Dehumidification processing equipment for biodegradable high-barrier plastic film material

A plastic film and biodegradation technology, applied in the field of plastic film processing, can solve problems such as affecting processing, and achieve the effects of reducing waste, rapid cooling, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

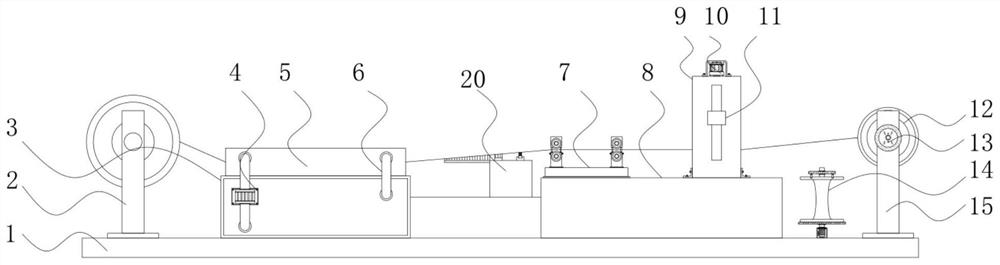

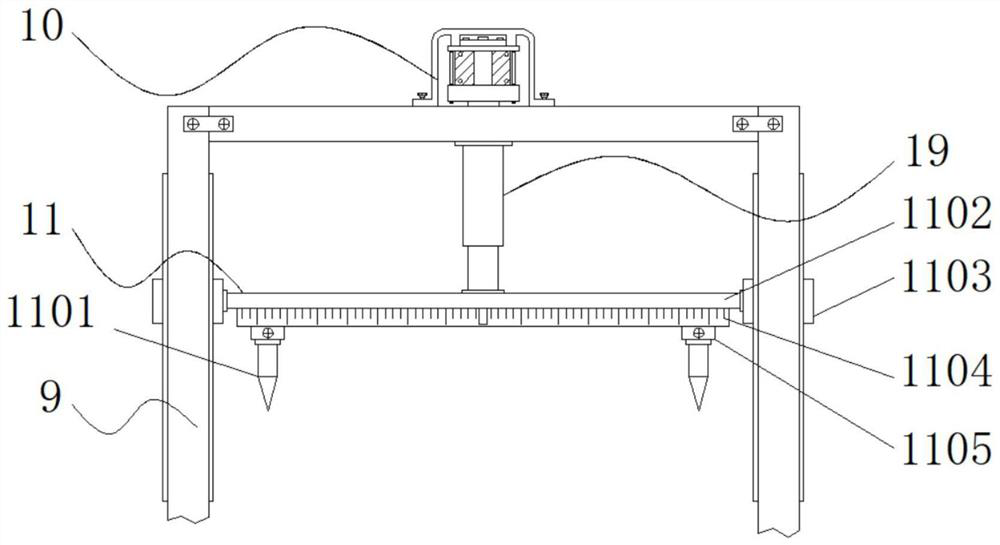

[0041] Example 1: See Figure 1-9 , a biodegradable high-barrier plastic film material dehumidification processing equipment, including a base 1 and a feeding roller 2, one side of the top of the base 1 is fixedly connected to the feeding roller 2, the top of the base 1 is fixedly connected to a workbench 8, and the top of the workbench 8 One side of the base 1 is fixedly connected with a blanking structure 7, the other side of the top of the base 1 is fixedly connected with a cover plate 9, and the top of the cover plate 9 is fixedly connected with a cylinder 10, the type of the cylinder 10 is SC, and the output end of the cylinder 10 is fixed A telescopic rod 19 is connected, the bottom end of the telescopic rod 19 is fixedly connected with a trimming structure 11, one side of the workbench 8 is provided with a recovery mechanism 14, and the other side of the top of the base 1 is fixedly connected with two sets of support rods 15, the support rods One end of 15 is fixedly co...

Embodiment 2

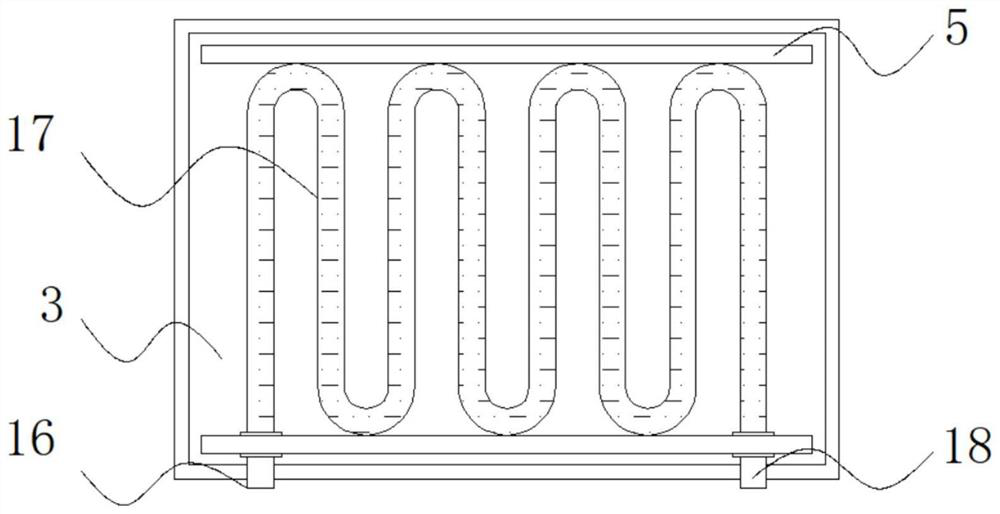

[0044] Embodiment 2: The cooling mechanism includes a cooling box 3, the cooling box 3 is fixedly connected to the top of the base 1, one end of the cooling box 3 is fixedly connected to a water pump 4, the model of the water pump 4 is W36, and the top of the cooling box 3 is fixedly connected to two Set of fixed plates 5, fixedly connected with cooling pipe 17 between the fixed plates 5, one side of one end of cooling pipe 17 is provided with water inlet 16, the other side of one end of cooling pipe 17 is provided with water outlet 18, and one end of water outlet 18 is fixed Connected with a water delivery pipe 6;

[0045] The output end of the water pump 4 is fixedly connected to one end of the water inlet 16, the input end of the water pump 4 is fixedly connected to one end of the cooling box 3, and one end of the water outlet 18 is fixedly connected to one end of the cooling box 3;

[0046] Specifically, such as figure 1 , figure 2 and Figure 4 As shown, the plastic f...

Embodiment 3

[0047] Embodiment 3: The blank-holding structure 7 is composed of a base plate 701, a first fixed rod 702, an adjustment rod 703, a second fixed rod 704, a pressure wheel 705 and an adjustment bolt 706. The base plate 701 is fixedly connected to the two ends of the top of the workbench 8, Both sides of the top of the bottom plate 701 are fixedly connected with two groups of first fixed rods 702, the top of the first fixed rods 702 is provided with a second fixed rod 704, and two groups of adjustment rods are arranged between the first fixed rods 702 and the second fixed rods 704. One end of the rod 703, the first fixed rod 702 and the second fixed rod 704 are fixedly connected with a pressure wheel 705, and one side of the adjusting rod 703 is provided with an adjusting bolt 706;

[0048] The bottom plate 701 is provided with two groups and is symmetrically distributed with respect to the vertical center line of the workbench 8, and one side of the adjusting bolt 706 runs throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com