Manufacturing Method of Large Prebaked Anode Electrolyzer Shell

A prebaked anode and electrolytic cell technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of inconvenient use, unfavorable production and processing of electrolytic cell shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

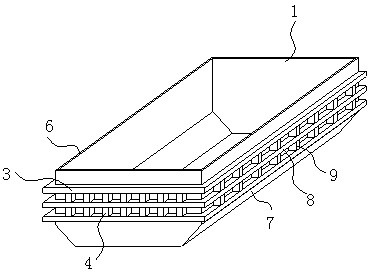

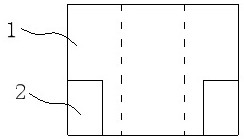

[0036] combine Figure 1-12 The manufacturing method of the large-scale prebaked anode electrolyzer shell comprises the following steps:

[0037] A. Material purchase acceptance; the materials used for the tank shell must meet the requirements of the design drawings and technical regulations. The purchased materials must have a material certificate, and all technical indicators must meet the corresponding national standards. Retest the chemical composition and mechanical properties of suspected materials, and those that do not meet the requirements must not be put into use. Check the appearance of the material before use, and those with defects such as cracks, shrinkage cavities, air bubbles, slag inclusions, and wrinkled skin must not be put into use. The material needs to be corrected when the following conditions exist: when the unevenness of the strip material is ≥ 1 / 1000, and the undulation of the profile is ≥ 1 / 1000. At the same time, in the whole process of making the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com