Material crushing and screening device

A screening device and grinding technology, which is applied in the fields of sieving, grain processing, solid separation, etc., can solve the problems of restricting the processing workshop, large area of equipment, low efficiency, etc., and achieve the effect of good versatility and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

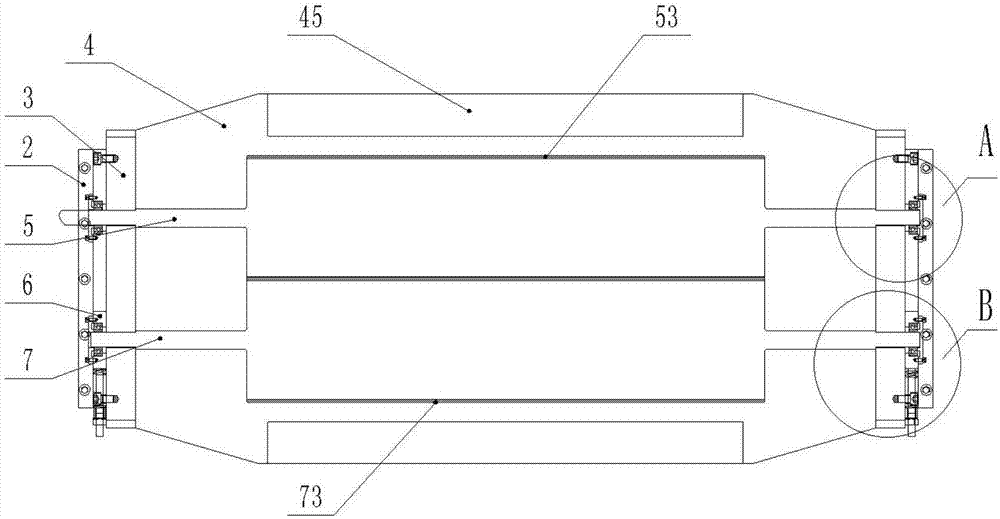

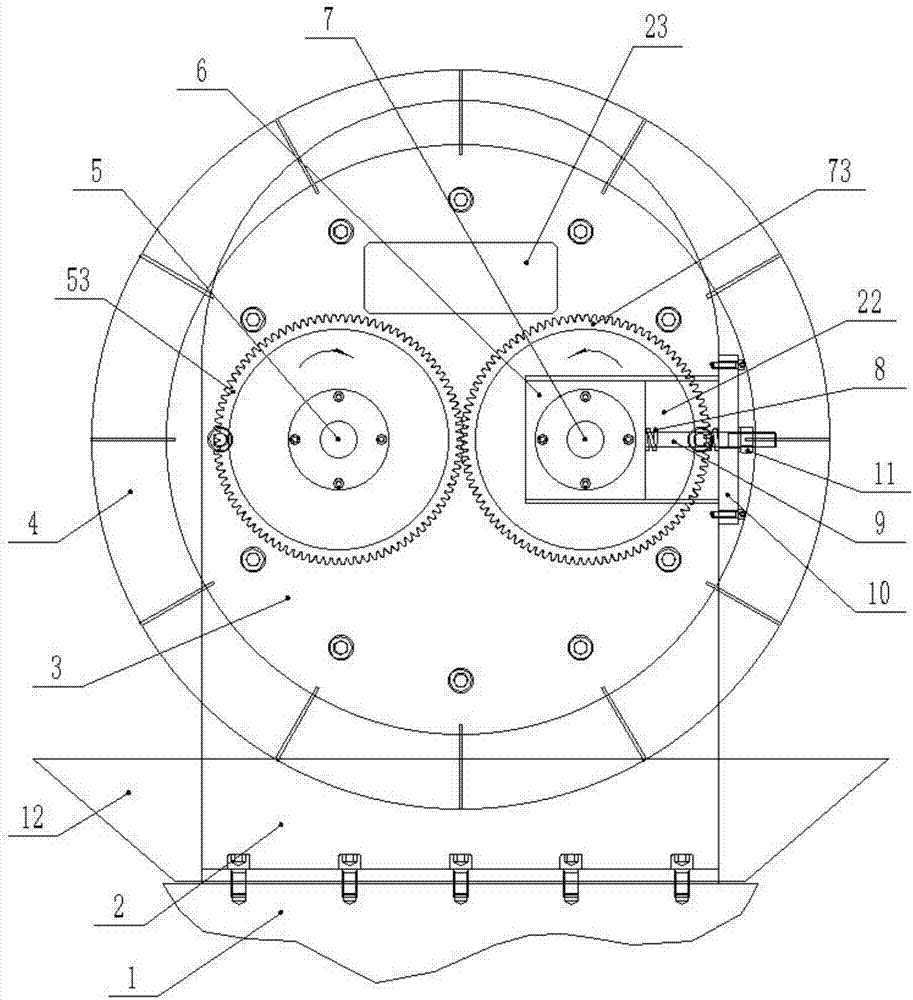

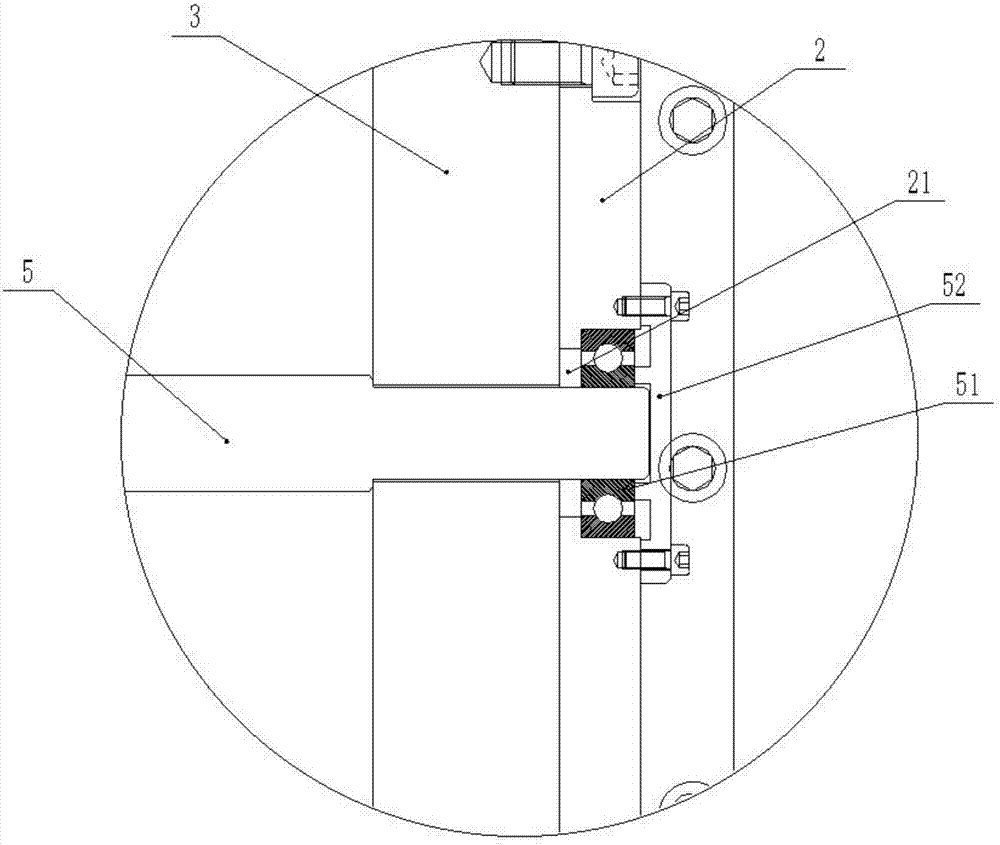

[0034] As shown in the figure, a material crushing and screening device described in the embodiment of the present invention includes: figure 1 , figure 2 As shown, the side plate 2 is a total of two L-shaped plates. The side plate 2 is symmetrically installed on the workbench 1. The side plate 2 is processed with a mounting hole 21 and a slideway 22. The outside of the slideway 22 is a fixed baffle plate 10. The side plate 2 is also processed with a feed inlet 23, and a collecting hopper 12 is also housed on the workbench 1 and between the side plates 2; image 3 As shown, the driving shaft 5 is installed on the mounting hole 21 and is equipped with a rolling bearing 51 and a bearing cover plate 52 at the joint, and the driving gear 53 is processed in the middle of the driving shaft 5; as figure 2 , Figure 4 As shown, the slide block 6 is located in the slideway 22; one end of the adjustment screw rod 9 is fixedly connected with the slide block 6 and the other end passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com