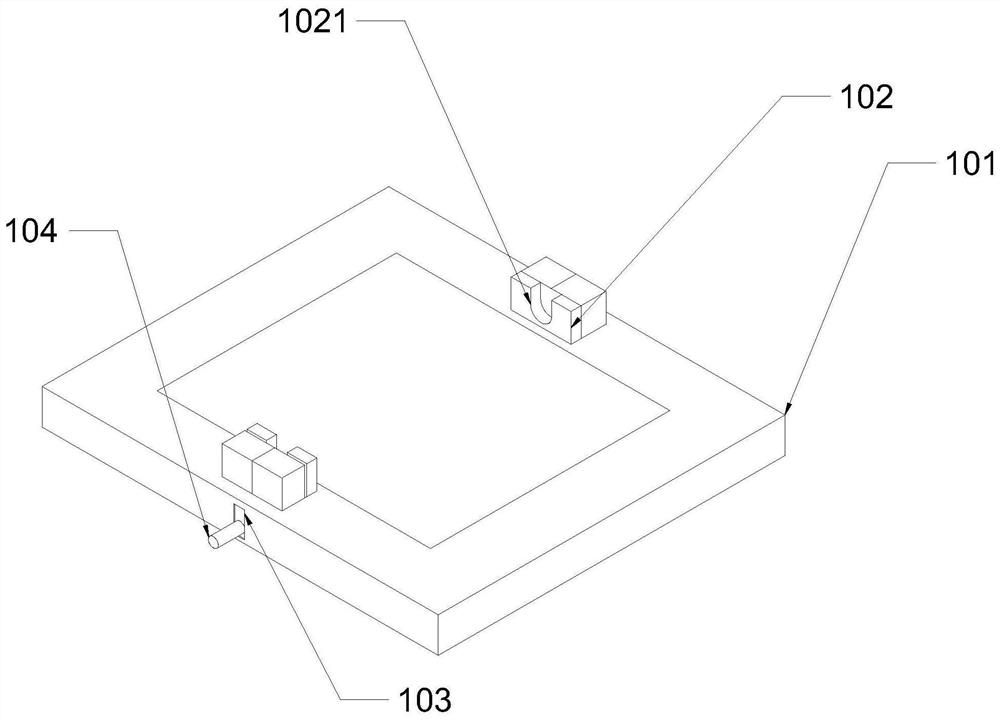

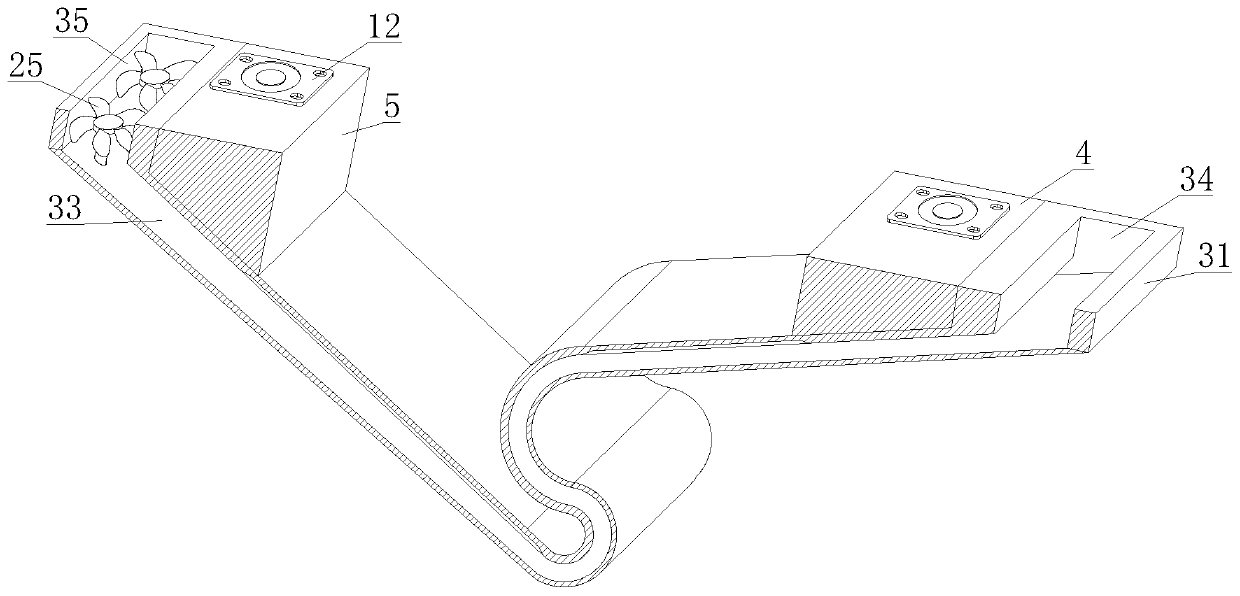

Quick-heat-dissipation anti-disengagement rubber roller

PendingCN107676374ASpeed up circulationHeat dissipation fastShaft and bearingsImpellerClassical mechanics

The invention relates to a quick-heat-dissipation anti-disengagement rubber roller. The rubber roller comprises a roller core, a rubber layer, an impeller, an impeller shaft, an installation seat, roller core bearings and bearing seats; the rubber layer is fixedly installed on the outer surface of the roller core; the rubber layer installation section of the roller core is a hollow roller; the impeller fixedly sleeves the impeller shaft; the two ends of the impeller shaft are fixedly installed on the installation seat; the installation seat is fixedly installed in an inner cavity of the rollercore; the impeller is parallel to the two end faces of the roller core and rotates in the circumferential direction of the roller core; gaps exist between the two top ends of the impeller and the inner cavity of the roller core; the end faces of the two sides of the inner cavity of the roller core are provided with through holes, and the through holes communicate with the inner cavity of the roller core; the roller core bearings are fixedly installed at the left end and the right end of the roller core; the roller core is fixedly installed on the bearing seats through the roller core bearings; the bearing seats are in sealed installation with the roller core and provided with oil filling ports; and a sealed oil storage cavity is formed between the bearing seats, the roller core and the roller core bearings. The quick-heat-dissipation anti-disengagement rubber roller is good in heat dissipation effect and lubrication effect, so that the maintaining and replacing cost is greatly reducedfor manufacturers.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

Concrete shear wall structure and its construction method based on 3D printing

ActiveCN104153493BAvoid constructionAvoid demolitionAdditive manufacturing apparatusWallsHorizontal barPrecast concrete

The invention discloses a concrete shear wall structure based on 3D printing and a construction method of the concrete shear wall structure. The construction method comprises the following steps that (a) a first layer of prefabricated concrete shell is manufactured by adopting 3D printing; (b) a first layer of tie bars and / or horizontal bars are arranged on the top of the first layer of prefabricated concrete shell; (c) a second layer of prefabricated concrete shell is manufactured on the top of the first layer of prefabricated concrete shell, and the two ends of the tie bars and / or the horizontal bars are embedded into the prefabricated concrete shells respectively; (d) a second layer of tie bars and / or horizontal bars are arranged on the top of the second layer of prefabricated concrete shell, the step (c) is repeated until the prefabricated concrete shells are completed to reach designed elevation, and concrete is poured. The tie bars are prefabricated between an inner wall faces and an outer wall faces of the prefabricated concrete shells to prevent formwork expansion, the horizontal bars of a shear wall are also embedded between the prefabricated concrete shells, construction inconvenience brought by the horizontal bars in the later mounting process is avoided, and construction is simplified.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

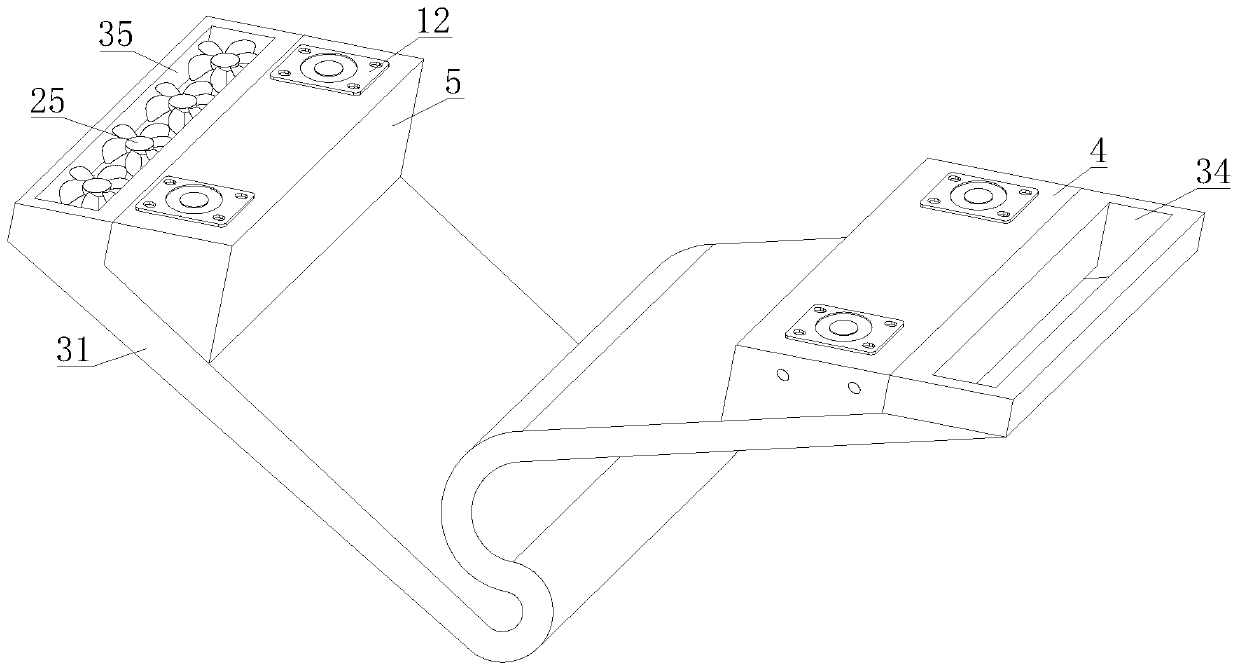

Optical fiber device packaging package with good anti-fracture effect

ActiveCN113253399AAvoid shellingAchieve the beneficial effect of protecting and preventing breakageCoupling light guidesLight guideDrive motor

The invention relates to the technical field of light guide connecting devices, and discloses an optical fiber device packaging package with a good anti-fracture effect, which comprises a fixing device, a protecting device, a transporting device, a filling device and a packaging device. According to the optical fiber device packaging package with the good anti-fracture effect, the filling shell is connected with the outer side of an optical fiber in a sleeving mode, the front end of a clamping nail is clamped to the front end of the inner side of a notch, at the moment, mortise and tenon butt joint is formed between the clamping nail and the notch, and due to the fact that the clamping nail and the notch are in one-way butt joint and cannot retreat, the optical fiber is effectively prevented from shelling in the using process after being fixed; the beneficial effect of fixing the optical fiber in the package and shelling is achieved, a driving motor drives a wheel shaft to rotate, the wheel shaft rotates to enable an adhesive film to be unfolded outwards, meanwhile, the optical fiber is in butt joint with an adhesive layer on the outer side of the adhesive film, the wheel shaft rotates to drive the optical fiber to rotate, the outer surface of the optical fiber is wrapped with the adhesive film, and at the moment, the notch is located on the outer side of the optical fiber, and the beneficial effect of protecting the optical fiber package to prevent breakage is achieved.

Owner:扬州港信光电科技有限公司

How to wrap bulbous flowers

ActiveCN113261411BDoes not take up spaceWith cleanAntifouling/underwater paintsCellulose coatingsFungicideOrganic matter

The invention relates to the field of plant application technology, and specifically discloses a method for wrapping bulbous flowers, which includes the following steps: (a) selecting suitable bulbous flowers; (b) spraying the selected bulbous flowers at least once before digging. suction fungicide; (c) dig out the bulbous flowers sterilized by systemic fungicides and dry them in the shade or in the sun, and remove the leaves and cut the roots of the bulbous flowers that have been dried in the shade or in the sun; (d) Carrying out secondary disinfection and sterilization on the bulbous flowers after removing leaves and cutting roots; (e) storing the bulbous flowers in the environment of 0-10 ℃ for more than 35 days; (f) storing The final bulbous flowers are taken out and then disinfected for the third time; (g) wrapping the degradable fiber paste on the outer surface of the bulbous flowers after the third disinfection. The invention has the characteristics of environmental protection, no pollution to the environment, the organic matter of the soil can be increased and the bulbous flowers will not be damaged or killed.

Owner:杭州旺源生物技术有限公司

A kind of rice drying device

ActiveCN110906729BTurn over to achieveAvoid shellingDrying gas arrangementsDrying chambers/containersAnimal scienceOryza sativa

The invention discloses a tedding and air drying device for rice. The tedding and air drying device for rice includes a walking mechanism, a suction mechanism, a device main body, a front mounting plate and a rear mounting plate. The lower ends of the front mounting plate and the rear mounting plate are each provided with the walking mechanism. The rear end of the device main body is provided witha suction mechanism. The device main body includes a barrel, an air duct, a feed inlet, a discharge outlet and an electric heating piece. The middle part of the barrel is the air duct, and the air duct is S-shaped. The inner wall of the barrel is provided with a suction mechanism. The rice under the feed inlet is inhaled into the air duct through the suction mechanism, discharged from the discharge outlet through the air duct and returned to the ground. The tedding and air drying device for rice changes the traditional way of tedding, the tedding efficiency is high, the rice is avoided from peeling, and air drying can be accelerated in the tedding process.

Owner:安徽信福乡田生态农业有限公司

Anti-shelling non-combustible thermal insulation system for aircraft testing

ActiveCN114575480AHigh bonding strengthAvoid shellingWeight reductionHeat proofingProduction lineThermal insulation

The invention provides an anti-shelling non-combustible heat preservation system for aircraft testing, and belongs to the technical field of aircraft testing. The heat preservation system is formed by splicing a plurality of heat preservation warehouse plates, and each heat preservation warehouse plate comprises an inner side face plate, an outer side face plate, a buckling frame used for connecting the inner side face plate and the outer side face plate and forming a heat preservation cavity, a heat preservation core material arranged in the heat preservation cavity and a reinforcing fastener. In the automatic production process, the inner side panel can be placed at the lower position of a production line, the bonding strength between the inner side panel and the heat preservation core material is remarkably improved, meanwhile, pitted-surface and matte stainless steel is used as the inner side panel, the heat preservation core material is reinforced through the reinforcing fasteners, and the heat preservation effect is improved. And the bonding strength of the inner side panel and the heat preservation core material can be further improved, and the heat preservation core material is prevented from being shelled.

Owner:CHINA AIRPLANT STRENGTH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com