Patents

Literature

33results about How to "Turn over to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

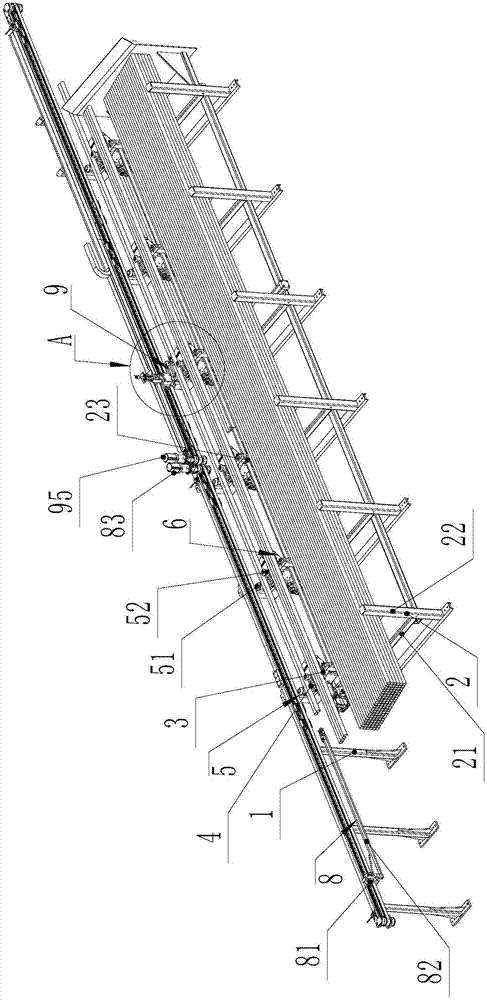

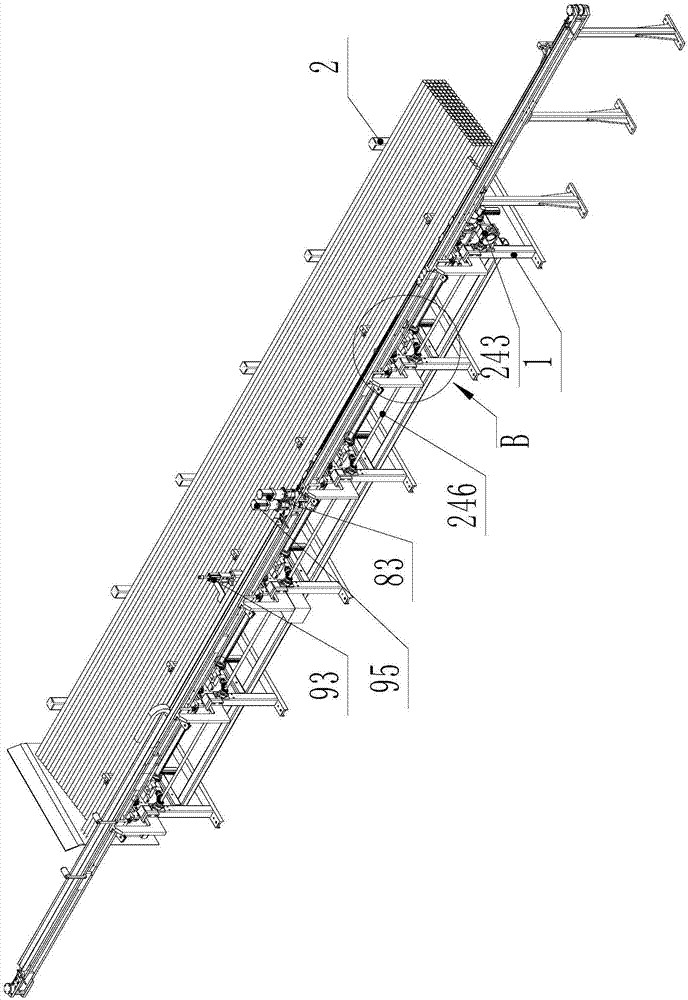

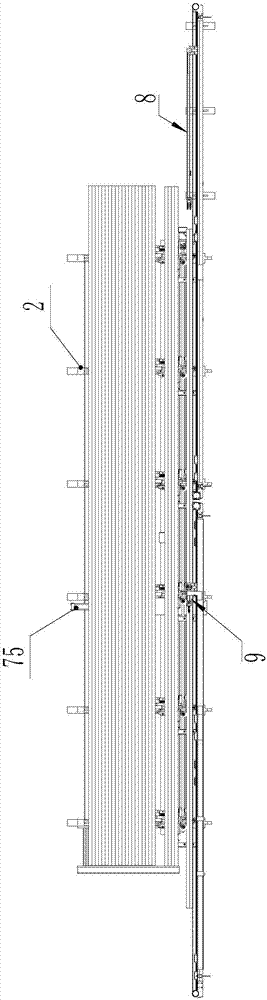

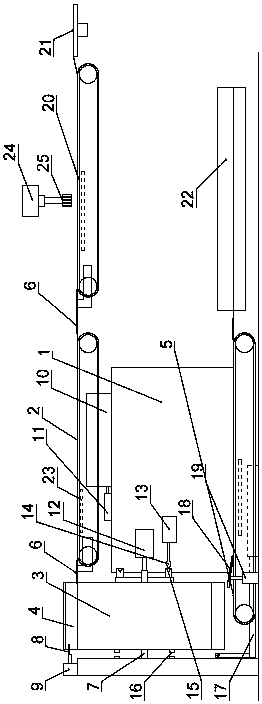

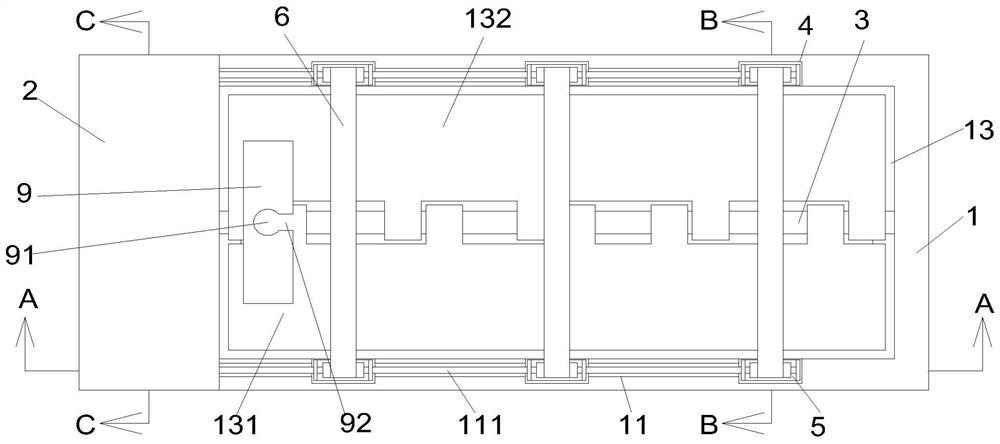

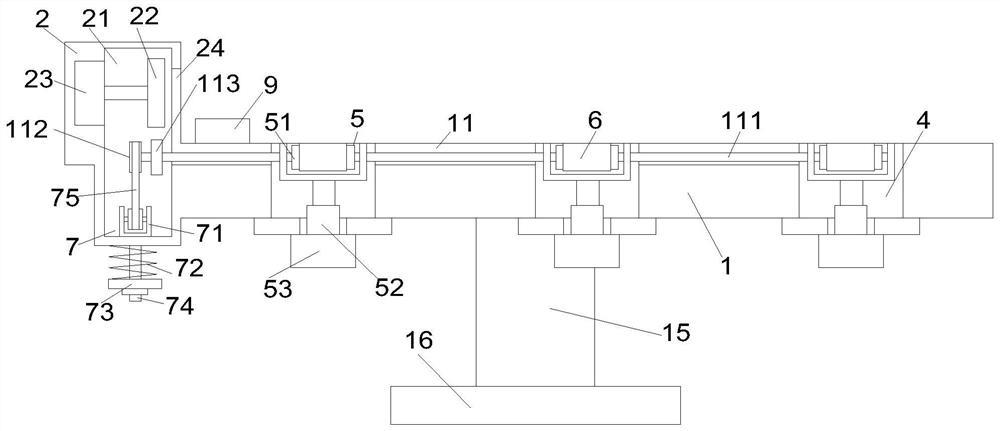

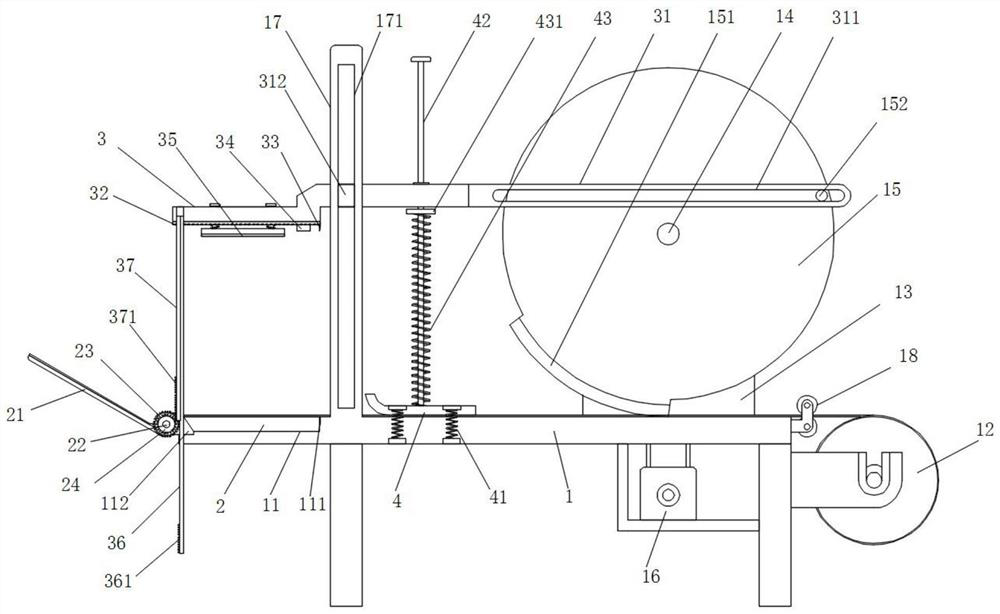

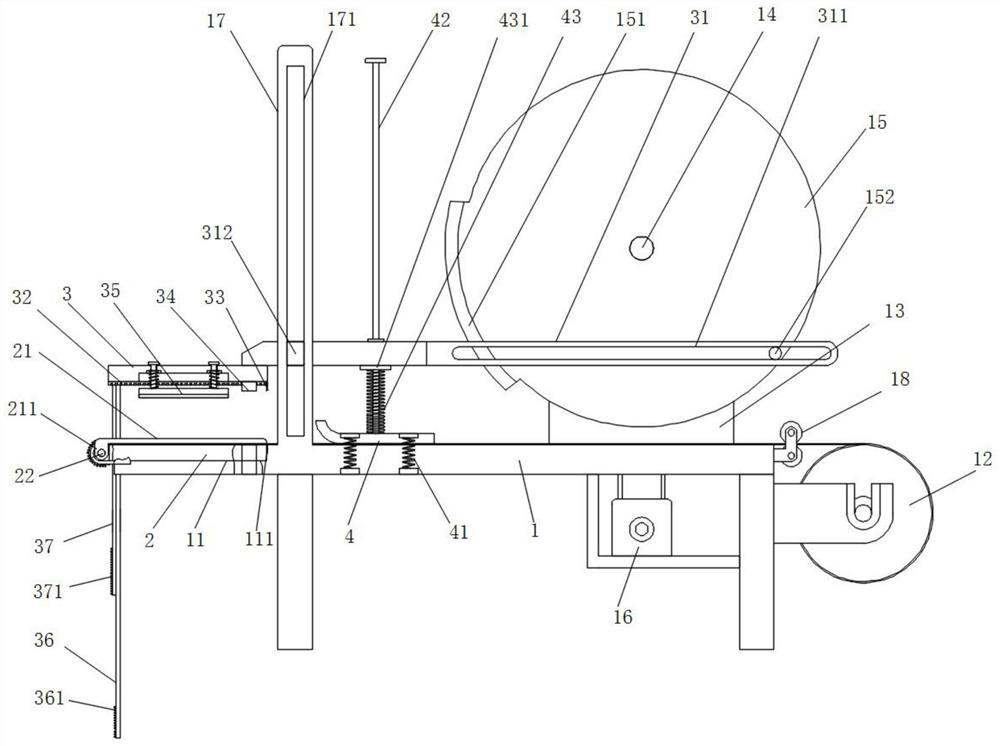

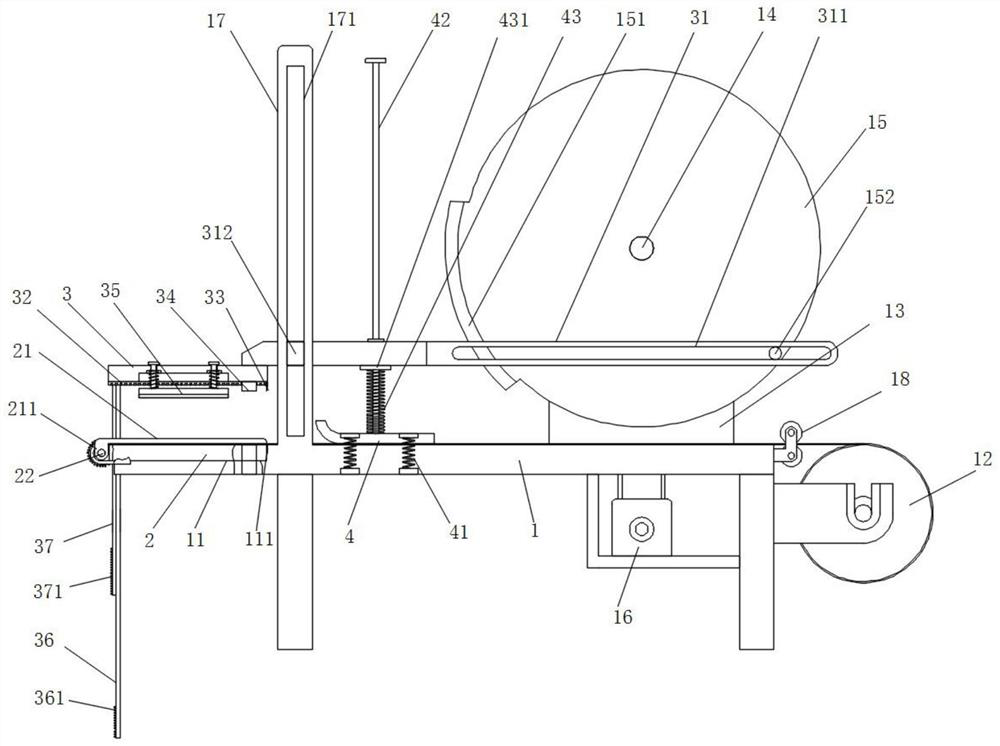

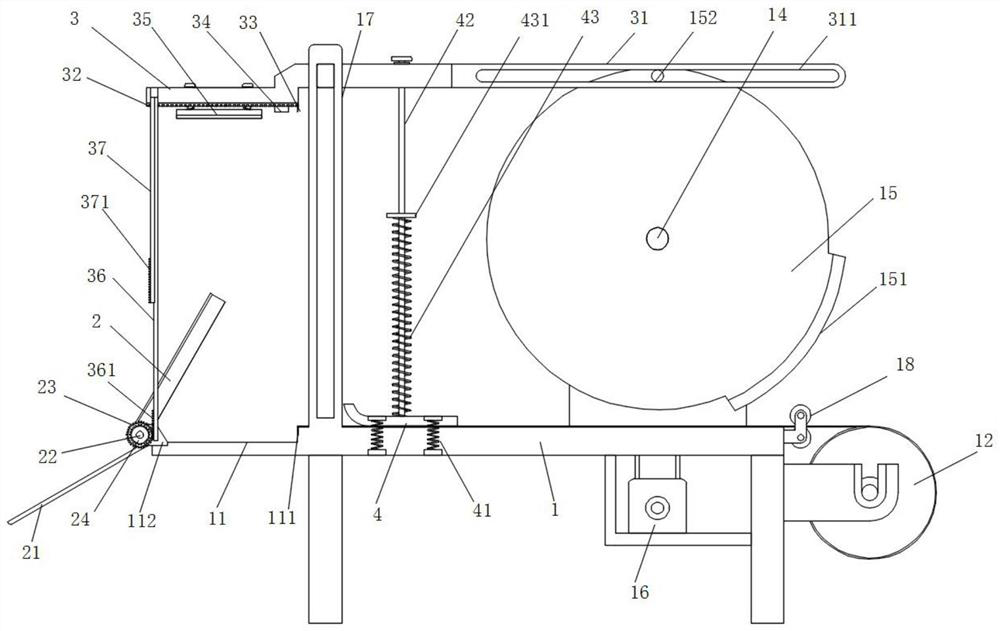

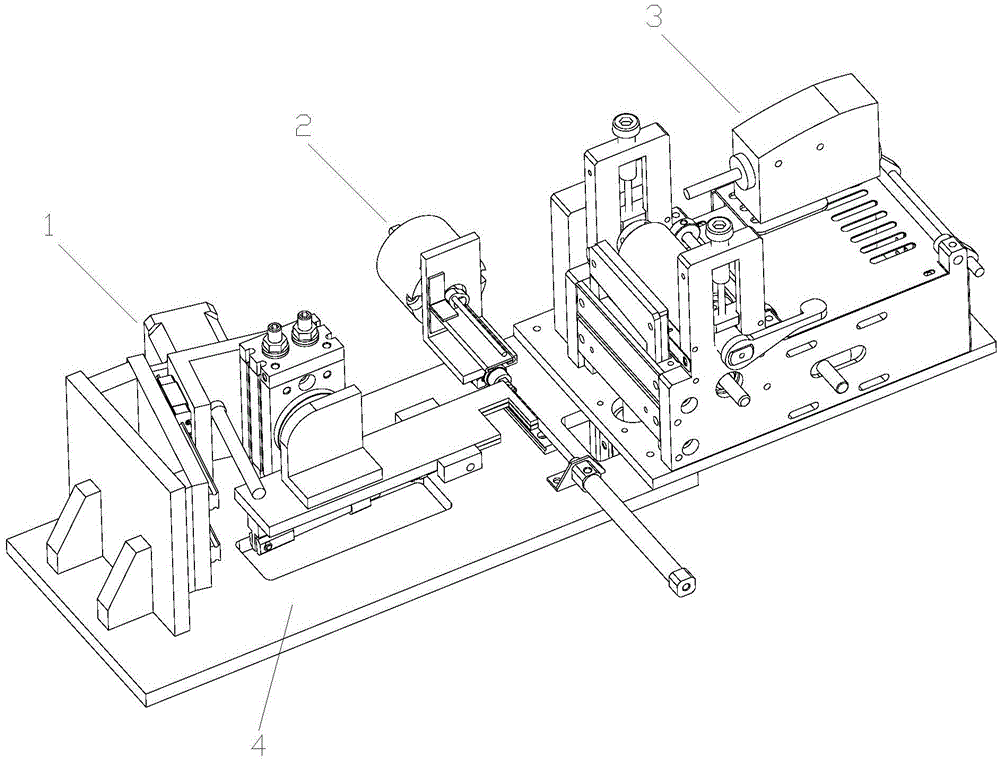

Feeding device and feeding method of saw cutting machine

The invention discloses a feeding device and feeding method of a saw cutting machine. The feeding device includes a rack, a material frame, a material storage platform, a material squeezing mechanism, a conveying platform, a limiting assembly and a material turning mechanism; the rack is provided with a first material pushing device and a second material pushing device in a sliding mode in the longitudinal direction, a first material pushing rod is used for pushing pipe materials to a first limiting position in the longitudinal direction, a second first material pushing rod is used for pushing pipe materials at the first limiting position to a second limiting position, the upstream end portions of the pipe materials located on the first limiting position are conveniently cooperated with the second material pushing rod, and upstream end portions of the pipe materials located on the second limiting position are located on the downstream position of the downstream end portion of the pipe materials on the material storage platform. The feeding device can achieve rapid feeding of the pipe materials and greatly improve the efficiency of feeding. The feeding method can greatly improve the feeding efficiency by using the feeding device.

Owner:SUZHOU KINKALTECK MACHINERY TECH

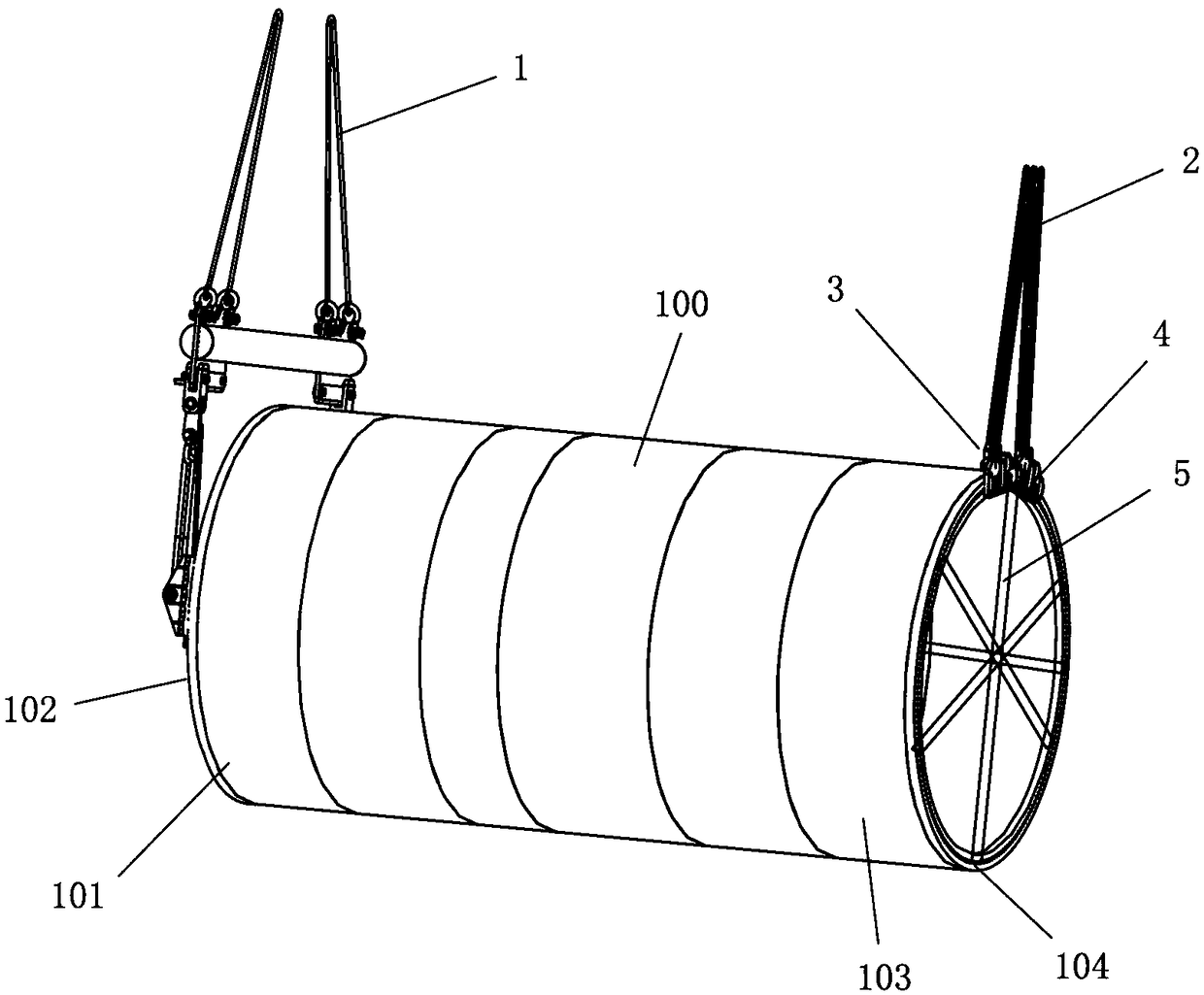

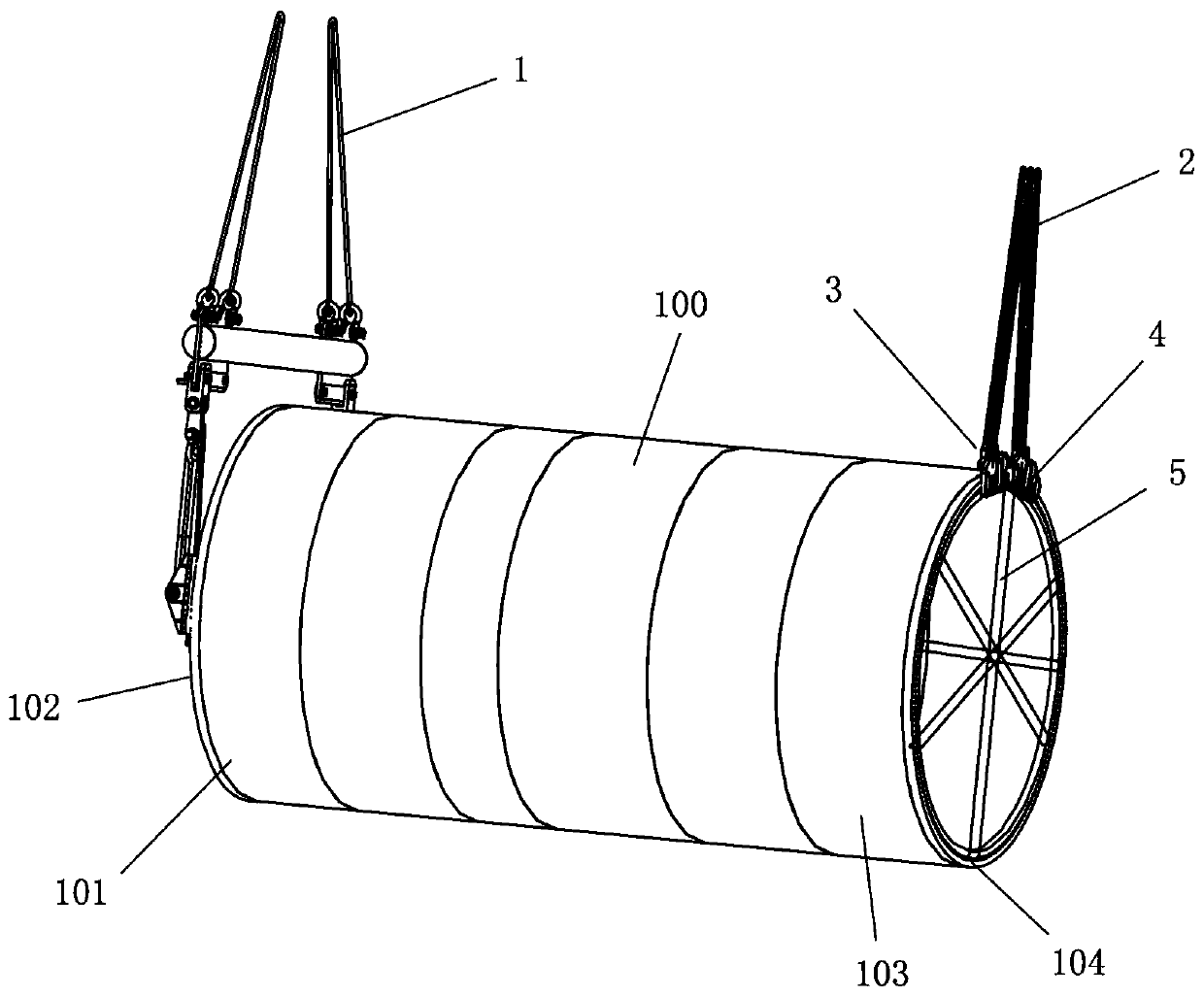

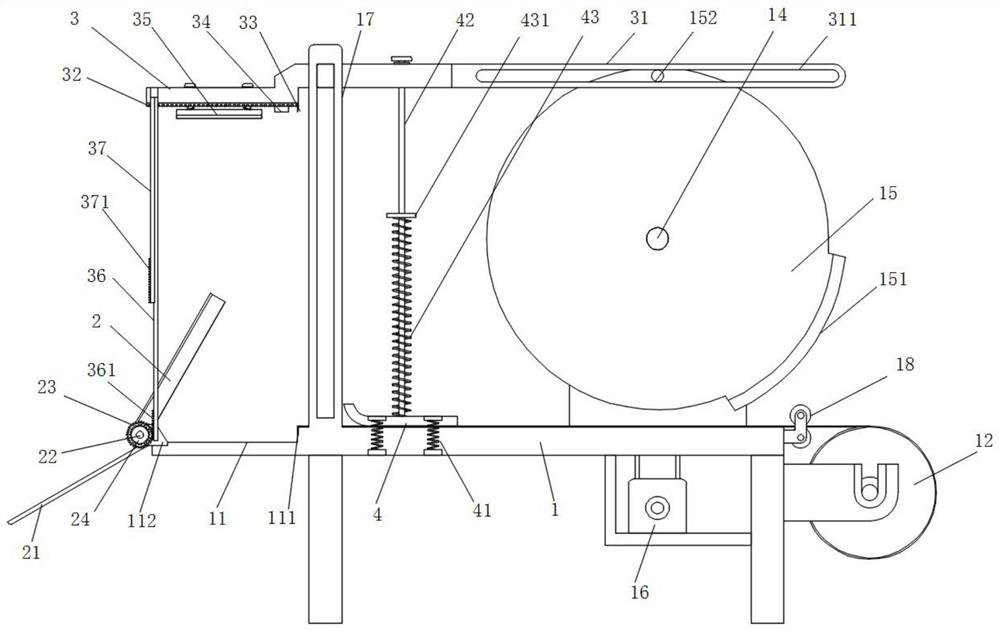

Tower drum overturning device and tower rack mounting system

The invention provides a tower drum overturning device and a tower rack mounting system. The tower drum overturning device is used for overturning a tower drum from a horizontal state to a vertical state, and comprises a tower drum overturning supporting seat; the tower drum overturning supporting seat comprises a first overturning supporting seat and a second overturning supporting seat; each ofthe first overturning supporting seat and the second overturning supporting seat comprises a fixed support and a rotary support; each rotary support comprises a rotary arm and a supporting portion; each rotary arm is rotatably connected with the corresponding fixed support; and a supporting portion is formed on each rotary arm in the radial direction and is used for fixedly supporting a first endof a tower drum. The tower rack mounting system comprises the tower drum overturning device. The tower drum can be overturned from the horizontal state to the vertical state, and deformation of a lower flange of the tower drum in an overturning process is relieved.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

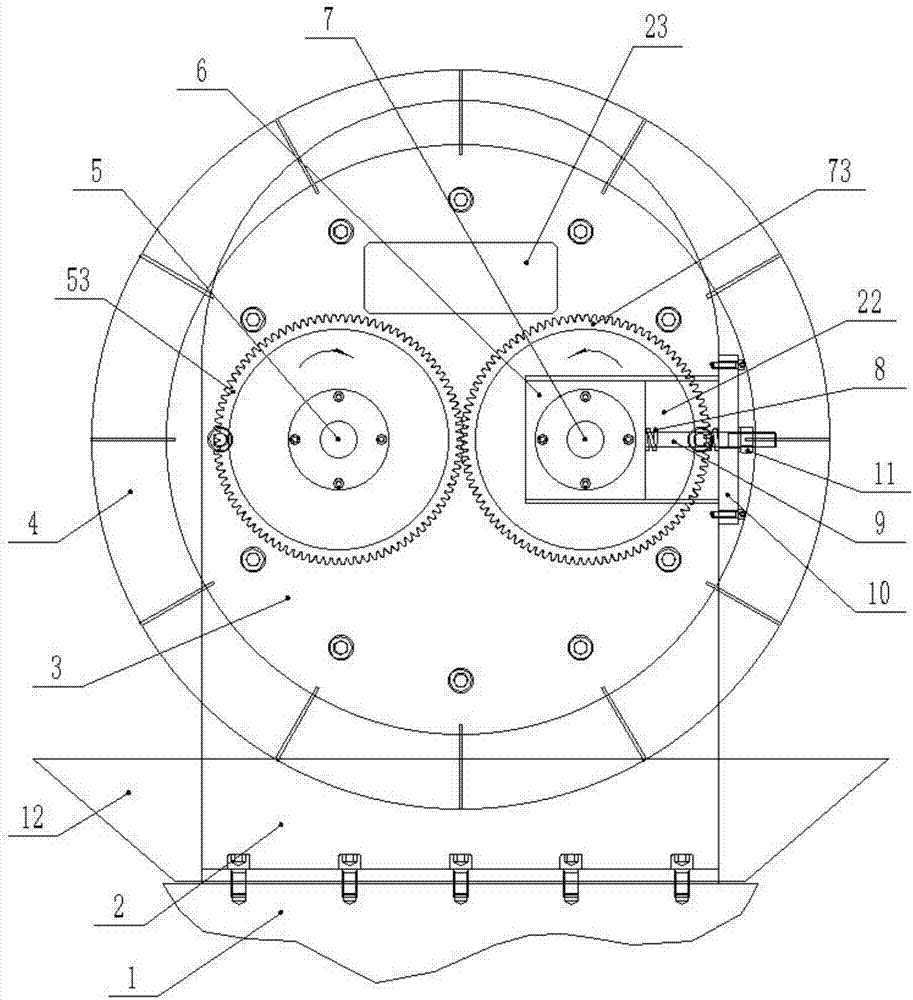

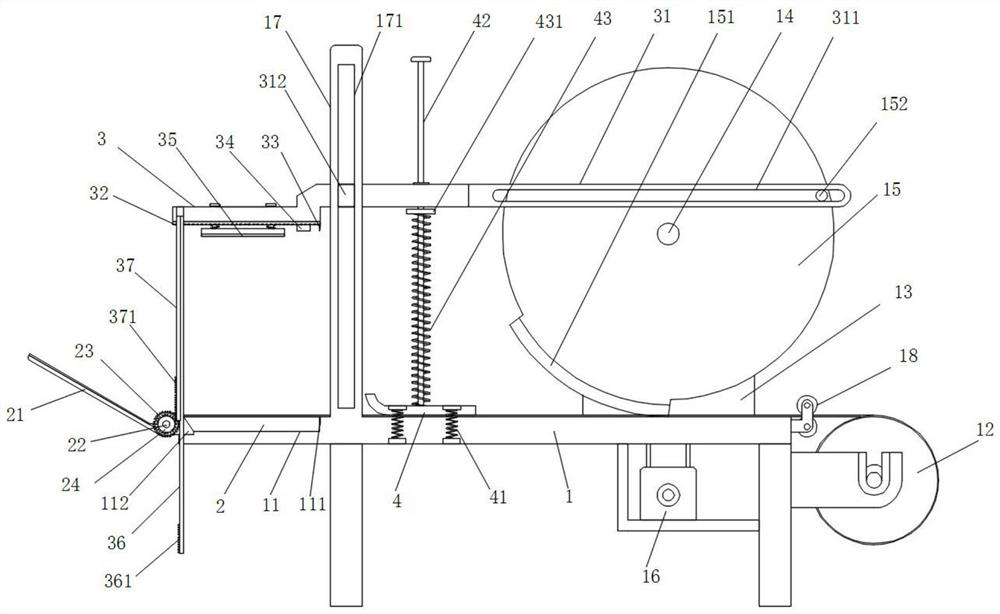

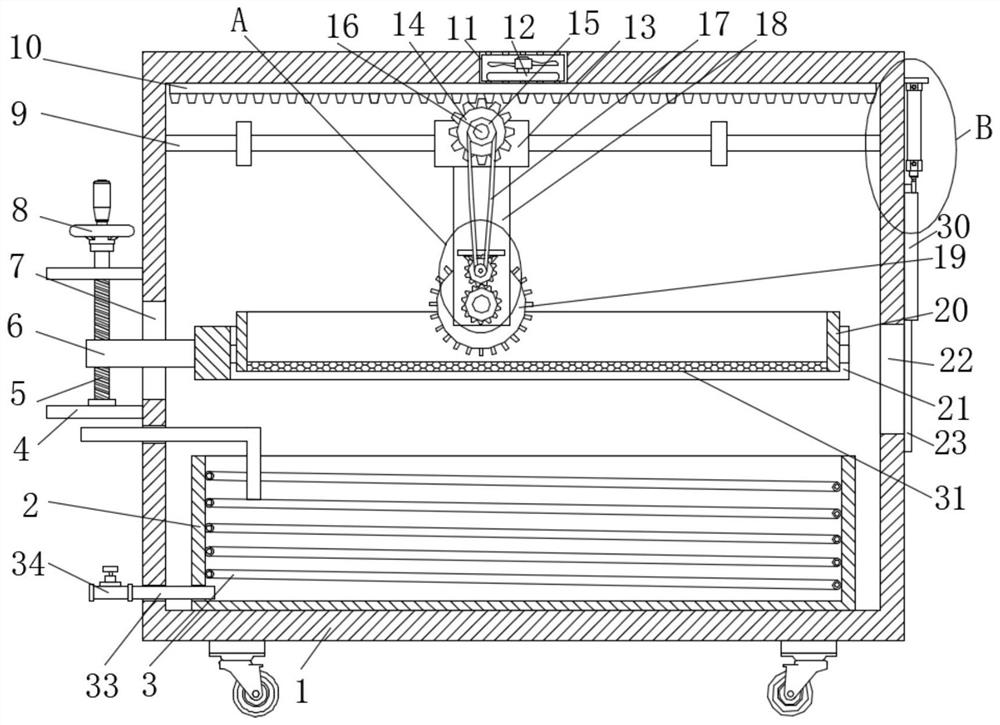

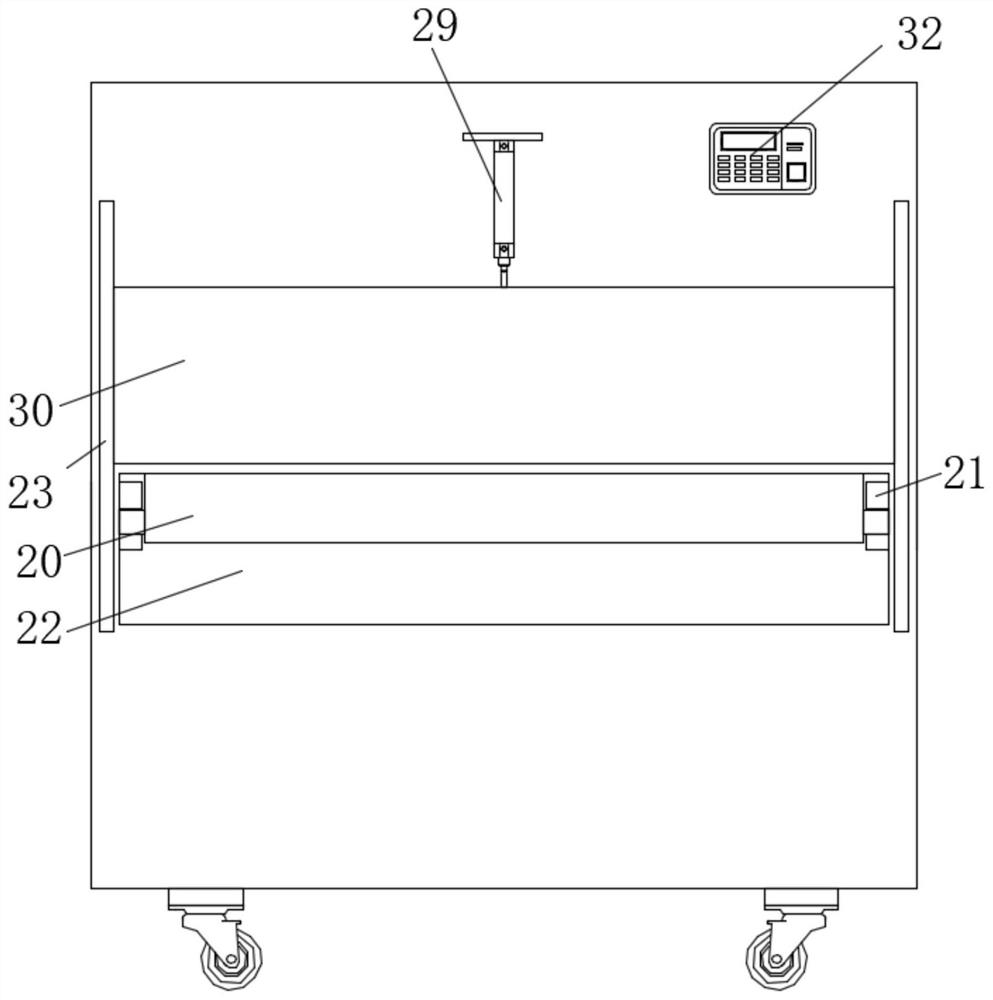

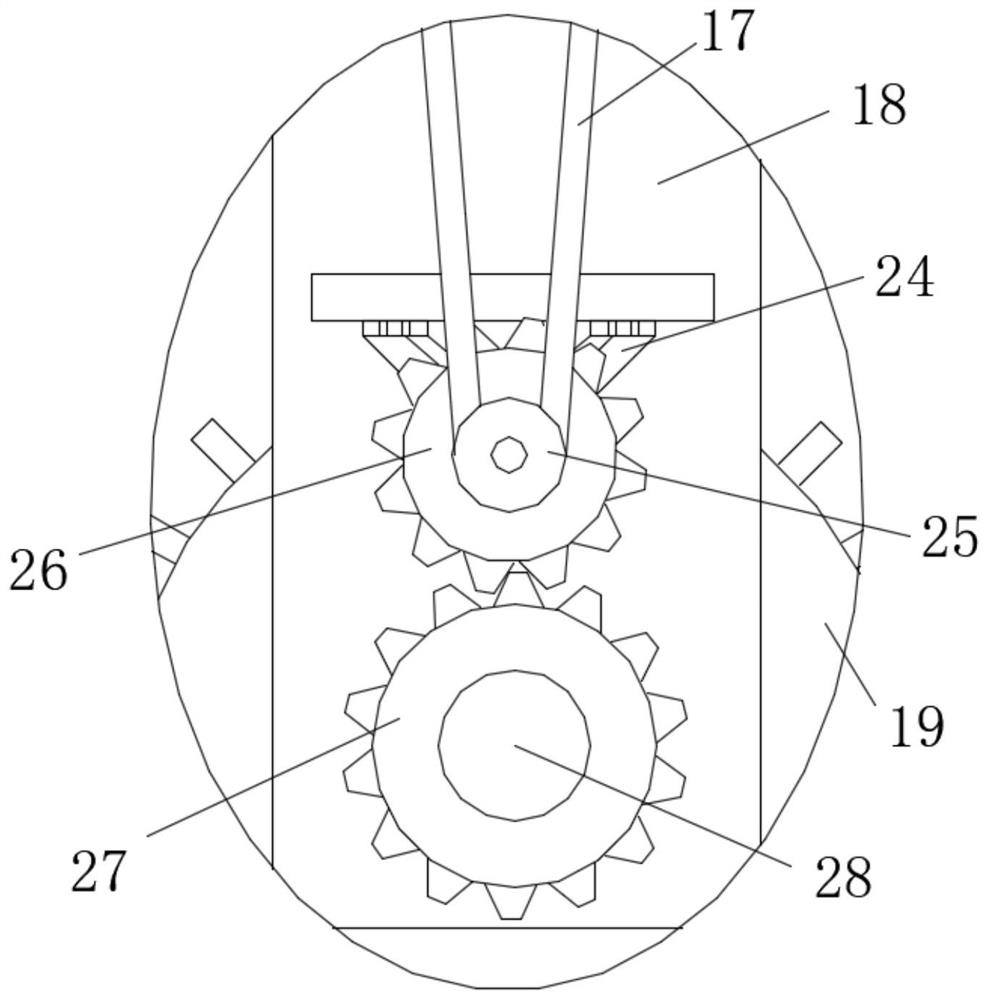

Material crushing and screening device

InactiveCN107297241AImprove crushing effectTurn over to achieveSievingScreeningFree fallingGear wheel

The invention discloses a material crushing and screening device, which comprises two side plates, wherein the side plates are symmetrically arranged on a workbench; a cylinder cover is fixedly connected with the side plates; two ends of a roller movably sleeve the cylinder cover; the roller comprises a turnover plate and a screening mesh; an installation hole and a slideway are processed in each side plate; a baffle plate is fixed at the outer side of each slideway; a driving shaft is arranged in the installation hole and matched with a rolling bearing and a bearing cover plate; a driving gear is processed on the driving shaft; a slide block is located in each slideway; a driven shaft is arranged between the slide blocks and matched with a rolling bearing I and a bearing cover plate I; a driven gear is processed on the driven shaft; one end of an adjusting screw rod is fixed on each slide block and the other end extends out of the baffle plate and is screwed with an adjusting nut; a pressure spring also sleeves each adjusting screw rod; the roller rotates and passes through the turnover plate to continuously take materials to a high place for free falling; and the driving shafts drive the driven shaft to rotate, and the materials are ground into powder and screened through the screening mesh under the grinding action of meshed driving gears and driven gear, so that the material crushing and screening device is compact in structure, suitable for grinding of various materials and good in universality.

Owner:舟山市敏瑞科技咨询有限公司

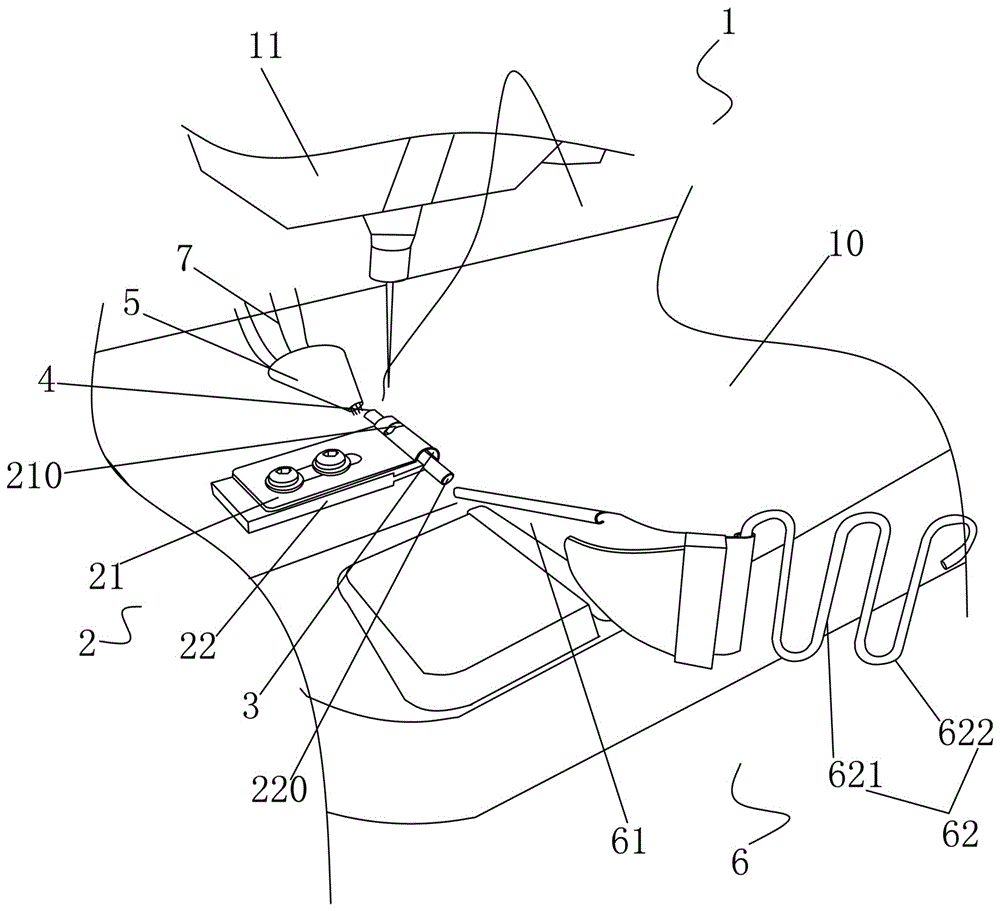

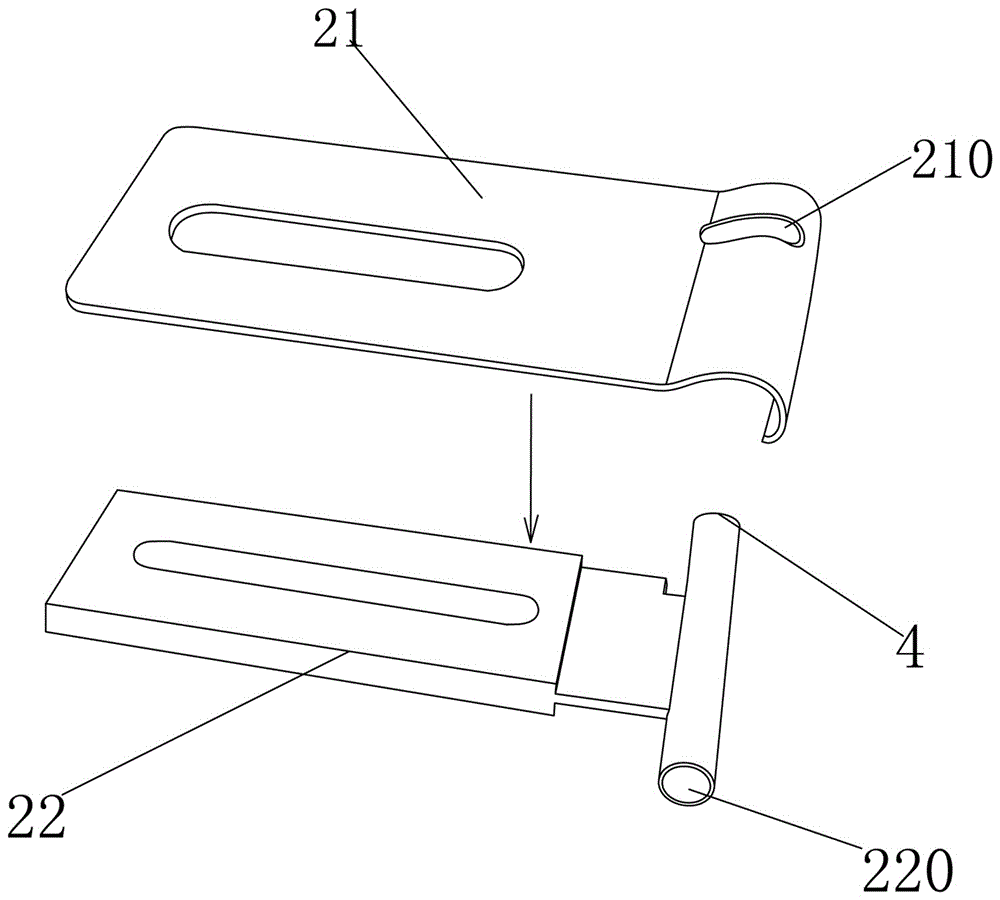

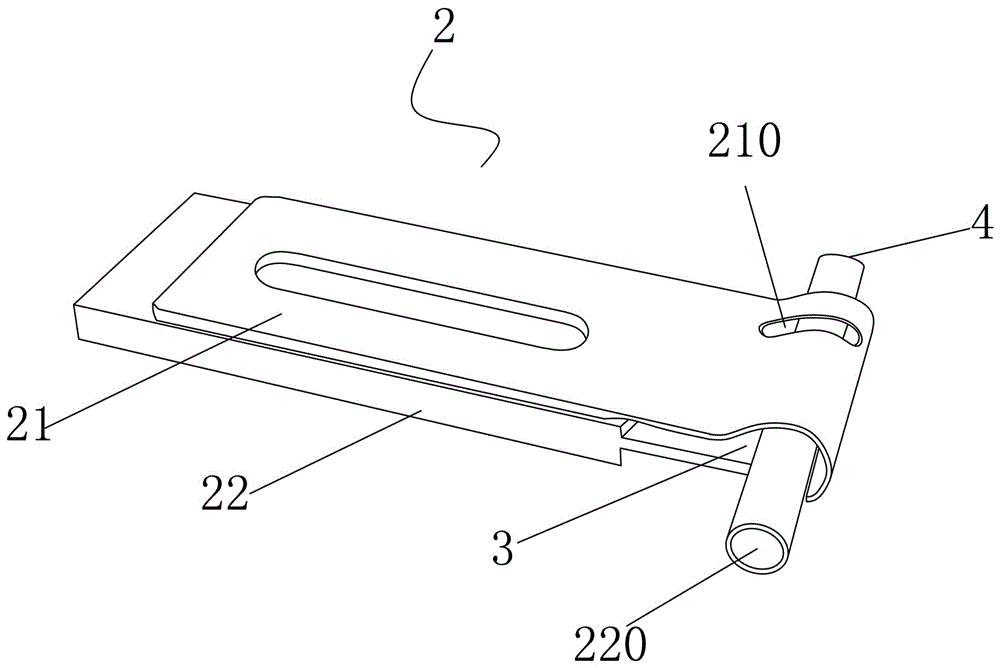

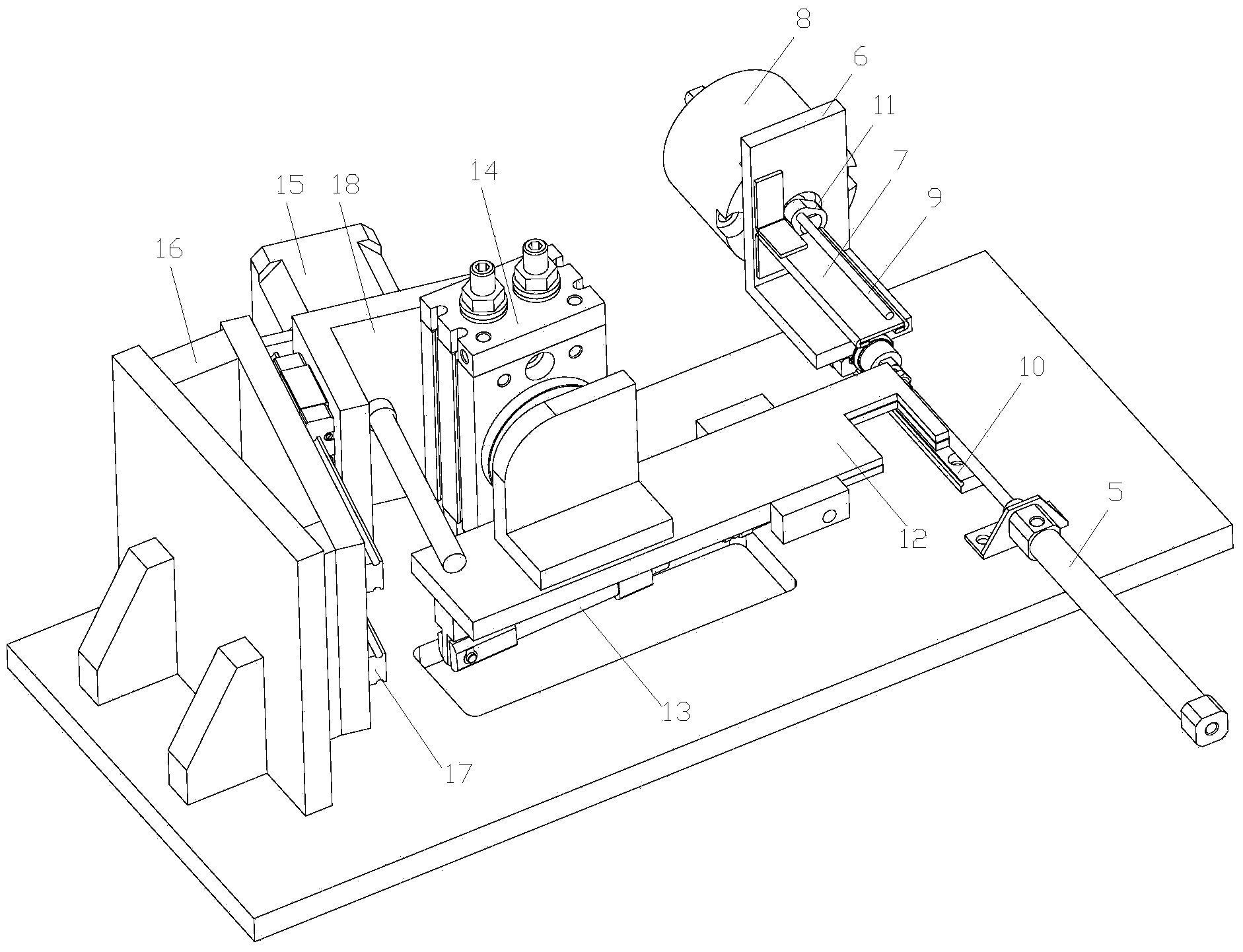

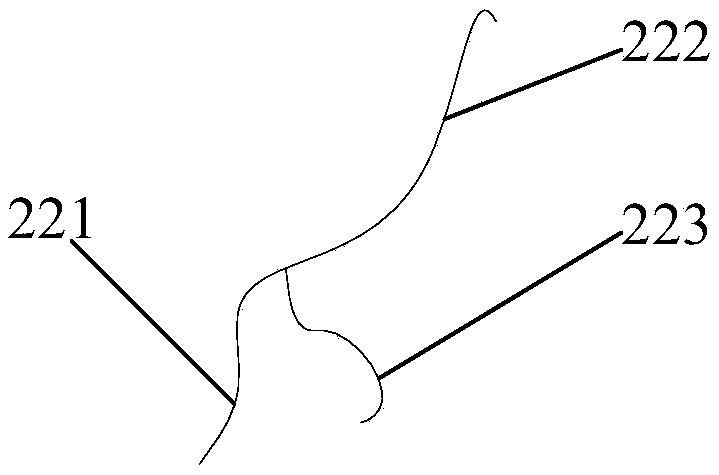

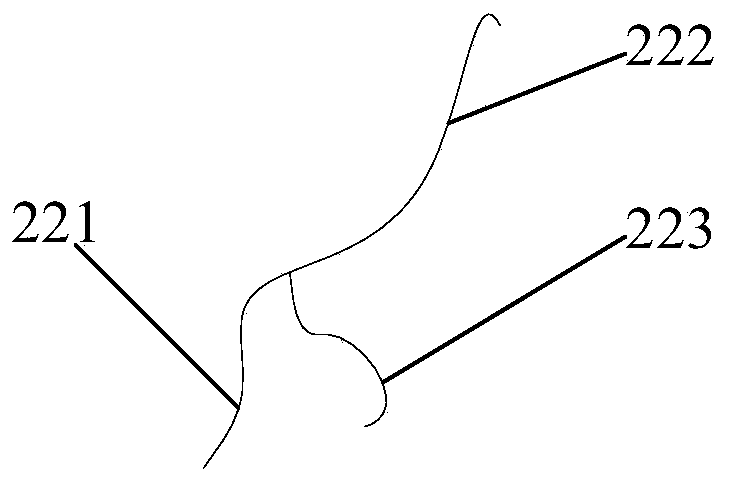

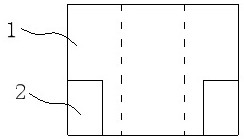

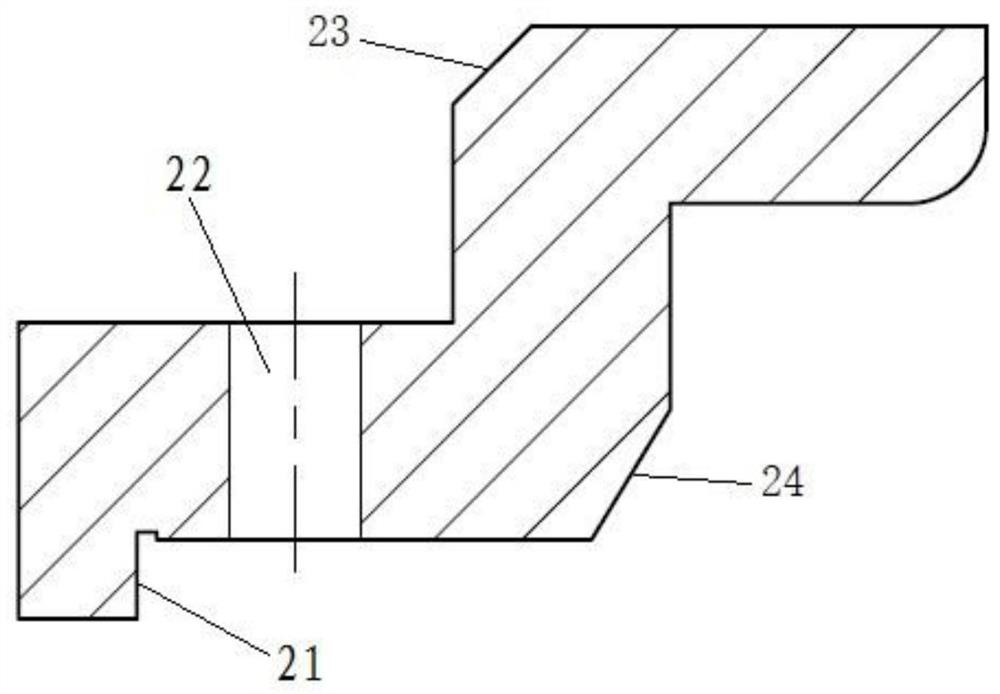

Integral sewing and overturning forming device for coiled button manufacture and forming method for coiled button manufacture

InactiveCN106087268AUniform lengthUniform sizeWork-feeding meansClothes buttonsEngineeringElectrical and Electronics engineering

The invention discloses an integral sewing and overturning forming device for coiled button manufacture. The integral sewing and overturning forming device comprises a sewing device and an overturning mechanism, wherein the overturning mechanism is installed on a working table of the sewing device; the overturning mechanism comprises a fixation plate and a connecting part disposed in the fixation plate; the connecting part comprises a hollow reverse-packing discharge channel; a material passing channel is also formed between the fixation plate and the connecting part; and a package overturning corner is formed at a junction part between the material passing channel and the reverse-packing discharge channel. The invention provides the integral sewing and overturning forming device for the coiled button manufacture and a forming method for the coiled button manufacture. The device and the method have the advantages that sewing and overturning can be completed synchronously in an integral manner; production efficiency is greatly increased; manufacture and forming of coiled buttons are consistent; the device and the method are suitable for batched production; the length, size, width and other parameters of the coiled buttons are uniform; the coiled buttons are smooth and plump as a whole and have a very strong stereoscopic impression and nicer appearance; and overturning of hard fabrics can be implemented as well, so that applicability is higher and production demands can be satisfied more easily.

Owner:FUJIAN SEVEN FASHION TECH CO LTD

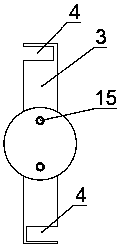

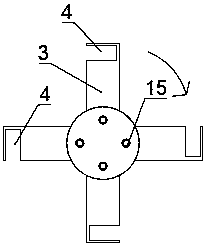

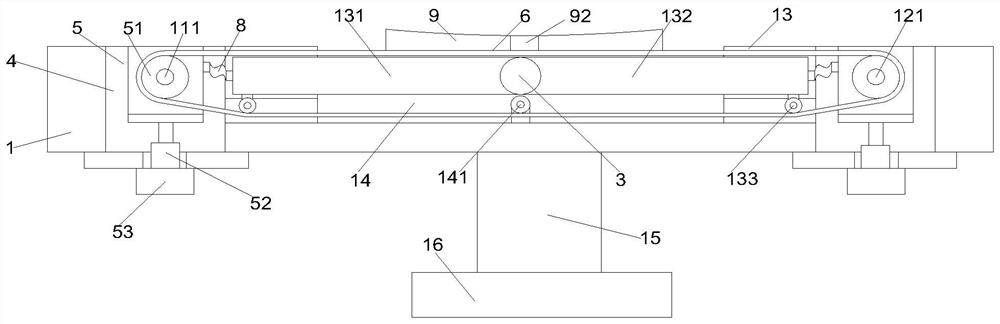

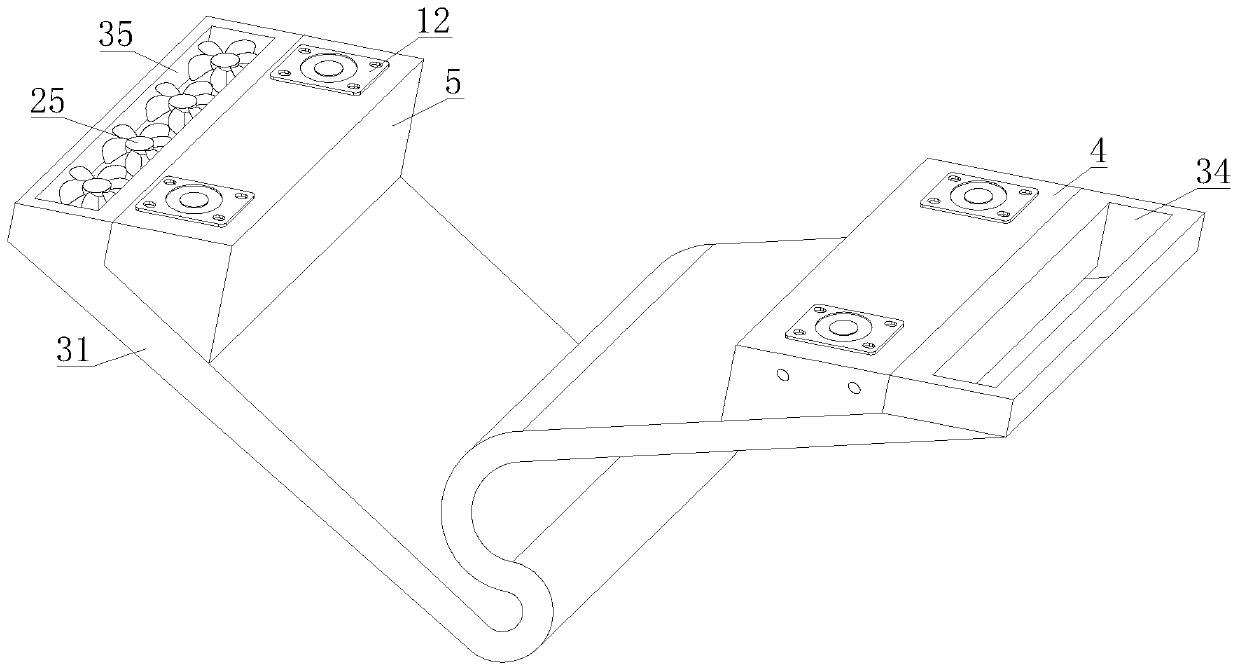

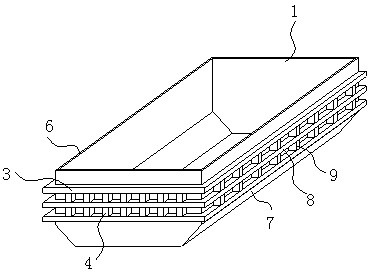

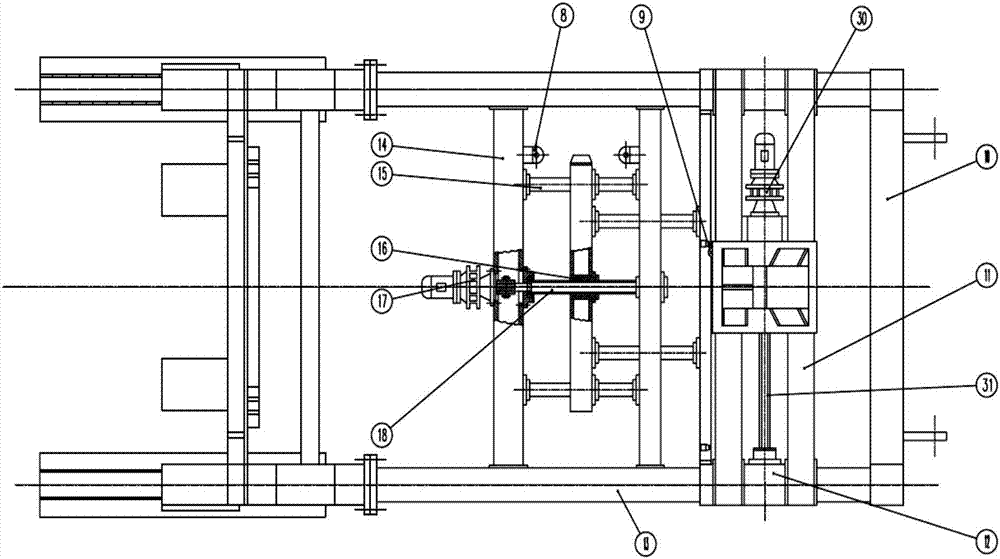

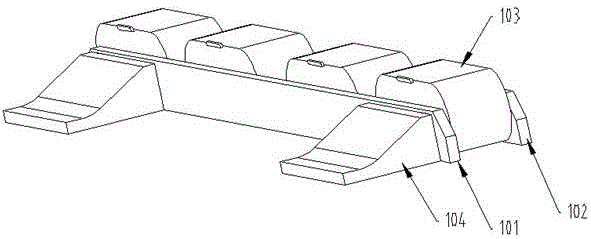

Magnetic core conveying and turnover device and magnetic core arrangement machine provided with device

The invention relates to the field of magnetic core arrangement equipment, in particular to a magnetic core conveying and turnover device. The magnetic core conveying and turnover device comprises a rack. A first conveying belt, a second conveying belt and a turnover frame are arranged on the rack. The turnover frame is arranged on the rack through a rotary shaft. One or more linear cavities allowing magnetic cores to be arranged are formed in the outer edge of the turnover frame. The first conveying belt and the second conveying belt are in butt joint with the linear cavities when the turnover frame rotates to a certain position correspondingly, and the conveying direction of the first conveying belt and the conveying direction of the second conveying belt are consistent with the axial direction of the linear cavities. A magnetic core arrangement machine provided with the magnetic core conveying and turnover device further comprises a third conveying belt, a rotating disc and a magnetic core arrangement device. According to the magnetic core conveying and turnover device and the magnetic core arrangement machine provided with the device, by means of the design of the turnover frame, turnover in the magnetic core arrangement process is achieved, the magnetic cores cannot be damaged in the turnover process, and safety and stability are remarkably improved.

Owner:桐乡市佳顺自动化机械有限公司

Label tailoring and folding device

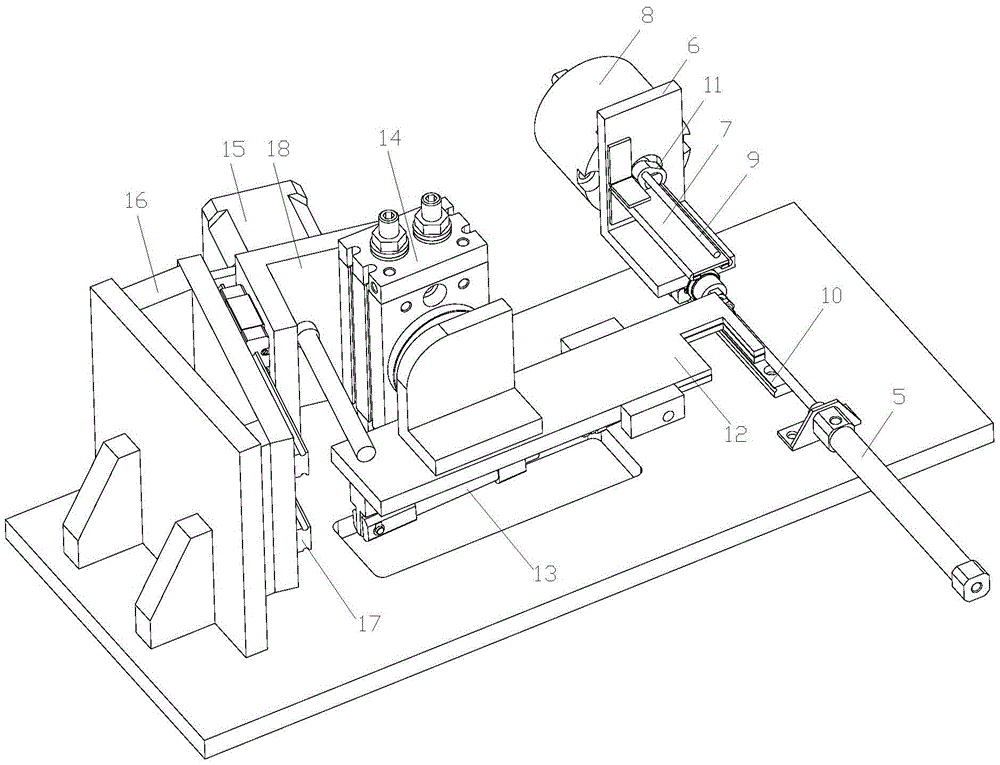

ActiveCN104355168ASimple structureImprove flexibilityOverturning articlesFolding thin materialsPhysicsEngineering

The invention discloses a label tailoring and folding device. The label tailoring and folding device comprises a label shearing device, a folding mechanism and a clamping turnover mechanism, wherein the folding mechanism is positioned in the discharge direction of the label shearing device; the folding mechanism comprises a first cylinder, a bracket, a supporting plate, a first motor and a ram; the supporting plate is arranged on the bracket; the ram driven by the first motor is arranged on the upper side of the supporting plate; a cam connected with the ram is arranged on a rotating shaft of the first motor; the ram takes the rotating shaft of the first motor as a central spindle to reciprocate on the upper side and the lower side of the supporting plate; the clamping turnover mechanism is arranged on the other side of the folding mechanism and comprises a pair of clamping plates, a second cylinder, a turnover seat, a second motor and a sliding rail seat; the pair of clamping plates clamp oppositely and are arranged at the equal height of the supporting plate; the second cylinder is fixed on the lower side of the pair of clamping plates and pushes the pair of clamping plates to move in the label conveying direction; the turnover seat is connected with the pair of clamping plates to drive the pair of clamping plates to turn over from the horizontal direction to the vertical direction; the turnover seat is driven by the second motor.

Owner:苏州琼派瑞特科技股份有限公司

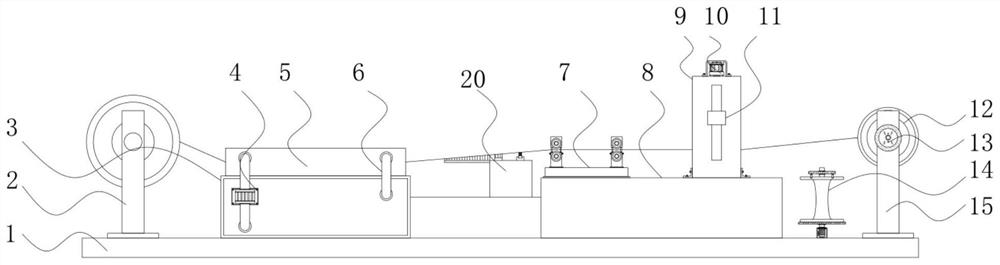

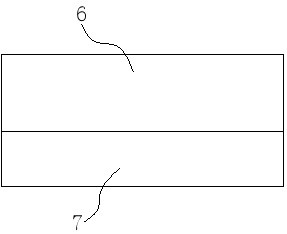

Dehumidification processing equipment for biodegradable high-barrier plastic film material

InactiveCN113580216AAchieve coolingRealize windingDrying machines with progressive movementsMetal working apparatusWater flowMoisture absorption

The invention discloses dehumidification processing equipment for a biodegradable high-barrier plastic film material, and specifically relates to the technical field of plastic film processing. The dehumidification processing equipment for the biodegradable high-barrier plastic film material comprises a base and a feeding roller, wherein the feeding roller is fixedly connected to one side of the top end of the base. According to the invention, by arranging a frame body, first water scraping plates, second water scraping plates, a moisture absorption plate, rubber pads, moisture absorption cotton and a water collecting tank, water mist at the two sides of the film is scraped through the two groups of first water scraping plates, water mist at the middle part of the film is scraped through the second water scraping plates when the film passes through the second water scraping plates, and the water mist is converged and flows down along the middle parts of the two first water scraping plates; and the water flow is collected through the arranged water collecting tank, the film passes through the moisture absorption plate, residual water on the film is absorbed and removed through the moisture absorption cotton, the bottom of the moisture absorption cotton is connected with a clamping groove in a clamped mode through a connecting plate, regular replacement is facilitated, the dehumidification effect on the film is guaranteed, the film is kept fully dry, and later winding and using are facilitated.

Owner:童起云

Large prebaked anode electrolytic cell shell manufacturing method

The invention relates to the technical field of large electrolytic cell machining, and provides a large prebaked anode electrolytic cell shell manufacturing method capable of effectively relieving thewelding deformation. The large prebaked anode electrolytic cell shell manufacturing method comprises the steps of: (A) material stock acceptance check; (B) end plate manufacturing; (C) side plate manufacturing; (D) base plate manufacturing; (E) delivery transportation; and (F) field assembly. Through control of the welding mode and the welding sequence, the influence by the welding deformation iseffectively reduced, the once pass percent in the electrolytic cell shell machining process is greatly increased, the construction period is shortened, and the quality of electrolytic cell shells isimproved.

Owner:云南建投机械制造安装工程有限公司

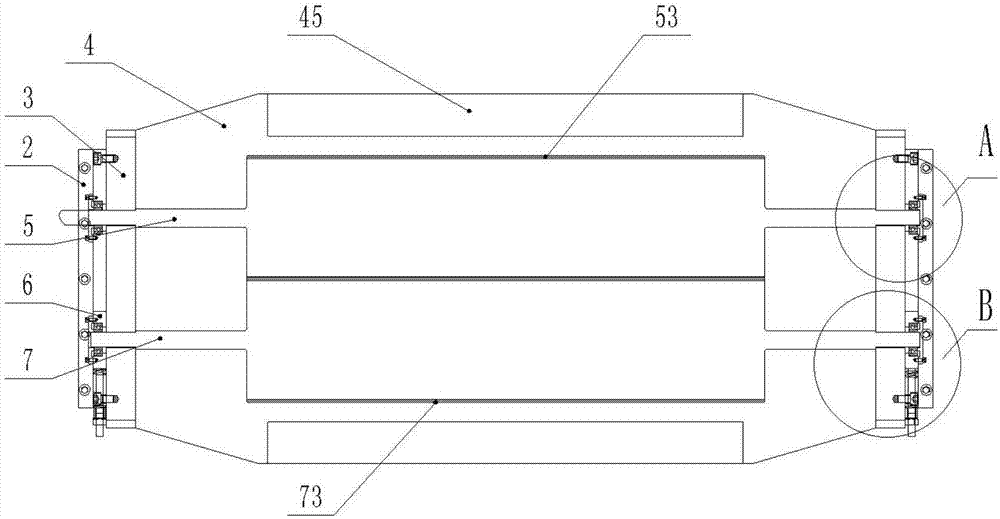

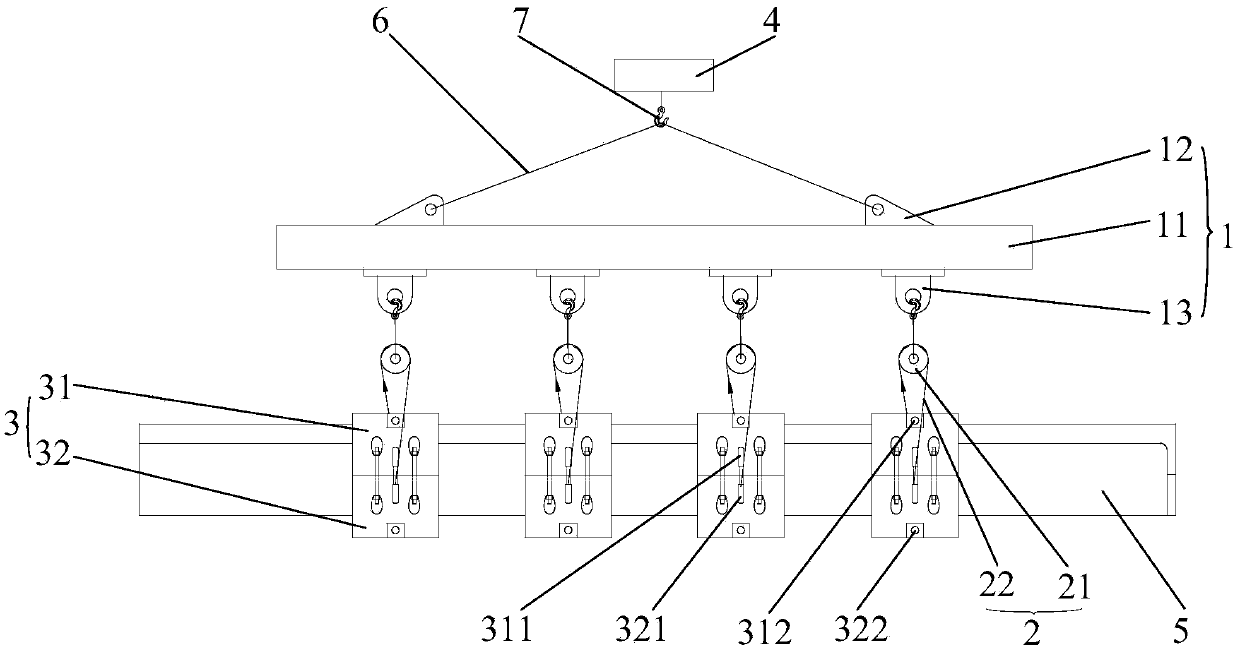

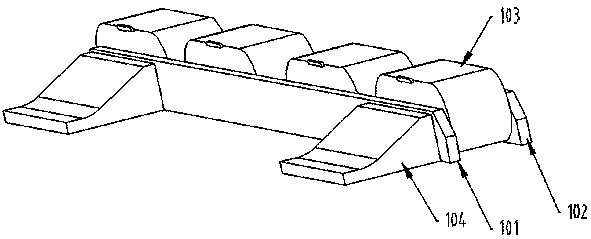

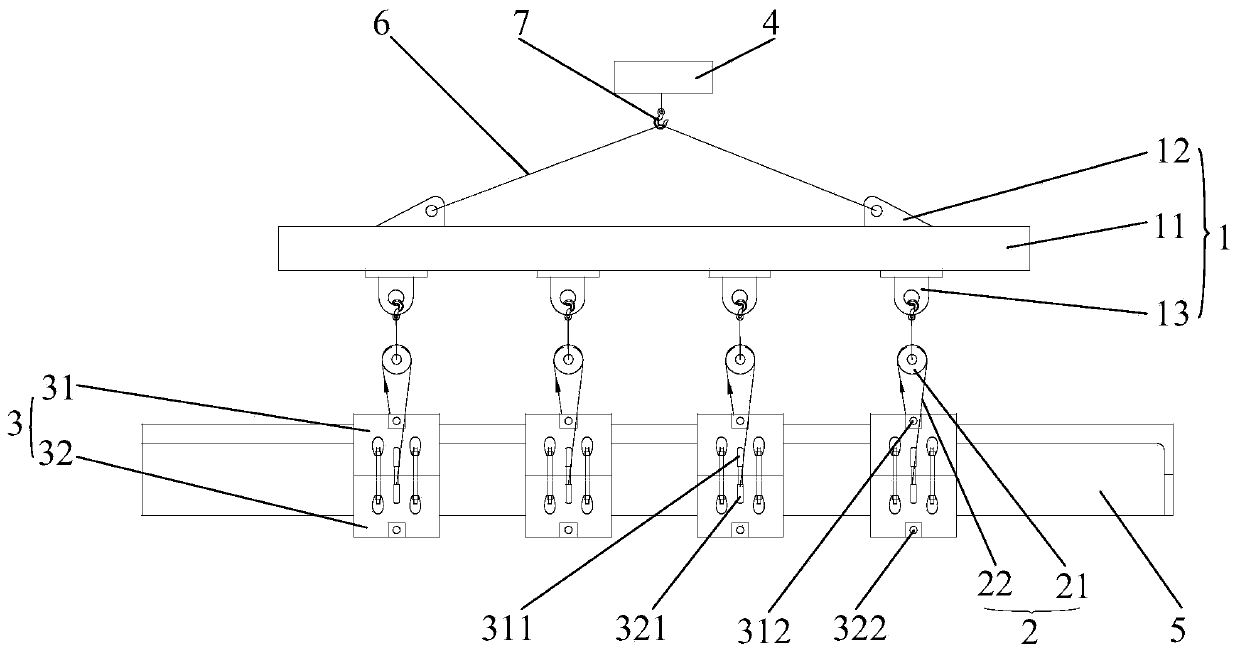

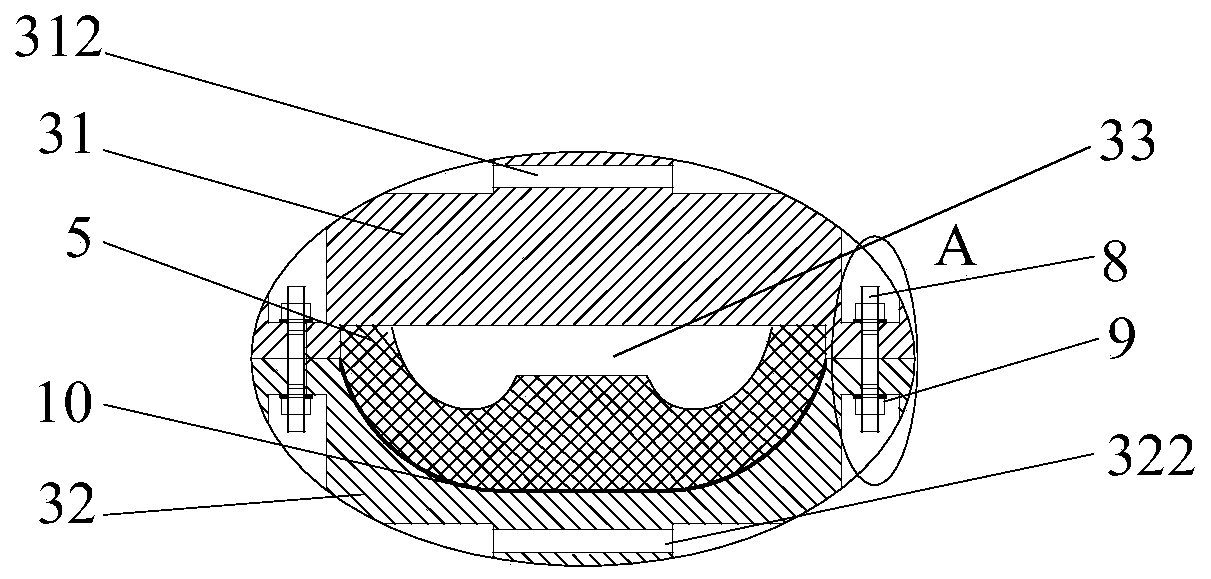

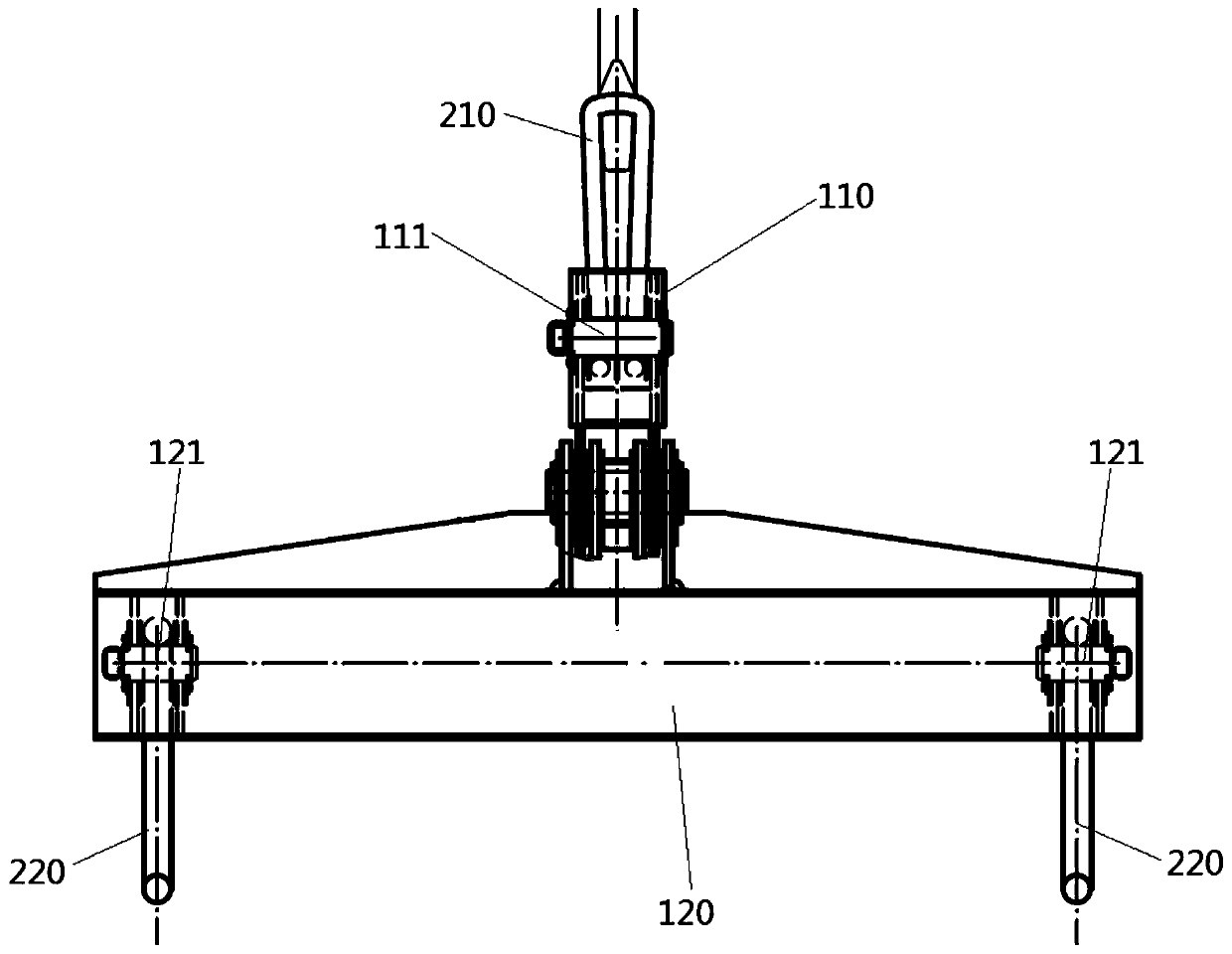

Turnover tooling and turnover method

The invention discloses a turnover tooling and a turnover method and belongs to the field of mechanical toolings. A lifting unit is connected with a travelling crane; each turnover unit comprises a fixed pulley and a forked sling, wherein the fixed pulley is connected with the lifting unit, and the forked sling is wound on the fixed pulley and comprises a first main end, a second main end and an auxiliary end; and upper locking blocks and lower locking blocks are detachably mounted together to form locking units correspondingly, clamping spaces used for clamping parts are formed between the upper locking blocks and the corresponding lower locking blocks, upper main lifting holes are formed in the two sides of an opening of each upper locking block correspondingly, lower main lifting holesare formed in the two sides of an opening of each lower locking block correspondingly, the two main ends of each forked sling are bound into the upper main lifting holes and the lower main lifting holes aligned with the upper main lifting holes of the corresponding locking unit, an upper auxiliary lifting hole is formed in each upper locking block, a lower auxiliary lifting hole is formed in eachlower locking block, the auxiliary end of each forked sling is bound into the corresponding upper auxiliary lifting hole or the corresponding lower auxiliary lifting hole, and the situation that whenparts are overturned, local stress is excessively large, the parts are deformed due to extrusion, and assembling of the parts is affected is avoided.

Owner:WUHAN MARINE MACHINERY PLANT

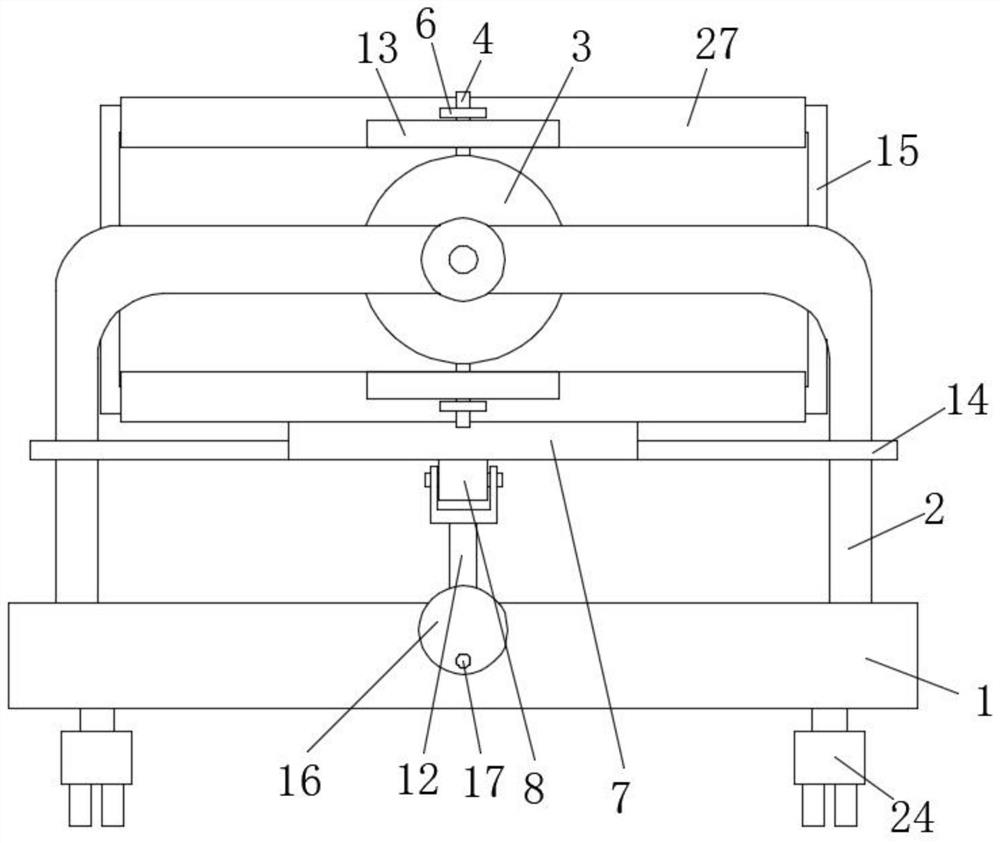

Operating bed convenient for patient to turn over

PendingCN112656630AEasy to turn overPrevent fallingOperating tablesPhysical medicine and rehabilitationTracheal tube

The invention relates to the technical field of medical instruments, and discloses an operating bed convenient for a patient to turn over, which comprises a bed body, a backrest, a base, a first bed plate, a second bed plate, a lifting mechanism and a tensioning mechanism, an accommodating cavity is opened on the top of the bed body, and the middle of the accommodating cavity is rotated and matched with a rotating shaft, one sides of the first bed plate and the second bed plate are rotationally matched and connected with the rotating shaft; the backrest is arranged on the left side of the bed body, the tensioning mechanism is arranged in the backrest, three sets of lifting holes sequentially distributed from left to right are formed in the front side and the rear side of the bed body respectively, the lifting mechanisms are arranged in the lifting holes, a lifting belt is connected between the lifting mechanisms on the front side and the rear side, and a rotating rod is connected between the lifting mechanisms on the same side, the left end of the rotating rod is connected with the tensioning mechanism, and a support is arranged between the bed body and the base; the problems that in the prior art, an operating bed does not have the function of turning over a patient, and a head needs to be manually supported to prevent a tracheal catheter for conveying oxygen from being folded in the turning-over process are solved.

Owner:ZHEJIANG UNIV

Tower turning device and tower installation system

ActiveCN108975244BTurn over to achieveSave design costWind motor assemblyLifting devicesEngineeringTower

The invention provides a tower drum overturning device and a tower rack mounting system. The tower drum overturning device is used for overturning a tower drum from a horizontal state to a vertical state, and comprises a tower drum overturning supporting seat; the tower drum overturning supporting seat comprises a first overturning supporting seat and a second overturning supporting seat; each ofthe first overturning supporting seat and the second overturning supporting seat comprises a fixed support and a rotary support; each rotary support comprises a rotary arm and a supporting portion; each rotary arm is rotatably connected with the corresponding fixed support; and a supporting portion is formed on each rotary arm in the radial direction and is used for fixedly supporting a first endof a tower drum. The tower rack mounting system comprises the tower drum overturning device. The tower drum can be overturned from the horizontal state to the vertical state, and deformation of a lower flange of the tower drum in an overturning process is relieved.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

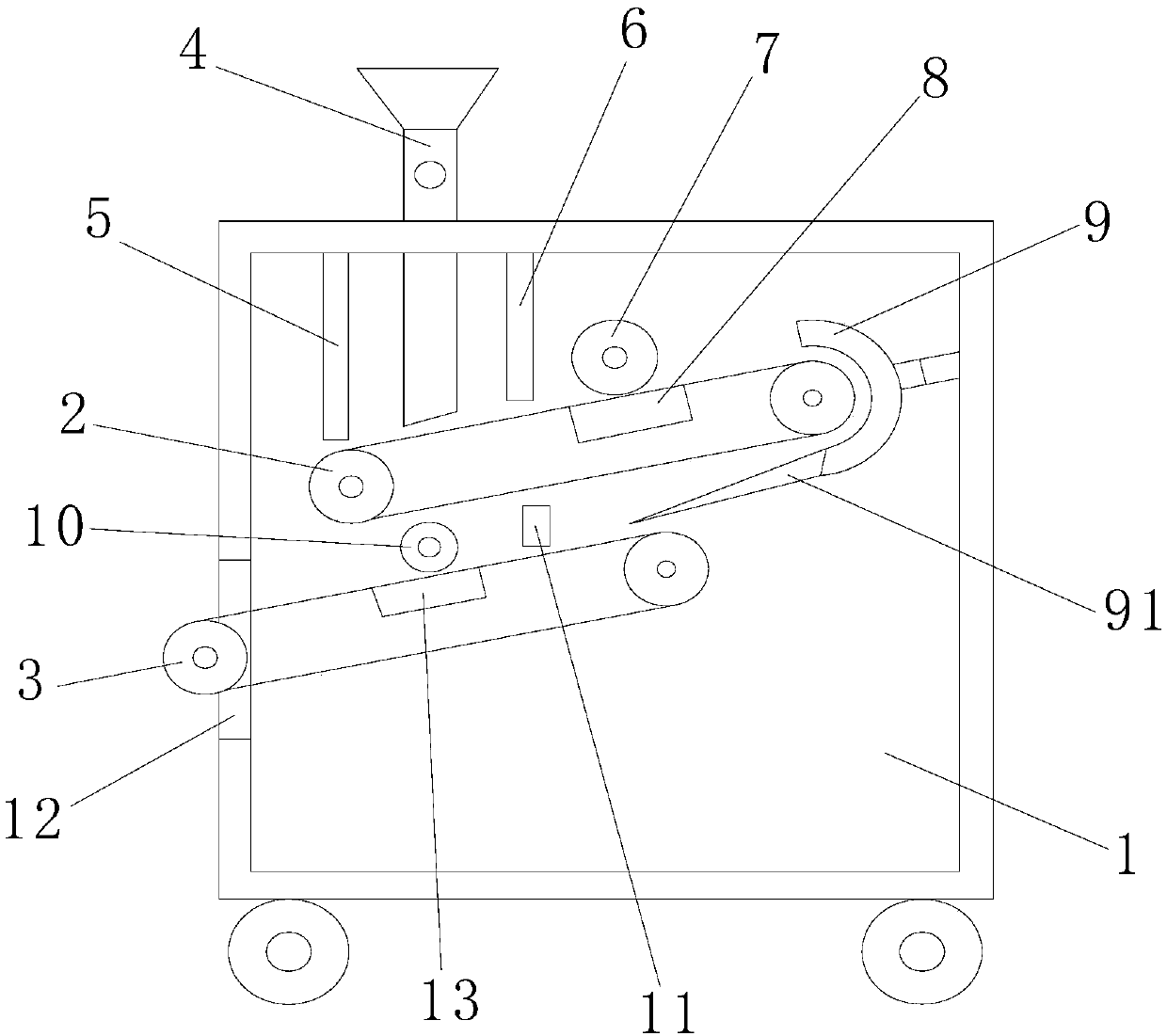

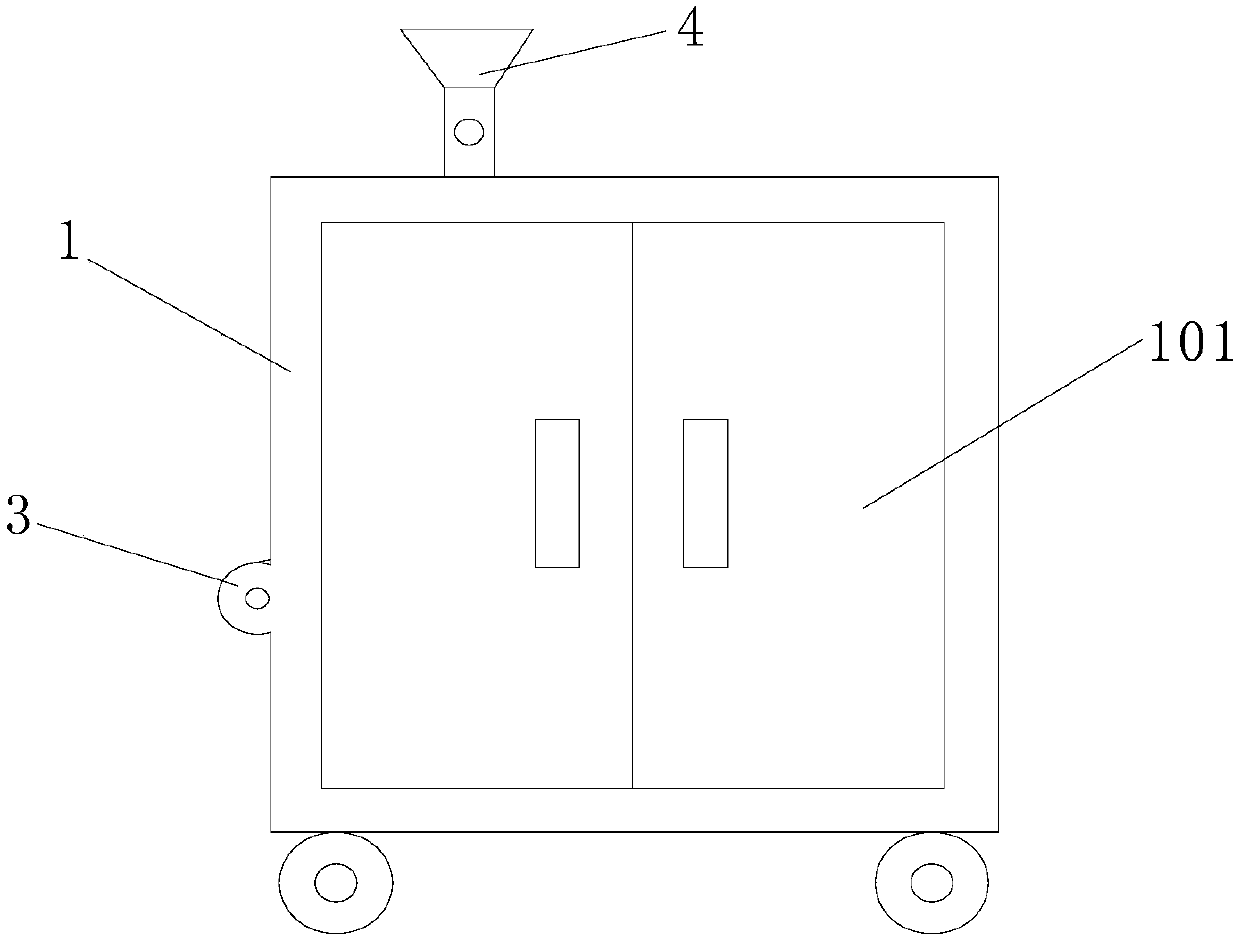

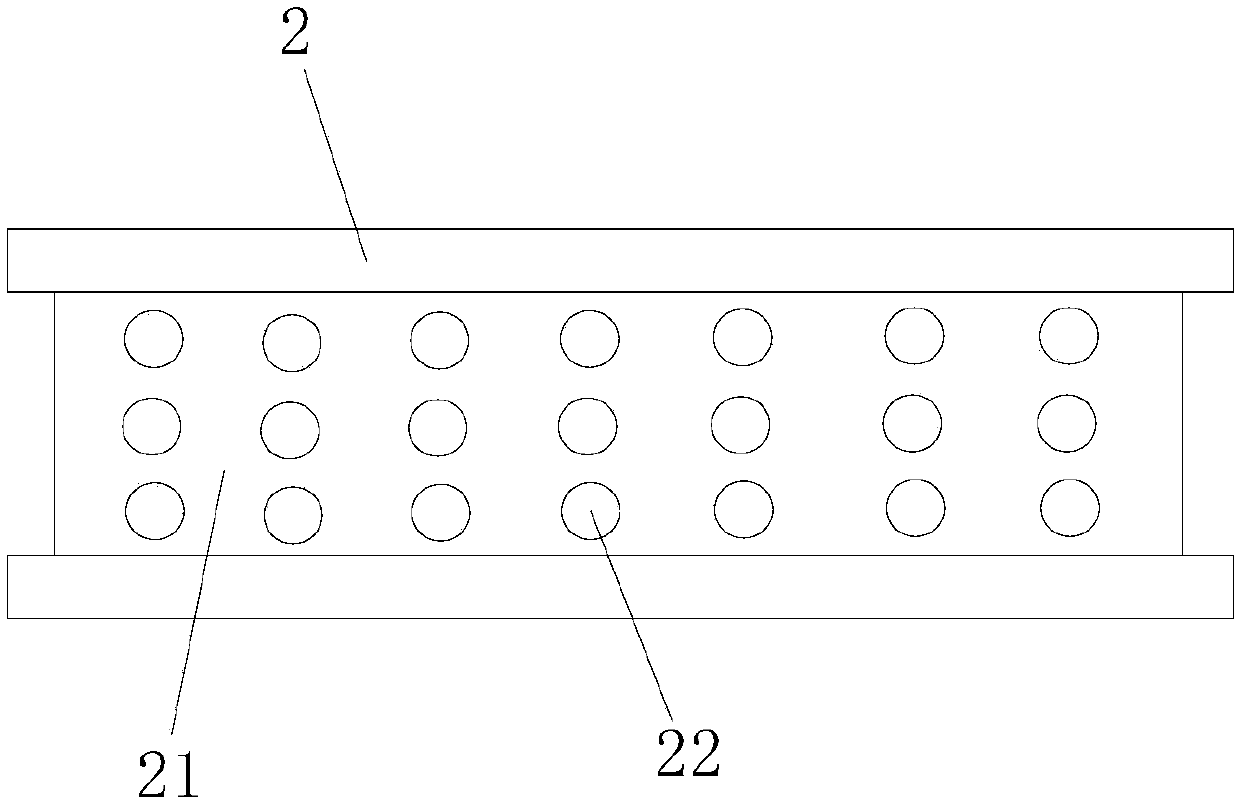

Nut end surface grinding equipment

PendingCN107598693APrevent flying outTurn over to achieveGrinding machine componentsPlane surface grinding machinesSurface grindingMagnet

The invention discloses a nut end surface grinding equipment. The nut end surface grinding equipment comprises a machine box, an upper conveying belt, a lower conveying belt, a feeding hopper, a baffle, a first fence plate, a first grinding roller, a first magnet block, an overturning baffle, a second grinding roller, a second fence plate, a discharging opening and a second magnet block. The machine box is internally provided with the upper conveying belt with the curled-up output end. An annular groove is formed in the belt surface of the upper conveying belt in the length direction, and a plurality of evenly-distributed storing grooves capable of storing nuts are formed in the groove bottom of the annular groove. The lower conveying belt with the curled-up input end is arranged in the machine box and located under the upper conveying belt. The structure of the lower conveying belt is completely the same as that of the upper conveying belt. According to the nut end surface grinding equipment, compared with the prior art, the two end surfaces of each nut can be quickly and efficiently ground, the efficiency and the effect of grinding the two end surfaces of each nut are improved, the labor intensity of workers is reduced, and great convenience is brought to nut machining.

Owner:海盐晋悦五金制品有限公司

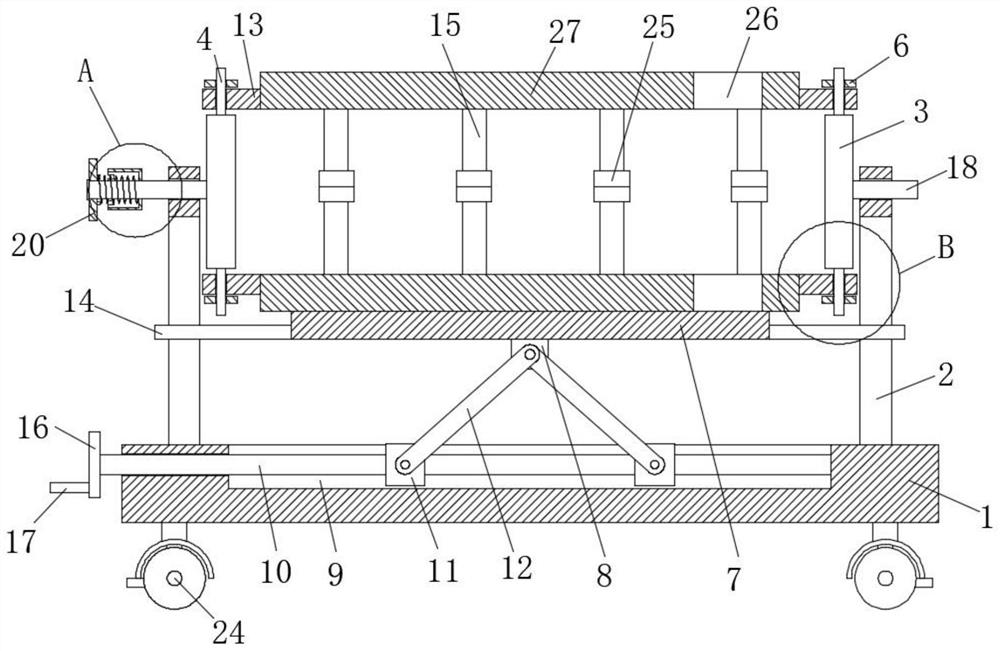

Teding and air drying device for rice

ActiveCN110906729ATurn over to achieveAvoid shellingDrying gas arrangementsDrying chambers/containersAnimal scienceEngineering

The invention discloses a tedding and air drying device for rice. The tedding and air drying device for rice includes a walking mechanism, a suction mechanism, a device main body, a front mounting plate and a rear mounting plate. The lower ends of the front mounting plate and the rear mounting plate are each provided with the walking mechanism. The rear end of the device main body is provided witha suction mechanism. The device main body includes a barrel, an air duct, a feed inlet, a discharge outlet and an electric heating piece. The middle part of the barrel is the air duct, and the air duct is S-shaped. The inner wall of the barrel is provided with a suction mechanism. The rice under the feed inlet is inhaled into the air duct through the suction mechanism, discharged from the discharge outlet through the air duct and returned to the ground. The tedding and air drying device for rice changes the traditional way of tedding, the tedding efficiency is high, the rice is avoided from peeling, and air drying can be accelerated in the tedding process.

Owner:安徽信福乡田生态农业有限公司

Suspension electromagnet turn over tool and turn over method

ActiveCN106080617BTurn over to achieveNo sheddingSliding/levitation railway systemsWork holdersElectromagnet

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Turning tool and turning method

Owner:WUHAN MARINE MACHINERY PLANT

Manufacturing Method of Large Prebaked Anode Electrolyzer Shell

ActiveCN108406152BImprove pass rateQuality improvementWelding apparatusMachining processWelding deformation

The invention relates to the technical field of large electrolytic cell machining, and provides a large prebaked anode electrolytic cell shell manufacturing method capable of effectively relieving thewelding deformation. The large prebaked anode electrolytic cell shell manufacturing method comprises the steps of: (A) material stock acceptance check; (B) end plate manufacturing; (C) side plate manufacturing; (D) base plate manufacturing; (E) delivery transportation; and (F) field assembly. Through control of the welding mode and the welding sequence, the influence by the welding deformation iseffectively reduced, the once pass percent in the electrolytic cell shell machining process is greatly increased, the construction period is shortened, and the quality of electrolytic cell shells isimproved.

Owner:云南建投机械制造安装工程有限公司

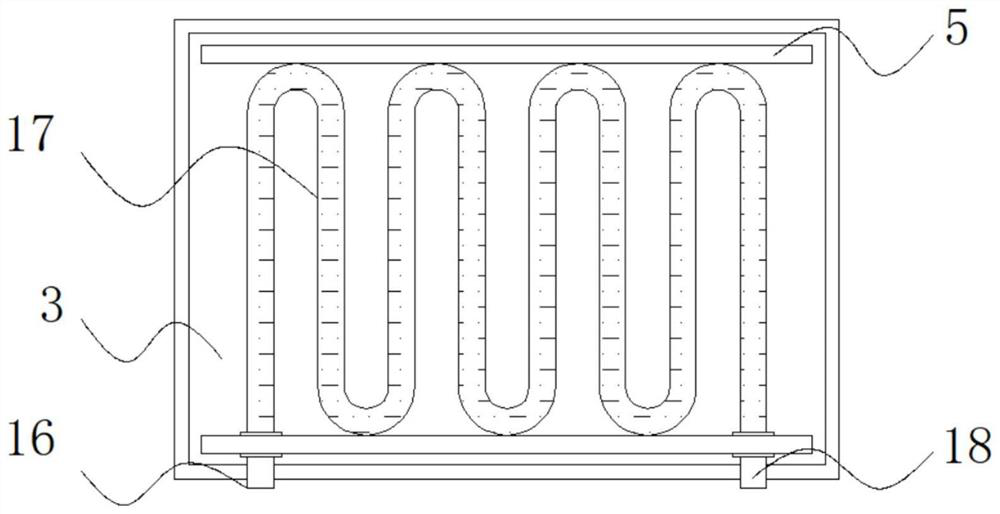

Packaging bag production and printing equipment

ActiveCN113370582ATurn over to achieveImprove production printing speedBag making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention discloses packaging bag production and printing equipment, and relates to the technical field of packaging bag processing. The packaging bag production and printing equipment comprises a processing flow table, one end of the processing flow table is rotatably provided with a plastic strip coil, one side of the top of the processing flow table is fixedly provided with a mounting plate, the top of the mounting plate is rotatably provided with a driving shaft, a rotating disc is arranged on the inner side of the mounting plate and fixedly connected with the driving shaft, a pushing protrusion is fixedly connected to the outer wall of the circumferential side of the rotating disc, and the diameter of the pushing protrusion is larger than that of the rotating disc. According to the packaging bag production and printing equipment, rotation of the rotating disc is utilized, the automatic interval feeding function of plastic belts is achieved through the pushing protrusion, a downward pressing processing table is driven to ascend and descend in an up-down mode, the functions of folding the plastic belts, bonding the edges of the plastic belts, printing the surfaces of packaging bags and the like are achieved, the processing functionality and practicability of the equipment are greatly improved, and the production and printing speed of the packaging bags is greatly increased.

Owner:南塑集团浙江包装有限公司

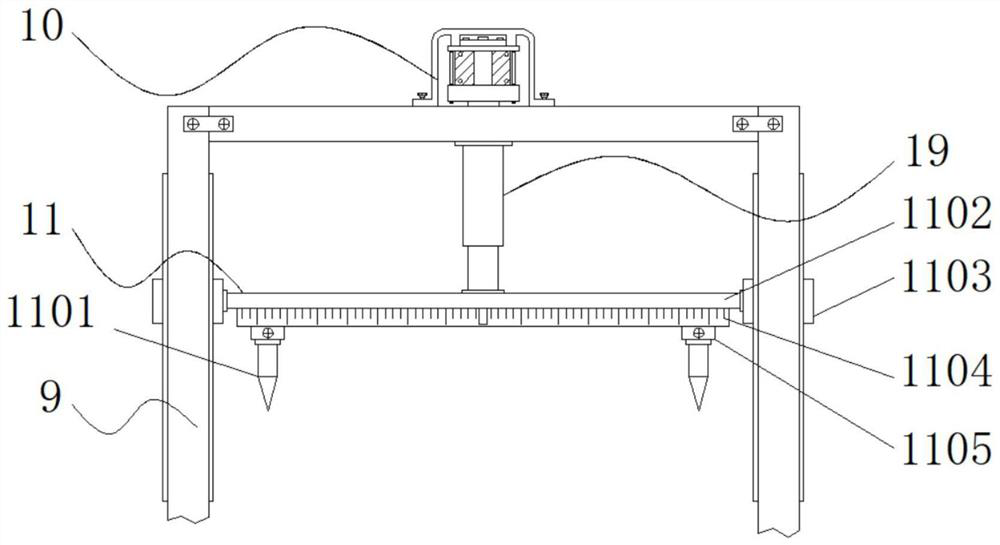

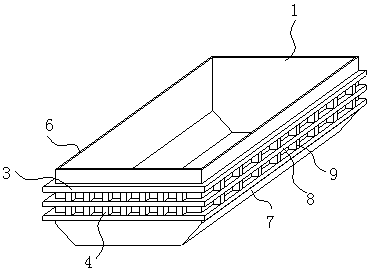

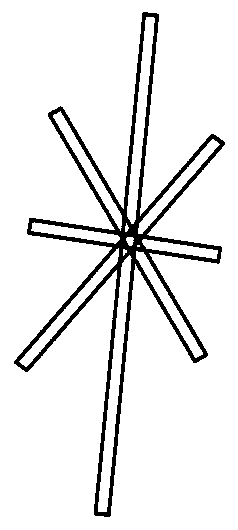

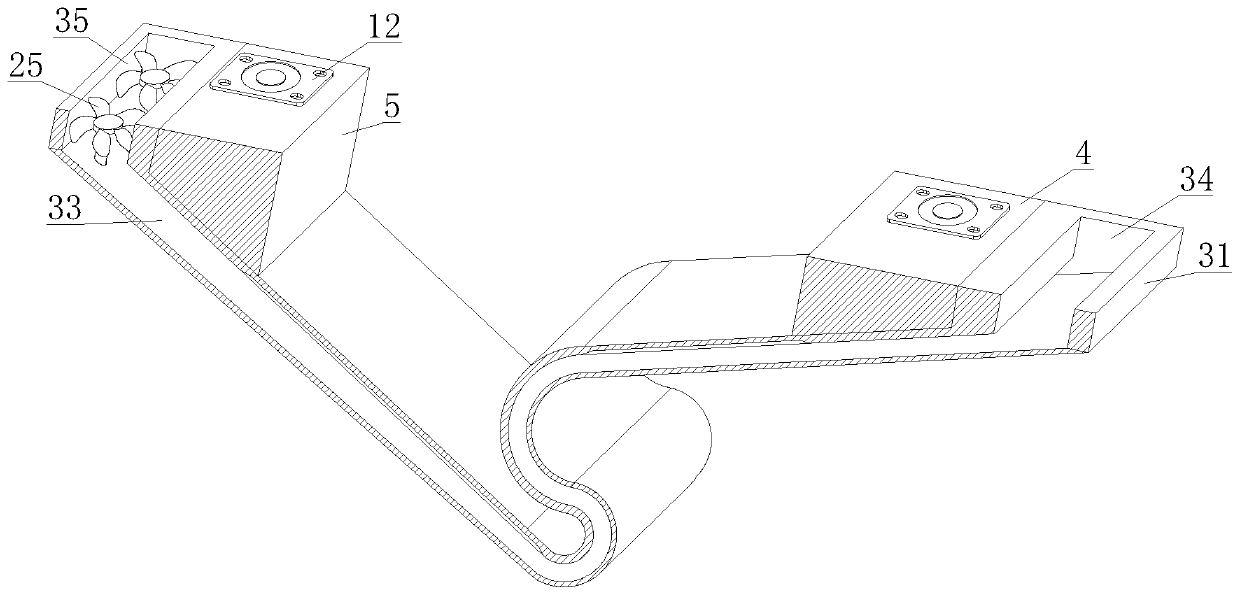

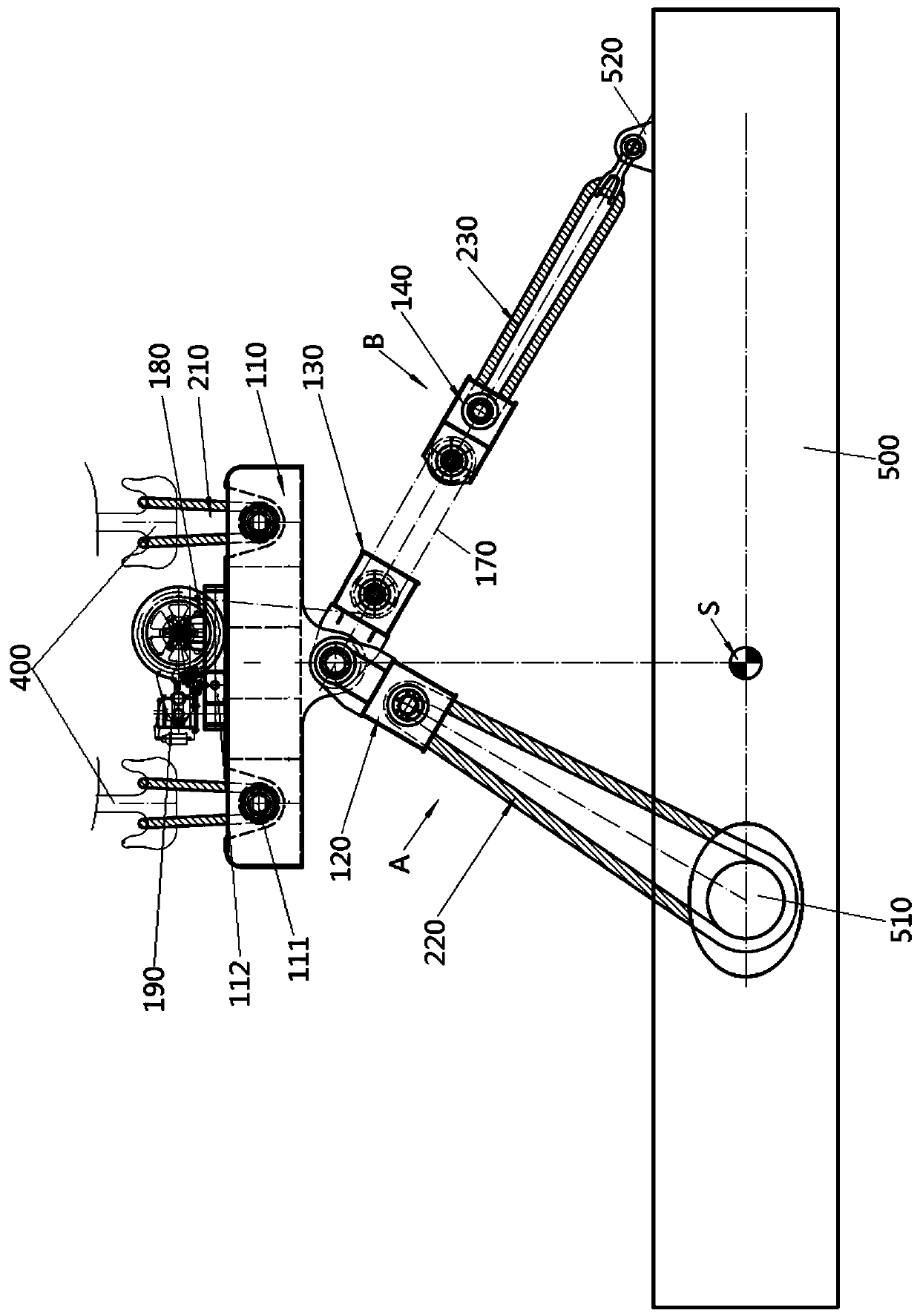

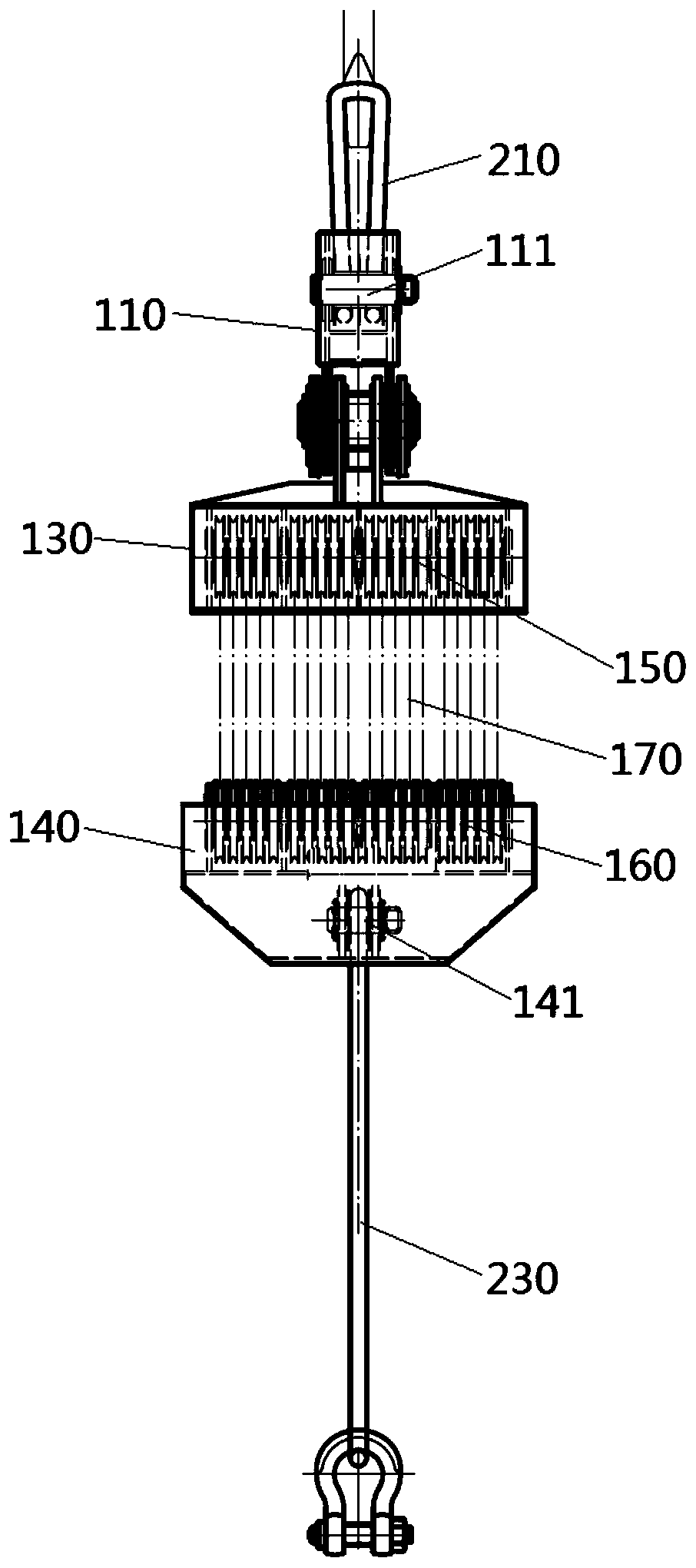

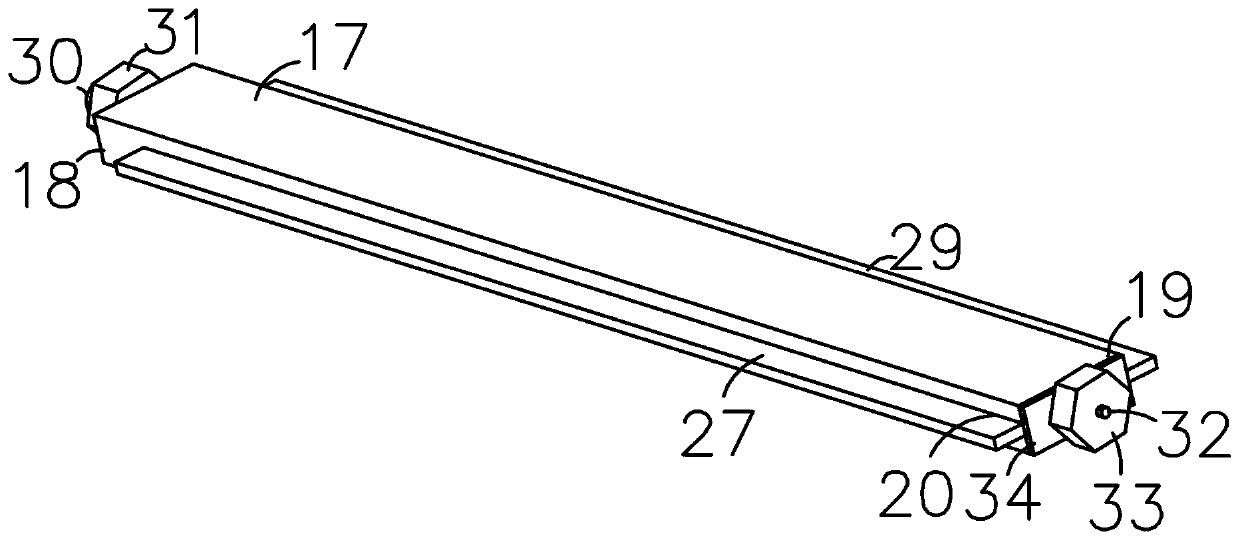

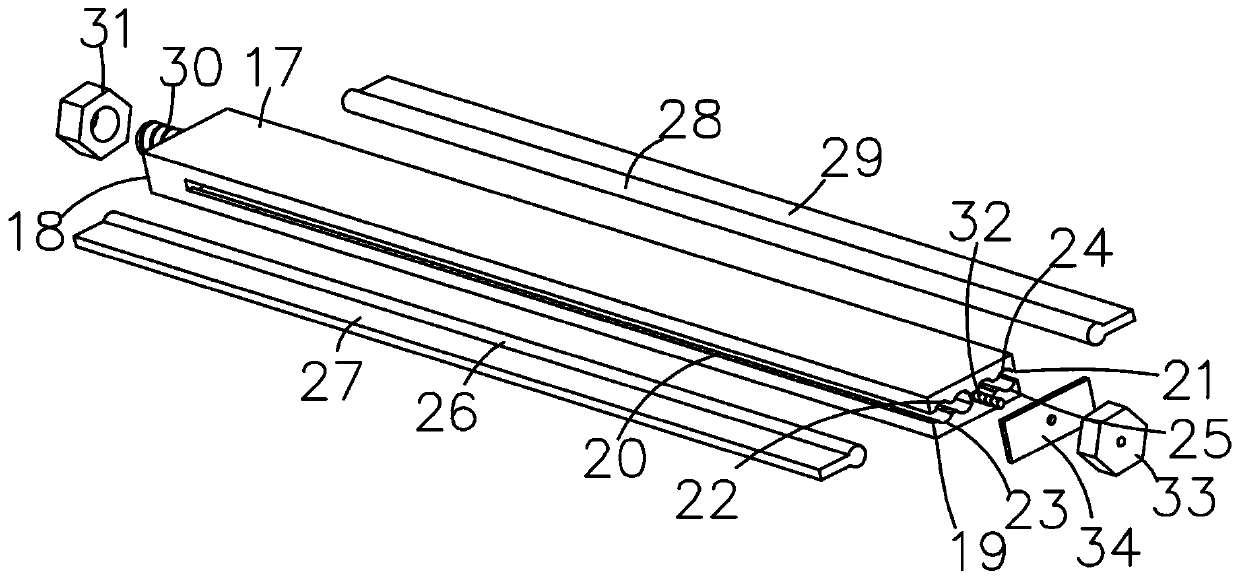

Turning tool and turning system with same

PendingCN111498675ATurn over to achieveEasy constructionLoad-engaging elementsStructural engineeringPipe

The invention discloses a turning tool and a turning system with the same. The turning tool is used for turning over a pipe pile and comprises a lifting beam, a first hanging beam, a second hanging beam and a third hanging beam; the second hanging beam is hinged with the lifting beam; the first hanging beam is hinged with the second hanging beam; and a telescopic structure is arranged between thesecond hanging beam and the third hanging beam. The turning tool further comprises a driving component; the driving component is used for driving the telescopic structure to move to drive the third hanging beam to rise or fall; the lifting beam is provided with at least one lifting point; the first hanging beam is provided with at least two first hanging points; and the third hanging beam is provided with at least one second hanging point. According to the structural design of the turning tool, the turning operation of the pipe pile from a horizontal posture to a vertical posture can be realized only by matching the turning tool with a hook part of hoisting equipment and the operation cost and operation time of pipe pile construction can be reduced.

Owner:HUADIAN HEAVY IND CO LTD

A functional fully formed knitted collar and preparation method thereof

Owner:DONGHUA UNIV

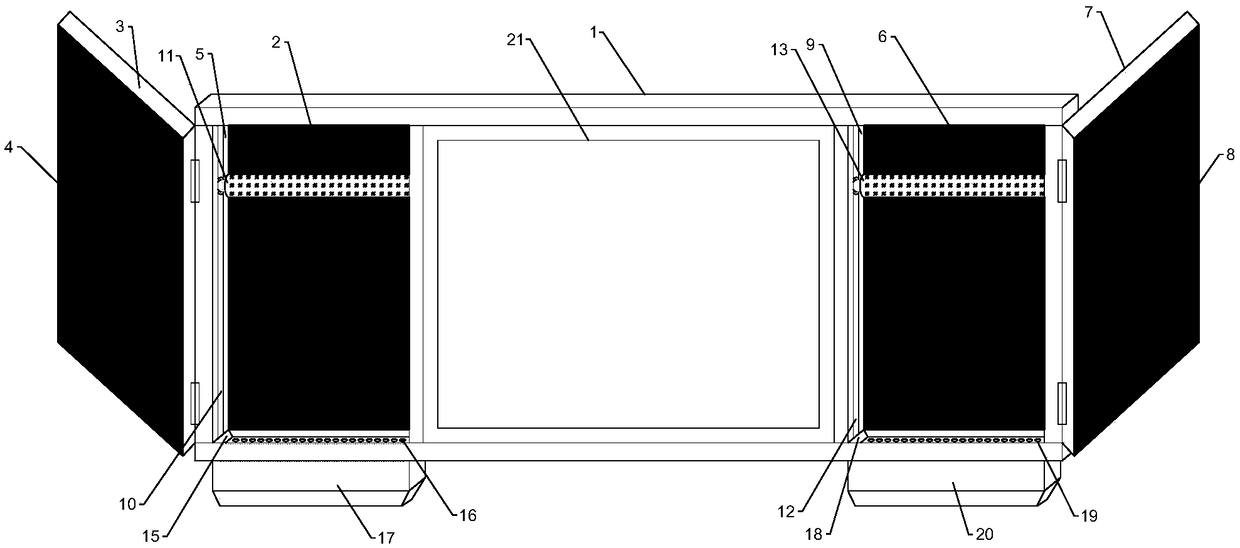

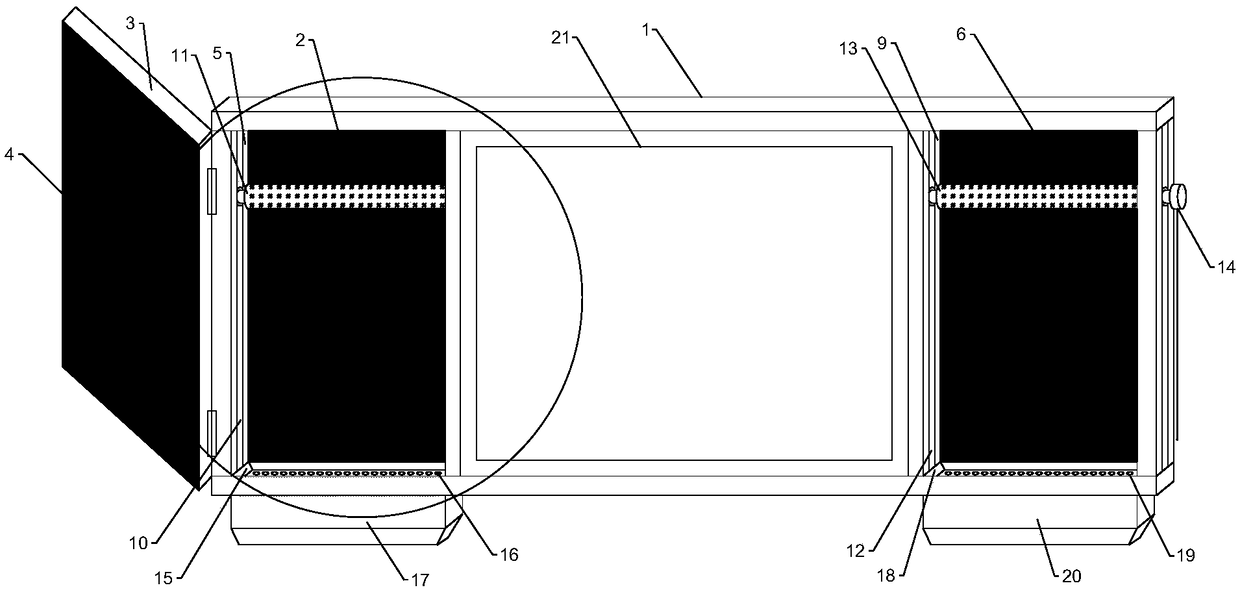

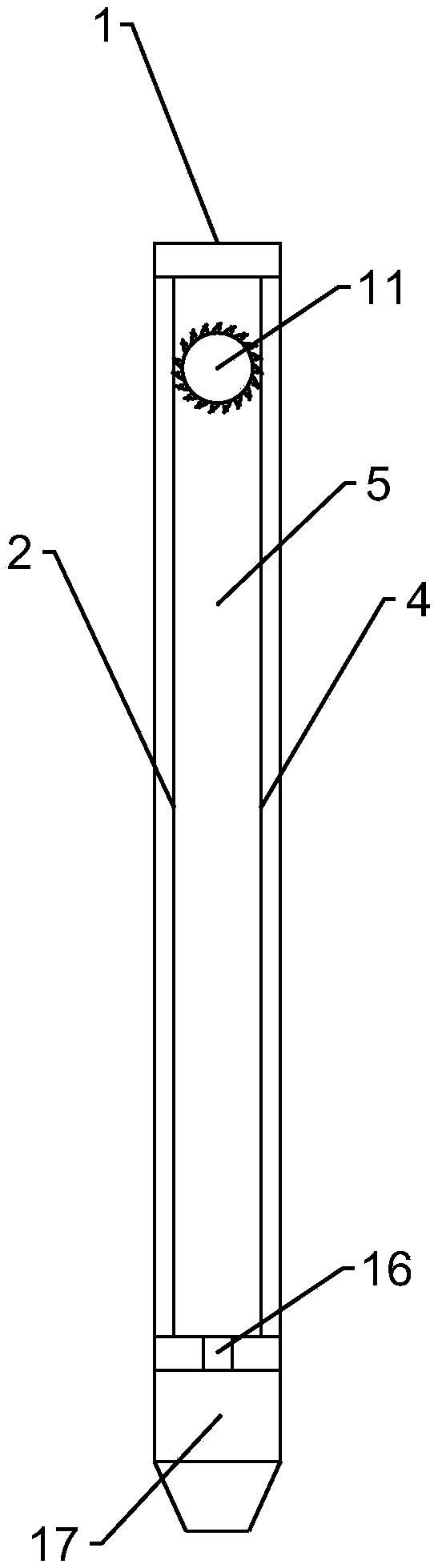

Turnover type dust isolation blackboard

PendingCN108859511ATurn over to achieveImprove erase efficiencyBoard cleaning devicesWriting boardsEngineering

Owner:贾石硕

A two-hook turning method for a steel pipe arch segment

ActiveCN109577208BTurn over to achieveImprove securityBridge erection/assemblyArch-type bridgeGravity centerIndustrial engineering

The invention discloses a two-hook turnover method for a steel tube arch section. The two-hook turnover method comprises the following steps: making a turnover area below a watering crane, processinga step type bearing table in the turnover area, and arranging a plurality of turnover bases on a step boundary of the step type bearing table towards the steel tube arch section; arranging two steel wire ropes on a single lifting point of the watering crane, and bundling the two steel wire ropes on two limb tubes of a chord tube; clearing and enabling a commander to enter a specified position; rising lifting hooks, lifting off the steel tube arch section, stopping lifting the hooks, enabling the commander to communicate with a driver of the watering crane, ensuring lifting weight of the two lifting hooks to be consistent, forwards moving a lifting beam crane according to the position of the gravity center of the steel tube arch section until the gravity center of the steel tube arch section reaches the position of the gravity center of the turnover base, enabling the two gravity centers to be balanced, forwards moving a watering crane beam crane, and enabling the steel tube arch section to get across a balance point of the two centers. The method can turn over the steel tube arch section by only needing two hooks, saves a set of lifting systems, greatly prolongs the service life ofthe watering crane, greatly increases a utilization rate of the watering crane, and increases a turnover safety coefficient of the steel tube arch section.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +3

A packaging bag production and printing equipment

ActiveCN113370582BTurn over to achieveImprove production printing speedBag making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention discloses a packaging bag production and printing equipment, which relates to the technical field of packaging bag processing. A mounting plate, the top of the mounting plate is rotatably installed with a driving shaft, the inner side of the mounting plate is provided with a turntable, the turntable is fixedly connected with the driving shaft, and the peripheral side outer wall of the turntable is fixedly connected with a push protrusion, so The diameter of the push protrusion is larger than the diameter of the turntable. The invention not only utilizes the rotation of the turntable to complete the automatic interval feeding function of the plastic belt by pushing the protrusions, but also drives the lower pressing processing table to move up and down, and also completes the folding of the plastic belt, as well as the edge bonding and packaging of the plastic belt. Bag surface printing and other functions greatly improve the functionality and practicability of equipment processing, and greatly improve the production and printing speed of packaging bags.

Owner:南塑集团浙江包装有限公司

A coil turning frame with a positioning control device

ActiveCN105931835BTurn over to achieveSimple structureInductances/transformers/magnets manufactureEngineeringPosition control

Owner:CHINA XD ELECTRIC CO LTD

Turning-over device for patients in neurology department

The present invention discloses a turning-over device for patients in the neurology department. 2 n-shaped frames are symmetrically and fixedly connected to a left side and a right side of an upper end face of a bottom plate, rotating disks are rotatably connected to opposite end faces of the two n-shaped frames, rotating devices are arranged on one sides of the rotating disks, threaded rods are symmetrically arranged on outer side walls of the rotating disks, placement bed plates are symmetrically arranged on upper sides and lower sides of the rotating disks, fixing blocks are symmetrically and fixedly connected to two sides of each placement bed plate, connecting holes are formed in the fixing blocks in a penetrating mode, when a patient needs to be turned over, the placement bed plate located on an upper side is assembled and fixed through nuts, so that the patient is located between the placement bed plates, the patient is prevented from falling off from the placement bed plate during overturning through fixing of connecting fixing belts, after the connecting fixing belts are mounted, a driving device enables an adjusting rod to rotate, the rotation of the adjusting rod cooperates with a sliding groove, so that a movable block can move in a same direction or an opposite direction.

Owner:张继红

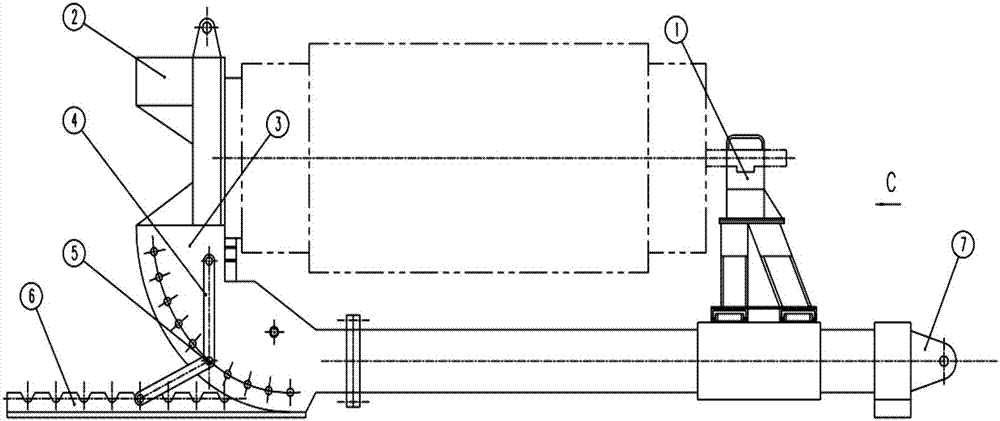

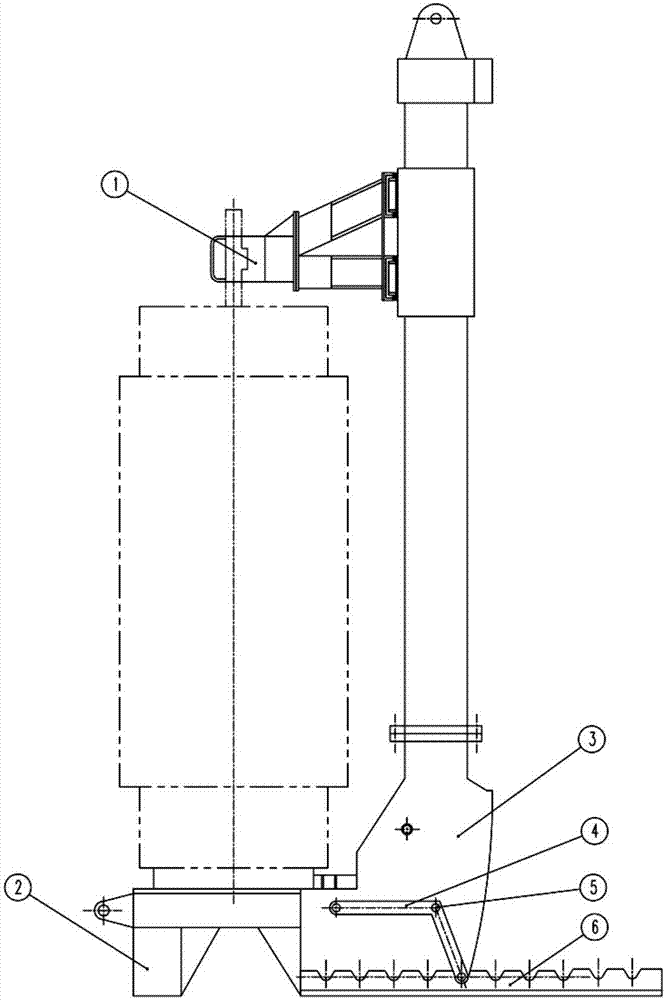

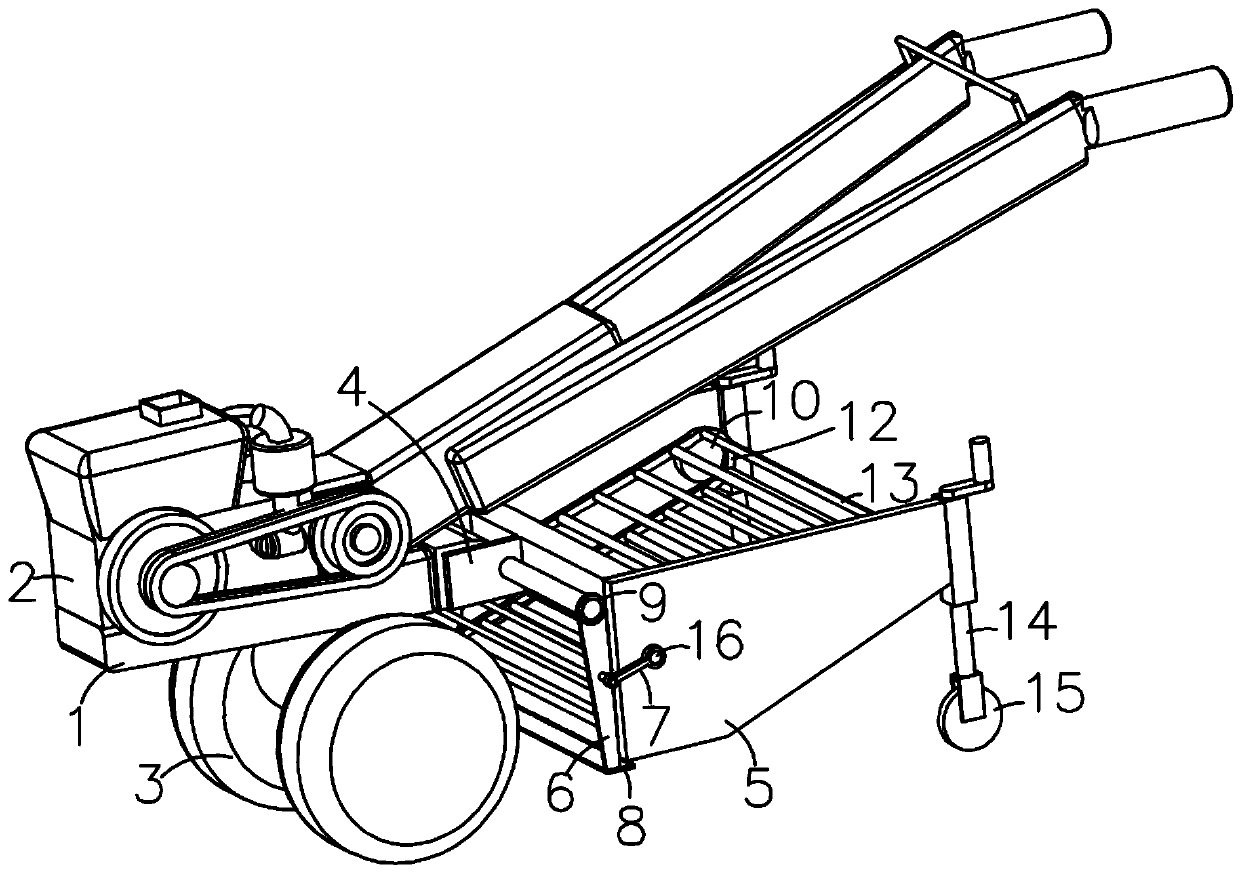

Harvesting device for tuberiferous plants and bulbiferous plants

PendingCN111567204ATurn over to achieveReduce labor burdenDiggersAgricultural scienceAgricultural engineering

The invention discloses a harvesting device for tuberiferous plants and bulbiferous plants. The harvesting device comprises a first rack, an engine, travelling wheels, a gear box and an overturning and digging device, wherein the overturning and digging device comprises a second rack, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a soil cutting shovel, a transmission shaft, a first eccentric wheel, a second eccentric wheel, a first transmission wheel, a second transmission wheel, a first chain wheel, a second chain wheel, a third chain wheel,a fourth chain wheel, a belt, a first chain, a second chain, a first rotary shaft, a second rotary shaft and a plurality of overturning and digging rods. Due to a linkage relationship, the soil cutting shovel and the plurality of overturning and digging rods move. Compared with the prior art, the harvesting device has good working independence, and therefore, harvesting efficiency is high.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE

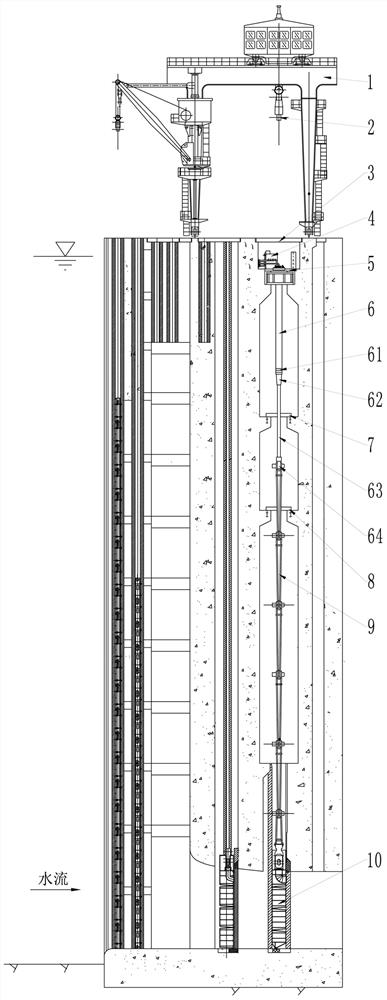

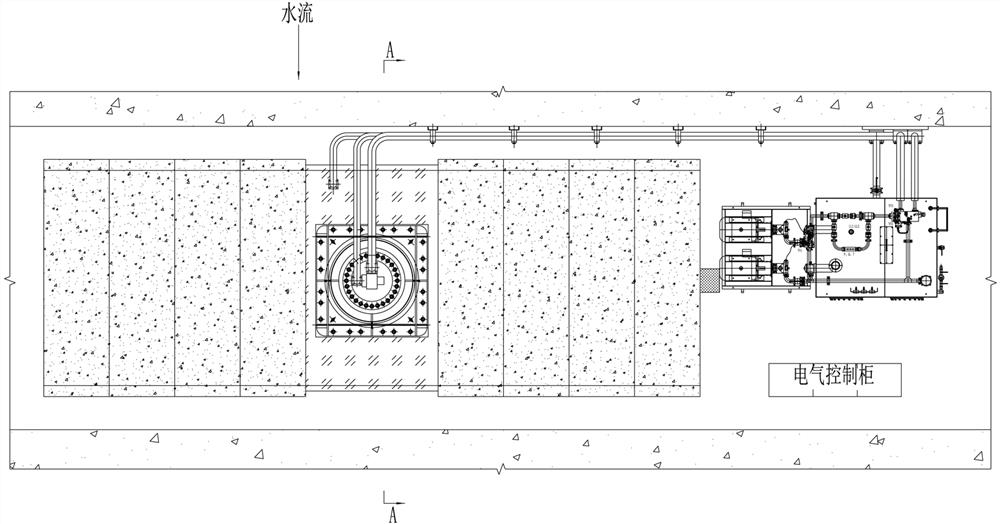

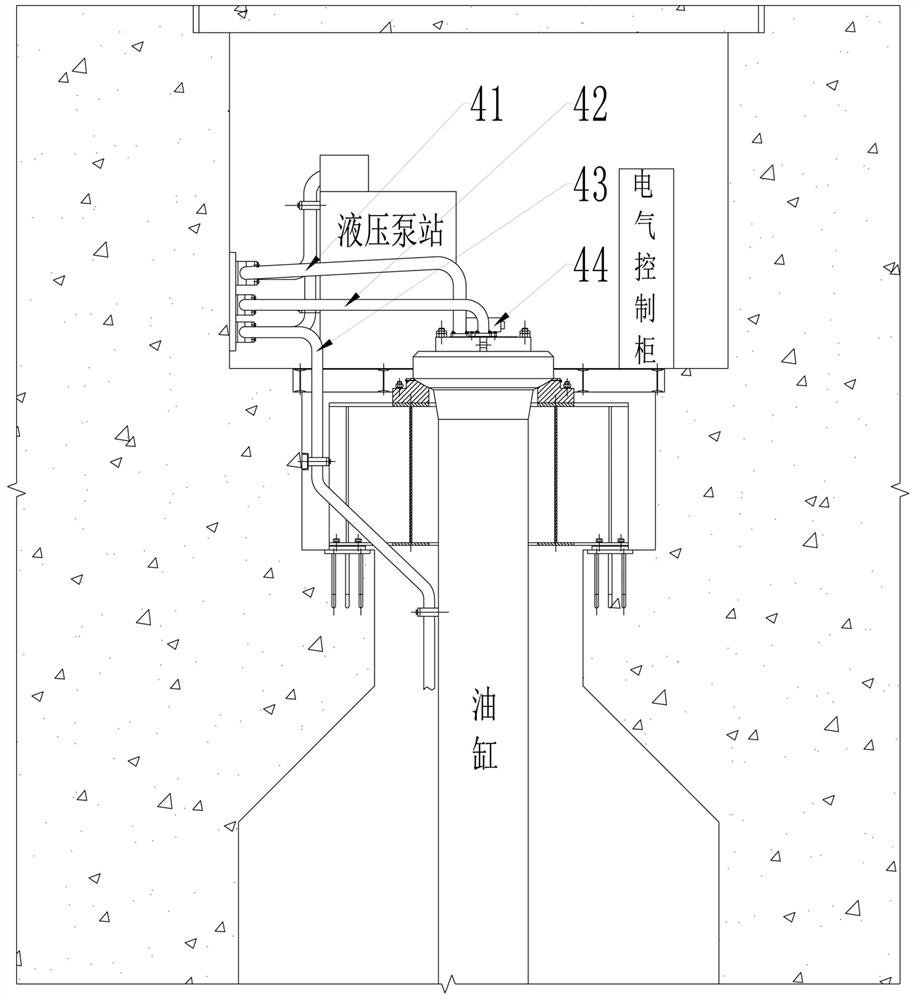

On-site dismantling and assembling method of large oil tank of fast gate for water inlet accident of high water head power station

ActiveCN113463583BEasy to controlEasy to crossWater-power plantsHydro energy generationPower stationMechanics

A method for on-site dismantling and assembling of a large-scale oil cylinder for an accident rapid gate of a water inlet of a high-water-head power station. The oil cylinder is hoisted out from the gate opening, turned over and laid flat on the dam surface, and the dismantling of the large-scale oil cylinder for an accident rapid gate is completed in a safe, efficient, and economical manner. The installation process overcomes the long maintenance period, heavy workload, difficult operation and high safety risks of disassembling and assembling large oil tanks in high water head power stations. The hose is convenient for the subsequent control of the cylinder piston rod and the lifting of the cylinder through the center hole of the cylinder support frame; before and after lifting, the lifting head is retracted and fixed to ensure the safe lifting of the cylinder. During the lifting process, the cylinder piston rod will not slide due to its own weight. Improve safety; use the turning tool to connect the upper end surface of the oil cylinder and the lifting lug, and cooperate with the door machine and the steam crane to realize the turning; adopt the method of quickly closing the gate to the fully closed position, and replace the oil pipe when the oil in the rod cavity of the oil cylinder is at least.

Owner:CHINA YANGTZE POWER

Blank steaming device for edible vegetable oil processing and using method thereof

InactiveCN112226277AImprove steaming efficiencySteam embryo evenlyFatty-oils/fats productionEngineeringSlide plate

The invention discloses a blank steaming device for edible vegetable oil processing and a using method thereof. The blank steaming device comprises a blank steaming box, a water tank is fixedly arranged on the inner wall of the bottom of the blank steaming box, a heating pipe is fixedly installed on the inner wall of the water tank, the inner walls of the two sides of the blank steaming box are slidably connected with the same U-shaped sliding plate, the inner walls of the two sides of the U-shaped sliding plate are detachably connected with the same frame in a sliding mode, the inner wall ofthe frame is fixedly connected with gauze, and the blank steaming box is provided with a power assembly for driving the U-shaped sliding plate to slide. Seeds are turned over through a rotating material turning roller, stacked plant seeds are evenly steamed, the ideal effect of steaming the seeds is achieved, the oil yield and the oil quality of the seeds are improved, the problem that operation is tedious in the aspect of seed taking and placing is well solved, the time for taking and placing the seeds is saved, the blank steaming efficiency is improved to a certain extent, and the workload of workers is reduced.

Owner:湖南谨航科技开发有限公司

A trademark cutting and folding device

ActiveCN104355168BTurn over to achieveSimple structureOverturning articlesFolding thin materialsTrademarkEngineering

The invention discloses a label tailoring and folding device. The label tailoring and folding device comprises a label shearing device, a folding mechanism and a clamping turnover mechanism, wherein the folding mechanism is positioned in the discharge direction of the label shearing device; the folding mechanism comprises a first cylinder, a bracket, a supporting plate, a first motor and a ram; the supporting plate is arranged on the bracket; the ram driven by the first motor is arranged on the upper side of the supporting plate; a cam connected with the ram is arranged on a rotating shaft of the first motor; the ram takes the rotating shaft of the first motor as a central spindle to reciprocate on the upper side and the lower side of the supporting plate; the clamping turnover mechanism is arranged on the other side of the folding mechanism and comprises a pair of clamping plates, a second cylinder, a turnover seat, a second motor and a sliding rail seat; the pair of clamping plates clamp oppositely and are arranged at the equal height of the supporting plate; the second cylinder is fixed on the lower side of the pair of clamping plates and pushes the pair of clamping plates to move in the label conveying direction; the turnover seat is connected with the pair of clamping plates to drive the pair of clamping plates to turn over from the horizontal direction to the vertical direction; the turnover seat is driven by the second motor.

Owner:SUZHOU TRANSPARENT TECH CO LTD

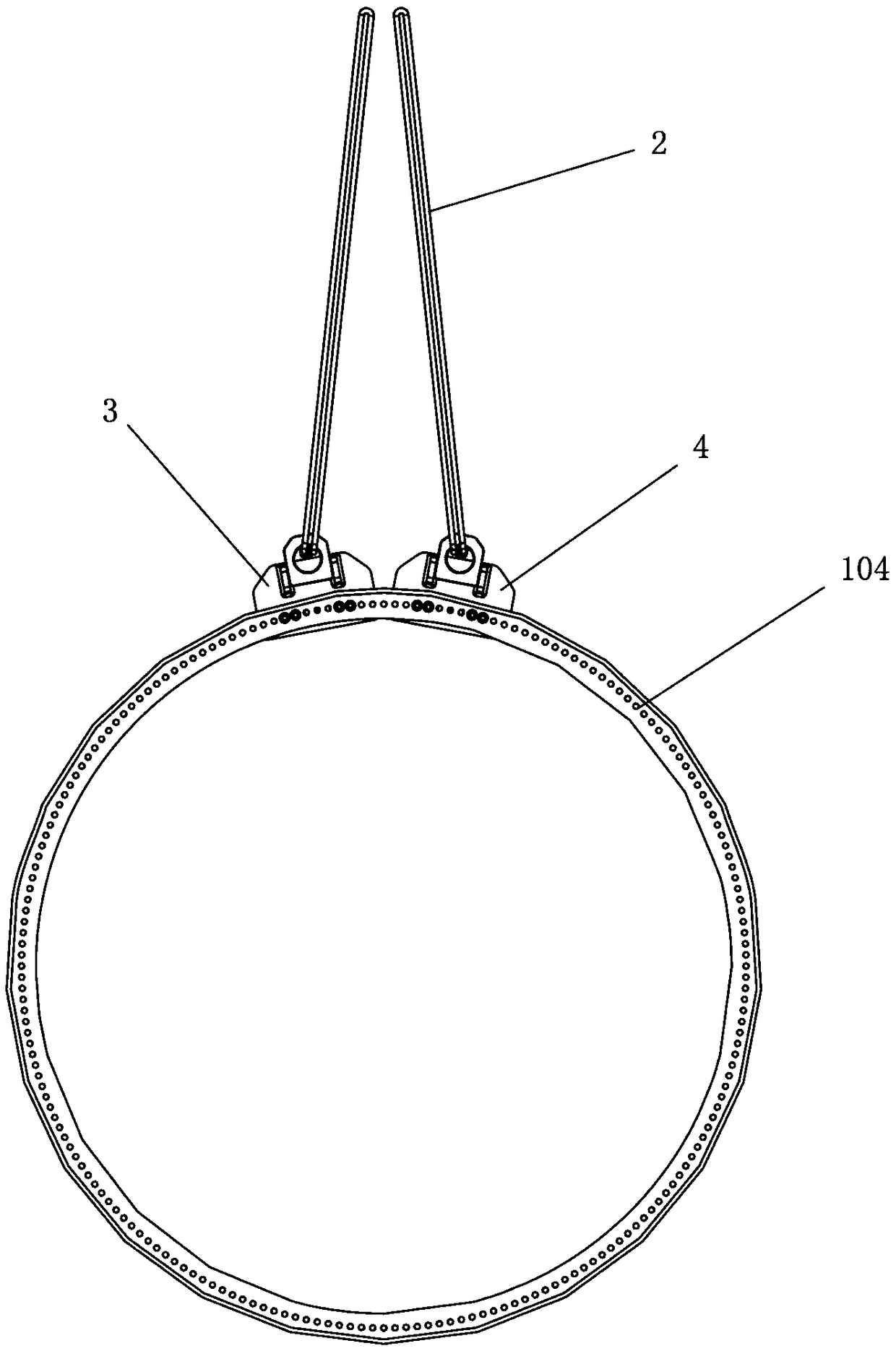

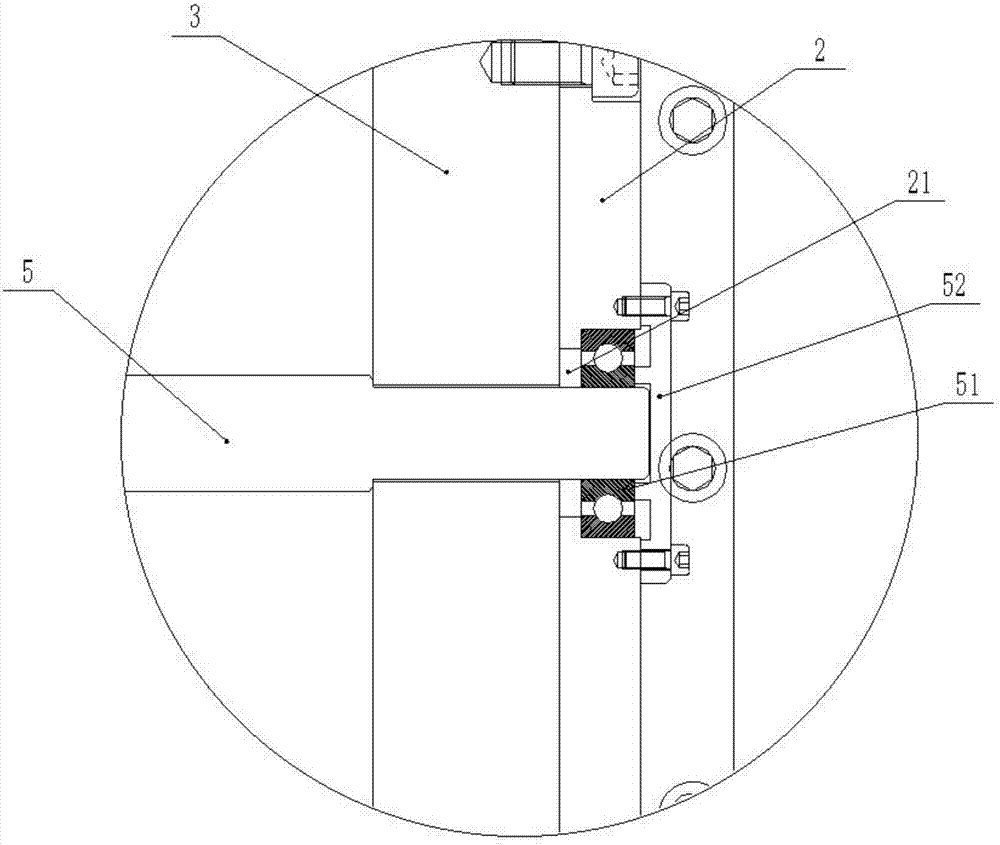

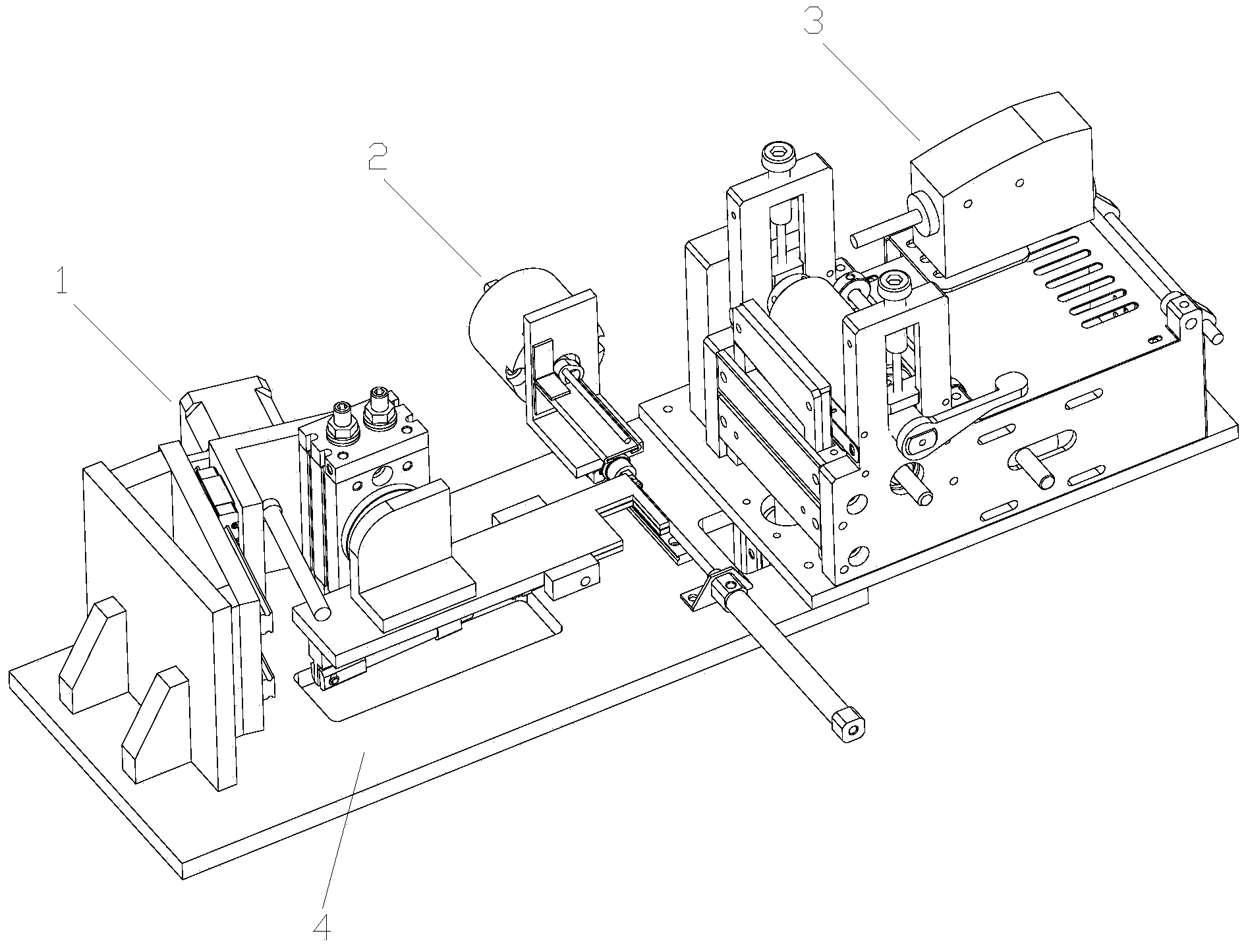

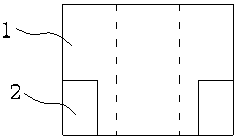

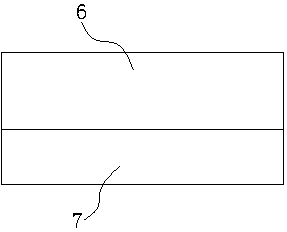

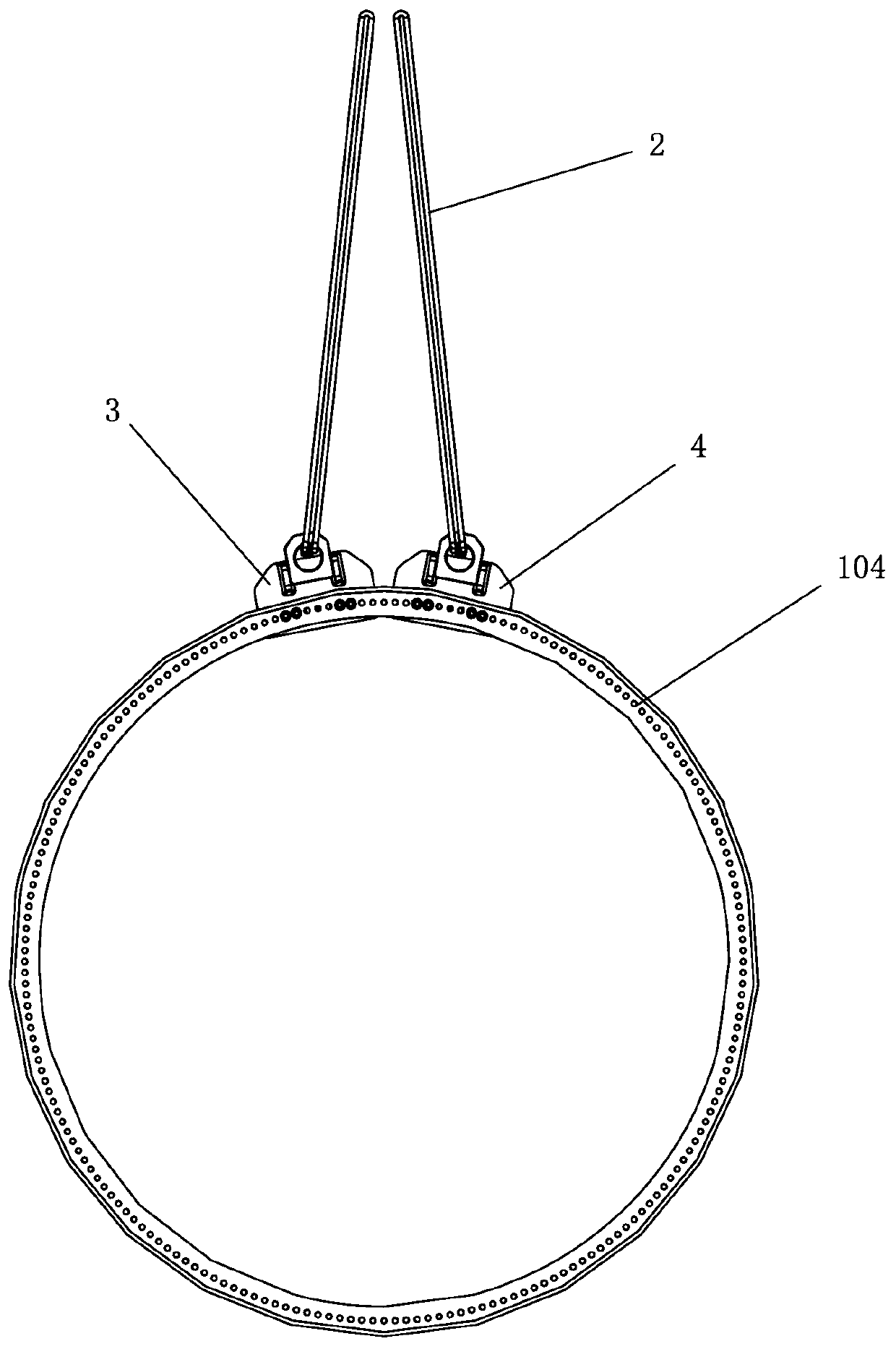

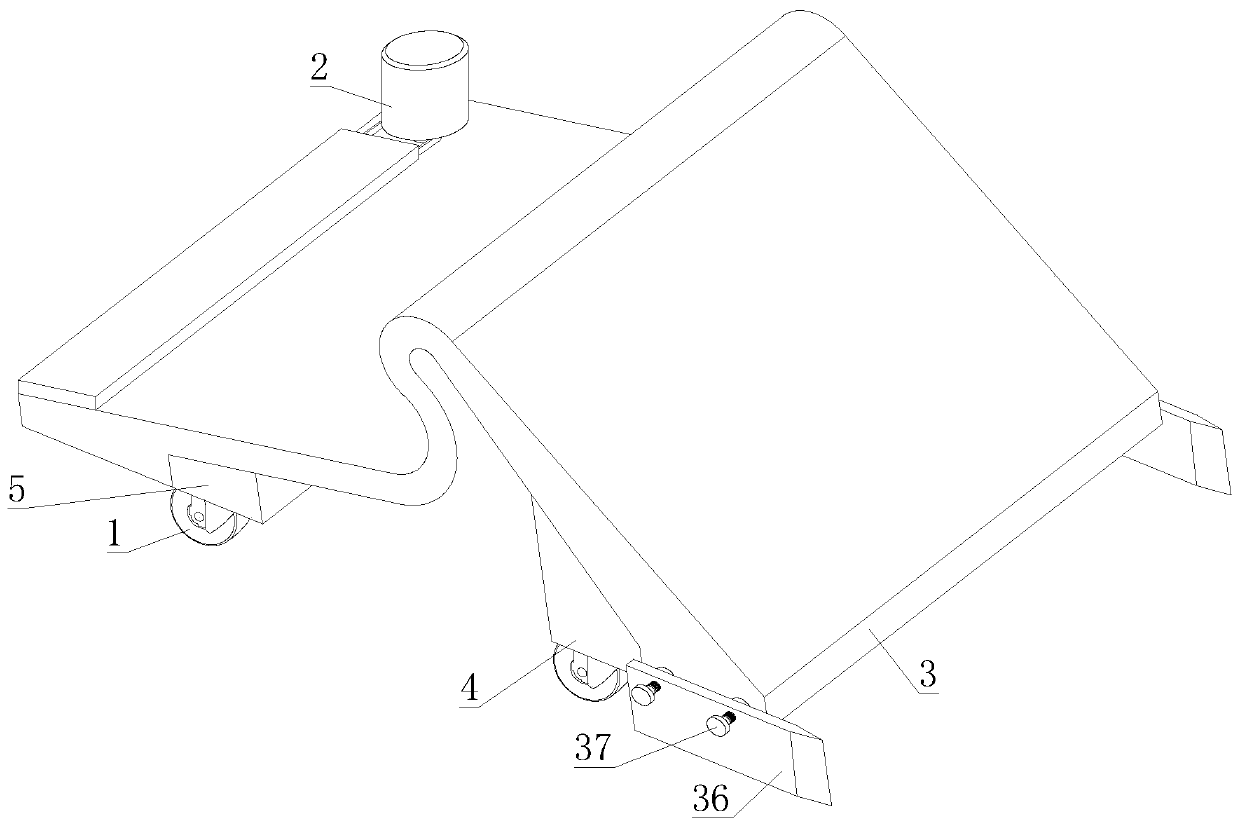

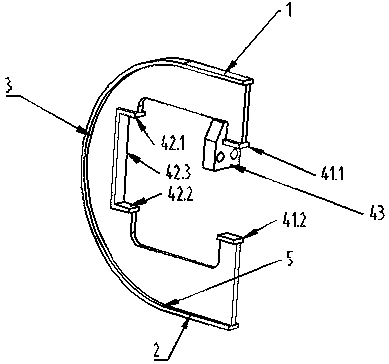

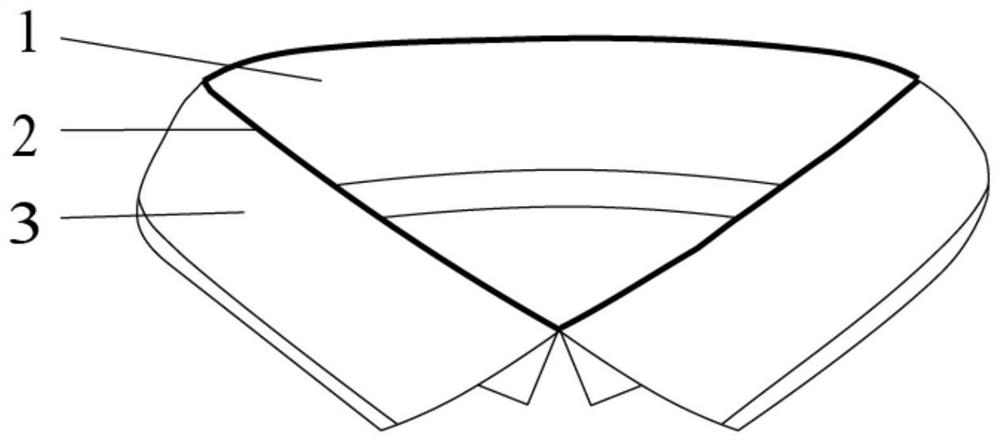

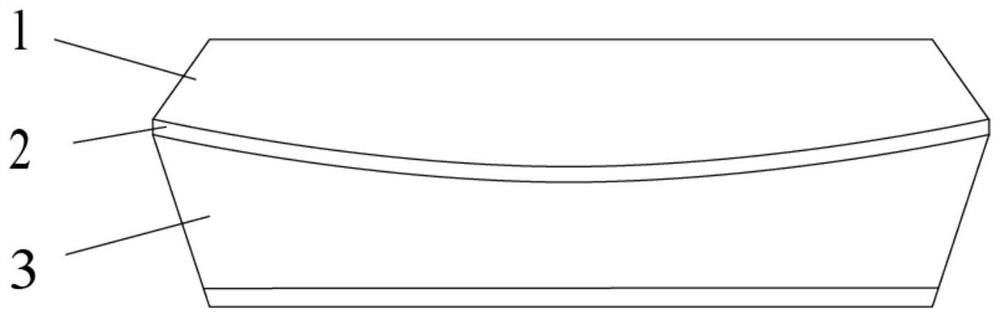

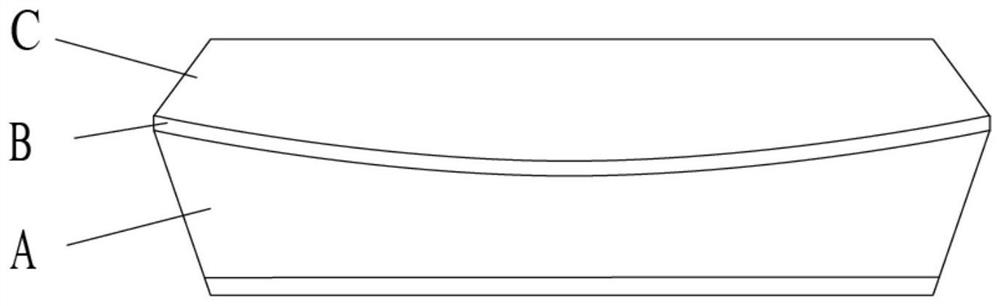

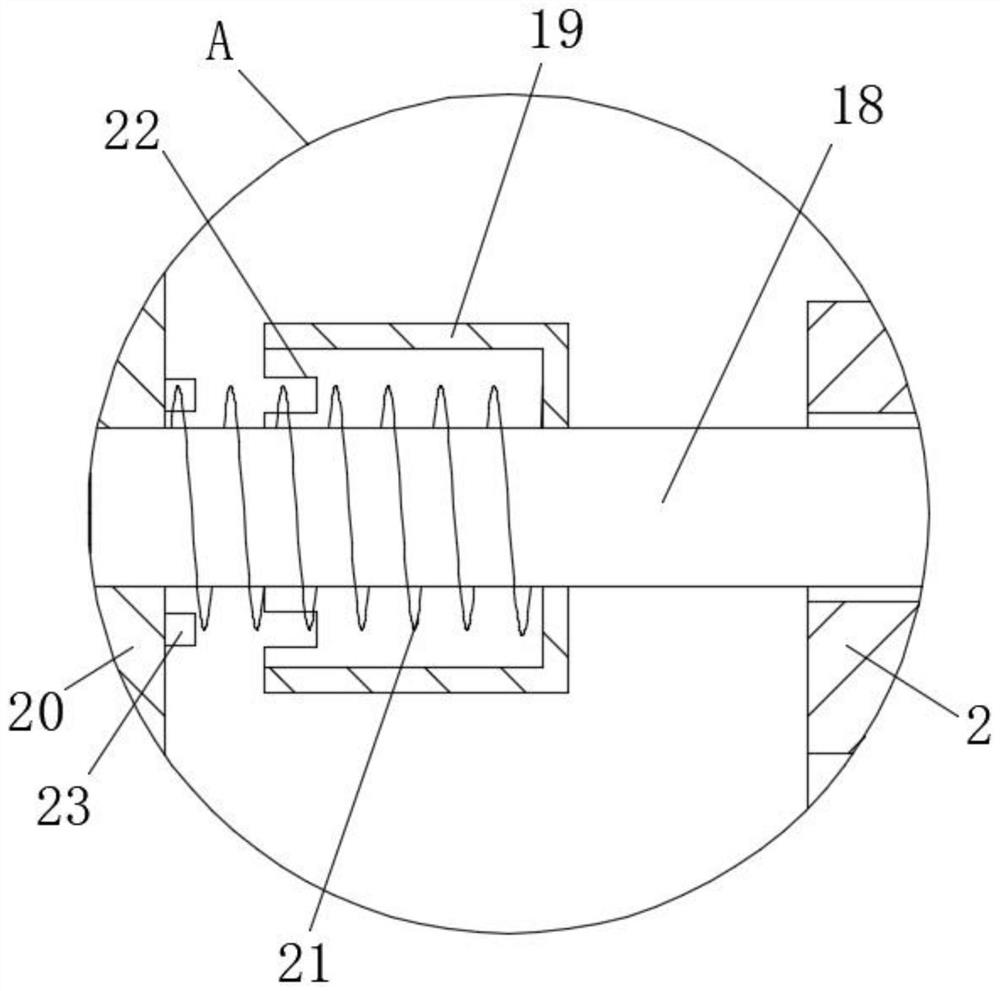

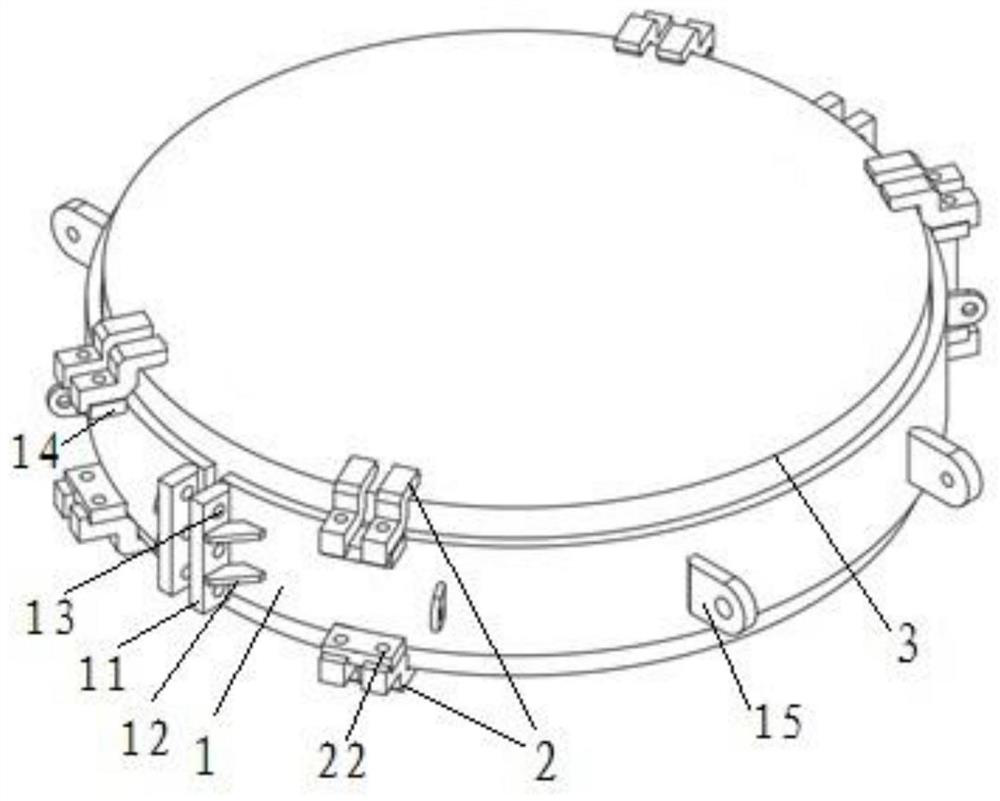

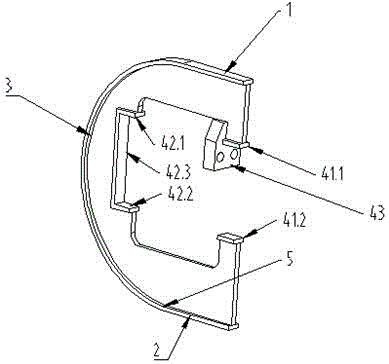

Steam generator tube plate overturning device and method

The invention relates to a steam generator tube plate overturning device and a method. The overturning device comprises a fixing ring (1) and a pressing plate (2), the fixing ring (1) is of an arc structure, fixing plates (11) are arranged at the two ends of the arc, and the fixing ring (1) and a tube plate (3) are fixedly connected into a whole through the pressing plate (2). The overturning device provided by the invention is ingenious in design, high in practicability, easy to manufacture and low in cost, assembly positioning can be effectively achieved through mechanical connection of the overturning device and a product, and the problem of tube plate hoisting and transferring due to the fact that a hoisting hoisting point capable of being directly used is not arranged on a body is solved.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

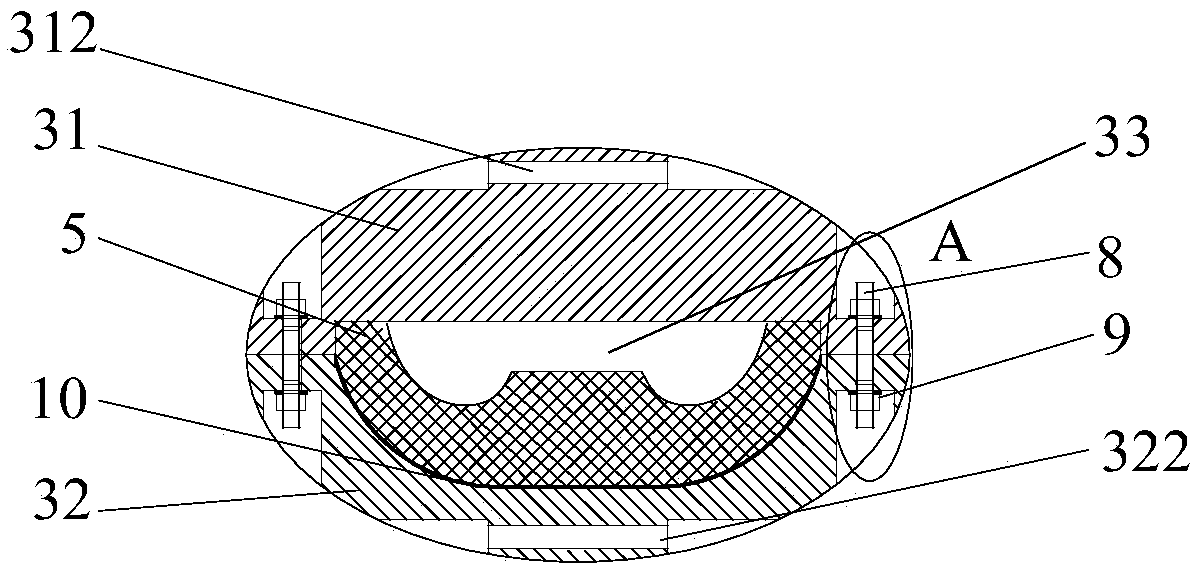

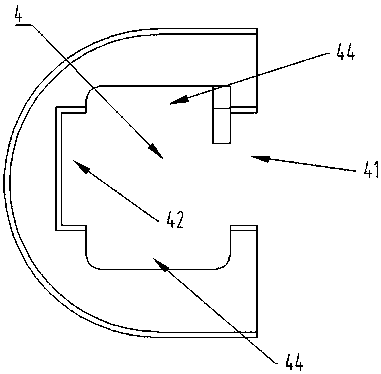

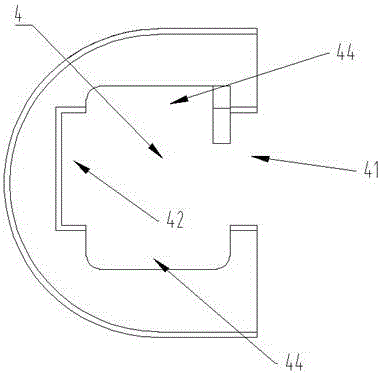

Overturning tool for suspended electric magnet and overturning method

ActiveCN106080617ANo sheddingTurn over with high safety performanceSliding/levitation railway systemsWork holdersEngineeringElectromagnet

An overturning tool for a suspended electric magnet is shaped like a C-shaped flat plate and comprises a top face, a bottom face, a semi-circular arc face and an opened part. The tool is characterized in that the top face and the bottom face of the overturning tool are vertically aligned horizontal faces; the top face and the bottom face are connected by the arc face; the top face and the bottom face are tangent to two ends of the arc face respectively; the opened part sleeves the electric magnet in the width direction of the electric magnet; an inner polar plate of the electric magnet is positioned at an opened end of the opened part; and an outer polar plate of the electric magnet is positioned at an inner end of the opened part. The overturning tool for the suspended electric magnet provided by the invention has the advantages that the suspended magnet can be overturned safely and easily, and coils are not damaged at the same time. The invention also provides an overturning method for the suspended electric magnet.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com