Turning tool and turning system with same

A technology for turning over workers and tooling, applied in the field of turning systems, can solve the problems of long construction time, high requirements, and shortage of floating crane resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] For ease of understanding and brevity of description, the turning tool and the turning system with the turning tool will be described below, and the beneficial effects will not be discussed again.

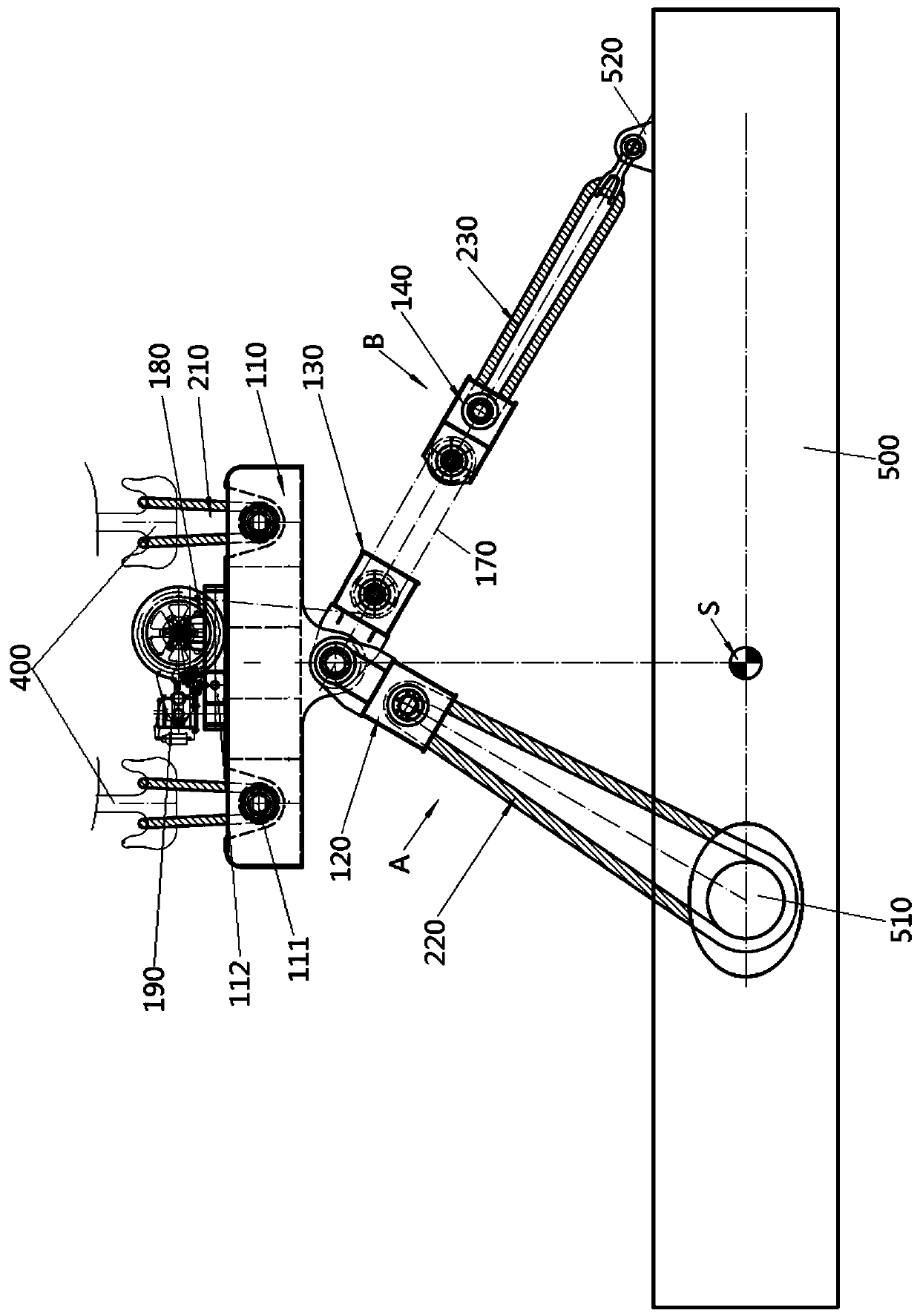

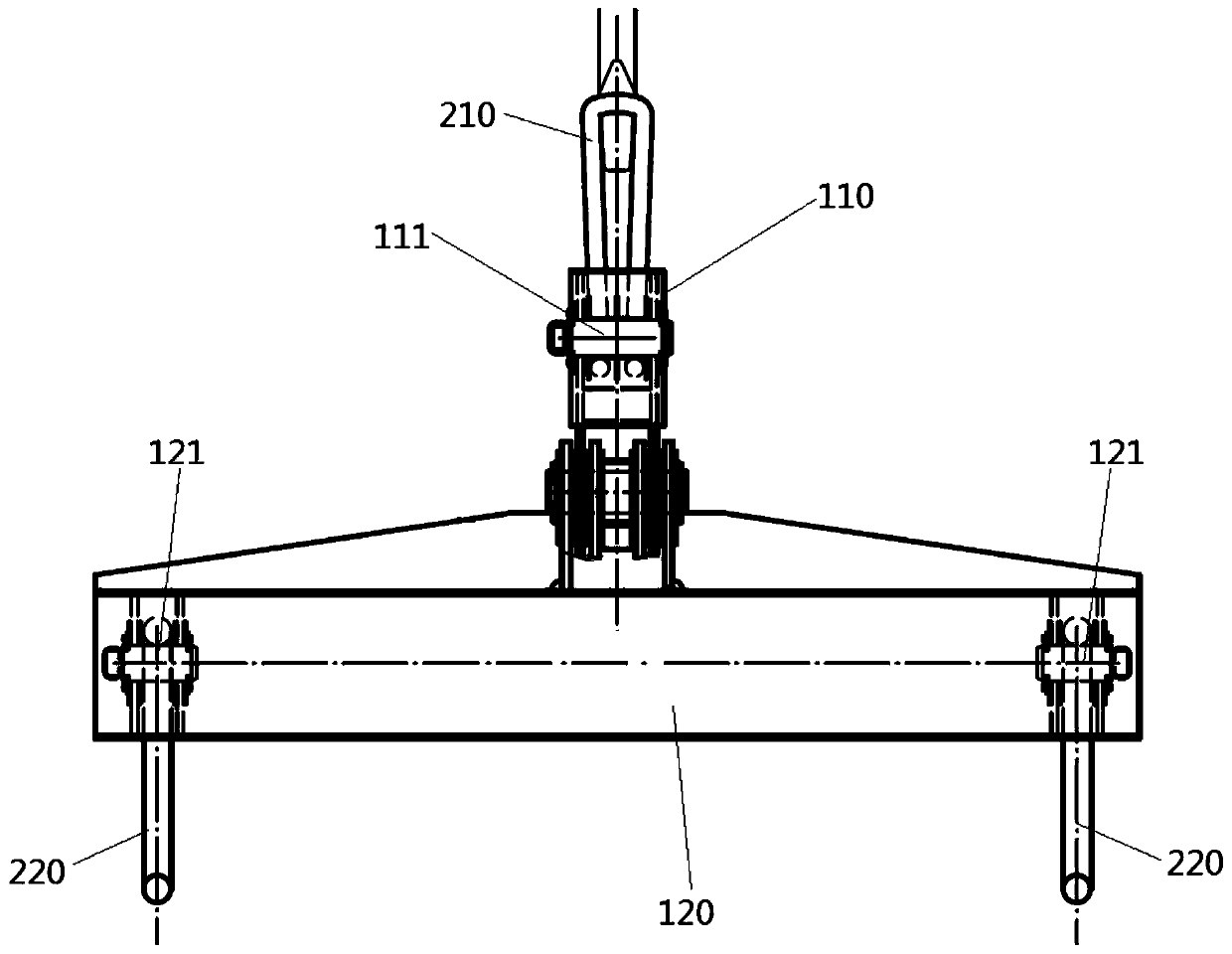

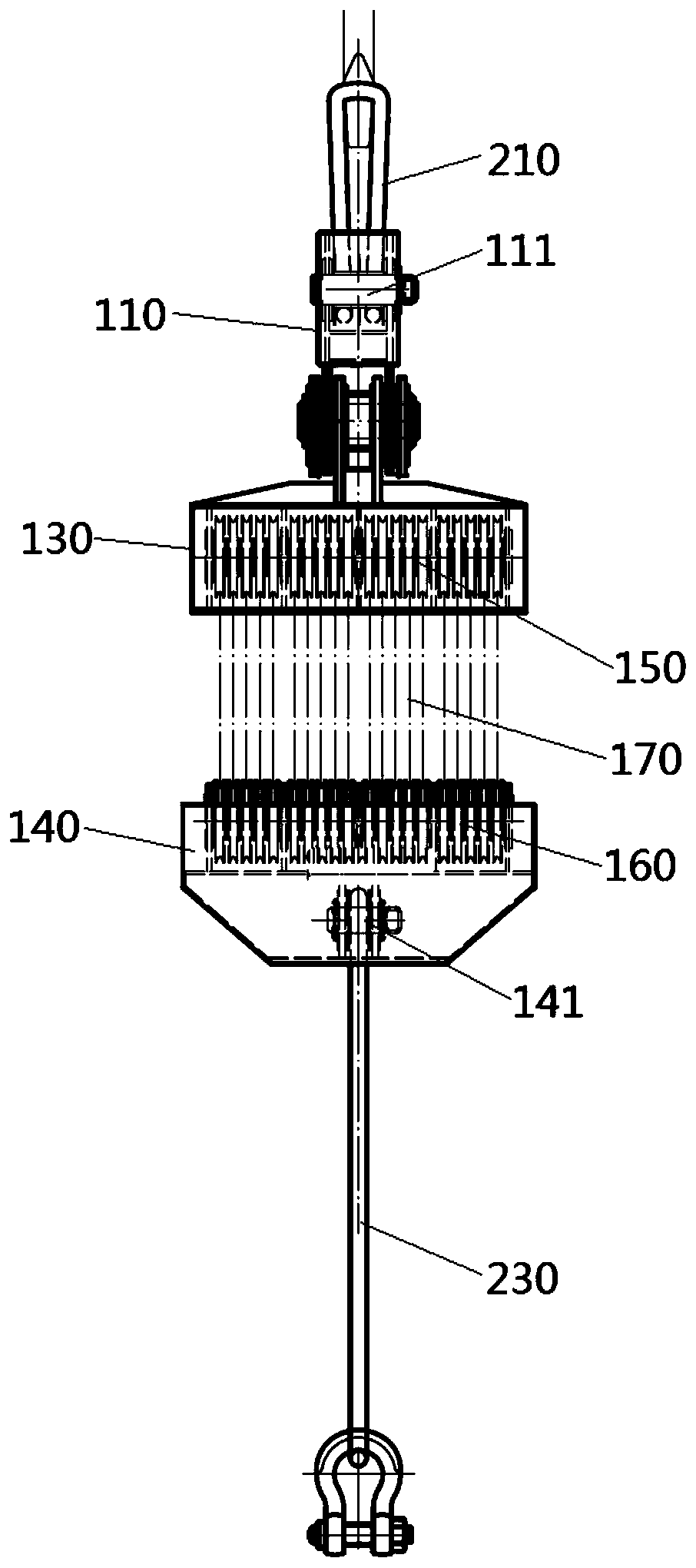

[0034] Please refer to Figure 1 to Figure 5 , figure 1 It is a schematic diagram of the structure after the stand-up tooling is articulated with the hook portion of the pipe pile and the hoisting equipment in the specific embodiment; figure 2 for figure 1 Schematic diagram of the structure from the perspective of A in the middle; image 3 for figure 1 Schematic diagram of the structure of the B-direction perspective; Figure 4 It is a structural schematic diagram of turning over the pipe pile to a certain angle by using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com