Integral sewing and overturning forming device for coiled button manufacture and forming method for coiled button manufacture

A molding device and a technology for buckles, applied in the directions of fasteners, buttons, applications, etc., can solve the problems of difficulty in pulling out metal hooks, lack of uniformity, and difficulty in operation, so as to facilitate the placement of cloth strips and meet market demand. , the effect of easy cloth input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

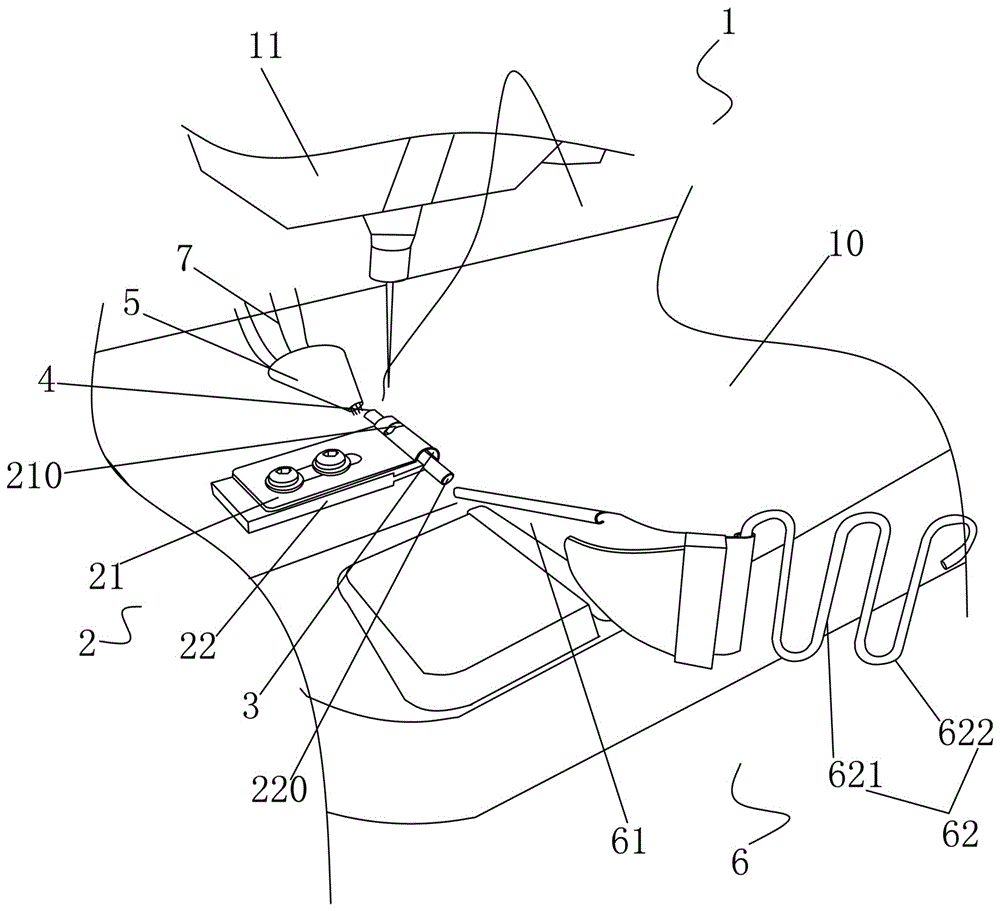

[0031] Specific implementation methods, such as Figure 1 to Figure 3 As shown in the present invention, a turn-over integrated molding device for preparing buckles mainly includes the following components: sewing device 1, fixing piece 21, connecting piece 22, filler feeding unit 5, guide feeding Body 61 and cloth arrangement unit 62;

[0032] Actual assembly and preparation, sewing device 1, which includes a workbench 10 and a drive assembly 11 that drives the sewing needle up and down through the sewing;

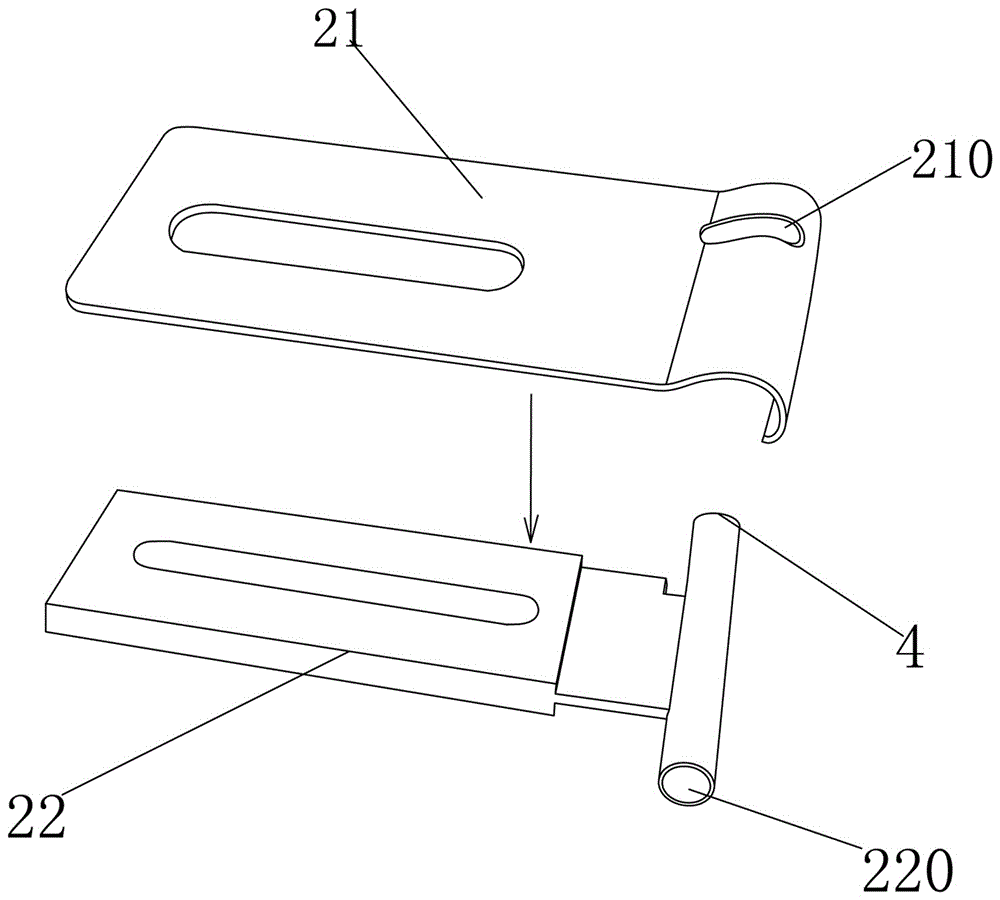

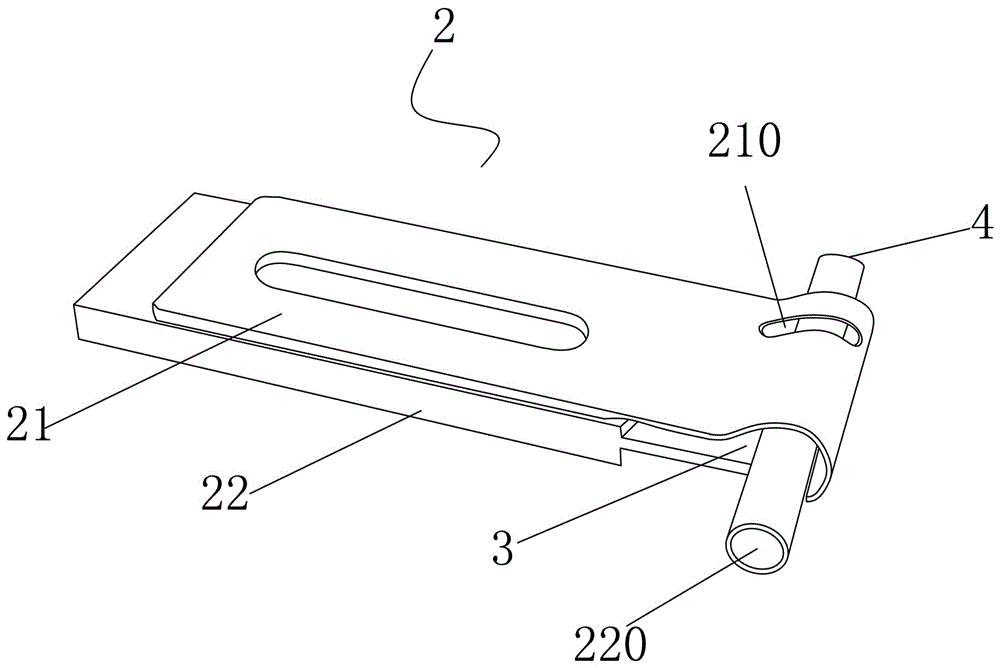

[0033] Turnover mechanism 2, the turnover mechanism 2 is installed on the workbench 10 of the sewing device 1; it includes a fixed piece 21 and a connecting piece 22, the connecting piece 22 is inserted into the fixed piece 21, and the connecting piece 22 is fixed An adjustable displacement is formed in the piece 21, and the displacement distance is set according to the size of the buckle required for production. After the setting is completed, the connecting piece 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com