A functional fully formed knitted collar and preparation method thereof

A fully formed and functional technology, applied in the field of collar knitting, can solve the problems of poor stability of the folded state and poor folding effect of the collar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A functional fully-molded knitted collar and a preparation method thereof, the steps of which are as follows:

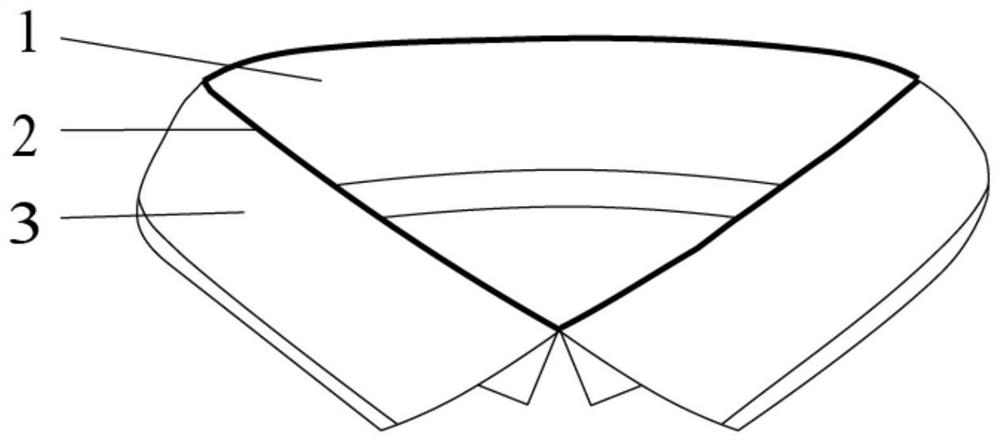

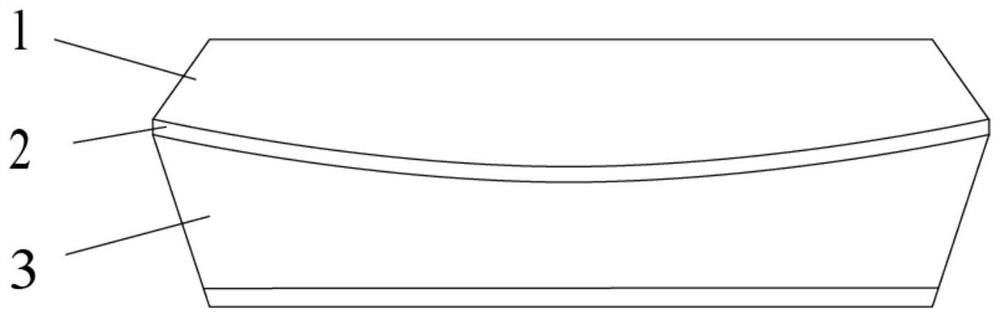

[0054] (1) if Figure 4 , 5 As shown, the woven outer collar (made of fabric such as figure 1 , 2 , and number 3 in 4):

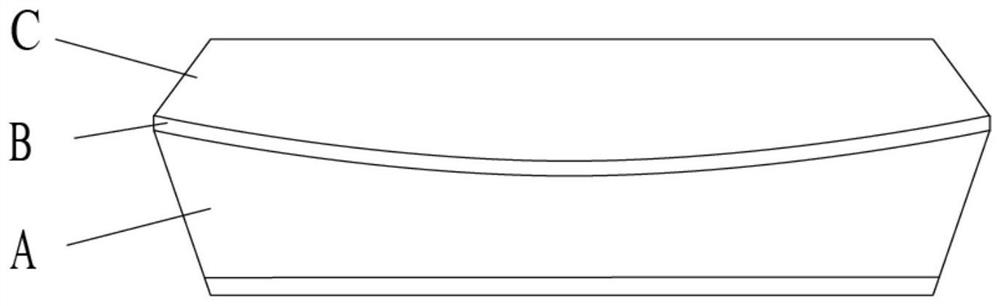

[0055] Use 58tex cotton yarn and 16tex TPU monofilament ( image 3 In A), knit 26 complete rows, the fabric weave is a full stitch rib weave, the number of needles used is 202 needles, and then knit Figure 4 The part shown in the serial number 4, refer to Figure 5 As shown in rows Ⅰ, Ⅱ, Ⅲ, Ⅳ, Ⅴ, and Ⅵ, knit loops on the designated knitting needles, starting from the first knitting needle on the left, knit two rows on 90 needles from left to right in sequence, and then From the same starting point, knit two rows on 82 needles from left to right, two rows on 74 needles from left to right, two rows on 68 needles from left to right, and knit two rows on 68 needles from left to right. Knit two rows on 60 needles from right, two rows on ...

Embodiment 2

[0064] A functional fully-molded knitted collar and a preparation method thereof, the steps of which are as follows:

[0065] (1) Braided outer collar

[0066] Use 58tex cotton yarn and 16tex TPU monofilament, weave the fabric as a double rib weave, knit 30 complete rows, use 210 needles, and then start from the first knitting needle on the left, from left to right Knit two rows on 90 needles, knit two rows on 82 needles from left to right, knit two rows on 74 needles from left to right, knit two rows on 68 needles from left to right, Knit two rows on 60 needles from left to right, knit two rows on 54 needles from left to right, knit two rows on 48 needles from left to right, knit two rows on 43 needles from left to right Knit two rows on needles, knit two rows on 38 needles from left to right, knit two rows on 34 needles from left to right, knit two rows on 30 needles from left to right, knit two rows on 30 needles from left to right, Knit 2 rows on 26 needles left to right...

Embodiment 3

[0075] A functional fully-molded knitted collar and a preparation method thereof, the steps of which are as follows:

[0076] (1) Braided outer collar

[0077] Use 45tex polyester high-elastic yarn, the fabric weave is a full-needle rib weave, knit 30 complete rows, the number of needles used is 250 needles, and then start from the first knitting needle on the left, and in turn 115 from left to right Knit two rows on needles, then from the same starting point, knit two rows on 100 needles from left to right, knit two rows on 88 needles from left to right, and knit on 76 needles from left to right Two rows, knit two rows on 66 needles left to right, two rows on 56 needles left to right, two rows on 48 needles left to right, knit two rows on left to right Knit two rows on 40 needles, knit two rows on 35 needles from left to right, knit two rows on 30 needles from left to right, knit two rows on 25 needles from left to right , knit two rows on 20 needles from left to right, kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com