Steam generator tube plate overturning device and method

A steam generator and tube sheet technology, applied in the field of mechanical processing, can solve problems such as difficulties in lifting and transferring tube sheets, limited operating space, and welding lugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

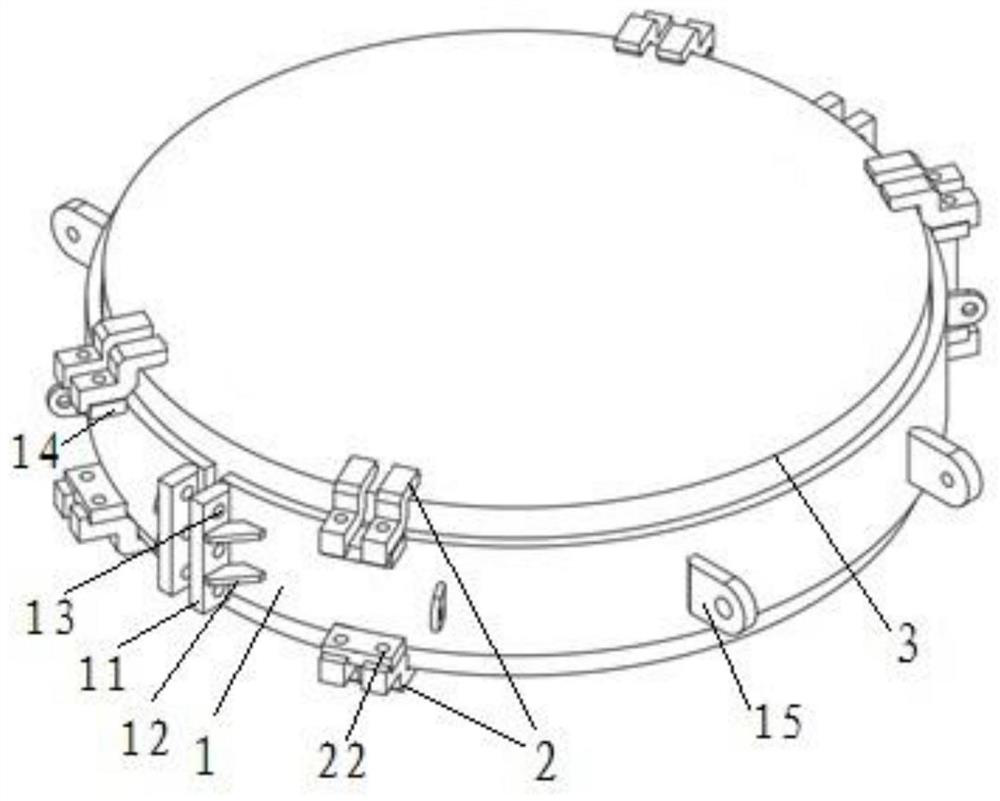

[0058] According to a preferred embodiment of the present invention, the connection between the fixing plate 11 and the fixing ring 1 is a non-detachable connection, and the non-detachable connection has the advantages of good connection integrity and light structure. Preferably, the connection between the fixing plate 11 and the fixing ring 1 is adhesive connection or welding connection; more preferably welding connection, especially sealing welding.

[0059] Since the tube sheet usually has a large tonnage, the device needs to be strong enough to avoid breakage during the flipping process, so welding is particularly important here. Compared with other methods, welding has the highest firmness and stronger durability.

[0060] According to a preferred embodiment of the present invention, the overall perimeter of the ring after splicing is slightly smaller than the perimeter of the tube sheet 3, and the spliced ring should ensure that there is a certain gap on the opposite si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com