Structural column structure formed based on 3D printed filling wall

A 3D printing and column construction technology, applied in building structures, walls, building components, etc., to increase friction, improve integrity, earthquake resistance and connection strength, and save construction processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

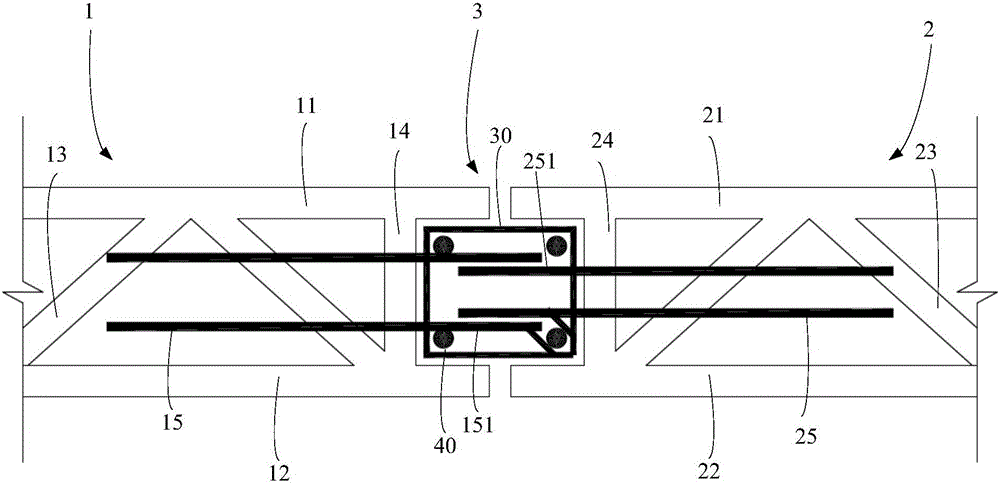

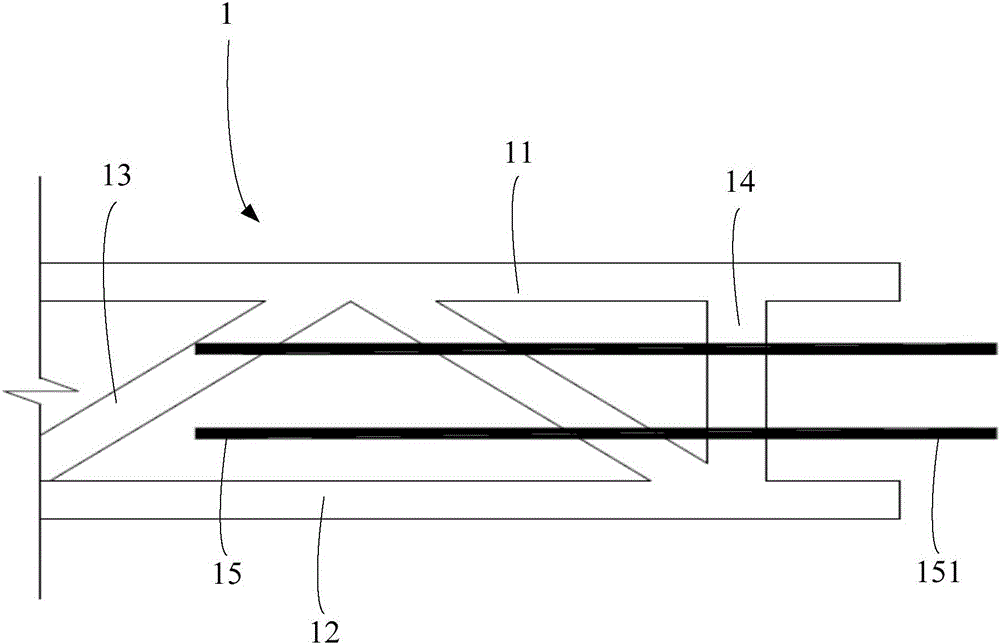

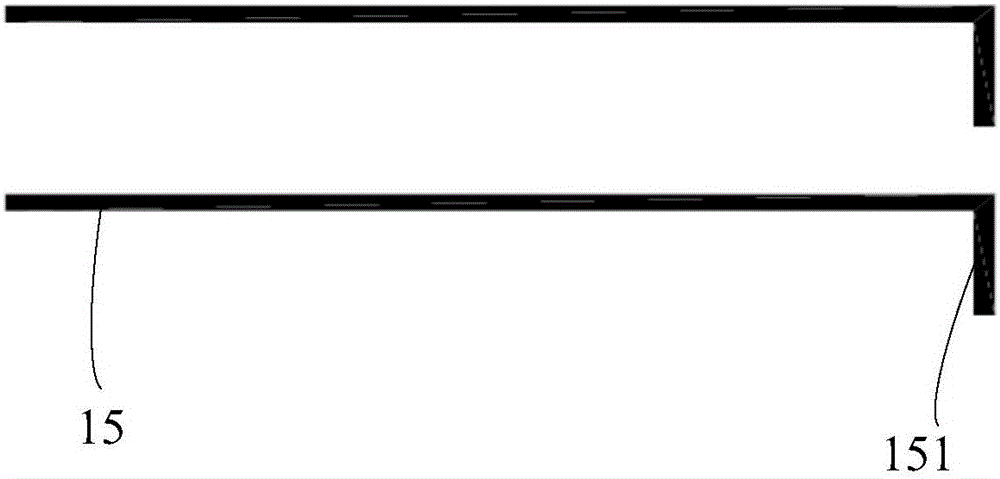

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a connection method and a connection structure between a 3D printed filling wall and a structural column, which are used to solve the connection problem between the 3D printing filling wall and the structural column, and improve the integrity and earthquake resistance of the filling wall. By docking and placing the first wall part of the 3D printed filling wall and the docking groove of the second wall part, a column space is formed between the butt grooves of the first wall part and the second wall part, and the anchoring of horizontal steel bars The end is placed in the column space, vertical steel bars are inserted in the column space, the vertical steel bars are tied through the stirrup ring, and then concrete is poured in the column space to complete the tie between the structural column and the filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com