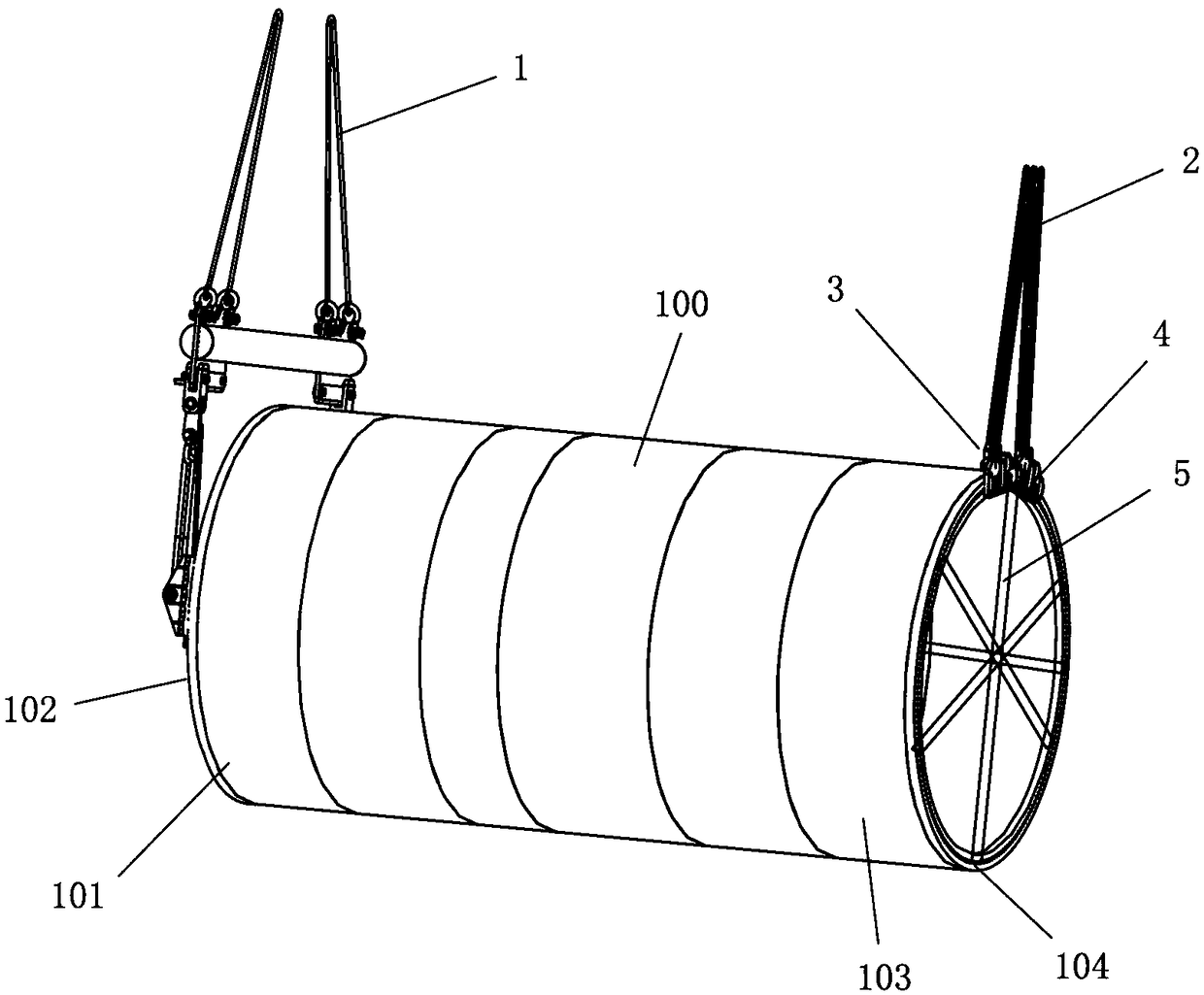

Tower drum overturning device and tower rack mounting system

A technology of turning device and installation system, which is applied in the assembly of lifting device, hoisting device, wind turbine, etc., can solve the problems of safety risk, difficulty in installation and disassembly, increase of tower wall thickness and flange width and thickness, etc. To achieve the effect of saving design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the tower turning device and the tower installation system according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0041] It will be understood that the use of the terms first, second, etc. may not indicate order or importance, but rather the terms first, second, etc. may be used to distinguish one component from another.

[0042] In addition, for the convenience of description, the “left”, “right”, “up” and “down” referred to below are consistent with the left, right, up, and down directions of the drawings themselves, but they do not limit the structure of the present invention.

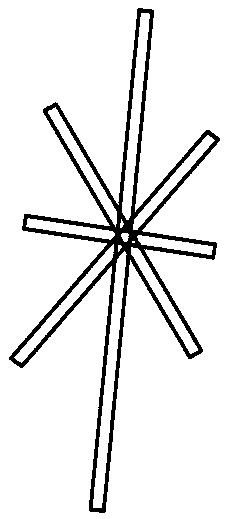

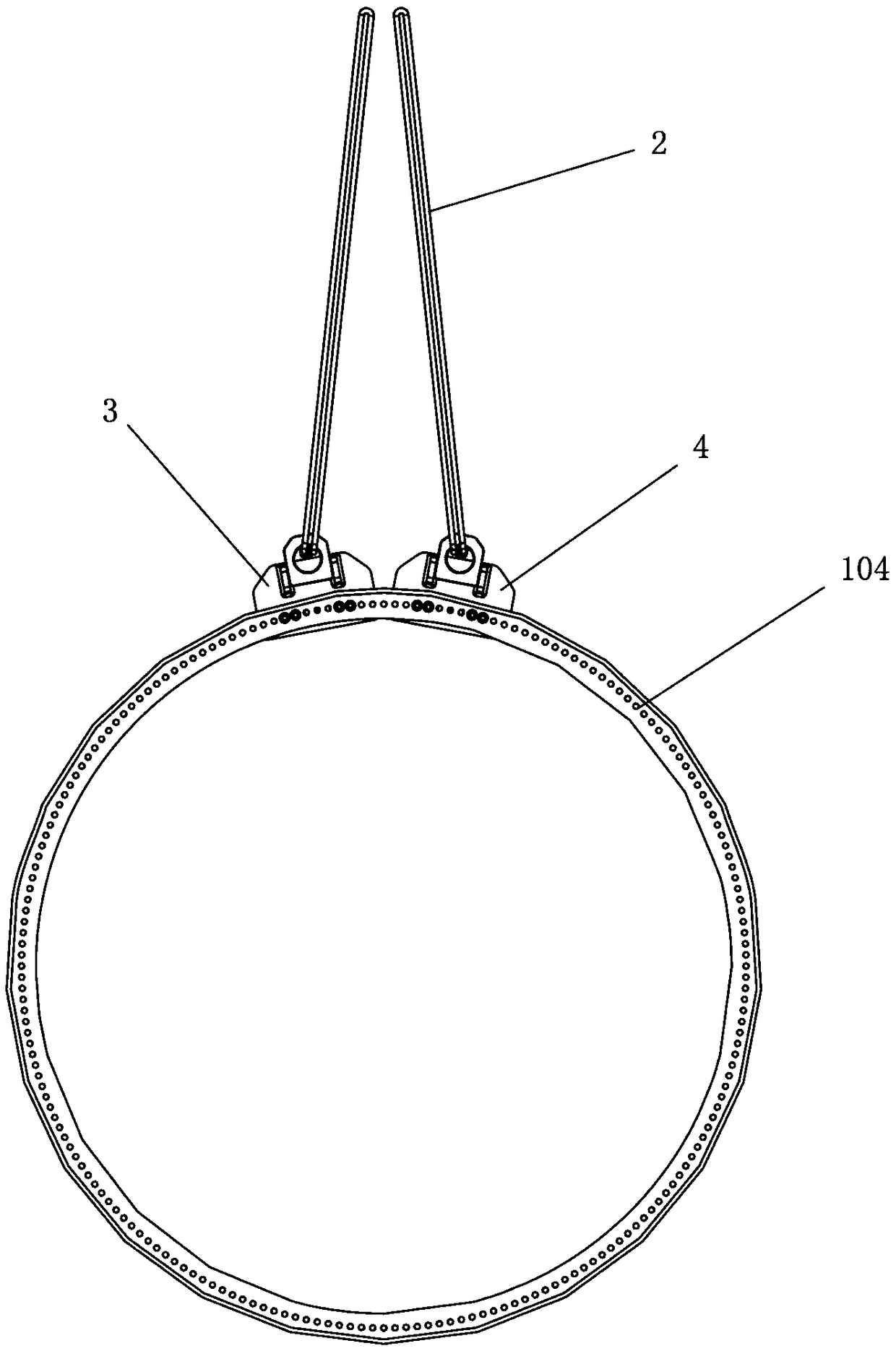

[0043] Figure 4 A schematic diagram of unloading conditions of the tower installation system according to an exemplary embodiment of the present invention. Figure 5 A schematic diagram of a turning over condition of the tower installation system according to an exemplary embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com